2017 Infiniti QX70 (S51) Service & Repair Manual (+ Wiring Diagrams)

What's Included?

Fast Download Speeds

Offline Viewing

Access Contents & Bookmarks

Full Search Facility

Print one or all pages of your manual

HAC-1

VENTILATION, HEATER & AIR CONDITIONER

C

D

E

F

G

H

J

K

L

M

SECTION HAC

A

B

HAC

N

O

P

CONTENTS

HEATER & AIR CONDITIONING CONTROL SYSTEM

AUTOMATIC AIR CONDITIONER

BASIC INSPECTION ................................... 4

DIAGNOSIS AND REPAIR WORKFLOW ......... 4

Work Flow ................................................................ 4

INSPECTION AND ADJUSTMENT .................... 7

WITHOUT ACCS ........................................................ 7

WITHOUT ACCS : Description & Inspection ............ 7

WITHOUT ACCS : Temperature Setting Trimmer ...... 8

WITHOUT ACCS : Foot Position Setting Trimmer ...... 9

WITHOUT ACCS : Inlet Port Memory Function ..... 10

WITH ACCS .............................................................. 10

WITH ACCS : Description & Inspection ................. 10

WITH ACCS : Temperature Setting Trimmer ......... 13

WITH ACCS : Foot Position Setting Trimmer ........ 14

WITH ACCS : Inlet Port Memory Function ............. 15

WITH ACCS : Exhaust exhaust gas/outside odor

detecting/Outside Odor Detecting Sensor Sensi-

tivity Adjustment Function ...................................... 15

WITH ACCS : Auto Intake Interlocking Movement

Change Function .................................................... 16

SYSTEM DESCRIPTION ............................ 17

COMPRESSOR CONTROL FUNCTION ...........17

WITHOUT ACCS ...................................................... 17

WITHOUT ACCS : Description .............................. 17

WITHOUT ACCS : Fail-safe ................................... 17

WITHOUT ACCS : Component Part Location ........ 18

WITHOUT ACCS : Component Description ........... 21

WITH ACCS .............................................................. 21

WITH ACCS : Description ...................................... 21

WITH ACCS : Fail-safe .......................................... 22

WITH ACCS : Component Part Location ............... 22

WITH ACCS : Component Description .................. 24

AUTOMATIC AIR CONDITIONER SYSTEM ....26

WITHOUT ACCS .......................................................26

WITHOUT ACCS : System Diagram ......................26

WITHOUT ACCS : System Description ..................26

WITHOUT ACCS : Component Part Location ........31

WITHOUT ACCS : Component Description ...........34

WITH ACCS ..............................................................34

WITH ACCS : System Diagram ..............................34

WITH ACCS : System Description .........................35

WITH ACCS : Component Part Location ................40

WITH ACCS : Component Description ...................42

PLASMACLUSTER SYSTEM ........................... 44

System Diagram .....................................................44

System Description .................................................44

Component Part Location .......................................45

Component Description ..........................................46

CAN COMMUNICATION SYSTEM ................... 47

System Description .................................................47

MODE DOOR CONTROL SYSTEM .................. 48

System Diagram .....................................................48

System Description .................................................48

AIR MIX DOOR CONTROL SYSTEM ............... 50

System Diagram .....................................................50

System Description .................................................50

INTAKE DOOR CONTROL SYSTEM ............... 52

WITHOUT ACCS .......................................................52

WITHOUT ACCS : System Diagram ......................52

WITHOUT ACCS : System Description ..................52

WITH ACCS ..............................................................53

WITH ACCS : System Diagram ..............................53

WITH ACCS : System Description .........................53

BLOWER MOTOR CONTROL SYSTEM .......... 55

System Diagram .....................................................55

System Description .................................................55

Revision: 2015 February 2015 QX70

HAC-2

MAGNET CLUTCH CONTROL SYSTEM ........ 57

System Diagram .................................................... 57

System Description ................................................ 57

DIAGNOSIS SYSTEM (UNIFIED METER & A/

C AMP.) ............................................................. 59

WITHOUT ACCS ...................................................... 59

WITHOUT ACCS : Diagnosis Description ............. 59

WITHOUT ACCS : CONSULT Function ................ 64

WITH ACCS ............................................................. 64

WITH ACCS : Diagnosis Description ..................... 64

WITH ACCS : CONSULT Function ........................ 69

DTC/CIRCUIT DIAGNOSIS ........................ 70

POWER SUPPLY AND GROUND CIRCUIT .... 70

UNIFIED METER AND A/C AMP. ............................ 70

UNIFIED METER AND A/C AMP. : Diagnosis Pro-

cedure .................................................................... 70

UNIFIED METER AND A/C AMP. .................... 71

Description ............................................................. 71

Component Function Check .................................. 71

Diagnosis Procedure ............................................. 71

MODE DOOR MOTOR ..................................... 72

Description ............................................................. 72

Component Function Check ................................ 72

Diagnosis Procedure ............................................. 72

AIR MIX DOOR MOTOR (DRIVER SIDE) ........ 74

Description ............................................................. 74

Component Function Check ................................ 74

Diagnosis Procedure ............................................. 74

AIR MIX DOOR MOTOR (PASSENGER SIDE)

