FORD ELM320 OBD PWM To RS323 INTERPRETER HOW To Make YOUR

What's Included?

Fast Download Speeds

Online & Offline Access

Access PDF Contents & Bookmarks

Full Search Facility

Print one or all pages of your manual

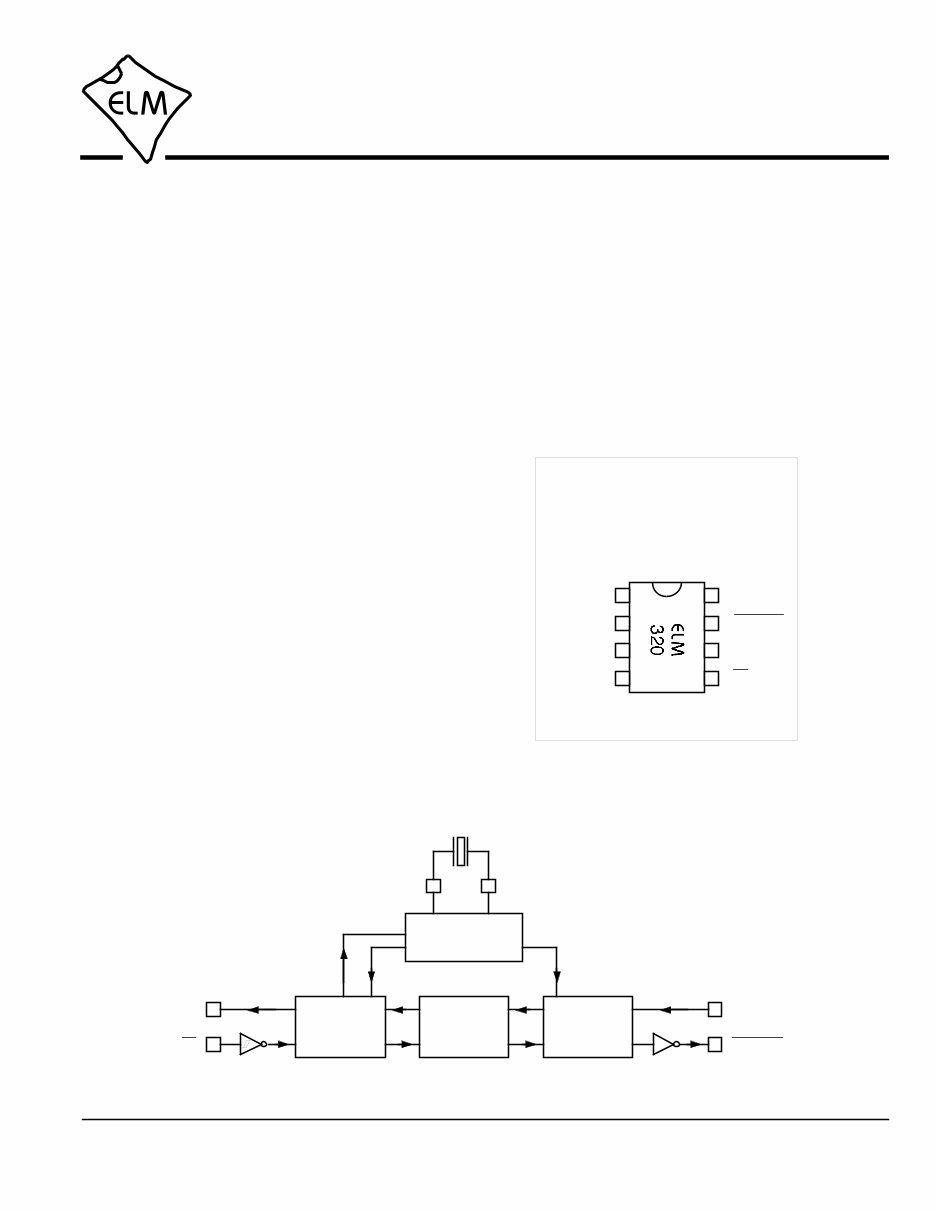

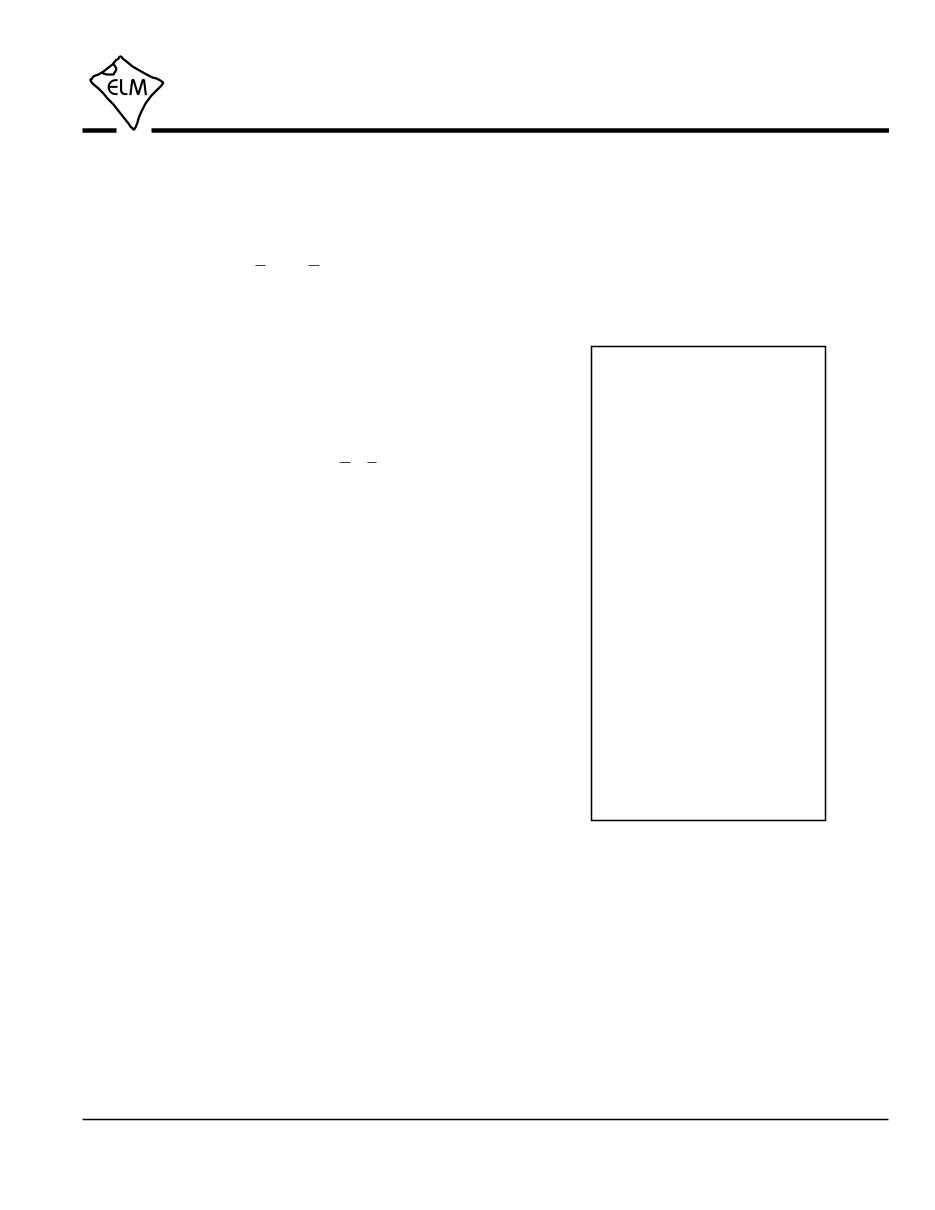

Connection Diagram

PDIP and SOIC

(top view)

