31-01-1

GROUP

31 CHARGING SYSTEM

(10000)

SECTION TITLE PAGE SECTION TITLE PAGE

ALTERNATOR-INTEGRAL REGULATOR-EXTERNAL FAN CHARGING SYSTEM-SERVICE ................................ 31-o1·1

TyPE ......................................................................... 31·17·1 IGNITION SWITCH ..................................................... 31-20-1

BATTERIES ............................................................... 31-02·1

SECTION 31-01 Charging System-Service

SUBJECT PAGE SUBJECT PAGE

DESCRIPTION AND OPERATION ................................ 31·01·1 SPECIFICATIONS ...................................................... 31-01·9

DIAGNOSIS ............................................................... 31·01·1 TESTING ................................................................... 31 ·01·4

SPECIAL SERVICE TOOLS ......................................... 31·01·9 VEHICLE APPLICATION ............................................. 31·01·1

VEHICLE APPLICATION

Capri.

DESCRIPTION AND OPERATION

The alternator charging system is a negative ground

system consisting of an alternator with an integral

regulator, a charge indicator lamp, a storage battery,

and associated wiring.

The integral regulator is solid·state.lt is mounted onto

the rear of the alternator and contains the alternator

brushes.

DIAGNOSIS

Battery and charging system trouble is frequently due

to physical rather than electrical factors including

loose or corroded wiring connections, damaged

wiring, slipping drive belts, dirty battery surfaces and

terminals, or poor maintenance.

Thoroughly inspect the system.

1. Make sure battery terminals and cable

connections are clean and tight. Refer to Section

31-02.

2. Inspect battery cable connections to starter and

engine ground for surface dirt or foreign matter.

3. Check alternator drive belt for glazing or cracking

which may have been caused by belt slippage. If

sides of belt are shiny or feel slick, replace them.

Check belt tension. Refer to Section 27 -02 for

belt replacement or tension adjustment.

4. Make sure that top surface of battery is clean and

free of moisture or foreign matter.

Charging system troubles such as low alternator

output, no alternator output (indicated by the indicator

lamp being on while the engine is running), or alternator

output voltage too high, require testing of both the

alternator and the voltage regulator.

Copyright © 1990, Ford Motor Co. www.techcapri.com

31-01-2 Charging System-Service 31-01-2

DIAGNOSIS (Continued)

Voltage regulator failures are usually not recognized

except by the direct affect on the alternator output.

and eventual battery discharge. The regulator is the

control valve for the alternator. It protects the battery

by preventing excessive voltage output.

Discharge of the battery to ground through the

alternator is prevented by the diodes of the alternator

which permit current flow in one direction (to the

battery) only.

A discharged battery is not always due to a problem in

the charging system. Excessive use of lamps and

accessories while the engine is either off or running at

low idle. corroded battery cables and connectors. low

acid level in the battery. or prolonged disuse of the

battery. which would permit self-discharge are all

possible reasons which should be considered when a

battery is run down or low in charge.

NOTE: Always determine the cause of failure as well

as making the repair.

1. Polarity and Connections. The alternator is for

use on negative ground electrical systems only.

Polarity cannot be reversed and any attempt to

do so will damage the alternator.

2. Installing Vehicle Battery. Reversed battery

connections will damage the alternator rectifiers.

When installing. first connect the positive

connector to the battery positive terminal and

then connect the negative connector to the

negative battery terminal.

3. Battery Charging. Disconnect the battery

negative cable to isolate the alternator from the

battery and external charging equipment.

4. Battery Connections. Never disconnect the

battery while the engine is running. Damage to

the rectifier and lor other electrical components

may occur. Using a slave battery to start the

engine and then reconnectil1g the original battery

while the engine is running must not be attempted.

Do not break or make any other connections in

the alternator circuit while the engine is running.

5. Alternator Main Output Cable.

• The cable connecting the alternator and the

battery has constant battery voltage even

when the engine is not running. Care must be

taken not to ground this cable if it should ever

be removed, or damage to the cable will occur.

• Never run the alternator with the main output

cable disconnected either at the alternator or

battery end while the field remains energized

or the rectifiers may be damaged.

6. Arc Welding. Isolate the control box and

alternator by disconnecting their wiring

connectors prior to performing any arc welding on

the vehicle.

7. lamps and Fuses Fall Prematurely, Short

Battery life. Other systems covered under this

heading are: battery uses excessive amount of

water; high battery charging rate. Check all

charging system wiring connections including the

regulator ground and battery sensing wire.

lighten or service as required. Check the

alternator voltage limiter setting. Replace if not to

specification.

8. Alternator Noisy. When diagnosing the

complaint of alternator noise. isolate the noise

area and make sure that the alternator is at fault

rather than the alternator belt. water pump. or

another part of the vehicle. Start the engine and

use a stethoscope or similar tool to isolate the

noise. An alternator bearing, water pump bearing

or belt noise is usually evidenced by a squealing

sound.

An alternator with a shorted diode will normally

whine (magnetic noise) and will be most

noticeable at idle speeds. Perform the alternator

output tests. If the output is approximately 10

amperes less than that specified. a shorted diode

is usually indicated.

To eliminate the belt(s} as the cause of noise,

check the belt(s} for bumps, apply a light spray of

water to the belt(s}. If the alternator belt is at

fault. adjust the belt to specification. or replace

the belt if necessary.

