2008 Jeep Grand Cherokee Service & Repair Manual Software

What's Included?

Fast Download Speeds

Online & Offline Access

Access PDF Contents & Bookmarks

Full Search Facility

Print one or all pages of your manual

2005-2010 JEEP GRAND CHEROKEE

SERVICE AND REPAIR MANUAL

ENGINE

3.0L Turbo Diesel - Service Information - Grand Cherokee

DESCRIPTION

3.0L COMMON RAIL DIESEL ENGINE

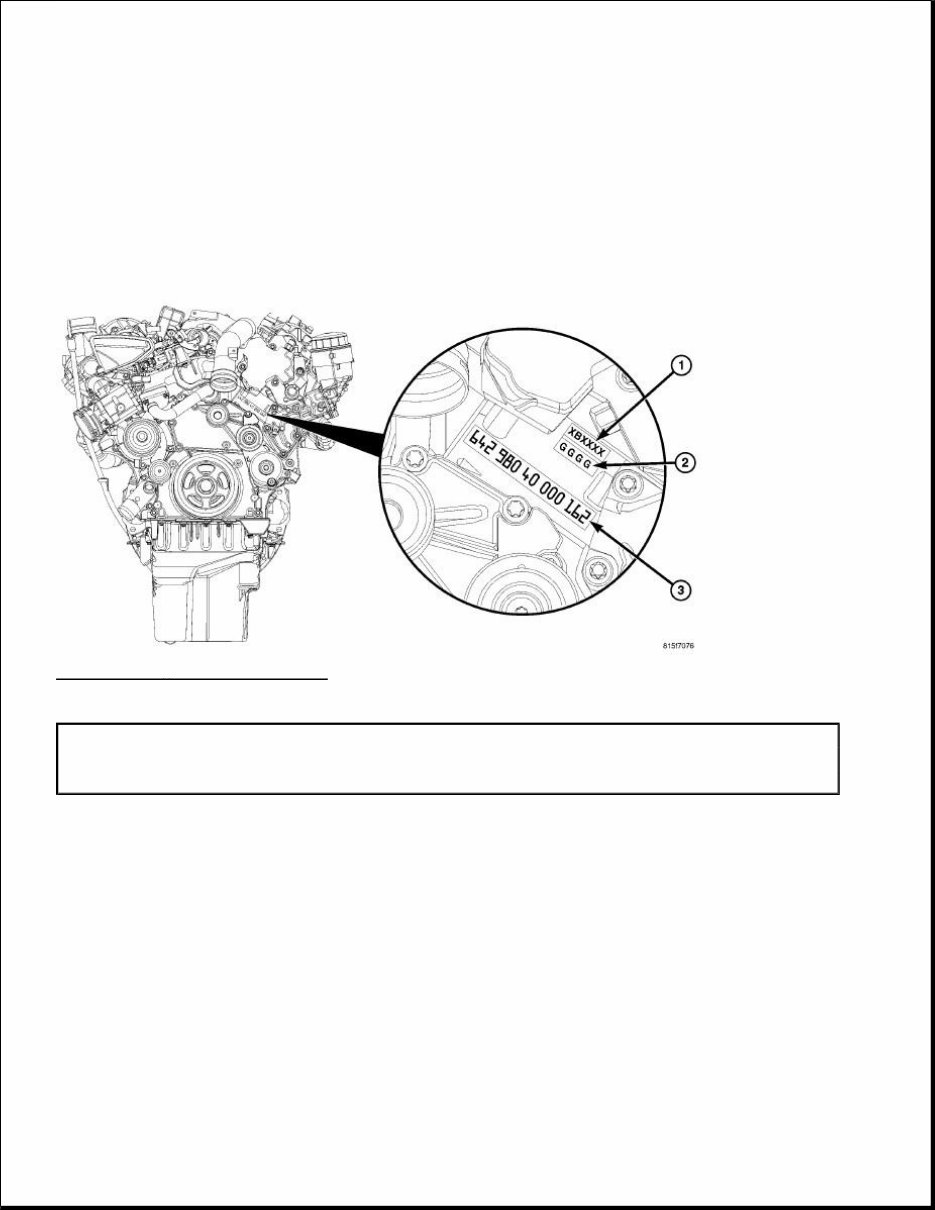

Fig. 1: 3.0L V - 6 DIESEL ENGINE

Courtesy of CHRYSLER LLC

The 3.0L (183 C.I.D.) six - cylinder "common rail" direct injection engine is a 72°, overhead valve design. The

engine utilize a cast aluminum cylinder block molded around cast iron piston sleeves. The engine has aluminum

cross flow cylinder heads, four valves per cylinder, central injectors and dual overhead camshafts. The 3.0L is

turbocharged, intercooled, and also equipped with a EGR cooler.