VDD VSS

Since the 1996 model year, North American

automobiles have been required to provide an OBD,

or On Board Diagnostics, port for the connection of

test equipment. Data is transferred serially between

the vehicle and the external equipment using this

connection, in a manner specified by the Society of

Automotive Engineers (SAE) standards. In addition

to operating at different voltage levels, these ports

also use a data format that is not compatible with the

standard used for personal computers.

The ELM320 is an 8 pin integrated circuit that is

able to change the data rate and reformat the OBD

signals into easily recognized ASCII characters. This

allows virtually any personal computer to

communicate with an OBD equipped vehicle using

only a standard serial port and a terminal program.

By also enhancing it with an interface program,

hobbyists can create their own custom scan tool.

This integrated circuit was designed to provide a

cost-effective way for experimenters to work with an

OBD system, so a few features such as RS232

handshaking, variable baud rates, etc., have not

been implemented. In addition, this device is only

able to communicate using the 41.6KHz J1850 PWM

protocol that is commonly used in Ford Motor

Company vehicles.

• Low power CMOS design

• High current drive outputs

• Crystal controlled for accuracy

• Fully configurable using AT commands

• Standard ASCII character output

• High speed RS232 communications

• 41.6KHz J1850 PWM protocol

• Diagnostic trouble code readers

• Automotive scan tools

OBDOut

Tx

Description

Applications

Block Diagram

Features

OBDIn Rx

1

2

3

8

7

6

5 4

XT1

XT2

Tx

RS232

Interface

3.58MHz

2 3

XT1 XT2

Rx

5

6

Timing and

Control

Interpreter

OBD

Interface

OBDOut

4

7

OBDIn

Elm Electronics – Circuits for the Hobbyist

< http://www.elmelectronics.com/ >

OBD (PWM) to RS232 Interpreter

1 of 16 ELM320DSD

ELM320

Elm Electronics – Circuits for the Hobbyist

< http://www.elmelectronics.com/ >

Pin Descriptions

Ordering Information

These integrated circuits are available in either the 300 mil plastic DIP format, or in the 208 mil SOIC surface

mount type of package. To order, add the appropriate suffix to the part number:

300 mil Plastic DIP............................... ELM320P 208 mil SOIC..................................... ELM320SM

2 of 16

All rights reserved. Copyright 2001 to 2009 by Elm Electronics Inc.

Every effort is made to verify the accuracy of information provided in this document, but no representation or warranty can be

given and no liability assumed by Elm Electronics with respect to the accuracy and/or use of any products or information

described in this document. Elm Electronics will not be responsible for any patent infringements arising from the use of these

products or information, and does not authorize or warrant the use of any Elm Electronics product in life support devices and/or

systems. Elm Electronics reserves the right to make changes to the device(s) described in this document in order to improve

reliability, function, or design.

VDD (pin 1)

This pin is the positive supply pin, and should

always be the most positive point in the circuit.

Internal circuitry connected to this pin is used to

provide power on reset of the microprocessor, so

an external reset signal is not required. Refer to

the Electrical Characteristics section for further

information.

XT1 (pin 2) and XT2 (pin 3)

A 3.579545 MHz NTSC television colourburst

crystal is connected between these two pins.

Crystal loading capacitors (typically 27pF) will

also normally be connected between each of the

pins and the circuit common (Vss).

OBDIn (pin 4)

The OBD data is input to this pin, with a high

logic level representing the active state (and a

low, the passive). No Schmitt trigger input is

provided, so the OBD signal should be buffered

to minimize transition times for the internal

CMOS circuitry. The external level shifting

circuitry is usually sufficient to accomplish this –

see the Example Application section for a typical

circuit.

Rx (pin 5)

The computer’s RS232 transmit signal can be

directly connected to this pin from the RS232

line, as long as a current limiting resistor

(typically about 47KΩ) is installed in series.

(Internal protection diodes will pass the input

currents safely to the supply connections,

protecting the ELM320.) Internal signal inversion

and Schmitt trigger waveshaping provide the

necessary signal conditioning.

Tx (pin 6)

The RS232 data output pin. The signal level is

compatible with most interface ICs, and there is

sufficient current drive to allow interfacing using

only a single PNP transistor, if desired.

OBDOut (pin 7)

This is the active low output signal which is used

to drive the OBD bus to the active state. Since

the J1850 PWM standard requires a differential

bus signal, the user must create the complement

of this signal to drive the other bus line. See the

Example Application section for more details.

VSS (pin 8)

Circuit common is connected to this pin. This is

the most negative point in the circuit.

ELM320DSD

ELM320

Elm Electronics – Circuits for the Hobbyist

< http://www.elmelectronics.com/ >

Electrical Characteristics

Absolute Maximum Ratings

Storage Temperature....................... -65°C to +150°C

Ambient Temperature with

Power Applied.................................... -40°C to +85°C

Voltage on VDD with respect to VSS............ 0 to +7.5V

Voltage on any other pin with

respect to VSS........................... -0.6V to (VDD + 0.6V)

Note:

Stresses beyond those listed here will likely damage

the device. These values are given as a design

guideline only. The ability to operate to these levels

is neither inferred nor recommended.

