2011-2016 Mahindra Genio Service & Repair Manual

What's Included?

Fast Download Speeds

Offline Viewing

Access Contents & Bookmarks

Full Search Facility

Print one or all pages of your manual

© 2011 Mahindra & Mahindra Ltd. All rights reserved. This book may not be reproduced or copied, in whole or in part, without

the written permission of Mahindra & Mahindra Ltd.

MAINTENANCE MANUAL

(BS-III/BS-IV)

www.teknetmahindra.com

ALL INFORMATION CONTAINED IN THIS MANUAL IS MOST UP-TO-DATE AT THE TIME OF PUBLICATION.

HOWEVER, SPECIFICATIONS AND PROCEDURES ARE SUBJECT TO CHANGE WITHOUT NOTICE. THIS

MANUAL IS STRICTLY MEANT FOR RESTRICTED INTERNAL CIRCULATION WITHIN M&M AUTHORIZED

DEALER SERVICE CENTERS.

RELEASED BY –

TECHNICAL PUBLICATION CELL

MAHINDRA & MAHINDRA LTD.

Rev1 – JULY 2011

MAN-00135

© 2011 Mahindra & Mahindra Ltd. All rights reserved. This book may not be reproduced or copied, in whole or in part, without

the written permission of Mahindra & Mahindra Ltd.

About the Maintenance Manual

The maintenance manual outlines the correct standard operating procedures (SOPs) for carrying out

maintenance operations in a Mahindra GENIO DC vehicle. Carrying out the periodic maintenance

operations, as specified, is crucial for safe and trouble-free operation of the vehicle.

The recommended maintenance schedule /operations are published in the owner’s handbook.

This manual covers the correct method of carrying out the maintenance operations, using the correct

process/procedures, tools, parts and lubricants. The manual consists of –

Maintenance Schedule – The maintenance schedules outlines the operations to be carried out a

specified interval. These operations are Adjust (A), Inspect & Correct (I), Replace (.R), Clean (C). The

maintenance periods are specified in Kilometers (Kms).

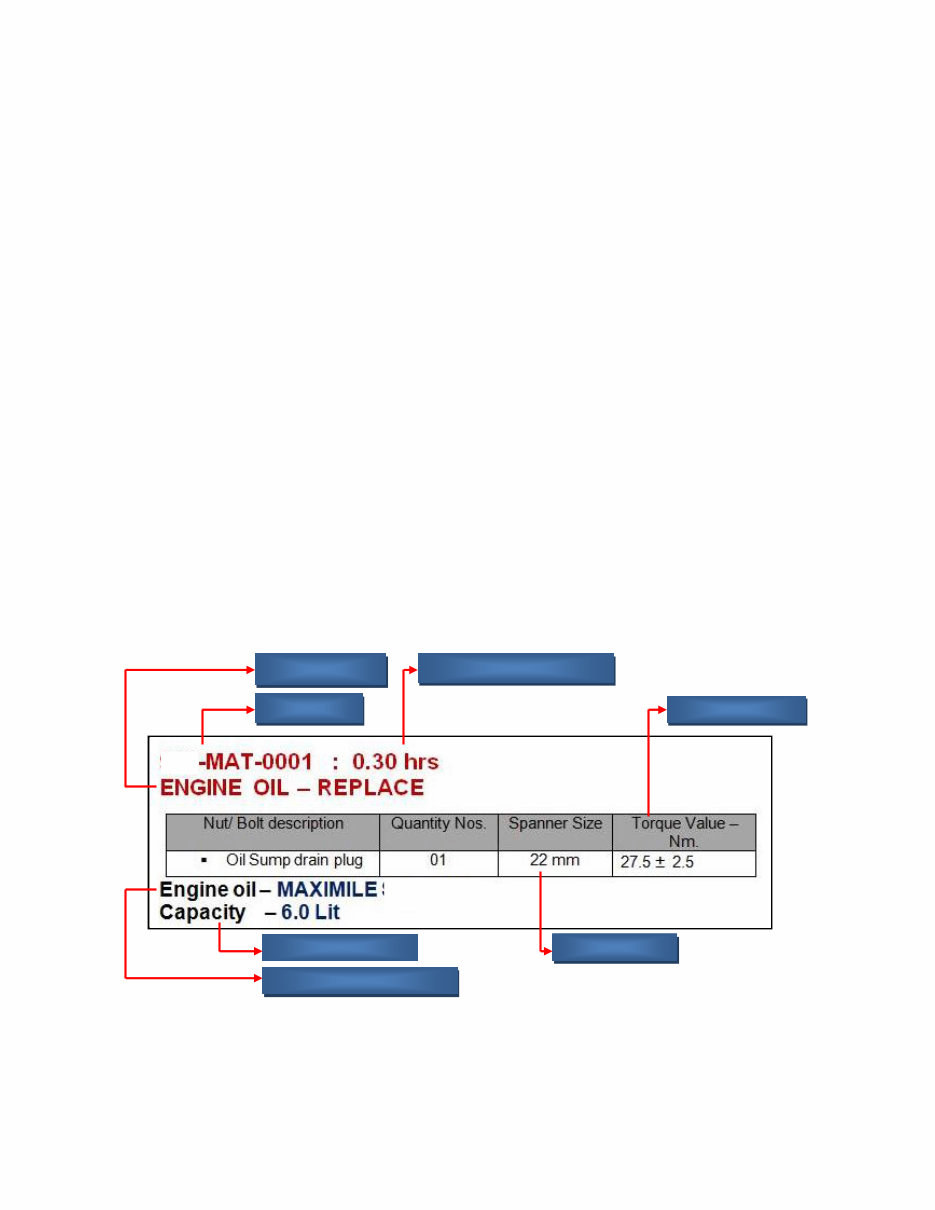

Standard Operating Procedures (SOP) – Each maintenance operation is coded by a operation code

– 705-MAT-xxxx. Here 705 stands for the model family code, MAT indicating it is a maintenance

operation and xxxx the operation number.