Additional features are:

Finger Follower Actuated Valves with Hydraulic Adjusters

Counter Rotating Balance Shaft

Oil Jet Cooled Pistons

Swirl Intake Ports

Chain driven D.O.H.C. per bank of cylinders, with 4 valves per cylinder

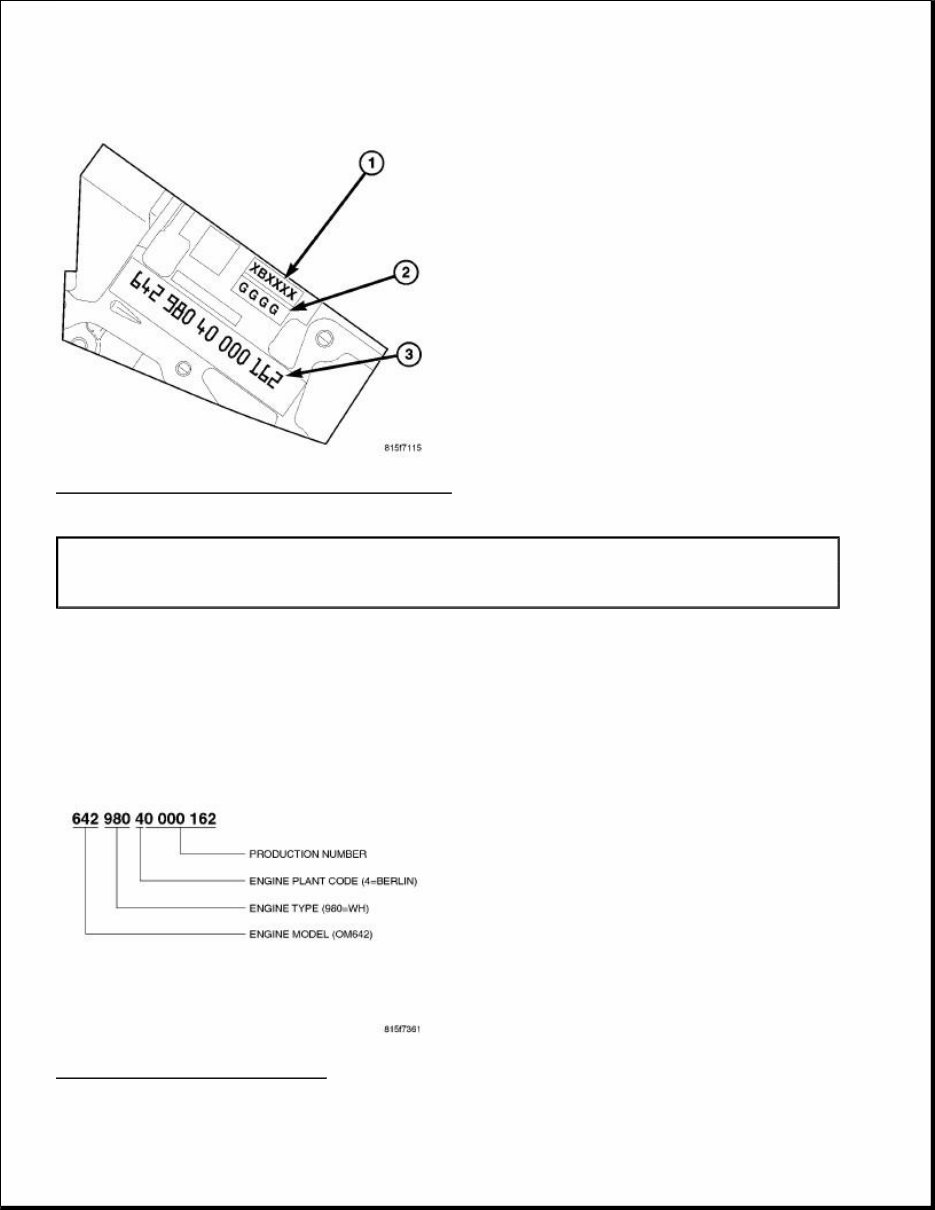

1 - CYLINDER BORE TOLERANCE IDENTIFICATION

2 - MAIN BEARING TOLERANCE IDENTIFICATION

3 - ENGINE IDENTIFICATION AND SERIAL NUMBER

Fig. 2: ENGINE IDENTIFICATION MARKINGS

Courtesy of CHRYSLER LLC

The engine identification stamp (3) for the 3.0L is located on the left side of the engine block, below the high

pressure pump along with the 4 digit main bearing identifying stamp (2) and the 6 digit cylinder bore

identifying stamp (1).

Fig. 3: ENGINE NUMBER CODE

Courtesy of CHRYSLER LLC

1 - CYLINDER BORE IDENTIFICATION

2 - MAIN BEARING IDENTIFICATION

3 - ENGINE IDENTIFICATION AND SERIAL NUMBER

The engine identification number encompasses the production number, engine plant code, engine type and

engine model.

ENGINE COVER

Fig. 4: ENGINE COVER

Courtesy of CHRYSLER LLC

The insulated engine cover (1) is made of composite material and used cosmetically to cover the top of the

engine and greatly reduce engine noise. Three brackets secure the cover to the engine.

