1995 JEEP CHEROKEE XJ, JEEP WRANGLE YJ Service & Repair Manual - !

What's Included?

Fast Download Speeds

Online & Offline Access

Access PDF Contents & Bookmarks

Full Search Facility

Print one or all pages of your manual

NOTE: Groups with the suffix “-S” are supplements to

the original service manual publication.

GROUP TAB LOCATOR PAGE

IN

Introduction

0

Lubrication and Maintenance

2

Front Suspension and Axle

3

Rear Suspension and Axles

5

Brakes

6

Clutch

7

Cooling System

8

Electrical

9

Engines

11

Exhaust System and Intake Manifold

13

Frame and Bumpers

14

Fuel System

16

Propeller Shafts

19

Steering

21

Transmissions and Transfer Cases

22

Wheels and Tires

23

Body Components

24

Heating and Air Conditioning

24-S

Air Conditioning

25

Emission Control Systems

Index

Index Supplement

Service Manual Comment Forms (Rear of Manual)

FOREWORD

The information contained in this service manual

has been prepared for the professional automotive

technician involved in daily repair operations. This

manual does not cover theory of operation, which is

addressed in service training material. Information

describing the operation and use of standard and op-

tional equipment is included in the Owner’s Manual

provided with the vehicle.

This manual is designed as a supplement to be

used along with the 1994 Jeep Cherokee/Wrangler

Service Manual, 81-370-4146. It includes information

related to 1994 vehicles built after December, 1993.

It should be used in conjunction with the initial man-

ual for complete vehicle coverage.

This contains general information, diagnosis, and

testing procedures for the new R134a refrigerant sys-

tem.

The Component and System Index of th is man-

ual identifies the correct page for the component or

system to be serviced. In addition, a Service Manual

Comment form is included at the rear of this manual.

Use the form to provide Chrysler Corporation with

your comments and suggestions.

Chrysler Corporation reserves the right to

change testing procedures, specifications, diagnosis,

repair methods, or vehicle wiring at any time without

prior notice or incurring obligation.

HEATING AND AIR CONDITIONING 1

INDEX 1

Service Manual Comment Forms (Rear of Manual)

NOTE: The acronyms, terminology and nomenclature used to identify emissions related components in

this manual may have changed from prior publications. These new terms are in compliance with S.A.E.

recommended practice J1930.

