1948-1956 Dodge Power Wagon Parts Catalog

What's Included?

Fast Download Speeds

Online & Offline Access

Access PDF Contents & Bookmarks

Full Search Facility

Print one or all pages of your manual

Page | 1

>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>> ELECTRONIC COPY OF FILE NOT AUTHORIZED <<<<<<<<<<<<<<<<<<<<<<<<<<<<<<<<<<<<<<<<<<<<<<<<<<<<<<<<

MASTER-PARTS-INTERCHANGE/TECHICAL DATA

HOW TO USE THIS DOCUMENT

a. Where you see “YES,” the part interchanges with trucks listed.

b. Parts are direct interchange with no modification.

c. Attempts have been made to identify the correct part using available reference materials.

d. Refer to TM-9-1808C Power Trains and Interchanges Military/Civilian trucks 1941 to 1970 (Dodge) for modifications to interchange parts between ½ ton and other trucks

listed.

e. When looking for parts online at NAPA or O’Reilly, use the parts interchange option. SMP is Standard Motor Products. “Part Source” links have been added that will

take you to either AutoZone, O’Reilly, NAPA, Midwest Military or Vintage Power Wagons for most parts listed.

f. To go to Table of Content sections or Web Sites, click section or Web Site to activate link.

g. Link to FFPW Oil Seal Part Numbers Oil Seal Part Numbers. Oil Seal part number prefixes mean/meant - "41" = reinforced double lip, "45" reinforced single lip, "47"

non-reinforced double lip, and "48" non-reinforced single lip.

h. For Detailed Guidance on Repairs, visit DIY Repairs

i. For Information of Ignition Distributors by Year, visit Ignition Distributors

j. For parts, look to: (MAKE SURE YOUR ANTI-VIRUS SOFTWARE IS UP-TO-DATE WHEN SURFING THE INTERNET) – Army Surplus Warehouse Link, Civilian

Dodge Power Wagon Parts (WDX - X3-WM300) Link, DC Truck Parts Link, Mark-K Manufacturing for Wood Bed Kits Link, Midwest Military Link, M Series

Rebuild Link, Oshkosh Equipment Link, Powder River Ordnance Link, Rough & Ready Link, Sands Truck Link, Snake River 4x4 Link, Tisdale Coachworks for

Reproduction Sheet Metal Link, Veterans Vehicles Link, and Vintage Power Wagons Link. For a variety of sources covering a wide range of parts and

services, visit Link. For 100% American Made Products, visit, Link.

NOTE: An excellent manual to have is the “Dodge Power Wagon Power Train Survival Manual .” It shows images of the various components for the Dodge Power

Wagon Models WDX (1946) – WM300 (1978) and lists updated part numbers for bearings and oil seals. Copies are available from Greg Coffin, 6318 Modena Lane,

Niwot, Colorado 80503

CONTENT

GROUP 1. FRONT AXLE........................................................................................................................................................................................................................................................................................................................ 7

1940 TO 1978 THIRD MEMBER PART INTERCHANGE ...................................................................................................................................................................................................................................................................... 11

GROUP 2. REAR AXLE ........................................................................................................................................................................................................................................................................................................................ 12

GROUP 3. HAND BRAKE .................................................................................................................................................................................................................................................................................................................... 13

GROUP 4. HYDRAULIC BRAKES .......................................................................................................................................................................................................................................................................................................... 13

Page | 2

GROUP 5. CLUTCH ............................................................................................................................................................................................................................................................................................................................. 17

GROUP 6. COOLING .......................................................................................................................................................................................................................................................................................................................... 19

HEATING ............................................................................................................................................................................................................................................................................................................................................ 21

GROUP 7. ELECTRICAL ....................................................................................................................................................................................................................................................................................................................... 22

A. REPLACEMENT PARTS ................................................................................................................................................................................................................................................................................................................ 22

B. ELECTRICAL WIRING – GENERATOR TO ALTERNATOR CONVERSION (IGNITION/CHARGING/FUEL PUMP SAFETY & CARB PRIMER SWITCH CIRCUIT; MOPAR 55 AMP. ALTERNATOR, 12 VOLT, 1965 CHRYSLER IMPERIAL) USING AN EXTERNAL BALLAST RESISTER ....... 26

C. ELECTRICAL WIRING – GENERATOR TO ALTERNATOR CONVERSION (IGNITION/CHARGING/FUEL PUMP SAFETY & CARB PRIMER SWITCH CIRCUIT; MOPAR 55 AMP. ALTERNATOR, 12 VOLT, 1965 CHRYSLER IMPERIAL) USING A 4 POSITION IGNITION STARTER SWITCH

27

D. ELECTRICAL WIRING – GENERATOR TO ALTERNATOR CONVERSION (IGNITION/CHARGING/FUEL PUMP SAFETY & CARB PRIMER SWITCH CIRCUIT; MOPAR 55 AMP. ALTERNATOR, 12 VOLT, 1965 CHRYSLER IMPERIAL) USING AN INTERNAL COIL RESISTER ............ 28

E. ELECTRICAL WIRING – GENERATOR TO ALTERNATOR CONVERSION (IGNITION/CHARGING/FUEL PUMP SAFETY & CARB PRIMER SWITCH CIRCUIT; MOPAR 55 AMP. ALTERNATOR, 12 VOLT, 1965 CHRYSLER IMPERIAL) USING THE STOCK FFPW FOOT PEDAL STARTER

SWITCH AND AN EXTERNAL BALLAST RESISTER ............................................................................................................................................................................................................................................................................................... 29

F. ELECTRICAL WIRING - GENERATOR TO ALTERNATOR CONVERSION (IGNITION/CHARGING/FUEL PUMP SAFETY & CARB PRIMER SWITCH CIRCUIT; GM 55 AMP. ALTERNATOR, 12 VOLT, 1965 CHEVY IMPALA, O’REILLY PART NUMBER - R111616A) USING AN

EXTERNAL BALLAST RESISTER ..................................................................................................................................................................................................................................................................................................................... 30

G. ELECTRICAL WIRING - GENERATOR TO ALTERNATOR CONVERSION (IGNITION/CHARGING/FUEL PUMP SAFETY & CARB PRIMER SWITCH CIRCUIT; GM 63 AMP. ALTERNATOR W/INTERNAL VOLTAGE REGULATOR, 12 VOLT, 10-SI SERIES, O’REILLY PART NUMBER -

R111621A) USING AN EXTERNAL BALLAST RESISTER ...................................................................................................................................................................................................................................................................................... 31

H. ELECTRICAL WIRING – 6V TO 12V GENERATOR CONVERSION USING 6V OR 12V STARTER AND A STARTER BUTTON USING AN EXTERNAL BALLAST RESISTER ....................................................................................................................................... 32