If the belt(s) is satisfactory and the noise is

believed to be in the alternator or water pump,

remove the alternator belt. Start the engine and

listen for the noise to be sure that the noise Is not

caused by another component. Use this test and

the sound detector test to isolate the noisy

component. If the noise Is traced to the

alternator, remove it and check bearings for play

or roughness.

9. Charge Indicator /Warning lamp Flickers.

This condition may be caused by loose or

damaged connections in the charging system

wiring harness, worn brushes. or improper brush

tension.

Copyright © 1990, Ford Motor Co. www.techcapri.com

31-01-3 Charging System-Service 31-01-3

DIAGNOSIS (Continued)

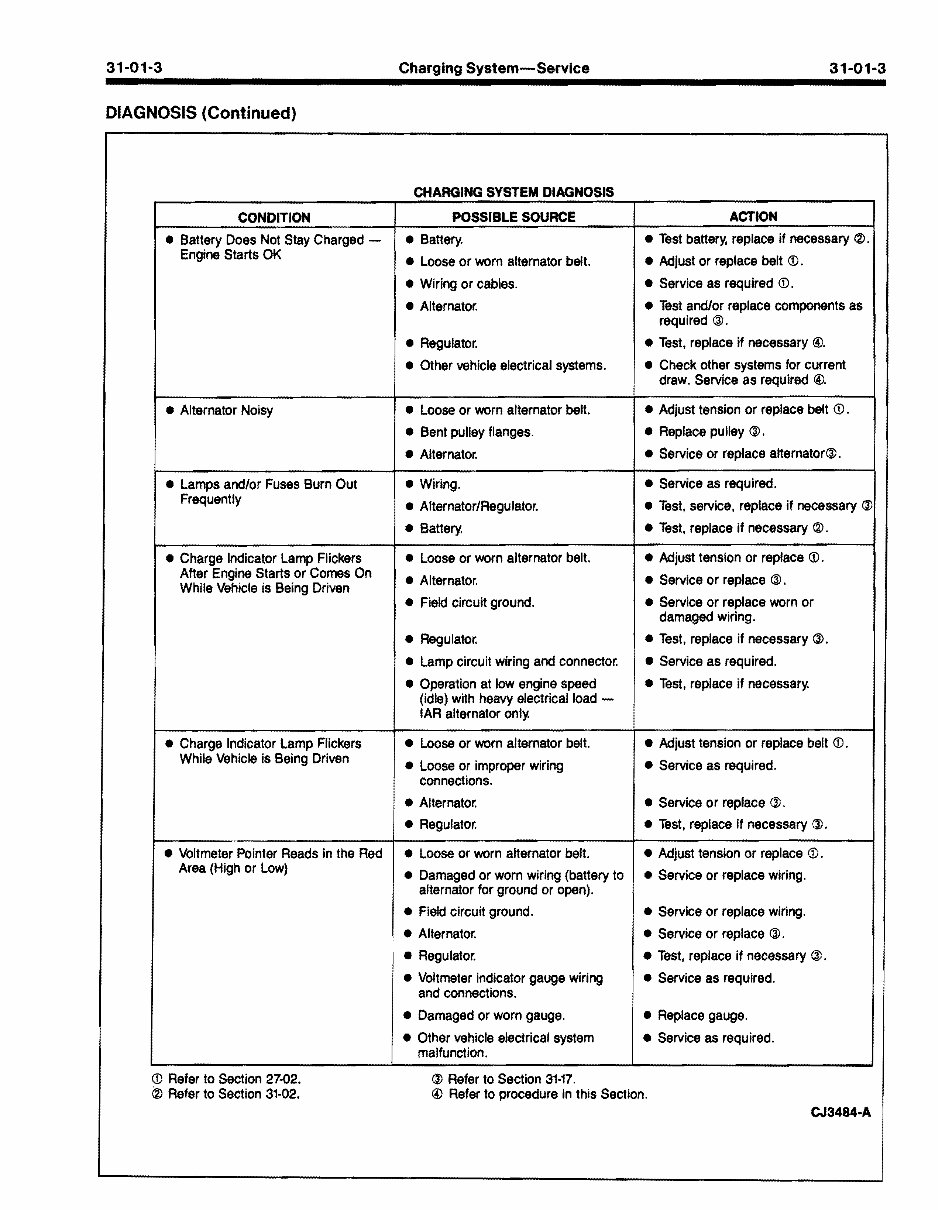

CHARGING SYSTEM DIAGNOSIS

CONDITION POSSIBLE SOURCE ACTION

• Battery Does Not Stay Charged -

• Battery.

• Test battery, replace if necessary <2J.

Engine Starts OK

• Loose or worn alternator belt.

• Wiring or cables.

• Alternator.

• Regulator.

• Other vehicle electrical systems.

• Adjust or replace belt (j).

• Service as required (j).

• Test and/or replace components as

required @.

• Test, replace if necessary @.

• Check other systems for current

draw. Service as required @.

• Alternator Noisy • Loose or worn alternator belt.

• Bent pulley flanges.

• Alternator.

• Adjust tension or replace belt (j).

• Replace pulley @.

• Service or replace alternator@.

• Lamps and/or Fuses Burn Out

Frequently

• Wiring.

• Alternator/Regulator.

• Battery.

• Service as required.

• Test, service, replace if necessary @

• Test, replace if necessary <2J.

• Charge Indicator Lamp Flickers • Loose or worn alternator belt. • Adjust tension or replace (j).