INTRODUCTION

CONTENTS

page page

DESIGNATIONS, LABELS/PLATES, CODES

AND DIMENSIONS ..................... 1

SPECIFICATIONS ........................ 8

DESIGNATIONS, LABELS/PLATES, CODES AND DIMENSIONS

INDEX

page page

Engine and Transmission/Transfer Case Identification .3

International Vehicle Control and Display Symbols .3

Major Component Identification ............... 3

Tire Inflation Pressure Label ................. 3

Vehicle Code Plate ........................ 2

Vehicle Designations ....................... 1

Vehicle Dimension Data .................... 3

Vehicle Identification Number (VIN) Plate ....... 1

Vehicle Load Data ........................ 3

Vehicle Safety Certification Label ............. 1

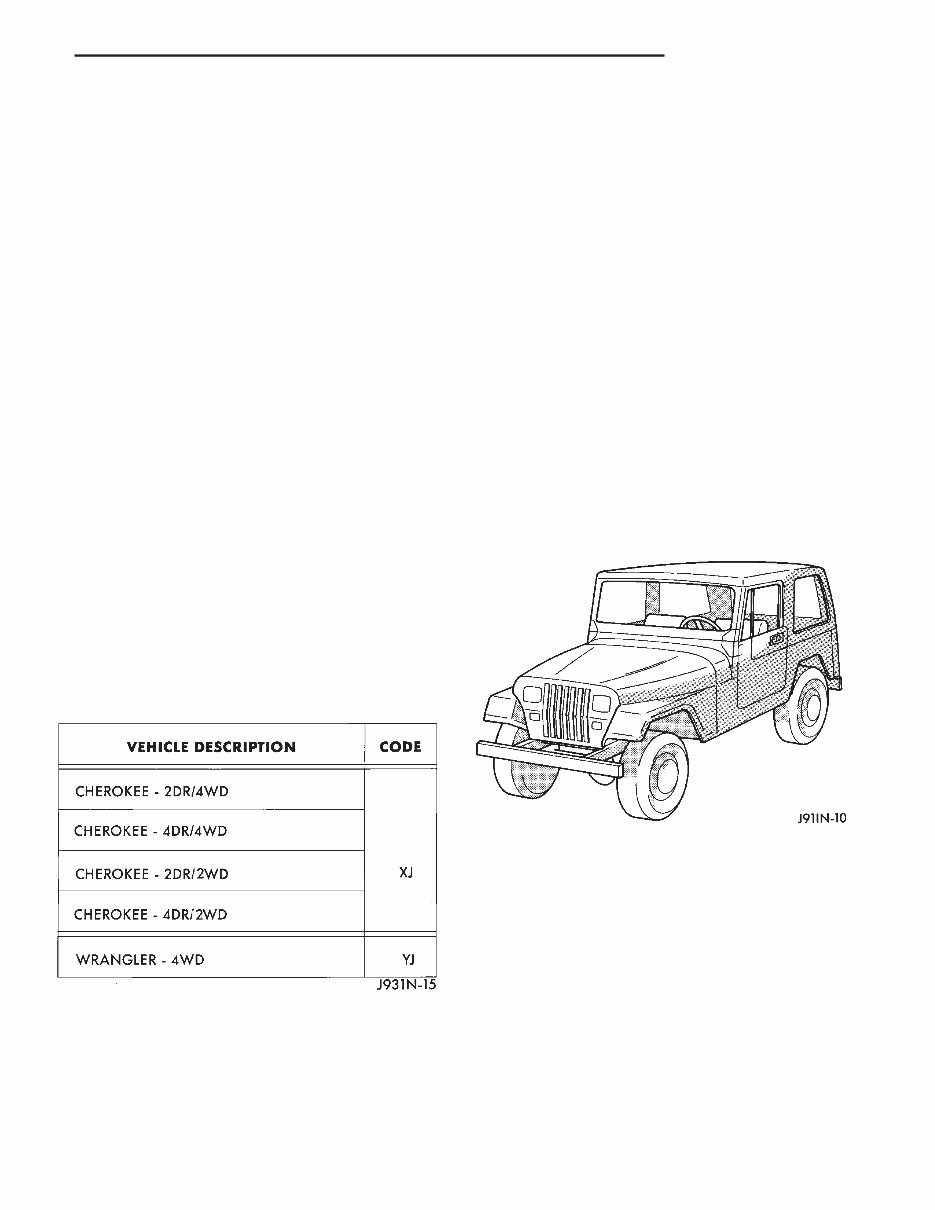

VEHICLE DESIGNATIONS

The Vehicle Designation Codes chart lists the vehi-

cle description(s) and the corresponding vehicle des-

ignation code for each type of Jeept vehicle (Figs. 1,

2, and 3 ). The vehicle designation codes are different

from the Vehicle Identification Number (VIN) or

body-type/style codes.

VEHICLE SAFETY CERTIFICATION LABEL

A vehicle safety certification label (Fig. 4) is at-

tached to each Jeept vehiclee. The label also lists

the:

• gross vehicle weight rating (GVWR) and the gross

front and rear axle weight ratings (GAWR’s) based

on a minimum tire rim size and a maximum cold tire

inflation pressure;

• month and year of vehicle manufacture;

• vehicle identification number (VIN);

• type of vehicle and

• month, day and hour (MDH) of final assembly.

The label is located on the driver’s side door edge.