I. ELECTRICAL WIRING – 6V TO 12V GENERATOR CONVERSION USING 6V OR 12V STARTER AND FOOT PEDAL USING AN EXTERNAL BALLAST RESISTER ................................................................................................................................................ 33

J. ELECTRICAL WIRING – WM300 12V GENERATOR CONVERSION TO ONE WIRE ALTERNATOR W/INTERNAL VOLTAGE REGULATOR USING EXITING WIRING HARNESS............................................................................................................................ 34

K. ELECTRICAL WIRING – WDX 6V GENERATOR CONVERSION TO ONE WIRE 6V ALTERNATOR W/INTERNAL VOLTAGE REGULATOR USING EXITING WIRING HARNESS ............................................................................................................................. 35

L. WDX-PW WIRING DIAGRAM ...................................................................................................................................................................................................................................................................................................... 36

M. 1952 B-1-PW WIRING DIAGRAM ................................................................................................................................................................................................................................................................................................ 37

N. 1955 C-3-PW WIRING DIAGRAM................................................................................................................................................................................................................................................................................................. 38

O. WM300-PW WIRING DIAGRAM.................................................................................................................................................................................................................................................................................................. 39

P. 1971 W100, W200 STARTER RELAY WIRING DIAGRAM................................................................................................................................................................................................................................................................ 40

Q. FUEL SENDER/GAUGE REQUIREMENTS....................................................................................................................................................................................................................................................................................... 41

R. GENERATOR TO ALTERNATOR CONVERSION PARTS ..................................................................................................................................................................................................................................................................... 42

S. ELECTRICAL WIRING – GENERATOR CHARGING CIRCUIT TESTING........................................................................................................................................................................................................................................................... 42

T. ELECTRICAL WIRING – FUSE GUIDE................................................................................................................................................................................................................................................................................................ 42

U. ELECTRICAL WIRING – BULB GUIDE ............................................................................................................................................................................................................................................................................................... 43

V. POLARIZING 6V & 12V GENERATOR VOLTAGE REGULATORS ....................................................................................................................................................................................................................................................... 44

W. 12V ALTERNATOR VOLTAGE REGULATORS.................................................................................................................................................................................................................................................................................. 44

X. COMPLETE WIRING HARNESSES/REGULATORS ........................................................................................................................................................................................................................................................................... 44

Y. TURN SIGNAL WIRING DIAGRAM, UNIVERSAL AND LINK TO VARIOUS POWER WAGON MODEL WIRING DIAGRAMS..................................................................................................................................................................... 44

Z. INSTRUMENT GAUGES/SWITCHES/ SWITCH KNOBS/CIRCUIT BREAKERS...................................................................................................................................................................................................................................... 46

GROUP 8. ENGINE ............................................................................................................................................................................................................................................................................................................................. 51

CRANK CASTING NUMBERS (CCN).............................................................................................................................................................................................................................................................................................................. 58

Page | 3

GROUP 9. ENGINE OILING ................................................................................................................................................................................................................................................................................................................. 58

GROUP 10. EXHAUST .......................................................................................................................................................................................................................................................................................................................... 60

GROUP 11. FENDERS AND SHEET METAL ............................................................................................................................................................................................................................................................................................ 60

GROUP 12. FRAME .............................................................................................................................................................................................................................................................................................................................. 61

GROUP 13. FUEL ................................................................................................................................................................................................................................................................................................................................. 62

GROUP 14. HOOD ............................................................................................................................................................................................................................................................................................................................... 63

GROUP 15. PROPELLER SHAFTS AND UNIVERSAL JOINTS .................................................................................................................................................................................................................................................................... 64

GROUP 16. SPRINGS ........................................................................................................................................................................................................................................................................................................................... 64

GROUP 17. STEERING.......................................................................................................................................................................................................................................................................................................................... 69

GROUP 18. TRANSMISSION................................................................................................................................................................................................................................................................................................................. 71

