Citroen XM Service Repair Manual

What's Included?

Fast Download Speeds

Online & Offline Access

Access PDF Contents & Bookmarks

Full Search Facility

Print one or all pages of your manual

CITROEN

XM jtteSar

rcwaoa? buss mas SavrosiSScra 1

1989 to 2000 (G to X registration) Petrol & Diesel

Haynes Service and Repair Manual

expert22 fl/ia http://rutracker.org

Includes Roadside Repairs and MOT Test Checks

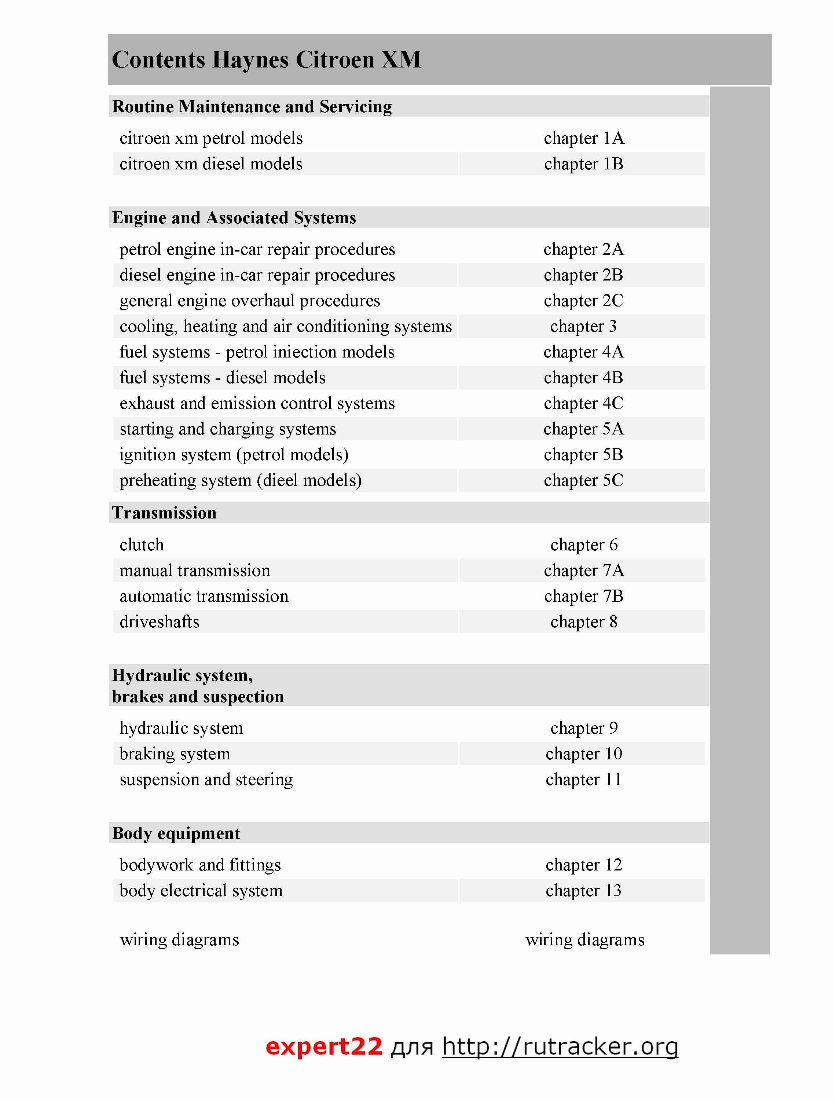

Contents Haynes Citroen XM

Routine Maintenance and Servicing

Citroen xm petrol models chapter 1A

citroen xm diesel models chapter IB

Engine and Associated Systems

petrol engine in-car repair procedures chapter 2A

diesel engine in-car repair procedures chapter 2B

general engine overhaul procedures chapter 2C

cooling, heating and air conditioning systems chapter 3

fuel systems - petrol iniection models chapter 4A

fuel systems - diesel models chapter 4B

exhaust and emission control systems chapter 4C

starting and charging systems chapter 5A

ignition system (petrol models) chapter 5B

preheating system (dieel models) chapter 5C

Transmission

clutch chapter 6

manual transmission chapter 7A

automatic transmission chapter 7B

drive shafts chapter 8

Hydraulic system,

brakes and suspection

hydraulic system chapter 9

braking system chapter 10

suspension and steering chapter 11

Body equipment

bodywork and fittings chapter 12

body electrical system chapter 13

wiring diagrams wiring diagrams

expert22 fl/ifl http://rutracker.org

1 A*1

Chapter 1 Part A:

Routine maintenance and servicing -

petrol engine models

1A

.