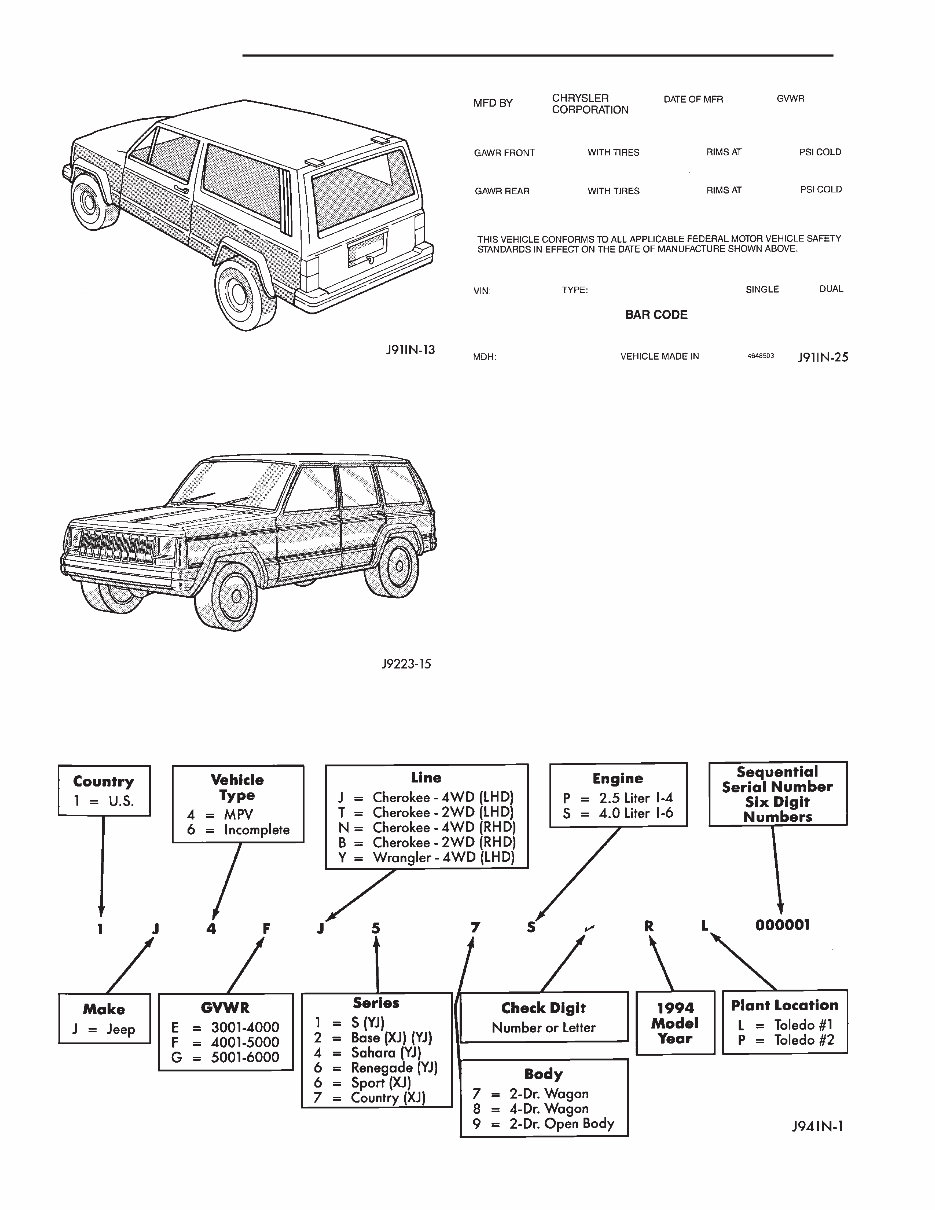

VEHICLE IDENTIFICATION NUMBER (VIN) PLATE

The vehicle identification number (VIN) plate is at-

tached to the top left side of the instrument panel at

the base of the windshield. Each VIN contains 17 al-

pha-numerical characters. Refer to the decoding

chart to determine the actual identification of a

Jeept vehicle.

VEHICLE DESIGNATION CODES

Fig. 1 YJ—Wrangler Multi-Purpose Vehicle (With

Hard Top)

J INTRODUCTION 1

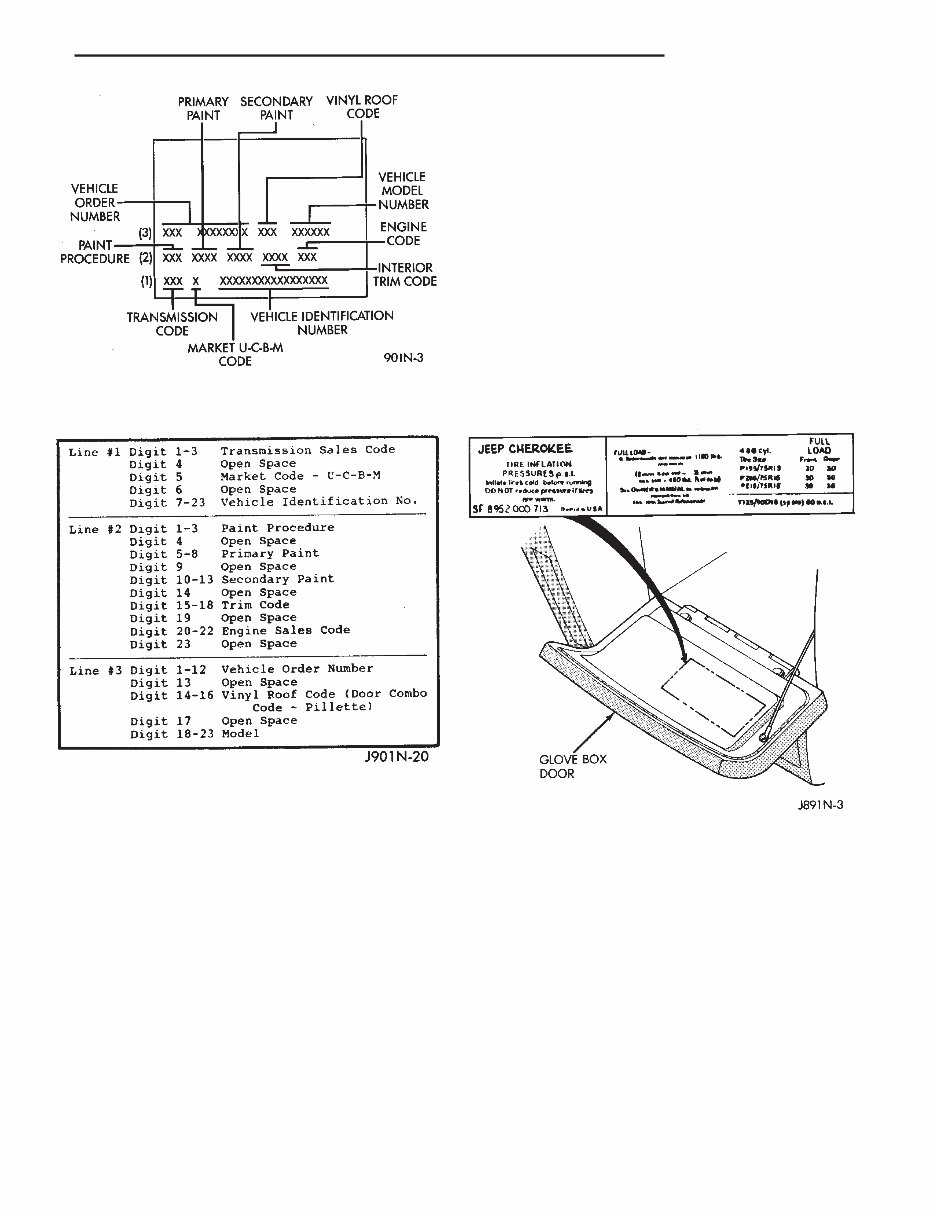

VEHICLE CODE PLATE

A metal vehicle code plate is attached to the left

(driver) side of the dash panel in the engine compart-

ment (Fig. 5). There can be a maximum of seven rows

of vehicle information imprinted on the plate. The in-

formation should be read from left to right, starting

with line 1 at the bottom of the plate up through line

7 (as applicable) at the top of the code plate.

