2007-2009 Dodge Nitro Service & Repair Manual

What's Included?

Fast Download Speeds

Offline Viewing

Access Contents & Bookmarks

Full Search Facility

Print one or all pages of your manual

2007 ENGINE

3.7L - Service Information - Nitro

DESCRIPTION

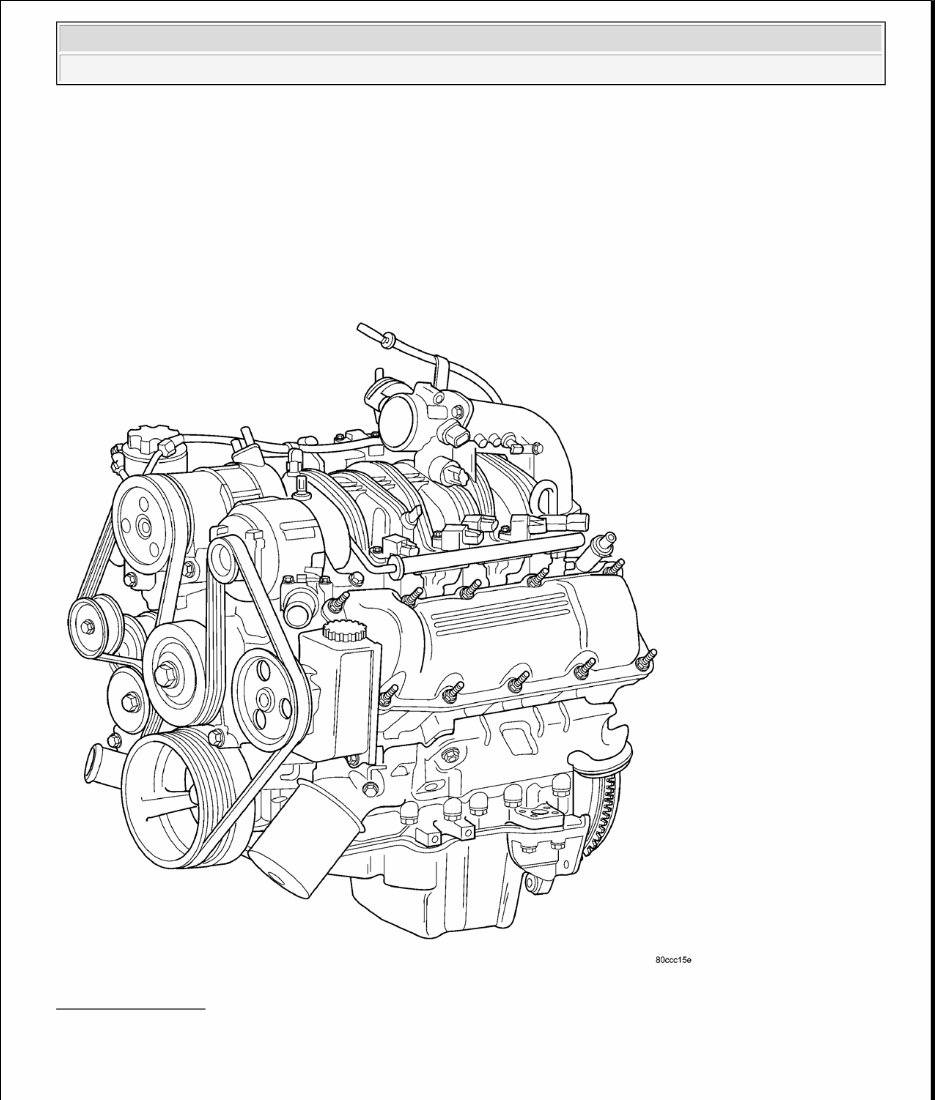

3.7L ENGINE DESCRIPTION

Fig. 1: 3.7L Engine

Courtesy of CHRYSLER LLC

The 3.7 liter (226 CID) six-cylinder engine is an 90° single overhead camshaft engine. The cast iron cylinder

block is made up of two different components; the first component is the cylinder bore and upper block, the

2007 Dodge Nitro R/T

2007 ENGINE 3.7L - Service Information - Nitro

2007 Dodge Nitro R/T

2007 ENGINE 3.7L - Service Information - Nitro

second component is the bedplate that comprises the lower portion of the cylinder block and houses the lower

half of the crankshaft main bearings. The cylinders are numbered from front to rear with the left bank being

numbered 1, 3, and 5 and the right bank being numbered 2, 4, and 6. The firing order is 1-6-5-4-3-2. The engine

serial number is located at the right front side of the engine block. See Fig. 1 .

DIAGNOSIS AND TESTING

CYLINDER COMPRESSION PRESSURE

The results of a cylinder compression pressure test can be utilized to diagnose several engine malfunctions.

Ensure the battery is completely charged and the engine starter motor is in good operating condition. Otherwise

the indicated compression pressures may not be valid for diagnosis purposes.

1. Clean the spark plug recesses with compressed air.

2. Remove the spark plugs.

3. Secure the throttle in the wide-open position.

4. Disable the fuel system (Refer to FUEL DELIVERY - GAS ).

5. Remove the ASD relay. Refer to REMOVAL .

6. Insert a compression pressure gauge and rotate the engine with the engine starter motor for three

revolutions.