Contents

Airfilter element renewal (normally-aspirated models}.................... 15

f t filter element renewal (Turbo models) ........................................ 11

Automatic transmission fluid strainer cleaning ........ ........................ 20

Automatic transmission fluid renewal ............................................... 4

Auxiliary drivebelt c h e c k .................. ................................................19

Clutch pedal height check .............................................................. 5

Coolant renewal .............................................................................. 14

Driveshaft c h e c k ................ ............................................................. 8

Engine oil and filter renewal ............................................................ 3

Fault diagnosis system memory check ............................................ 10

Front and rear brake pad and disc check ........................................ 13

Fuel filter renewal .....................................................- ...................... 17

Hinge and lock lubrication................................................................. 9

Hose and fluid leak ch e ck ................................................................. 6

Hydraulic fluid renewal and fluid return filter cleaning .................... 16

Introduction....................................................................................... 1

Manual transmission oil level c h e c k .............. ..................... 18

Regular maintenance .................... .............................................. 2

Road te s t ........................................................................................... 21

Spark plug renewal ...................................... .................................... 12

Steering and suspension check ....................................................... 7

Timing belt renewal ...........................................................................22

Degrees of difficulty

Easy, suitable for ;i

novice with little

expenence

Fairfy easy, su itable

for beginner with

some experience ^

Fairly difficult,

suitable for competent ^

DIY mechanic ^

Difficult, suitable for ^

experienced DIY

mechanic ^

Very difficult, ^

suitable for expert DIY

or professional ^

ia -2 Servicing specifications - petrol models

Champion F104

Champion F118

Protection down to -15°C (5°F)

Protection down to -30°C (-22°F)

Lubricants and fluids

Refer to the end of Weekly checks

Capacities (approximate)

Engine oil

Non-turbo modeis ...................................................................... 5.40 litres

Turbo models:

Models without air conditioning ........................................................ 4.75 litres

Models with air conditioning.............................................................. 4.50 litres

Cooling system

Non-turbo models ................................................................................ 7.30 litres

Turbo models ........................................................................................ 10.80 or 11.30 litres (according to equipment)

Transmission

Manual transmission........................................ ...................................... 1.90 litres

Automatic transmission:

From d r y ............................................................................................ 7.50 litres

Fluid c h a n g e ...................................................................................... 2.40 litres

Hydraulic LHM fluid

All models .............................................................................................. 5.40 litres

Fuel tank

All models .............................................................................................. 80.00 litres

Engine

Oil filter:

Models up to 1994 ........................................................................

Models from 1995 ..........................................................................

Cooling system

Antifreeze mixture:

28% antifreeze .................................... . ......................................

50% antifreeze ...................................... .......................................

Note: Refer to antifreeze manufacturer's recommendations

Fuel system

Air filter element ............ ....................................................................... Champion U561

Fuel filte r ................................................................................................ Champion L206

Ignition system

Spark plugs:

Non-turbo models without catalytic converter.................................. Champion RC7YCC

Non-turbo models with catalytic converter ...................................... Champion RC9YCC

Turbo models .................................................................................... Champion RC7BMC

Spark plug electrode gap* .................................................................... 0.8 mm

Ignition HT lead set:

Models with distributor ignition system ............................................ Champion LS-55

Models with distributorfess ignition system ...................................... Champion LS-51

*The spark plug gap quoted is that recommended by Champion for their specified plugs listed above. If spark plugs of any other type are to be

fitted, refer to their manufacturer’s recommendations

Brakes

Brake pad friction material minimum thickness:

Front pads ......................................................................................

Rear pads ......................................................................................

Wiper blades

Front ..................................................................................................

Rear:

Hatchback models ........................................................................

Estate models .............................................. . ............................

Clutch

Clutch pedal travel ..........................................................................

Tyre pressures

See end of Weekly checks

Torque wrench settings

Roadwheel b o lts ..............................................................................

3.0 mm

2.0 mm

Manual transmission oil filler/level plug

Champion X55

Champion X45

Champion X41

45 -0+10 mm

Nm Ibf ft

90 66

25 16

20 15

30 22

Maintenance schedule - petrol models 1A .3

1 The maintenance intervals in this manual are provided with the

assumption that you, not the dealer, will be carrying out the work.

These are the minimum maintenance intervals recommended by us for

vehicles driven daily. If you wish to keep your vehicle in peak condition

at all times, you may wish to perform some of these procedures more

often. We encourage frequent maintenance, because it enhances the

efficiency, performance and resale value of your vehicle.