Refer to the decoding chart to decode lines 1 up

through 3.

Lines 4 through 7 (if used) on the vehicle code

plate are imprinted on the plate (in sequence) accord-

ing to the following:

• 3-character sales code,

• 3-digit numerical code, and

• 6-digit SEC code.

Fig. 2 XJ—Cherokee 2-Door Multi-Purpose Vehicle

Fig. 3 XJ—Cherokee 4-Door Multi-Purpose Vehicle

Fig. 4 Vehicle Safety Certification Label

VEHICLE IDENTIFICATION NUMBER (VIN) DECODING

2 INTRODUCTION J

If there is not enough space left in the row for all

of the 6-digit SEC code (if used):

• the unused space will remain blank, and

• the code will be listed in the next row.

The last nine positions of row 7 will contain a 2-digit

code, when applicable, and a 6-digit gateline serial

number (same as the last 6 numbers of the VIN).

The last code imprinted on a vehicle code plate will

be followed by the imprinted word END. When two

vehicle code plates are required, the last available

spaces on the first plate will be imprinted with the

letters CTD (for continued).

When a second vehicle code plate is necessary, the

first four spaces on each row will not be used because

of the plate overlap.

ENGINE AND TRANSMISSION/TRANSFER CASE

IDENTIFICATION

When required, refer to Group 9—Engines for all

engine identification data. Refer to Group 21—Trans-

missions for all transmission/transfer case identifica-

tion data.

MAJOR COMPONENT IDENTIFICATION

When required, refer to the applicable service infor-

mation group for major component identification data.

TIRE INFLATION PRESSURE LABEL

The tire inflation pressures label is located on the

glove box door inside panel (Fig. 6). The tires should

also be inspected for visible wear. Also, inspect the

tires for cracks, bulges and other road hazard dam-

age. Refer to Group 22—Tires And Wheels.