... 76

Description ............................................................. 76

Component Function Check ................................ 76

Diagnosis Procedure ............................................. 76

INTAKE DOOR MOTOR ................................... 78

WITHOUT ACCS ...................................................... 78

WITHOUT ACCS : Description .............................. 78

WITHOUT ACCS : Component Function Check ... 78

WITHOUT ACCS : Diagnosis Procedure ............... 78

WITH ACCS ............................................................. 79

WITH ACCS : Description ..................................... 79

WITH ACCS : Component Function Check ......... 79

WITH ACCS : Diagnosis Procedure ...................... 80

BLOWER MOTOR ............................................ 82

Description ............................................................. 82

Component Function Check ................................ 82

Diagnosis Procedure ............................................. 82

Component Inspection ........................................... 85

MAGNET CLUTCH ........................................... 86

Description ............................................................. 86

Component Function Check .................................. 86

Diagnosis Procedure .............................................. 86

ECV (ELECTRICAL CONTROL VALVE) ......... 88

Description ............................................................. 88

Diagnosis Procedure .............................................. 88

AMBIENT SENSOR .......................................... 90

Description ............................................................. 90

Component Function Check ................................. 90

Diagnosis Procedure .............................................. 90

Component Inspection ........................................... 91

IN-VEHICLE SENSOR ...................................... 93

Description ............................................................. 93

Component Function Check ................................. 93

Diagnosis Procedure .............................................. 93

Component Inspection ........................................... 94

SUNLOAD SENSOR ........................................ 96

Description ............................................................. 96

Component Function Check ................................. 96

Diagnosis Procedure .............................................. 96

Component Inspection ........................................... 97

INTAKE SENSOR ............................................. 99

Description ............................................................. 99

Component Function Check ................................. 99

Diagnosis Procedure .............................................. 99

Component Inspection ......................................... 100

EXHAUST GAS/OUTSIDE ODOR DETECT-

ING SENSOR ................................................... 101

Description ........................................................... 101

Component Function Check ............................... 101

Diagnosis Procedure ............................................ 101

IONIZER ........................................................... 104

Description ........................................................... 104

Component Function Check ................................ 104

Diagnosis Procedure ............................................ 104

ECU DIAGNOSIS INFORMATION ............ 106

UNIFIED METER AND A/C AMP. ................... 106

Reference Value .................................................. 106

Wiring Diagram - AIR CONDITIONER CONTROL

SYSTEM - ............................................................ 108

Fail-safe ............................................................... 117

ECM ................................................................. 119

VQ37VHR FOR USA AND CANADA ..................... 119

VQ37VHR FOR USA AND CANADA : Reference

Value .................................................................... 119

VQ37VHR FOR MEXICO ....................................... 135

VQ37VHR FOR MEXICO : Reference Value ....... 135

VK50VE .................................................................. 150

VK50VE : Reference Value .................................. 150

Revision: 2015 February 2015 QX70

HAC-3

C

D

E

F

G

H

J

K

L

M

A

B

HAC

N

O

P

SYMPTOM DIAGNOSIS ........................... 169

AIR CONDITIONER CONTROL ...................... 169

Diagnosis Chart By Symptom .............................. 169

INSUFFICIENT COOLING .............................. 170

Description ........................................................... 170

Inspection procedure ............................................ 170

INSUFFICIENT HEATING ............................... 172

Description ........................................................... 172

Inspection procedure ............................................ 172