Each maintenance operation is explained step-by-step, in the SOP section of the manual. The man-hours

required to complete the operation is also mentioned along with the operation code. The correct grade of

lubricants /coolants to be used, torque values, special tools are also mentioned wherever applicable.

Check Sheets – Check sheets for each service list outs the operation which need to be carried out by

the technician, when the vehicles report for scheduled maintenance service. These check sheets need to be

attached to the Repair order.

Repair Code

Repair Time {Manhours} Job Description

Lubricant Quantity

Lubricant Recommended

Tool Specified

Torque Specified

This chart is only a sample.

Crown

705

© 2011 Mahindra & Mahindra Ltd. All rights reserved. This book may not be reproduced or copied, in whole or in part, without

the written permission of Mahindra & Mahindra Ltd.

Good Workshop Practices

Attire/Dress

Always wear clean uniform

Wear safety shoes

Wear gloves, when required

Wear belt cover

Vehicle Protection

Put seat cover, fender cover, steering wheel cover, before starting the operations.

Safety

When working with 2 or more persons, be sure to check safety for one another

When working with engine running, make sure to provide ventilation for exhaust fumes in the

workshop

If working on high temperature, high pressure, rotating, moving, or vibrating parts, wear

appropriate safety gear and take extra care not to injure yourself or others.

When jacking up the vehicle, be sure to support the specified location with a safety stand.

When lifting up the vehicle, use appropriate safety equipment.

Parts and tools

Before starting operation, prepare tool stand, MST, Gauges, oils and parts for replacement.

Removed Parts

Place removed parts in a separate box to avoid mixing them up with new parts or contaminating

new parts.

For non-reusable parts such as gaskets, O-rings, and self-locking nuts, replace them with new

ones as instructed in the manual

Retain the removed parts for customer inspection, if requested.

IMPORTANT

Mahindra Xylo mEagle is fitted with LSPV (Load Sensing Pressure Regulating Valve) in the

brake circuit. Hence it is imperative that the LSPV spring is disconnected before lifting

the vehicle on a 2‐post lift. Failure to do so can lead to elongation of the spring,

disturbing the LSPV settings, leading to different braking characteristics.

Ensure to re‐connect the LSPV spring and measure the fitted length after lowering the

vehicle from the 2‐post lift.

Maintenance Manual MAN-00135

GENIO DC (BS-III & BS-IV) JULY 2011/Rev1

The repair methods given by the manufacturer in this document are based on the technical specifications, current at the time of release. The methods may be modified as a result of changes

introduced by the manufacturer in the production of the various component units and accessories from which the vehicles are manufactured. The reproduction, translation, transmission, in part of or

whole of the present document, are prohibited without the prior written consent of Mahindra & Mahindra Ltd. The use of this document by any person other than the trained personnel, at the

Authorized Service Centre of Mahindra & Mahindra Ltd., will amount to unauthorized use and shall be liable for penalty/prosecution © 2011 Mahindra & Mahindra Ltd.

