1997 Dodge Intrepid Service & Repair Manual

What's Included?

Fast Download Speeds

Offline Viewing

Access Contents & Bookmarks

Full Search Facility

Print one or all pages of your manual

ENGINES

CONTENTS

page page

3. 3L ENGINE .......................... 12

3. 5L ENGINE .......................... 48

ENGINE DIAGNOSIS ...................... 7

STANDARD SERVICE INFORMATION ........ 1

STANDARD SERVICE INFORMATION

INDEX

page page

GENERAL INFORMATION

CHECKING ENGINE OIL LEVEL ............. 3

ENGINE OIL SERVICE .................... 4

ENGINE PERFORMANCE ................. 2

FORM-IN-PLACE GASKETS ................ 1

MEASURING MAIN BEARING AND

CONNECTING ROD BEARING

CLEARANCES ........................ 2

SERVICE PROCEDURES

ENGINE CORE PLUGS ................... 6

HONING CYLINDER BORES ............... 5

HYDROSTATIC LOCKED ENGINE ........... 5

REPAIR OF DAMAGED OR WORN THREADS .. 5

GENERAL INFORMATION

FORM-IN-PLACE GASKETS

There are numerous places where form-in-place

gaskets are used on theengine. Care must be taken

when applying form-in-place gaskets to assure

obtaining the desired results. Do not use form-in-

place gasket material unless specified. Bead size,

continuity , and location are of great importance. T oo

thin a bead can result in leakage while too much can

result in spill-over which can break off and obstruct

fluid feed lines. A continuous bead of the proper

width is essential toobtain a leak-free gaskets.

There are numerous types of form-in-place gasket

materials are used in the engine area. Mopar Sili-

cone Rubber Adhesive Sealant and Mopar Gasket

Maker gasket materials, eachhave different proper-

ties and cannot be used in place of the other .

MOPAR SILICONE RUBBER ADHESIVE

SEALANT

Mopar Silicone Rubber Adhesive Sealant or equiv-

alent, normally black in color , is available in three

ounce tubes. Moisture in the air causes the Mopar

Silicone Rubber Adhesive Sealant material tocure.

This material is normally used on flexible metal

flanges. It has a shelf life of one year and will not

properly cure ifover age. Always inspectthe package

for theexpiration date before use.

MOPAR GASKET MAKER

Mopar Gasket Maker is an anaerobic type gasket

material. The material cures in the absence of air

when squeezed between two metallic surfaces. It will

not cure if left in the uncovered tube. The anaerobic

material is for use between two machined surfaces.

Do not use on flexible metal flanges.

GASKET DISASSEMBLY

Parts assembled with form-in-place gaskets may be

disassembled without unusual effort. In some

instances, it may be necessary to lightly tap the part

with a mallet or other suitable tool to break the seal

between the mating surfaces. Aflat gasket scraper

may also be lightly tapped into the joint but care

must be takennotto damage the mating surfaces.

SURFACE PREPARATION

Scrape clean or wire brush all gasket surfaces

removing all loose material. Inspect stampedparts to

assure gasket rails are flat. Flatten rails with a ham-

mer on a heavy steel plate if required. Gasket sur-

faces must be free of oil and dirt. Make sure old

gasket material is removed from blind attaching

holes.

LH ENGINES 9 - 1

FORM-IN-PLACE GASKET APPLICATION

Assembling parts using a form-in-place gasket

requires care but it’s easier thenusing precut gas-

kets.

Mopar Gasket Maker material should be applied

sparingly 1 mm (0.040 inch.) diameter or less of seal-

anttoone gasket surface. Be certain the material

surrounds each mounting hole. Excess material can

easily be wiped off. Componentsshould be torqued in

place within 15 minutes. The use of a locating dowel

is recommended during assembly to prevent smear-

ing material off the location.

The Mopar Silicone Rubber Adhesive Sealant gas-

ket material or equivalent should be applied in a con-

tinuous bead approximately 3 mm (0.120 inch) in

diameter . All mounting holes must be circled. For

corner sealing, a 3.17 or 6.35 mm (1/8 or 1/4 inch.)

drop is placed in the center of the gasket contact

area. Uncured sealant may be removed with a shop

towel. Componentsshould be torqued in place while

the sealant isstill wetto the touch (within 10 min-

utes). The usage of a locating dowelis recommended

during assembly to prevent smearing material off the

location.

ENGINE PERFORMANCE

If a loss of performance is noticed, ignition timing

should be checked. If ignition timing is retarded by 9,

18 or 27° “it indicates” 1, 2 or 3 (timing belt or chain)

teeth may have skipped. The camshaft and crank-

shafttiming should be checked. Refer to Engine Tim-

ing Sprockets and Oil Seals of the Engine Section.

T o provide best vehicle performance and lowest

vehicle emissions, it is most important that the

tune-up be done accurately . Use the specifications

listed on the V ehicle Emission Control Information

label found in theengine compartment.

(1) T est cranking amperage draw. See Starting

Motor Cranking Amperage Draw ElectricalSection of

this manual.

(2) Tighten the intake manifold bolts to specifica-

tions.

(3) Perform cylinder compression test. See diagno-

sis and testing in thissection.

(4) Clean orreplace spark plugs as necessary and

adjust gap asspecified in Electrical Group 8. Tighten

to specifications.

(5) T est resistance of spark plug cables. Refer to

Ignition System Secondary Circuit Inspection Electri-

calSection Group 8.

(6) Inspectthe primary wire. T est coil output volt-

age, primary and secondary resistance. Replace parts

as necessary . Refer to Ignition System and make nec-

essary adjustment.

(7) T est fuel pump for correct pressure. Refer to

FuelSystem Group 14, Specifications.

(8) The air filter elements should be replaced as

specified in Lubrication and Maintenance, Group 0.

(9) Inspect crankcase ventilation system as out

lined in Lubrication and Maintenance, Group 0. For

emission controlssee Emission Controls Group 25 for

service procedures.

(10) Inspect and adjust accessory belt drives refer-

ring to Accessory Belt Drive in Cooling System,

Group 7 for proper adjustments.

(11) Road test vehicle as a final test.

