2003 Ford Focus Service & Repair Manual

What's Included?

Fast Download Speeds

Online & Offline Access

Access PDF Contents & Bookmarks

Full Search Facility

Print one or all pages of your manual

SECTION 100-01: Identification Codes 2003 Focus Workshop Manual

DESCRIPTION AND OPERATION

Identification Codes

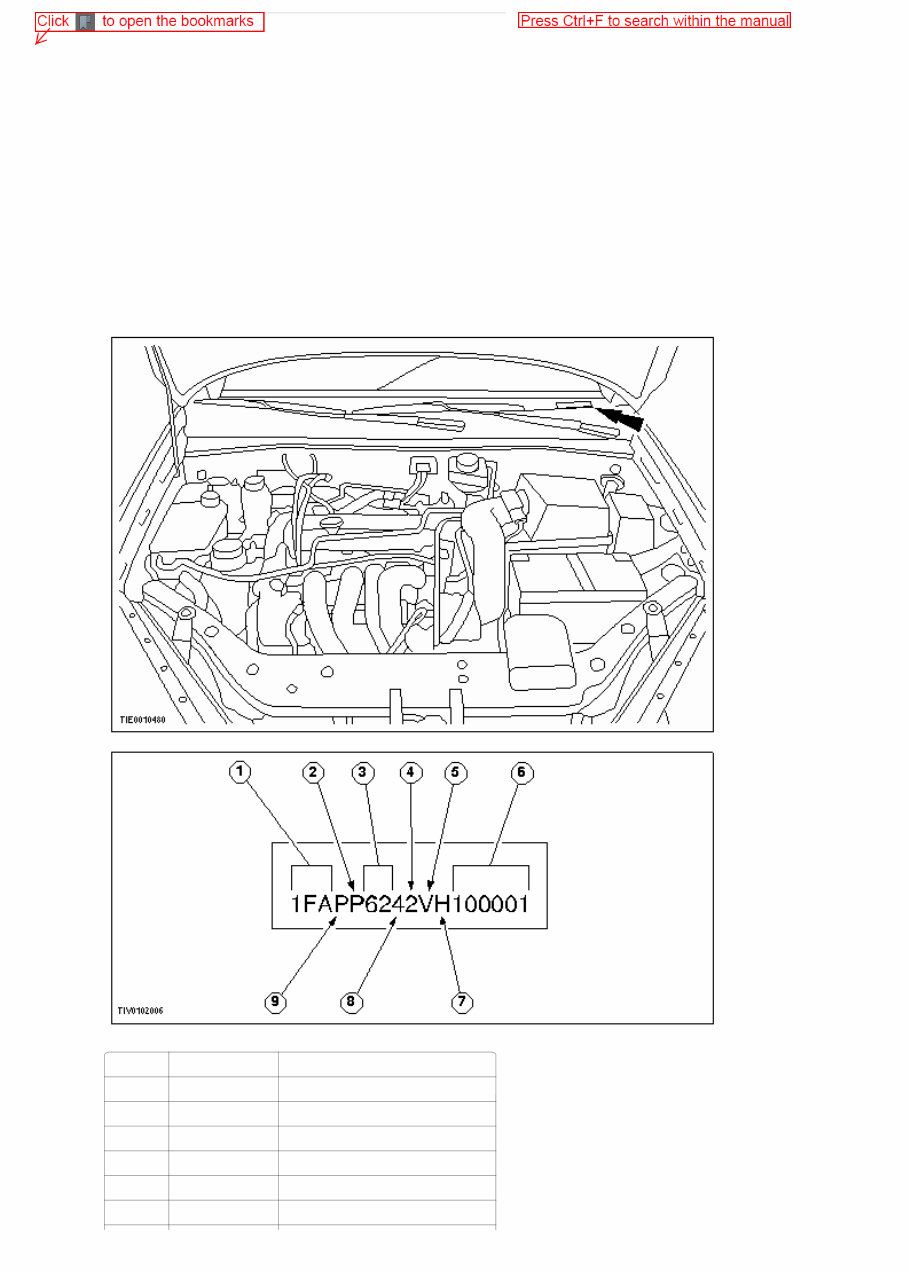

The vehicle identification number is stamped on the vehicle certification label. It is positioned on the

left-hand B-pillar, above the latch.

The visible VIN (label) is fastened to the instrument panel. It is positioned close to the windshield

glass on the left-hand side of the vehicle and is visible from the outside.

Visible VIN (label)

Vehicle Identification Number (VIN)