2 If the vehicle is driven in very dusty areas, used to tow a trailer,

spends long periods with the engine idling, is driven frequently at slow

speeds (eg in heavy traffic) or is used mainly for short journeys, then

more frequent maintenance intervals are recommended.

3 When the vehicle is new, it should be serviced by a factory-

authorised dealer service department, in order to preserve the factory

warranty.

Every 250 miles (400 km) or weekly

□ Refer to Weekly checks.

Every 9000 miles or 12 months,

whichever comes first

□ Renew the engine oil and filter (Section 3)

D Renew the automatic transmission fluid - where

applicable (Section 4)

□ Check the clutch pedal height - models with cable-

operated clutch {Section 5)

Ip Check all components, pipes and hoses for fluid

leaks (Section 6)

I Check the condition and security of the steering

and suspension components (Section 7)

' Check the condition of the driveshafts (Section 8)

I Lubricate all hinges and locks (Section 9)

I Check the fault diagnosis system memory for fault

codes (Section 10)

Every 18 000 miles

n Renew the air filter element - Turbo models

(Section 11)

□ Renew the spark plugs (Section 12)

□ Check the condition of the front and rear brake

pads and discs {Section 13)

Every 2 years, regardless of mileage

□ Renew the coolant (Section 14)

Every 36 000 miles

□ Renew the air filter element - normally-aspirated

models (Section 15)

□ Renew the hydraulic fluid and clean the hydraulic

fluid return filters (Section 16)

□ Renew the fuel filter (Section 17)

□ Check the manual transmission oil level

(Section 18)

□ Check the condition of the auxiliary drivebelts

{Section 19)

Q Clean the automatic transmission fluid strainer -

where applicable (Section 20)

□ Carry out a road test (Section 21)

Every 72 000 miles

□ Renew the tinning belt (Section 22)

Note: Although this is the normal interval for timing belt renewal, it is

strongly recommended that the interval is reduced on vehicles which

are subjected to intensive y§e, ie, mainly short journeys or a lot of

stop-start driving. The actual belt renewal is therefore very much up

to the individual owner, but bear in mind that severe engine damage

may result if the belt breaks

ia .4 Component locations - petrol models

Underbonnet view of a 2.0 litre turbo petrol engine

1 Headlight washer fluid reservoir

2 Air suspension hydraulic fluid reservoir

bulb

3 Hydraulic fluid reservoir

4 Windscreen 'tailgate washer fluid reservoir

5 Air cleaner housing

6 Battery

7 Headlight beam adjustment screws

S Engine oil filler cap

9 Engine oil level dipstick

10 VIN plate

11 Cruise control vacuum actuator

12 Hydraulic fluid pump

13 Electronic control unit housing

14 Coolant reservoir <expansion tank)

Underbonnet view of a 2.0 litre non-turbo petrol engine

1 Air suspension hydraulic fluid reservoir

bulb

2 Engine oil level dipstick

3 Hydraulic fluid reservoir

4 Windscreen/tailgate washer fluid reservom

5 Battery

6 Headlight beam ad/ustment screw

7 Automatic transmission fluid level dtpstich

8 Engine oil filler cap

9 Engine oil filter

10 VIN plate

11 Alternator

12 Hydraulic fluid pump

13 Electmnic control unit housing

14 Coolant reservoir lexpanston tank)

Component locations - petrol models ia* s

Front underbody view (diesel engine model shown, petrol engine model similar)

1 Manual transmission

2 Driveshaft

3 Brake caliper

4 Front suspension lower arm

5 Track-rod

6 Anti-roll bar

7 Suspension soft-setting hydraulic fluid

reservoir bulb

8 Front suspension subframe

1A

Rear underbody view (diesel engine model shown, petrol engine model similar)

7 Exhaust expansion box

2 Spare wheel carrier

3 Hydraulic fluid reservoir bulb

4 Rear suspension trailing arm

5 Rear suspension hydraulic unit

6 Fuel tank

7 Rear suspension crosstube

8 Rear anti-mii bar

1 a *6 Routine maintenance - petrol models

1 Introduction

1 This Chapter is designed to help the home

mechanic maintain his/her vehicle for safety,

economy, iong life and peak performance.

2 The Chapter contains a maintenance

schedule, followed by Sections dealing

specifically with each task in the schedule.

Visual checks, adjustments, component

renewal and other helpful items are included.

Refer to the accompanying illustrations of the

engine compartment and the underside of the

vehicle for the locations of the various

components.

3 Servicing your vehicle in accordance with

ttie above recommendations and the

following Sections wilt provide a planned

maintenance programme, which should result

in a long and reliable service life. This is a

comprehensive plan, so maintaining some

items but not others at the specified service

intervals, will not produce the same results.