7. Record the compression pressure on the 3rd revolution. Continue the test for the remaining cylinders.

8. See SPECIFICATIONS for the correct engine compression pressures.

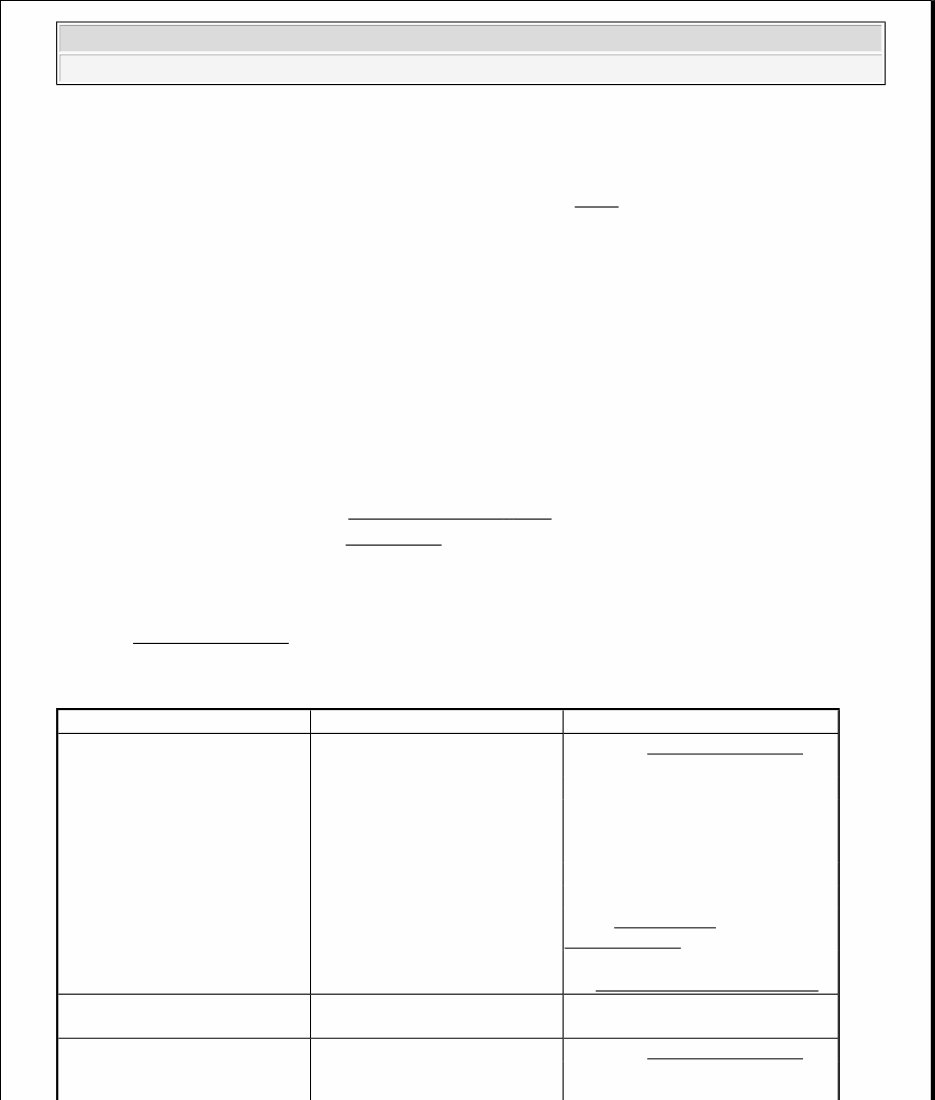

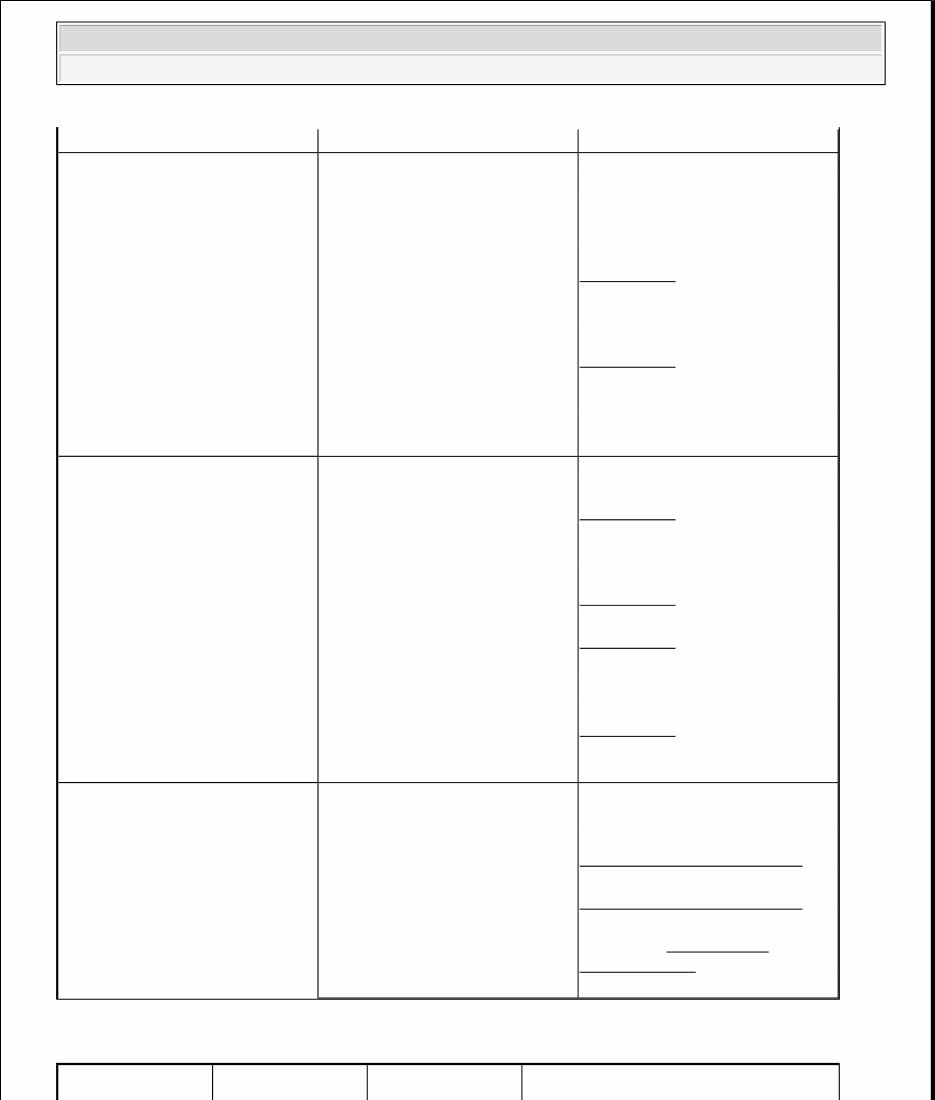

ENGINE MECHANICAL DIAGNOSTIC TABLE

CONDITION POSSIBLE CAUSES CORRECTIONS

NOISY VALVES 1. High or low oil level in

crankcase.