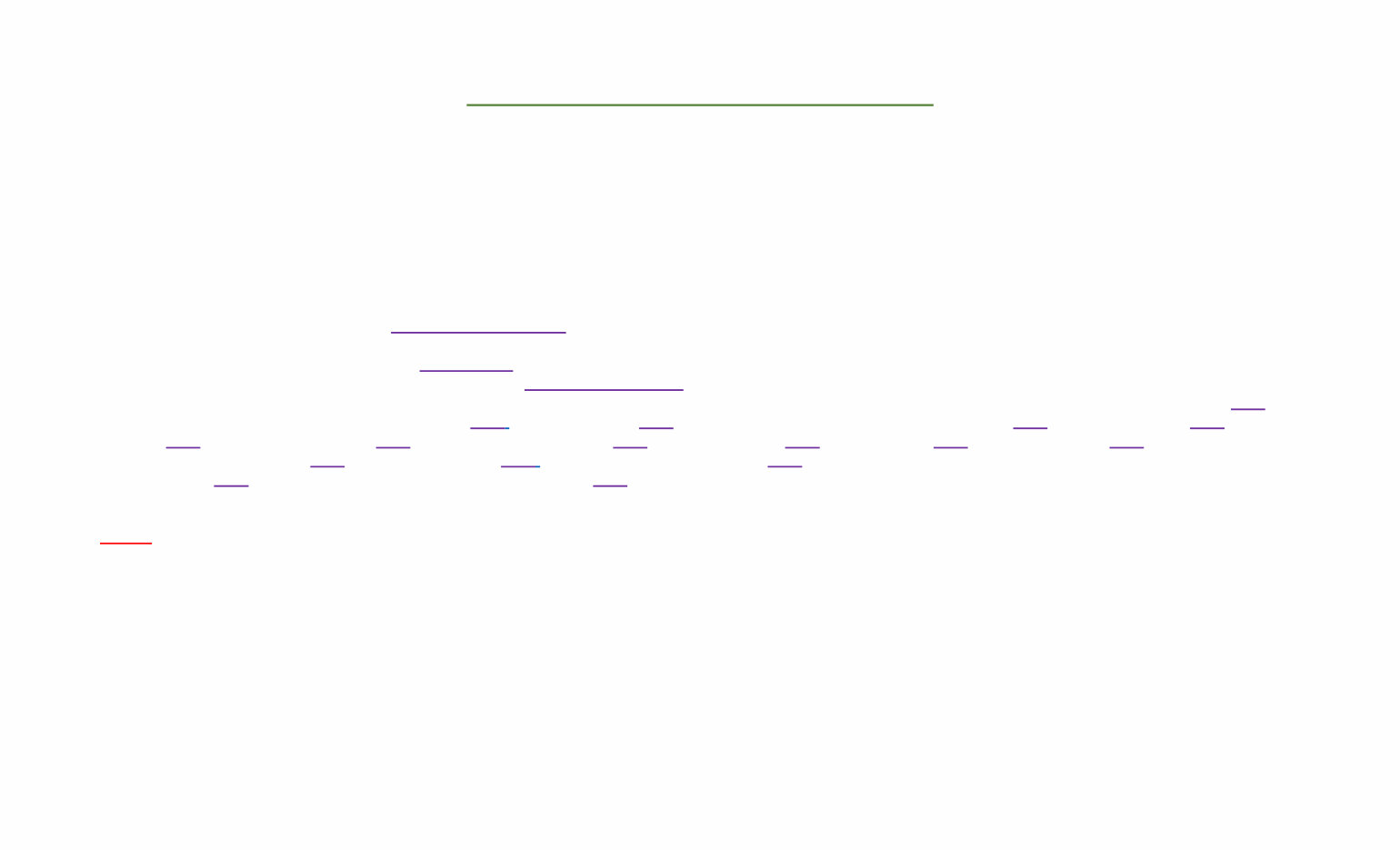

a. 1933 – 1951 DODGE TRUCK PARTS INTERCHANGE BETWEEN THE WARNER T9 SPUR GEAR AND NEW PROCESS SPUR GEAR TRANSMISSIONS, 35661, AND 38126 AS INDICATED BY PART NUMBERS ..................................... 74

b. 1940 – 1951 OTHER TRUCK PARTS INTERCHANGE BETWEEN THE WARNER T9 SPUR GEAR AND NEW PROCESS SPUR GEAR TRANSMISSIONS, 35661, AND 38126 AS INDICATED BY PART NUMBERS ...................................... 76

c. 1941 – 1956 DODGE TRUCK PARTS INTERCHANGE BETWEEN THE 38711 HEAVY DUTY TRANSMISSION, 38750, AND 38780 AS INDICATED BY PART NUMBERS ............................................................................................... 78

d. IMAGES OF NEW GEARS ........................................................................................................................................................................................................................................................................................................ 80

e. AFTERMARKET TRANSMISSION GEARS by BORG-WARNER & PERFECTION GEAR COMPANIES (B&P) – PART NUMBERS ........................................................................................................................................................... 81

f. DIFFERENCE BETWEEN THE EARLY M37 TRANSMISSION MODEL 88950 AND LATE M37B1 MODEL 4201 AND K6-W300-X3-WM300 TRANSMISSION MODEL NP420 ....................................................................................... 81

g. TRANSMISSION REPAIR MANUAL REFERENCE NUMBERS........................................................................................................................................................................................................................................................ 87

h. OVERDRIVE UNITS ................................................................................................................................................................................................................................................................................................................. 87

GROUP 19. TRANSFER CASE ................................................................................................................................................................................................................................................................................................................ 87

GROUP 20. PTO................................................................................................................................................................................................................................................................................................................................... 89

GROUP 21. WINCH .............................................................................................................................................................................................................................................................................................................................. 92

GROUP 22. BELT PULLEY ..................................................................................................................................................................................................................................................................................................................... 95

GROUP 23. WHEELS ............................................................................................................................................................................................................................................................................................................................ 95

GROUP 24. BODY ................................................................................................................................................................................................................................................................................................................................ 99

GROUP 25. TECHNICAL/GENERAL INFORMATION/PART SOURCES.................................................................................................................................................................................................................................................... 100

A. VARIOUS DIMENSIONS AFFECTED BY GROSS VEHICLE WEIGHT.................................................................................................................................................................................................................................................. 102

B. FRAME DEMENSIONS CHART ................................................................................................................................................................................................................................................................................................... 105

C. GEAR LUBRICANT..................................................................................................................................................................................................................................................................................................................... 106

D. WC 3/4/FFPW/M37 TOWING CAPACITY ................................................................................................................................................................................................................................................................................... 108

GROUP 26. U. S. MILITARY TRUCKS, WWII & KOREA ERA MODELS – UNIVERSAL JOINTS .................................................................................................................................................................................................................. 109

Page | 4

¼ TON MILITARY TRUCKS – MADE BY FORD AND WILLYS ............................................................................................................................................................................................................................................................................... 109

½ TON MILITARY TRUCKS – MADE BY DODGE ............................................................................................................................................................................................................................................................................................. 109

½ TON MILITARY TRUCKS – MADE BY INTERNATIONAL .................................................................................................................................................................................................................................................................................. 109

¾ TON MILITARY TRUCKS – MADE BY CHEVROLET ........................................................................................................................................................................................................................................................................................ 109

¾ TON MILITARY TRUCKS – MADE BY DODGE ............................................................................................................................................................................................................................................................................................. 109

1 TON MILITARY TRUCKS – MADE BY INTERNATIONAL ................................................................................................................................................................................................................................................................................... 110

1-1/2 TON MILITARY TRUCKS – MADE BY CHEVROLET .................................................................................................................................................................................................................................................................................. 110

1-1/2 TON MILITARY TRUCKS – MADE BY DODGE ....................................................................................................................................................................................................................................................................................... 110

2-1/2 TON MILITARY TRUCKS – MADE BY INTERNATIONAL............................................................................................................................................................................................................................................................................. 110

2-1/2, 3 TON MILITARY TRUCK – MADE BY INTERNATIONAL .......................................................................................................................................................................................................................................................................... 110

2-1/2 TON MILITARY TRUCKS – MADE BY REO & STUDEBAKER ....................................................................................................................................................................................................................................................................... 110

2-1/2 TON MILITARY TRUCKS – MADE BY GMC ......................................................................................................................................................................................................................................................................................... 111

3 TON MILITARY TRUCK – MADE BY INTERNATIONAL .................................................................................................................................................................................................................................................................................... 111

3-1/2 TON MILITARY TRUCK – MADE BY INTERNATIONAL .............................................................................................................................................................................................................................................................................. 111

4 TON MILITARY TRUCKS – MADE BY DIAMOND T ........................................................................................................................................................................................................................................................................................ 111

4-5 TON MILITARY TRUCKS – MADE BY AUTOCAR, WHITE, FEDERAL ................................................................................................................................................................................................................................................................ 111

5 TON MILITARY TRUCKS – MADE BY DIAMOND T, INT. HAR., & MACK ............................................................................................................................................................................................................................................................ 112

5-6 TON MILITARY TRUCKS – MADE BY AUTOCAR ........................................................................................................................................................................................................................................................................................ 112

5-6 TON MILITARY TRUCKS – MADE BY COLEMAN ....................................................................................................................................................................................................................................................................................... 112

6 TON MILITARY TRUCKS – MADE BY BROCKWAY, FOUR-WHEEL-DRIVE & WHITE ............................................................................................................................................................................................................................................... 112

6 TON MILITARY TRUCKS – MADE BY MACK ............................................................................................................................................................................................................................................................................................... 112

7-1/2 TON MILITARY TRUCKS – MADE BY BIEDERMAN ................................................................................................................................................................................................................................................................................. 113