DIAGNOSIS AND TESTING

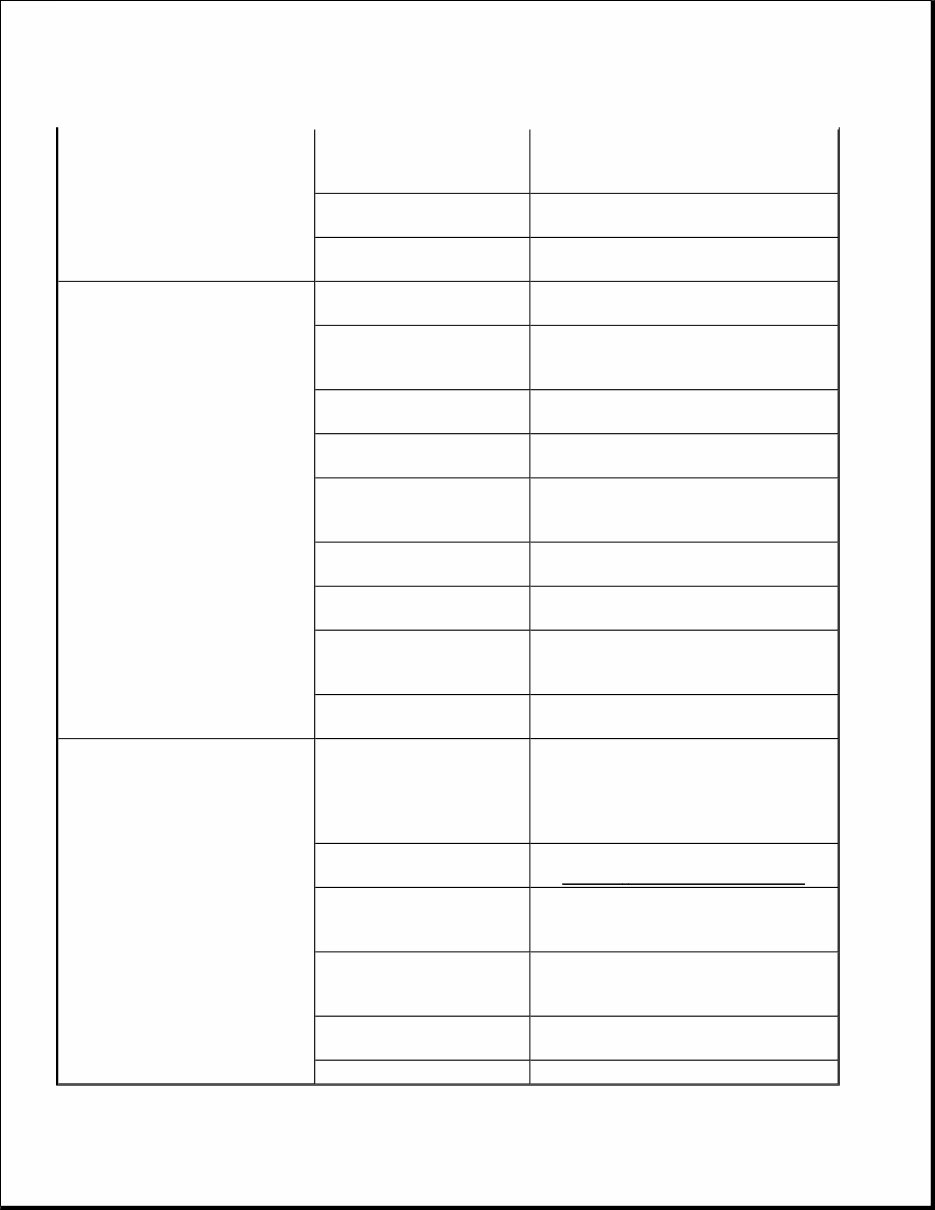

ENGINE DIAGNOSIS - MECHANICAL

1 - ENGINE COVER

CONDITION POSSIBLE CAUSES CORRECTION

LUBRICATING OIL

PRESSURE LOW

1. Low oil level. 1. (a) Check and fill with clean engine

oil.

(b) Check for a severe oil leak, worn

rings (burning oil), oil leaking from the

turbocharger to the intake, or other root

causes for low oil level.

2. Oil viscosity thin, diluted

or wrong specification.

2. (a) Verify the correct engine oil is

being used.

(b) Look for reduced viscosity from fuel

dilution.

3. Improperly operating 3. Verify the pressure switch is

pressure switch/gauge. functioning correctly. If not, replace

switch/gauge.

4. Relief valve stuck open. 4. Check/replace valve.

5. If cooler was replaced,

shipping plugs may have

been left in cooler

5. Check/remove shipping plugs.

6. Worn oil pump. 6. Check and replace oil pump.

7. Suction tube loose or seal

leaking.

7. Check and replace seal.

8. Loose main bearing cap. 8. Check and install new bearing.

Tighten cap to proper torque.

9. Worn bearings or wrong

bearings installed.

9. Inspect and replace connecting rod or

main bearings. Check and replace

directed piston cooling nozzles.

10. Directed piston cooling

nozzles under piston, bad fit

into main carrier.

10. Check directed piston cooling

nozzles position.

12. Loose directed piston

cooling nozzle.

12. Tighten directed piston cooling

nozzle.

LUBRICATING OIL

PRESSURE TOO HIGH

1. Pressure switch/gauge not

operating properly.

1. Verify pressure switch is functioning

correctly. If not, replace switch/gauge.

2. Engine running too cold. 2. Coolant Temperature Below Normal

3. Oil viscosity too thick. 3. Make sure the correct oil is being

used.

4. Oil pressure relief valve

stuck closed or binding

4. Check and replace valve.

LUBRICATING OIL LOSS 1. External leaks. 1. Visually inspect for oil leaks. Repair

as required.

2. Crankcase overfilled. 2. Verify that the correct dipstick is

being used.

3. Incorrect oil specification

or viscosity.

3. (a) Make sure the correct oil is being

used.

(b) Look for reduced viscosity from

dilution with fuel.