MEASURING MAIN BEARING AND CONNECTING

ROD BEARING CLEARANCES

PLASTIGAGE METHOD

Engine crankshaft bearing clearances can be deter-

mined by use of Plastigage or equivalent. The follow-

ing is the recommended procedure for the use of

Plastigage:

NOTE: The total clearance of the main bearings

can only be determined by removing the weight of

the crankshaft. This can be accomplished by either

of two methods:

PREFERRED METHOD

Shimming the bearings adjacentto the bearing to

be checked in order to remove the clearance between

upper bearing shell and the crankshaft. This can be

accomplished by placing a minimum of 0.254 mm

(0.010 in.) shim (e. g. cardboard, matchbook cover ,

etc.) between the bearing shell and the bearing cap

on the adjacent bearings and tightening bolts to

14-20 N·m (10-15 ft. lbs.). The number of main bear-

ing will vary from engine to engine.

ENGINE WITH 5 MAIN BEARINGS

• When checking #1 main bearing shim #2 main

bearing.

• When checking #2 main bearing shim #1 & 3

main bearing.

• When checking #3 main bearing shim #2 & 4

main bearing.

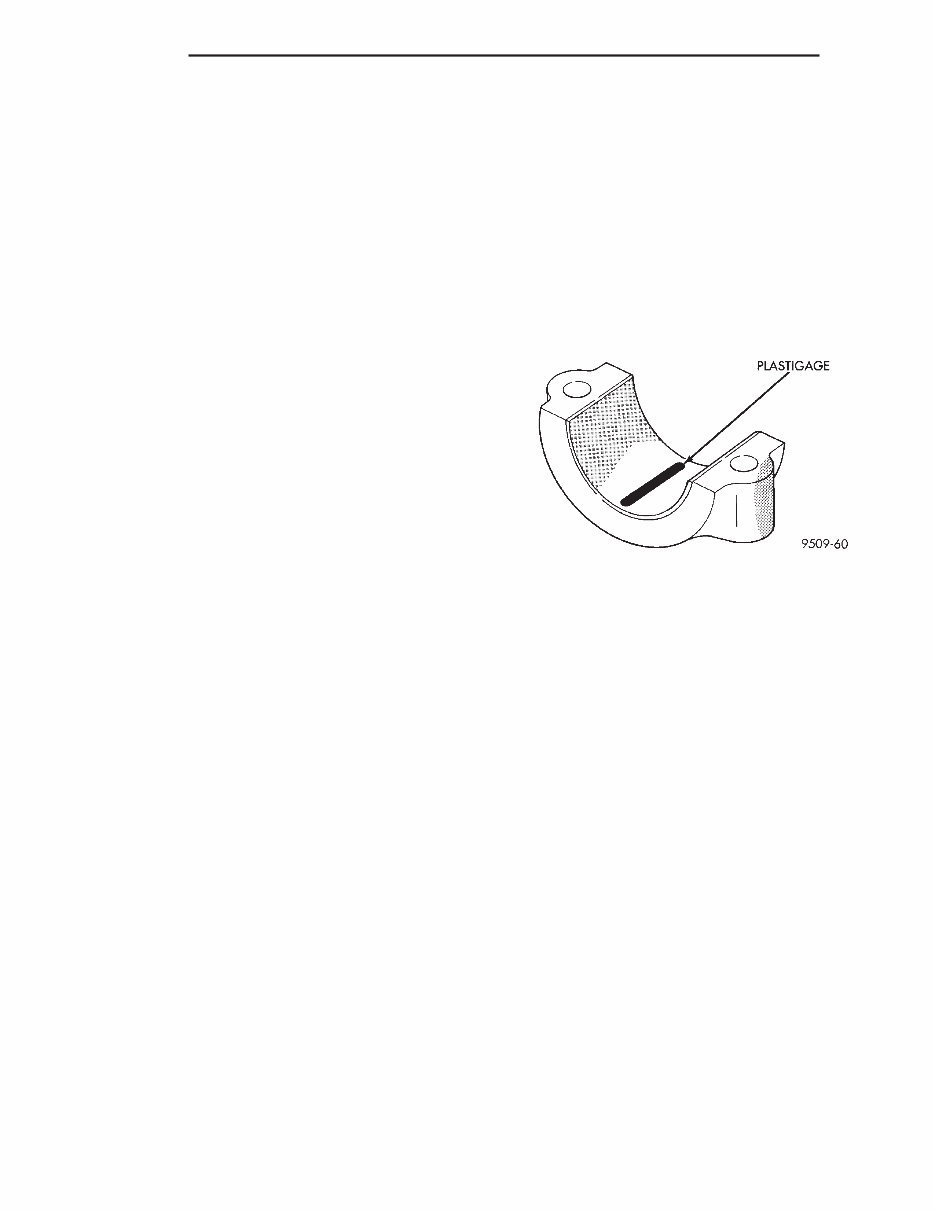

Fig. 1 Plastigage Placed in Lower Shell

PLASTIGAGE

9 - 2 ENGINES LH

GENERAL INFORMATION (Continued)

• When checking #4 main bearing shim #3 & 5

main bearing.

• When checking #5 main bearing shim #4 main

bearing.

ENGINE WITH 4 MAIN BEARING

• When checking #1 main bearing shim #2 main

bearing.

• When checking #2 main bearing shim #1 & #3

main bearing.

• When checking #3 main bearing shim #2 & #4

main bearing.

• When checking #4 main bearing shim #3 main

bearing.

NOTE: REMOVE ALL SHIMS BEFORE REASSEM-

BLING ENGINE

ALTERNATIVE METHOD

The weight of the crankshaft can be supported by a

jack under the counterweight adjacentto the bearing

being checked.

PLASTIGAGE PROCEDURE

(1) Remove oil film from surface to be checked.

Plastigage issoluble in oil.

(2) Place a piece of Plastigage across the entire

width of the bearing shell in the cap approximately

6.35 mm (1/4 in.) off center and away from the oil

holes (Fig. 1). (In addition, suspected areas can be

checked by placing the Plastigage in the suspected

area). T orque the bearing cap bolts of the bearing

being checked to the proper specifications.

(3) Remove the bearing cap and compare the

width of the flattened Plastigage (Fig. 2) with the

metric scale provided on the package. Locate the

band closestto the same width. This band shows the

amount of clearance in thousandths of a millimeter .

Differences in readings between theends indicate the

amount of taper present. Record all readings taken.