NOISE .............................................................. 174

Description ........................................................... 174

Inspection procedure ............................................ 174

SELF-DIAGNOSIS CANNOT BE PER-

FORMED ......................................................... 176

Description ........................................................... 176

Inspection procedure ............................................ 176

MEMORY FUNCTION DOES NOT OPERATE .. 177

Description ........................................................... 177

Inspection procedure ............................................ 177

PRECAUTION ........................................... 178

PRECAUTIONS ............................................... 178

Precaution for Supplemental Restraint System

(SRS) "AIR BAG" and "SEAT BELT PRE-TEN-

SIONER" .............................................................. 178

Precautions Necessary for Steering Wheel Rota-

tion After Battery Disconnection ........................... 178

Precaution for Procedure without Cowl Top Cover .. 179

Working with HFC-134a (R-134a) ........................ 179

General Refrigerant Precaution ........................... 179

Refrigerant Connection ........................................ 180

Service Equipment ............................................... 184

COMPRESSOR ............................................... 187

VQ37VHR ............................................................... 187

VQ37VHR : General Precautions ......................... 187

VK50VE .................................................................. 187

VK50VE : General Precautions ............................ 187

LEAK DETECTION DYE ................................. 188

General Precautions ............................................ 188

PREPARATION ........................................ 189

PREPARATION ............................................... 189

Special Service Tool ............................................ 189

Commercial Service Tool ..................................... 192

Sealant or/and Lubricant ...................................... 192

REMOVAL AND INSTALLATION ............ 193

PRESET SWITCH ........................................... 193

Exploded View ...................................................... 193

Removal and Installation ...................................... 193

UNIFIED METER AND A/C AMP. ................... 194

Exploded View ...................................................... 194

Removal and Installation ...................................... 194

AMBIENT SENSOR ........................................ 195

Exploded View ...................................................... 195

Removal and Installation ...................................... 195

IN-VEHICLE SENSOR .................................... 196

Exploded View ...................................................... 196

Removal and Installation ...................................... 196

SUNLOAD SENSOR ....................................... 197

Exploded View ...................................................... 197

Removal and Installation ...................................... 197

INTAKE SENSOR ........................................... 198

Exploded View ...................................................... 198

Removal and Installation ...................................... 199

EXHAUST GAS/OUTSIDE ODOR DETECT-

ING SENSOR .................................................. 200

Exploded View ...................................................... 200

Removal and Installation ...................................... 200

REFRIGERANT PRESSURE SENSOR .......... 201

Exploded View ...................................................... 201

Removal and Installation ...................................... 201

DOOR MOTOR ................................................ 202

Exploded View ...................................................... 202

MODE DOOR MOTOR ............................................ 202

MODE DOOR MOTOR : Removal and Installation .. 202

AIR MIX DOOR MOTOR ......................................... 203

AIR MIX DOOR MOTOR : Removal and Installa-

tion ........................................................................ 203

INTAKE DOOR MOTOR ......................................... 204

INTAKE DOOR MOTOR : Removal and Installa-

tion ........................................................................ 204

IONIZER .......................................................... 205

Exploded View ...................................................... 205

Removal and Installation ...................................... 205

Revision: 2015 February 2015 QX70

HAC-4

< BASIC INSPECTION >

[AUTOMATIC AIR CONDITIONER]

DIAGNOSIS AND REPAIR WORKFLOW

BASIC INSPECTION

DIAGNOSIS AND REPAIR WORKFLOW

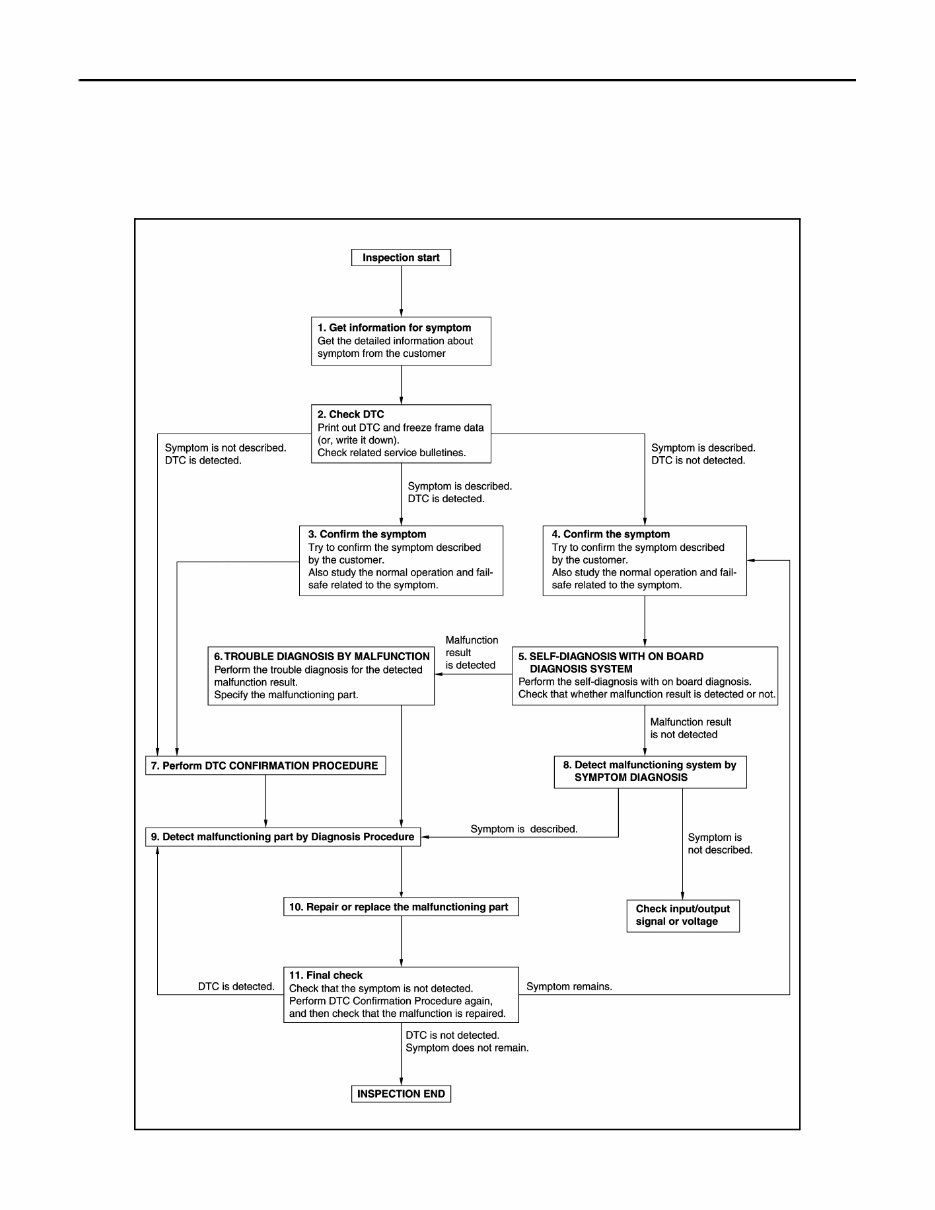

Work Flow INFOID:0000000010581326

OVERALL SEQUENCE

DETAILED FLOW

JMIIA2097GB

Revision: 2015 February 2015 QX70

DIAGNOSIS AND REPAIR WORKFLOW

HAC-5

< BASIC INSPECTION >

[AUTOMATIC AIR CONDITIONER]