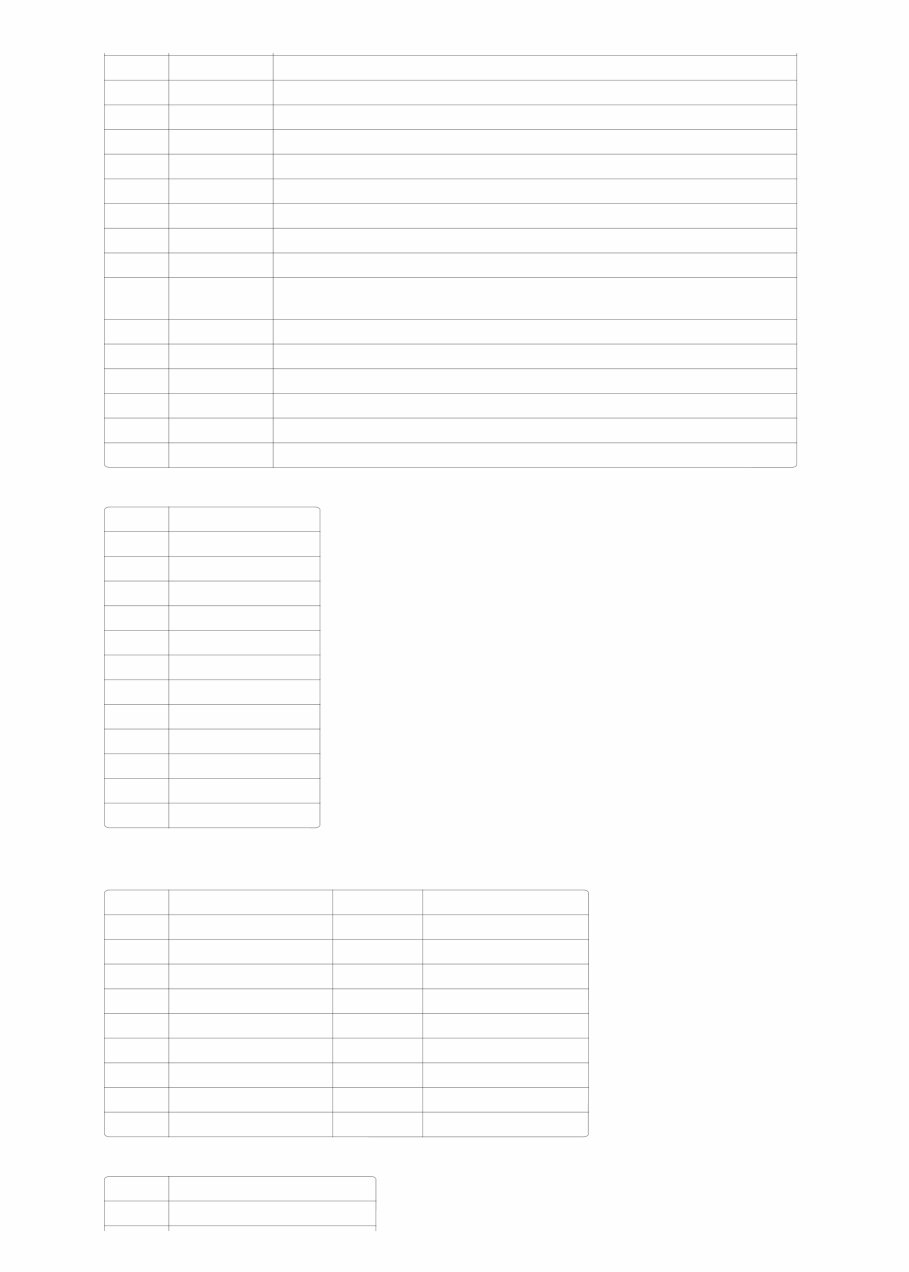

Item Part Number Description

1 - World manufacturer identifier

2 - Manufacturer specification

3 - Line, series, body type

4 - Check digit

5 - Vehicle model year

6 - Production sequence number

7 - Assembly plant

Unfiled Notes Page 1

7 - Assembly plant

8 - Engine type

9 - Restraint system type

Vin Position 1, 2, and 3

Codes Manufacturer Make Type

1FA Ford Motor Company, USA Ford Passenger vehicle

1FM Ford Motor Company, USA Ford MPV

1FT Ford Motor Company, USA Ford Truck (complete vehicle)

1FD Ford Motor Company, USA Ford Incomplete vehicle

1FC Ford Motor Company, USA Ford Basic (stripped) Chassis

1FB Ford Motor Company, USA Ford Bus

1FF Ford Motor Company, USA Ford Motor vehicle equipment W/O

Engine/Powertrain (glider)

1ME Ford Motor Company, USA Mercury Passenger vehicle

1MH Ford Motor Company, USA Mercury Incomplete vehicle

1LN Ford Motor Company, USA Lincoln Passenger vehicle

1LJ Ford Motor Company, USA Lincoln Incomplete vehicle

1ZV Auto Alliance International, Inc Ford Passenger vehicle

1ZW Ford Motor Company, USA Mercury Passenger vehicle

2FA Ford Motor Company of

Canada, Ltd.

Ford Passenger vehicle

2FM Ford Motor Company of

Canada, Ltd.

Ford MPV

2FT Ford Motor Company of

Canada, Ltd.

Ford Truck (complete vehicle)

2FD Ford Motor Company of

Canada, Ltd.

Ford Incomplete vehicle

2FC Ford Motor Company of

Canada, Ltd.

Ford Basic (stripped) chassis

2FB Ford Motor Company of

Canada, Ltd.

Ford Bus

2FF Ford Motor Company of

Canada, Ltd.

Ford Motor vehicle equipment (W/O Engine/

Powertrain (Glider)

2ME Ford Motor Company of

Canada, Ltd.

Mercury Passenger vehicle

2MH Ford Motor Company of

Canada, Ltd.