(c) Review/reduce oil change intervals.

4. Oil cooler leak 4. Check and replace the oil cooler.

5. High blow-by forcing oil

out the breather.

5. Check the breather tube area for signs

of oil loss. Perform the required repairs.

6. Turbocharger leaking oil

to the air intake.

6. Inspect the air ducts for evidence of oil

transfer. Repair as required (slight oil

residue is normal).

COMPRESSION KNOCKS 1. Air in the fuel system. 1. Identify location of air leak and repair.

Do not bleed high pressure fuel system.

2. Poor quality fuel or 2. Verify by operating from a temporary

water/gasoline contaminated

fuel.

tank with good fuel. Clean and flush the

fuel tank. Replace fuel/water separator

filter.

3. Engine overloaded. 3. Verify the engine load rating is not

being exceeded.

4. Improperly operating

injectors.

4. Check and replace

misfiring/inoperative injectors.

EXCESSIVE VIBRATION 1. Loose or broken engine

mounts.

1. Replace engine mounts.

2. Damaged fan or

improperly operating

accessories.

2. Check and replace the vibrating

components.

3. Improperly operating

vibration damper

3. Inspect/replace vibration damper.

4. Improperly operating

balance shaft

4. Inspect/replace balance shaft.

5. Improperly operating

electronically controlled

viscous fan drive.

5. Inspect/replace fan drive.

6. Worn or damaged

generator bearing.

6. Check/replace generator.

7. Flywheel housing

misaligned.

7. Check/correct flywheel alignment.

8. Loose or broken power

component.

8. Inspect the crankshaft and rods for

damage that causes an unbalance

condition. Repair/replace as required.

9. Worn or unbalanced

driveline components.

9. Check/repair driveline components.

EXCESSIVE ENGINE NOISES 1. Drive belt squeal,

insufficient tension or

abnormally high loading.

1. Check the automatic tensioner and

inspect the drive belt. Make sure water

pump, tensioner pulley, fan hub,

generator and power steering pump turn

freely.

2. Intake air or exhaust

leaks.

2. Refer to Excessive Exhaust Smoke.

See Engine - Diagnosis and Testing .

3. Excessive valve lash. 3. Adjust valves. Make sure the rocker

arms are not bent. Replace bent or

severely worn components.

4. Turbocharger noise. 4. Check turbocharger impeller and

turbine wheel for housing contact.

Repair/replace as required.

5. Gear train noise. 5. Visually inspect and measure gear

backlash. Replace gears as required.