1. Refer to SPECIFICATIONS .

2. Thin or diluted oil. 2. Change oil and filter.

3. Low oil pressure. 3. Check oil pump, if Ok, check rod

and main bearings for excessive

wear.

4. Dirt in lash adjusters. 4. Clean or replace as necessary.

5. Worn rocker arms. 5. Replace as necessary.

6. Worn valve guides. 6. See STANDARD

PROCEDURE .

7. Excessive runout of valve

seats.

7. Service valves and valve seats.

See STANDARD PROCEDURE .

ENGINE VIBRATION 1. Counter Balance Shaft not

timed properly

1. Refer to Engine Timing in this

article

CONNECTING ROD NOISE 1. Insufficient oil supply. 1. Refer to SPECIFICATIONS .

2. Low oil pressure. 2. Check oil pump, if Ok, check rod

and main bearings for excessive

2007 Dodge Nitro R/T

2007 ENGINE 3.7L - Service Information - Nitro

ENGINE DIAGNOSIS - INTRODUCTION

Engine diagnosis is helpful in determining the causes of malfunctions not detected and remedied by routine

maintenance.

These malfunctions may be classified as either performance (e.g, engine idles rough and stalls) or mechanical

(e.g, a strange noise).

See ENGINE PERFORMANCE DIAGNOSTIC TABLE and ENGINE MECHANICAL DIAGNOSTIC

TABLE for possible causes and corrections of malfunctions. Refer to DIAGNOSIS AND TESTING .

Additional tests and diagnostic procedures may be necessary for specific engine malfunctions that can not be

isolated with the Service Diagnosis charts. Information concerning additional tests and diagnosis is provided

within the following diagnosis:

Cylinder Compression Pressure Test. See DIAGNOSIS AND TESTING .

Cylinder Combustion Pressure Leakage Test. See DIAGNOSIS AND TESTING .

Engine Cylinder Head Gasket Failure Diagnosis. See DIAGNOSIS AND TESTING .

Intake Manifold Leakage Diagnosis. See DIAGNOSIS AND TESTING .

CYLINDER COMBUSTION PRESSURE LEAKAGE

The combustion pressure leakage test provides an accurate means for determining engine condition.

Combustion pressure leakage testing will detect:

Exhaust and intake valve leaks (improper seating).

wear.

3. Thin or diluted oil. 3. Change oil and filter.

4. Excessive bearing clearance. 4. Replace as necessary.

5. Connecting rod journal out-of-

round.

5. Service or replace crankshaft.

6. Misaligned connecting rods. 6. Replace bent connecting rods.

MAIN BEARING NOISE 1. Insufficient oil supply. 1. Refer to SPECIFICATIONS .

2. Low oil pressure. 2. Check oil pump, if Ok, check rod

and main bearings for excessive

wear.

3. Thin or diluted oil. 3. Change oil and filter.

4. Excessive bearing clearance. 4. Replace as necessary.

5. Excessive end play. 5. Check thrust washers for wear.

6. Crankshaft journal out-of

round.

6. Service or replace crankshaft.

7. Loose flywheel or torque

converter.

7. Tighten to correct torque

2007 Dodge Nitro R/T

2007 ENGINE 3.7L - Service Information - Nitro

Leaks between adjacent cylinders or into water jacket.

Any causes for combustion/compression pressure loss.

1. Check the coolant level and fill as required. DO NOT install the radiator cap.

2. Start and operate the engine until it attains normal operating temperature, then turn the engine OFF.

3. Remove the spark plugs.

4. Remove the oil filler cap.

5. Remove the air cleaner.

6. Calibrate the tester according to the manufacturer's instructions. The shop air source for testing should

maintain 483 kPa (70 psi) minimum, 1,379 kPa (200 psi) maximum and 552 kPa (80 psi) recommended.

7. Perform the test procedures on each cylinder according to the tester manufacturer's instructions. Set

piston of cylinder to be tested at TDC compression. While testing, listen for pressurized air escaping

through the throttle body, tailpipe and oil filler cap opening. Check for bubbles in the radiator coolant.

All gauge pressure indications should be equal, with no more than 25% leakage.

FOR EXAMPLE: At 552 kPa (80 psi) input pressure, a minimum of 414 kPa (60 psi) should be maintained in

the cylinder.

Refer to step CYLINDER COMBUSTION PRESSURE LEAKAGE DIAGNOSIS CHART .