After Engine Starts or Comes On

While Vehicle is Being Driven

• Alternator.

• Field circuit ground.

• Regulator.

• Lamp circuit wiring and connector.

• Operation at low engine speed

(idle) with heavy electrical load -

IAR alternator onl)(

• Service or replace @.

• Service or replace worn or

damaged wiring.

• Test, replace if necessary @.

• Service as required.

• Test, replace if necessar)(

• Charge Indicator Lamp Flickers • Loose or worn alternator belt. • Adjust tension or replace belt (j).

While Vehicle is Being Driven

• Loose or improper wiring

connections.

• Alternator.

• Regulator.

• Service as required.

• Service or replace @.

• Test, replace if necessary @.

• Voltmeter Pointer Reads in the Red • Loose or worn alternator belt. • Adjust tension or replace (j).

Area (High or Low)

• Damaged or worn wiring (battery to

alternator for ground or open).

• Field circuit ground.

• Alternator.

• Regulator.

• Voltmeter indicator gauge wiring

and connections.

• Damaged or worn gauge.

• Other vehicle electrical system

malfunction.

• Service or replace wiring.

• Service or replace wiring.

• Service or replace @.

• Test, replace if necessary @.

• Service as required.

• Replace gauge.

• Service as required.

(j) Refer to Section 27"()2. @ Refer to Section 31·17.

(ID Refer to Section 31-02. @ Refer to procedure in this Section.

CJ3484·A

Copyright © 1990, Ford Motor Co. www.techcapri.com

Charging System-Service

TESTING

The following system test charts have been arranged

in a series to isolate the component or cause of a

charging system complaint.

Start at the beginning and continue through the test

steps even after the cause of the complaint is found.

This will rule out the possibility that the original

condition was not caused by more than one charging

system problem.

Copyright © 1990, Ford Motor Co. www.techcapri.com

31-01-5 Charging System-Service 31-01-5

TESTING (Continued)

CHARGING SYSTEM TEST

TEST STEP RESULT ACTION TO TAKE

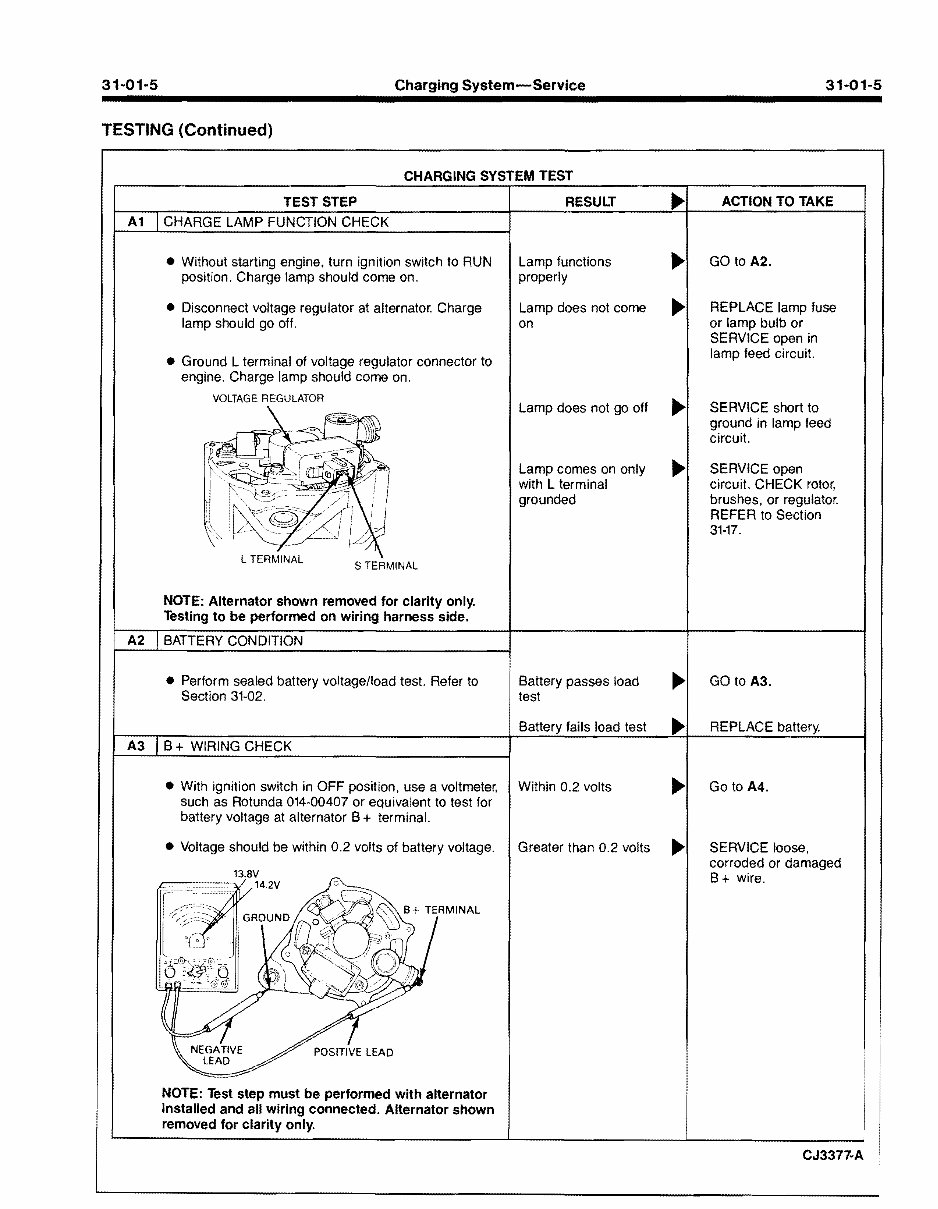

A1 CHARGE LAMP FUNCTION CHECK

• Without starting engine, turn ignition switch to RUN

position. Charge lamp should come on.