C

D

E

F

G

H

J

K

L

M

A

B

HAC

N

O

P

1.GET INFORMATION FOR SYMPTOM

1. Get detailed information from the customer about the symptom (the condition and the environment when

the incident/malfunction occurs).

2. Check operation condition of the function that is malfunctioning.

>> GO TO 2.

2.CHECK DTC

1. Check DTC.

2. Perform the following procedure if DTC is detected.

- Record DTC and freeze frame data (Print them out using CONSULT.)

- Erase DTC.

- Study the relationship between the cause detected by DTC and the symptom described by the customer.

3. Check related service bulletins for information.

Are any symptoms described and any DTC detected?

Symptom is described, DTC is detected>>GO TO 3.

Symptom is described, DTC is not detected>>GO TO 4.

Symptom is not described, DTC is detected>>GO TO 7.

3.CONFIRM THE SYMPTOM

Try to confirm the symptom described by the customer.

Also study the normal operation and fail-safe related to the symptom.

Verify relation between the symptom and the condition when the symptom is detected.

>> GO TO 7.

4.CONFIRM THE SYMPTOM

Try to confirm the symptom described by the customer.

Also study the normal operation and fail-safe related to the symptom.

Verify relation between the symptom and the condition when the symptom is detected.

>> GO TO 5.

5.SELF-DIAGNOSIS WITH ON BOARD DIAGNOSIS SYSTEM

Perform the self-diagnosis with on board diagnosis. Check that whether malfunction result is detected or not.

Is malfunction result detected?

YES >> GO TO 6.

NO >> GO TO 8.

6.TROUBLE DIAGNOSIS BY MALFUNCTION

Perform the trouble diagnosis for the detected malfunction result. Specify the malfunctioning part.

>> GO TO 9.

7.PERFORM DTC CONFIRMATION PROCEDURE

Perform DTC CONFIRMATION PROCEDURE for the detected DTC, and then check that DTC is detected

again. At this time, always connect CONSULT to the vehicle, and check self diagnostic results in real time.

If two or more DTCs are detected, refer to DTC INSPECTION PRIORITY CHART, and determine trouble diag-

nosis order.

NOTE:

• Freeze frame data is useful if the DTC is not detected.

• Perform Component Function Check if DTC CONFIRMATION PROCEDURE is not included on Service

Manual. This simplified check procedure is an effective alternative though DTC cannot be detected during

this check.

If the result of Component Function Check is NG, it is the same as the detection of DTC by DTC CONFIR-

MATION PROCEDURE.

Is DTC detected?

Revision: 2015 February 2015 QX70

HAC-6

< BASIC INSPECTION >

[AUTOMATIC AIR CONDITIONER]

DIAGNOSIS AND REPAIR WORKFLOW

YES >> GO TO 9.

NO >> Check according to GI-47, " Intermittent Incident " .

8.DETECT MALFUNCTIONING SYSTEM BY SYMPTOM DIAGNOSIS

Detect malfunctioning system according to SYMPTOM DIAGNOSIS based on the confirmed symptom in step

4, and determine the trouble diagnosis order based on possible causes and symptom.

Is the symptom described?

YES >> GO TO 9.

NO >> Monitor input data from related sensors or check voltage of related module terminals using CON-

SULT.

9.DETECT MALFUNCTIONING PART BY DIAGNOSIS PROCEDURE

Inspect according to Diagnosis Procedure of the system.

Is malfunctioning part detected?

YES >> GO TO 10.

NO >> Check according to GI-47, " Intermittent Incident " .

10.REPAIR OR REPLACE THE MALFUNCTIONING PART

1. Repair or replace the malfunctioning part.

2. Reconnect parts or connectors disconnected during Diagnosis Procedure again after repair and replace-

ment.

3. Check DTC. If DTC is detected, erase it.

>> GO TO 11.

11.FINAL CHECK

When DTC is detected in step 2, perform DTC CONFIRMATION PROCEDURE again, and then check that the

malfunction is repaired securely.

When symptom is described by the customer, refer to confirmed symptom in step 3 or 4, and check that the

symptom is not detected.

Is DTC detected and does symptom remain?

YES-1 >> DTC is detected: GO TO 9.

YES-2 >> Symptom remains: GO TO 4.

NO >> Before returning the vehicle to the customer, always erase DTC.