Refer to Engine Specifications. Plastigage gener-

ally is accompanied by two scales. Onescale is

in inches, the other is a metric scale.

NOTE: Plastigage is available in a variety of clear-

ance ranges. Use the most appropriate range for

the specifications you are checking.

CONNECTING ROD BEARING CLEARANCE

Engine connecting rod bearing clearances can be

determined by use of Plastigage or equivalent. The

following is the recommendedprocedure for the use

of Plastigage:

(1) Rotate the crankshaft until the connecting rod

to be checked is atthe bottom of itsstroke.

(2) Remove oil film from surface to be checked.

Plastigage issoluble in oil.

(3) Place a piece of Plastigage across the entire

width of the bearing shell in the bearing cap approx-

imately 6.35 mm (1/4 in.) off center and away from

the oil hole (Fig.1). In addition, suspect areas can be

checked by placing plastigage in the suspect area.

(4)Assemble the rod cap with Plastigage in place.

Tighten the rod cap to the specified torque. Do not

rotate the crankshaft while assembling the cap

orthe Plastigage may besmeared, giving inac-

curate results.

(5) Remove the bearing cap and compare the

width of the flattened Plastigage (Fig. 2) with the

scale provided on the package. Locate the band clos-

est to the same width. This band indicates the

amount of oil clearance. Differences in readings

between the ends indicate the amount of taper

present. Record all readings taken. Refer to Engine

Specifications. Plastigage generally is accompa-

nied by two scales. Onescale is in inches, the

other is a metric scale. If the bearing clearance

exceeds 0.076 mm (0.003 in.) replace bearing.

NOTE: Plastigage is available in a variety of clear-

ance ranges. Use the most appropriate range for

the specifications you are checking.

CHECKING ENGINE OILLEVEL

The besttime tocheck engine oil levelis after it

hassat overnight, or if theengine has been running,

allow theengine to be shut off for at least 5 minutes

before checking oil level.

Checking the oil while the vehicle is on level

ground will improve the accuracy of the oil level

reading. Add only when the levelis at or below the

ADD mark.

Fig. 2 Clearance Measurement

LH ENGINES 9 - 3

GENERAL INFORMATION (Continued)

ENGINE OIL SERVICE

WARNING: NEW OR USED ENGINE OIL CAN BE

IRRITATING TO THE SKIN. AVOID PROLONGED OR

REPEATED SKIN CONTACT WITH ENGINE OIL.

CONTAMINANTS IN USED ENGINE OIL, CAUSED BY

INTERNAL COMBUSTION, CAN BE HAZARDOUS TO

YOUR HEALTH. THOROUGHLY WASH EXPOSED

SKIN WITH SOAP AND WATER. DO NOT WASH

SKIN WITH GASOLINE, DIESEL FUEL, THINNER, OR

SOLVENTS, HEALTH PROBLEMS CAN RESULT. DO

NOT POLLUTE, DISPOSE OF USED ENGINE OIL

PROPERLY. CONTACTYOUR DEALER OR GOVERN-

MENT AGENCY FOR LOCATION OF COLLECTION

CENTER IN YOUR AREA.

API SERVICE GRADE CERTIFIED

Use an engine oil that is API Service Grade Certi-

fied or an oil that conforms to the API Service Grade

SH or SH/CD. MOPAR provides engine oils that con-

form to all of these service grades.