• Disconnect voltage regulator at alternator. Charge

lamp should go off.

• Ground L terminal of voltage regulator connector to

engine. Charge lamp should come on.

VOLTAGE REGULATOR

S TERMINAL

NOTE: Alternator shown removed for clarity only.

Testing to be performed on wiring harness side.

Lamp functions

properly

Lamp does not come

on

Lamp does not go off

Lamp comes on only

with L terminal

grounded

..

..

..

..

GO to A2.

REPLACE lamp fuse

or lamp bulb or

SERVICE open in

lamp feed circuit.

SERVICE short to

ground in lamp feed

circuit.

SERVICE open

circuit. CHECK rotor,

brushes, or regulator.

REFER to Section

31-17.

A2 BATTERY CONDITION

• Perform sealed battery voltagelload test. Refer to

Section 31-02.

Battery passes load

test

Battery fails load test

..

..

GO to A3.

REPLACE battery.

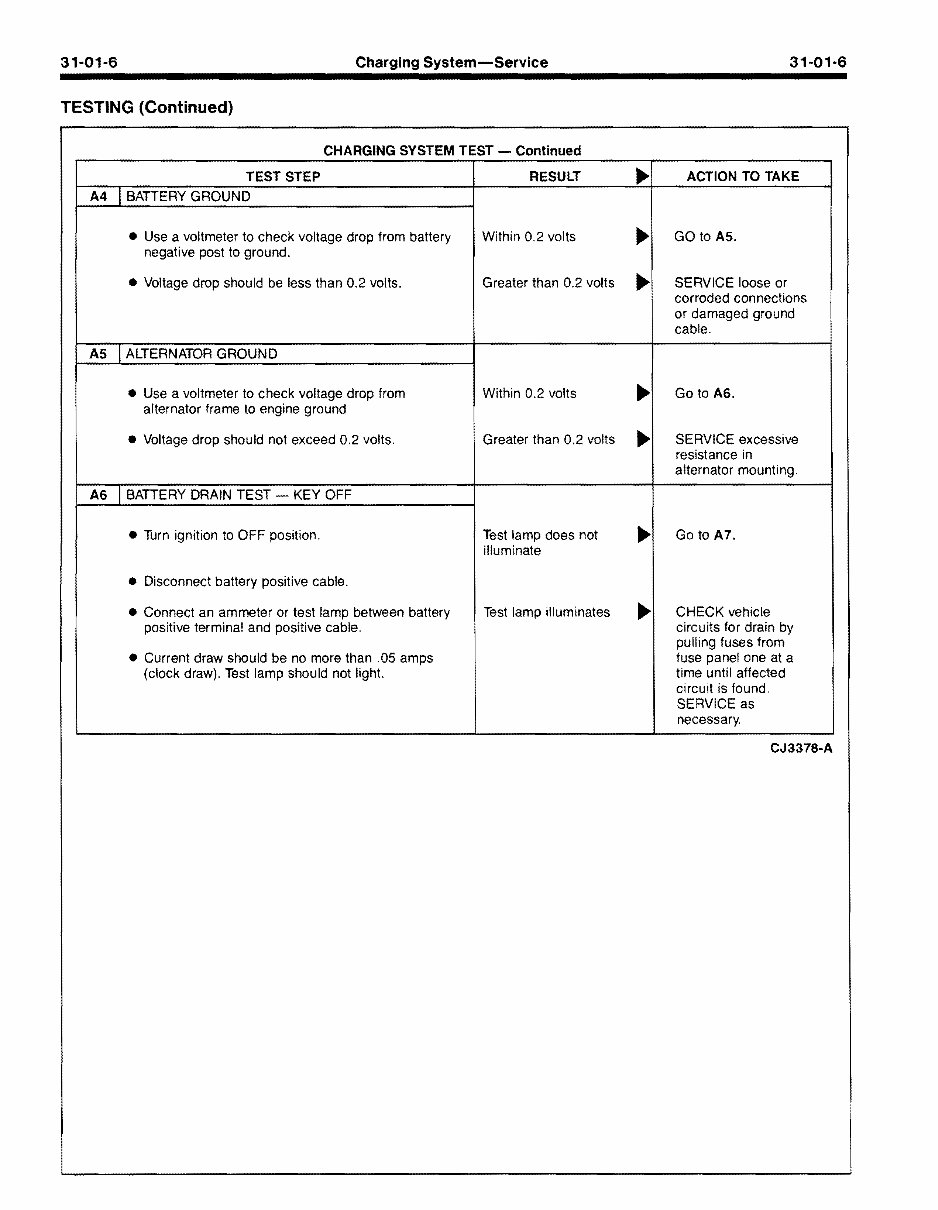

A3 B + WIRING CHECK

• With ignition switch in OFF position, use a voltmeter,

such as Rotunda 014-00407 or equivalent to test for

battery voltage at alternator B + terminal.

• Voltage should be within 0.2 volts of battery voltage.