1

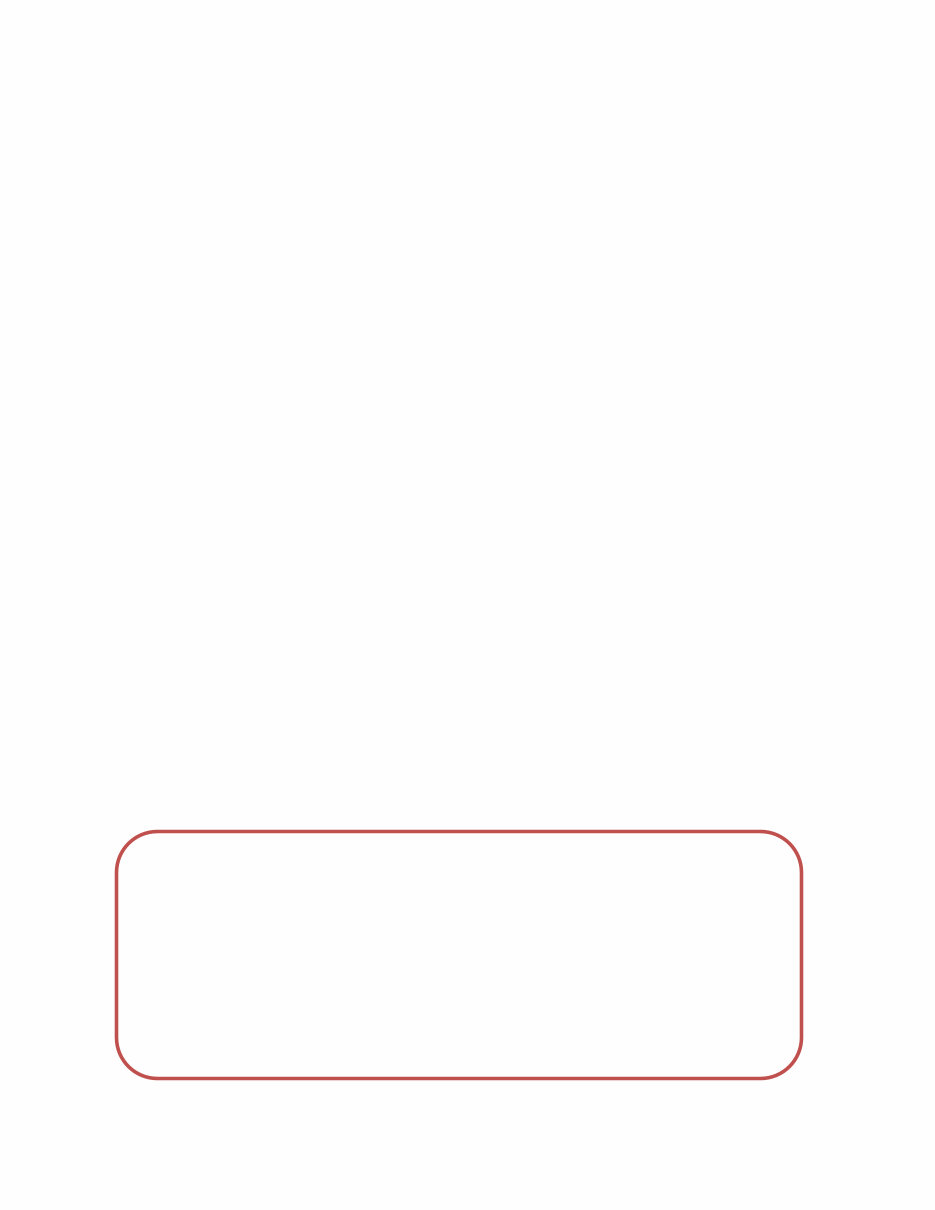

Refer below Maintenance Schedule chart for GENIO DC (BS-III & BS-IV) models :-

Maintenance Manual MAN-00135

GENIO DC (BS-III & BS-IV) JULY 2011/Rev1

The repair methods given by the manufacturer in this document are based on the technical specifications, current at the time of release. The methods may be modified as a result of changes

introduced by the manufacturer in the production of the various component units and accessories from which the vehicles are manufactured. The reproduction, translation, transmission, in part of or

whole of the present document, are prohibited without the prior written consent of Mahindra & Mahindra Ltd. The use of this document by any person other than the trained personnel, at the

Authorized Service Centre of Mahindra & Mahindra Ltd., will amount to unauthorized use and shall be liable for penalty/prosecution © 2011 Mahindra & Mahindra Ltd.

2

* on chargeable basis.

705 - MAT-xxxx

Maintenance item Operation Code Page No

Engine oil - Replace 705 - MAT - 0001 03

Engine oil - Level Check 705 - MAT - 0002 04

Engine oil filter - Replace 705 - MAT - 0003 05

Auto tensioner - Inspect 705 - MAT - 0004 06

Auto tensioner - Replace 705 - MAT - 0005 07

Accessory drive belts - Inspect 705 - MAT - 0006 08

Accessory drive belts - Replace 705 - MAT - 0007 10

Coolant - Check 705 - MAT - 0008 11

Coolant - Replace 705 - MAT - 0009 12

Air filter element - Replace 705 - MAT - 0010 13

Fuel filter element - Replace 705 - MAT - 0011 14

Fuel tank - Clean 705 - MAT - 0012 15

Water sediments drain – Fuel filter 705- MAT - 0013 16

Transmission oil - Replace 705 - MAT - 0014 17

Differential oil (Rear) - Replace 705 - MAT - 0015 18

Tyre rotation 705 - MAT - 0016 19

Rear Wheel Greasing 705 - MAT - 0260 20

Propeller Shaft Greasing 705 - MAT - 0221 24

LSPV setting 705 - MAT - 0017 25

Brake + Clutch fluid - level & leak Check 705 - MAT - 0018 26

Brake + Clutch fluid - Replace 705 - MAT - 0019 27

Brake pads/ Calipers - Check 705 - MAT - 0020 29

Brake drum and lining - Check 705 - MAT - 0021 30

Parking brake operation - Check & Adjust 705 - MAT - 0022 31

Front Suspension bolts torque - Check 705 - MAT - 0023 32

Front suspension bushes- Inspect 705 - MAT - 0025 33

Rear Suspension bolts torque - Check 705 - MAT - 0024 32

Rear Suspension bushes - Check 705 - MAT - 0026 35

Power steering fluid - level & leak 705 - MAT - 0027 36

Power steering belt - Check 705 - MAT - 0028 37

Power steering belt - Replace 705 - MAT - 0029 39

Wheel alignment * 705 - MAT - 0030 40

Battery electrolyte level - Check 705 - MAT - 0031 43

Battery specific gravity - Check 705 - MAT - 0032 44

All Lights, Horns, Wipers & Washers - Check 705 - MAT - 0033 45

Head light aiming - Check & Adjust 705 - MAT - 0034 47

HVAC – Clean mesh 705 – MAT - 0035 49

Door setting 705 - MAT - 0036 50

Tyre pressure - Check & Adjust 705 - MAT - 0037 51

Body & Cargo mounting bolts for tightness-Check & Adjust 705 - MAT - 0038 52

Exhaust pipe mtgs. & damage/leakage - Check 705 - MAT - 0039 53

Road Test- if any complaints reported 705 - MAT - 0040

Maintenance Manual MAN-00135

GENIO DC (BS-III & BS-IV) JULY 2011/Rev1

The repair methods given by the manufacturer in this document are based on the technical specifications, current at the time of release. The methods may be modified as a result of changes

introduced by the manufacturer in the production of the various component units and accessories from which the vehicles are manufactured. The reproduction, translation, transmission, in part of or

whole of the present document, are prohibited without the prior written consent of Mahindra & Mahindra Ltd. The use of this document by any person other than the trained personnel, at the

Authorized Service Centre of Mahindra & Mahindra Ltd., will amount to unauthorized use and shall be liable for penalty/prosecution © 2011 Mahindra & Mahindra Ltd.

