1997 Ford F-150 OEM Service & Repair Manual

What's Included?

Fast Download Speeds

Online & Offline Access

Access PDF Contents & Bookmarks

Full Search Facility

Print one or all pages of your manual

PALMTREESALES1967 - NO RESALE

0-3

Gontents

Introductory pages

About thismanual 0-2

Introduction to the Ford Pick-ups, Expedition and

Lincoln Navigator 04

Vehicle identification numbers 0-5

Buying parts 0€

Maintenance techniques, tools andworking facilities 0-6

Jacking and towing 0-'12

Booster battery

fiump)

starting 0-12

Automotive chemicals andlubricants 0-13

Conversion factors 0-14

Safetyfirst! 0-15

'Troubleshooting

0-16

Ghapter 1

Tune-up and routine maintenance 1-1

Ghapter 2 ParlA

VO engine 2A-1

Ghapter 2 PartB

V8 engines

Chapter 2 PartC

General engine overhaul procedures

Chapter 3

Gooling, heating and air conditioning systems

Chapter 4

Fuel and exhaust svstems

Chapter 5

Engine electrical systems

Ghapter 6

Emissions and engine control systems

Chapter 7 PartA

Manual transmission 7A-l

Chapter 7 PartB

Automatic transmission

3.1

5-l

Chapter 7 PartC

Transfer case 7C-',l

Chapter 8

Clutch and driveline

Chapter 9

Brakes 9-l

Chapter 10

Suspension and steering systems 10-l

Ghapter 11

Body

Ghapter 12

Chassis electricalsystem 12-1

Wiringdiagrams

lndex

12-17

PALMTREESALES1967 - NO RESALE

0-5

Vehicle identification numbers

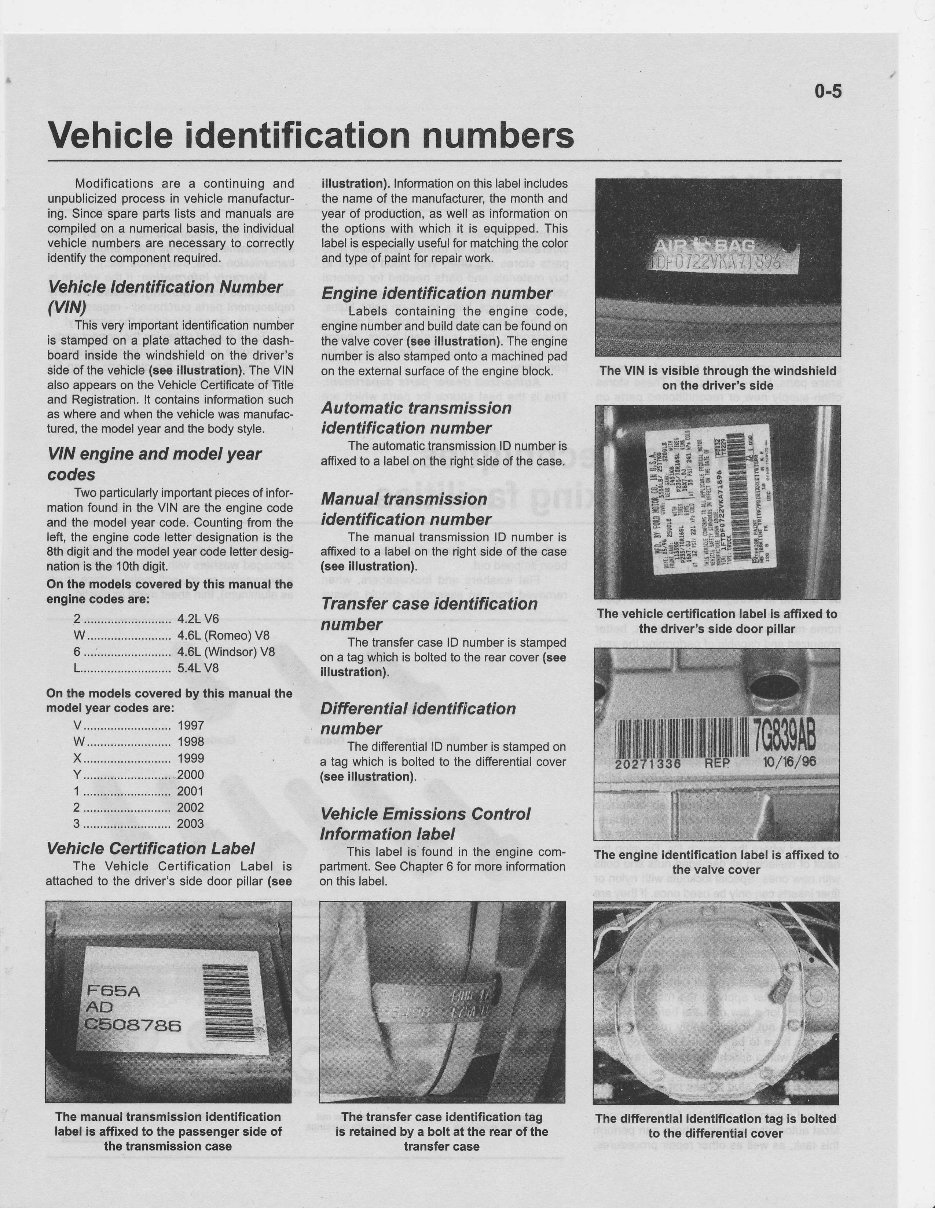

Modifications are a continuing and

unpublicized process in vehicle manufactur-

ing.Since spare parts lists and manuals are

compiled on a numerical basis, the individual

vehicle numbers are necessary to correctly

identify thecomponent required.

Veh icle I dentifi catio n N umbe r

(vtN)

This very importantidentification number

is stamped on a plate attachedto the dash-

board inside the windshield on the driver's

side of the vehicle (see illustration).The VIN

also appears on the Vehicle Certificate of Title

and Registration. lt contains informationsuch

as where and when the vehicle was manufac-

tured, the model year and the body style.

VIN engine and model year

codes

Two particularly important pieces of infor-

mation found in the VINare the engine code

andthe model year code. Counting fromthe

left, the engine code letter designation is the

8thdigit andthe model year code letter desig-

nation is the 1Oth digit.

On the modelscovered by thls manual the

engine codes are:

2 .......................... 4.21 V6

W ......................... 4.61 (Romeo) V8

6 ...i ...................... 4.61 (Windsor) V8

1 ........................... 5.41 V8

On the models covered by this manual the

model yearcodes are:

v .......................... 1997

w ......................... 1998

x.., ....................... 1999

y ..........................

.2000

1 .......................... 2001

2 ..................... ..... 2002

3 .......................... 2003

Veh i cle Certifi cati on Labe I

The Vehicle Certification Label is

attachedto the driver's side door pillar (see

The manual transmission identification

label is affixed to the passenger side of

the transmission case

i!lustration). Information onthis label includes

the name of the manufacturer, the month and

year of production, as wellas information on

the options with whichit is equipped. This

label is especially useful for matching thecolor

andtype of paint for repair work.

Engine identification number

Labelscontaining the enginecode,

engine number and build date can befound on

thevalve cover (see illustration). The engine

number is also stamped onto a machined pad

on theexternal surface of theengine block.

Automatic trans m ission

identificationnumber

The automatic transmission lD number is

affixed to a label on the right side of the case.

Manualtransmission

identificationnumber

Themanual transmission lD number is

affixed to a label on the right sideof the case

(see illustratlon).

Transfer c ase ide ntific atio n

number

The transfer case lD number is stamoed

on a tagwhich is bolted to the rear cover (see

illustration).

D ifferenti al i dentifi cati on

number

The differential lD number is stamped on

a tag which is bolted to the differential cover

(see illustration).