Mercury Incomplete vehicle

3FA Ford Motor Company (Mexico) Ford Passenger vehicle

3FB Ford Motor Company (Mexico) Ford Bus

3FC Ford Motor Company (Mexico) Ford Basic (stripped) chassis

3FE Ford Motor Company (Mexico) Ford Incomplete vehicle

3FM Ford Motor Company (Mexico) Ford MPV

3FT Ford Motor Company (Mexico) Ford Truck (complete vehicle)

3ME Ford Motor Company (Mexico) Mercury Passenger vehicle

4F2 Ford Motor Company, USA Mazda MPV

4F3 Ford Motor Company, USA Mazda Incomplete vehicle

4F4 Ford Motor Company, USA Mazda Truck (complete vehicle)

4M2 Ford Motor Company, USA Mercury MPV

4M3 Ford Motor Company, USA Mercury Incomplete vehicle

4M4 Ford Motor Company, USA Mercury Truck (complete vehicle)

4N2 Ford Motor Company, USA Nissan MPV

Unfiled Notes Page 2

4N2 Ford Motor Company, USA Nissan MPV

4N3 Ford Motor Company, USA Nissan Incomplete vehicle

4N4 Ford Motor Company, USA Nissan Truck complete vehicle

KNJ Kia Motors Inc. Korea Ford Passenger vehicle (imported aspire)

World Manufacturer Identifier

VIN Position 4

Code Description

B Active belts (all positions)

F Active belts (all positions) and front air bags (driver and passenger)

H Active belts (all positions) and front and side air bags (driver and passenger)