6. Power function knock. 6. Check/replace rod and main bearings.

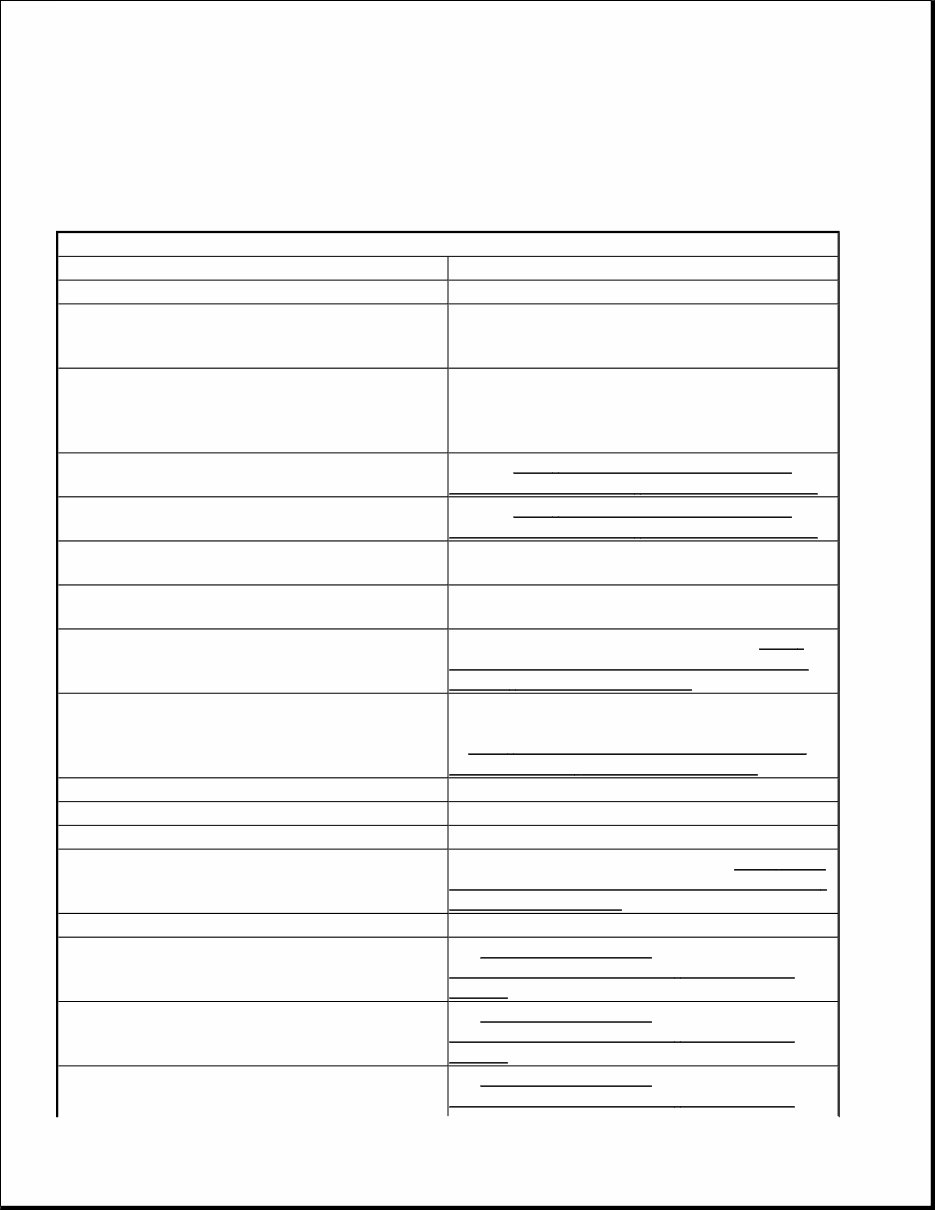

SMOKE DIAGNOSIS CHARTS

The following charts include possible causes and corrections for excess or abnormal exhaust smoke. Small

amounts of exhaust smoke (at certain times) are to be considered normal for a diesel powered engine.

EXCESSIVE BLACK SMOKE

POSSIBLE CAUSE CORRECTION

Air filter dirty or plugged. Check and replace the filter if necessary.

Air intake system restricted. Check entire air intake system including all hoses

and tubes for restrictions, collapsed parts or damage.

Repair/replace as necessary.

Air Leak in Intake System. Check entire air intake system including all hoses

and tubes for collapse, cracks, loose clamps, or

holes in rubber ducts. Also check intake manifold

for loose mounting hardware.

Diagnostic Trouble Codes (DTC's) active or

multiple, intermittent DTC's.

Refer to DTC - Based Diagnostics/MODULE,

Engine Control (ECM) - Diagnosis and Testing .

Engine Control Module (ECM) has incorrect

calibration.

Refer to DTC - Based Diagnostics/MODULE,

Engine Control (ECM) - Diagnosis and Testing .

Exhaust system restriction is above specifications. Check exhaust pipes for damage/restrictions. Repair

as necessary.

Fuel grade is not correct or fuel quality is poor. Temporarily change fuel brands and note condition.

Change brand if necessary.

Fuel injection pump malfunctioning. A DTC may have been set. If so. Refer to DTC -

Based Diagnostics/MODULE, Engine Control

(ECM) - Diagnosis and Testing .

Fuel injector malfunctioning. A DTC may have been set. Perform "Injector

Classification Programming" using scan tool. Refer

to DTC - Based Diagnostics/MODULE, Engine

Control (ECM) - Diagnosis and Testing .

Fuel injector lower washer doubled or missing. Remove and inspect injector washer.

Fuel return system restricted. Check fuel return lines for restriction.

Intake manifold restricted. Remove restriction.

Manifold Air Pressure (Boost) Sensor or sensor

circuit malfunctioning.

A DTC should have been set. Refer to DTC - Based

Diagnostics/MODULE, Engine Control (ECM) -

Diagnosis and Testing .

Turbocharger air intake restriction. Remove restriction.

Turbocharger damaged. See Engine/Turbocharger

System/TURBOCHARGER - Diagnosis and

Testing .

Turbocharger has excess build up on compressor

wheel or diffuser vanes.

See Engine/Turbocharger

System/TURBOCHARGER - Diagnosis and

Testing .

Turbocharger wheel clearance out of specification. See Engine/Turbocharger

System/TURBOCHARGER - Diagnosis and

Testing .

EXCESSIVE WHITE SMOKE

POSSIBLE CAUSE CORRECTION

Air in fuel supply: Possible leak in fuel supply side. Inspect fuel system

Coolant leaking into combustion chamber. Perform pressure test of cooling system.

Diagnostic Trouble Codes (DTC's) active or

multiple, intermittent DTC's.

Refer to DTC - Based Diagnostics/MODULE,

Engine Control (ECM) - Diagnosis and Testing .

In very cold ambient temperatures, engine block

heater is malfunctioning (if equipped).

Refer to Cooling/Engine/HEATER, Engine Block

- Diagnosis and Testing

Engine coolant temperature sensor malfunctioning. A DTC should have been set. Refer to DTC - Based

Diagnostics/MODULE, Engine Control (ECM) -

Diagnosis and Testing . Also check thermostat

operation.

Engine Control Module (ECM) has incorrect

calibration.

A DTC should have been set. Refer to DTC - Based

Diagnostics/MODULE, Engine Control (ECM) -

Diagnosis and Testing .

Fuel filter plugged. Refer to Non - DTC Diagnostics/Driveability -

Diesel - Diagnosis and Testing .

Fuel grade not correct or fuel quality is poor. Temporarily change fuel brands and note condition.

Change brand if necessary.

Fuel injector malfunctioning. A DTC should have been set. Perform "Injector

Identification Programming" or "Cylinder Cutout

Test" using scan tool to isolate individual cylinders.

Refer to DTC - Based Diagnostics/MODULE,

Engine Control (ECM) - Diagnosis and Testing .

Fuel injector hold-down(s) loose. Replace the copper washer(s) (shim) and tighten to

specifications.

Fuel injector protrusion not correct. Check washer (shim) at bottom of fuel injector for

correct thickness.