Ve hi cle Emrbsions Co ntro I

lnformation label

Thislabel is'found in the engine com-

partment. SeeChapter 6 for more information

onthislabel.

The transfer case identification tag

is retained by a bolt at the rear of the

transfer case

The VIN is visible through the windshield

on the driver's side

Thevehiclecertification label is affixedto

the driver'g sidedoor pillar

The differential identification tag is bolted

to the differential cover

The engine identification label ls affixed to

the valve cover

PALMTREESALES1967 - NO RESALE

0-6

Buying

parts

Replacement partsare available from

many sources, which generally fall intoone

of two calegories

-

authorized dealer parts

departments andindependent retail auto parts

stores. Our advice conceming thesepartsis

as follows:

Retail auto parts sto/es.' Good auto

parts stores willstock frequently needed com-

ponents which wearout relatively fast,such

as clutchcomponents, exhaust systems,

brake parts, tune-up parts, etc.These stores

oftensupply new or reconditioned partson

an exchange basis, whichcan savea con-

siderable amount of money. Discount auto

parts stores are often very good- placesto

buy materials and parts needed for general

vehicle maintenance suchas oil, grease, fil-

ters, spark plugs, belts, touch-up paint, bulbs,

etc.They alsousually selltools andgeneral

accessories, haveconvenient hours, charge

lower prices and can oftenbe found not far

fromhome.

Authorized dealer parts department:

This is the bestsource for

parts

whichare

unique to the vehicle andnotgenerally avail-

ableelsewhere (such as major engine parts,

transmission parts, trim pieces, etc.).

Warranty informatlon: lf the vehicle is

stillcovered under wananty, be surethatany

replacement partspurchased

-

regardless of

the source

-

do not invalidate thewananty!

Tobe sure of obtaining the correct parts,

have engine and chassis numbers available

and,if possible, takethe old parts along for

positive identification.

Maintenance techniques,

tools andworking facilities

Maintenancetech niques

Thare are a numberof techniques

involved in maintenance and repair thatwill

be referred to throughout this manual, Appli-

cation of these techniques will enable the

home mechanic to be moreefficient, better

organized andcapable of performing the vari-

ous tasksproperly, which will ensure thatthe

repair

job

is thorough andcomplete.

Fasteners

Fasteners are nuts,bolts, studsand

screws used to hold two or more parts

together. There are a few things to keepin

mind when working withfasteners. Almost all

of themuse a locking device of some type,

eithera lockwasher, locknut, locking tab

or thread adhesive. All threaded fasteners

should be cleanand straight, with undam-

aged threads and undamaged corners on the

hex head where the wrench fits. Develop the

habit of replacing all damaged nutsand bolts

withnewones. Special locknuts with nylon or

fiber inserts canonly be used once. lf they are

removed, they losetheirlocking ability and

must be replaced withnew ones.

Rusted nutsand bolts should be treated

with a penetrating fluid to ease removal and

prevent breakage. Somemechanics usetur-

pentine in a spout-type oil can, which works

quite well. Afterapplying the rustpenetrant,

let it work for a few minutes before tryingto

loosen the nut or bolt.Badly rusted fasten-

ers may haveto be chiseled or sawed off or

removed witha soecial nut breaker, available

at toolstores.

lf a boltor stud breaks off in an assem-

bly,it can be drilled and removed witha spe-

cialtool commonly available for this purpose.

Most automotive machine shops can perform

this task,as well as otherrepair procedures,

such as the repair of threaded holes that have

been stripped out.

Flat washers and lockwashers, when

removed from an assembly,should always

be replaced exactly as removed. Replace any

damaged washers withnew ones. Never use

a lockwasher on anysoftmetal surface (such

as aluminum), thin sheet metal or plastic.

Grado

l!.8 lilut

Cr&S

H6rftA

Grd6A

Standard hexnul

sirBngilh marldngs

@@@

Class Clas

10.9 S.8

Metie €ud sq€ngth marklngs

lslmffil

## d

GradF I Grade 1 or 2 Grada 5

Bolt stnng0r rlar*lng (sl8ndardFAf,/Us8; bottom

-

moltlc)

ld6ntifica$orl

#$,,

&ilSf

Arabic 0

,{F,.

I'.I *.I

i{tC,t

Araua 10

iler l*rt

Pmprty

Clffi9

llcr lklt

Pfoprrtt

ClmlO

ldentiflooton

^re.

T3I FI

w

g

Dole

1fi&

*Flt

aL.r4t

E,-l'

6 Dot!

Itetrio hqx nut

BtrEnlth matldnge

Class

8.8

PALMTREESALES1967 - NO RESALE

Maintenance techniques, tools and working facilities 0-7

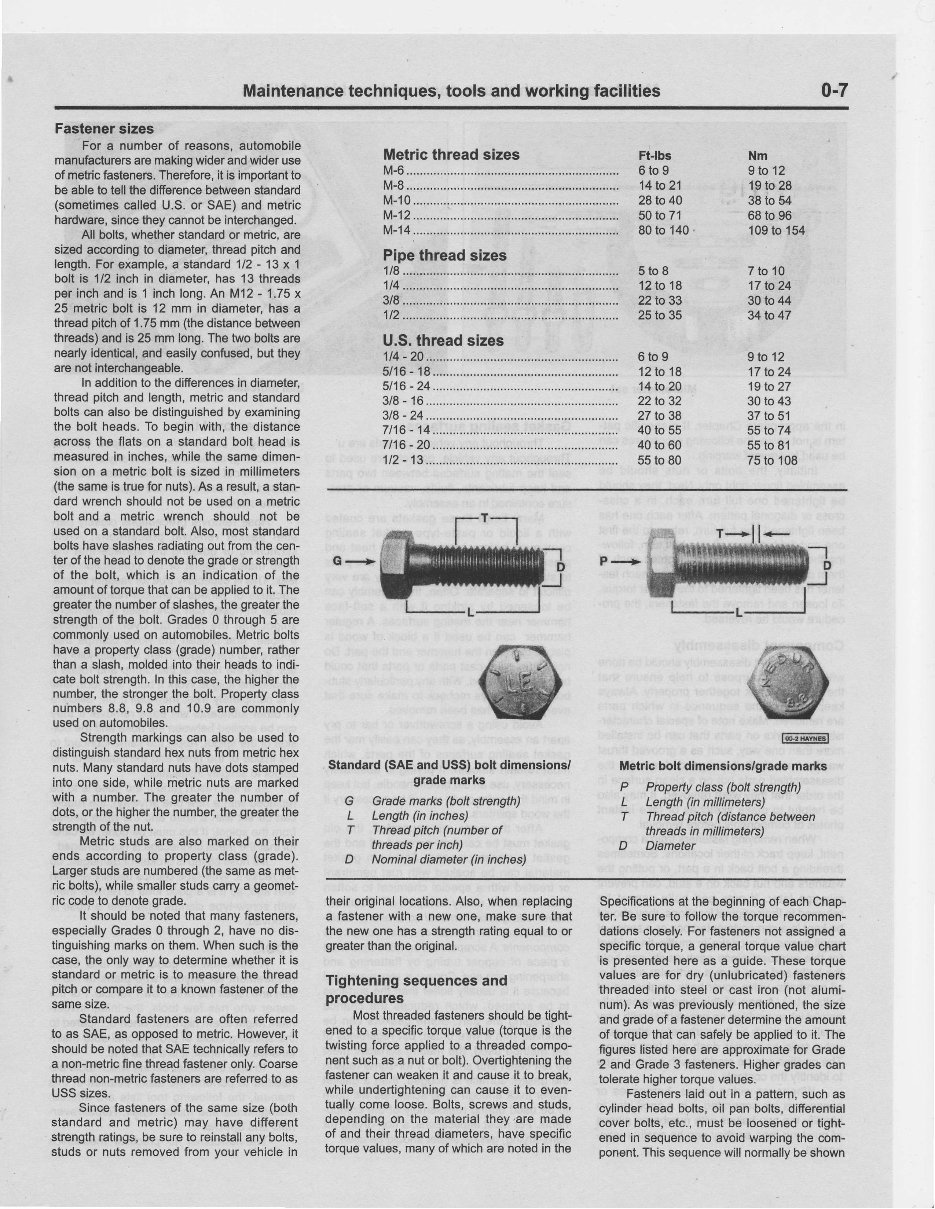

Fastener sizes

For a number of reasons, automobile

manufacturers aremaking wider and wider use

of metric fasteners. Therefore, it is imporiant to

be able to tellthedifierence between standard

(sometimes called U.S.or SAE)and metric

hardware, since they cannot be interchanged.