7-1/2 & 10 TON MILITARY TRUCKS – MADE BY MACK ................................................................................................................................................................................................................................................................................. 113

10 TON MILITARY TRUCKS – MADE BY MACK & WHITE ................................................................................................................................................................................................................................................................................ 113

12 TON MILITARY TRUCKS – MADE BY DIAMOND T & FOUR-WHEEL-DRIVE....................................................................................................................................................................................................................................................... 113

12 & 20 TON MILITARY TRUCKS – MADE BY FEDERAL................................................................................................................................................................................................................................................................................... 114

10 TON CRANE CARRIERS OR ¾ YARD POWER SHOVEL – MADE BY AVAILABLE AND P. & H. ................................................................................................................................................................................................................................... 114

20 TON CRANE CARRIERS– MADE BY FOUR-WHEEL-DRIVE ............................................................................................................................................................................................................................................................................ 114

20 TON CRANE CARRIERS– MADE BY AVAILABLE AND HENDRICKSON ................................................................................................................................................................................................................................................................ 114

6X6 CRASH TRUCKS – MADE BY BIEDERMAN, AMERICAN LA FRANCE & MARMON-HERRINGTON ............................................................................................................................................................................................................................ 115

TRANSPORTERS, TOW TRACTORS & FIRE TRUCKS ......................................................................................................................................................................................................................................................................................... 115

GROUP 27. IMAGES - RARE PARTS .................................................................................................................................................................................................................................................................................................... 116

A. UNIVERSAL JOINTS ....................................................................................................................................................................................................................................................................................................................... 116

B. RUBBER TRANSMISSION PAD........................................................................................................................................................................................................................................................................................................... 118

C. MILITARY DODGE REGULATORS ....................................................................................................................................................................................................................................................................................................... 119

D. REAR PTO SHAFT CENTER BEARING INSULATOR .................................................................................................................................................................................................................................................................................. 120

E. CAB RUBBER INSULATORS .............................................................................................................................................................................................................................................................................................................. 121

F. PINTLE HOOKS ............................................................................................................................................................................................................................................................................................................................ 122

G. THERMOSTAT ELBOWS .................................................................................................................................................................................................................................................................................................................. 127

Page | 5

H. 218/230 EXHAUST MANIFOLDS...................................................................................................................................................................................................................................................................................................... 128

I. OEM FFPW POWER STEERING UNITS .............................................................................................................................................................................................................................................................................................. 129

J. 251 ENGINE ............................................................................................................................................................................................................................................................................................................................... 130

K. REPRODUCTION BODY MOUNT RUBBER INSULATORS ............................................................................................................................................................................................................................................................................ 131

L. NEW ITEM.................................................................................................................................................................................................................................................................................................................................. 133

GROUP 28. TIPS ................................................................................................................................................................................................................................................................................................................................ 134

A. WAKING A SLEEPY TRUCK............................................................................................................................................................................................................................................................................................................... 134

B. STORING A TRUCK LONG TERM........................................................................................................................................................................................................................................................................................................ 135

C. AXLES ....................................................................................................................................................................................................................................................................................................................................... 135

D. BODY ........................................................................................................................................................................................................................................................................................................................................ 135

E. MANUALS .................................................................................................................................................................................................................................................................................................................................. 136

F. TROUBLE SHOOTING ..................................................................................................................................................................................................................................................................................................................... 137

G. SPICER PARTS TO MAKE A FRONT PTO SHAFT ..................................................................................................................................................................................................................................................................................... 137

H. STEERING ADJUSTMENT ................................................................................................................................................................................................................................................................................................................. 137

I. PTO REASSEMBLY ........................................................................................................................................................................................................................................................................................................................ 138

J. DIY PTO 60 DEGREE CONICAL SCREWS ............................................................................................................................................................................................................................................................................................ 142

DIFFERENCE BETWEEN MILITARY AND CIVILIAN CLUTCH FORKS ........................................................................................................................................................................................................................................................................ 148

K. CONVERTING THE CLUTCH FORK FLANGE FROM OIL TO GREASE. ................................................................................................................................................................................................................................................................ 149

L. DISASSEMBLY/ASSEMBLY OF THE AFTER-TYPE TRANSMISSION (BIG SPUR GEAR), CASE# 38711 ..................................................................................................................................................................................................................... 150

M. DISASSEMBLY/ASSEMBLY OF THE AFTER-TYPE TRANSMISSION (BIG SPUR GEAR), CASE# 38711 GEARSHIFT LEVER HOUSING................................................................................................................................................................................. 165

N. INSTALLING A TORQUEFLITE BACK-UP LIGHT SWITCH ON A SPUR GEAR TRANSMISSION.................................................................................................................................................................................................................................. 180

O. TRANSMISSION INTERCHANGE ......................................................................................................................................................................................................................................................................................................... 181

P. DRY ICE CLEANING ....................................................................................................................................................................................................................................................................................................................... 183

Q. STEERING KNUCKLE ASSEMBLY ........................................................................................................................................................................................................................................................................................................ 183

R. INSTALLING STAINLESS STEEL BALANCING BEADS AND VALVES ................................................................................................................................................................................................................................................................. 190

S. INSTALLING A LOCKING GAS CAP ...................................................................................................................................................................................................................................................................................................... 191

T. WATER DISTRIBUTOR TUBE REMOVAL/INSTALLATION ........................................................................................................................................................................................................................................................................... 192

U. USE PLASTIC ZIP TIES TO SEPARATE IGNITION WIRES............................................................................................................................................................................................................................................................................. 199

V. KNUCKLE/SPINDLE REDI-SLEEVE INSTALLATION (UNDER DEVELOPMENT) .................................................................................................................................................................................................................................................... 200

W. TRUCK BUILD CARD CONTACT ......................................................................................................................................................................................................................................................................................................... 201

X. DIY TRANSFER CASE LEVER MOUNTING SHAFT REPLACEMENT ................................................................................................................................................................................................................................................................ 202

Y. WORKING WITH LARGER ELECTRICAL CABLES ...................................................................................................................................................................................................................................................................................... 206

Z. INSTALLING REAR MAIN SEALS, OIL PAN GASKET, AND OIL PUMP ............................................................................................................................................................................................................................................................ 207

AA. INSTALLING THE ARTIC RADIATOR COVER ON THE M37 TRUCK ............................................................................................................................................................................................................................................................ 210

BB. INSTALLING THE SS FUEL TANK ON THE M37 TRUCK. ........................................................................................................................................................................................................................................................................ 212

CC. INSTALLING MANUAL HUB PROTECTORS. ....................................................................................................................................................................................................................................................................................... 213

DD. INSTALLING DRAG LINK DUST COVERS FOR A TIGHT FIT ..................................................................................................................................................................................................................................................................... 214

