2002-2004 Isuzu Axiom Service & Repair Manual

What's Included?

Fast Download Speeds

Online & Offline Access

Access PDF Contents & Bookmarks

Full Search Facility

Print one or all pages of your manual

SECTION TABLE OF CONTENTS

GENERAL INFORMATION

0A General Information

0B Maintenance and Lubrication

WORKSHOP MANUAL

HEATING, VENTILATION AND AIR

CONDITIONING

1A HVAC System

STEERING

2A Power-Assisted System

AXIOM

(UPR/S)

SUSPENSION

3C Front Suspension

3D Rear Suspension

3E Wheel and Tire System

3F Intelligent Suspension System

DRIVELINE/AXLE

4A1 Differential (Front)

4A2 Differential (Rear)

4B1 Driveline Control System

4B2 Driveline Control System (TOD)

4C Drive Shaft System

4D2 Transfer Case (TOD)

FOREWORD

This manual includes special notes, important points, service data,

precautions, etc. That are needed for the maintenance, adjustments,

service, removal and installation of vehicle components.

All information, illustrations and specifications contained in this manual

are based on the latest product information available at the time of

publication.

All rights are reserved to make changes at any time without notice.

Arrangement of the material is shown in the table of contents on the

right-hand side of this page. A black spot on the first page of each

section can be seen on the edge of the book below each section title.

These point to a more detailed table of contents preceding each

section.

BRAKE

5A Brake Control System

5B Anti-Lock Brake System

5C Power-Assisted Brake System

5D1 Parking Brake System (4×4 model)

5D2 Parking Brake System (4×2 model)

ENGINE

6A Engine Mechanical

6B Engine Cooling

6C Engine Fuel

6D1 Engine Electrical

6D2 Ignition System

6D3 Starting and Charging System

6E Driveability and Emissions

6F Engine Exhaust

6G Engine Lubrication

6H Engine Speed Control System

6J Induction

TRANSMISSION

7A Automatic Transmission

7A1 Transmission Control System

BODY AND ACCESSORIES

8A Lighting System

8B Wiper/Washer System

8C Entertainment

8D Wiring System

8E Meter and Gauge

8F Body Structure

8G Seats

8H Security and Locks

8I Sun Roof/Convertible Top

8J Exterior/Interior Trim

RESTRAINTS

9A Seat Belt System

9J Supplemental Restraint System (Air Bag System)

9J1 Restraint Control System

CONTROL SYSTEM

10A Cruise Control System

0A–1 GENERAL INFORMATION

AXIOM

GENERAL INFORMATION

CONTENTS

General Information 0A . . . . . . . . . . . . . . . . . . . . .

Maintenance and Lubrication 0B . . . . . . . . . . . . .

General Information

CONTENTS

General Repair Instruction 0A–1 . . . . . . . . . . . . . . . .

Illustration Arrows 0A–2 . . . . . . . . . . . . . . . . . . . . . . .

Identification 0A–3 . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Theft Prevention Standard 0A–5 . . . . . . . . . . . . . . . .

Lifting Instructions 0A–9 . . . . . . . . . . . . . . . . . . . . . . .

Standard Bolts Torque Specifications 0A–11 . . . . . .

Abbreviations Charts 0A–12 . . . . . . . . . . . . . . . . . . . .

Service Parts Identification Plate 0A–13 . . . . . . . . . .

General Repair Instruction

1. If a floor jack is used, the following precautions are

recommended.

Park vehicle on level ground, “block” front or rear

wheels, set jack against the recommended lifting

points (see “Lifting Instructions” in this section), raise

vehicle and support with chassis stands and then

perform the service operations.

2. Before performing service operations, disconnect

ground cable from the battery to reduce the chance of

cable damage and burning due to short circuiting.

3. Use a cover on body, seats and floor to protect them

against damage and contamination.

4. Brake fluid and anti–freeze solution must be handled

with reasonable care, as they can cause paint

damage.

5. The use of proper tools and recommended essential

and available tools, where specified, is important for

efficient and reliable performance of service repairs.

6. Use genuine Isuzu parts.

7. Used cotter pins, plastic clips, gaskets, O–rings, oil

seals, lock washers and self–locking nuts should be

discarded and new ones should be installed, as

normal function of the parts cannot be maintained if

these parts are reused.

8. To facilitate proper and smooth reassembly

operation, keep disassembled parts neatly in groups.

Keeping fixing bolts and nuts separate is very

important, as they vary in hardness and design

depending on position of installation.

9. Clean the parts before inspection or reassembly. Also

clean oil ports, etc. using compressed air, and make

certain they are free from restrictions.

10. Lubricate rotating and sliding faces of the parts with

oil or grease before installation.

11.When necessary, use a sealer on gaskets to prevent

leakage.

12. Carefully observe all specifications for bolt and nut

torques.

13. When removing or replacing parts that require

refrigerant to be discharged from the air conditioning

system, be sure to use the Vehicle Refrigerant

Recovery and Recycling Equipment (VRRRE) to

recover and recycle Refrigerant–134a.

14. When a service operation is completed, make a final

check to be sure the service has been done properly

and the problem has been corrected.