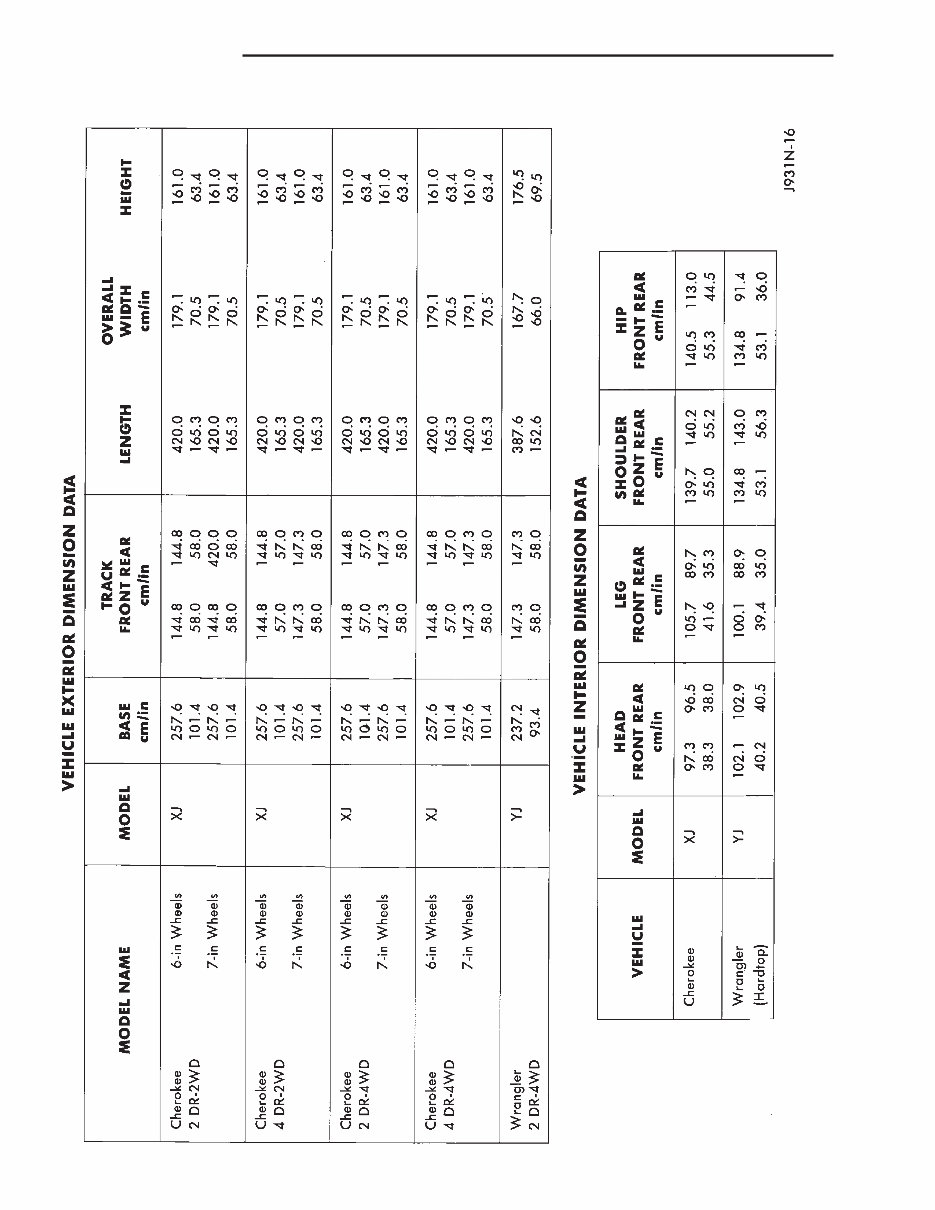

VEHICLE DIMENSION DATA

The vehicle dimension data charts list the exterior

and interior dimensions for each type of Jeept vehicle.