EE. PARKING BRAKE ADJUSTMENT......................................................................................................................................................................................................................................................................................................... 215

FF. INSTALLING B-3-PW TO X3-WM300 AND M601/M615 NEW REAR ENGINE MOUNT RUBBER INSULATORS USING M37 PARTS. ......................................................................................................................................................................... 217

Page | 6

GG. HOMEMADE TOOLS ................................................................................................................................................................................................................................................................................................................ 221

HH. EXHAUST MANIFOLD HEAT RISER REPAIR ....................................................................................................................................................................................................................................................................................... 222

II. CRANKSHAFT PULLEY REDI-SLEEVE REPAIR ......................................................................................................................................................................................................................................................................................... 223

JJ. FIXING MINOR SHAFT/YOKE PITTING WITH PAINT ................................................................................................................................................................................................................................................................................ 224

KK. NP200 TRANSFER CASE (TC) RE-ASSEMBLY ....................................................................................................................................................................................................................................................................................... 225

LL. PROPELLER (DRIVELINE) VIBRATION .................................................................................................................................................................................................................................................................................................. 236

MM. VENTILATOR WING WEATHERSTRIP REPLACEMENT........................................................................................................................................................................................................................................................................... 237

NN. WINDSHIELD OUTTER GASKET INSTALLATION. ................................................................................................................................................................................................................................................................................. 250

GROUP 29. TROUBLE SHOOTING....................................................................................................................................................................................................................................................................................................... 255

A. ENGINE BACKFIRES ....................................................................................................................................................................................................................................................................................................................... 255

B. VAPOR LOCK ............................................................................................................................................................................................................................................................................................................................... 255

C. ENGINE STALLS ............................................................................................................................................................................................................................................................................................................................ 257

D. ALTERNATOR GOOD, NOT CHARGING BATTERY ................................................................................................................................................................................................................................................................................... 257

E. NEW LUG NUT SEATS.................................................................................................................................................................................................................................................................................................................... 258

F. NEW ITEM.................................................................................................................................................................................................................................................................................................................................. 259

GROUP 30. POWER/DRIVETRAIN CONVERSIONS .............................................................................................................................................................................................................................................................................. 260

A. EARLY HEMI/POLY ENGINE BELLHOUSING .......................................................................................................................................................................................................................................................................................... 260

GROUP 31. MILITARY STANDARDS.................................................................................................................................................................................................................................................................................................... 261

B. RIM – ARMY DWG. NO. 7388452 (RIM ASSEMBLY 2530-00-784-4437 CANCELLED ON OCTOBER 2, 1996, WITH A CANCELLED STATUS OF "ITEM IS CANCELLED WITHOUT REPLACEMENT) ........................................................................................... 261

C. WW2 RUN FLAT OR COMBAT RIM – ARMY DWG. NO. UNKNOWN (CC-924617) ..................................................................................................................................................................................................................................... 263

D. M37 PINTLE HOOK ...................................................................................................................................................................................................................................................................................................................... 264

GROUP 32. MILITARY TOOLS............................................................................................................................................................................................................................................................................................................. 265

Page | 7

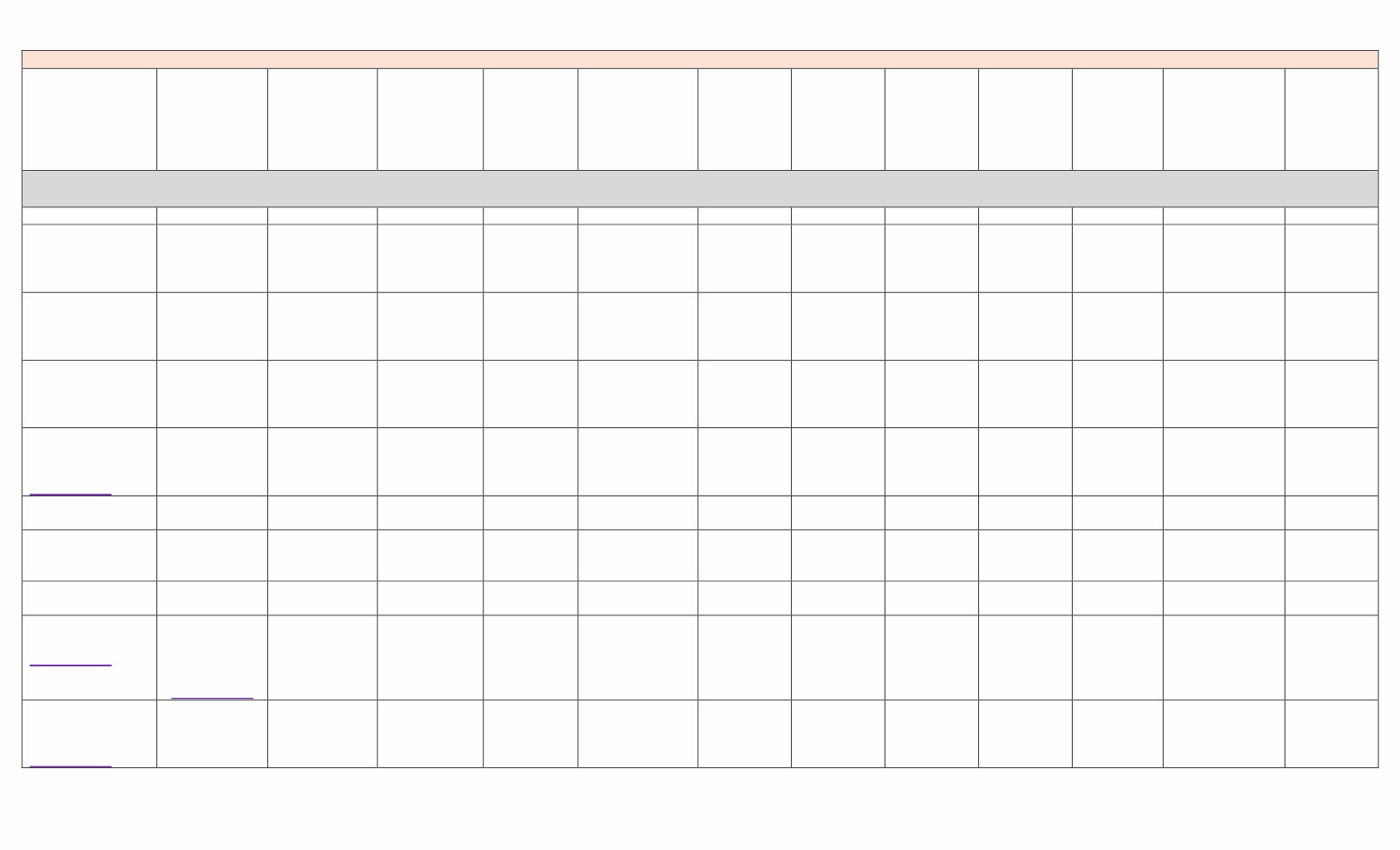

DODGE CIVILIAN and MILITARY TRUCK MODELS

MODULE

COMPONENTS

PRE/WWII

(1/2 Ton 4x4)