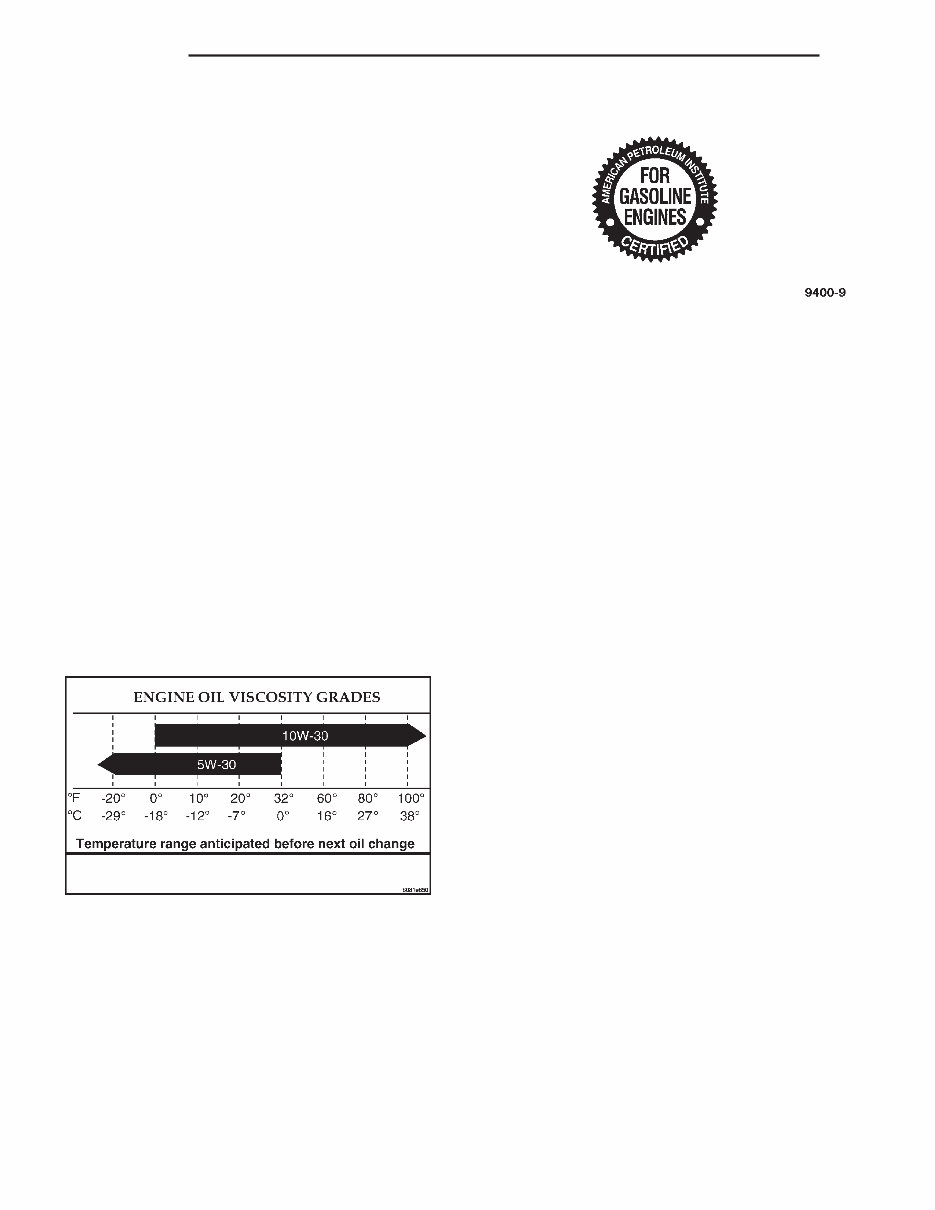

SAE VISCOSITY

An SAE viscositygrade is used to specify the vis-

cosity of engine oil. SAE 30 specifies a single viscos-

ity engine oil. Engine oils also have multiple

viscosities. These are specified with a dualSAE vis-

cositygrade which indicates the cold-to-hottempera-

ture viscosity range. Select an engine oil that is best

suited to your particular temperature range and vari-

ation (Fig.3).

ENERGY CONSERVING OIL

An Energy Conserving type oil is recommended for

gasoline engines. They are designated as either

ENERGY CONSERVING or ENERGY CONSERV-

ING II.

CONTAINER IDENTIFICATION

Standard engine oil identification notations have

been adopted to aid in the proper selection of engine

oil. The identifying notations are located on the label

of engine oil plastic bottles and the top of engine oil

cans (Fig.4).

ENGINE OIL CHANGE

Change engine oil at mileage and time intervals

described in the Maintenance Schedule.

TO CHANGEENGINE OIL

Run engine until achieving normal operating tem-

perature.

(1) Position the vehicle on a level surface and turn

engine off.

(2) Hoist and support vehicle on safety stands.

Refer to Hoisting and Jacking Recommendations.

(3) Remove oil fill cap.

(4) Place a suitable drain pan under crankcase

drain.

(5) Remove drain plug from crankcase and allow

oil to drain into pan. Inspect drain plug threads for

stretching or other damage. Replace drain plug and

gasket if damaged.

(6) Install drain plug in crankcase.

(7) Lower vehicle and fill crankcase with specified

type and amount of engine oil described in thissec-

tion.

(8) Install oil fill cap.

(9) Start engine and inspect for leaks.

(10) Stop engine and inspect oil level.

ENGINE OIL FILTER CHANGE

FIL TERSPECIFICATION

All engines areequipped with a high quality full-

flow, disposable type oil filter . Chrysler Corporation

recommends a Mopar or equivalent oil filter be used.

OIL FIL TERREMOVAL

Refer to Removal and Installation Section in Group

9, Engine for procedure.

USED ENGINE OIL DISPOSAL

Care should be exercised when disposing used

engine oil after it has been drained from a vehicle

engine. Refer to the WARNING listed above.

Fig. 3 Temperature/Engine Oil Viscosity

ENGINE OIL VISCOSITY GRADES Tem erature range antici ated before next oil change

Fig. 4 Engine Oil Container Standard Notations

9 - 4 ENGINES LH

GENERAL INFORMATION (Continued)

SERVICE PROCEDURES

REPAIR OF DAMAGED OR WORN THREADS

Damaged or worn threads (including aluminum

head spark plug threads)can be repaired. Essen-

tially , this repair consists of drilling out worn or

damaged threads, tapping the hole with a special

Heli-Coil Tap, (or equivalent) and installing an insert

into the tapped hole. This brings the hole back to its

original thread size.

CAUTION: Be sure that the tapped holes maintain

the original centerline.

Heli-Coil tools and inserts are readily available

from automotive parts jobbers.

HONING CYLINDER BORES

(1) Used carefully , the cylinder bore resizing hone

C-823 equipped with 220 grit stones, is the besttool

for this job. In addition to deglazing, it will reduce

taper and out-of-round as well as removing light

scuffing, scoring or scratches. Usually a few strokes

will cleanup a bore and maintain the required lim-

its.

(2) Deglazing of the cylinder walls may be done

using a cylinder surfacing hone, T ool C-3501,

equipped with 280 grit stones, if the cylinder bore is

straight and round. 20-60 strokes depending on the

bore condition, will be sufficientto provide a satisfac-

tory surface. Inspect cylinder walls after each 20

strokes, using a light honing oil. Do not use engine

or transmission oil, mineral spirits or kerosene.