Within 0.2 volts

Greater than 0.2 volts

..

..

Go to A4.

SERVICE loose,

corroded or damaged

B + wire.

NOTE: Test step must be performed with alternator

installed and all wiring connected. Alternator shown

removed for clarity only.

CJ3377-A

Copyright © 1990, Ford Motor Co. www.techcapri.com

31-01-6 Charging System-Service 31-01-6

TESTING (Continued)

CHARGING SYSTEM TEST - Continued

TEST STEP RESULT

."

ACTION TO TAKE

A4 I BATTERY GROUND

Within 0.2 volts

."

GO to AS.

negative post to ground.

• Use a voltmeter to check voltage drop from battery

Greater than 0.2 volts

."

SERVICE loose or

corroded connections

or damaged ground

cable.

• Voltage drop should be less than 0.2 volts.

AS J ALTERNATOR GROUND

Within 0.2 volts

."

Go to AS.

alternator frame to engine ground

• Use a voltmeter to check voltage drop from

Greater than 0.2 volts

."

SERVICE excessive

resistance in

alternator mounting.

• Voltage drop should not exceed 0.2 volts.

AS I BATTERY DRAIN TEST - KEY OFF

Test lamp does not

."

Go to A7.

illuminate

• Turn ignition to OFF position.

• Disconnect battery positive cable.

Test lamp illuminates

."

CHECK vehicle

positive termina! and positive cable.

• Connect an ammeter or test lamp between battery

circuits for drain by

pulling fuses from

fuse panel one at a

(clock draw). Test lamp should not light.

• Current draw should be no more than .05 amps

time until affected

circuit is found.

SERVICE as

necessary.

CJ3378-A

Copyright © 1990, Ford Motor Co. www.techcapri.com

31-01-7

31-01-7 Charging System-Service

TESTING (Continued)

CHARGING SYSTEM TEST - Continued

TEST STEP RESULT ACTION TO TAKE

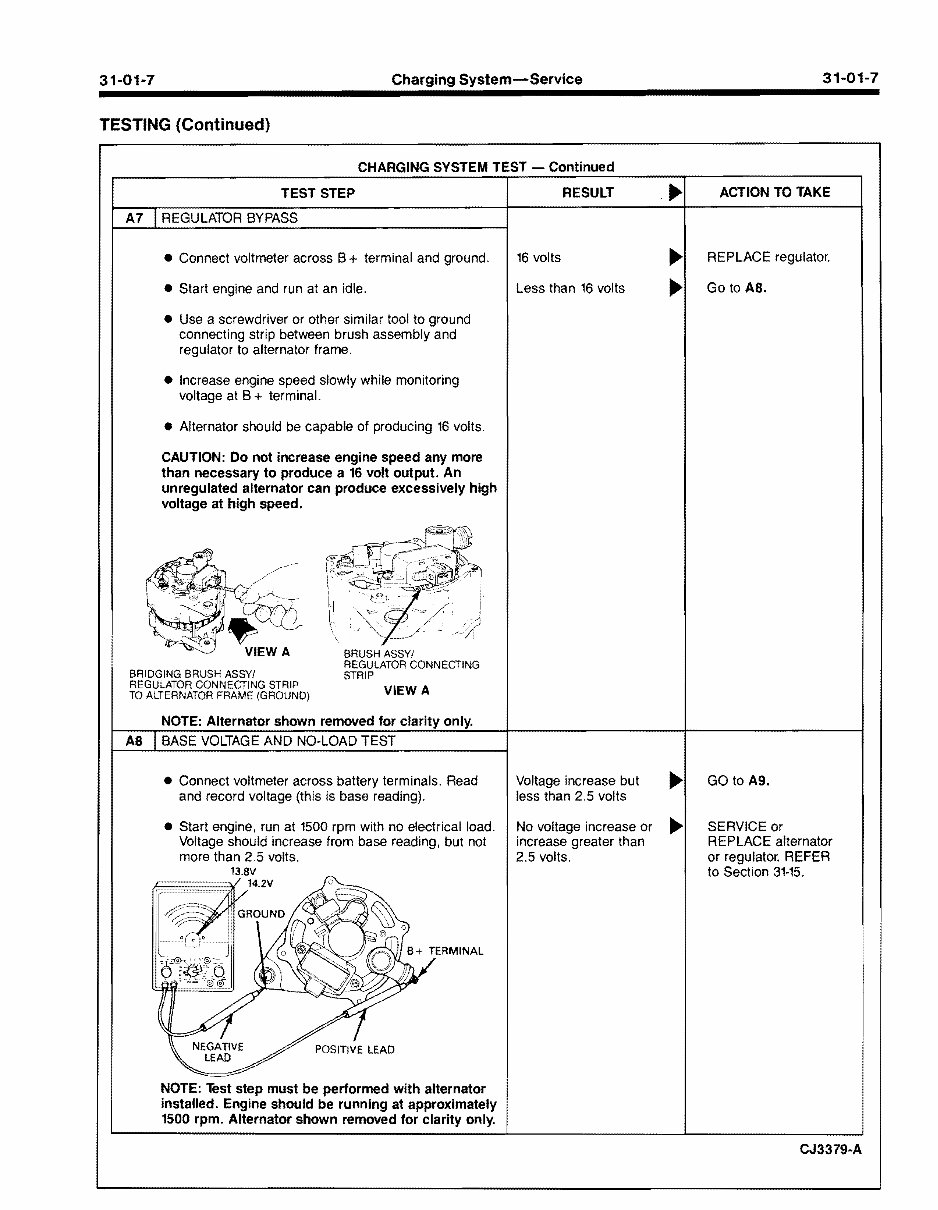

A7 REGULATOR BYPASS

16 volts

Less than 16 volts

REPLACE regulator.