VC 1-6

VF 401-407

WC 1-50

1940-42

WWII

(3/4 Ton 4x4)

WC 51-60

1942-45

WWII

(1.5 Ton 6x6)

WC 62-63

1943-45

WDX

(1 Ton 4x4)

1946-48

B1-B3

(1 Ton 4x4)

1948-53

F2PW, F3PW

(1 Ton 4x4)

Fargo

1950-51

C1-C4

(1 Ton 4x4)

1954-56

K-6-300

(1 Ton 4x4)

1957

W300M

(1 Ton 4x4)

1958-59

WM300

(1 Ton 4x4)

1960-1968

X3-WM300

X37BC2

(1 Ton

4x4)

1969-1971

M37/M37B1/M43

(3/4 Ton 4x4)

1950-71

M601/M615

(1 Ton 4x4)

1958-1978

GROUP 1. FRONT AXLE

TRACK WIDTH 61-3/8 64-3/4 64-3/4 64-3/4 64-3/4 64-3/4 64-3/4 64-3/4 64-3/4 64-3/4 62 64-3/4

Axle Differential

Carrier

Assembly

Gasket

No Yes Yes Yes Yes Yes Yes Yes Yes Yes Yes Yes

Axle Differential

Carrier

Assembly Oil

Seal

No Yes Yes Yes Yes Yes Yes Yes Yes Yes Yes Yes

Axle Differential

Carrier

Assembly-3

rd

Member

No Yes Yes Yes Yes Yes Yes Yes Yes Yes Yes Yes

Axle Differential

Locker –

LockRight

Part Source

1210 1210 1210 1210 1210 1210 1210 1210 1210 1210 1210

Axle Drive

Flange

No Yes Yes Yes Yes Yes Yes Yes Yes Yes Yes Yes

Axle Drive

Flange Gasket –

Fel-Pro J26288

No Yes Yes Yes Yes Yes Yes Yes Yes Yes Yes Yes

Axle Housing Oil

Seal

No Yes Yes Yes Yes Yes Yes Yes Yes Yes Yes Yes

Axle Locking

Hub – Selectro

Part Source

11027-01

(Interchanges

w/1954

Chevy Truck)

Part Source

11022-01 11022-01 11022-01 11022-01 11022-01 11022-01 11022-01 11022-01 11022-01 11022-01 11022-01

Axle Locking

Hub –

Superwinch

Part Source

N/A 400508 400508 400508 400508 400508 400508 400508 400508 400508 400508 400508

Page | 8

DODGE CIVILIAN and MILITARY TRUCK MODELS

MODULE

COMPONENTS

PRE/WWII

(1/2 Ton 4x4)

VC 1-6

VF 401-407

WC 1-50

1940-42

WWII

(3/4 Ton 4x4)

WC 51-60

1942-45

WWII

(1.5 Ton 6x6)

WC 62-63

1943-45

WDX

(1 Ton 4x4)

1946-48

B1-B3

(1 Ton 4x4)

1948-53

F2PW, F3PW

(1 Ton 4x4)

Fargo

1950-51

C1-C4

(1 Ton 4x4)

1954-56

K-6-300

(1 Ton 4x4)

1957

W300M

(1 Ton 4x4)

1958-59

WM300

(1 Ton 4x4)

1960-1968

X3-WM300

X37BC2

(1 Ton

4x4)

1969-1971

M37/M37B1/M43

(3/4 Ton 4x4)

1950-71

M601/M615

(1 Ton 4x4)