All bolts, whether standard or metric, are

sized according to diameter, thread pitci and

fength. Forexample, a standard 112

-

13 x 1

bolt is 1/2 inch in diametet has 13 threads

per inch and is 1 inchlong. An M12

-

1.75 x

25 metric bolt is 12 mm in diameter, has a

thread pitch of 1,75 mm(the distance between

threads) andis 25 mmlong. Thetwo bolts are

nearly identical, andeasily confused, butthey

arenotinterchangeable.

ln addition to the differences in diameter.

thread pitchand length, metric and standard

bolts canalso be distinguished by examining

the bolt heads. To begin with,the distance

across the flats on a standard bolt headis

measured in inches, while the same dimen-

sionon a metric bolt is sizedin millimeters

(the same is true for nuts). As a result, a stan-

dardwrench should not be usedon a metric

boltand a metric wrench should not be

used on a standard bolt. Also.most standard

bolts have slashes radiating outfrom the cen-

ter of the head to denote thegrade or strength

of the bolt, which is an indication of the

amount of torque thatcanbe applied to it.The

greater the number of slashes, thegreater the

strength of the bolt.Grades 0 through 5 are

commonly usedon automobiles. Metric bolts

havea property class(grade) number, rather

than a slash, molded into their heads to indi-

cateboltstrength. In this case, the higher the

number, the stronger the bolt.Property class

nuinbers 8.8, 9.8 and 10.9are commonly

used on automobiles.

Strength markings can alsobe used to

distinguish standard hexnuts frommetric hex

nuts. Many standard nutshave dotsstamped

intoone side, whilemetric nutsare marked

with a number. The greater the number of

dots, or the higher the number, thegreater the

strength of the nut.

Metric studsare also marked on their

ends according to property class (grade).

Larger studs arenumbered (the same as met-

ric bolts), while smaller studs carry a geomet-

ric codg to denote grade.

It should be noted that many fasteners,

especially Grades 0 through 2, have no dis-

tinguishing marks on them. When suchis the

case, the onlyway to determine whether it is

standard or metricis to measure the thread

pitch or @mpare it to a known fastener of the

same size.

Standard fasteners are often referred

to as SAE, as opposed to metric. However, it

should be noted thatSAE technically refers to

a non-metric finethread fastener only. Coarse

thread non-metric fasteners are refened to as

USS sizes.

Since fasteners of the same size(both

standard and metric)may have different

strength ratings, be sure to reinstall anybolts,

studs or nutsremoved from yourvehicle in

U.S. threadsizes

1t4

-

20

FtJbs

6tog

14to21

28to 40

50 to 71

80to 140.

5to8

12to18

221o33

25 to 35

6to9

12to18

14to20

22to 32

27 to38

40 to 55

40 to 60

55 to 80

Nm

9to12

19to 28

38 to 54

68 to 96

109 to 154

7to10

'17

to24

30 to 44

34to 47

9to12

17to24

19 to 27

30 to 43

37to 51

55 to 74

55to 81

75to 108

Q->

Standard (SAE and USS) bolt dimensions/

grademarks

G Grade marks(boft strength)

L Length (in inches)

T Thread pitch (number of

threads perinch)

D Nominal diameter (in inches)

P..-..>

fmffil

Metricbolt dimensions/grade marks

P Property class (bolt strength)

L Lenglh (in millimeters)

T Thread pitch (distance between

threads in millimeters)

D Diameter

their original locations. Also, when replacing

a fastener with a new one, makesurethat

the newone hasa strength rating equal to or

greater than the original.

Tightening sequences and

procedures

Most threaded fasteners should be tight-

ened to a specific torque value (torque is the

twisting force applied to a threaded compo-

nent such as a nut or bolt). Overtightening the

fastener can weaken it and cause it to break,

while undertightening can cause it to even-

tually come loose. Bolts, screws and studs,

dependingon the materialthey.are made

of and their thread diameters,have specific

torque values, many of which are noted in the

Specifications at the beginning of each Chap-

ter. Be sure to followthe torquerecommen-

dations closely. Forfasteners not assigned a

specific torque, a general torque valuechart

is presented hereas a guide. These torque

values are for dry (unlubricated) fasteners

threaded into steelor cast iron (not alumi-

num). As was previously mentioned, the size

andgrade of a fastener determine the amount

of torque that cansafely be applied to it. The

figures listed here are approximate for Grade

2 and Grade 3 fasteners. Higher grades can

tolerate higher torque values.

Fasteners laid out in a pattem, suchas

cylinder headbolts, oil pan bolts, difierential

cover bolts, etc.,must be loosened or tight-

enedin sequence to avoid warping the com-

ponent. This sequence will normally beshown

tL

PALMTREESALES1967 - NO RESALE

0-8 Maintenance techniques, tools and working facilities

Micrometer set Dial indicator set

in the appropriate Chapter.lf a specific pat-

tern is not given, the following procedures can

be used to prevent warping.

Initially, the bolts or nuts should be

assembled finger{ightonly.Next,they should

be tightened one full turn each, in a criss-

cross or diagonal pattern. After each one has

been tightened one full turn, returnto the first

one and tighten them all one-half turn, follow-

ing the same pattern. Finally, tighteneach of

them one-ouarter turn at a time untileach fas-

tener has beentightened to the proper torque.

To loosenand removethe fasteners, the pro-

cedure would be reversed.

Component disassembly

Component disassembly should be done

with care and purposeto help ensure that

the parts go back together properly. Always

keep track of the sequencein which parts

are removed. Make note of special character-

isticsor marks on parts that can be installed

more than one way, such as a grooved thrust

washeron a shaft. lt is a good idea to lay the

disassembled parts out on a clean surfacein

the orderthat they were removed. lt may also

be helpful to make sketches or take instant

photos of components before removal.

When removing fasteners from a compo-

nent,keep trackof their locations. Sometimes

threading a bolt back in a part, or putting the

washersand nut back on a stud, can prevent

mix-uos later. lf nuts and bolts cannot be

returned to theiroriginal locations, they should

be kept in a compartmented box or a series of

small boxes.A cupcakeor muffintin is ideal

for this purpose,since each cavity can hold

the bolts and nuts from a particular area (i.e.

oil pan bolts,valve cover bolts,enginemount

bolts,etc.).A pan of this type is especially

helpful when working on assemblies with very

small

parts,

such as the carburetor, alternator,

valve train or interior dash and trim pieces.

The cavities can be marked with paintor tape

to identify the contents.

Wheneverwiring looms, harnesses or

connectors are separated, it is a good idea to

identify the two halveswith numbered pieces

of masking tape so they can be easily recon-

nected.

Gasket sealing surfaces

Throughout any vehicle, gaskets are u

Throughout any vehicle,gasketsare used to

seal the mating surfaces betweentwo parts

and keep lubricants, fluids, vacuumor pres-

sure contained in an assembly.