Go to AS.

• Connect voltmeter across B + terminal and ground.

• Start engine and run at an idle.

• Use a screwdriver or other similar tool to ground

connecting strip between brush assembly and

regulator to alternator frame.

• Increase engine speed slowly while monitoring

voltage at B + terminal.

• Alternator should be capable of producing 16 volts.

CAUTION: Do not increase engine speed any more

than necessary to produce a 16 volt output. An

unregulated alternator can produce excessively high

voltage at high speed.

BRIDGING BRUSH ASSYI

REGULATOR CONNECTING STRIP

TO ALTERNATOR FRAME (GROUND)

BRUSH ASSYI

REGULATOR CONNECTING

STRIP

VIEW A

NOTE: Alternator shown removed for clarity only.

AS BASE VOLTAGE AND NO·LOAD TEST

Voltage increase but

less than 2.5 volts

No voltage increase or

increase greater than

2.5 volts.

GO to A9.

SERVICE or

REPLACE alternator

or regulator. REFER

to Section 31·15.

• Connect voltmeter across battery terminals. Read

and record voltage (this is base reading).

• Start engine, run at 1500 rpm with no electrical load.

Voltage should increase from base reading, but not

more than 2.5 volts.

NOTE: Test step must be performed with alternator

installed. Engine should be running at approximately

1500 rpm. Alternator shown removed for clarity only.

CJ3379·A

Copyright © 1990, Ford Motor Co. www.techcapri.com

31-01-8 Charging System-Service 31-01-8

TESTING (Continued)

CHARGING SYSTEM TEST - Continued

TEST STEP RESULT ACTION TO TAKE

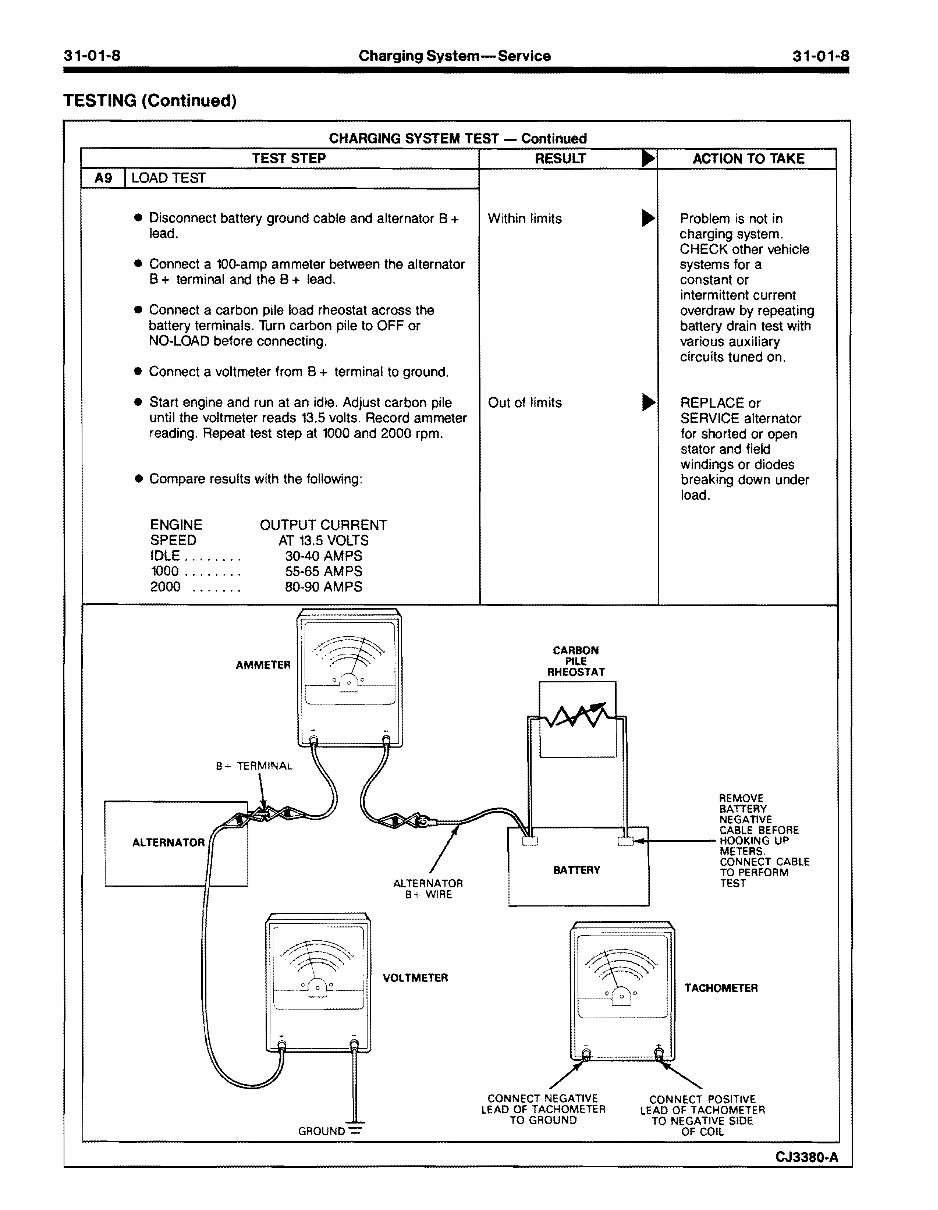

A9 LOAD TEST

Within limits

Out of limits

Problem is not in

charging system.