Restraint System Type

VIN Position 5

Code Vehicle

M Passenger

vehicle

Lincoln, Mercury, North American Vehicles

P Passenger

vehicle

Ford North American vehicles

T Passenger

vehicle

All passenger vehicles imported from outside North America or non-Ford

built passenger vehicle marketed by Ford in North America

Manufacturer Specification

VIN Position 6 and 7

Code Line Series Additional Optional Exterior Nameplate Body Type Body Code

30 Focus ECO - 3-door ECO

31 Focus ZX3 - 3-door ZX3

33 Focus LX - 4-door LX4

34 Focus SE - 4-door SE4

36 Focus ZTS - 4-door LTS

38 Focus SE - wagon SEW

Line, Series and Body Type

VIN Position 8

Code Displacement Liters Displacement CID Cylinders Fuel Manufacturer

P 2.0 SPI 121 4 Gasoline Ford

3 2.0 Zetec 121 4 Gasoline Ford

Engine Type

VIN Position 9

VIN position 9 is a check digit

VIN Position 10

Code Year of Manufacture

Y 2000

1 2001

2 2002

3 2003

4 2004

5 2005

Year of Manufacture

VIN Position 11

Code Assembly Plant

Unfiled Notes Page 3

A Atlanta: Hapeville, Georgia

B Oakville: Oakville, Ontario

D Ohio: Avon Lake, Ohio

F Dearborn: Dearborn, Michigan

G Chicago: Chicago, Illinois

H Lorain: Lorain, Ohio

J IMMSA: Monterrey, Mexico

K Kansas City: Claycomo, Missouri

N Norfolk: Norfolk, Virginia

P Twin Cities: St. Paul, Minnesota

R Hermosillo: Hermosillo, Mexico

T Edison: Edison, New Jersey

U Louisville: Louisville, Kentucky

W Wayne: Wayne, Michigan

X St. Thomas: Talbotville, Ontario

Y Wixom: Wixom, Michigan

Z St. Louis: Hazelwood, Missouri

5 AAI: Flat Rock, Michigan

6 Mazda-Kia: Kyrung Ki-Do Korea

Assembly Plant

VIN Position 12 through 17

Sequence Number

100,001 through 599,999 - Ford Division Vehicles

600,001 through 999,999 - Lincoln and Mercury Division vehicles

Production Sequence Number

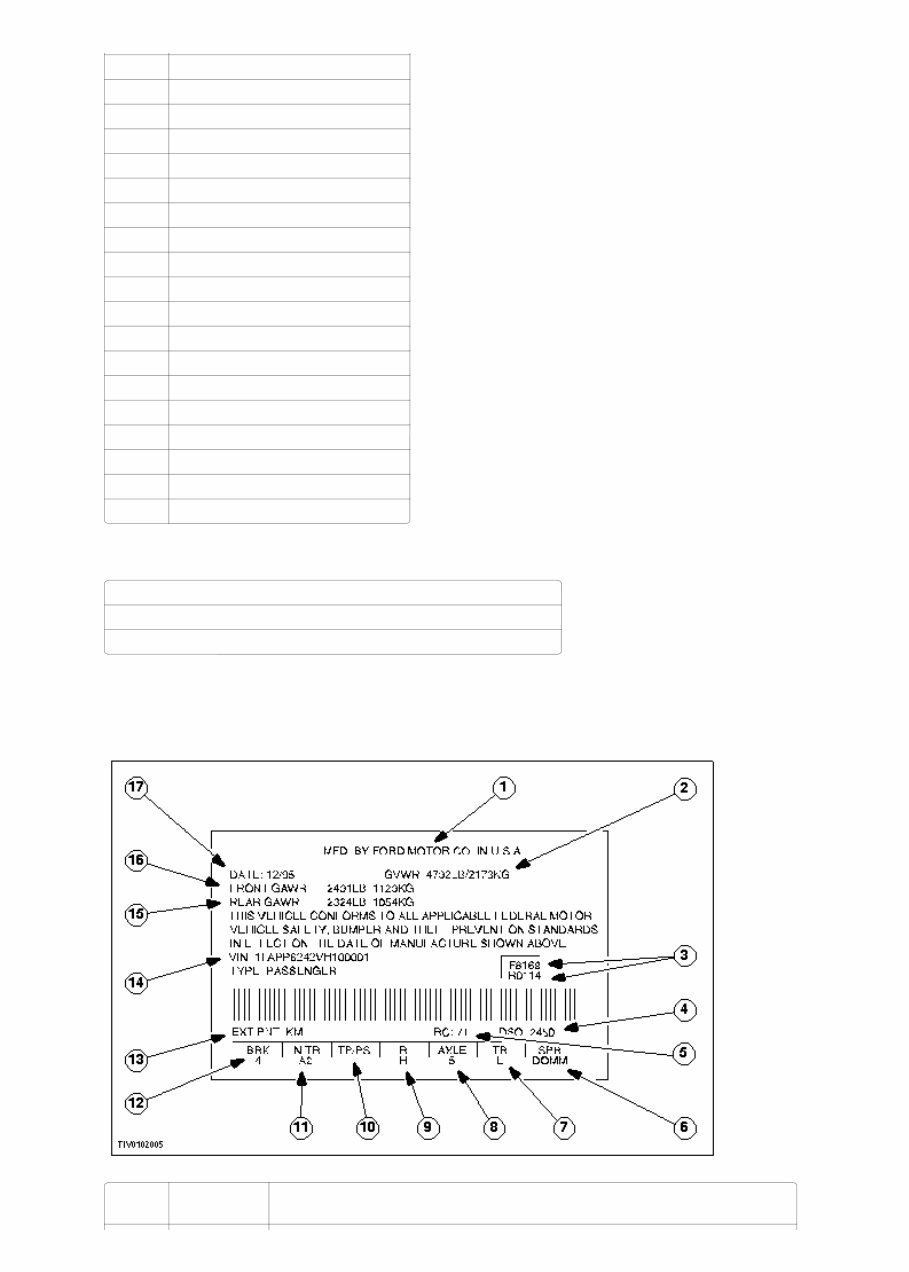

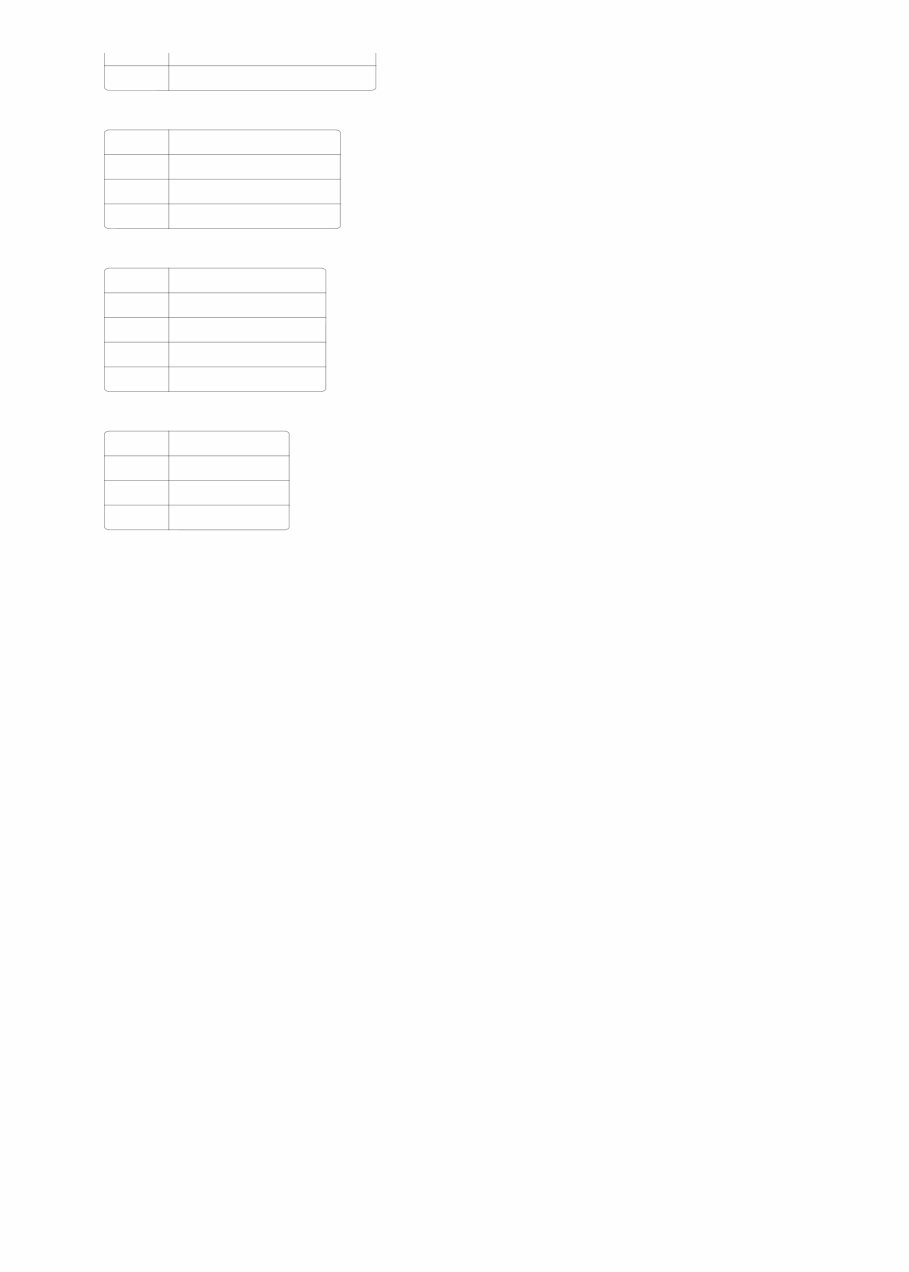

Vehicle Certification (VC) Label (Typical)

The vehicle certification label also contains the 17 character vehicle identification number. This

number is used for warranty identification of the vehicle.