15. SUPPLEMENTAL RESTRAINT SYSTEM

The vehicle is equipped with a Supplemental

Restraint System (SRS) – Air Bags. This system is

not to be serviced without consulting the appropriate

service information. Consult Section 9J “SRS

System” if work is to be done on the front of the

vehicle such as bumper, sheet metal, seats, wiring,

steering wheel or column. Also review SRS system

information if any arc welding is to be done on the

vehicle. The SRS system equipped vehicle can be

identified by:

1. “AIR BAG” warning light on the instrument

cluster.

2. A Code “K” or “M” for fifth digit of Vehicle

Identification Number.

0A–2

GENERAL INFORMATION

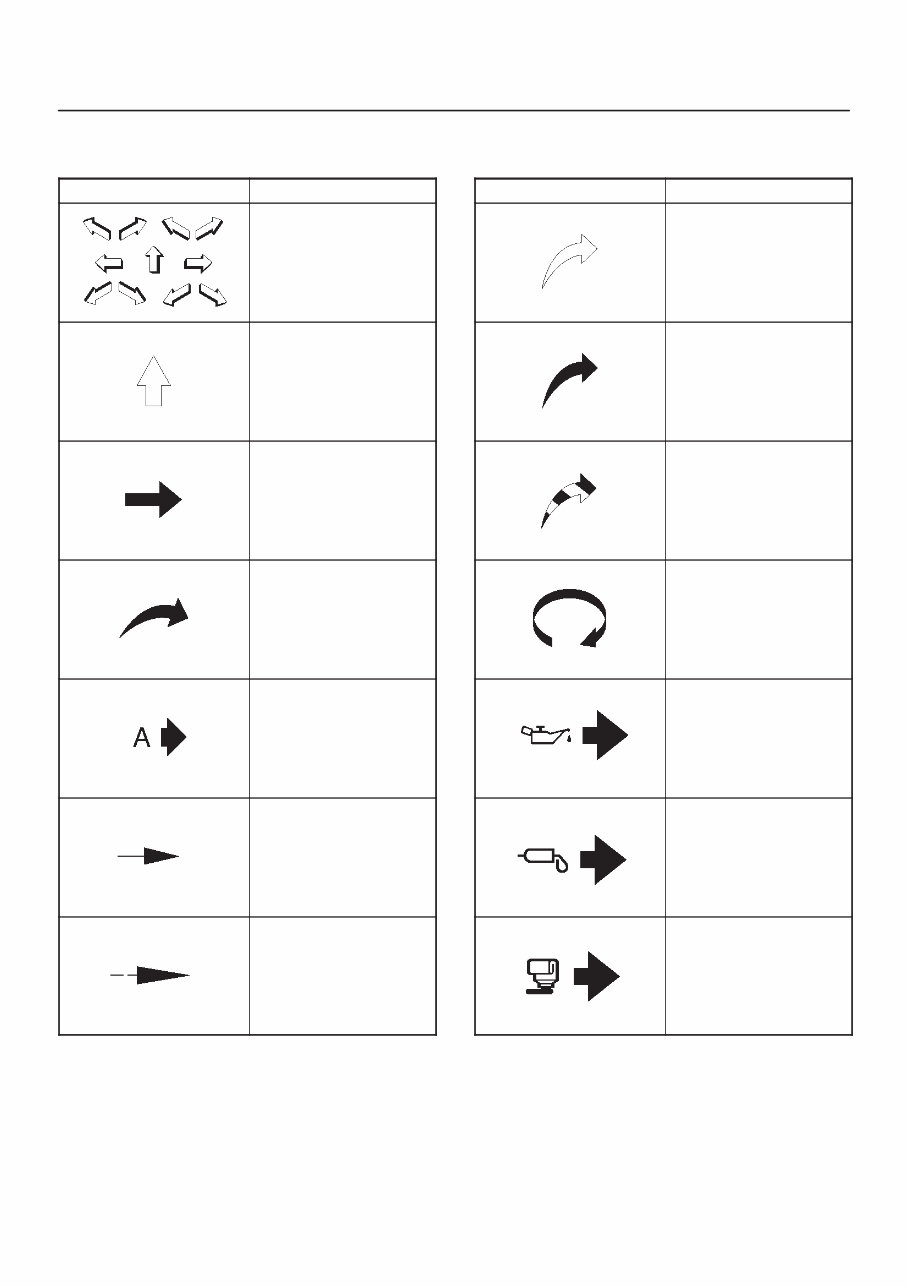

Illustration Arrows

Arrows are designed for specific purposes to aid your understanding of technical illustrations.