3 of 16

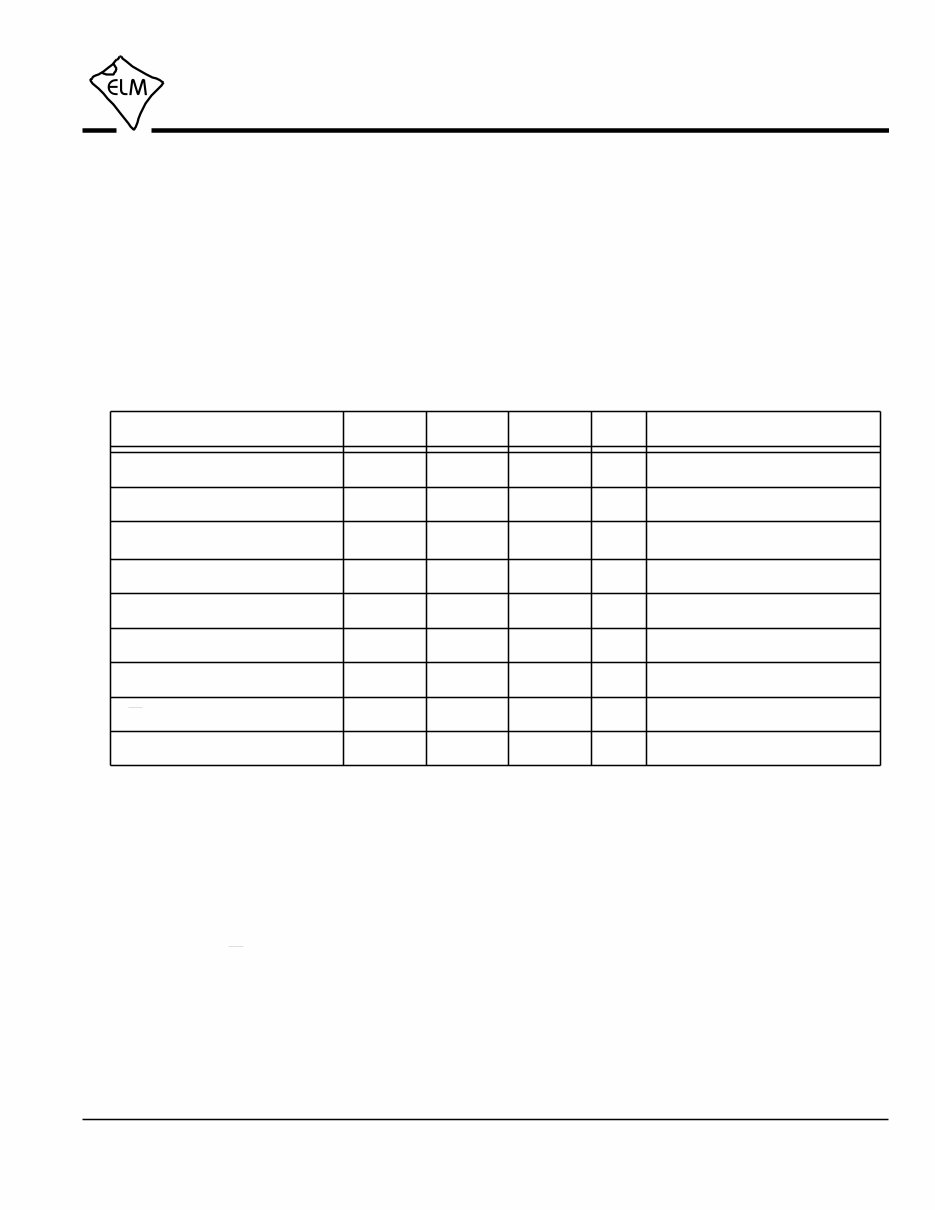

All values are for operation at 25°C and a 5V supply, unless otherwise noted. For further information, refer to note 1 below.

Characteristic Minimum Typical Maximum Conditions Units

Supply voltage, VDD 4.5 5.0 5.5 V

VDD rate of rise 0.05 V/ms

Average supply current, IDD 1.0 2.4 mA

Notes:

1. This integrated circuit is produced with a Microchip Technology Inc.’s PIC12C509A as the core embedded

microcontroller. For further device specifications, and possibly clarification of those given, please refer to the

appropriate Microchip documentation (available at http://www.microchip.com/).

2. This spec must be met in order to ensure that a correct power on reset occurs. It is quite easily achieved

using most common types of supplies, but may be violated if one uses a slowly varying supply voltage, as

may be obtained through direct connection to solar cells, or some charge pump circuits.

3. Device only. Does not include any load currents.

4. This specification represents the current flowing through the protection diodes when applying large voltages

to the Rx input (pin 5) through a current limiting resistance. Currents quoted are the maximum that should be

allowed to flow continuously.

5. Nominal data transfer rate when a 3.58 MHz crystal is used as the frequency reference. Data is transferred

to and from the ELM320 with 8 data bits, no parity, and 1 stop bit (8 N 1).

Input low voltage VSS 0.15 VDD V

Input high voltage VDD V 0.85 VDD

Output low voltage 0.6 V

Output high voltage V VDD - 0.7

Current (sink) = 8.7mA

Current (source) = 5.4mA

see note 2

ELM320DSD

see note 3

Rx pin input current mA see note 4 -0.5

RS232 baud rate baud see note 5 9600

+0.5

ELM320

4 of 16 ELM320DSD Elm Electronics – Circuits for the Hobbyist

< http://www.elmelectronics.com/ >

Overview

The ELM320 relies on a standard RS232 type

serial connection to communicate with the user. The

data rate is fixed at 9600 baud, with 8 data bits, no

parity bit, 1 stop bit, and no handshaking (often

referred to as 9600 8N1). All responses from the IC

are terminated with a single carriage return character

and, by default, a line feed character as well. Make

sure your software is configured properly for the mode

you have chosen.

Properly connected and powered, the ELM320 will

initially display the message:

ELM320 v2.0

>

In addition to identifying the version of the IC,

receipt of this string is a convenient way to be sure

that the computer connections and the settings are

correct. However, at this point no communications

have taken place with the vehicle, so the state of that

connection is still unknown.

The ‘>’ character displayed above is the ELM320’s

prompt character. It indicates that the device is in its

idle state, ready to receive characters on the RS232

port. Characters sent from the computer can either be

intended for the ELM320’s internal use, or for

reformatting and passing on to the vehicle’s OBD bus.

Commands for the ELM320 are distinguished from

those to the vehicle by always beginning with the

characters ‘AT’ (as is common with modems), while

commands for the OBD bus must contain only the

ASCII characters for hexadecimal digits (0 to 9 and A

to F). This allows the ELM320 to quickly determine

where the received characters are to be directed.

Whether an ‘AT’ type internal command or a hex

string for the OBD bus, all messages to the ELM320

must be terminated with a carriage return character

(hex ‘0D’) before it will be acted upon. The one

exception is when an incomplete string is sent and no

carriage return appears. In this case, an internal timer

will automatically abort the incomplete message after

about 10 seconds, and the ELM320 will print a single

question mark to show that the input was not

understood (and was ignored).

Messages that are misunderstood by the ELM320

(syntax errors) will always be signalled by a single

question mark (‘?’). These include incomplete

messages, invalid hexadecimal digit strings, or

incorrect AT commands. It is not an indication of

whether or not the message was understood by the

vehicle. (The ELM320 is a protocol interpreter that

makes no attempt to assess OBD messages for

validity – it only ensures that an even number of hex

digits were received, combined into bytes, and sent

out the OBD port, so it cannot determine if the

message sent to the vehicle is in error.)