Revision: 2015 February 2015 QX70

INSPECTION AND ADJUSTMENT

HAC-7

< BASIC INSPECTION >

[AUTOMATIC AIR CONDITIONER]

C

D

E

F

G

H

J

K

L

M

A

B

HAC

N

O

P

INSPECTION AND ADJUSTMENT

WITHOUT ACCS

WITHOUT ACCS : Description & Inspection INFOID:0000000010581327

DESCRIPTION

The purpose of the operational check is to check that the individual system operates normally.

INSPECTION PROCEDURE

1.CHECK MEMORY FUNCTION

1. Start the engine.

2. Turn temperature control dial (driver side) clockwise until 32.0°C (90°F) is displayed.

3. Press the OFF switch.

4. Turn the ignition switch OFF.

5. Turn the ignition switch ON.

6. Press the AUTO switch.

7. Check that the temperature setting before turning the ignition switch OFF is stored.

Is the inspection result normal?

YES >> GO TO 2.

NO >> Memory function malfunction: HAC-177, " Inspection procedure " .

2.CHECK BLOWER MOTOR SPEED

1. Start the engine.

2. Press fan (UP: +) switch. Check that the fan speed changes. Check the operation for all fan speeds.

3. Set the fan speed to max speed.

Is the inspection result normal?

YES >> GO TO 3.

NO >> Blower motor system malfunction: HAC-82, " Diagnosis Procedure " .