1958-1978

Warn M13 Style

New Production

Hubs

Part Source

Yes Yes Yes Yes Yes Yes Yes Yes Yes Yes Yes

Axle Locking

Hub – AVM

Part Source

408 408 408 408 408 408 408 408 408 408 408

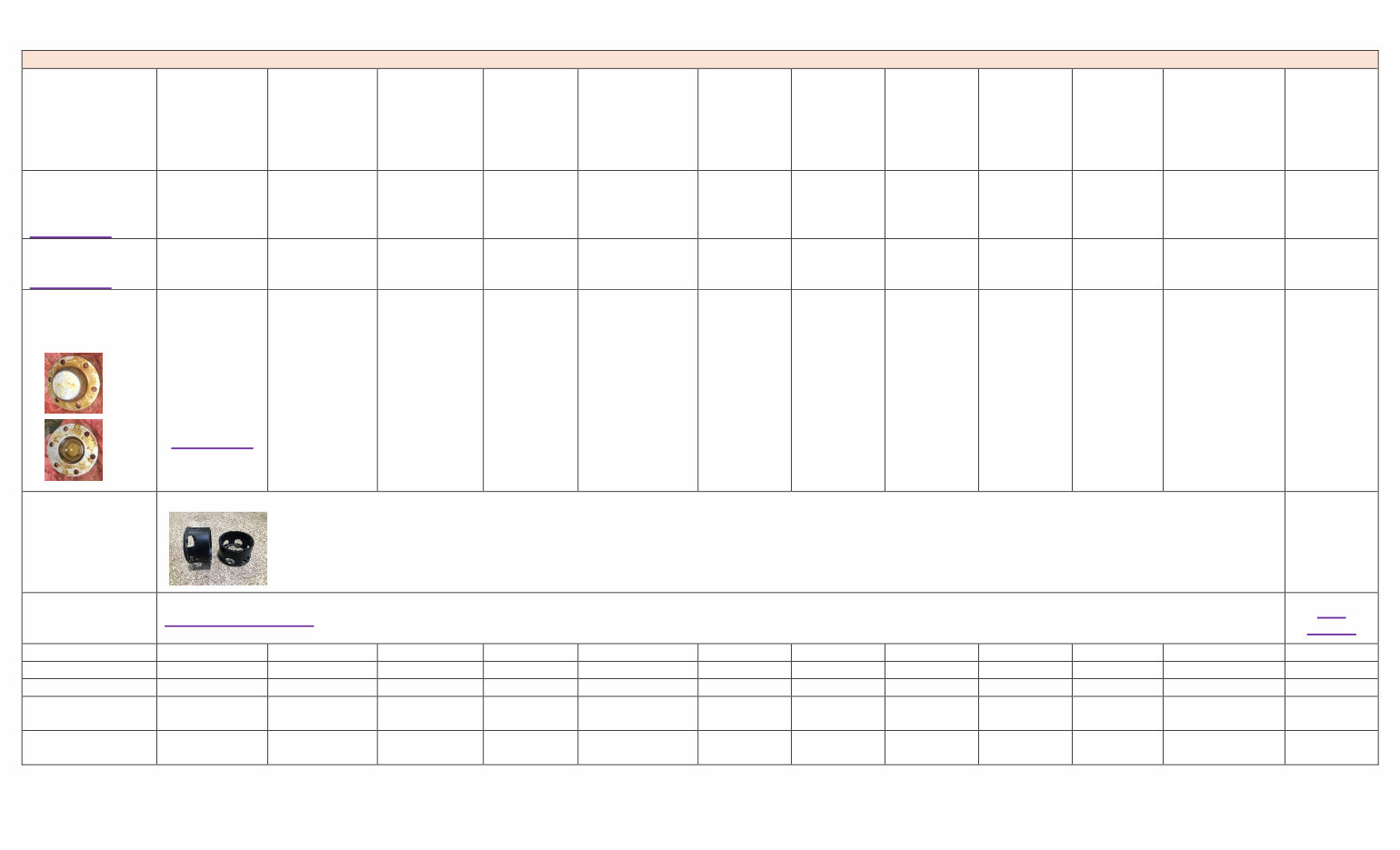

CLARY FLANGE

– Power Wagon,

M-37/WC

Gov't

Contract DA-

04-200-ORD-

448 by the

CAM TOOL

CO. Oakland

CA–Dissolved

Part Source

G-741-

8327043

NSN# 5340-

00-040-1909

G-741-

8327043

NSN# 5340-

00-040-1909

G-741-

8327043

NSN#

5340-00-

040-1909

G-741-8327043

NSN# 5340-00-

040-1909

G-741-

8327043

NSN#

5340-00-

040-1909

G-741-

8327043

NSN#

5340-00-

040-1909

G-741-

8327043

NSN#

5340-00-

040-1909

G-741-

8327043

NSN#

5340-00-

040-1909

G-741-

8327043

NSN#

5340-00-

040-1909

G-741-8327043

NSN# 5340-00-

040-1909

G-741-

8327043

NSN#

5340-00-

040-1909

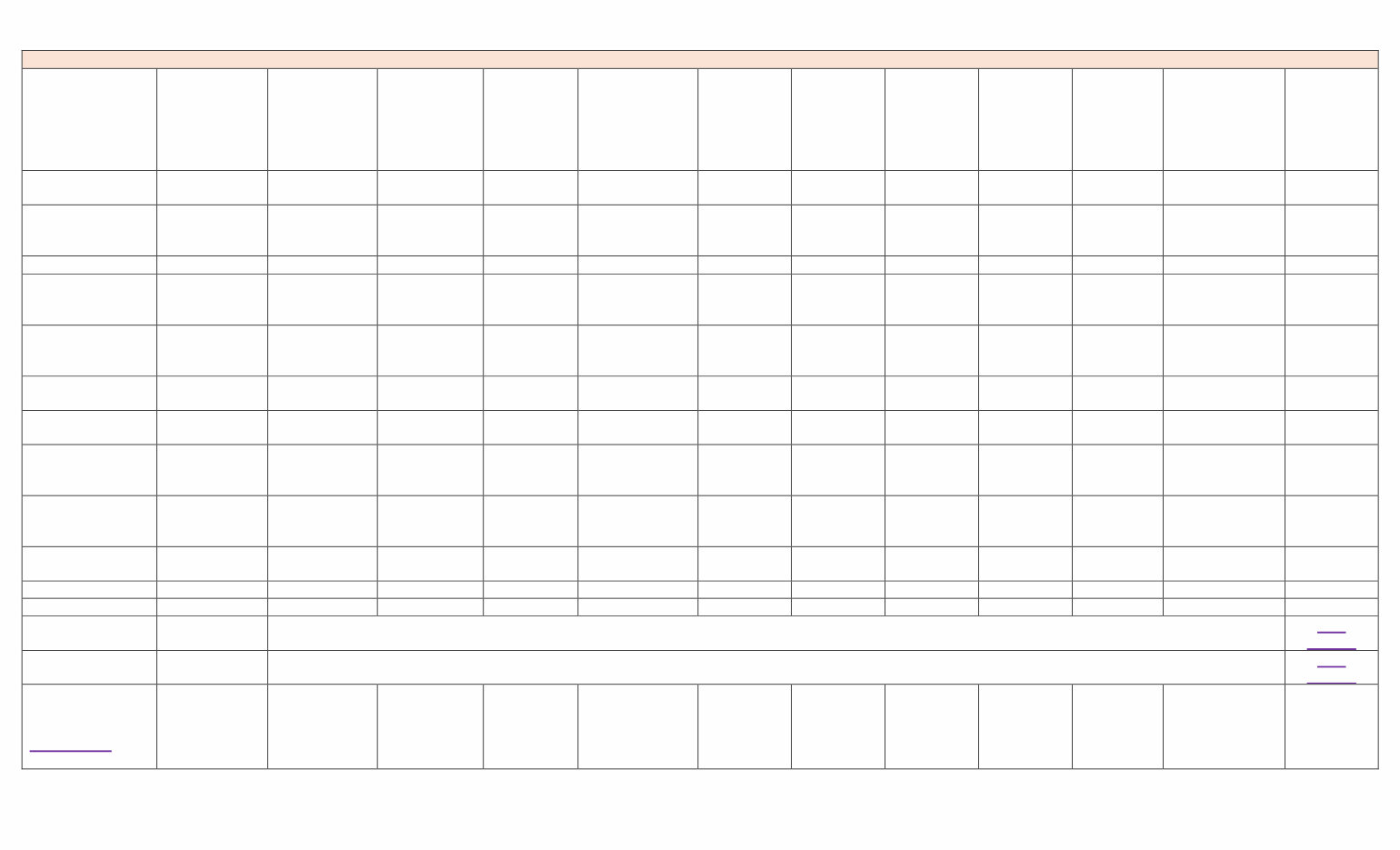

Manual Locking

Hub Protectors

If interested in a set, post a request on the forum, see TIPS Group for installation.