Many times these gasketsare coated

with a liquid or paste-type gasket sealing

compound before assembly. Age, heat and

pressure can sometimes cause the two parts

to stick togetherso tightlythat they are very

difficult to separate. Often,the assembly can

be loosened by striking it with a soft-face

hammer near the mating surfaces. A regular

hammer can be used if a block of wood is

olacedbetween the hammerand the

part.

Do

not hammeron cast oarts or oarts that could

be easily damaged. With any particularly stub-

born part, always recheckto make sure that

everyfastener has been removed.

Avoid using a screwdriver or bar to pry

apartan assembly, as they can easilymar the

gasket sealing surfaces of the parts,which

must remainsmooth.lf pryingis absolutely

necessary, use an old broomhandle, but keep

in mindthat extracleanup will be necessary if

the wood solinters.

After the oarts are seoarated. the old

gasket must be carefully scrapedoff and the

gasket surfacescleaned.Stubborngasket

material can be soaked with rust penetrant

or treated with a soecial chemical to soften

it so it can be easily scrapedoff. Gaution:

Never use gasket removal solutionsor caus-

tic chemicals on plastic or other composite

components. Ascraper can be fashioned from

a piece of copper tubing by flattening and

sharpening one end. Copperis recommended

becauseit is usually softer than the surfaces

to be scraped,which reduces the chance

of gougingthe part. Some gasketscan be

removed with a wire brush,but regardless of

the methodused, the matingsurfaces must

be left clean and smooth. lf for some reason

the gasket surface is gouged, then a gasket

sealerthick enoughto fill scratches will have

to be used during reassembly of the compo-

nents.For most applications, a non-drying (or

semi-drying) gasketsealer shouldbe used.

Hoseremoval tips

Warning: lf the vehicle is equipped with air

conditioning, do not disconnectany of the NC

hoses without first having lhe syslem depres-

surized by a dealer service department or a

service station.

Hose removal precautions closelypar-

allel gasket removal precautions. Avoid

scratching or gougingthe surfacethat the

hose mates againstor the connection may

leak. This is especially true for radiator hoses.

Because of variouschemical reactions, the

rubber in hoses can bond itself to the metal

spigot that the hose fits over. To remove

a hose, first loosen the hose clamps that

secureit to the spigot. Then,with slip-joint pli-

ers, grab the hose at the clamp and rotate it

around the spigoi.Work it back and forth until

it is completely free, then pull it off. Silicone

or other lubricants will ease removal if they

can be applied between the hose and the out-

side of the spigot. Apply the same lubricant to

the insideof the hose and the outsideof the

spigot to simplify installation.

As a last resort(and if the hose is to be

replaced with a new one anyway), the rubber

can be slit with a knife and the hose peeled

from the spigot.lf this must be done, be care-

ful that the metalconnection is not damaged.

lf a hose clamp is broken or damaged, do

not reuseit. Wiretype clampsusually weaken

with age, so it is a good idea to replace them

with screw{ype clamps whenever a hose is

removed.

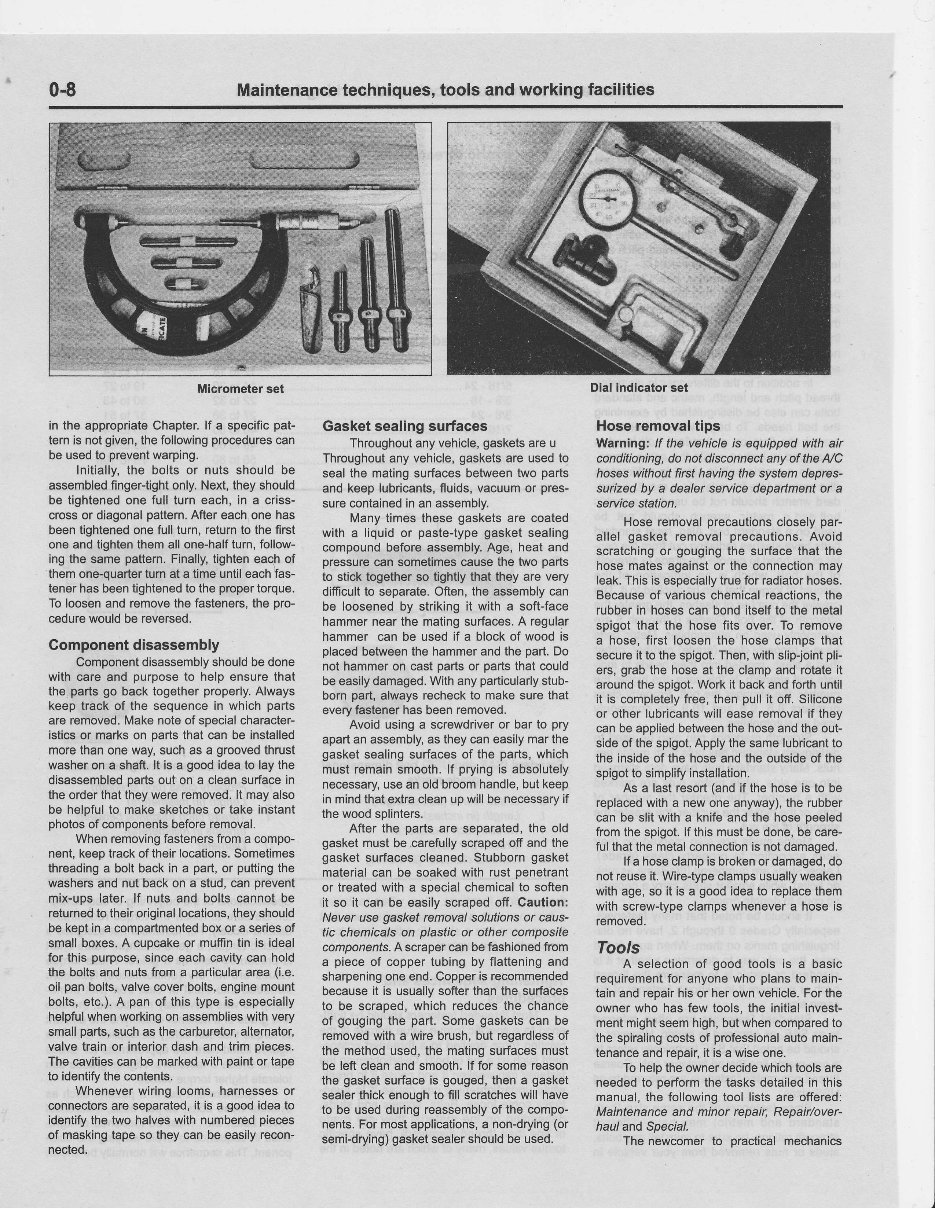

Iools

A selection of good tools is a basic

requirement for anyonewho plansto main-

tain and reoairhis or her own vehicle. For the

owner who has few tools,the initialinvest-

ment mightseem high,but when compared to

the spiraling costs of professional auto main-

tenance and repair, it is a wise one.

To helo the ownerdecide whichtools are

needed to perform the tasks detailed in this

manual, the following tool lists are offered:

Maintenance and minor repair, Repair/over-

haul and Special.