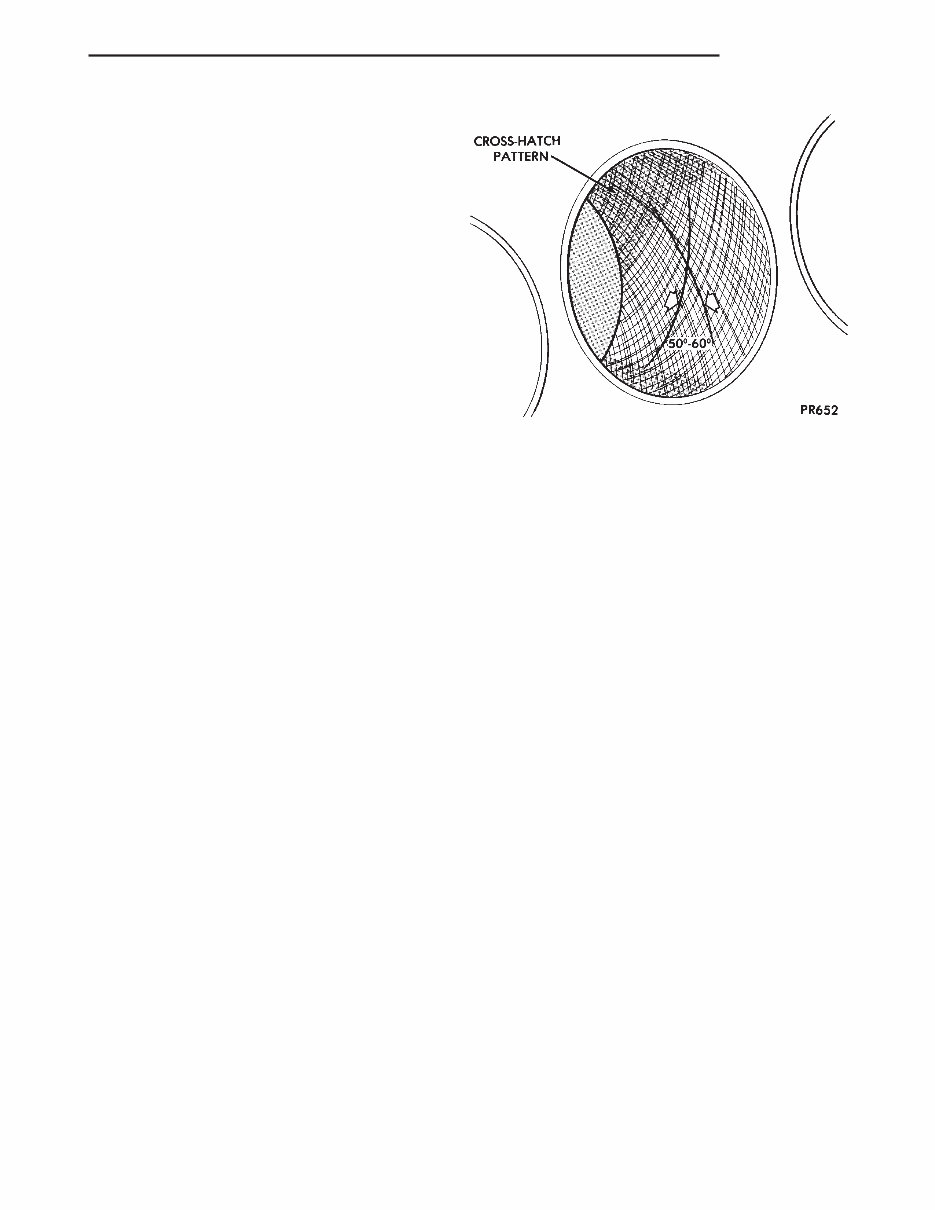

(3) Honing should be done by moving the hone up

and down fast enough to get a cross-hatch pattern.

When hone marks intersect at 50-60 degrees, the

cross hatch angle is most satisfactory for proper seat-

ing of rings (Fig.5).

(4) A controlled hone motor speed between

200-300 RPM is necessary toobtain the proper cross-

hatch angle. The number of up anddown strokes per

minute can be regulated to get the desired 50-60

degree angle. Faster up and down strokes increase

the cross-hatch angle.

(5) After honing, it is necessary thatthe block be

cleaned again to remove all traces of abrasive.

CAUTION: Ensure all abrasives are removed from

engine parts after honing. It is recommended that a

solution of soap and hot water be used with a

brush and the parts then thoroughly dried. The bore

can be considered clean when it can be wiped

clean with a white cloth and cloth remains clean.

Oil the bores after cleaning to prevent rusting.

HYDROSTATIC LOCKED ENGINE

When an engine issuspected to be hydrostatically

locked, regardless of what caused the problem, these

stepsshould be used.

CAUTION: Do Not Use Starter Motor To Rotate

Engine, severe damage may occur.

(1) Inspect air cleaner , induction system and

intake manifold to insure system is dry and clear of

foreign material.

(2) Remove negative battery cable.

(3) Place a shop towel around the spark plugs

when removing them from theengine. This will catch

any fluid that may possibly be in the cylinder under

pressure.

(4) With all spark plugs removed, rotate engine

crankshaft using a breaker bar and socket.

(5) Identify the fluid in the cylinder(s)(i.e., cool-

ant, fuel, oil or other).

(6) Make sure all fluid has been removed from the

cylinders. Inspect engine for damage (i.e., Connecting

Rods, Pistons, V alves etc.)

(7) Repair engine or components as necessary to

preventthis problem from occurring again.

CAUTION: Squirt approximately 1 teaspoon of oil

into cylinders, rotate engine to lubricate the cylin-

der walls to prevent damage on restart.

(8) Install new spark plugs.

(9) Drain engine oil and remove oil filter .

(10) Fill engine with specified amount of approved

oil and install new oil filter .

(11) Connect negative battery cable.

(12) Start engine and check for any leaks.