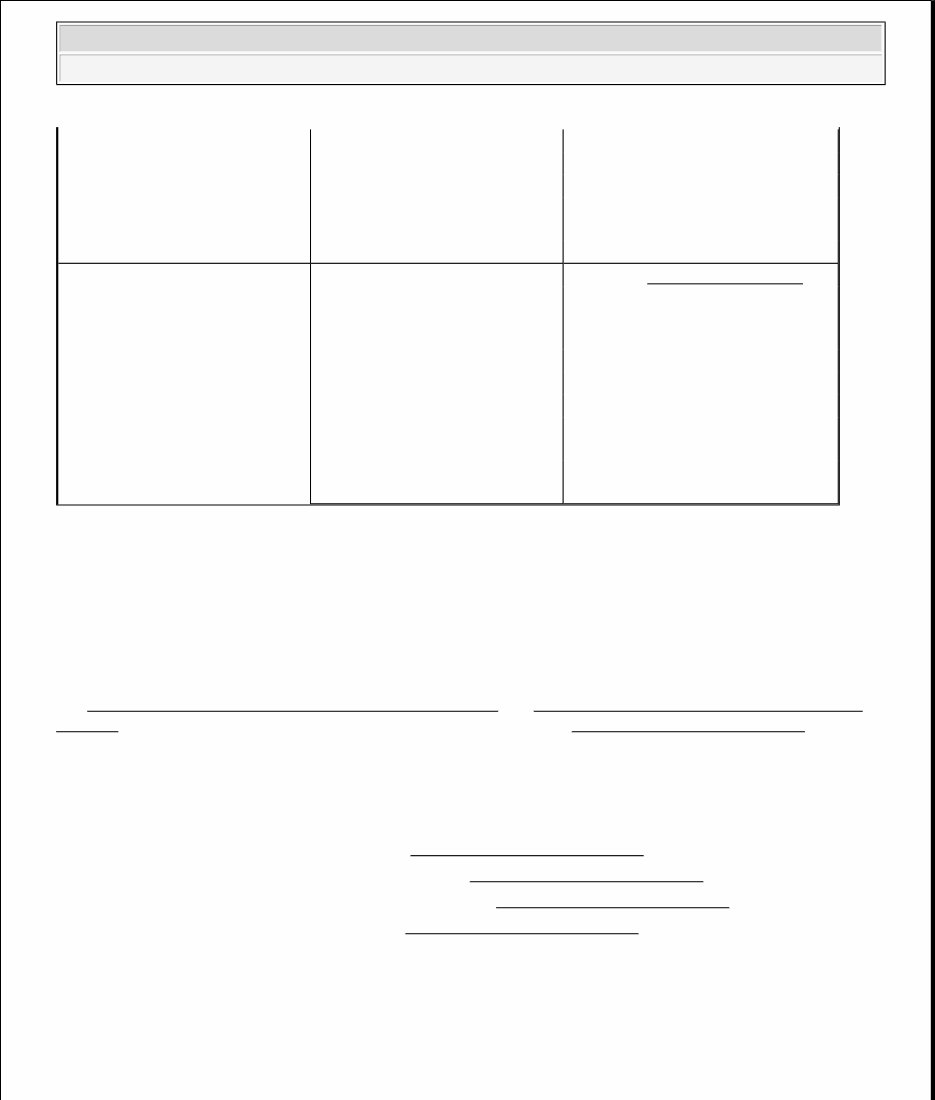

CYLINDER COMBUSTION PRESSURE LEAKAGE DIAGNOSIS CHART

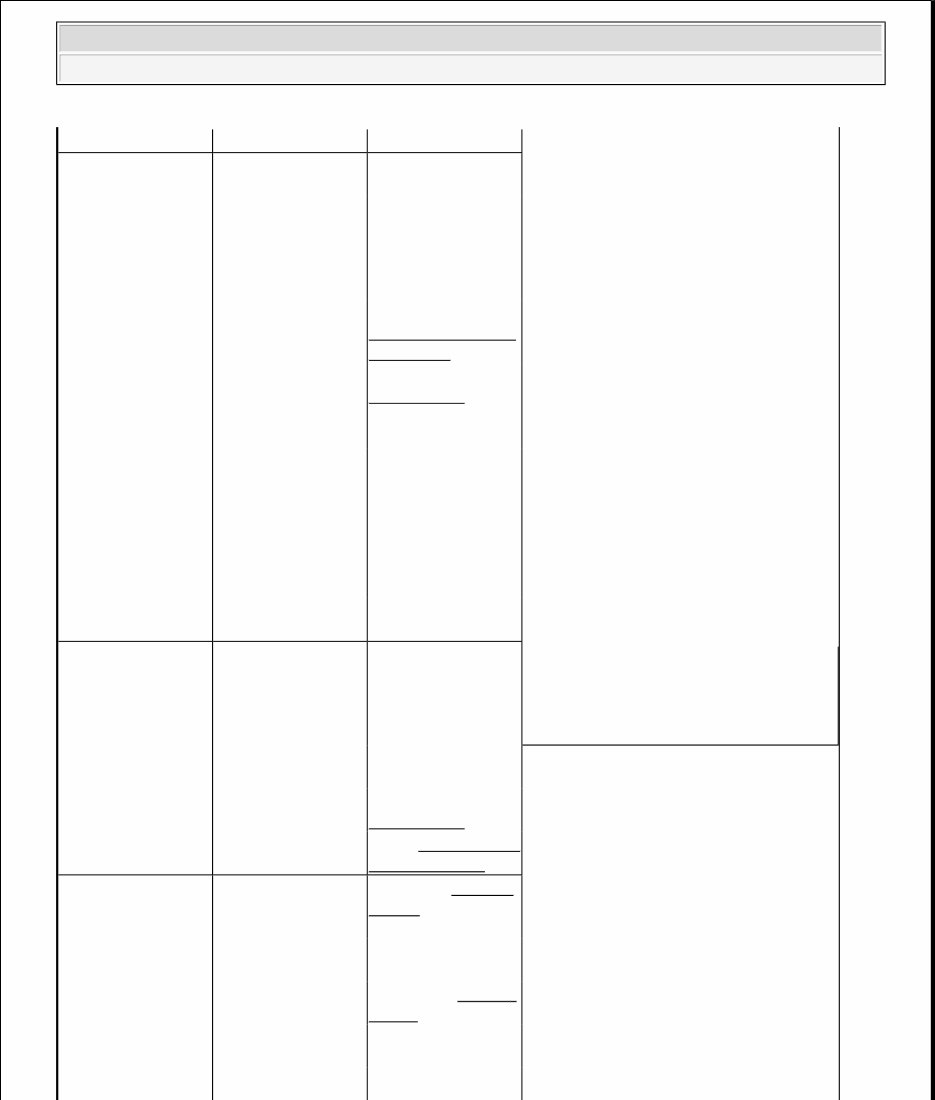

ENGINE LUBRICATION DIAGNOSTIC TABLE

CONDITION POSSIBLE CAUSE CORRECTION

AIR ESCAPES THROUGH

THROTTLE BODY

Intake valve bent, burnt, or not

seated properly

Inspect valve and valve seat.

Reface or replace, as necessary.

Inspect valve springs. Replace as

necessary.

AIR ESCAPES THROUGH

TAILPIPE

Exhaust valve bent, burnt, or not

seated properly

Inspect valve and valve seat.

Reface or replace, as necessary.