The newcomer to practical mechanics

PALMTREESALES1967 - NO RESALE

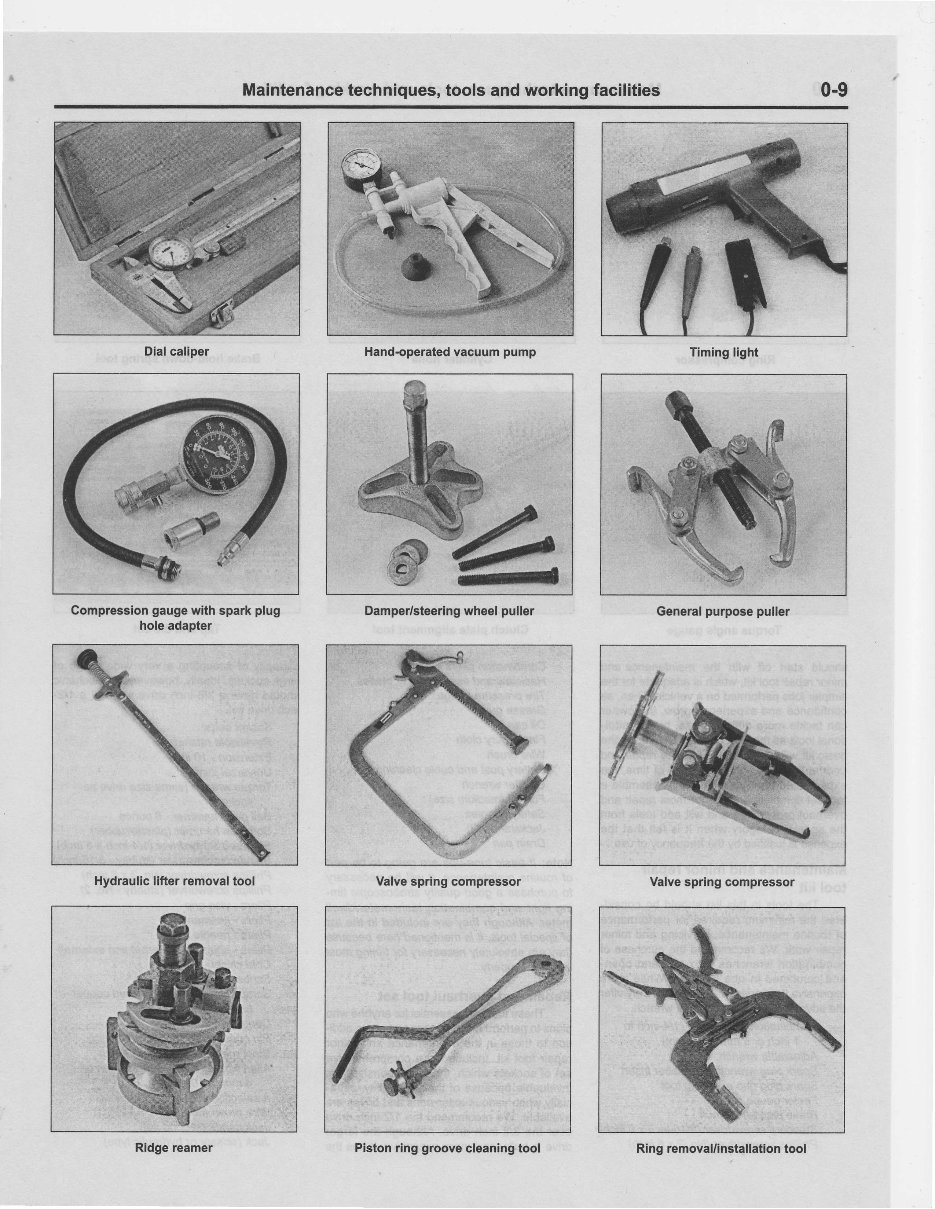

Maintenance techniques, tools and working facilities 0-9

ru

Damper/steering wheel puller

Timing light

General purpose puller

Valve springcompressor

Ring removal/installation tool

Compression gauge with sparkplug

holeadapter

Hydraulic lifter removal tool

Ridge reamer

Valve springcompressor

Piston ring groove cleaning tool

Dial caliper Hand-operated vacuum pump

PALMTREESALES1967 - NO RESALE

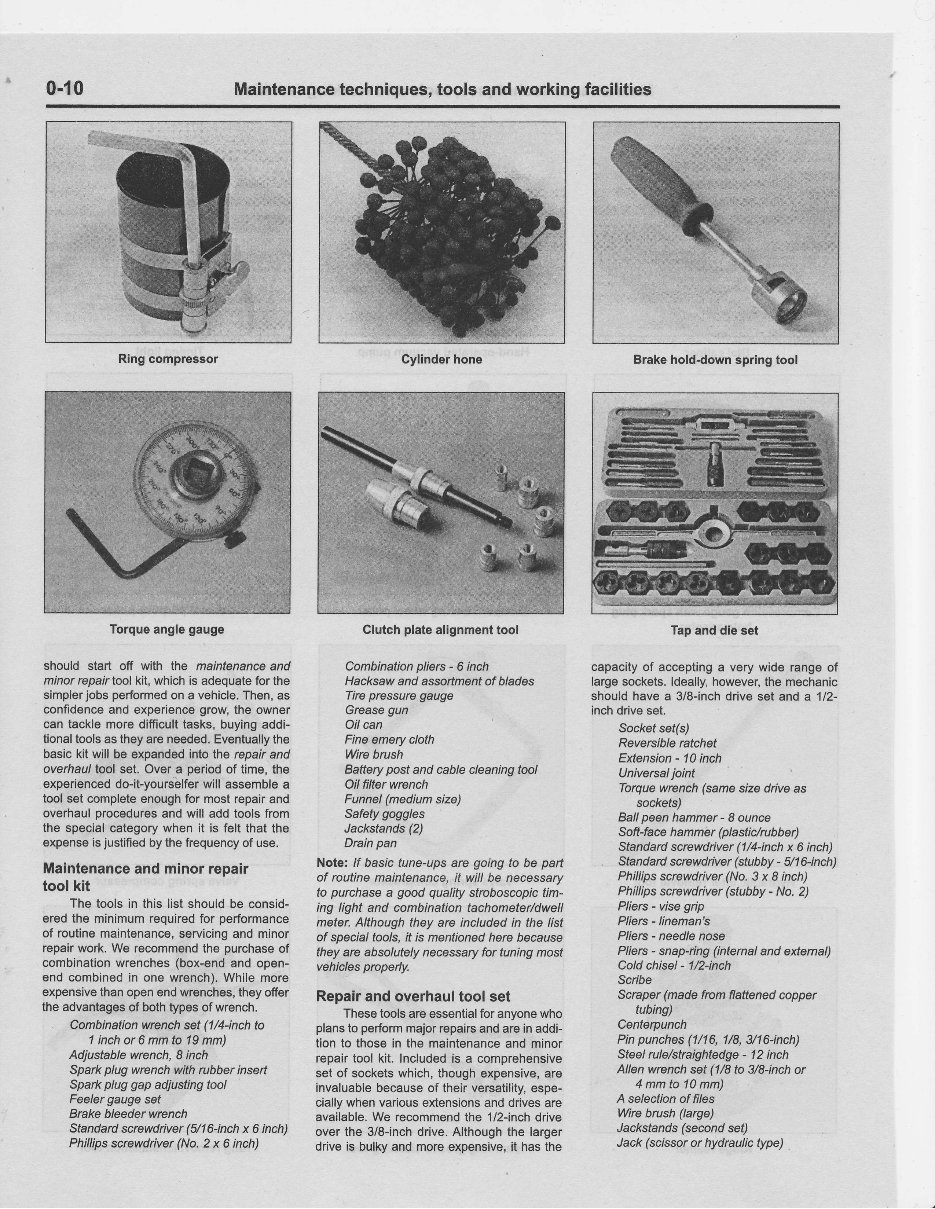

0-10 Maintenance techniques, tools and working facilities

Ring compressor

shoufd start off with the maintenance and

minorrepairtool kit,which is adequate for the

simpler jobsperformed on a vehicle, Then, as

confidence and experience grow the owner

can tackle more difficult tasks, buying addi-

tional tools as they areneeded, Eventually the

basickit will be expanded intothe repair and

overhaul tool set. Overa period of time,the

experienced do-it-yourselfer will assemble a

tool set complete enough for mostrepair and

overhaul procedures and will add toolsfrom

the special category whenit is felt that the

expense is justified

by thefrequency of use.