Fig. 5 Cylinder Bore Cross-Hatch Pattern

CROSS-HATCH PATTERN

LH ENGINES 9 - 5

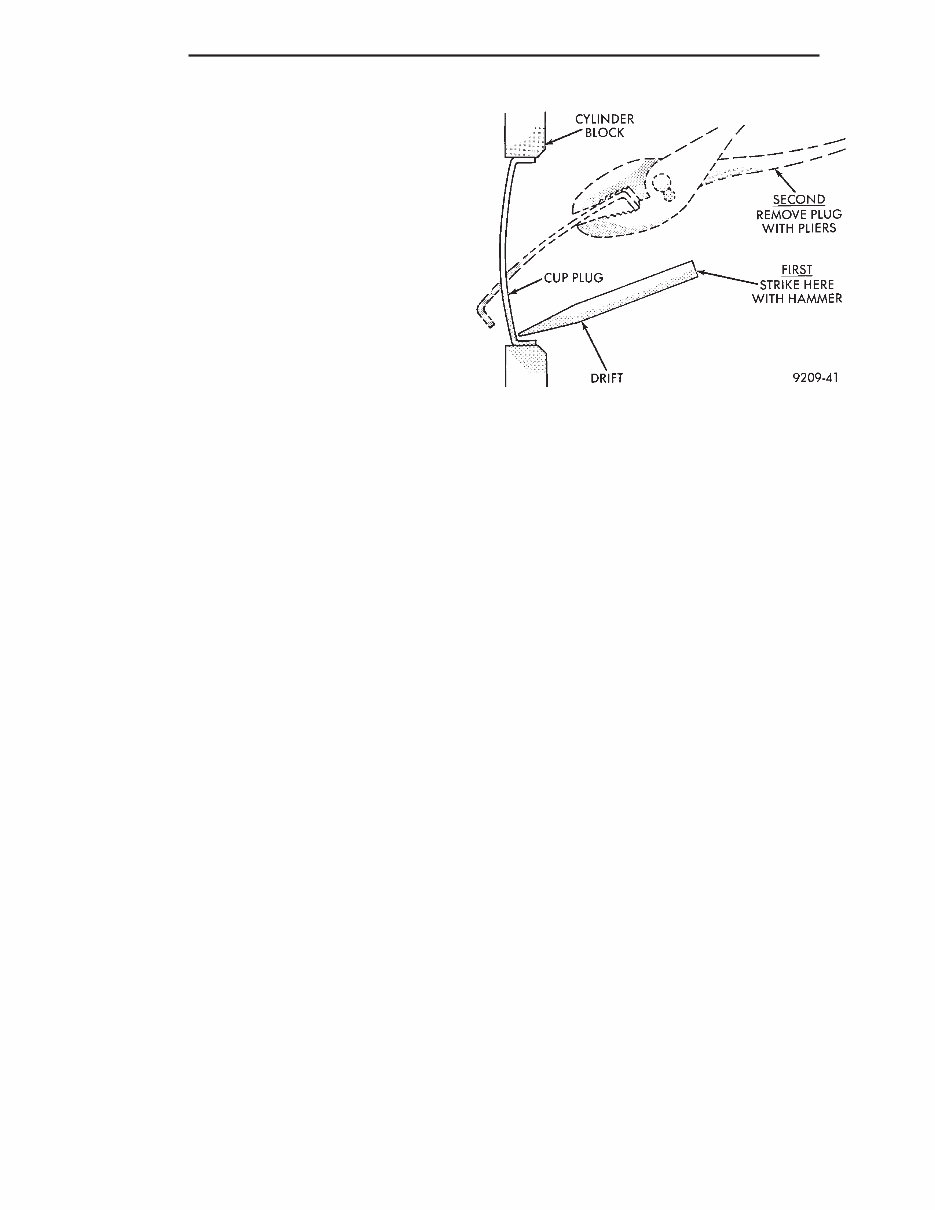

ENGINECORE PLUGS

REMOVAL

Using a blunttool such as a drift or a screwdriver

and a hammer , strike the bottom edge of the cup

plug (Fig.6). With the cupplug rotated, grasp firmly

with pliers or other suitable tool and remove plug

(Fig.6).

CAUTION: Do not drive cup plug into the casting

as restricted cooling can result and cause serious

engine problems.

INSTALLATION

Thoroughly remove all rust and clean inside of cup

plug hole in cylinder block or head. Be sure to

remove old sealer . Lightly coat inside of cupplug hole

with sealer . Make certain the new plug is cleaned of

all oil or grease. Using proper drive plug, drive plug

into hole so thatthe sharp edge of the plug is at

least 0.5 mm (0.020 inch.) inside the lead in chamfer

(Fig.6).

It is innot necessary to wait for curing of the seal-

ant. The cooling system can be refilled and the vehi-

cle placed in service immediately .

Fig. 6 Core Hole Plug Removal

9 - 6 ENGINES LH

SERVICE PROCEDURES (Continued)

ENGINE DIAGNOSIS

INDEX

page page

DIAGNOSIS AND TESTING

CYLINDER COMBUSTION PRESSURE

LEAKAGE TEST ....................... 8

CYLINDER COMPRESSION TEST ........... 7

ENGINE DIAGNOSIS—MECHANICAL ........ 11

ENGINE DIAGNOSIS—PERFORMANCE ..... 10

GENERAL INFORMATION ................. 7

INSPECTION (ENGINE OIL LEAKS IN

GENERAL) ........................... 8

INTAKE MANIFOLD LEAKAGE DIAGNOSIS .... 7

LASH ADJUSTER (TAPPET) NOISE DIAGNOSIS

....................................... 8

DIAGNOSIS AND TESTING

GENERAL INFORMATION

Engine diagnosis is helpful in determining the

causes of malfunctions not detected and remedied by

routine tune-ups.

These malfunctions may be classified as either

mechanical (e.g., a strange noise), or performance

(e.g., engine idles rough and stalls).

Refer to the Service Diagnosis—Mechanical Chart

and the Service Diagnosis—Performance Chart, for

possible causes and corrections of malfunctions. Refer

to Group 14, FuelSystem, for the fuel system diag-

nosis.

Additional tests anddiagnostic procedures may be

necessary for specific engine malfunctions that can-

not be isolated with the Service Diagnosis charts.

Information concerning additional tests and diagno-

sis is provided within the following:

• Cylinder Compression Pressure T est

• Cylinder Combustion Pressure Leakage T est

• Engine Cylinder Head Gasket Failure Diagnosis

• Intake Manifold Leakage Diagnosis

INTAKE MANIFOLD LEAKAGE DIAGNOSIS

An intake manifold air leak is characterized by

lower than normal manifold vacuum. Also, one or

more cylinders may not be functioning.

WARNING: USE EXTREME CAUTION WHEN THE

ENGINE IS OPERATING. DO NOT STAND IN A

DIRECT LINE WITH THE FAN. DO NOT PUT YOUR

HANDS NEAR THE PULLEYS, BELTS OR THE FAN.

DO NOT WEAR LOOSE CLOTHING.

(1) Starttheengine.

(2) Spray a small stream of water (Spray Bottle) at

the suspected leak area.

(3) If a change in RPM’S, the area of the suspected

leak has been found.

(4) Repair as required.

CYLINDER COMPRESSION TEST

(1) Before performing a cylinder compression test.

Ensure the battery is completely charged and the

engine starter motor is in good operating condition.

Otherwise the indicated compression pressures may

not be valid for diagnosis purposes.

(2) Check engine oil level and add oil if necessary .

(3) Drive the vehicle until engine reaches normal

operating temperature.

(4) Select a route free from traffic and other forms

of congestion, observe all traffic laws, and accelerate

through the gearsseveral times briskly .

CAUTION: Do not overspeed the engine. The

higher engine speed may help clean out valve seat

deposits which can prevent accurate compression

readings.

a. Clean the spark plug recesses with compressed

air .

b. Remove all spark plugs from engine. Asspark

plugs are being removed, check electrodes for abnor-

mal firing indicators fouled, hot, oily , etc. Record cyl-

inder number of spark plug for future reference.

c. Disconnectthe coil connector for Direct Ignition

System (DIS).

d. Be sure throttle blade is fully open during the

compression check.

e. Insert compression gage adaptor into the #1

spark plug hole in cylinder head. Crank engine until

maximum pressure is reached on gage. Record this

pressure as #1 cylinder pressure.

f. Repeat Step e for all remaining cylinders.

g. Compression should not be less than (689kPa)

100 psi and not vary more than 25 percent from cyl-

inder tocylinder .

h. Ifone or more cylinders have abnormally low

compression pressures, repeat steps 4e through 4g.

i. If the same cylinder or cylinders repeat an

abnormally low reading on the second compression

test, it could indicate the existence of a problem in

the cylinder in question.