Vehicle Certification Label

Item Part

Number

Description

1 - Name and location of manufacturer

Unfiled Notes Page 4

2 - Gross vehicle weight ratings in pounds (LB) and Kilograms (KG)

3 - Accessory reserve load codes

4 - District/special order codes

5 - Sales region codes

6 - Suspension identification

7 - Transmission/transaxle codes

8 - Axle ratio codes

9 - Radio type codes

10 - Tape stripe/paint stripe codes

11 - Interior trim codes (first code letter = fabric and seat type, second code

letter = color

12 - Brake type codes

13 - Exterior paint codes

14 - Vehicle identification number

15 - Rear gross axle weight ratings in pounds (LB) and Kilograms (KG)

16 - Front gross axle weight ratings in pounds (LB) and Kilograms (KG)

17 - Build date

Exterior Paint Color Codes

Code Color

TS Silver Frost

BL Harvest Gold

FL Toreador Red

K6 Atlantic Blue

SU Amazon Green

BG Bright Amber

LV Light Sapphire Blue

YZ Performance White

E4 Vermillion Solid

UA Ebony Solid

MK Twilight Blue

K7 Bright Atlantic Blue

Interior Trim (Fabric) Codes

Code Trim Scheme Fabric Seat Type Trim Color

DA Shadow/Oasis Sport seat Medium dark graphite

DW Shadow/Oasis Sport seat Midnight black

EA Finnesse/Oasis Individual Medium dark graphite

EW Finnesse/Oasis Individual Midnight black

EH Finnesse/Oasis Individual Medium parchment

CA Kirk/Oasis Individual Medium dark graphite

CH Kirk/Oasis Individual Medium parchment

8A Leather/Leather Individual Medium dark graphite

8H Leather/Leather Individual Medium parchment

Brake Type Codes

Code Brake Type

2 Anti-lock brakes (ABS)

Non-ABS, FR disk/RR drum

Unfiled Notes Page 5

2 Anti-lock brakes (ABS)

Non-ABS, FR disk/RR drum

Interior Color

Code Trim Color

A Medium Dark Graphite

W Midnight Black

H Medium Parchment

Axle Ratio Codes

Code Axle Ratio

II 3:61 SPI Manual

NN 3:693 SPI Automatic

UU 3:820 SPI Manual

WW 3:904 SPI Automatic

Transaxle Codes

Code Axle Ratio

5 iB5 Manual

A FN Automatic

M MTX75 Manual

Unfiled Notes Page 6

SECTION 100-00: General Information 2003 Focus Workshop Manual

DESCRIPTION AND OPERATION

About This Manual

Introduction

This manual has been written in a format that is designed to meet the needs of Ford technicians

worldwide. The objective is to use common formats and include similar content in each manual

worldwide.

This manual provides general descriptions for accomplishing service and repair work with tested,

effective techniques. Following them will help assure reliability.

Replacement Parts

Ford and Motorcraft parts are made to the same exacting standards as the original factory fitted

components. For this reason, it is recommended that only genuine Ford or Motorcraft parts are

installed during service or repair.

Special Tools

The Special Tool(s) Table provided at the beginning of each procedure shows all special tools

required to carry out a repair. Where possible, illustrations are provided to assist in identifying the

special tool required.

Special tools may be ordered from Loewener OTC GmbH, Rotunda Equipment, or their

agents/distributors.