Maintenance and minor repair

toolkit

The toolsin this list should be consid-

eredthe minimum required for performance

of routine maintenance, servicing and minor

repair work. We recommend the purchase of

combination wrenches (box-end and open-

end combined in one wrench). Whilemore

expensive than open endwrenches, they ofier

the advantages of both types of wrench.

Combination wrench set(l/4-inch to

1 inch or 6 mm to 19mm)

Adjustable wrench, 8 inch

Spark plug wrench withrubber inseft

Spark plug gap adjusting tool

Feeler gauge set

Brake bleeder wrench

Standard screwdriver (5/16-inch x 6 inch)

Phillips screwdiver (No. 2 x 6 inch)

Clutch plate alignment tool

Combination pliers

-

6 inch

Hacksaw and assortment of blades

Tire pressure gauge

Grease gun

Oil can

Fineemery cloth

Wre brush

Batterypost and cablecleaning tool

Oil filterwrench

Funnel (medium size)

Safety goggles

Jackstands (2)

Drain pan

Note: /f basic tune-ups are goingto be part

of routine maintenance, it will be necessary

to purchase a good quality stroboscopic tim-

ing light and combination tachometer/dwell

meter.Although they are includedin the list

of special tools, it is mentioned here because

theyare absolutely necessary for tuning most

vehicles prcperly.

Repair and overhaul tool set

These tools areessential for anyone who

plans to perform major repairs andarein addi-

tion to those in the maintenance and minor

repair tool kit. Included is a comprehensive

set of sockets which, though expensive, are

invaluable because of their versatility, espe-

cially when various extensions anddrives are

available. We recommend the 1/2-inch drive

overthe 3/8-inch drive. Although the larger

driveis bulky and moreexpensive, it hasthe

Brake holddownspring tool

capacity of accepting a very wide range of

large sockets. ldeally, however, the mechanic

should havea 3/8-inch drive set anda 112-

inch drive set.

Sockel sef(s)

Reversible ratchet

Extension

-

10inch

lJniversal joint

Torque wrench (samesize driveas

sockets)

Ball peen hammer

-

I ounce

Soft-face h a m m e r (pl a stic/ru bber)

Standard screwdiver(1/4-inch x 6 inch)

Standard screwdiver (stubby

-

5/16-inch)

Phillips screwdriver (No. 3 x I inch)

Phillips screwdriver (stubby

-

No. 2)

Pliers

-

vise grip

Pliers

-

lineman's

Pliers

-

needle nose

Pliers

-

snap-ring (intemal and extemal)

Cold chisel

-

1/2-inch

Scnbe

Scraper (made fromflattened copper

tubing)

Centerpunch

Pinpunches (1n6, U8, 3h6-inch)

Steel rule/straightedge

-

12inch

Allen wrench set(1/8to 3/8-inch or

4 mmto 10mm)

A selection of files

Wre brush(large)

J acksta n d s (se con d set)

Jack (scissor or hydraulic type)

Cylinder hone

Torque angle gauge

Tap anddle set

PALMTREESALES1967 - NO RESALE

Maintenance techniques, tools and working facilities 0-11

Note: Anofher tool which is often useful is an

electric dill with a chuck capactty of 3/&inch

and a set of good quality dill bits.

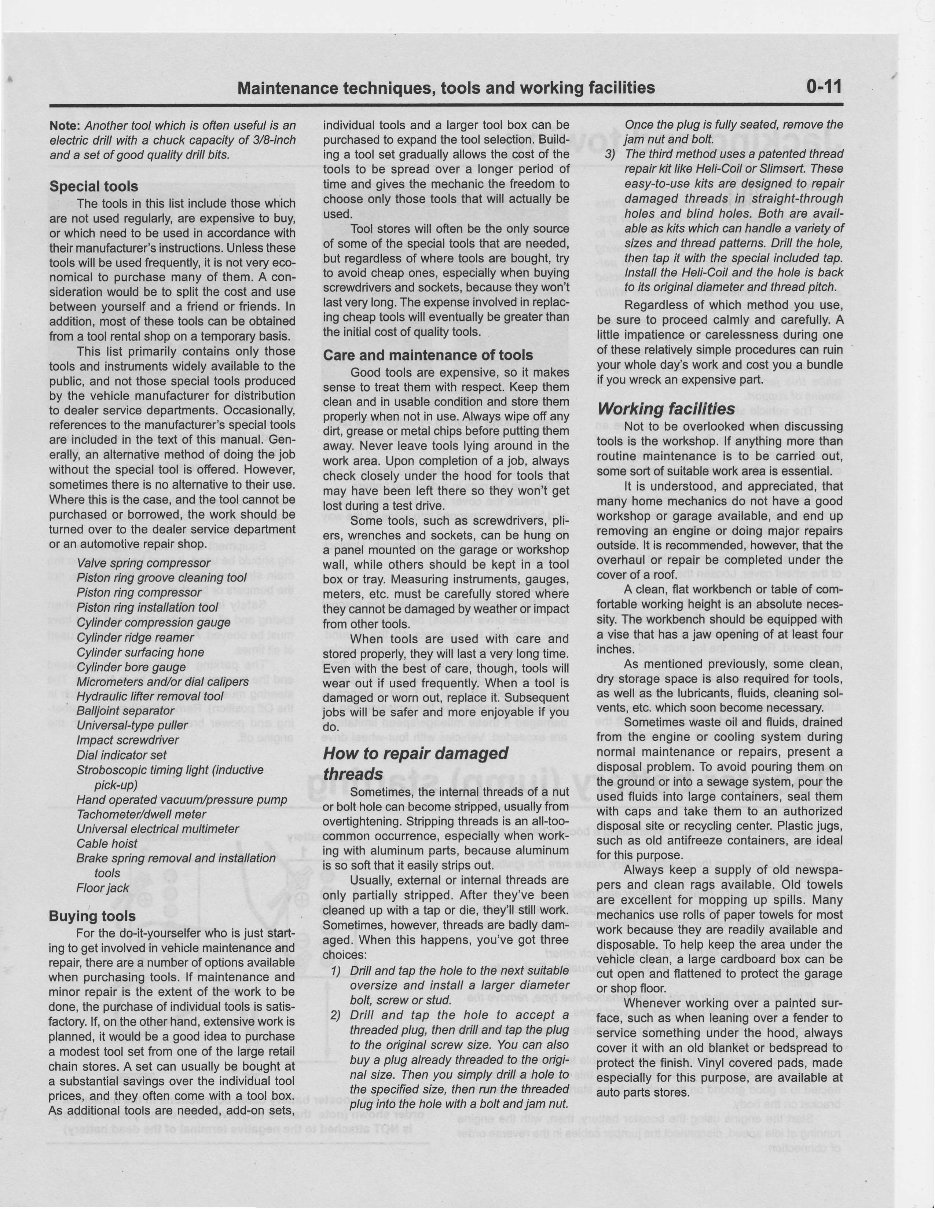

Specialtools

The tools in this list include those which

arenotused regularly, are expensive to buy,

or which need to be usedin accordance with

their manufacturer's instructions. Unless these

tools willbe used frequently, it is notvery eco-

nomical to purchase manyof them. A con-

sideration would be to split the cost and use

between yourself and a friendor friends. In

addition, most of these toolscan be obtained

froma toolrental shop on a temporary basis.