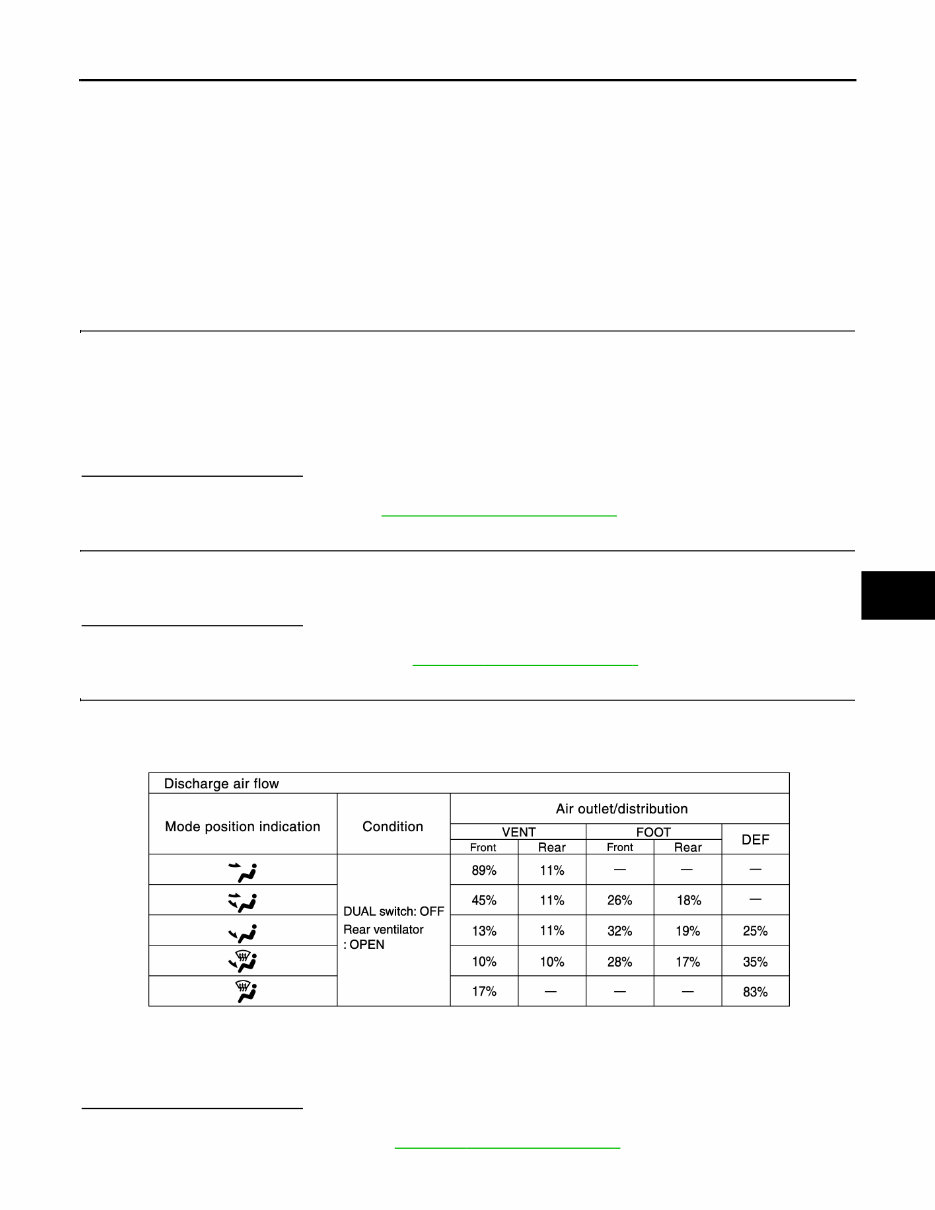

3.CHECK DISCHARGE AIR

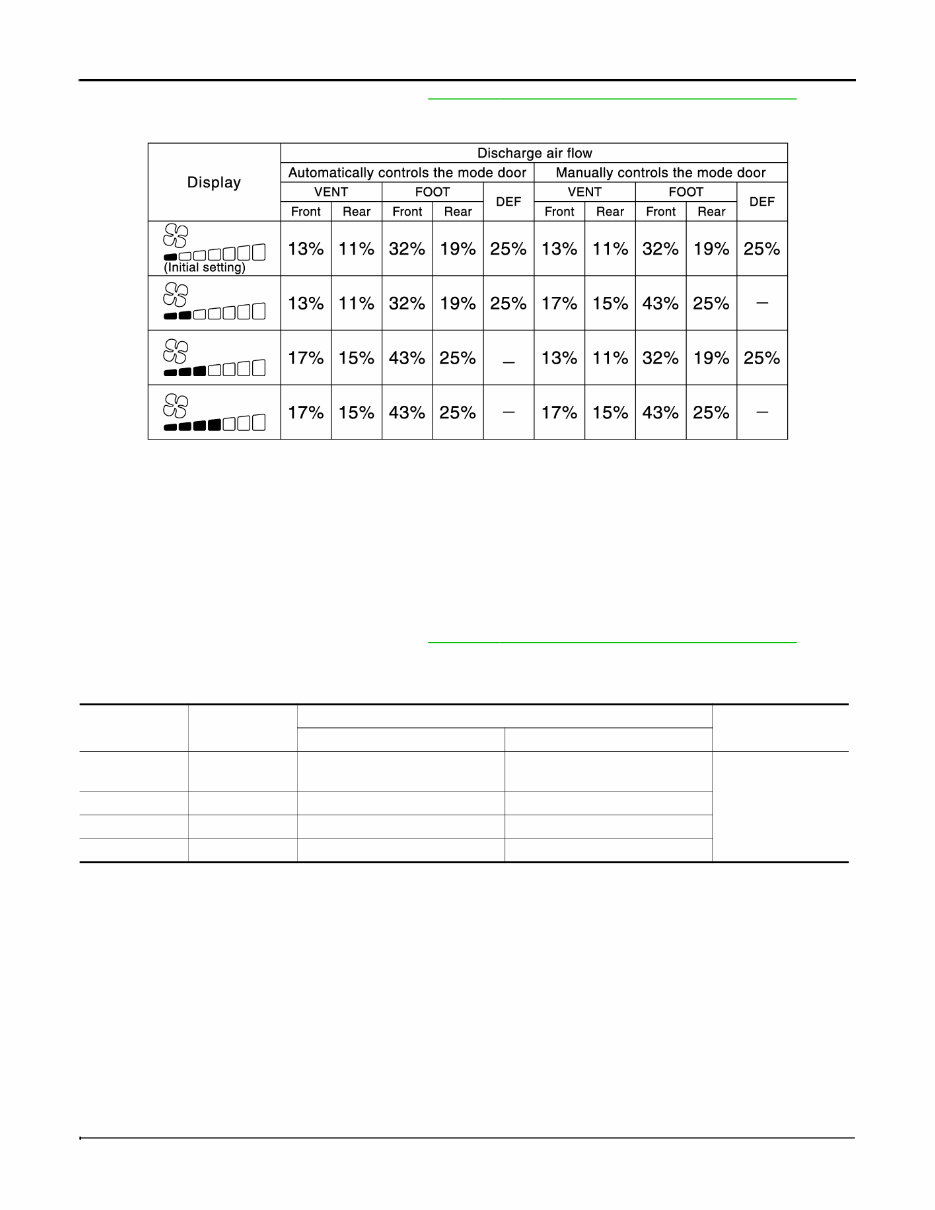

1. Press the MODE switch and the DEF switch.

2. Each position indicator should change shape.

3. Confirm that discharge air comes out according to the air distribution table as follows:

NOTE:

Confirm that the compressor clutch is engaged (sound or visual inspection) and the intake door position is at

FRE when D/F or DEF is selected.

Is the inspection result normal?

YES >> GO TO 4.

NO >> Mode door system malfunction: HAC-72, " Diagnosis Procedure " .

Conditions : Engine running at normal operating temperature

JSIIA1208GB

Revision: 2015 February 2015 QX70

HAC-8

< BASIC INSPECTION >

[AUTOMATIC AIR CONDITIONER]

INSPECTION AND ADJUSTMENT

4.CHECK INTAKE AIR

1. Press intake switch. REC indicator turns ON.

2. Press intake switch again. FRE indicator turns ON.

3. Listen for intake door position change. (Slight change of blower sound can be heard.)

NOTE:

Confirm that the compressor clutch is engaged (sound or visual inspection) and the intake door position is at

FRE when D/F or DEF is selected.

Is the inspection result normal?

YES >> GO TO 5.

NO >> Intake door system malfunction: HAC-78, " WITHOUT ACCS : Diagnosis Procedure " .

5.CHECK A/C SWITCH

1. Press the A/C switch.

2. A/C switch indicator turns ON.

Confirm that the compressor clutch engages (sound or visual inspection).

Is the inspection result normal?

YES >> GO TO 6.