3

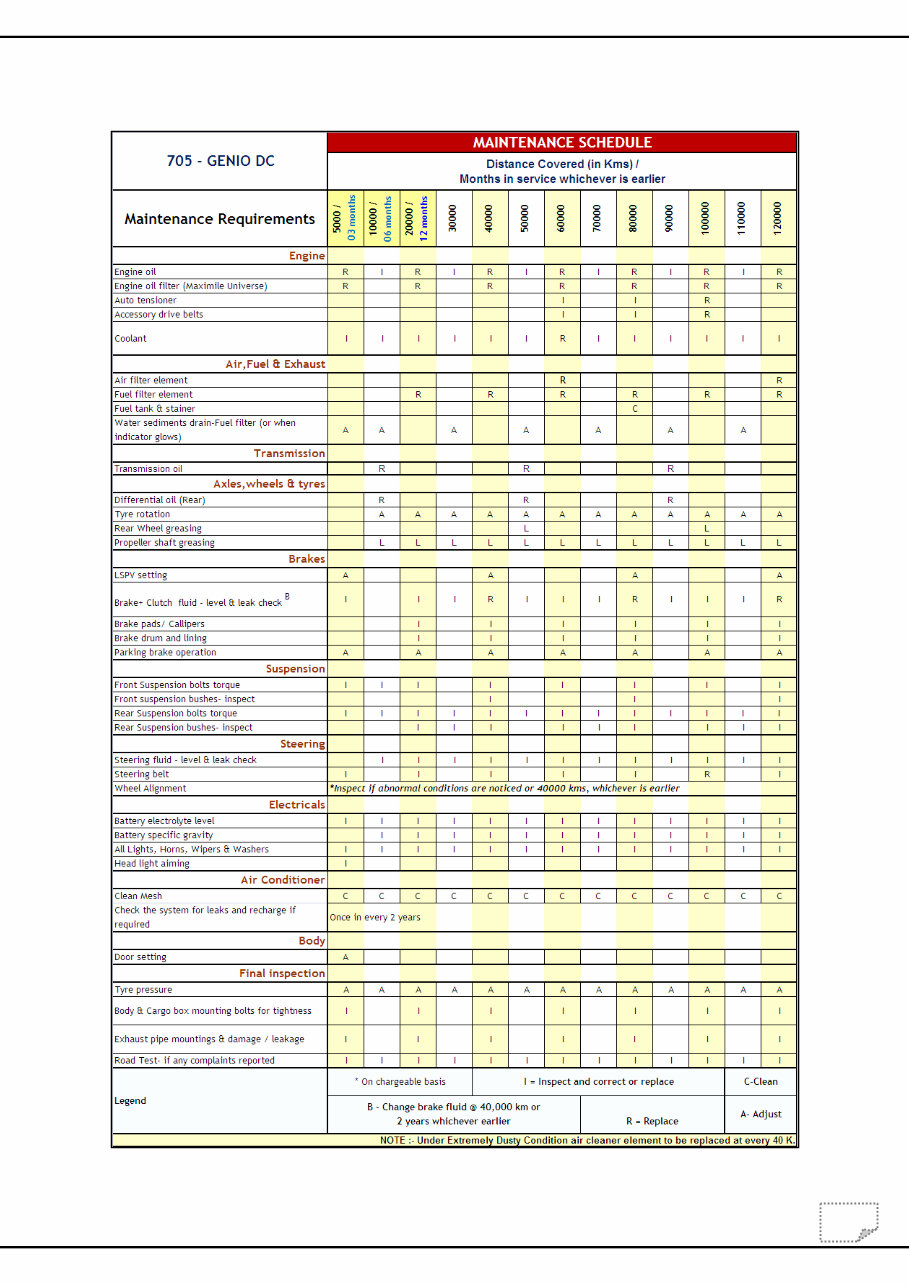

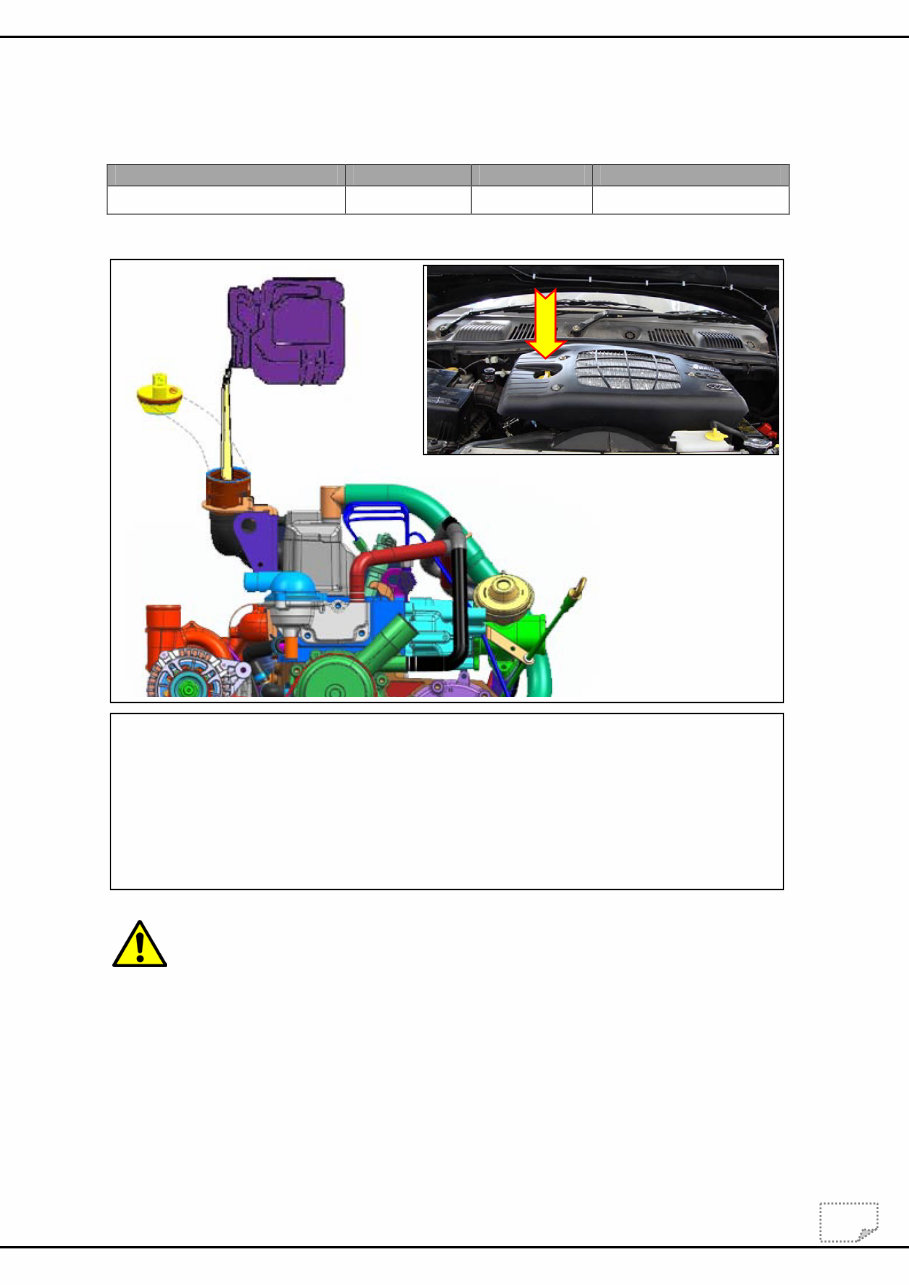

705-MAT-0001 : 0.30 hrs.

ENGINE OIL – REPLACE

Engine oil – MAXIMILE CROWN (SAE 15W-40) API CH4

Capacity – 6.0 Lit.

Park the vehicle on level ground/2 post lift* /4 post lift

If the activity is done on a 2 post lift, ensure that the LSPV spring is disconnected

before lifting the vehicle. After lowering, re-connect the LSPV spring and ensure

that the setting height is correct.

Engine should be hot while draining the oil.

For other than Maximile brand, the oil change interval has to be reduced to

10000kms if the oil meets minimum of API CH-4 SAE 15W-40 specification.

Recommended intervals for Maximile CROWN engine Oil change are at 5000,

20000kms & then at every 20000kms.

Nut/ Bolt description Quantity Nos. Spanner Size Torque Value – Nm.

Oil Sump drain plug 01 22 mm 27.5 ± 2.5

Oil Drain & Refill –

1. Open the oil filler cap.

2. Put the oil collecting tray below the sump, loosen & remove the oil sump drain plug.

Allow the oil to drain for 15 min.

3. Fit the drain plug with a new gasket/ washer. Torque tightens the Drain Plug –Torque -

27.5 ± 2.5 Nm.

4. Fill fresh oil as per the recommended quantity and specification.

5. Refit the oil filer cap & check the oil level as per procedure 910-MAT-0002.

Oil Filler Cap

Maintenance Manual MAN-00135

GENIO DC (BS-III & BS-IV) JULY 2011/Rev1

The repair methods given by the manufacturer in this document are based on the technical specifications, current at the time of release. The methods may be modified as a result of changes

introduced by the manufacturer in the production of the various component units and accessories from which the vehicles are manufactured. The reproduction, translation, transmission, in part of or

whole of the present document, are prohibited without the prior written consent of Mahindra & Mahindra Ltd. The use of this document by any person other than the trained personnel, at the

Authorized Service Centre of Mahindra & Mahindra Ltd., will amount to unauthorized use and shall be liable for penalty/prosecution © 2011 Mahindra & Mahindra Ltd.