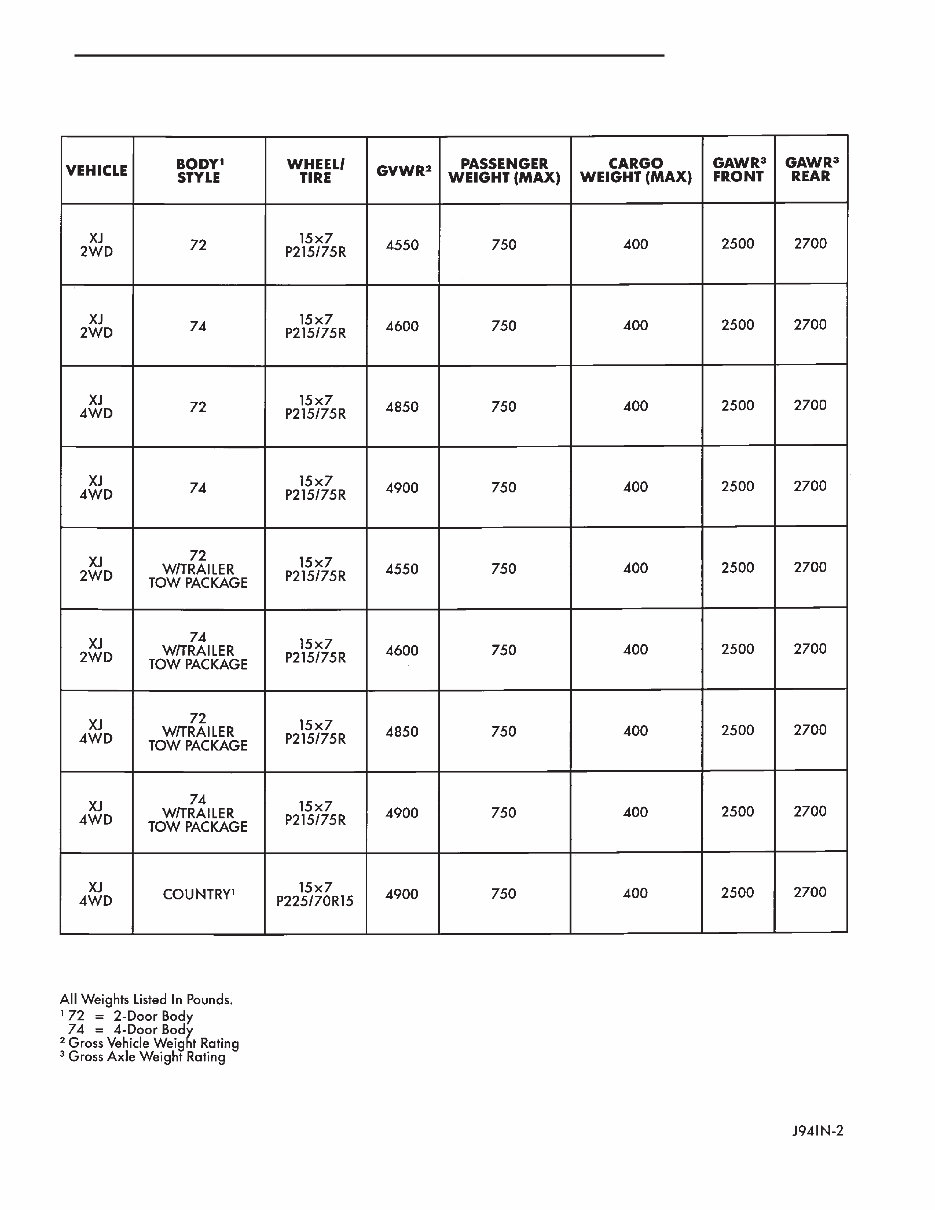

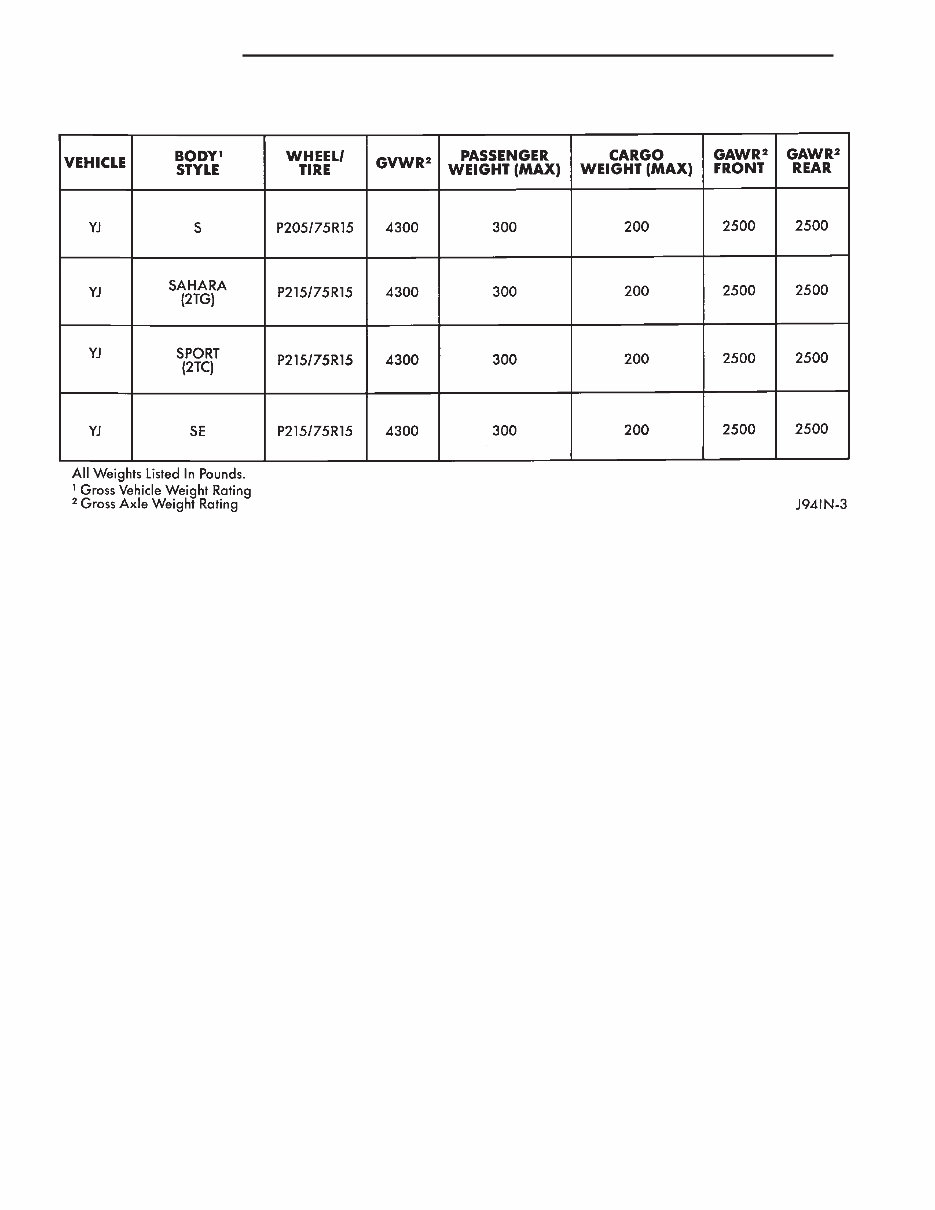

VEHICLE LOAD DATA

The Vehicle Load Data chart lists the following in-

formation:

• the gross vehicle weight rating (GVWR),

• the gross axle weight ratings (GAWR),

• the cargo weight, and

• the passenger weight for each Jeept type/body

style.