Arrow Type Application

Front of vehicle

Up Side

Task Related

View Detail

View Angle

Dimension (1:2)

Sectioning (1:3)

Arrow Type Application

B Ambient/Clean air

flow

B Cool air flow

B Gas other than

ambient air

B Hot air flow

B Ambient air mixed

with another gas

B Can indicate

temperature change

Motion or direction

Lubrication point oil or

fluid

Lubrication point grease

Lubrication point jelly

0A–3 GENERAL INFORMATION

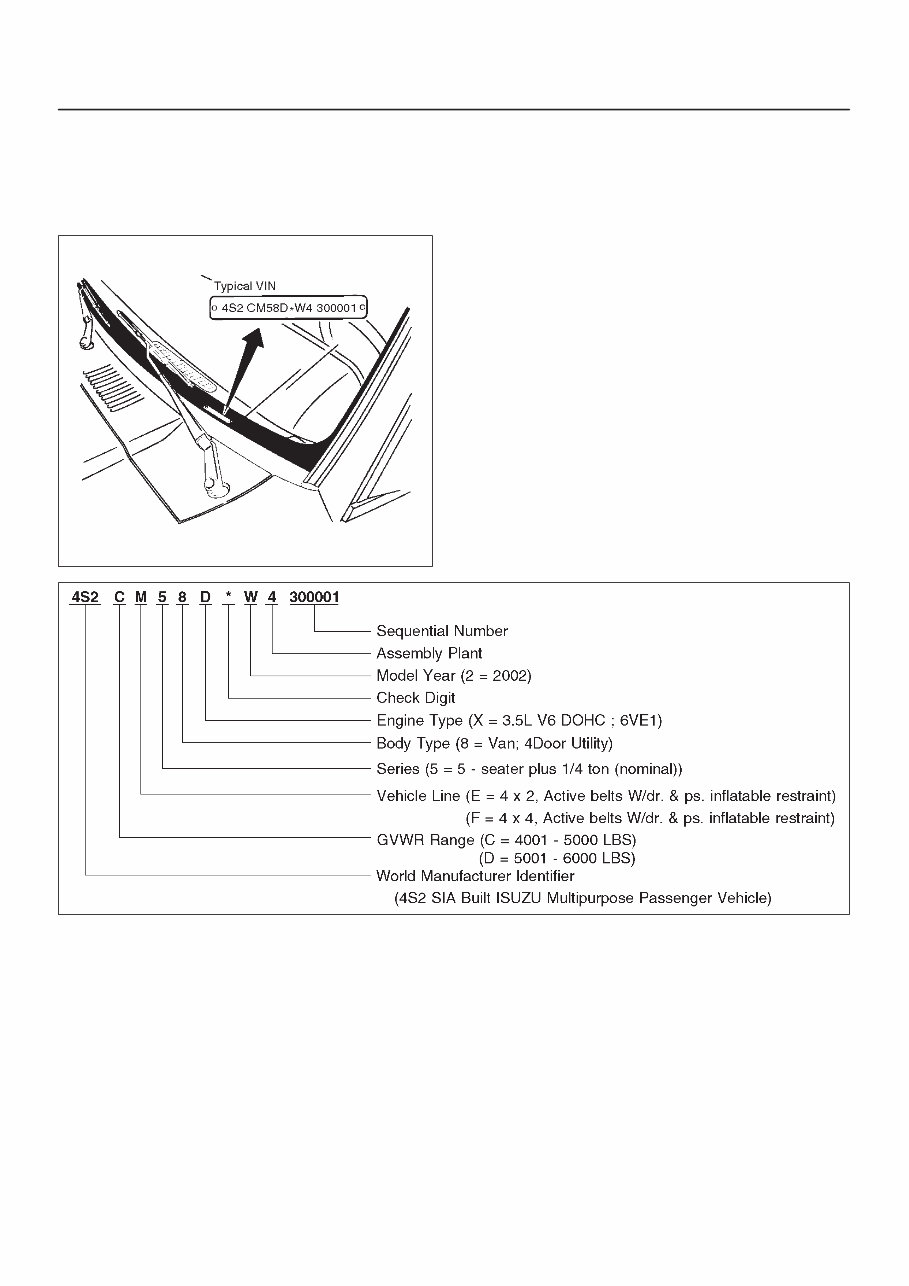

Identification

Vehicle Identification Number (VIN)

This is the legal identification of the vehicle. it is located on

the left bottom of the windshield. It can be easily seen

through the windshield from outside the vehicle.