CHECK other vehicle

systems for a

constant or

intermittent current

overdraw by repeating

battery drain test with

various auxiliary

circuits tuned on.

REPLACE or

SERVICE alternator

for shorted or open

stator and field

windings or diodes

breaking down under

load.

• Disconnect battery ground cable and alternator B +

lead.

• Connect a 100-amp ammeter between the alternator

B + terminal and the B + lead.

• Connect a carbon pile load rheostat across the

battery terminals. Turn carbon pile to OFF or

NO· LOAD before connecting.

• Connect a voltmeter from B + terminal to ground.

• Start engine and run at an idle. Adjust carbon pile

until the voltmeter reads 13.5 volts. Record ammeter

reading. Repeat test step at 1000 and 2000 rpm.

• Compare results with the following:

ENGINE

SPEED

OUTPUT CURRENT

IDLE ....... .

1000 ....... .

2000 ...... .

AT 13.5 VOLTS

30·40 AMPS

55·65 AMPS

80-90 AMPS

AMMETER

ALTERNATOR

GROUND-=-

ALTERNATOR

B+ WIRE

VOLTMETER

CARBON

PILE

RHEOSTAT

BATTERY

CONNECT NEGATIVE

LEAD OF TACHOMETER

TO GROUND

REMOVE

BATTERY

NEGATIVE

CABLE BEFORE

0 ........ ---- HOOKING UP

METERS.