Inspect valve springs. Replace as

necessary.

AIR ESCAPES THROUGH

RADIATOR

Head gasket leaking or cracked

cylinder head or block

Remove cylinder head and

inspect. Replace defective part

MORE THAN 50% LEAKAGE

FROM ADJACENT

CYLINDERS

Head gasket leaking or crack in

cylinder head or block between

adjacent cylinders

Remove cylinder head and

inspect. Replace gasket, head, or

block as necessary

MORE THAN 25% LEAKAGE

AND AIR ESCAPES THROUGH

OIL FILLER CAP OPENING

ONLY

Stuck or broken piston rings;

cracked piston; worn rings and/or

cylinder wall

Inspect for broken rings or piston.

Measure ring gap and cylinder

diameter, taper and out-of-round.

Replace defective part as

necessary

2007 Dodge Nitro R/T

2007 ENGINE 3.7L - Service Information - Nitro

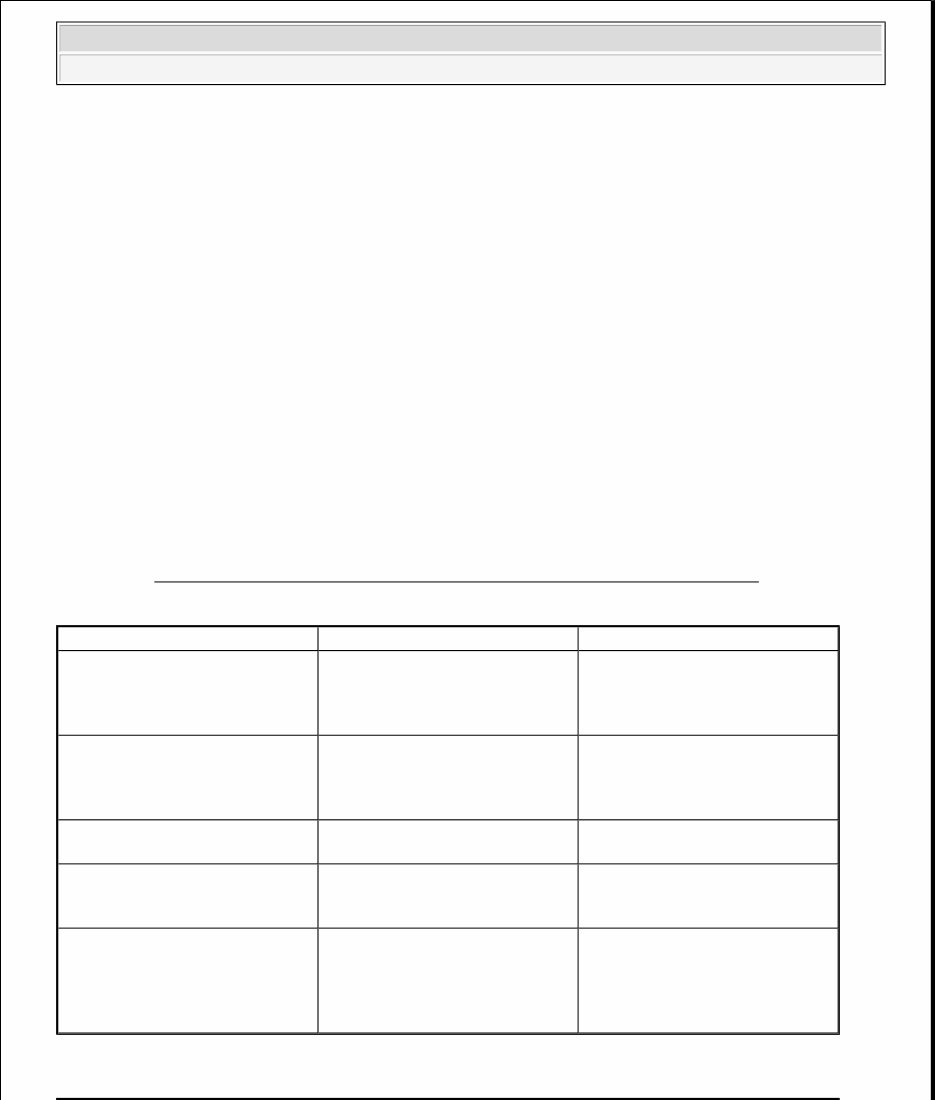

ENGINE PERFORMANCE DIAGNOSTIC TABLE

CONDITION POSSIBLE CAUSES CORRECTION

OIL LEAKS 1. Gaskets and O-Rings. -

(a) Misaligned or damaged. (a) Replace as necessary.

(b) Loose fasteners, broken or

porous metal parts.

(b) Tighten fasteners, Repair or

replace metal parts.

2. Crankshaft rear seal 2. Replace as necessary. See

REMOVAL .

3. Crankshaft seal flange.

Scratched, nicked or grooved.

3. Polish or replace crankshaft.

4. Oil pan flange cracked. 4. Replace oil pan. See

REMOVAL .

5. Timing chain cover seal

damaged.

5. Re-seal timing cover.

6. Scratched or damaged vibration

damper hub.

6. Polish or replace damper.

OIL PRESSURE DROP 1. Low oil level. 1. Check and correct oil level.

2. Faulty oil pressure sending unit. 2. Replace sending unit. See

REMOVAL .

3. Low oil pressure. 3. Check oil pump and bearing

clearance.

4. Clogged oil filter. 4. Replace oil filter. See

REMOVAL .

5. Worn oil pump. 5. Replace oil pump. See

REMOVAL .

6. Thin or diluted oil. 6. Change oil and filter.

7. Excessive bearing clearance. 7. Replace as necessary.

8. Oil pump relief valve stuck. 8. Replace oil pump. See

REMOVAL .

9. Oil pick up tube loose, damaged

or clogged.

9. Replace as necessary.

OIL PUMPING AT RINGS;

SPARK PLUGS FOULING

1. Worn or damaged rings. 1. Hone cylinder bores and replace

rings.

2. Carbon in oil ring slots. 2. Replace rings. See

STANDARD PROCEDURE .