Incomplete or misunderstood messages can also

occur if the controlling computer attempts to write to

the ELM320 before it is ready to accept the next

command (as there are no handshaking signals to

control the data flow). To avoid a data overrun, users

should always wait for the prompt character (‘>’)

before issuing the next command.

Finally, a few convenience items to note. The

ELM320 is not case-sensitive, so ‘ATZ’ is equivalent to

‘atz’, and to ‘AtZ’. The device ignores space characters

as well as control characters (tab, linefeed, etc.) in the

input, so they can be inserted anywhere to improve

readability and, finally, issuing only a single carriage

return character will repeat the last command (making

it easier to request updates on dynamic data such as

engine rpm).

Communicating with the ELM320

The following describes how to use the ELM320 to

obtain a great deal of information from your vehicle. To

many, the quantity of information will be overwhelming,

and to others it is not nearly enough.

We begin by discussing just how to talk to the IC,

then how to adjust some options through the use of

‘AT’ commands, and finally go on to actually talk to the

vehicle, obtaining trouble codes and resetting them.

For the more advanced experimenters, there are also

sections on how to use some of the programmable

features of this product as well.

It is not as daunting as it first appears. Many users

will never need to issue an ‘AT’ command, adjust

timeouts or change the headers. For most, all that is

required is a PC or a PDA with a terminal program

(such as HyperTerminal or ZTerm), and knowledge of

one or two OBD commands, which we provide in the

following…

ELM320

5 of 16 ELM320DSD Elm Electronics – Circuits for the Hobbyist

< http://www.elmelectronics.com/ >

AT Commands

Several parameters within the ELM320 can be

adjusted in order to modify its behaviour. These do not

normally have to be changed before attempting to talk

to the vehicle, but occasionally the user may wish to

customize the settings, for example by turning the

character echo off, adjusting the timeout value, or

changing the header addresses. In order to do this,

internal ‘AT’ commands must be issued.

Those familiar with PC modems will immediately

recognize AT commands as a standard way in which

modems are internally configured. The ELM320 uses

essentially the same method, always watching the

data sent by the PC, looking for messages that begin

with the character ‘A’ followed by the character ‘T’. If

found, the next characters will be interpreted as

internal configuration or ‘AT’ commands, and will be

executed upon receipt of a terminating carriage return

character. The ELM320 will reply with the characters

‘OK’ on the successful completion of a command, so

the user knows that it has been executed.

Some of the following commands allow passing

numbers as arguments in order to set the internal

values. These will always be hexadecimal numbers

which must be provided in pairs. The hexadecimal

conversion chart in the next section may prove useful

if you wish to interpret the values. Also, one should be

aware that for the on/off types of commands, the

second character is a number (1 or 0), the universal

terms for on and off, respectively.

The following is a summary of all of the AT

commands that are recognized by the current version

of the ELM320, sorted alphabetically. Users of

previous versions of this product (v1.x) should note

that their ICs will only support the E, H and Z options.

AR [ A utomatically set the R eceive address ]

Responses from the vehicle will be acknowledged

and displayed by the ELM320, if its internally stored

receive address matches the address that the

message is being sent to. With the auto receive

mode in effect, the value used for the receive

address will be chosen based on the current header

bytes, and will automatically be updated whenever

the header bytes are changed.

The value that is used for the receive address is

determined based on the contents of the first header

byte. If it shows that the message uses physical

addressing, the third header byte of the header is

used for the receive address, otherwise (for

functional addressing) the second header byte,

increased in value by 1, will be used. Auto Receive

is turned on by default.

D [ set all to D efaults ]

This command is used to set the E, H, L, and R

options to their default (or factory) settings, as when

power is first applied. Additionally, the Auto Receive

mode (AR) will be selected, data will be transmitted

in the standard formatted way (as if chosen by FD),

the ‘NO DATA’ timeout will be set to its default value,

and the header bytes will be set to the proper values

for the OBDII operation.

E0 and E1 [ E cho off (0) or on(1) ]

These commands control whether or not characters

received on the RS232 port are retransmitted (or

echoed) back to the host computer. To reduce traffic

on the RS232 bus, users may wish to turn echoing

off by issuing ATE0. The default is E1 (echo on).

FD [ send F ormatted D ata ]

This command requests that all responses be

returned as standard ASCII characters which are

readable on virtually any standard terminal program.

Hex digits are shown as two ASCII characters, and

spaces are provided between each byte as a

separator. Also, every line will end with a carriage

return character and (optionally) a linefeed

character, ensuring that every response appears on

a new line. This is the default mode.

H0 and H1 [ H eaders off (0) or on(1) ]

These commands control whether or not the header

information is shown in the responses. All OBD

messages have an initial (header) string of three

bytes and a trailing check digit which are normally

not displayed by the ELM320. To see this extra

information, users can turn the headers on by

issuing an ATH1. The default is H0 (headers off).

ELM320

6 of 16 ELM320DSD Elm Electronics – Circuits for the Hobbyist

< http://www.elmelectronics.com/ >

AT Commands (continued)

I [ I dentify yourself ]

Issuing this command causes the chip to identify

itself, by printing the startup product ID string (this is

currently ‘ELM320 v2.0’). Software can use this to

determine exactly which integrated circuit it is talking

to, without resorting to resetting the entire IC.

L0 and L1 [ L inefeeds off (0) or on(1) ]

Whether the ELM320 transmits a linefeed character

after each carriage return character is controlled by

this option. If an ATL1 is issued, linefeed generation

will be turned on, and for ATL0, it will be off. Users

may wish to have this option on if using a terminal

program, but off if using a custom interface (as the

extra characters transmitted will only serve to slow

the vehicle polling down). The default setting is L1

(linefeeds on)

MA [ M onitor A ll messages ]

Using this command places the ELM320 into a bus

monitoring mode, in which it displays all messages

as it sees them on the OBD bus. This continues

indefinitely until stopped by activity on the RS232

input. To stop the monitoring, one should send any

single character then wait for the ELM320 to respond

with a prompt character (‘>’). Waiting for the prompt

is necessary as the response time is unpredictable,

varying depending on the IC was doing when

interrupted. If for instance it is in the middle of

printing a line, it will first complete the line then

return to the command state, issuing the prompt

character. If it were simply waiting for input, it would

return immediately. The character which stops the

monitoring will always be discarded, and will not

affect subsequent commands.

MR hh [ M onitor for R eceiver hh ]

This command also places the IC in a bus monitoring

mode, displaying only messages that were sent to

the hex address given by hh (i.e. messages which

are found to have that value in their second byte).

Any RS232 activity (single character) aborts the

monitoring, as with the MA command.