4

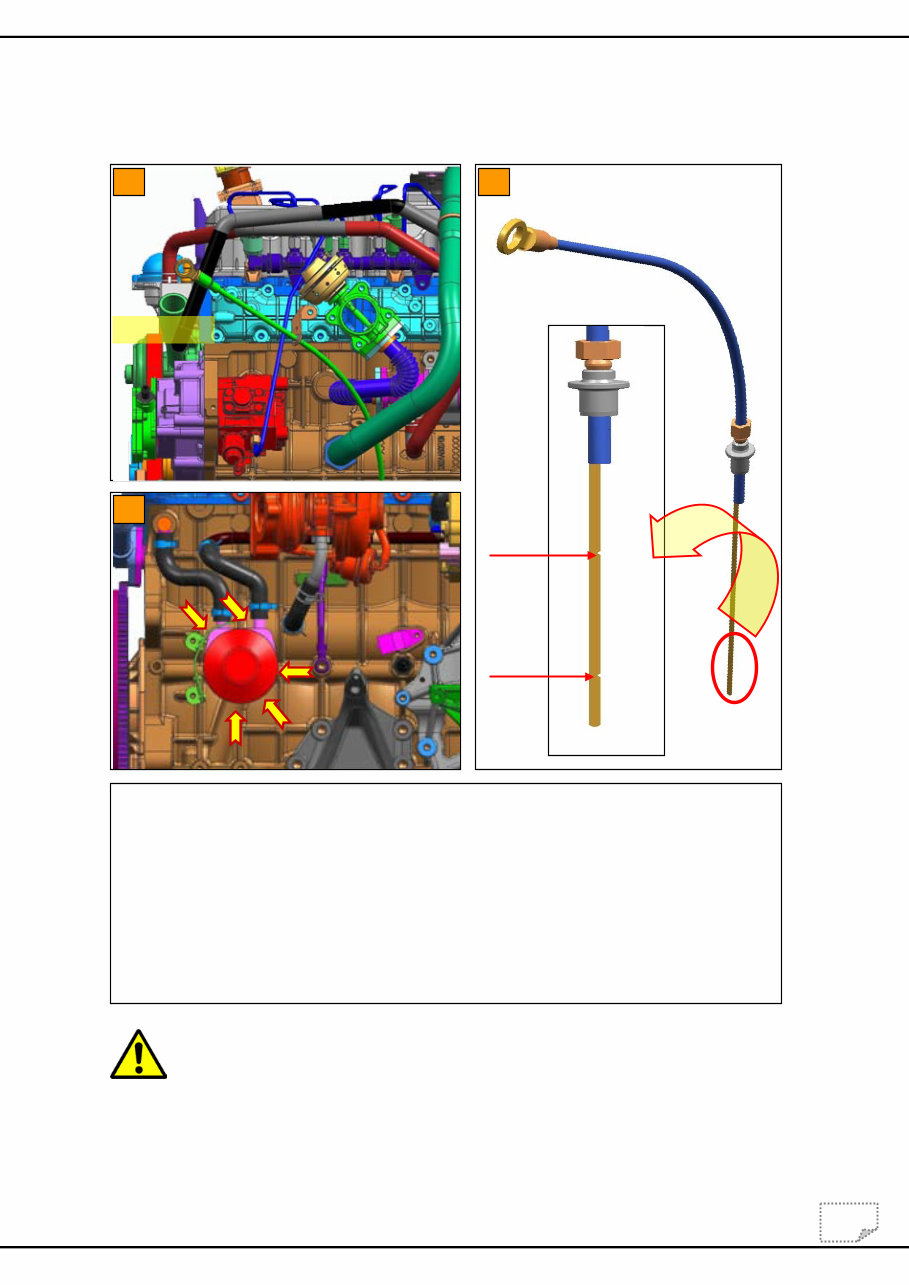

705-MAT-0002: 0.05 hrs.

ENGINE OIL – LEVEL & LEAK – CHECK

Ensure that the vehicle is parked on level ground/2 post lift/4 post lift.

If the activity is done on a 2 post lift, ensure that the LSPV spring is disconnected

before lifting the vehicle. After lowering, re-connect the LSPV spring and ensure

that the setting height is correct.

Ensure that the engine is not running when oil level check is being done.

If the engine was running before, wait for 10-12 minutes to accumulate oil in the

sump and then do oil level check.

Oil Level Check – Refer illustrations shown.

1. Pull out the dip stick gauge and wipe it clean with a cloth/paper.

2. Insert the dip stick gauge into the dip stick guide fully till the end.

3. Pull out the dip stick slowly and check for the oil level between Maximum and

Minimum level - if found below, top up with recommended oil.

4. Start the engine and check for oil leakage/ seepage at –

Refer illustration [C] checkpoints are shown with arrows.

Oil sump & crankcase joint.

Oil sump drain plug.

Oil filter joint.

DIPSTICK

DIPSTICK

DIPSTICK

GUIDE

MAX

MIN

A B

C

Maintenance Manual MAN-00135

GENIO DC (BS-III & BS-IV) JULY 2011/Rev1

The repair methods given by the manufacturer in this document are based on the technical specifications, current at the time of release. The methods may be modified as a result of changes

introduced by the manufacturer in the production of the various component units and accessories from which the vehicles are manufactured. The reproduction, translation, transmission, in part of or

whole of the present document, are prohibited without the prior written consent of Mahindra & Mahindra Ltd. The use of this document by any person other than the trained personnel, at the

Authorized Service Centre of Mahindra & Mahindra Ltd., will amount to unauthorized use and shall be liable for penalty/prosecution © 2011 Mahindra & Mahindra Ltd.