710RW003

0A–4

GENERAL INFORMATION

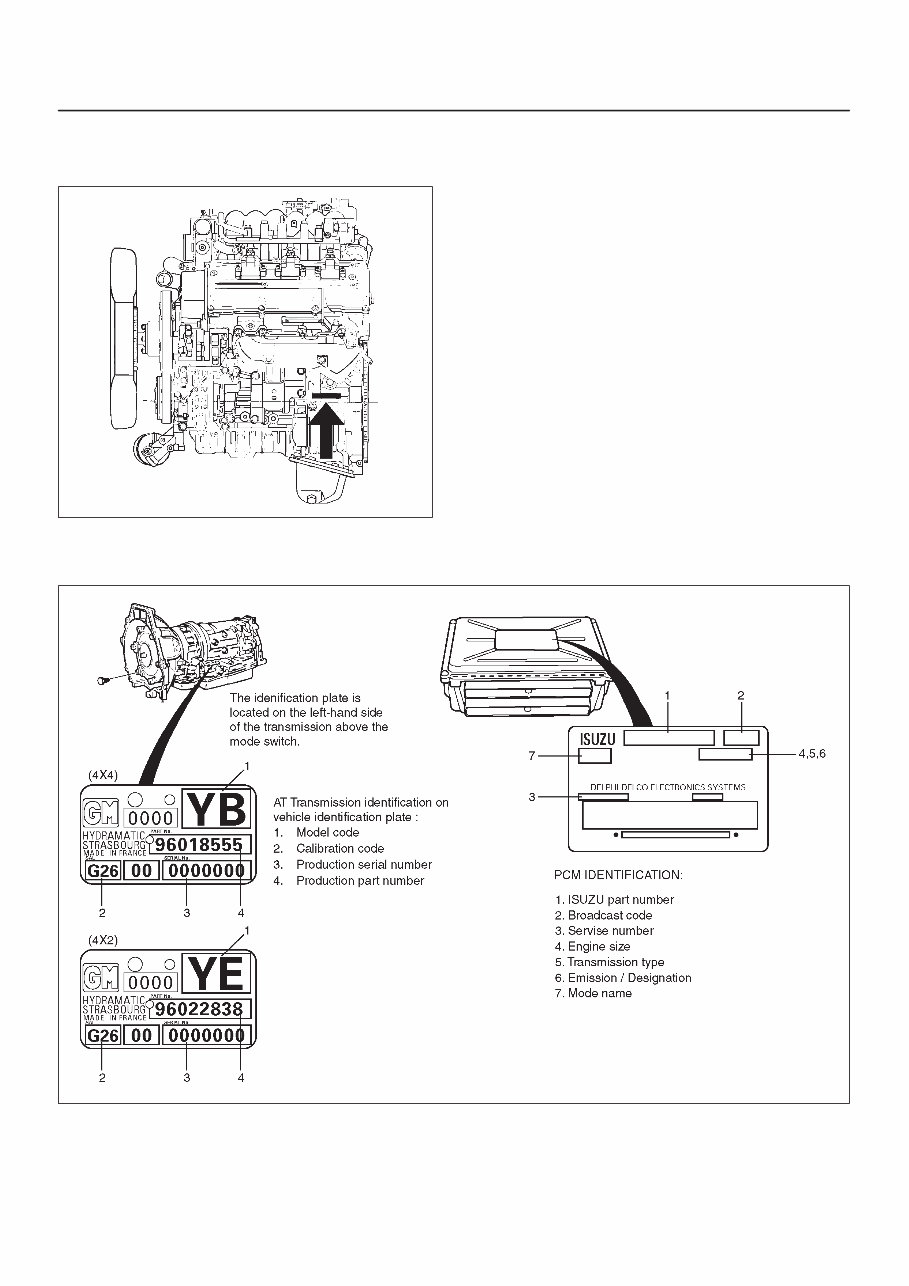

Engine Serial Number

The gasoline engine serial number is stamped on the left

rear lower area of the cylinder block above the starter.

240R200014

Automatic : Stamped on the identification plate, located

on the left side of the transmission above the mode

switch.