MT hh [ M onitor for T ransmitter hh ]

Another monitoring command, which displays only

messages sent by Transmitter address hh. As with

the MA and MR monitoring modes, any RS232

activity (single character) aborts the monitoring.

PD [ send P acked D ata ]

This option is for those that are building a computer

interface and want the fastest data transfer rate

possible while still operating at 9600 baud. When

selected, responses from the vehicle will be

formatted as an initial length byte followed by the

actual response bytes from the vehicle, with no

trailing carriage returns or linefeed characters. The

data will not be altered in any way, except for the

conversion to standard RS232 bytes.

Note that the length byte only represents the total

number of data bytes following, and does not include

itself. Also, if there was a data (checksum) error, the

length byte will have its most significant bit set, so

the user should always check first to see if the length

is greater than 127. (The other 7 bits still provide a

valid byte count if there is an error, so one need only

ignore the msb, or subtract 128 from the value.)

A ‘NO DATA’ response has no data bytes, but still

sends a length byte with value ‘0’.

R0 and R1 [ R esponses off (0) or on(1) ]

These commands control the ELM320’s automatic

display of responses. If responses have been turned

off, the IC will not wait for anything to be returned

from the vehicle after sending a request, and will

return immediately to waiting for RS232 commands.

This is useful if sending commands blindly when

using the IC for a non-OBD network application, or

simulating an ECU, in a basic learning environment.

It is not recommended that this option normally be

used, however, as the vehicle may have difficulty if it

is expecting an acknowledgement byte and never

receives one. The default is R1 (responses on).

SH xx yy zz [ S et the H eader to xx yy zz ]

This command allows the user to control the values

that are sent as the three header bytes in the

message. The value of hex digits xx will be used for

the first or priority/type byte, yy will be used for the

second or target byte, and zz will be used for the

third or source byte. These remain in effect until set

again, or until restored to the default values with the

AT D, or AT Z commands. The default header values

ELM320

7 of 16 ELM320DSD Elm Electronics – Circuits for the Hobbyist

< http://www.elmelectronics.com/ >

AT Commands (continued)

ELM320 AT Commands

general

responses

requests

set all to Defaults D

show the ID string I

reset all Z

repeat last command <CR>

Echo on/off E1/0

Headers on/off H1/0

Linefeeds on/off L1/0

Responses on/off R1/0

ST hh Set Timeout (hh*4ms)

SH xx yy zz Set Header

SR hh Set Rx address

AR Auto Receive

MA Monitor All

MR hh Monitor for Rxer hh

use Packed Data PD

use Formatted Data FD

MT hh Monitor for Txer hh

are 61 6A F1, as required by the SAE J1979

Diagnostic Test Modes (OBDII) standard.

SR hh [S et the R eceive address to hh ]

Depending on the application, users may wish to

manually set the address to which the ELM320 will

respond. Issuing this command will turn off the AR

mode, and force the IC to only accept responses

addressed to hh. Use caution with this setting, as

depending on what you set it to, you may end up

accepting (acknowledging with an IFR) a message

that was actually meant for another module.

ST hh [ S et T imeout to hh ]

After sending a request, the ELM320 waits a preset

time before declaring that there was no response

from the vehicle (the ‘NO DATA’ response).

Depending on the application (and priority of the

request), users may want modify this timeout period

before declaring the request a failure. The ST

command is used to do that.

The actual time used is (approximately) 4 ms x the

byte value passed as the hexadecimal argument.

Passing a value of FF thus results in a maximum

time of about 1020 ms. Values less than 08 will be

ignored and forced to a value of 8, providing a

minimum time of 32ms. The default value is 32

(decimal 50) providing a timeout of 200 ms.

Z [ reset all ]

This command causes the chip to perform a

complete reset as if power were cycled off and then

on again. All settings are returned to their default

values, and the chip will be put in the idle state,

waiting for characters on the RS232 bus.