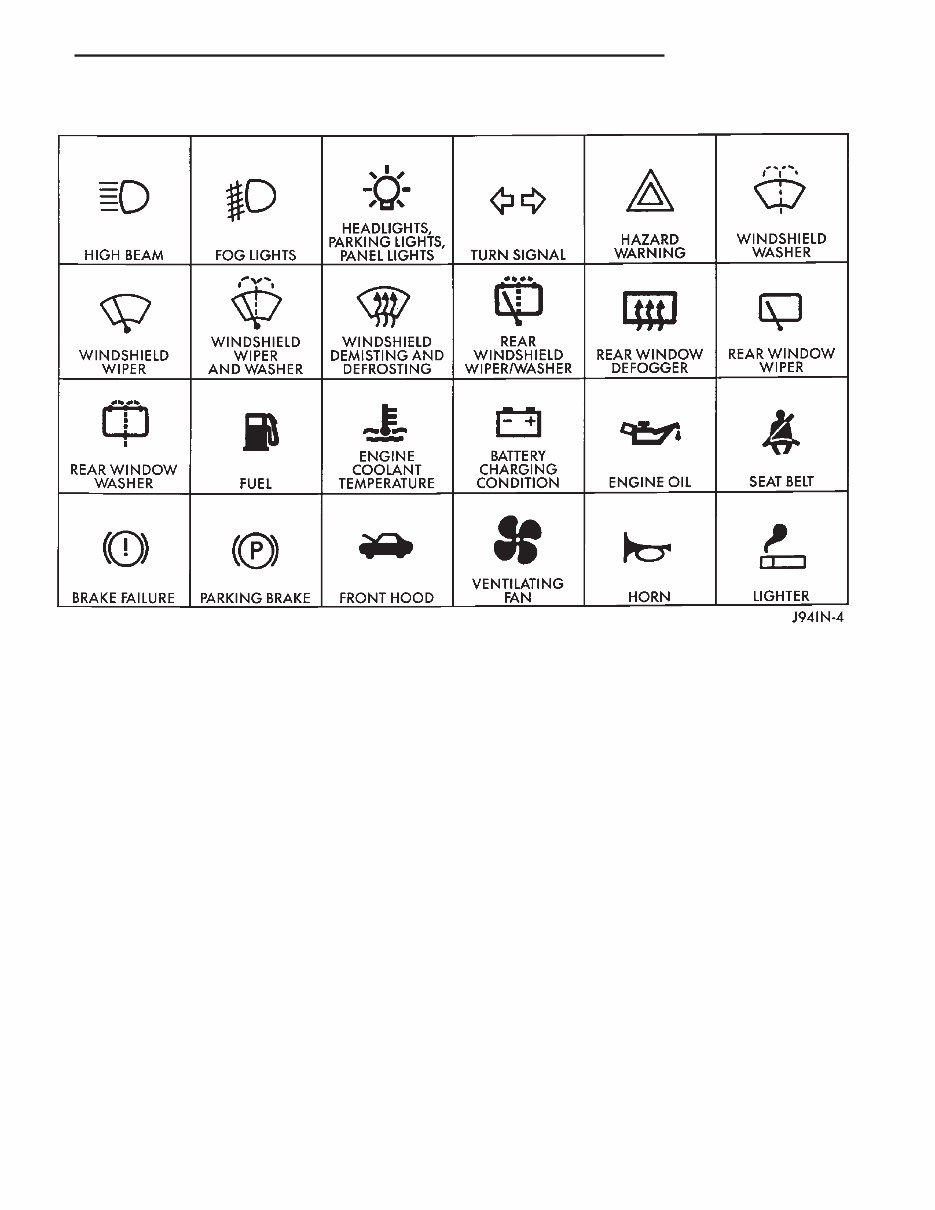

INTERNATIONAL VEHICLE CONTROL AND DISPLAY

SYMBOLS

Most of the graphic symbols illustrated in the fol-

lowing chart are used to identify various instrument

controls and displays.