240R200013

0A–5 GENERAL INFORMATION

Theft Prevention Standard

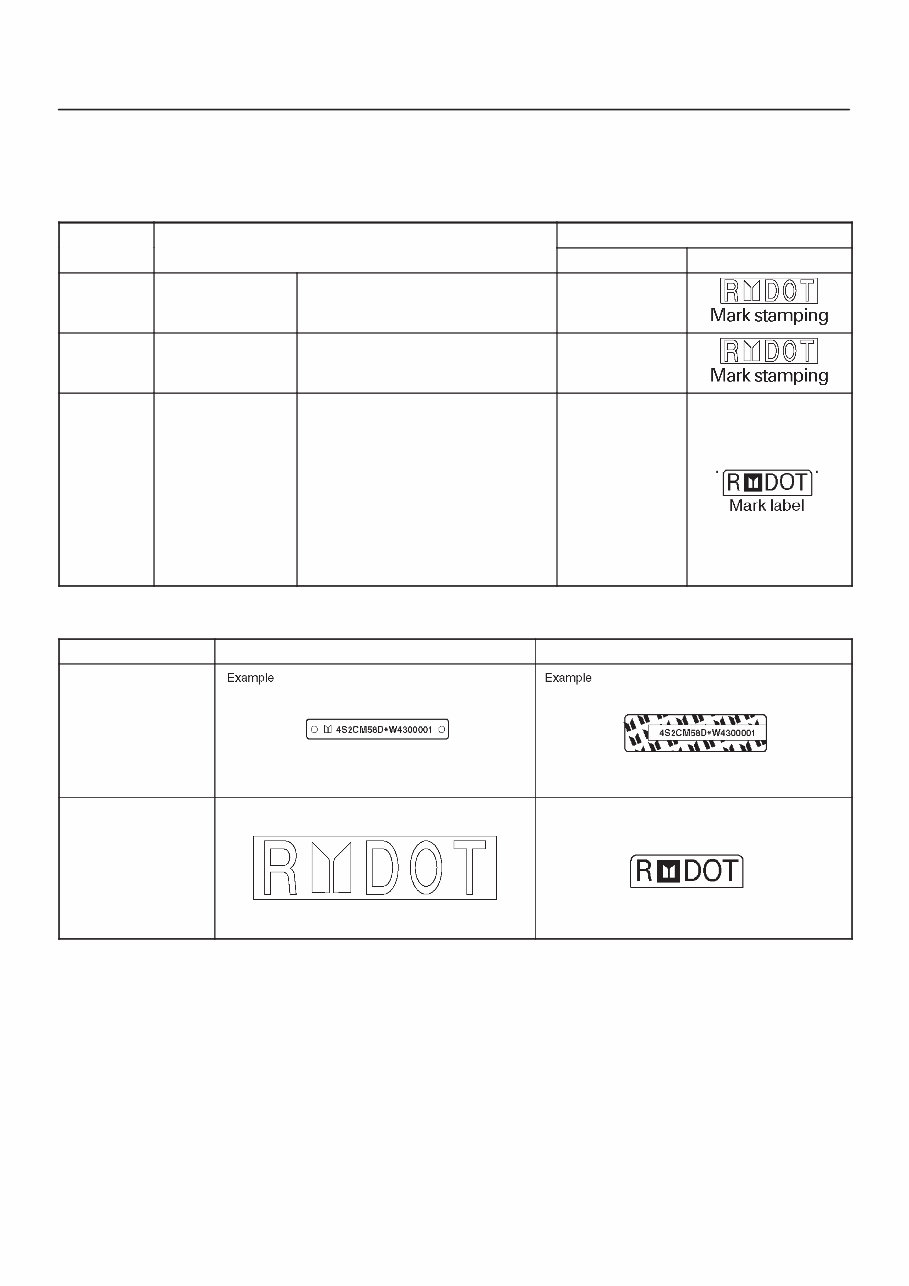

The 11 major components listed below will be marked

with 17 digit VIN at the stage of production. In addition its

service parts will be marked with manufacturer’s trade

mark, “R” mark and “DOT” mark.

Reference

COMPONENT

INDICATION

Figure No.