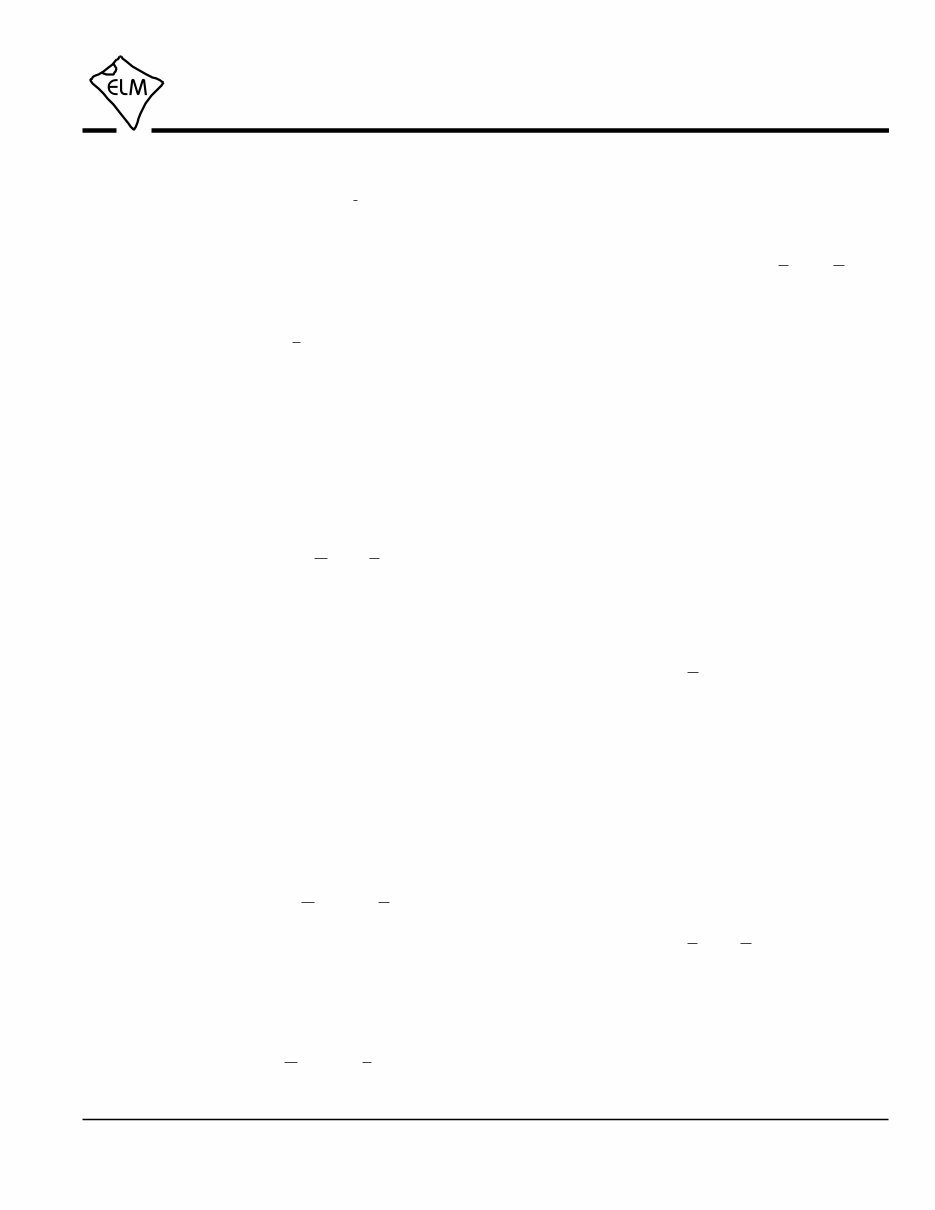

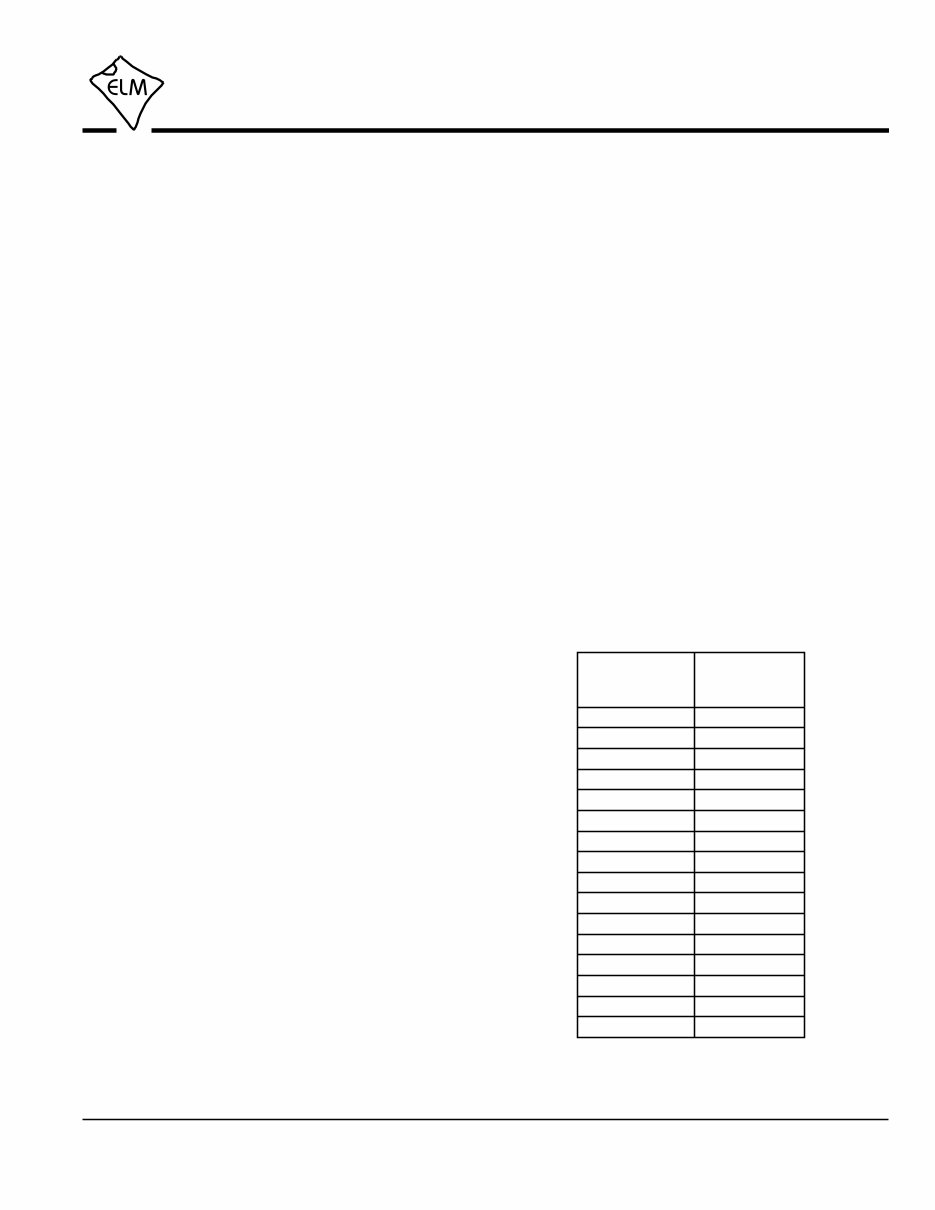

AT Command Summary

Figure 1 (at the right) shows all of the ELM320

commands in one convenient chart. In order to help

with the understanding of these, we have grouped

the commands into three functional areas, but this

has no bearing on how the commands are to be

used, it is only for clarity. You may find this chart to

be useful when experimenting with the IC.

Figure 1. ELM320 AT Commands

ELM320

If the bytes received on the RS232 bus do not

begin with the letters A and T, they are assumed to be

commands for the vehicle’s OBD bus. The bytes will

be tested to ensure that they are valid pairs of

hexadecimal digits and, if they are, will be combined

into bytes for transmitting to the vehicle. Recall that no

checks are made as to the validity of the OBD

command – data is simply retransmitted as received.

OBD commands are actually sent to the vehicle

embedded in a data message. The standards require

that every message begin with three header bytes and

end with a checksum byte, which the ELM320 adds

automatically to every message. The ELM320 powers-

on expecting to be used for the OBDII mandated

emissions diagnostics, and sets the header bytes

accordingly. If you wish to perform more advanced

functions, these bytes may be changed through the

use of AT commands. To view the extra bytes that are

received with the vehicle’s messages, turn the header

display on by issuing an ATH1 command.

The command portion of most OBD messages is

usually only one or two bytes in length, but can

occasionally be longer as the standard allows for as

many as seven. The current version of the ELM320

will accept the maximum seven command bytes (or 14

hexadecimal digits) per message, while users of

previous versions (v1.x) were limited to only three

command bytes. In either case, attempts to send more

than the maximum number of bytes allowed will result

in a syntax error, with the entire command being

ignored and a single question mark printed.

The use of hexadecimal digits for all of the data

exchange was chosen as it is the most common data

format used in the relevant SAE standards. It is

consistent with mode request listings and is the most

frequently used format for displaying results. With a

little practice, it should not be very difficult to deal in

hex numbers, but some may initially find the table in

Figure 2 or a calculator to be invaluable. All users will

eventually be required to manipulate the results in

some way, though (combine bytes and divide by 4 to

obtain rpm, divide by 2 to obtain degrees of advance,

etc.), and may find a software front-end more helpful.