3. Incorrect ring size installed. 3. Replace rings. See

STANDARD PROCEDURE .

4. Worn valve guides. 4. Ream guides and replace

valves. See STANDARD

PROCEDURE .

5. Leaking valve guide seals. 5. Replace valve guide seals.

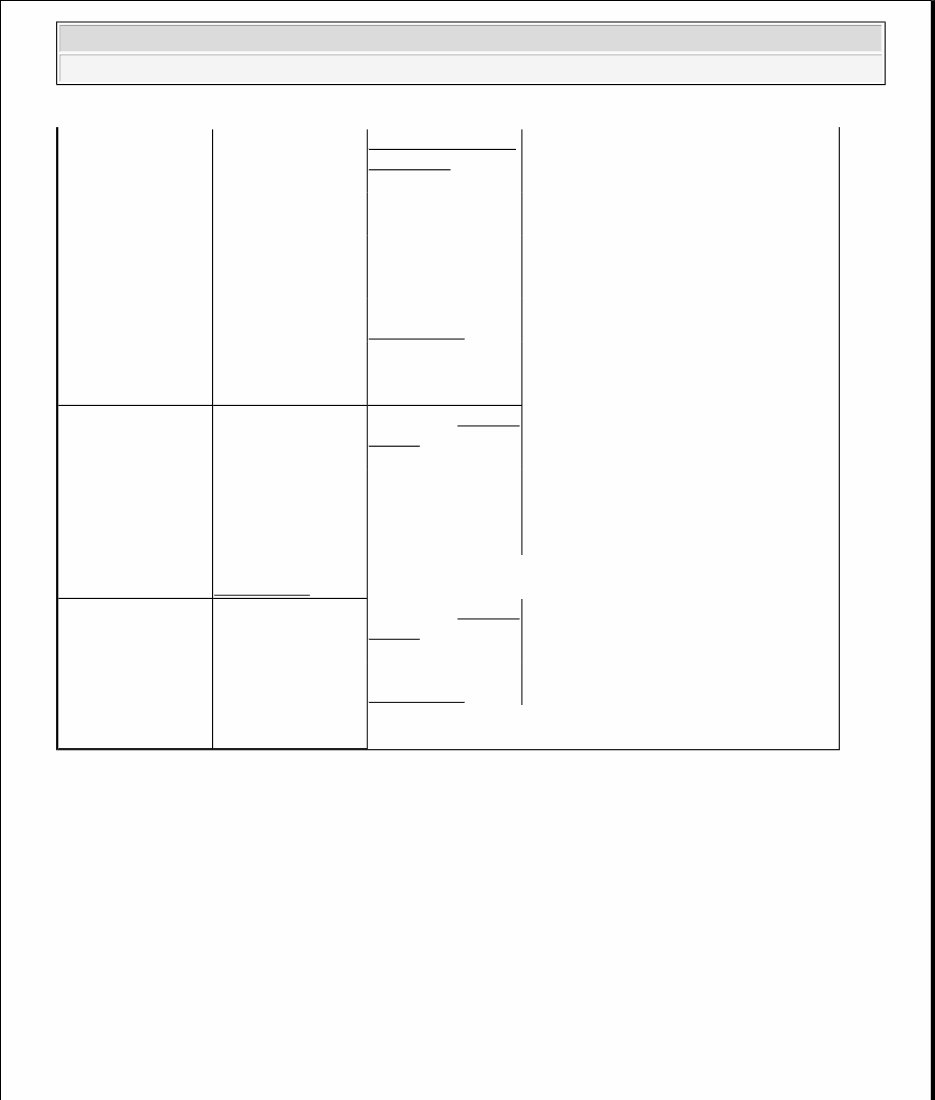

CONDITION POSSIBLE CORRECTION

2007 Dodge Nitro R/T

2007 ENGINE 3.7L - Service Information - Nitro

CAUSE

ENGINE WILL

NOT START

1. Weak battery 1. Charge or replace

as necessary.

2. Corroded or loose

battery connections.

2. Clean and tighten

battery connections.

Apply a coat of

light mineral grease

to the terminals.

3. Faulty starter. 3. Refer to

DIAGNOSIS AND

TESTING .

4. Faulty coil or

control unit.

4. Refer to

REMOVAL .

5. Incorrect spark

plug gap.

5.

6. Incorrect right

bank cam timing.

6. Refer to engine

timing in this

article.

7. Dirt or water in

fuel system.

7. Clean system and

replace fuel filter.

8. Faulty fuel pump,

relay or wiring.

8. Repair or replace

as necessary.

9. Faulty cam or

crank sensor

9. Refer to Ignition

system.

ENGINE STALLS

OR ROUGH IDLE

1. Vacuum leak. 1. Inspect intake

manifold and

vacuum hoses,

repair or replace as

necessary.

-

2. Faulty crank

position sensor

2. Replace crank

position sensor.

3. Faulty coil. 3. Refer to

REMOVAL .

4. Incorrect cam

timing.

4. See STANDARD

PROCEDURE .

ENGINE LOSS OF

POWER

1. Dirty or

incorrectly gapped

spark plugs.

1. Refer to SPARK

PLUG

2. Dirt or water in

fuel system.

2. Clean system and

replace fuel filter.

3. Faulty fuel pump. 3. (Refer to PUMP -

FUEL ).

4. Blown cylinder

head gasket.

4. Replace cylinder

head gasket.

5. Low 5. See

2007 Dodge Nitro R/T

2007 ENGINE 3.7L - Service Information - Nitro

STANDARD PROCEDURE

ENGINE GASKET SURFACE PREPARATION

compression. DIAGNOSIS AND

TESTING , repair

as necessary.

6. Burned, warped

or pitted valves.

6. Replace as

necessary.

7. Plugged or

restricted exhaust

system.

7. Inspect and

replace as

necessary.

8. Faulty coil. 8. Refer to

REMOVAL .

9. Incorrect cam

timing.

9. Refer to Engine

Timing in this

article.

ENGINE MISSES

ON

ACCELERATION

1. Spark plugs dirty

or incorrectly

gapped.