NO >> Magnet clutch system malfunction: HAC-86, " Diagnosis Procedure " .

6.CHECK WITH TEMPERATURE SETTING LOWERED

1. Turn temperature control dial (driver side) counterclockwise until 18.0°C (60°F) is displayed.

2. Check that the cool air blows from the outlets.

Is the inspection result normal?

YES >> GO TO 7.

NO >> Insufficient cooling: HAC-170, " Inspection procedure " .

7.CHECK WITH TEMPERATURE SETTING RAISED

1. Turn temperature control dial (driver side) clockwise until 32.0°C (90°F) is displayed.

2. Check that the warm air blows from the outlets.

Is the inspection result normal?

YES >> GO TO 8.

NO >> Insufficient heating: HAC-172, " Inspection procedure " .

8.CHECK LEFT AND RIGHT VENTILATION TEMPERATURE SEPARATELY CONTROL SYSTEM FUNC-

TION

1. Press the DUAL switch, and then check that “DUAL” is shown on the display.

2. Operate temperature control dial (driver side). Check that the discharge air temperature (driver side)

changes.

3. Operate the temperature control dial (passenger side). Check that the discharge air temperature (passen-

ger side) changes.

4. Press the DUAL switch, and then check that the temperature setting (LH/RH) is unified to the driver side

temperature setting.

Is the inspection result normal?

YES >> GO TO 9.

NO >> Refer to HAC-169, " Diagnosis Chart By Symptom " and perform the appropriate diagnosis.

9.CHECK AUTO MODE

1. Press the AUTO switch, and then check that “AUTO” is shown on the display.

2. Check that the discharge air and blower speed depend on ambient temperature, in-vehicle temperature

and temperature setting.

Is the inspection result normal?

YES >> INSPECTION END

NO >> Refer to HAC-169, " Diagnosis Chart By Symptom " and perform the appropriate diagnosis.