As an example of sending a command to the

vehicle, assume that A6 (or decimal 166) is the

command that is required to be sent. In this case, the

user would type the letter A, then the number 6, then

would press the return key. These three characters

would be sent to the ELM320 on the RS232 bus. The

ELM320 would store the characters as they are

received, and when the third character (the carriage

return) is received, begin to assess the other two. It

would see that they are both valid hex digits, and

would convert them to a one byte value (with a

decimal value of 166). Three header bytes and a

checksum byte would be added, so a total of five bytes

would be sent to the vehicle. Note that the carriage

return character is only a signal to the ELM320, and is

not sent on to the vehicle.

After sending a command, the ELM320 listens on

the OBD bus for any responses that are directed to it.

Each received byte is converted to the equivalent

hexadecimal pair of ASCII characters and transmitted

on the RS232 port for the user. Rather than send

control characters which are unprintable on most

terminals, the digits are sent as numbers and letters

(e.g. the hex digit ‘A’ is transmitted as decimal value

65, and not 10).

If there was no response from the vehicle, due to

no data being available, or because the command is

not supported, a ‘NO DATA’ message will be sent. See

the error messages section for a description of this

message and others.

8 of 16 ELM320DSD Elm Electronics – Circuits for the Hobbyist

< http://www.elmelectronics.com/ >

OBD Commands

Figure 2. Hex to Decimal Conversion

Hexadecimal

Number

Decimal

Equivalent

0

1

3

2

4

5

6

0

1

3

2

4

5

6

7 7

8 8

9 9

A 10

B 11

C 12

D 13

E 14

F 15

ELM320

9 of 16 ELM320DSD Elm Electronics – Circuits for the Hobbyist

< http://www.elmelectronics.com/ >

Talking to the Vehicle

The ELM320 cannot be directly connected to a

vehicle as it is, but needs support circuitry as shown in

the Example Applications section. Once incorporated

into such a circuit, you only need to use a terminal

program to send bytes to, and receive them from, the

vehicle.

SAE standards specify that command bytes sent

to the vehicle must adhere to a set format. The first

byte (known as the ‘mode’) always describes the type

of data being requested, while the second, third, etc.

bytes specify the actual information required (given by

a ‘parameter identification’ or PID number). The

modes and PIDs are described in detail in the SAE

standard documents J1979 and J2190, and may also

be expanded on by the vehicle manufacturers.

Normally, one is only concerned with the nine

diagnostic test modes described in J1979 (although

there is provision for more). Note that it is not a

requirement for all of them to be supported. These are

the nine modes:

01 : show current data

02 : show freeze frame data

03 : show diagnostic trouble codes

04 : clear trouble codes and stored values

05 : test results, oxygen sensors

06 : test results, non-continuously monitored

07 : test results, continuously monitored

08 : special control mode

09 : request vehicle information

Within each mode, PID 00 is normally reserved to

show which PIDs are supported by that mode. Mode

01, PID 00 is required to be supported by all vehicles,

and can be accessed as follows…

Ensure that the ELM320 is properly connected to

your vehicle, and powered. Most vehicles will not

respond without the ignition key in the ON position, so

turn the ignition on, but do not start the vehicle. At the

prompt, issue the mode 01 PID 00 command:

>01 00

A typical response could be as follows:

41 00 BE 1F B8 10

The 41 00 signifies a response (4) from a mode 1

request with PID 00 (a mode 2, PID 00 request is

answered with a 42 00, etc.). The next four bytes (BE,

1F, B8, and 10) represent the requested data, in this

case a bit pattern showing which of PIDs 1 through 32

are supported by this mode (1=supported, 0=not).

Although this information is not very useful for the

casual user, it does serve to show that you are

communicating with the vehicle.

Another example requests the current engine

coolant temperature (ECT). This is PID 05 in mode 01,

and is requested as follows:

>01 05

The response will be of the form:

41 05 7B

This shows a mode 1 response (41) from PID 05,

with value 7B. Converting the hexidecimal 7B to

decimal, one gets 7 x 16 + 11 = 123. This represents

the current temperature in degrees Celsius, with the

zero value offset by 40 degrees to allow operation at

subzero temperatures. To convert to the actual coolant

temperature, simply subtract 40 from the value. In this

case, then, the ECT is 123 - 40 = 83 degrees Celsius.

A final example shows a request for the OBD

requirements to which this vehicle was designed. This

is PID 1C of mode 01, so at the prompt, type:

>01 1C

A typical response would be:

41 1C 01

The returned value (01) shows that this vehicle

conforms to OBDII (California ARB) standards. The

presently defined responses are :

01 : OBDII (California ARB)

02 : OBD (Federal EPA)

03 : OBD and OBDII

04 : OBD I

05 : not intended to meet any OBD requirements

06 : EOBD (Europe)

Some modes may provide multi-line responses

(09, if supported, can display the vehicle’s serial

number). The ELM320 will attempt to display all

responses in these cases, but only if it is allowed

sufficient time to process each. There may be

occasions when the vehicle responds too quickly to

allow time for reprocessing, and lines could be lost.

Hopefully this has shown how typical requests

proceed. It has not been meant to be a definitive

source on modes and PIDs – this information can be

obtained from the manufacturer of your vehicle, from

the SAE (www.sae.org), ISO (www.iso.org), or from

various other sources on the web.

ELM320

Interpreting Trouble Codes

10 of 16 ELM320DSD Elm Electronics – Circuits for the Hobbyist

< http://www.elmelectronics.com/ >

Likely the most common use that the ELM320 will

be put to is in obtaining the current Diagnostic Trouble

Codes or DTCs. Minimally, this requires that a mode

03 request be made, but first one should determine

how many trouble codes are presently stored. This is

done with a mode 01 PID 01 request as follows:

>01 01

To which a typical response might be:

41 01 81 07 65 04

The 41 01 signifies a response to our request, and

the first data byte (81) is the result that we are looking

for. Clearly there would not be 81(hex) or 129(decimal)

trouble codes if the vehicle is operational. In fact, this

byte does double duty, with the most significant bit

being used to indicate that the malfunction indicator

lamp (MIL, or ‘Check Engine’) has been turned on by

one of this module’s codes (if there are more than

one), while the other 7 bits provide the actual number

of stored codes. To determine the number of stored

codes, then, one needs to subtract 128 (or 80 hex)

from the number if it is greater than 128, and otherwise

simply read the number of stored codes directly.

The above response then indicates that there is

one stored code, and it was the one that set the MIL or

‘Check Engine’ lamp on. The remaining bytes in the

response provide information on the types of tests

supported by that particular module (see SAE

document J1979 for further information).

In this instance, there was only one line to the

response, but if there were codes stored in other

modules, they each could have provided a line of

response. To determine which module is reporting the

trouble code, one would have to turn the headers on

(ATH1) and then look at the third byte of the three byte

header for the address of the module that sent the

information.