Manual Locking

Hub Protector

Studs

https://arp-bolts.com/ Part - APJ2.500-1SB (Stud, 8740 Chromoly, Black Oxide, 7/16-14 in. Base Thread, 3/8-24 in. Top Thread, 2.5 in. Length)

Part

Source

Axle Shaft Inner No Yes Yes Yes Yes Yes Yes Yes Yes Yes No Yes

Axle Shaft Outter No Yes Yes Yes Yes Yes Yes Yes Yes Yes Yes Yes

Axle Shaft UJ No Yes Yes Yes Yes Yes Yes Yes Yes Yes Yes Yes

Axle Steering

Arm

No Yes No Yes Yes Yes Yes Yes Yes Yes No Yes

Axle Steering

Arm Ball

Yes Yes No Yes Yes Yes Yes Yes Yes Yes No Yes

Page | 9

DODGE CIVILIAN and MILITARY TRUCK MODELS

MODULE

COMPONENTS

PRE/WWII

(1/2 Ton 4x4)

VC 1-6

VF 401-407

WC 1-50

1940-42

WWII

(3/4 Ton 4x4)

WC 51-60

1942-45

WWII

(1.5 Ton 6x6)

WC 62-63

1943-45

WDX

(1 Ton 4x4)

1946-48

B1-B3

(1 Ton 4x4)

1948-53

F2PW, F3PW

(1 Ton 4x4)

Fargo

1950-51

C1-C4

(1 Ton 4x4)

1954-56

K-6-300

(1 Ton 4x4)

1957

W300M

(1 Ton 4x4)

1958-59

WM300

(1 Ton 4x4)

1960-1968

X3-WM300

X37BC2

(1 Ton

4x4)

1969-1971

M37/M37B1/M43

(3/4 Ton 4x4)

1950-71

M601/M615

(1 Ton 4x4)

1958-1978

Axle Trunnion

Pin

No Yes Yes Yes Yes Yes Yes Yes Yes Yes Yes Yes

Axle/Steering

Knuckle Bronze

Bushing

No Yes Yes Yes Yes Yes Yes Yes Yes Yes Yes Yes

Drag Link Tube No Yes No Yes Yes Yes Yes Yes Yes Yes No Yes

Dust Cover

Package – Axle

End

Yes Yes No Yes Yes Yes Yes Yes Yes Yes No Yes

Dust Cover

Package –

Steering End

Yes Yes No Yes Yes Yes Yes Yes Yes Yes No Yes

Felt Pressure

Spring-Retainer

No Yes Yes Yes Yes Yes Yes Yes Yes Yes Yes Yes

Knuckle Flange

Felt Seal-Joint

No Yes Yes Yes Yes Yes Yes Yes Yes Yes Yes Yes

Knuckle Flange

Felt Seal-

Retainer

No Yes Yes Yes Yes Yes Yes Yes Yes Yes Yes Yes

Knuckle Flange

Bronze Upper

Cone

No Yes Yes Yes Yes Yes Yes Yes Yes Yes Yes Yes

Knuckle Flange

Lower Cup

No Yes Yes Yes Yes Yes Yes Yes Yes Yes Yes Yes

Knuckle Flange No Yes Yes Yes Yes Yes Yes Yes Yes Yes Yes Yes

Link Package Yes Yes Yes Yes Yes Yes Yes Yes Yes Yes No Yes

Pinion Oil Seal

No

Timken 6127, SKF 18950 – 1.875 Shaft Dia., Housing Bore Dia. 4.010, Seal Width 1.000 (Leather)

47.630mm 101.850mm 25.400mm

Part

Source

Pinion Oil Seal

Yes

SKF 18924 – 1.875 Shaft Dia., Housing Bore Dia. 3.501, Seal Width .438 (Nitrile)

47.63mm 88.90mm 11.11mm

Part

Source

Pinion Yoke

Speedi-Sleeve#

99187

Part Source

No Yes Yes Yes Yes Yes Yes Yes Yes Yes Yes Yes

Page | 10

DODGE CIVILIAN and MILITARY TRUCK MODELS

MODULE

COMPONENTS

PRE/WWII

(1/2 Ton 4x4)

VC 1-6

VF 401-407

WC 1-50

1940-42

WWII

(3/4 Ton 4x4)

WC 51-60

1942-45

WWII

(1.5 Ton 6x6)

WC 62-63

1943-45

WDX

(1 Ton 4x4)

1946-48

B1-B3

(1 Ton 4x4)

1948-53

F2PW, F3PW

(1 Ton 4x4)

Fargo

1950-51

C1-C4

(1 Ton 4x4)

1954-56

K-6-300

(1 Ton 4x4)

1957

W300M

(1 Ton 4x4)

1958-59

WM300

(1 Ton 4x4)

1960-1968

X3-WM300

X37BC2

(1 Ton

4x4)

1969-1971

M37/M37B1/M43

(3/4 Ton 4x4)

1950-71

M601/M615

(1 Ton 4x4)

1958-1978

Dura Sleeve

Parts Source

Steering Knuckle

- Front

No Yes Yes Yes Yes Yes Yes Yes Yes Yes Yes Yes

Knuckle/Spindle

- Rear Axle

Housing

Yes Yes Yes Yes Yes Yes Yes Yes Yes Yes Yes Yes

Steering Knuckle

Speedi-Sleeve#

99281

Part Source

Yes Yes Yes Yes Yes Yes Yes Yes Yes Yes Yes Yes

Steering Knuckle

Bushing

No Yes Yes Yes Yes Yes Yes Yes Yes Yes Yes Yes

Tie Rod Ends No Yes Yes Yes Yes Yes Yes Yes Yes Yes Yes Yes

Tie Rod End

Right – GMC

CCKW 2.5 Ton

No Yes Yes Yes Yes Yes Yes Yes Yes Yes Yes Yes

Model-Chrysler

F-375 - Full

Floating Front

Axle – WDX to

WM300 Truck

Dana 44, 3,000

Pound Front

Axle – 1957 to

1971, W100 &

W200 Trucks

Identified by 8 Bolt Ball Seals

Part

Source Dana 44, 3,500

Pound HD Front

Axle – 1957 to

1971, W100 &

W200 Trucks

Identified by 12 Bolt Ball Seals

Dana 60 – 1

st

Generation

Identified by its straight axle tubes, passenger side differential drop, 10 bolt asymmetrical cover, a "60" cast into the housing, and 30 spline axles.

You're Reading a Preview

What's Included?

Fast Download Speeds

Online & Offline Access

Access PDF Contents & Bookmarks

Full Search Facility

Print one or all pages of your manual

$41.99

Viewed 18 Times Today

Loading...

Secure transaction

What's Included?

Fast Download Speeds

Online & Offline Access

Access PDF Contents & Bookmarks

Full Search Facility

Print one or all pages of your manual

$41.99

- 1948-1956 Dodge Power Wagon Parts Catalog

- This complete parts catalog provides detailed exploded-view illustrations and parts diagrams, including every OEM part number for any component on your vehicle.

- Parts catalogs are especially useful when looking to order replacement parts or trying to cross-reference part numbers between OEM and aftermarket manufacturers.

- Moreover, while parts catalogs typically do not contain step-by-step procedures like a traditional repair manual would, having access to the exploded-view illustrations can be quite helpful when a workshop manual can't be found.

- In all cases, if you are looking to rebuild/overhaul pretty much anything on your machine or need to order replacement parts and want to be sure you get the right stuff, this is the manual you need!

- Printable: Yes

- Language: English

- Compatibility: Pretty much any electronic device, incl. PC & Mac computers, Android and Apple smartphones & tablet, etc.

- Requirements: Adobe Reader (free)