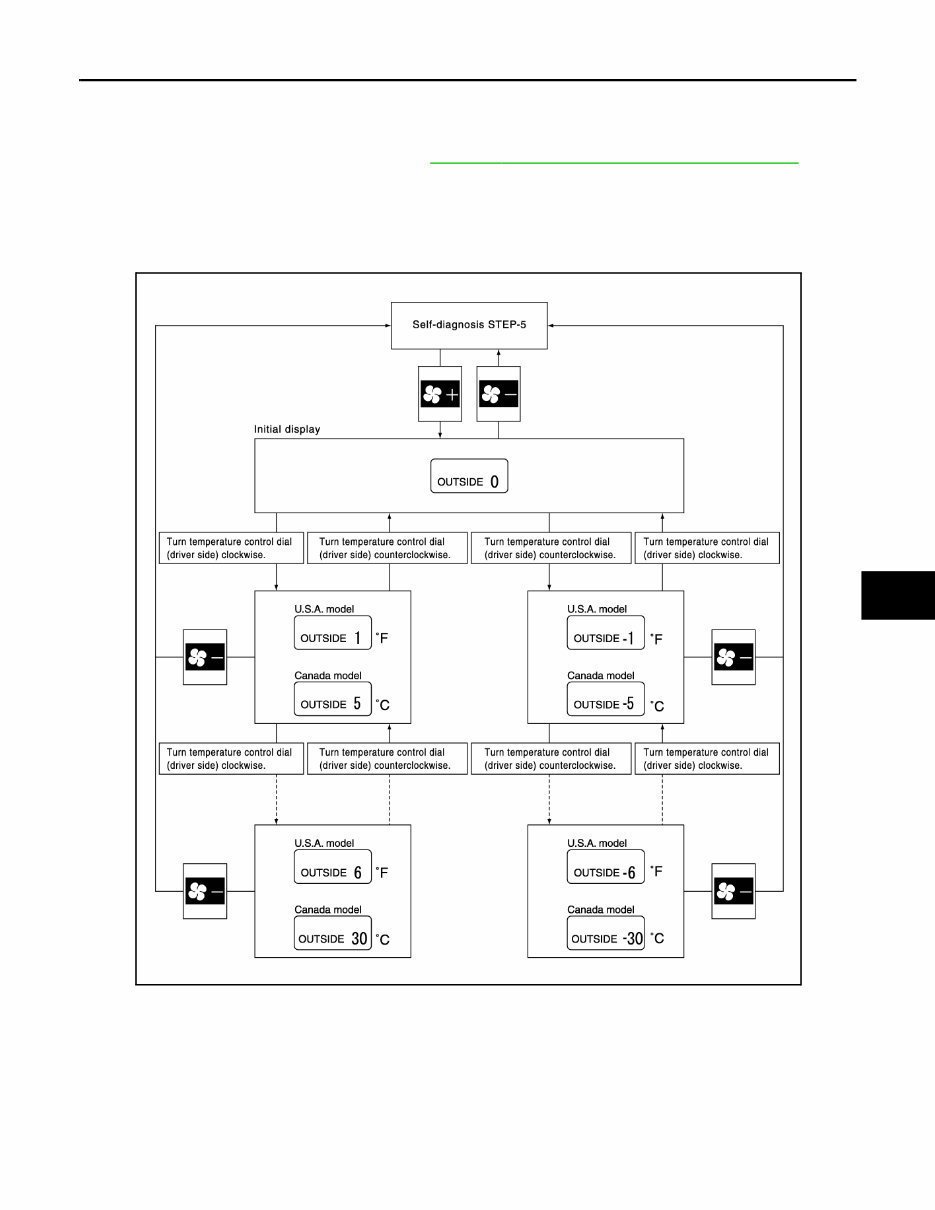

WITHOUT ACCS : Temperature Setting Trimmer INFOID:0000000010581328

DESCRIPTION

Revision: 2015 February 2015 QX70

INSPECTION AND ADJUSTMENT

HAC-9

< BASIC INSPECTION >

[AUTOMATIC AIR CONDITIONER]

C

D

E

F

G

H

J

K

L

M

A

B

HAC

N

O

P

The trimmer compensates for differences in range of ±3°C (±6°F) between temperature setting (displayed dig-

itally) and temperature felt by customer.

Operating procedures for this trimmer are as per the following:

1. Begin self-diagnosis STEP-5 mode. Refer to HAC-59, " WITHOUT ACCS : Diagnosis Description " .

2. Press fan (UP: +) switch to set system in auxiliary mode.

3. Display shows “61” in auxiliary mechanism. It takes approximately 3 seconds to enable setting operation.

4. Turn temperature control dial (driver side) as desired. Temperature will change at a rate of 0.5°C (1.0°F)

each time a dial is turned.

CAUTION:

A decimal point is not indicated on the display.

NOTE:

When battery cable is disconnected or battery voltage is below 10 V, trimmer operation is canceled. Tempera-

ture set becomes that of initial condition.

WITHOUT ACCS : Foot Position Setting Trimmer INFOID:0000000010581329

DESCRIPTION

Wind distribution ratio in FOOT mode can be set.

Operating procedures for this trimmer are as per the following:

JSIIA1210GB

Revision: 2015 February 2015 QX70

HAC-10

< BASIC INSPECTION >

[AUTOMATIC AIR CONDITIONER]

INSPECTION AND ADJUSTMENT

1. Begin self-diagnosis STEP-5 mode. Refer to HAC-59, " WITHOUT ACCS : Diagnosis Description " .

2. Press fan (UP: +) switch to set system in auxiliary mode.

3. Press mode switch as desired.

NOTE:

When battery cable is disconnected or battery voltage is below 10 V, trimmer operation is canceled. Air distri-

bution ratio set becomes that of initial condition.

WITHOUT ACCS : Inlet Port Memory Function INFOID:0000000010581330

DESCRIPTION

When ignition switch is turned from OFF to ON, inlet port can be set to AUTO or manual.

Operating procedures for this trimmer are as per the following:

1. Begin self-diagnosis STEP-5 mode. Refer to HAC-59, " WITHOUT ACCS : Diagnosis Description " .

2. Press fan (UP: +) switch to set system in auxiliary mode.

3. Press intake switch as desired.

NOTE:

When battery cable is disconnected or battery voltage is below 10 V, memory function is canceled. Memory

function set becomes that of initial condition.

WITH ACCS

WITH ACCS : Description & Inspection INFOID:0000000010581331

DESCRIPTION

The purpose of the operational check is to check that the individual system operates normally.

INSPECTION PROCEDURE

1.CHECK MEMORY FUNCTION

1. Start the engine.

JSIIA1209GB

FRE indicator REC indicator

Setting status

Setting changeover

method

FRE REC

OFF ON AUTO control (Initial setting)

Manual REC status is memorized.

(Initial setting)

Intake switch: ON

ON ON Manual FRE status is memorized. Manual REC status is memorized.

ON OFF Manual FRE status is memorized. AUTO control

OFF OFF AUTO control AUTO control

Conditions : Engine running at normal operating temperature

Revision: 2015 February 2015 QX70

You're Reading a Preview

What's Included?

Fast Download Speeds

Offline Viewing

Access Contents & Bookmarks

Full Search Facility

Print one or all pages of your manual

$35.99

Viewed 55 Times Today

Loading...

Secure transaction

What's Included?

Fast Download Speeds

Offline Viewing

Access Contents & Bookmarks

Full Search Facility

Print one or all pages of your manual

$35.99

- The 2017 Infiniti QX70 (S51) Service & Repair Manual (+ Wiring Diagrams) is a comprehensive resource for fixing vehicle issues using a Do-It-Yourself approach.

- It includes troubleshooting and replacement procedures recommended by the manufacturer, along with step-by-step instructions, clear images, and exploded-view illustrations.

- Regular maintenance is essential for the vehicle's durability, and this manual provides the manufacturer's recommended troubleshooting charts and replacement procedures.

- By using this manual, you can save on repairs, enhance your vehicle's reliability, and reduce visits to the repair shop.

- It offers easy access to specific information without the hassle of flipping through numerous pages, making it more convenient than traditional bound manuals.

- The manual is available in a printable format and is compatible with various electronic devices, including PC & Mac computers, Android and Apple smartphones & tablets, etc.

- It requires Adobe Reader, which is available for free.