1. (Refer to SPARK

PLUG ).

2. Dirt in fuel

system.

2. Clean fuel

system.

3. Burned, warped

or pitted valves.

3. Replace as

necessary.

4. Faulty coil. 4. Refer to

REMOVAL .

ENGINE MISSES

AT HIGH SPEED

1. Spark plugs dirty

or incorrectly

gapped.

1. (Refer to SPARK

PLUG ).

2. Faulty coil. 2. Refer to

REMOVAL .

3. Dirt or water in

fuel system.

3. Clean system and

replace fuel filter.

2007 Dodge Nitro R/T

2007 ENGINE 3.7L - Service Information - Nitro

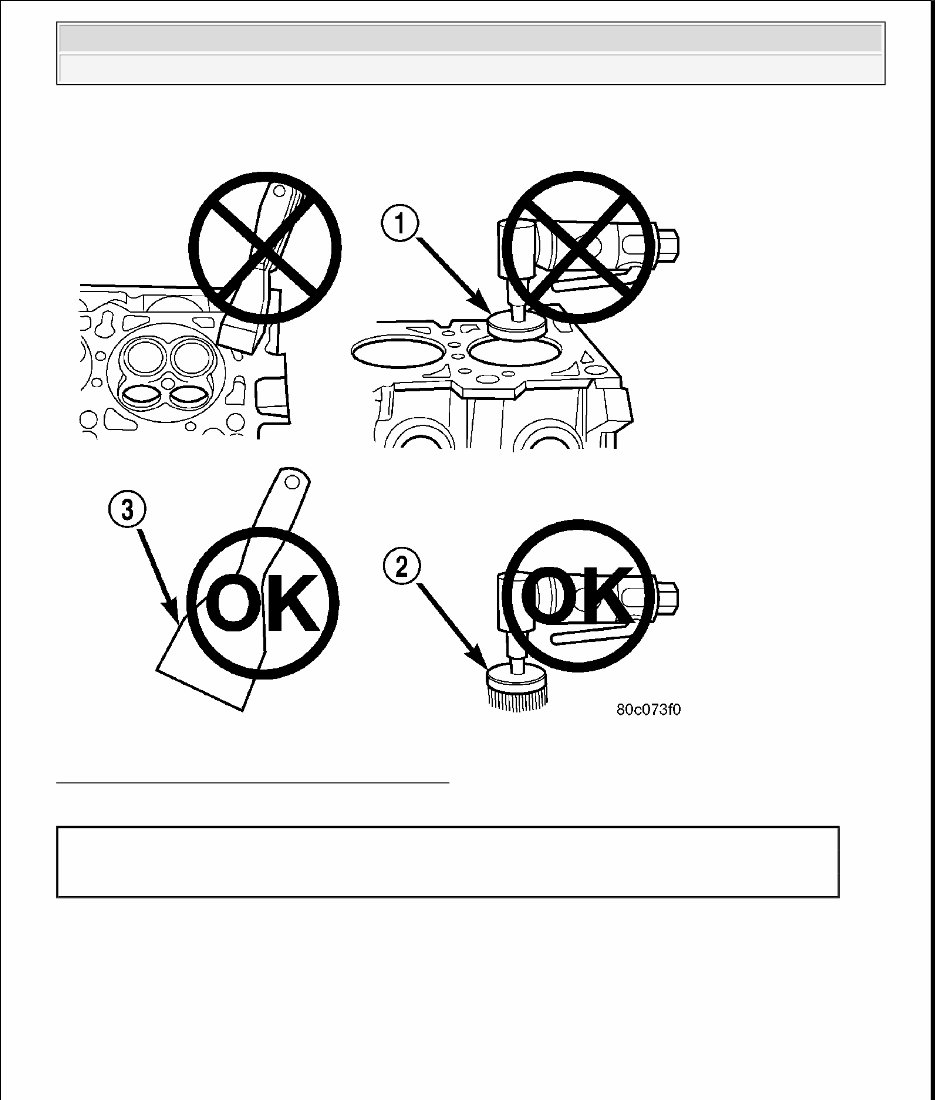

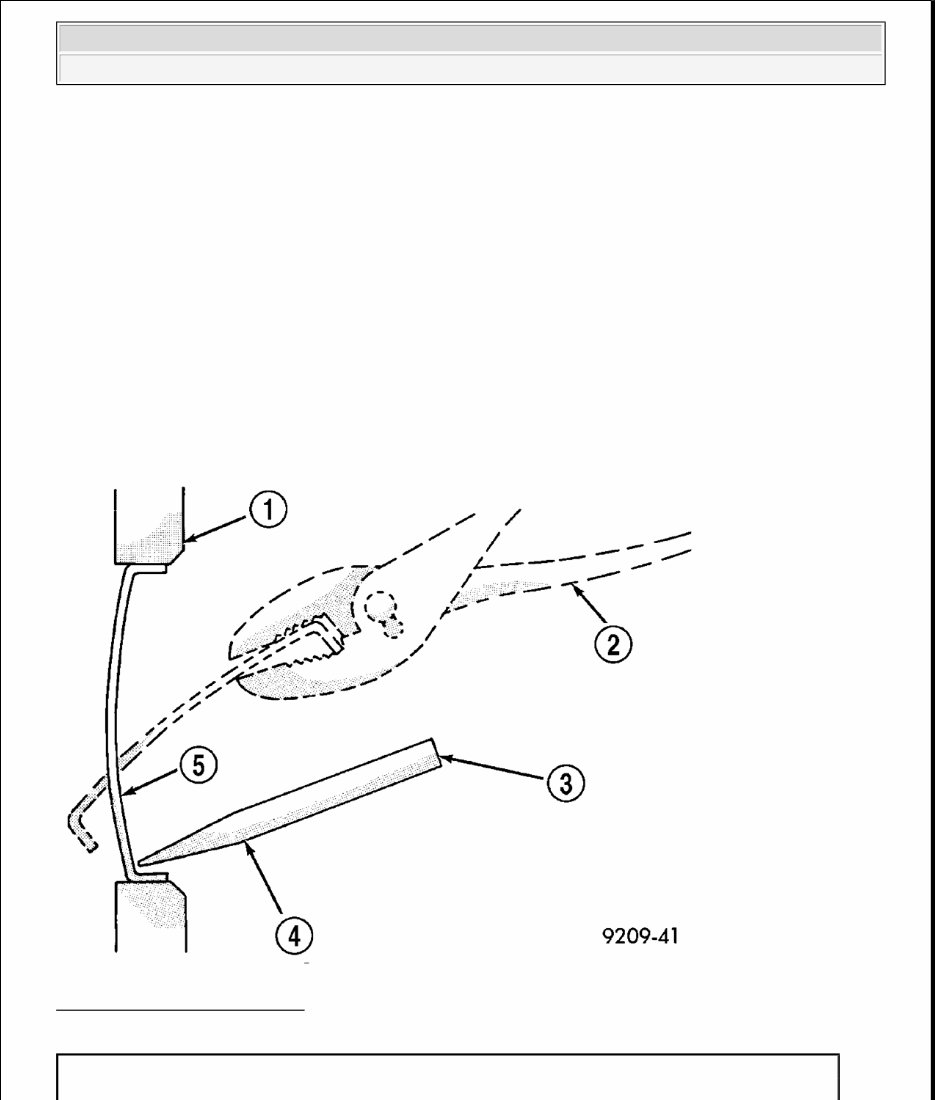

Fig. 2: Proper Tool Usage for Surface Preparation

Courtesy of CHRYSLER LLC

To ensure engine gasket sealing, proper surface preparation must be performed, especially with the use of

aluminum engine components and multi-layer steel cylinder head gaskets.

Never use the following to clean gasket surfaces:

Metal scraper (3).

Abrasive pad (1) or paper to clean cylinder block and head.

High speed power tool (1) with an abrasive pad or a wire brush.

1 - ABRASIVE PAD

2 - 3M ROLOC™ BRISTLE DISC

3 - PLASTIC/WOOD SCRAPER

2007 Dodge Nitro R/T

2007 ENGINE 3.7L - Service Information - Nitro

Only use the following for cleaning gasket surfaces:

Solvent or a commercially available gasket remover

Plastic or wood scraper.

Drill motor with 3M Roloc™ Bristle Disc (white or yellow).

ENGINE CORE AND OIL GALLERY PLUGS

Fig. 3: Core Hole Plug Removal

Courtesy of CHRYSLER LLC

NOTE: Multi-Layer Steel (MLS) head gaskets require a scratch free sealing surface.

CAUTION: Excessive pressure or high RPM (beyond the recommended speed), can

damage the sealing surfaces. The mild (white, 120 grit) bristle disc is

recommended. If necessary, the medium (yellow, 80 grit) bristle disc may

be used on cast iron surfaces with care.

1 - CYLINDER BLOCK

2 - REMOVE PLUG WITH PLIERS

2007 Dodge Nitro R/T

2007 ENGINE 3.7L - Service Information - Nitro

Using a blunt tool such as a drift and a hammer, strike the bottom edge of the cup plug (5). With the cup plug

rotated, grasp firmly with pliers or other suitable tool and remove plug. See Fig. 3 .

Thoroughly clean inside of cup plug hole in cylinder block or head. Be sure to remove old sealer. Lightly coat

inside of cup plug hole with Mopar® Stud and Bearing Mount. Make certain the new plug is cleaned of all oil

or grease. Using proper drive plug, drive plug into hole so that the sharp edge of the plug is at least 0.5 mm

(0.020 in.) inside the lead-in chamfer.