Having determined the number of codes stored,

the next step is to request the actual trouble codes

with a mode 03 request:

>03

A response to this could be:

43 01 33 00 00 00 00

The ‘43’ in the above response simply indicates

that this is a response to a mode 03 request. The other

6 bytes in the response have to be read in pairs to

show the trouble codes (the above would be

interpreted as 0133, 0000, and 0000). Note that there

is only one trouble code here. The response has been

padded with 00’s as is required by the standard, and

the extra 0000’s do not represent actual trouble codes.

As was the case when requesting the number of

stored codes, the most significant bits of each trouble

code also contain additional information. It is easiest to

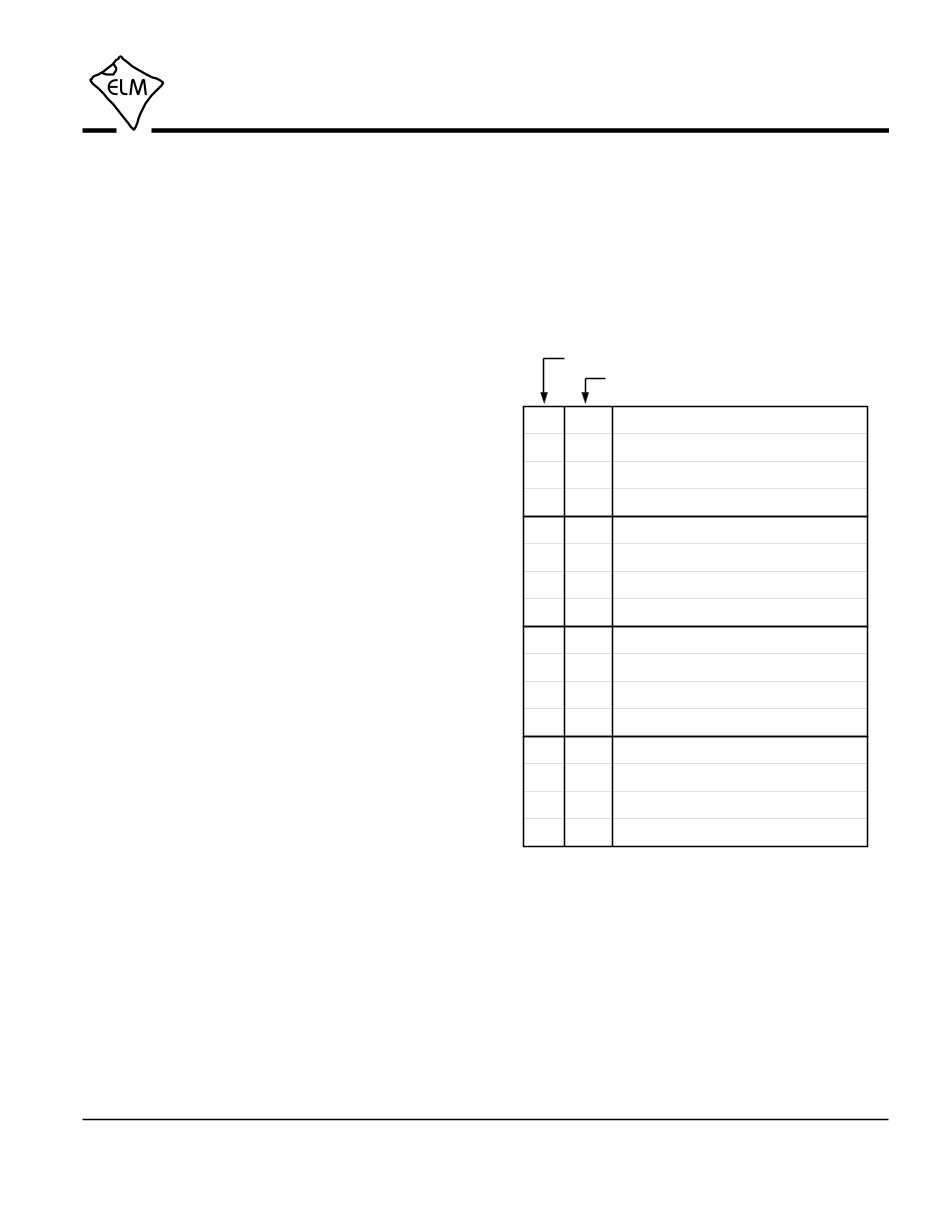

use the following table to interpret the first digit of

trouble codes as follows:

Powertrain Codes - SAE defined

0

“ “ - manufacturer defined

“ “ - SAE defined

“ “ - jointly defined

1

2

3

If the first hex digit received is this,

Replace it with these two characters

Chassis Codes - SAE defined

4

“ “ - reserved for future

5

6

7

Body Codes - SAE defined

8

9

A

B

Network Codes - SAE defined

C

D

E

F

P0

P1

P2

P3

C0

C1

C2

C3

B0

B1

B2

B3

U0

U1

U2

U3

“ “ - reserved for future

“ “ - manufacturer defined

“ “ - manufacturer defined

“ “ - manufacturer defined

“ “ - manufacturer defined

“ “ - manufacturer defined

“ “ - manufacturer defined

“ “ - reserved for future

Taking the example trouble code (0133), the first

digit (0) would then be replaced with P0, and the 0133

reported would become P0133 (which is the code for

an ‘oxygen sensor circuit slow response’). As for

further examples, if the response had been D016, the

code would be interpreted as U1016, while 1131 would

be P1131.

Had there been codes stored by more than one

module, or more than three codes stored in the same

module, the above response would have consisted of

multiple lines. To determine which module is reporting

each trouble would then require turning the headers on

with an ATH1 command.

ELM320

You're Reading a Preview

What's Included?

Fast Download Speeds

Online & Offline Access

Access PDF Contents & Bookmarks

Full Search Facility

Print one or all pages of your manual

$31.99

Viewed 81 Times Today

Loading...

Secure transaction

What's Included?

Fast Download Speeds

Online & Offline Access

Access PDF Contents & Bookmarks

Full Search Facility

Print one or all pages of your manual

$31.99

If you're looking to create your own cable for the FORD ELM320 OBD PWM to RS323 interpreter, you'll need to follow these steps:

- First, gather the necessary materials, including an OBD-II connector, RS232 connector, and appropriate cables.

- Next, refer to the pinout diagram for the ELM320 and identify the corresponding pins for the OBD-II and RS232 connectors.

- Then, carefully solder the cables to the respective pins on the connectors, ensuring proper connections.

- After the soldering is complete, insulate the connections with heat shrink tubing to prevent any short circuits.

- Finally, test the cable to ensure it is functioning correctly with the FORD ELM320 OBD PWM to RS323 interpreter.

Creating your own cable can be a cost-effective solution for connecting the FORD ELM320 OBD PWM to RS323 interpreter, and it's a useful skill for both professional mechanics and DIY enthusiasts.