5

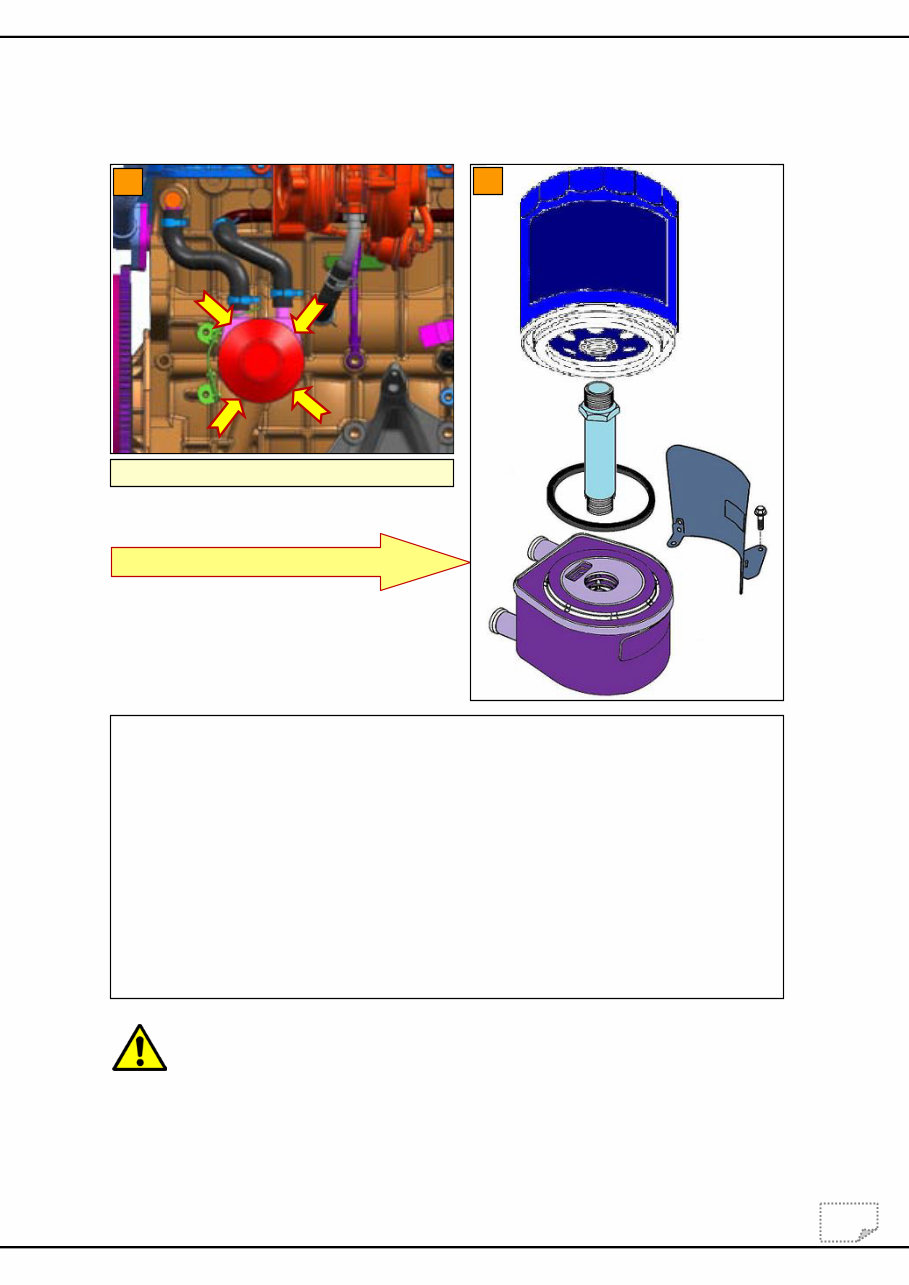

705-MAT-0003 : 0.20 hrs.

ENGINE OIL FILTER– REPLACE

Never use a wrench/spanner to tighten the oil filter.

Oil filters need to be replaced during engine Oil change. Recommended intervals

are at 5000, 20000kms & then at every 20000kms. Use Maximile UNIVERSE oil

filter.

Oil filter Removal – Refer illustrations.

1. Remove the oil filter by unscrewing it in anti-clockwise direction, using an oil filter

wrench.

2. Check the oil cooler stud for tightness – Torque 27.5 ± 2.5 Nm.

3. Smear a layer of fresh engine oil on the oil filter “O” ring

4. Fit the oil filter and turn it clockwise till the “O” ring touches the oil cooler face.

5. Turn the filter another 3/4th turn by hand.

6. Check for Oil leakage/ seepage at –

Refer illustration [A] checkpoints are shown with arrows.

Oil pan & crankcase joint

Oil pan Drain Plug.

Oil filter joint.

Oil cooler joint

Oil Filter & Cooler disassembly

B

Oil Leak - Check Points near Oil Filter

A

Maintenance Manual MAN-00135

GENIO DC (BS-III & BS-IV) JULY 2011/Rev1

The repair methods given by the manufacturer in this document are based on the technical specifications, current at the time of release. The methods may be modified as a result of changes

introduced by the manufacturer in the production of the various component units and accessories from which the vehicles are manufactured. The reproduction, translation, transmission, in part of or

whole of the present document, are prohibited without the prior written consent of Mahindra & Mahindra Ltd. The use of this document by any person other than the trained personnel, at the

Authorized Service Centre of Mahindra & Mahindra Ltd., will amount to unauthorized use and shall be liable for penalty/prosecution © 2011 Mahindra & Mahindra Ltd.