It is not necessary to wait for curing of the sealant. The cooling system can be refilled and the vehicle placed in

service immediately.

REPAIR DAMAGED OR WORN THREADS

Damaged or worn threads can be repaired. Essentially, this repair consists of:

Drilling out worn or damaged threads.

Tapping the hole with a special Heli-Coil Tap, or equivalent.

Installing an insert into the tapped hole to bring the hole back to its original thread size.

REMOVAL

REMOVAL

3 - STRIKE HERE WITH HAMMER

4 - DRIFT PUNCH

5 - CUP PLUG

CAUTION: Do not drive cup plug into the casting as restricted cooling can result and

cause serious engine problems.

CAUTION: Be sure that the tapped holes maintain the original center line.

2007 Dodge Nitro R/T

2007 ENGINE 3.7L - Service Information - Nitro

You're Reading a Preview

What's Included?

Fast Download Speeds

Offline Viewing

Access Contents & Bookmarks

Full Search Facility

Print one or all pages of your manual

$36.99

Viewed 14 Times Today

Loading...

Secure transaction

What's Included?

Fast Download Speeds

Offline Viewing

Access Contents & Bookmarks

Full Search Facility

Print one or all pages of your manual

$36.99

Official Factory Service Repair Workshop Manual for 2007-2009 Dodge Nitro

- File Format: PDF

- Compatibility: Win95/98/ME/XP/Vista/7/8/8.1/10/Linux/MAC/IOS/Android

- Language: English

This comprehensive 2007-2009 Dodge Nitro service and repair manual is designed for both professional mechanics and DIY enthusiasts. It delivers all the necessary instructions needed for any repair your vehicle may require from bumper to bumper. Technicians and mechanics use this manual to diagnose and repair vehicles with confidence, relying on clear, concise text and detailed illustrations. Whether you have a basic or advanced level of mechanical knowledge, this manual offers comprehensive diagrams, in-depth illustrations, and all the manufacturer’s specifications and technical information required.

Contents of the Manual:

- Introduction

- Electrical Wiring Manual

- Maintenance

- Preparation

- Service Specifications

- Diagnostics

- Engine Mechanical

- Emission Control

- Fuel Systems

- Cooling Systems

- Lubrication

- Ignition

- Starter

- Charging System

- Clutch

- Manual Transmission

- Automatic Transmission

- Transfer Case

- Propeller Shaft

- Suspension & Axle

- Brake

- Steering

- Restraint System

- Body Electrical

- Body

- Air Conditioning

- And much more