COMPONENT

PRODUCTION SERVICE PARTS

0A-10 ENGINE 1– 6VE1 VIN plate

0A-11 TRANSMISSION 2– Automatic transmission VIN plate

0A-11 BODY 3– Engine hood

4– Front door

5– Rear door

6– Fender

7– Rear Quarter panel

8– Front bumper

9– Back door left side

10– Back door right side

11– Rear bumper

VIN label

Anti Theft Stamping/Plate/Label

STAMPING/PLATE LABEL

PRODUCTION

SERVICE PARTS

0A–6

GENERAL INFORMATION

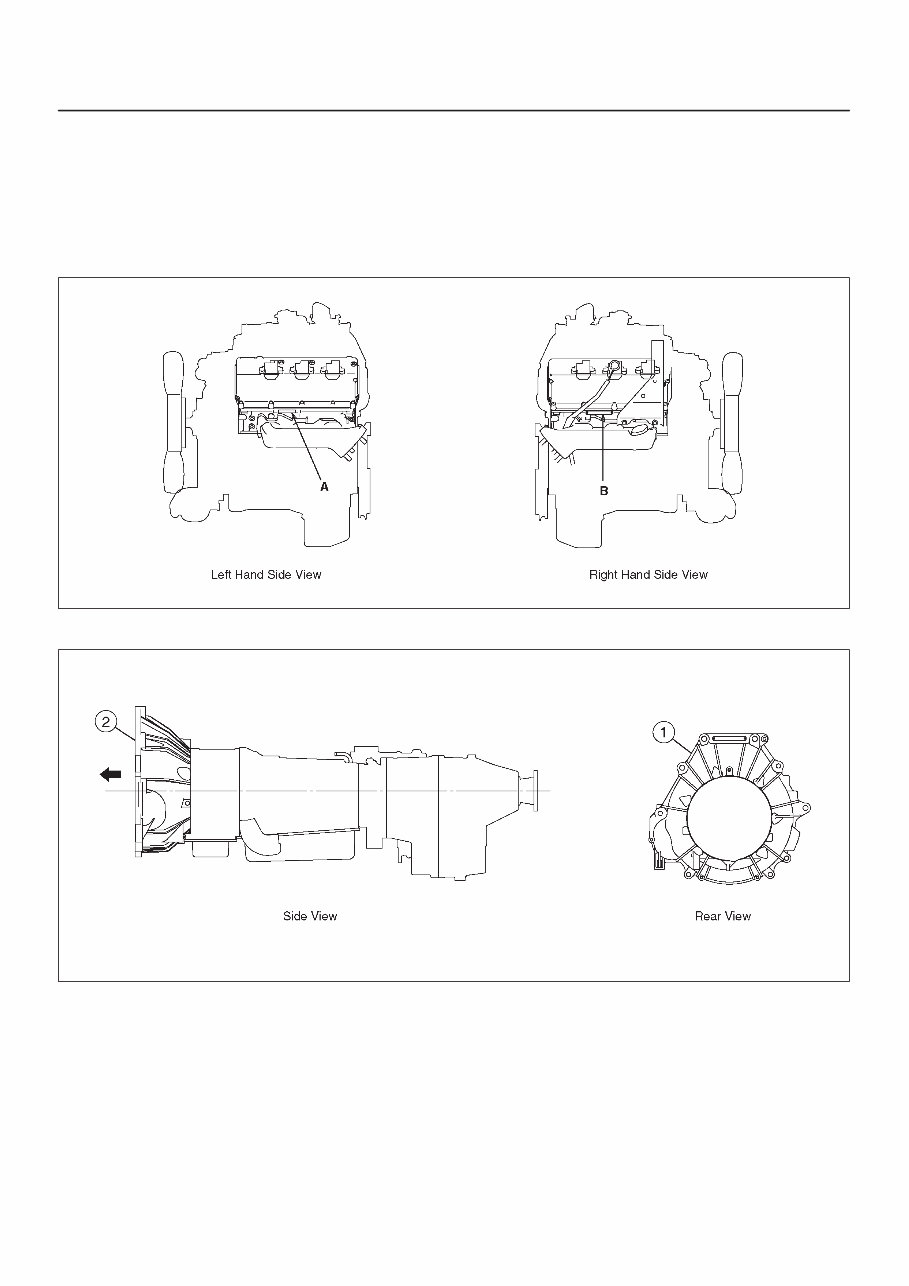

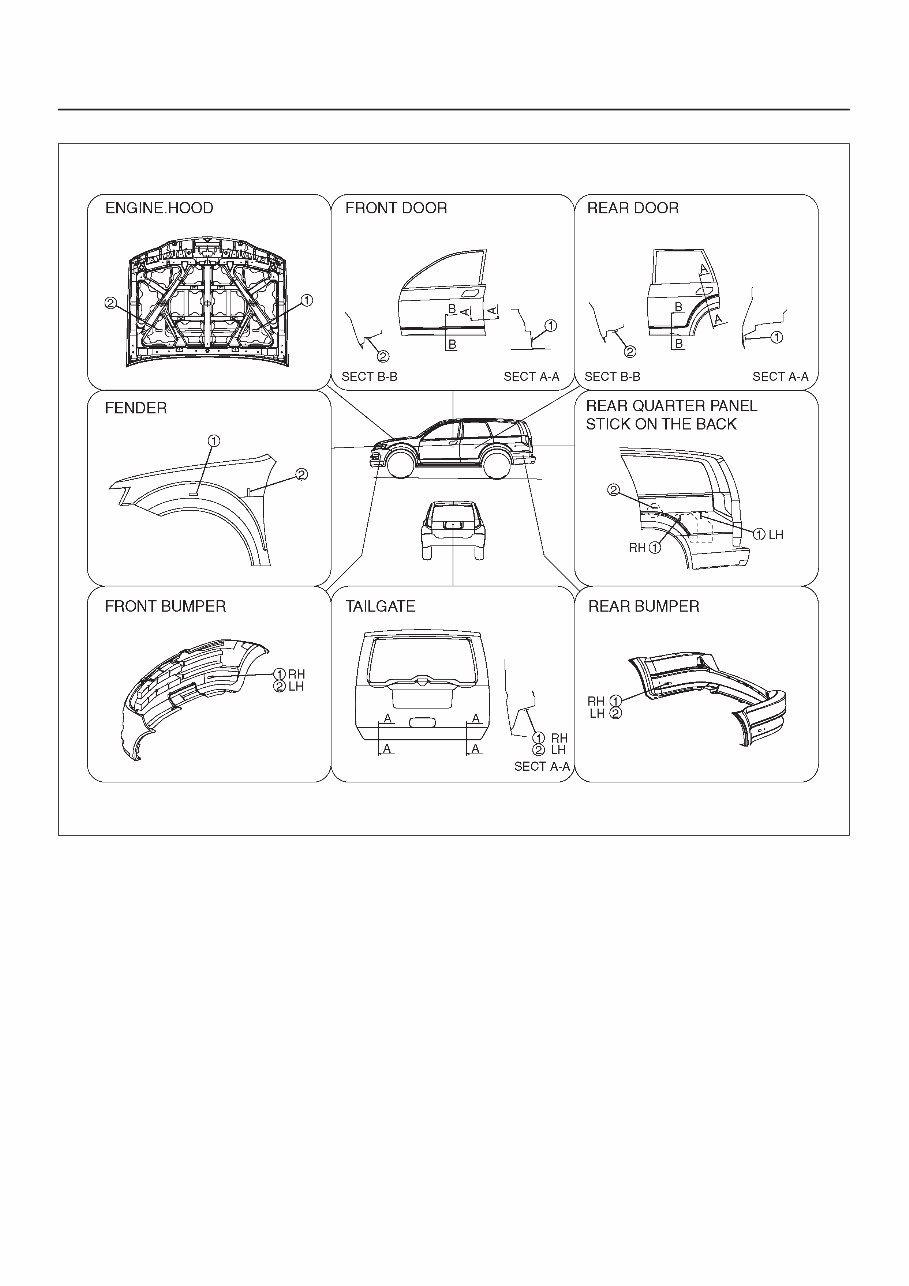

Anti Theft Stamping/Label/Plate Location

The stamping, label and plate locations are indicated by

arrows in the illustration below.