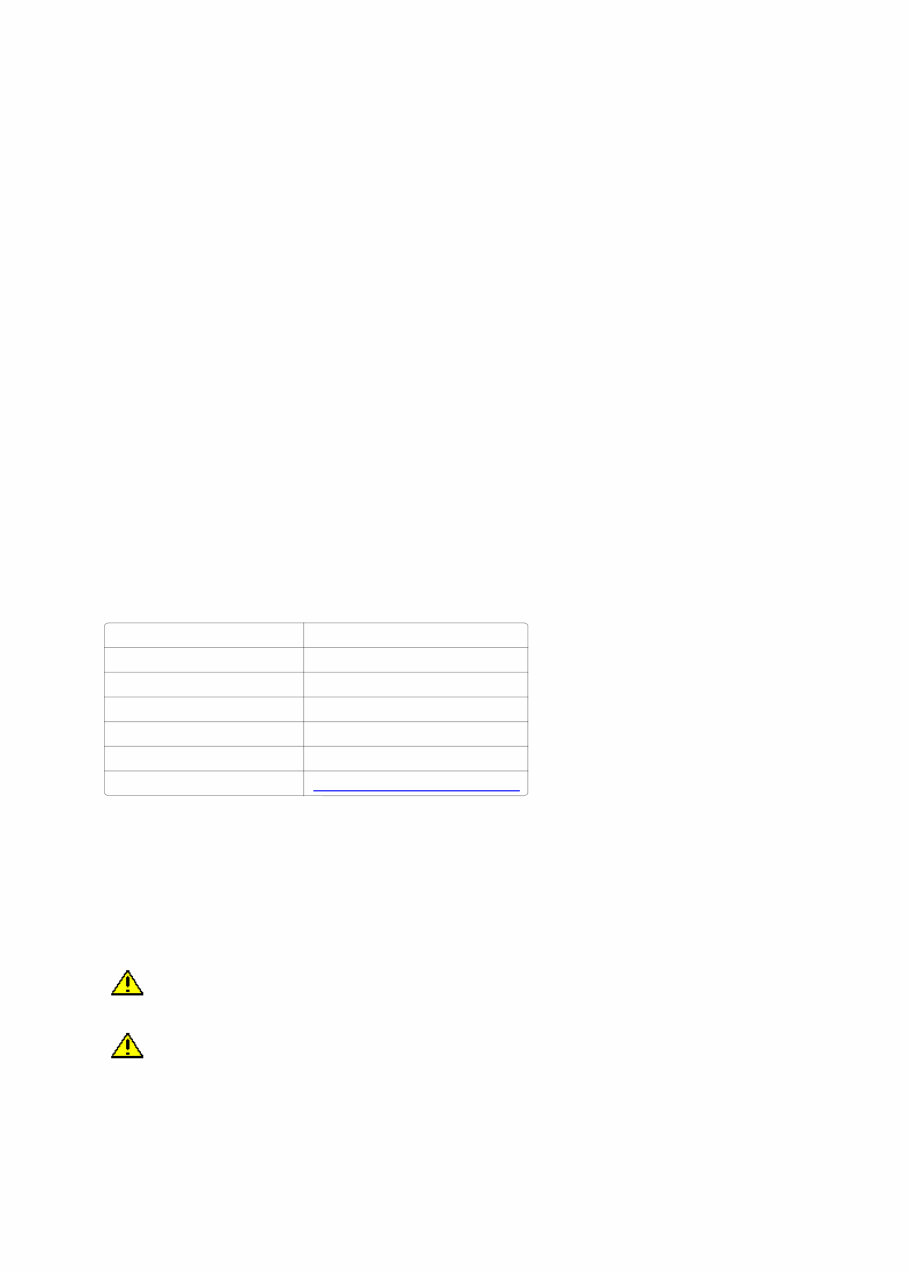

Europe North America

Loewener OTC GmbH Rotunda Equipment

Industriestrasse 67 PO Box 1450

D40764 Langenfeld Kenosha W1 53141-1450

Germany Phone 1-800-ROTUNDA

Tel: +49 (0) 2173 928-0 FAX 1-800-762-6181

Fax: +49 (0) 2173 928-199 WWW.FORDROTUNDA.COM

Important Safety Instructions

Appropriate service methods and correct repair procedures are essential for the safe, reliable

operation of all motor vehicles as well as the personal safety of the individual carrying out the work.

This manual cannot possibly anticipate all such variations and provide advice or cautions as to each.

Anyone who departs from the instructions provided in this manual must first establish that he

compromises neither his personal safety nor the vehicle integrity by his choice of methods, tools or

parts.

Warnings, Cautions and Notes in This Manual

WARNING: Warnings are used to indicate that failure to follow a procedure correctly may

result in personal injury.

CAUTION: Cautions are used to indicate that failure to follow a procedure correctly may result

in damage to the vehicle or equipment being used.

NOTE: Notes are used to provide additional essential information required to carry out a complete

and satisfactory repair.

As you read through this manual, you will come across WARNINGS, CAUTIONS and NOTES.

A warning, caution or note is placed at the beginning of a series of steps if it applies to multiple steps.

If the warning, caution or note only applies to one step, it is placed at the beginning of the specific

step (after the step number).

How to Use This Manual

Unfiled Notes Page 1

How to Use This Manual

This manual covers service and repair procedures.

This manual is structured into groups and sections, with specific system sections collected together

under their relevant group.

A group covers a specific portion of the vehicle. The manual is divided into five groups, General

Information, Chassis, Powertrain, Electrical and Body and Paint. The number of the group is the first

number of a section number.

Pages at the start of the manual list all sections available. Each section has a contents list detailing

General Specifications, Description and Operation and Service Adjustment and Checks.

If components need to be removed or disassembled in sequence, the sequence will be identified

numerically in a graphic and the corresponding text will be numbered accordingly (refer to `Samples').

All left and right-hand references to the vehicle are taken from a position sitting in the driver seat

looking forward.

All left and right-hand references to the engine are taken from a position at the flywheel looking

towards the front camshaft pulley.

Where appropriate, instructions will be given for the use of WDS, FDS2000 or New Generation STAR

Tester diagnostic equipment.

Inspection and Verification

Visual Inspection Charts, Symptom Charts and other information charts (such as diagnostic routines),

supplement test procedures with technical specifications, or navigate the user to a specific test

procedure.

Sympton Chart

The symptom chart indicates symptoms, sources and actions to address a condition.

Pinpoint Tests

For electrical systems, pinpoint test steps are used to identify the source of a concern in a logical,

step-by-step manner. Pinpoint tests have two columns: CONDITIONS and

DETAILS/RESULTS/ACTIONS.

The CONDITIONS column is used exclusively for graphics and icons (with or without captions) and

the DETAILS/RESULTS/ACTIONS column provides direction to another test step or specific

corrective actions.

The boxed numbers indicate the order in which the described action is to be performed.

Component Tests

A component test is used when a component is tested in multiple pinpoint tests, or if a procedure is

too complicated to be formatted within a single page of the pinpoint test.

Graphics

Test graphics show the measurement or test to be performed in a test step.

A representative tester graphic is used for voltmeters and ohmmeters.

If multiple measurements are made in a single graphic, the test leads are drawn with a solid line until

the test lead splits to indicate the multiple measurements, at which point dashed lines are used.

Breakout box-type testers are represented by a double circle test pin. Test pins are labelled with the

pin number.