This list primarily contains only those

tools and instruments widely available to the

public, and notthose special tools produced

by the vehicle manufacturer for distribution

to dealer service departments. Occasionally,

references to the manufacturer's special tools

are included in the textof this manual. Gen-

erally, an altemative method of doing the job

without the special tool is offered. However,

sometimes there is no altemative to their use.

Where thisis the case, andthetoolcannot be

purchased

or borrowed, the workshould be

turned over to the dealer service department

or an automotive repair shop.

Valve spring compressor

Piston ing groove cleaning tool

Piston ing compressor

Piston ing installation tool

Cyl in d e r com pression gauge

Cylinder idge reamer

Cylinder surtacing hone

Cylinder boregauge

Micrometers and/or dial calipers

Hydraulic lifterremoval tool

Balljoint separator

Universal-type puller

lmpactscrewdiver

Dialindicator set

Sfroboscoplc timing light (inductive

pick-up)

Hand operated vacuum/pressure pump

Tachomete r/dwell mete r

U n ive rsale le ctri ca I m u ltimete r

Cable hoist

Brake sping removal and installation

fools

Floor jack

Buying tools

For the do-it-yourselfer who is just start-

ing to get involved in vehicle maintenance and

repair, thereare a number of options available

when purchasingtools. lf maintenance and

minor repair is the extent of the work to be

done,the purchase of individual tools is satis-

factory.lf, on the other hand, extensive work is

planned, it would be a good idea to purchase

a modest tool set from one of the large retail

chain stores.A set can usually be bought at

a substantial savingsover the individual tool

prices, and they often come with a tool box.

As additional tools are needed,add-on sets,

individual tools and a larger toolboxcan be

purchased to expand thetool selection. Build-

ing a toolset gradually allows the costof the

toolsto be spread over a longer period of

time and givesthe mechanic the freedom to

choose onlythose tools thatwill actually be

used.

Tool stores will oftenbe the onlysource

of some of the special toolsthat are needed,

but regardless of where toolsare bought, try

to avoid cheap ones, especially whenbuying

screwdrivers andsockets, because they won't

last very long. The expense involved in replac-

ingcheap tools will eventually be greater than

the initial cost of quality tools.

Gare and maintenance of tools

Good toolsare expensive, so it makes

sense to treatthemwith respect. Keep them

clean andin usable condition andstore them

properly when not in use. Always wipe ofi any

dirt, grease or metal chips before putting them

away. Never leave toolslying around in the

workarea.Upon completion of a

job,

always

check closely under the hoodfor toolsthat

may havebeenleft thereso theywon'tget

lost during a test drive.

Some tools, suchas screwdrivers, pli-

ers,wrenches and sockets, can be hung on

a panel mounted on the garage or workshop

wall, while others should be kept in a tool

boxor tray. Measuring instruments, gauges,

meters, etc. must be carefully stored where

they cannot bedamaged byweather or impact

ftomother tools.

When tools are used with care and

stored properly, they will lasta verylong time.

Even withthe best of care, though, tools will

wear out if usedfrequently. Whena tool is

damaged or worn out,replace it. Subsequent

jobs will be saferand moreenjoyable if you

do.

How to repair damaged

threads

Sometimes. the internal threadsof a nut

or bolt holecan become stripped, usually from

overtightening. Stripping threadsis an all-too-

common occurrence, especially when work-

ing with aluminumparts, becausealuminum

is so soft that it easily strips out.

Usually, externalor internal threadsare

only partially stripped. After they've been

cleaned up with a tap or die, they'll still work.

Sometimes,however,threads are badly dam-

aged. When this happens,you've got three

choices:

1) Dill and tap the hole to the next suitable

oversize and install a larger diameter

boft, screw or stud.

2) Drill and tap the hole to accept a

threaded plug, then dill and tap the plug

to the original screw size. You can also

buy a plug already threaded to the oigi-

nal size. Then you simply drill a hole to

the specified size, then run the threaded

plug into the hole with a bolt and jam nut.

Once theplug is fully seated, remove the

jam nut andbolt.

3) The third method uses a patented thread

repair kitlike Heli-Coil or Slimserf. Ihese

easy-to-use kitsare designed to repair

damaged threads in straight-through

holesand blind holes. Both are avail-

ableas kifs which canhandle a variety of

slzes and thread patterns. Drill the hole,

then tap it with the special included tap.

lnstall the Heli-Coil and the holeis back

to itsoiginal diameter andthread pitch.

Regardless of whichmethod you use,

be sure to proceed calmly and carefully. A

little impatience or carelessness during one

of these relatively simple procedures can ruin

your whole day's workandcostyou a bundle

if youwreck an expensive part.

Working facilities

Not to be overlooked whandiscussing

tools is the workshop. lf anything more than

routine maintenance is to be carriedout.

some sortof suitable work area is essential.

It is understood, and appreciated, that

many home mechanics do not have a good

workshop or garage available, and end up

removing an engine or doingmajor repairs

outside. lt is recommended, however, that the

overhaul or repair be completed under the

cover of a roof.

A clean, flat workbench or tableof com-

fortable working height is an absolute neces-

sity. Theworkbench should be equipped with

a visethat hasa jaw opening of at least four

inches.

As mentioned previously, someclean,

dry storage space is alsorequired for tools,

as wellas the lubricants, fluids, cleaning sol-

vents, etc. which soon become necessary.

Sometimes wasleoil and fluids, drained

from the engine or cooling system during

normal maintenance or repairs, present a

disposal problem. To avoid pouring themon

the ground or intoa sewage system, pour the

used fluids into large containers, sealthem

with caos and take them to an authorized

disposal siteor recycling center. Plastic jugs,

suchas old antifreeze containers, are ideal

forthis purpose.

Always keep a supply of old newspa-

pers and clean rags available. Old towels

are excellent for mopping up spills. Many

mechanics use rolls of paper towels for most

workbecause theyare readily available and

disposable. To helpkeep the areaunder the

vehicle clean, a large cardboard boxcan be

cut openand flattened to protect the garage

or shop floor.

Whenever working overa painted sur-

face, such as when leaning over a fender to

service something under the hood,always

cover it withan old blanket or bedspread to

protect the finish. Vinylcovered pads,made

especially for this purpose, are available at

autoDarts stores.

PALMTREESALES1967 - NO RESALE

0-12

Jacking and towing

Jacking

Warning l: Some modelscoveredby this

manual are equipped withair suspenslon sys-

tems.Always disconnect electrical power to

fhe suspenslon system before liftingor towing

the vehicle (see Chapter 10). Failure to per-

form thisprocedure may resultin unexpected

shiftingor movement of the vehicle which

couldcausepersonal injury.

Warning 2: The jack

supplied with the vehicle

shouldonly be usedfor changing a tire or

placing jackstands

under the frame. Never

work under the vehicleor start the engine

while this

jack

is being used as the only

means of support.

The vehicle should be on level ground.

Place the shiftlever in Park, if you have an

automatic, or Reverse if you havea manual

transmission. Blockthe wheeldiagonally

opposite the wheelbeing changed. Set the

parking brake.

Remove the sparetire and

jack

from

stowage. Remove the wheel cover andtrim

ring(if so equipped) withthe tapered endof

the lug nut wrench by inserting and twisting

the handle andthenprying against the back

ofthe wheel cover. Loosen thewheel lug nuts

about 1 I 4-to-1 12 tum each.

Place the

jack

under the vehicle in the

indicated position (see illustrations). Turn

the

jack

handle clockwise until the tire clears

theground. Remove the lugnuts andpull the

wheel off.Replace it with the spare.

Install the lug nuts with the beveled

edges facing in. Tighten themsnugly. Don't

attempt to tighten them completely until

the vehicle is lowered or it could slip off the

jack.Turnthe jack handle counterclockwise

Front

jacking

locatlon

-

positlonthe

jack

underthe weldedbracket (anow)

to lower the vehicle. Remove the jack and

tighten the lugnuts in a diagonal paftem.