NOTE:

1. VIN plate locations for production.

2. Stamping locations for service parts.

Engine

901RW195

Automatic Transmission

240R200012

0A–7 GENERAL INFORMATION

Body

604R200007

0A–8

GENERAL INFORMATION

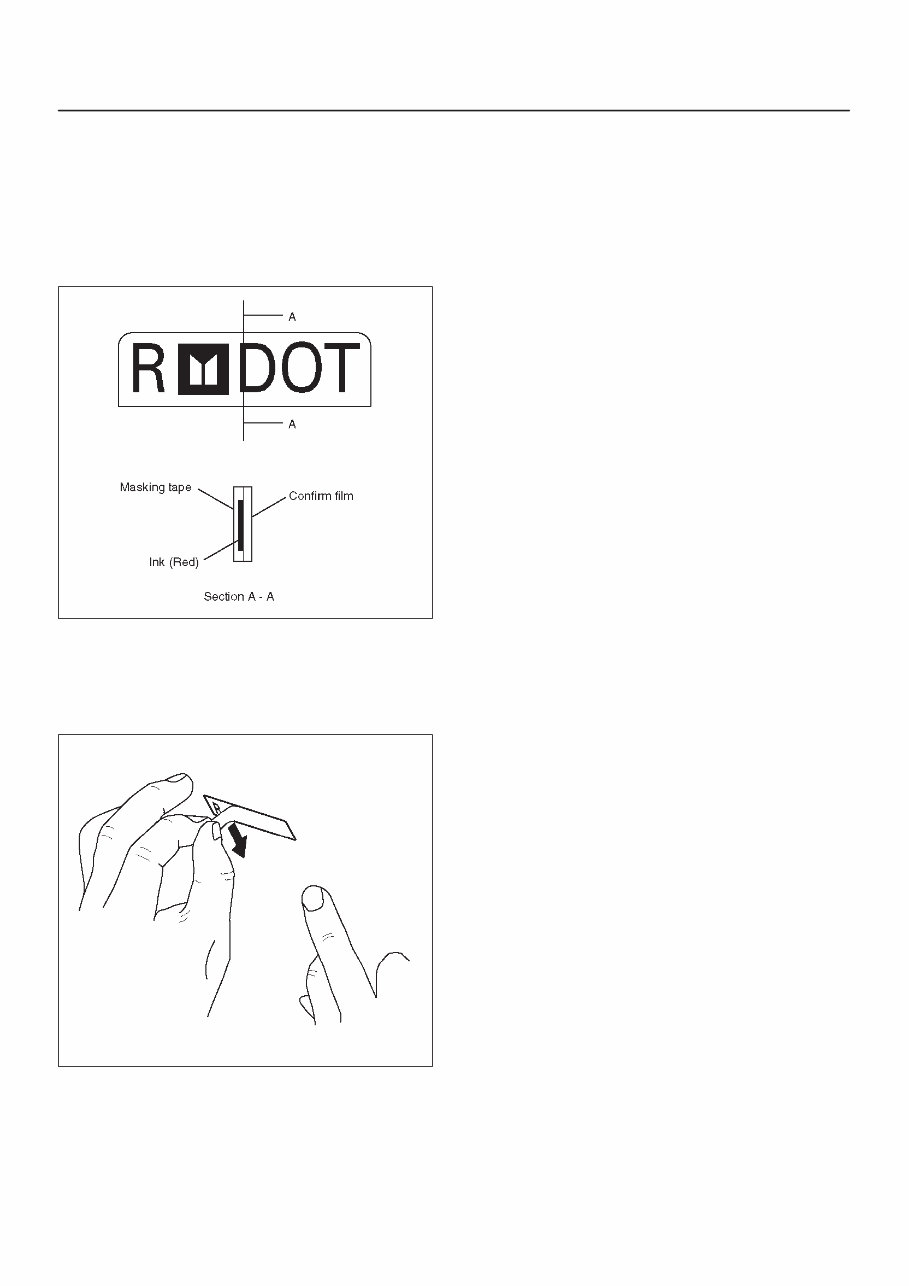

Body Label Instructions

Do not peel off the masking tape until completion of paint

work when replacing these parts, as the tape is affixed on

the label attached to service parts for body of the

anti–theft component.

NOTE: Be sure to pull off the masking tape after paint

work has been completed.

Do not attempt to remove this label for any reason.

901RW083

Precautions in pulling off the masking tape

1. Use only your finger nail or a similar blunt instrument

to peel off the masking tape. Use of a sharp object will

damage the underlying anti–theft label.