Samples

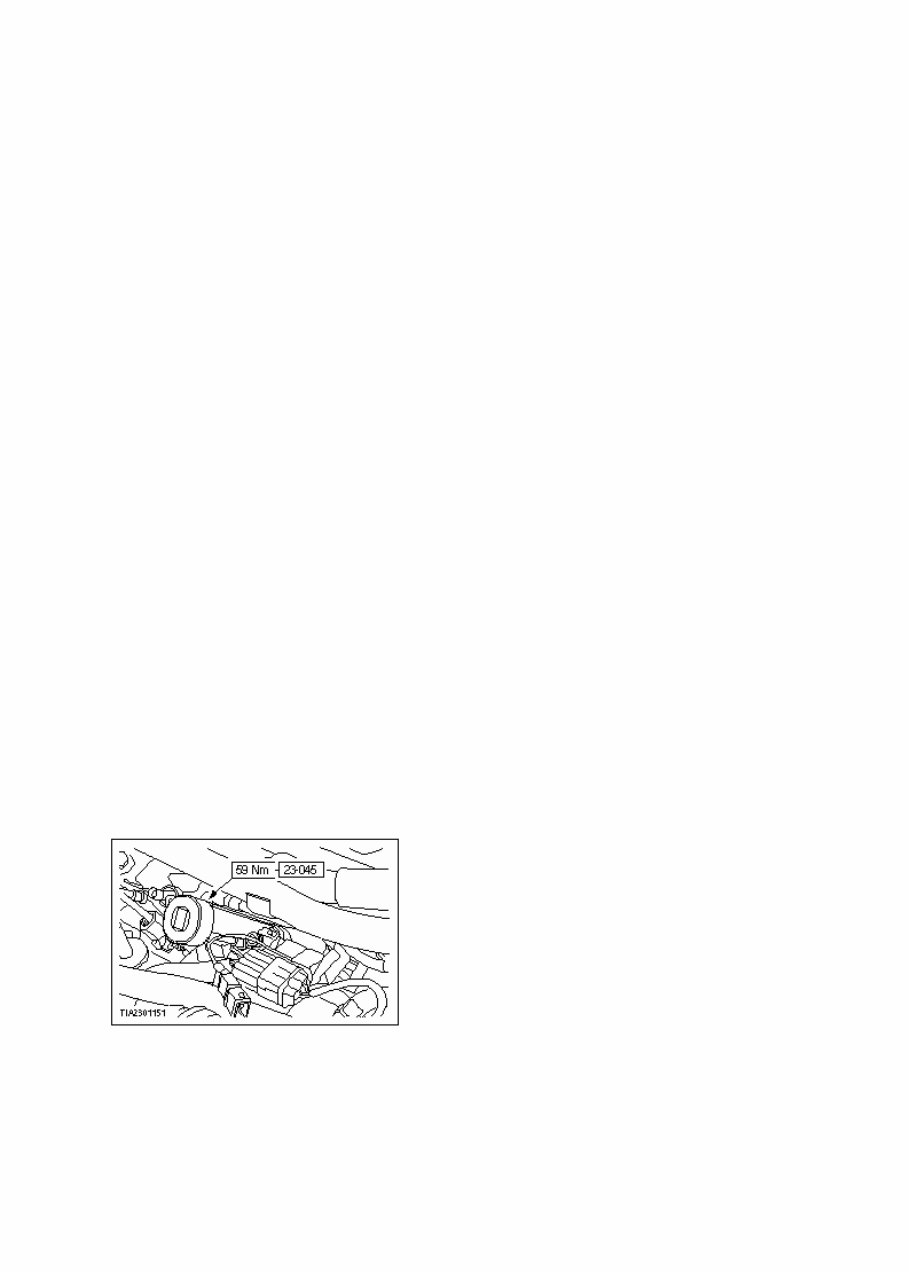

Special Tools and Torque Figures

Any requirement for special tools will picture the tool, showing it in use and with its tool number

shown. Torque settings will be given at the relevant point in the procedure.

Unfiled Notes Page 2

SECTION 100-00: General Information 2003 Focus Workshop Manual

DESCRIPTION AND OPERATION

Health and Safety Precautions

Introduction

Many of the procedures associated with vehicle maintenance and repair involve physical hazards or

other risks to health. This subsection lists, alphabetically, some of these hazardous operations and

the materials and equipment associated with them. Precautions necessary to avoid these hazards are

identified.

The list is not exhaustive and all operations and procedures, and the handling of materials, should be

carried out with health and safety in mind.

Before using any product the Materials Safety Data Sheet supplied by the manufacturer or supplier

should be consulted.

Acids and Alkalis

See also Battery Acids.

For example caustic soda, sulphuric acid.

Used in batteries and cleaning materials.

Irritant and corrosive to the skin, eyes, nose and throat. Cause burns. Can destroy ordinary protective

clothing.

Avoid splashes to the skin, eyes and clothing. Wear suitable protective impervious apron, gloves and

goggles. Do not breath mists.

Make sure access to eye wash bottles, shower and soap are readily available for splashing accidents.

Display Eye Hazard sign.

Air Bags

See also Fire, Chemical Materials

Highly flammable, explosive – observe No Smoking policy.

Used as a safety restraint system mounted in the steering wheel and passenger side of the

instrument panel.

The inflator contains a high-energetic propellant which, when ignited, produces a VERY HOT GAS

(2500°C).

The gas generant used in air bags is Sodium Azide. This material is hermetically sealed in the module

and is completely consumed during deployment. No attempt should be made to open an air bag

inflator as this will lead to the risk of exposure to Sodium Azide. If a gas generator is ruptured, full

protective clothing should be worn when dealing with the spillage.

After normal deployment, gloves and safety goggles should be worn during the handling process.

Deployed air bags should be disposed of in a plastic bag in accordance with local regulations at an

approved chemical waste site.

• wash affected areas thoroughly with water.

• seek medical assistance if necessary.

Following any direct contact with gas generant.

• do store modules in an upright position.

• do keep modules dry.

• do carry modules with the cover side pointing away from the body.

• do place modules with their cover side upwards.

• do carefully inspect modules for damage.