LH ENGINES 9 - 7

NOTE: The recommended compression pressures

are to be used only as a guide to diagnosing engine

problems. An engine should not be disassembled to

determine the cause of low compression unless

some malfunction is present.

(5) Clean orreplace spark plugs as necessary and

adjust gap asspecified in Electrical Group 8. Tighten

to specifications.

CYLINDER COMBUSTION PRESSURE LEAKAGE

TEST

The combustion pressure leakage test provides an

accurate means for determining engine condition.

Combustion pressure leakage testing will detect:

• Exhaust and intake valve leaks (improper seat-

ing).

• Leaks between adjacent cylinders or into water

jacket.

• Any causes for combustion/compression pressure

loss.

WARNING: DO NOT REMOVE THE RADIATOR CAP

WITH THE SYSTEM HOT AND UNDER PRESSURE

BECAUSE SERIOUS BURNS FROM COOLANT CAN

OCCUR.

Check the coolant level and fill as required. DO

NOT install the radiator cap.

Start and operate the engine until it attains nor-

mal operating temperature, then turn the engine

OFF .

Clean spark plug recesses with compressed air .

Remove the spark plugs.

Remove the oil filler cap.

Remove the air cleaner .

Calibrate the tester according to the manufactur-

er’s instructions. The shop air source for testing

should maintain 483 kPa (70 psi) minimum, 1 379

kPa (200 psi) maximum and 552 kPa (80 psi) recom-

mended.

Perform the test procedures on each cylinder

according to the tester manufacturer’s instructions.

While testing, listen for pressurized air escaping

through the throttle body , tailpipe and oil filler cap

opening. Check for bubbles in the radiator coolant.

All gauge pressure indications should be equal,

withno more than 25% leakage.

FOR EXAMPLE: At 552 kPa (80 psi) input pres-

sure, a minimum of 414 kPa (60 psi) should be main-

tained in the cylinder .

LASH ADJUSTER (TAPPET) NOISE DIAGNOSIS

A tappet-like noise may be produced from several

items. Check the following items.

(1) Engine oil level too high or too low. This may

cause aerated oil to enter the adjusters and cause

them to be spongy .

(2) Insufficient running time afterrebuilding cylin-

der head. Low speed running up to 1 hour may be

required.

(3) During this time, turn engine off and let set for

a few minutes before restarting. Repeatthisseveral

times after engine has reached normal operating

temperature.

(4) Low oil pressure.

(5) The oil restrictor pressed into the vertical oil

passage to the cylinder head is plugged with debris.

(6)Air ingested intooil due to broken or cracked

oil pumppickup.

(7) Worn valve guides.

(8) Rocker arm ears contacting valve spring

retainer .

(9) Rocker arm loose, adjuster stuck or at maxi-

mum extension and still leaves lash in the system.

(10) Faulty lash adjuster .

a. Check lash adjusters for sponginess while

installed in cylinder head. Depress part of rocker

arm over adjuster . Normal adjustersshould feel very

firm. Spongy adjusters can be bottomed out easily .

NOTE: 3.5L Engine the lash adjuster is serviced

with the rocker arm, do not disassemble.

b. Remove suspected lash adjusters, anddisassem-

ble Do notreuse retainer caps . Do not inter-

change parts and make sure that care and

cleanliness is exercised in the handling of parts.

c. Clean out dirt and varnish with solvent.

d. Reassemble with engine oil.

e. Check for sponginess.

f. If still spongy , replace withnew adjuster .

INSPECTION (ENGINE OILLEAKS INGENERAL)

Begin with a through visual inspection of the

engine, particularly atthe area of the suspected leak.

If an oil leak source is not readily identifiable, the

following stepsshould be followed:

(1) Do not clean or degrease the engine at this

time because some solvents may cause rubber to

swell, temporarily stopping the leak.

(2)Add an oil soluble dye (use as recommended by

manufacturer). Start the engine and let idle for

approximately 15 minutes. Check the oil dipstick to

make sure the dye is thoroughly mixed as indicated

with a bright yellow color under a black light.

(3) Using a black light, inspectthe entire engine

for fluorescent dye, particularly atthe suspected area

of oil leak. If the oil leak is found and identified,

repair per service manualinstructions.

9 - 8 ENGINES LH

DIAGNOSIS AND TESTING (Continued)

(4) If dye is not observed, drive the vehicle at var-

iousspeeds for approximately 24km (15 miles), and

repeat inspection.

(5) If the oil leak source is not positively

identified atthis time , proceed with the air leak

detection test method as follows:

(6) Disconnectthe fresh air hose (makeup air) at

the cylinder head cover andplug or cap the nipple on

the cover .

(7) Remove the PCV valve hose from the cylinder

head cover . Cap or plug the PCV valve nipple on the

cover .

(8)Attach an air hose with pressure gauge and

regulator to the dipstick tube.

CAUTION: Do not subject the engine assembly to

more than 20.6 kpa (3 PSI) of test pressure.

(9) Gradually apply air pressure from 1 psi to 2.5

psi maximum while applying soapy water atthe sus-

pected source. Adjustthe regulator to the suitable

test pressure that provide the best bubbles which

will pinpoint the leak source. If the oil leak is

detected and identified, repair per service manual

procedures.

(10) If the leakage occurs atthe rear oil seal area,

refer to the section, Inspection for Rear Seal Area

Leak.

(11) If no leaks are detected, turn off the air sup-

ply and remove the air hose and all plugs and caps.

Install the PCV valve and breather cap hose. Proceed

to next step.

(12) Clean the oil off the suspect oil leak area

using a suitable solvent. Drive the vehicle at various

speeds approximately 24 km (15 miles). Inspectthe

engine for signs of an oil leak by using a black light.

INSPECTION FOR REAR SEAL AREA LEAKS

Since it is sometimes difficult to determine the

source of an oil leak in the rear seal area of the

engine, a more involved inspection is necessary . The

following steps should be followed to help pinpoint

the source of the leak.