Fuel injection pump malfunctioning. A DTC should have been set. Refer to DTC - Based

Diagnostics/MODULE, Engine Control (ECM) -

Diagnosis and Testing .

Fuel supply side restriction. Refer to Non - DTC Diagnostics/Driveability -

Diesel - Diagnosis and Testing for fuel system

testing.

Intake manifold air temperature sensor

malfunctioning.

A DTC should have been set. Refer to DTC - Based

Diagnostics/MODULE, Engine Control (ECM) -

Diagnosis and Testing .

Intake manifold heater circuit not functioning

correctly in cold weather.

A DTC should have been set. Refer to DTC - Based

Diagnostics/MODULE, Engine Control (ECM) -

Diagnosis and Testing . Also check heater

elements for correct operation.

Intake manifold heater elements not functioning

correctly in cold weather.

A DTC should have been set if heater elements are

malfunctioning. Refer to DTC - Based

STANDARD PROCEDURE

ENGINE GASKET SURFACE PREPARATION

Diagnostics/MODULE, Engine Control (ECM) -

Diagnosis and Testing .

Internal engine damage (scuffed cylinder). Analyze engine oil and inspect oil filter to locate

area of probable damage.

Restriction in fuel supply side of fuel system. Refer to Non - DTC Diagnostics/Driveability -

Diesel - Diagnosis and Testing for fuel system

testing.

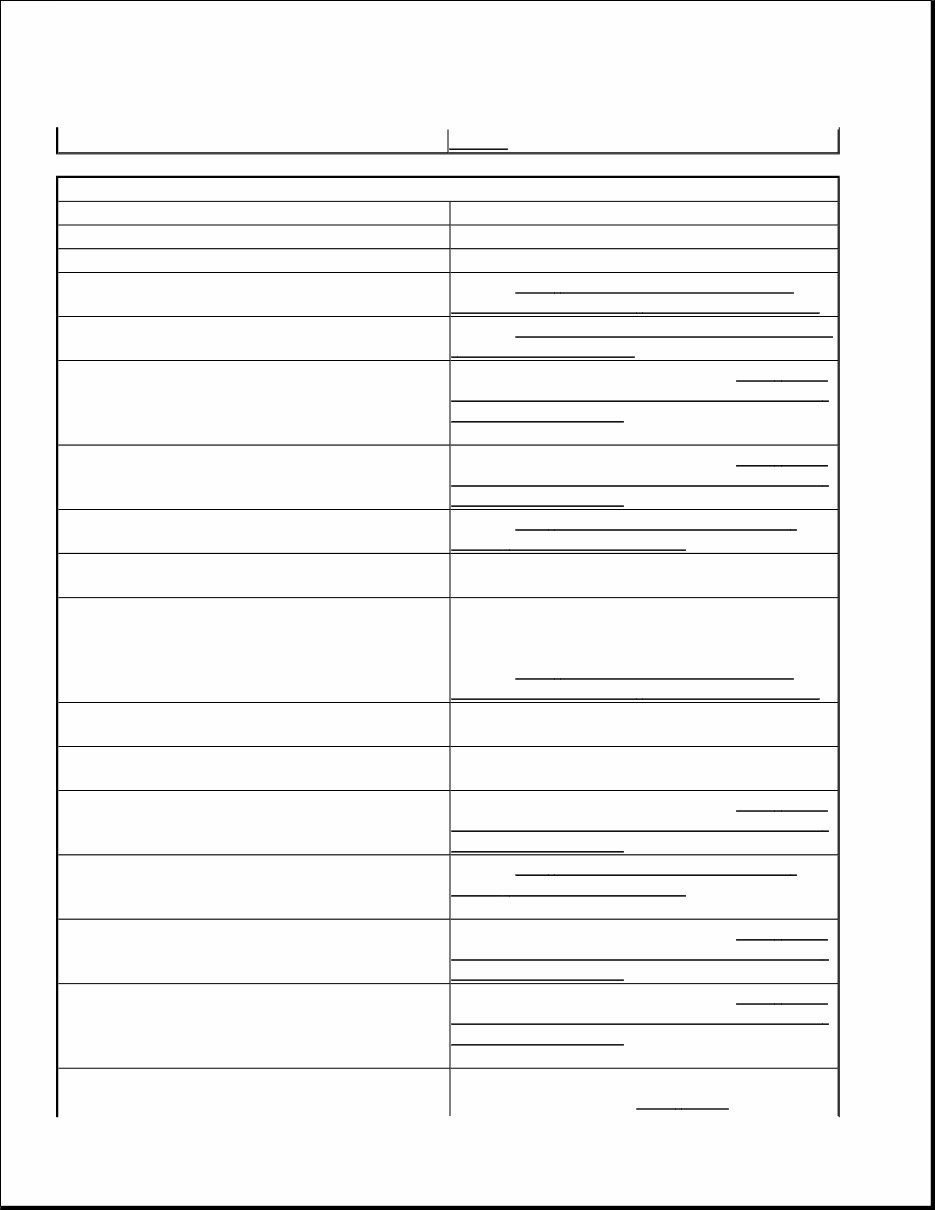

EXCESSIVE BLUE SMOKE

POSSIBLE CAUSE CORRECTION

Dirty air cleaner or restricted turbocharger intake

duct.