• do stand to one side when connecting modules.

• do make sure all test equipment is properly calibrated and maintained.

• do wash hands after handling deployed air bags.

Air Bags - Do's

• do not store highly flammable material together with modules or gas generators.

• do not store gas generators at temperatures exceeding 80°C.

• do not store modules upside down.

• do not attempt to open a gas generator housing.

• do not expose gas generators to open flame or sources of heat.

• do not place anything on top of a module cover.

Air Bags - Do Nots

Unfiled Notes Page 1

• do not place anything on top of a module cover.

• do not use damaged modules.

• do not touch a fired module or gas generator for at least 10 minutes.

• do not use any electrical probes on the wiring circuit.

Air Conditioning Refrigerant

See also Chlorofluorocarbon, Chemical Materials

Highly flammable, combustible – observe No Smoking policy.

Skin contact may result in frostbite.

Instructions given by the manufacturer must be followed. Avoid naked lights, wear suitable protective

gloves and goggles.

If refrigerant comes into contact with the skin or eyes, rinse the affected areas with water immediately.

Eyes should also be rinsed with an appropriate irrigation solution and should not be rubbed. SEEK

MEDICAL ASSISTANCE IF NECESSARY.

• do not expose refrigerant bottles to sunlight or heat.

• do not stand refrigerant bottles upright; when filling, hold them with the valve downwards.

• do not expose refrigerant bottles to frost.

• do not drop refrigerant bottles.

• do not vent refrigerant to atmosphere under any circumstance.

• do not mix refrigerants, for example R12 (Freon) and R134a.

Air Conditioning Refrigerant - Do Nots

Adhesives and Sealers

See also Fire, Chemical Materials

Highly flammable, flammable, combustible – observe No Smoking policy.

Generally should be stored in No Smoking areas. Cleanliness and tidiness in use should be observed,

for example disposable paper covering benches; should be dispensed from applicators where

possible; containers, including secondary containers, should be labelled appropriately.

Solvent-based Adhesives/Sealers - See Solvents

Follow manufacturers instructions.

Water-based Adhesives/Sealers

Those based on polymer emulsions and rubber latexes may contain small amounts of volatile toxic

and harmful chemicals. Skin and eye contact should be avoided and adequate ventilation provided

during use.

Hot Melt Adhesives

In the solid state, they are safe. In the molten state they may cause burns and health hazards may

arise from the inhalation of toxic fumes.

Use appropriate protective clothing and a thermostatically controlled heater with a thermal cut-out and

adequate extraction.

Resin-based Adhesives/Sealers, for example Epoxide and Formaldehyde Resin-based

Mixing should be carried out in well ventilated areas, as harmful or toxic volatile chemicals may be

released.

Skin contact with uncured resins and hardeners can result in irritation, dermatitis, and absorption of

toxic or harmful chemicals through the skin. Splashes can damage the eyes.

Provide adequate ventilation and avoid skin and eye contact.

Anaerobic, Cyanoacrylate (super-glues) and other Acrylic Adhesives

Many are irritant, sensitizing or harmful to the skin and respiratory tract. Some are eye irritants.

Skin and eye contact should be avoided and the manufacturers instructions followed.

Cyanoacrylate adhesives (super-glues) MUST NOT contact the skin or eyes. If skin or eye tissue is

bonded, cover with a clean moist pad and SEEK IMMEDIATE MEDICAL ATTENTION. Do not attempt

to pull tissue apart. Use in well ventilated areas as vapours can cause irritation to the nose and eyes.

For two-pack systems see Resin-based and Isocyanate Adhesives/Sealers.

Isocyanate (Polyurethane) Adhesives/Sealers

See also Resin-based Adhesives

Individuals suffering from asthma or respiratory allergies should not work with or near these materials

as sensitivity reactions can occur.

Over exposure is irritating to the eyes and respiratory system. Excessive concentrations may produce

effects on the nervous system including drowsiness. In extreme cases, loss of consciousness may

result. Long term exposure to vapour concentrations may result in adverse health effects.

Prolonged contact with the skin may have a defatting effect which may lead to skin irritation and in

some cases, dermatitis.

Splashes entering the eye will cause discomfort and possible damage.

Any spraying should preferably be carried out in exhaust ventilated booths, removing vapours and

spray droplets from the breathing zone.

Wear appropriate gloves, eye and respiratory protection.

Antifreeze

See also Fire, Solvents.

Unfiled Notes Page 2

You're Reading a Preview

What's Included?

Fast Download Speeds

Online & Offline Access

Access PDF Contents & Bookmarks

Full Search Facility

Print one or all pages of your manual

$36.99

Viewed 94 Times Today

Loading...

Secure transaction

What's Included?

Fast Download Speeds

Online & Offline Access

Access PDF Contents & Bookmarks

Full Search Facility

Print one or all pages of your manual

$36.99

This is a comprehensive 2003 Ford Focus Service & Repair Manual, providing detailed information for servicing and repairing the vehicle. It includes step-by-step instructions, diagrams, illustrations, and specifications covering the engine, transmission, electrical system, suspension, brakes, and more. Whether you're a professional mechanic or a DIY enthusiast, this manual is essential for proper maintenance and repair of the 2003 Ford Focus. It is designed to be user-friendly, offering clear explanations and helpful tips.

Included Models:

- 2003 Ford Focus LX

- 2003 Ford Focus SE

- 2003 Ford Focus ZTS

- 2003 Ford Focus ZTW

- 2003 Ford Focus SVT

This manual equips you to confidently tackle any maintenance or repair task, ensuring the longevity and performance of your vehicle.