Install the cover (and trimring, if used)

andbe sure it'ssnapped intoplace all theway

around.

Stow the tire, jack andwrench. Unblock

thewheels.

Towing

We recommend thesevehicles (except

four-wheel drive models) be towedfrom the

rear,with the rear wheelsoff the ground,

lf it's absolutely necessary, thesevehicles

can be towed from the front with the front

wheels off the ground, provided thatspeeds

don't exceed 35 mph and the distance,is

lessthan50 miles; the transmission can be

damaged if these mileage/speed limitations

are exceeded. Vehicles withfour-wheel drive

Rear

jacking

locatlons - poaitlon the jack

underthe rearframerall or (on plck-up

models only) underthe U.boltson the

rear leaf spring

must not be towed withall fourwheels on the

ground. They must only betowed with allfour

wheels ofi theground.

Equipment specifically designed for tow-

ingshould be used. lt must be attached to the

main structural members of the vehicle, not

the bumpers or brackets.

Safety is a majorconsideration when

towing and all applicable state and local laws

must be obeyed. A safety chain must be used

at alltimes.

The parking brake must be released

andthetransmission must be in Neutral. The

steering mustbe unlocked (ignition switch in

the Offposition). Remember thatpower steer-

ing and powerbrakes won't work with the

engine ofi.

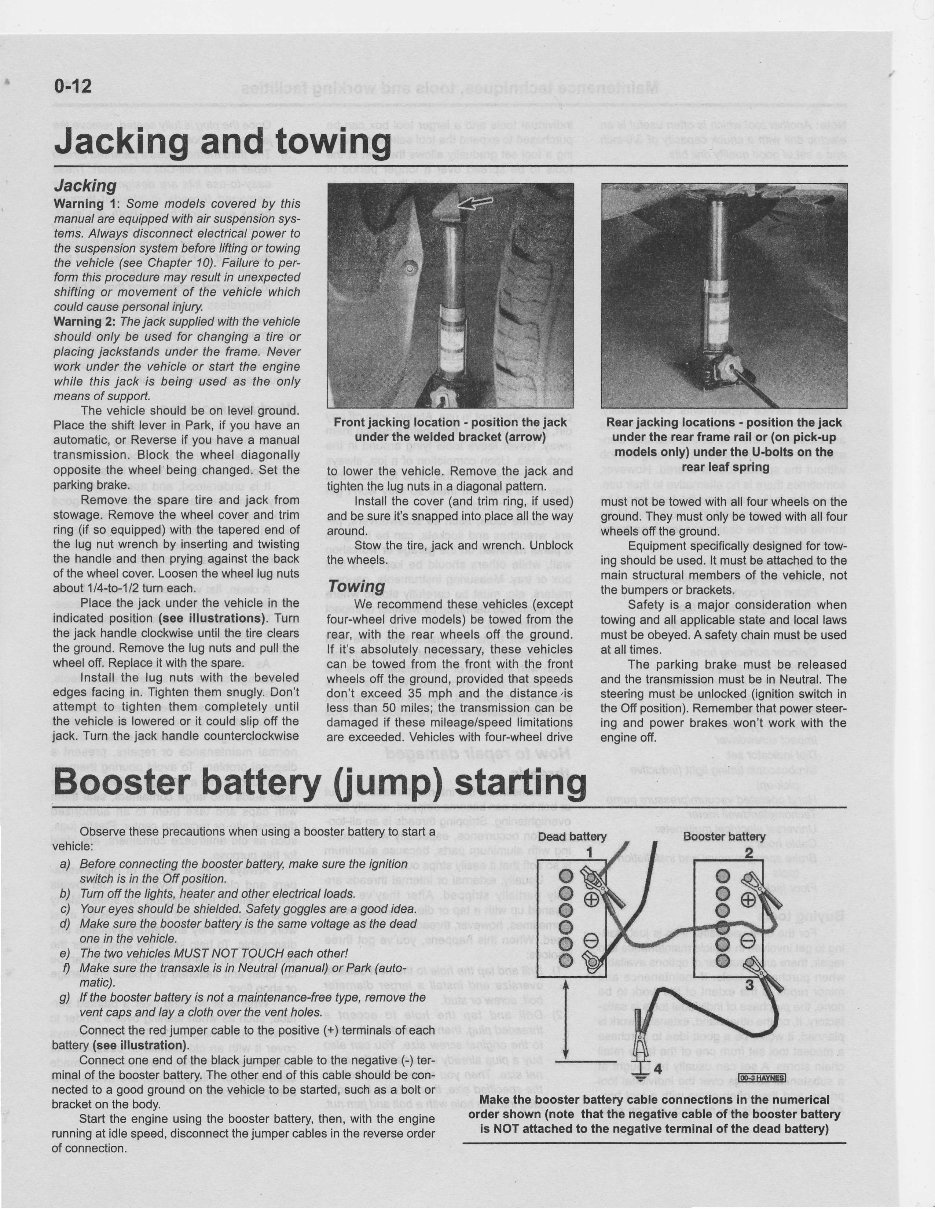

Booster battery

fiump)

starting

Observe these precautions when using a booster battery to start a

vehicle:

a) Before connecting the booster baftery, ma4esure the ignition

switch is in the Off position.

b) Tum otr the lights, heater and otherelectical loads.

c) Yaureyes should be shielded. Safety goggles are a goodidea.

d) Make sure the booster baftery is the same voftage as the dead

onein the vehicle.

e) The two vehicles MUST NOT TQUCH each other!

f) Make sure the transaxlq is in Neutral (manual) or Park(auto-

matic).

g) lf the booster baftery is not a maintenance-free type,remove the

ventcaps andlay a cloth over the ventholes.

Connect the red

jumper

cable to the positive (+)terminals of each

battery (seeillustration).

Connect oneendof the black

jumper

cable to the negative

C)

ter-

minal of the booster baftery. Theother endof thiscable should be con-

nected to a goodground on the vehicle to be started, such as a boltor

bracket on the body.

Start the engine using the booster battery, then, withthe engine

running at idle speed, disconnect the jumper cables inthereverse order

of connection.

Make the boosterbattery cableconnectione In the numerical

ordershown (note that the negative cableof the boosterbatiery

is NOT attached to the negative teminal of the deadbattery)

PALMTREESALES1967 - NO RESALE

You're Reading a Preview

What's Included?

Fast Download Speeds

Online & Offline Access

Access PDF Contents & Bookmarks

Full Search Facility

Print one or all pages of your manual

$31.99

Viewed 52 Times Today

Loading...

Secure transaction

What's Included?

Fast Download Speeds

Online & Offline Access

Access PDF Contents & Bookmarks

Full Search Facility

Print one or all pages of your manual

$31.99

This comprehensive OEM service and repair manual is meticulously designed for the 1997 Ford F-150. Developed as a complete factory guide, it furnishes accurate repair and maintenance procedures tailored specifically to your truck.

This digital manual is easy to navigate with built-in bookmarks and a straightforward search function, making it an essential resource for both professional mechanics and DIY enthusiasts.

- Detailed coverage of general information, chassis, powertrain, electrical systems, body and paint, and wiring diagrams

- In-depth sections on identification codes, maintenance schedules, suspension, brake and steering systems

- Extensive guidance on engine systems, exhaust, fuel systems, climate control, entertainment, and lighting

Its accessible format allows you to print specific sections as needed, ensuring that you have the crucial information at your fingertips while working on your vehicle.

If you have any inquiries or need further assistance, our dedicated support team is ready to help. Your satisfaction remains our top priority.