If the leakage occurs atthe crankshaft rear oil seal

area:

(1) Disconnectthe battery .

(2) Raise the vehicle.

(3) Remove torque converter or clutch housing

cover and inspect rear of block for evidence of oil.

Use a black lighttocheck for the oil leak. If a leak is

present in this area remove transmission for further

inspection.

(a) Circular spray pattern generally indicates

sealleakage or crankshaft damage.

(b) Where leakage tends to run straight down,

possible causes are a porous block, oil galley cup

plug, bedplate tocylinder block mating surfaces

and seal bore. See proper repair procedures for

these items.

(4) If no leaks are detected, pressurized the crank-

case as outlined in the, Inspection (Engine oil Leaks

in general)

CAUTION: Do not exceed 20.6 kPa (3 psi).

(5) If the leak is not detected, very slowly turn the

crankshaft and watch for leakage. If a leak is

detected between the crankshaft and seal while

slowly turning the crankshaft, it is possible the

crankshaft seal surface is damaged. The seal area on

the crankshaft could have minor nicks or scratches

that can be polished out with emery cloth.

CAUTION: Use extreme caution when crankshaft

polishing is necessary to remove minor nicks and

scratches. The crankshaft seal flange is especially

machined to complement the function of the rear oil

seal.

(6) For bubbles that remain steady with shaft

rotation, nofurther inspection can be done until dis-

assembled.

(7) After the oil leak root cause and appropriate

corrective actionhave been identified. Refer to Rear

Crankshaft Seals, for properreplacement procedures.

LH ENGINES 9 - 9

DIAGNOSIS AND TESTING (Continued)

ENGINE DIAGNOSIS—PERFORMANCE

CONDITION POSSIBLE CAUSE CORRECTION

ENGINE WILL NOT

START

1. Weak battery. 1. Test battery specific gravity. Charge or replace as

necessary.

2. Corroded or loose battery

connections.

2. Clean and tighten battery connections. Apply a coat of

light mineral grease to the terminals.

3. Faulty starter. 3. Refer to Group 8A, Battery/Starter/Charging System

Diagnostics.

4. Moisture on ignition wires. 4. Wipe wires clean and dry.

5. Faulty ignition cables. 5. Replace any cracked or shorted cables.

6. Faulty coil or control unit. 6. Test and replace, if necessary (refer to Group 8D, Ignition

system).

7. Incorrect spark plug gap. 7. Set gap (refer to Group 8D, Ignition System).

8. Dirt or water in fuel system. 8. Clean system and replace fuel filters.

9. Faulty fuel pump. 9. Install new fuel pump (refer to Group 14, Fuel System).

ENGINE STALLS OR

ROUGH IDLE

1. Idle speed set too low. 1. Refer to Group 14, Fuel System.

2. Idle mixture too lean or too

rich.

2. Refer to Group 14, Fuel System.

3. Leak in intake manifold. 3. Inspect intake manifold gasket and vacuum hoses.

Replace, if necessary (refer to Group 11), Exhaust System &

Intake Manifold.

4. Incorrect ignition wiring. 4. Install correct wiring.

5. Faulty coil. 5. Test and replace, if necessary (refer to Group 8D, Ignition

System).

ENGINE LOSS OF

POWER

1. Dirty or incorrectly gapped

spark plugs.

1. Clean plugs and set gap (refer to Group 8D, Ignition

System).

2. Dirt or water in fuel system. 2. Clean system and replace fuel filter.

3. Faulty fuel pump. 3. Install new fuel pump.

4. Incorrect valve timing. 4. Correct valve timing.

5. Blown cylinder head gasket. 5. Install new cylinder head gasket.

6. Low compression. 6. Test compression of each cylinder.

7. Burned, warped or pitted

valves.

7. Install new valves.

8. Plugged or restricted

exhaust system.

8. Install new parts, as necessary.

9. Faulty ignition cables. 9. Replace any cracked or shorted cables.

10. Faulty coil. 10. Test and replace, as necessary (refer to Group 8D,

Ignition System).

ENGINE MISSES ON

ACCELERATION

1. Dirty or gap set too wide in

spark plug.

1. Clean spark plugs and set gap (refer to Group 8D,

Ignition System).

2. Dirt in fuel system. 2. Clean fuel system.

3. Burned, warped or pitted

valves.

3. Install new valves.

4. Faulty coil. 4. Test and replace if necessary, (refer to Group 8D, Ignition

System).

ENGINE MISSES AT

HIGH SPEED

1. Dirty or gap set too wide in

spark plug.

1. Clean spark plugs and set gap (refer to Group 8D,

Ignition System).

2. Faulty coil. 2. Test and replace, as necessary (refer to Group 8D,

Ignition System).

3. Dirty injector. 3. Clean injectors.

4. Dirt or water in fuel system. 4. Clean system and replace fuel filter.

9 - 10 ENGINES LH

DIAGNOSIS AND TESTING (Continued)

You're Reading a Preview

What's Included?

Fast Download Speeds

Offline Viewing

Access Contents & Bookmarks

Full Search Facility

Print one or all pages of your manual

$37.99

Viewed 93 Times Today

Loading...

Secure transaction

What's Included?

Fast Download Speeds

Offline Viewing

Access Contents & Bookmarks

Full Search Facility

Print one or all pages of your manual

$37.99

Introducing the 1997 DODGE INTREPID Service and Repair Manual.

Ensure the optimal performance of your 1997 DODGE INTREPID with this comprehensive service and repair manual. Designed to provide detailed instructions, diagrams, and specifications, this manual is a valuable resource for DIY enthusiasts and professional mechanics alike.

- Includes step-by-step procedures for routine maintenance tasks, such as oil changes, filter replacements, and brake inspections.

- Provides comprehensive diagnostic information, troubleshooting guides, and repair procedures for common issues.

- Covers electrical systems, engine components, transmission, suspension, steering, and more.

- Features detailed illustrations, diagrams, and photographs to assist with repairs and part identification.

- Written by expert technicians with years of experience in servicing the 1997 DODGE INTREPID.

With the 1997 DODGE INTREPID Service and Repair Manual, you can confidently tackle maintenance and repair tasks, saving time and money. Whether you are a professional or a DIY enthusiast, this manual is an essential tool for keeping your 1997 DODGE INTREPID running smoothly.