Check Air Cleaner Housing for debris and replace

filter as necessary

Air leak in boost system between turbocharger

compressor outlet and intake manifold.

Service charge air system.

Obstruction in exhaust manifold. Remove exhaust manifold and inspect for blockage.

Restricted turbocharger drain tube. Remove turbocharger drain tube and remove

obstruction.

Crankcase ventilation system plugged. Inspect oil separator system for function and clear

drain back hole in cylinder head cover/intake

manifold

Valve seals are worn, brittle, or improperly

installed.

Replace valve stem oil seals

Valve stems or guides are worn. Remove valves and inspect valves and guides.

Broken or Improperly installed piston rings. Tear down engine and inspect piston rings.

Excessive piston ring end gap. Remove pistons and measure piston ring end gap.

Excessive cylinder liner wear and taper. Remove pistons and measure cylinder liner wear

and taper.

Cylinder damage. Remove pistons and inspect cylinder liner for cracks

or porosity. Repair with new cylinder liner if

necessary.

Piston damage. Remove pistons and inspect for cracks, holes.

Measure piston for out-of-round and taper.

Turbocharger failure. See Engine/Turbocharger

System/TURBOCHARGER - Diagnosis and

Testing .

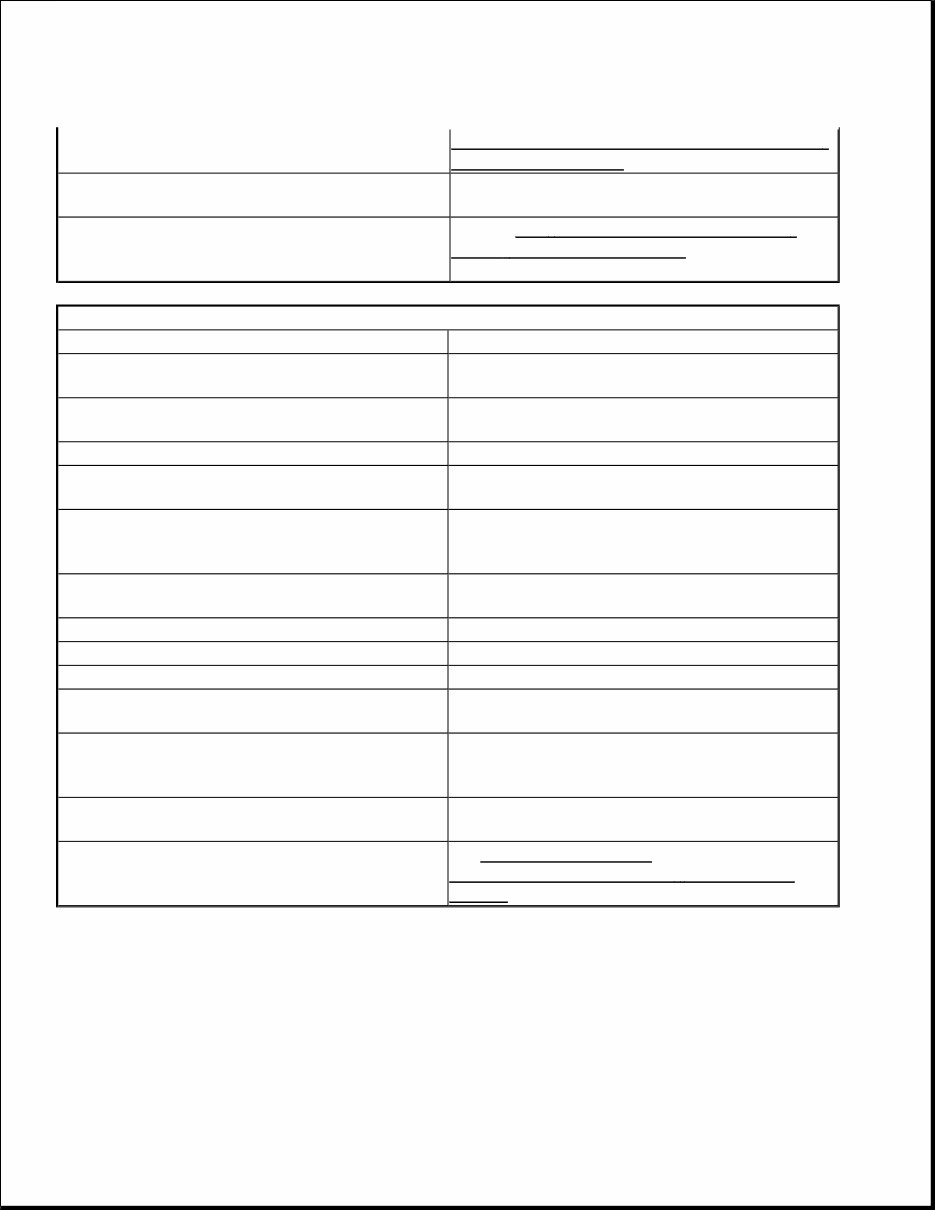

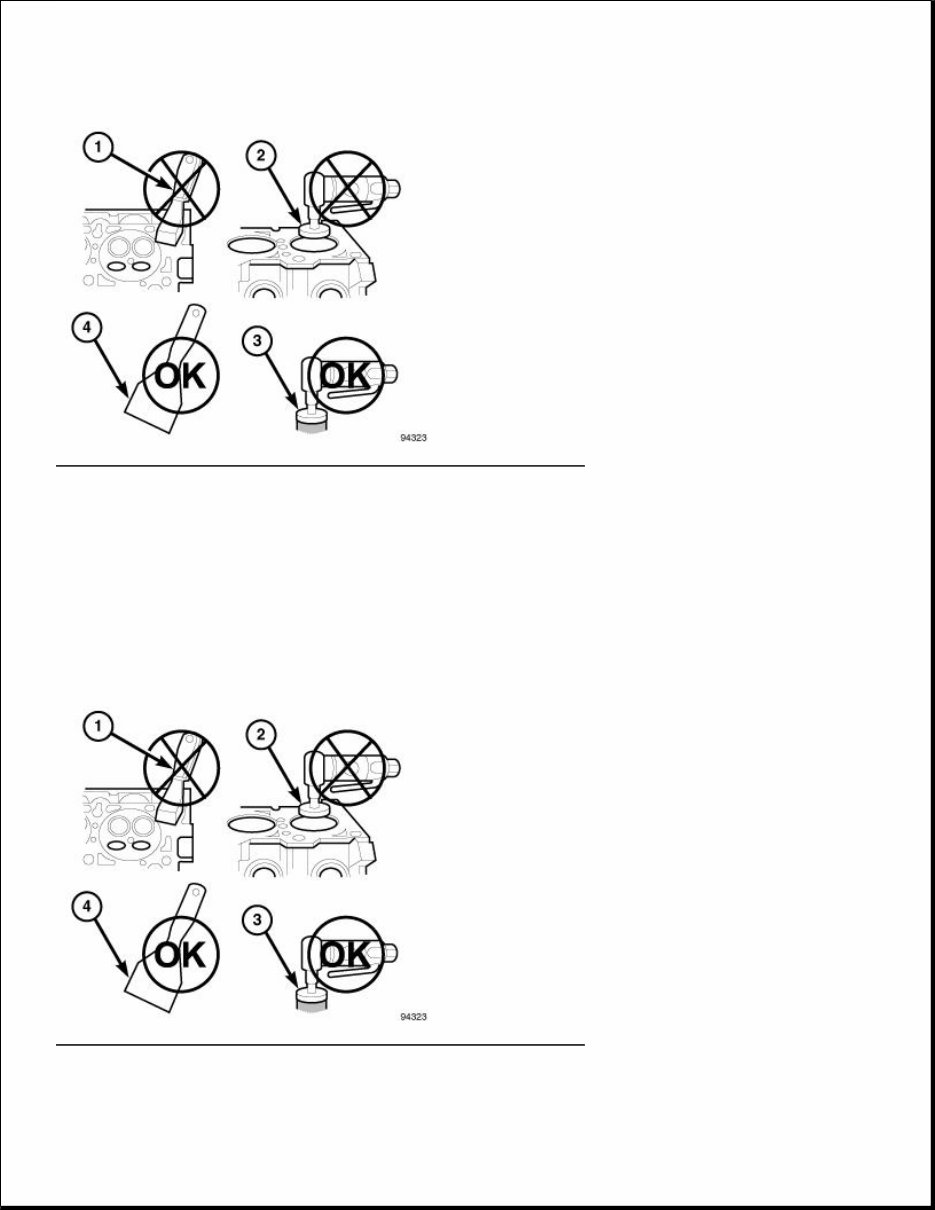

Fig. 5: PROPER TOOL USAGE FOR SURFACE PREPARATION

Courtesy of CHRYSLER LLC

To ensure engine gasket sealing, proper surface preparation must be performed, especially with the use of

aluminum engine components and multi-layer steel cylinder head gaskets.

Never use the following to clean gasket surfaces:

Metal scraper (1).

Abrasive pad or paper to clean cylinder block and head.

High speed power tool with an abrasive pad or a wire brush (2,3).

Fig. 6: PROPER TOOL USAGE FOR SURFACE PREPARATION

Courtesy of CHRYSLER LLC

NOTE: Multi-Layer Steel (MLS) head gaskets require a scratch free sealing surface.

You're Reading a Preview

What's Included?

Fast Download Speeds

Online & Offline Access

Access PDF Contents & Bookmarks

Full Search Facility

Print one or all pages of your manual

$36.99

Viewed 14 Times Today

Loading...

Secure transaction

What's Included?

Fast Download Speeds

Online & Offline Access

Access PDF Contents & Bookmarks

Full Search Facility

Print one or all pages of your manual

$36.99

The 2008 Jeep Grand Cherokee Service & Repair Manual Software is a comprehensive resource designed to assist owners in maintaining and repairing their vehicles. With detailed instructions and diagrams, this software provides all the necessary information to tackle any service or repair task on the 2008 Jeep Grand Cherokee.

Features:

- Step-by-step instructions for various repairs and maintenance tasks

- Detailed diagrams and illustrations to aid in understanding

- Coverage of all models of the 2008 Jeep Grand Cherokee:

- Laredo

- Limited

- Overland

- SRT-8

- Includes information on engine, transmission, electrical systems, suspension, brakes, and more

- Compatible with Windows operating systems

Whether you are a professional mechanic or a DIY enthusiast, the 2008 Jeep Grand Cherokee Service & Repair Manual Software is an invaluable tool for keeping your vehicle in top condition.