2. Be careful not to damage the paint around the label.

901RW084

0A–9 GENERAL INFORMATION

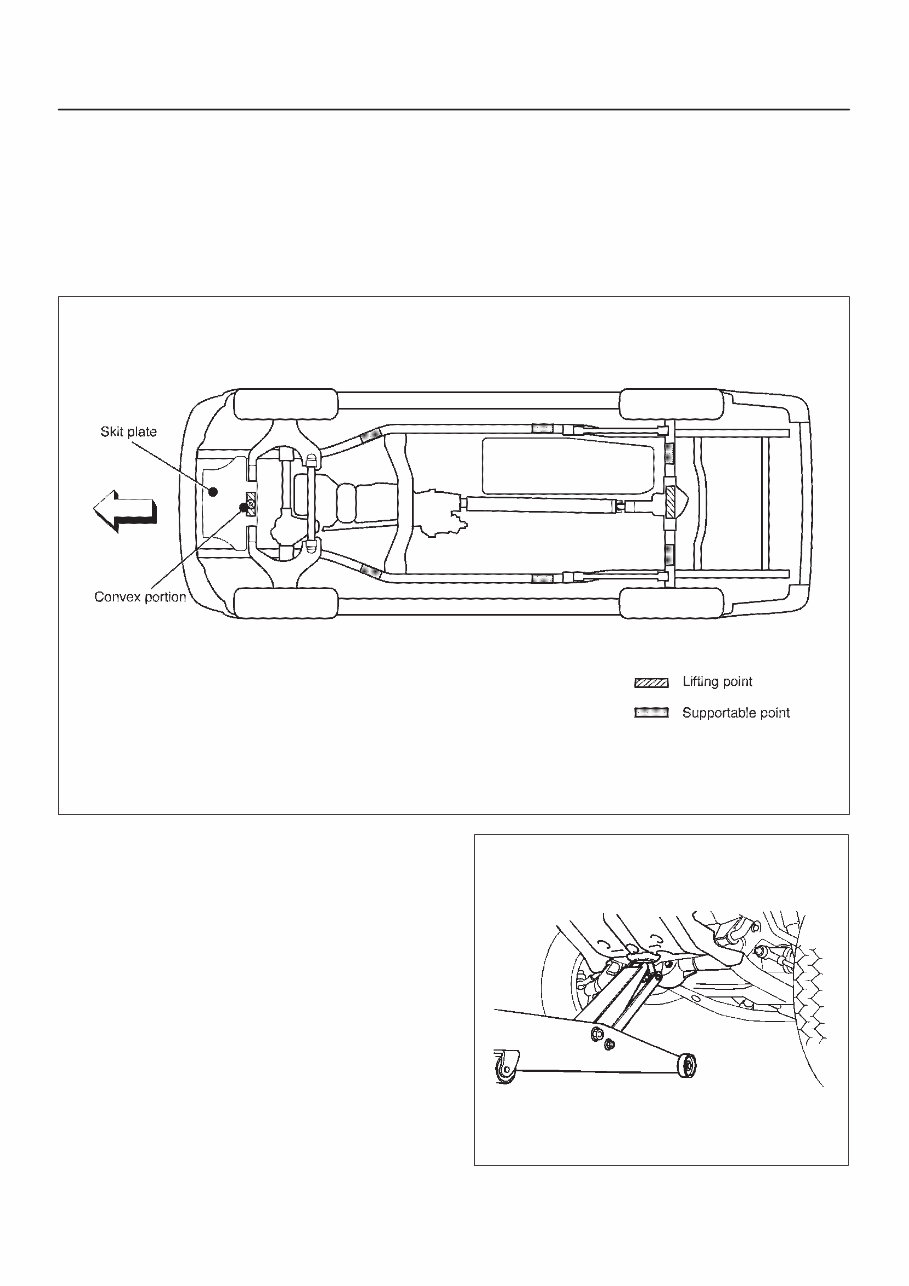

Lifting Instructions

CAUTION:

B If a lifting device other than the original jack is

used, it is most important that the device be

applied only to the correct lifting points. Raising

the vehicle from any other point may result in

serious damage.

B When jacking or lifting a vehicle at the frame side

rail or other prescribed lift points, be certain that

lift pads do not contact the catalytic converter,

brake pipes or cables, or fuel lines. Such contact

may result in damage or unsatisfactory vehicle

performance.

Lifting Points and Supportable Point Locations

C00RX002

Lifting Point: Front

B When using a floor jack, lift on the Convex portion of

the skid plate.

545RS001

You're Reading a Preview

What's Included?

Fast Download Speeds

Online & Offline Access

Access PDF Contents & Bookmarks

Full Search Facility

Print one or all pages of your manual

$31.99

Viewed 19 Times Today

Loading...

Secure transaction

What's Included?

Fast Download Speeds

Online & Offline Access

Access PDF Contents & Bookmarks

Full Search Facility

Print one or all pages of your manual

$31.99

Get instant access to the Complete Factory Service Repair Workshop Manual without any extra fees or expiry dates. This Professional Manual is suitable for both professional Mechanics and DIY enthusiasts, covering all repairs, servicing, and troubleshooting procedures with step-by-step instructions, detailed photos, diagrams, and highly detailed exploded diagrams & pictures.

Print out a single page or the entire manual as per your choice. The Manual can be used on multiple computers without any limitations or trial periods and can be used for life. It is fully compatible with all Windows & MAC Computers.

Click the button to get your hands on this comprehensive manual.