Fig. 5 Vehicle Code Plate

VEHICLE CODE DECODING

Fig. 6 Tire Inflation Pressures Label—Typical

J INTRODUCTION 3

VEHICLE DIMENSION DATA

4 INTRODUCTION J

XJ VEHICLE LOAD DATA

J INTRODUCTION 5

YJ-VEHICLE LOAD DATA

6 INTRODUCTION J

VEHICLE CONTROL AND DISPLAY SYMBOLS

J INTRODUCTION 7

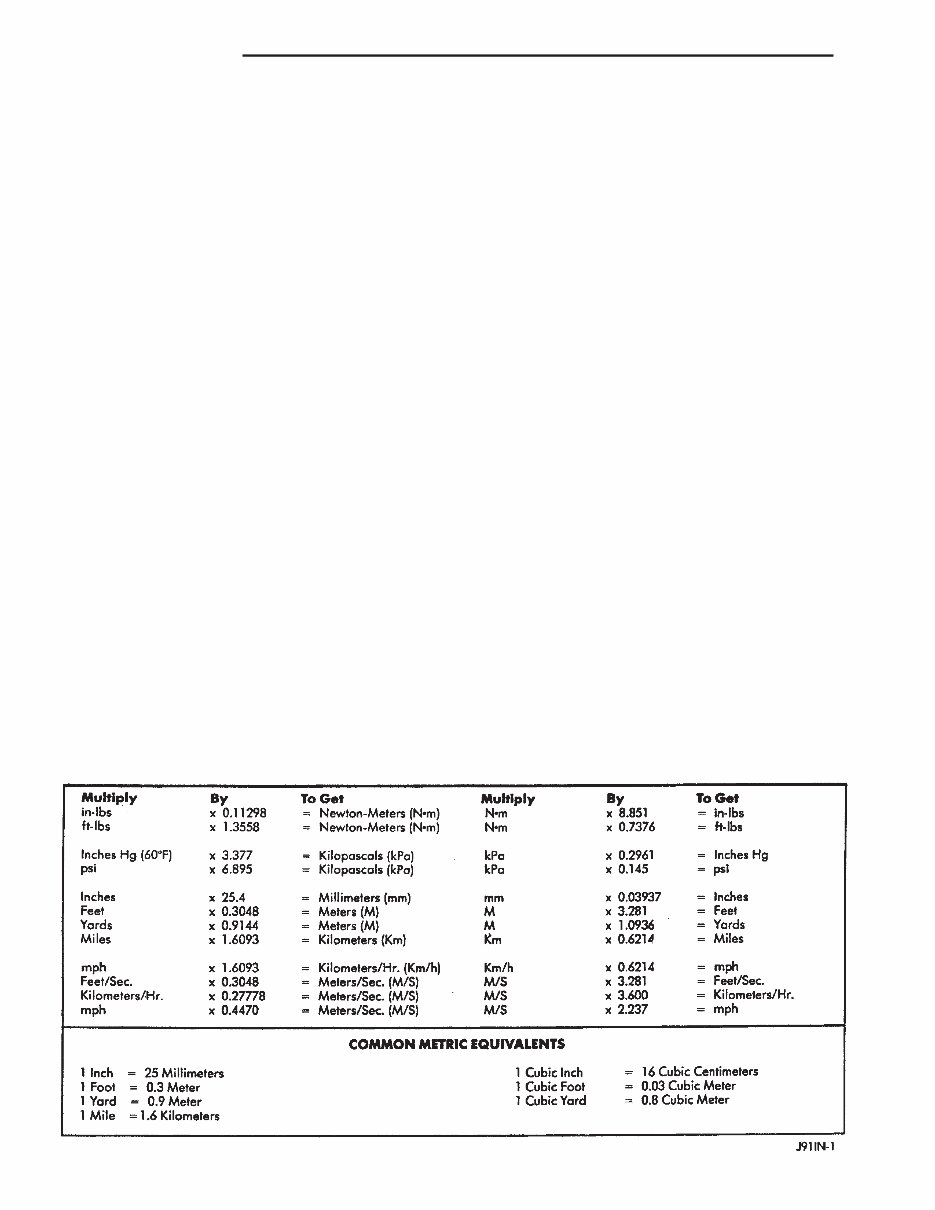

SPECIFICATIONS

SPECIFICATION NOTATIONS

All torque specifications listed in this service man-

ual are in both metric system and SAE/English sys-

tem.

WARNING: THE USE OF INCORRECT ATTACHING

HARDWARE CAN RESULT IN COMPONENT DAM-

AGE AND/OR PERSONAL INJURY.

During all procedures, it is important to retain the

original attaching hardware. If the hardware is not

reusable, replace new hardware with equivalent

specifications.

METRIC SYSTEM NOTATION

The following conversion chart will assist in con-

verting SAE/English units to equivalent metric

units.

TORQUE SPECIFICATIONS

TORQUE CHARTS

If applicable, torque chart(s) for screws, bolts and

nuts is/are provided at the end of each service infor-

mation group. Refer to the Standard Torque Specifi-

cations chart and the bolt grade/class identification

illustrations (Figs. 7 and 8).

It is important to be aware that the torque values

listed in the chart are based on clean and dry bolt

threads. Reduce the applicable listed torque value by

10 percent when the bolt threads are lubricated with

engine oil and by 20 percent if new, plated bolts are

being tightened.

Various sizes of (Torx) head fasteners are used

as attaching hardware for numerous compo-

nents in Jeept vehicles.

BOLT THREAD AND GRADE/CLASS

IDENTIFICATION

THREAD IDENTIFICATION

SAE and metric bolt/nut threads are different. The

difference is described in the Thread Notation chart.

GRADE/CLASS IDENTIFICATION

The SAE bolt strength grades range from grade 2

to grade 8. The higher the grade number, the greater

the bolt strength. The grade identification is deter-

mined by the line marks on the top of each bolt head

(Fig. 7). The actual bolt strength grade corresponds

to the number of line marks plus 2. For example:

• a grade 2 bolt has no line marks on top of the bolt

head;

• a grade 5 bolt has 3 line marks on top of the bolt

head;

• a grade 7 bolt has 5 line marks on top of the bolt

head; and

• a grade 8 bolt has 6 line marks on top of the bolt

head.

The most commonly used metric bolt strength

classes are 9.8 and 12.9. The metric strength class

identification number is imprinted on the head of the

bolt (Fig. 8). The higher the class number, the

greater the bolt strength. Some metric-dimension

nuts are also imprinted with a single-digit strength

class identification number on the nut face.

CONVERSION FORMULAS AND EQUIVALENT VALUES

8 INTRODUCTION J

You're Reading a Preview

What's Included?

Fast Download Speeds

Online & Offline Access

Access PDF Contents & Bookmarks

Full Search Facility

Print one or all pages of your manual

$31.99

Viewed 51 Times Today

Loading...

Secure transaction

What's Included?

Fast Download Speeds

Online & Offline Access

Access PDF Contents & Bookmarks

Full Search Facility

Print one or all pages of your manual

$31.99

This manual is a valuable resource for servicing and repairing the 1995 Jeep Cherokee XJ and Jeep Wrangler YJ models.

- 1995 Jeep Cherokee XJ

- Jeep Wrangler YJ

It contains comprehensive instructions and detailed diagrams covering various topics such as engine, transmission, electrical system, and suspension. Whether you are a professional mechanic or a DIY enthusiast, this manual is designed to ensure the proper functioning and longevity of your vehicle.