6

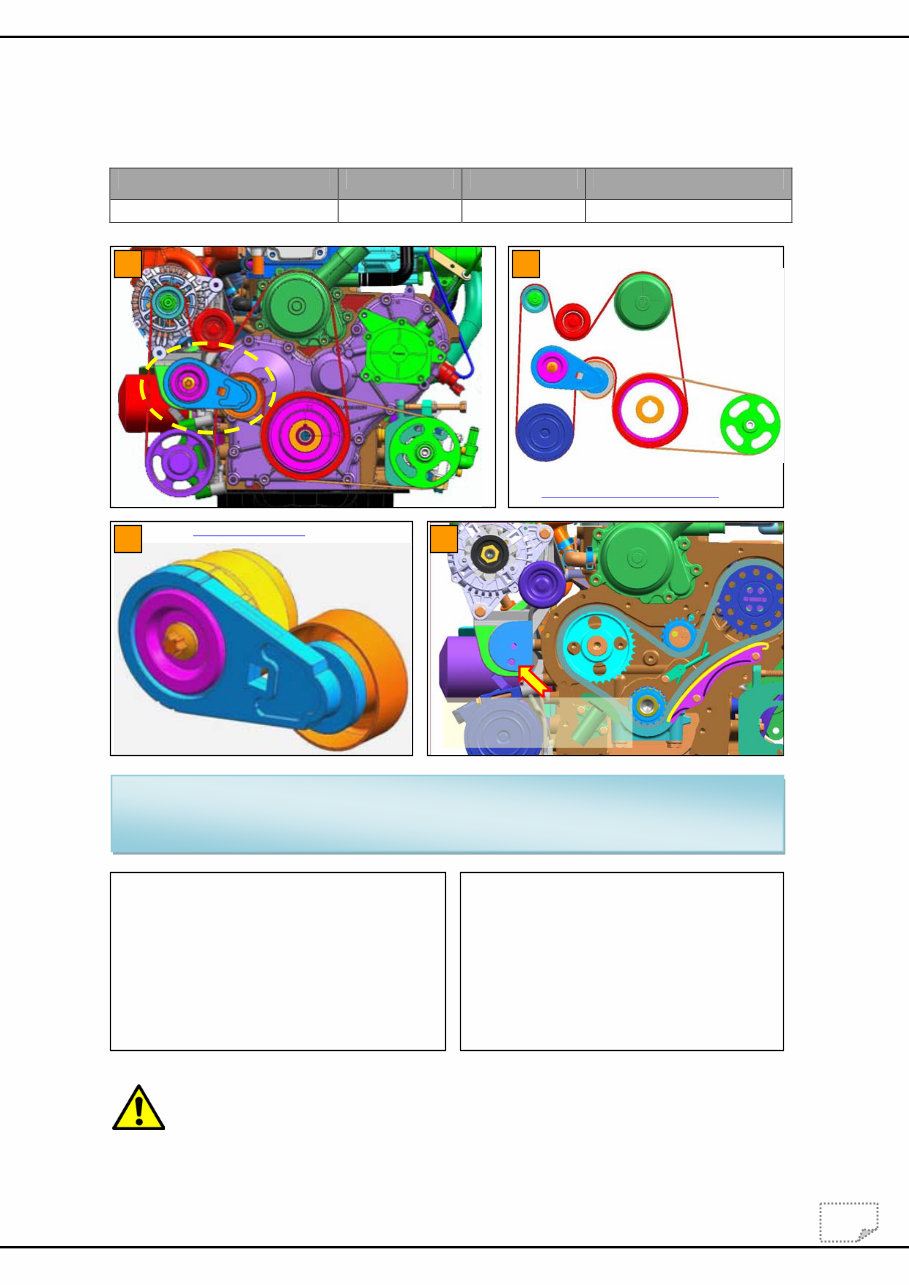

705-MAT-0004 : 0.05 hrs.

AUTO TENSIONER - CHECK

Auto tensioner to be check at 60000, 80000kms and it is recommended to

replace it at every 100000kms.

Auto Tensioner Inspection:

Refer illustrations shown.

Inspect automatic tensioner carefully for symptoms such as cracked arms, excessive vibration

during idle speeds, looseness, noise (clatter or rattling) and sticking or seized operation. These

can all be signs that a tensioner needs replacing.

Refer slots shown by arrow marks on Auto tensioner in sketch [C] & [D]. Two slots marked on

Auto tensioner arm, and one slot marked on its coil hub. The slot marked on coil hub should

always match in between two slots marked on Tensioner Arm when the belt is in its position. If

there is mismatch, either the belt needs to be check and replaced or Auto tensioner needs to

be replaced.

D

Marking on Auto Tensioner

Marking on Auto Tensioner

C

DRIVE BELTS - LAYOUT

B

Auto Tensioner mounting on Engine

A

Maintenance Manual MAN-00135

GENIO DC (BS-III & BS-IV) JULY 2011/Rev1

The repair methods given by the manufacturer in this document are based on the technical specifications, current at the time of release. The methods may be modified as a result of changes

introduced by the manufacturer in the production of the various component units and accessories from which the vehicles are manufactured. The reproduction, translation, transmission, in part of or

whole of the present document, are prohibited without the prior written consent of Mahindra & Mahindra Ltd. The use of this document by any person other than the trained personnel, at the

Authorized Service Centre of Mahindra & Mahindra Ltd., will amount to unauthorized use and shall be liable for penalty/prosecution © 2011 Mahindra & Mahindra Ltd.

7

705-MAT-0005 : 0.60 hrs.

AUTO TENSIONER - REPLACE

Auto tensioner to be check at 60000, 80000kms and it is recommended to

replace it at every 100000kms.

Nut/ Bolt description Quantity Nos. Spanner Size Torque Value – Nm.

Auto tensioner mtg. bolt 01 12 mm. 35 ± 05

Removal Steps –

1. Remove NVH cover.

2. Remove fan & shroud

3. Remove power steering belt (705-

MAT-0029) & Accessory drive belt

(705-MAT-0007)

4. Remove Auto tensioner assy.

Assembly Procedure –

1. Refit Auto tensioner assy.

2. Refit Accessory drive belt (705-

MAT-0007) & power steering belt

(705-MAT-0029)

3. Refit fan & shroud.

4. Refit NVH cover.

NOTE: Auto tensioner is provided with dowel-pin on its mounting face for correct fitment;

while assembling the dowel should match & fixed carefully.

Refer sketch [D] Dowel Pin location shown by arrow mark.

DRIVE BELTS - LAYOUT

B A

C

Auto Tensioner

D

Auto Tensioner dowel

Pin mounting hole

You're Reading a Preview

What's Included?

Fast Download Speeds

Offline Viewing

Access Contents & Bookmarks

Full Search Facility

Print one or all pages of your manual

$31.99

Viewed 32 Times Today

Loading...

Secure transaction

What's Included?

Fast Download Speeds

Offline Viewing

Access Contents & Bookmarks

Full Search Facility

Print one or all pages of your manual

$31.99

This is a comprehensive service and repair manual for the 2011-2016 Mahindra Genio, containing essential information for maintenance, troubleshooting, and repair.

- It is a valuable resource for both professional mechanics and DIY enthusiasts, providing easy-to-read text sections, high-quality diagrams, and step-by-step instructions.

- The manual covers every single detail of the 2011-2016 Mahindra Genio, including comprehensive diagrams, in-depth illustrations, and all the manufacturer's specifications and technical information.

- It is available in English and can be zoomed in/out for better clarity. The file format is PDF, compatible with all versions of Windows and Mac, and requires Adobe Reader and WinZip for access.

- With this manual, you can easily find the relevant information, print it off, and start working on your machine without worrying about damaging an expensive paper manual with grease and dirt.

- Instant access to the material allows for quick repairs without waiting for postal delivery, making it convenient for on-the-spot troubleshooting and repairs.

- The manual includes a wide range of topics such as MOT test checks, roadside repairs, routine maintenance, engine and associated systems, cooling, heating and air conditioning systems, fuel and exhaust systems, electrical systems, transmission, braking system, suspension, steering systems, body equipment, wiring diagrams, tools, general repair procedures, spare parts, fault finding, and a glossary of technical terms.

Get your 2011-2016 Mahindra Genio fully equipped with this comprehensive service and repair manual for efficient maintenance and repairs.