CONNECT CABLE

TO PERFORM

TEST

TACHOMETER

CONNECT POSITIVE

LEAD OF TACHOMETER

TO NEGATIVE SIDE

OF COIL

CJ3380·A

Copyright © 1990, Ford Motor Co. www.techcapri.com

31-01-9 Charging System-Service 31-01·9

SPECIFICATIONS SPECIAL SERVICE TOOLS

ROTUNDA EQUIPMENT

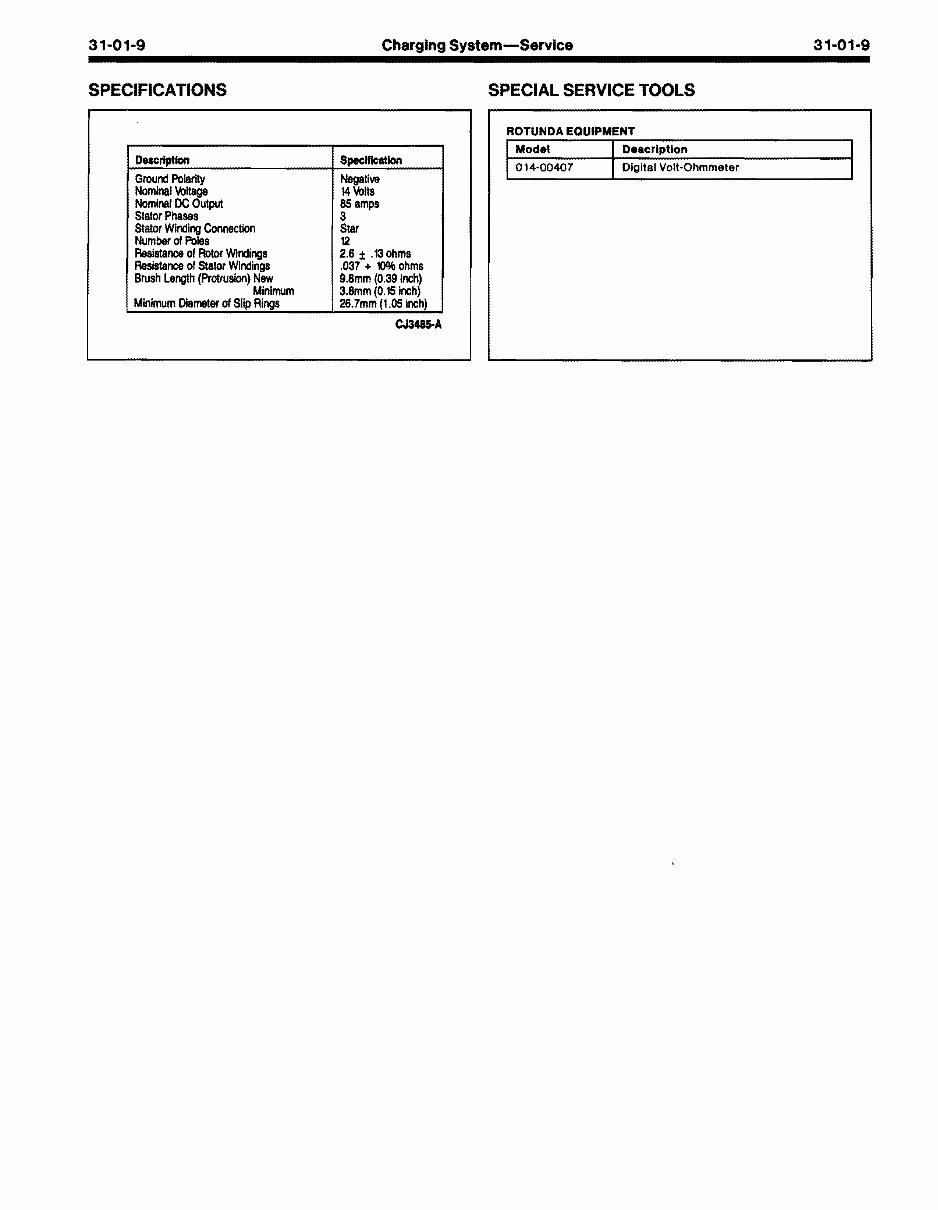

Model Description

014-00407 Digital Volt-Ohmmeter

Deec:r!ptIon Specification

Ground Polarity Negative

Nominal '«Iltage 14 \tits

Nominal DC Output 85 amps

Stator Phases 3

Stator Winding Connection Star

Number 01 Poles 12

Resistance 01 Rotor Windings 2,6 ± ,13 ohms

Resistance 01 Stator Windings ,037 + 10% ohms

Brush Length (Prolrusion) New 9,8mm (0,39 Inch)

Minimum 3,Smm (0,15 Inch)

Minimum Diameter 01 Slip Rings 26.7mm (1.05 Inch)

CJ3485-A

Copyright © 1990, Ford Motor Co. www.techcapri.com

31-02-1 Batteries

SECTION 31-02 Batteries

SUBJECT PAGE

MAINTENANCE

Battery Cleaning ..••••••••.••••••••••.••..•.•.•.•.••.••••••••••• .... 31·02·6

Jump Starting ........................................................ 31·02·6

REMOVAL AND INSTALLATION

Battery .................................................................. 31·02·4

SERVICE

Battery Cable Clamp Spreader ............................... 31·02-5

Battery Cable Puller ............................................... 31-02-4

Battery Carrier ....................................................... 31·02-5

Battery Pliers ......................................................... 31·02·4

SUBJECT PAGE

SERVICE (Cont'd.)

Terminal Cleaning Brush ........................................ 31-02-5

Tools ..................................................................... 31-02-4

SPECIAL SERVICE TOOLS ......................................... 31-02-6

TESTING

Battery Capacity Test ............................................ 31-02-3

Battery Charging ................................................... 31-02-3

Battery Voltage Check ........................................... 31-02-1

VEHICLE APPLICATION ............................................. 31-02-1

VEHICLE APPLICATION

Capri.

TESTING

Tests are made on a battery to determine the state of

charge and also its capacity or ability to crank an

engine. The ultimate result of these tests is to show

that the battery is good, needs recharging, or must be

replaced.

Before attempting to test a battery, it is important to

give it a thorough examination to determine if it has

been damaged.

WARNING: ALWAYS DISCONNECT THE BATTERY

CABLE WHEN CHARGING THE BATrERY OR ARC

WELDING ON THE VEHICLE. KEEP ALL FIRE

AWAY FROM 'rHE TOP OF THE BATTERY WHEN

CHARGING "rHE BATTERY. AVOID CONTACT OF

SULFURIC ACID WITH SKIN, EYES, CLOTHING

AND VEHICLE.

WARNING: BATTERIES NORMALLY PRODUCE

EXPLOSIVE GASES WHICH CAN CAUSE

PERSONAL INJURY. THEREFORE, DO NOT

ALLOW FLAMES, SPARKS OR I.lGHTED

TOBACCO TO COME NEAR THE BATTERY. WHEN

CHARGING OR WORKING NEAR A BATTERY,

ALWAYS SHIELD YOUR FACE AND PROTECT

YOUR EYES. ALWAYS PROVIDE VENTILATION.

Battery Voltage Check

1. With the ignition OFF and no electrical loads on,

connect the negative (-) lead of Rotunda

Voltmeter 059-000 1 a or equivalent to the

negative battery cable clamp.

NOTE: The range setting on the voltmeter should

be at least a to 15.

WHEN LIFTING A PLASTIC-CASED BATTERY,

EXCESSIVE PRESSURE ON THE END WALLS

COULD CAUSE ACID TO SPEW THROUGH THE

VENT CAPS, RESULTING IN PERSONAL INJURY.

LIFT WITH A BATTERY CARRIER OR WITH YOUR

HANDS ON OPPOSITE CORNERS.

WARNING: KEEP OUT OF REACH OF CHILDREN.

BATTERIES CONTAIN SULFURIC ACID. AVOID

CONTACT WITH SKIN, EYES, OR CLOTHING.

ALSO, SHIELD YOUR EYES WHEN WORKING

NEAR THE BATTERY TO PROTECT AGAINST

POSSIBLE SPLASHING OF THE ACID SOLUTION.

IN CASE OF ACID CONTACT WITH SKIN OR EYES,

FLUSH IMMEDIATELY WITH WATER FOR A

MINIMUM OF 15 MINUTES AND GET PROMPT

MEDICAL ATTENTION. IF ACID IS SWALLOWED,

CALL A PHYSICIAN IMMEDIATELY.

2. Connect the positive (+) lead of the voltmeter to

the positive battery cable clamp.

3. Ifthe voltmeter reading is over 12.4 volts at 21°C

(70°F) the battery voltage is acceptable. If the

reading is 12.4 volts or less, the battery needs

charging.

Copyright © 1990, Ford Motor Co. www.techcapri.com

You're Reading a Preview

What's Included?

Lifetime Access

Access Contents & Bookmarks

Print one or all pages of your manual