4 As you service your vehicle, you will

discover that many of the procedures can -

and should - be grouped together, because of

the particular procedure being performed, or

because of the proximity of two otherwise-

unrelated components to one another. For

example, if the vehicle is raised for any reason,

the exhaust can be inspected at the same time

as the suspension and steering components.

5 The first step in this maintenance

programme is to prepare yourself before the

actual work begins. Read through all the

Sections relevant to the work to be carried

out, then make a list and gather all the parts

and tools required. If a problem is

encountered, seek advice from a parts

specialist, or a dealer service department.

2 Regular maintenance

1 If, from the time the vehicle is new, the

routine maintenance schedule is followed

closely, and frequent checks are made of fluid

levels and high-wear items, as suggested

throughout this manual, the engine will be

kept in relatively good running condition, and

the need for additional work will be minimised.

2 (t is possible that there will be times when

the engine is running poorly due to the lack of

regular maintenance. This is even more likely

if a used vehicle, which has not received

regular and frequent maintenance checks, is

purchased. In such cases, additional work

may need to be carried out. outside of the

regular maintenance intervals.

3 If engine wear is suspected, a compression

test {refer to the relevant Part of Chapter 2)

will provide valuable information regarding the

overall performance of the main internal

components. Such a test can be used as a

basis to decide on the extent of the work to

be carried out. if, for example, a compression

test indicates serious internal engine wear,

conventional maintenance as described in this

Chapter will not greatly improve the!

performance of the engine, and may prove a

waste of time and money, unless extensive

overhaul work is carried out first.

4 The following series of operations are those

most often required to improve the perform*

ance of a generally poor-running engine:

Primary operations

a) Clean, inspect and test the battery (See '

Weekly checks and Chapter 5A).

b) Check all the engine-related fluids (See

Weekly checks).

c) Check the condition and tension of the

auxiliary drivebeltfs) (Section 19).

d) Renew the spark plugs (Section 12).

e) Check the condition of the air filter, and

renew if necessary (Sections 1J and 15). f

f) Check the fuel filter (Section 17).

g) Check the condition of all hoses, and

check for fluid leaks (Section 6).

5 If the above operations do not prove fully!

effective, carry out the following secondary

operations:

Secondary operations

All items listed under Primary operations, plus

the following:

a) Check the charging system (Chapter 5A).

b) Check the ignition system (see relevant I

Part of Chapter 5).

c) Check the fuel system (see relevant Part

of Chapter 4).

Every 9000 miles or 12 months, whichever comes first

3 Engine oil and filter renewal

Note: A suitable square-section wrench may

be required to undo the sump drain plug on

some models. These wrenches can be

obtained from most motor factors or your

Citroen dealer.

1 Frequent oil and filter changes are the most

important preventative maintenance

procedures which can be undertaken by the

DIY owner. As engine oil ages, it becomes

diluted and contaminated, which leads to

premature engine wear.

2 Before starting this procedure, gather

together all the necessary tools and materials.

Make sure that you have plenty of clean rags

and newspapers handy, to mop up any spills,

and a container of suitable size to drain the oil

into. Ideally, the engine oil should be warm, as

it will drain better, and more built-up sludge will

be removed with it. Take care, however, not to

touch the exhaust or any other hot parts of the

engine when working under the vehicle. To

avoid any possibility of scalding, and to protect

yourself from possible skin irritants and other

harmful contaminants in used engine oils, it is

advisable to wear gloves when carrying out this

work. Access to the underside of the vehicle

will be greatly improved if it can be raised on a

lift, driven onto ramps, or jacked up and

supported on axle stands (see Jacking and

Vehicle Support). Whichever method is chosen,

make sure that the vehicle remains level, or if it

is at an angle, that the drain plug is at the

lowest point. Where necessary remove the

sptash guard from under the engine.

3 Slacken the drain plug about half a turn; on

some models, a square-section wrench may

be needed to slacken the plug. Position the

draining container under the drain plug, then

remove the plug completely. If possible, try to

keep the plug pressed Into the sump while!

unscrewing it by hand the last couple of turns;

(see illustration and Haynes Hint).

3.3 Slackening the sump drain plug

As the drain plug re/eases from the

threads, move if away sharply, so that !

the stream of oil issuing from the sump I

runs into the container -not down your |

arm.

Every 9000 miles - petrol models ia .7

slacken the filter...

I iRtcover the sealing ring from the drain

15 Mow some time for the old oil to dram.

Uet^g that (t may be necessary to reposition

M container as the oil flow slows to a

|h>

I After all the oil has drained, wipe off the

wain .Jug with a clean rag. and fit a new

i s» ig wasfiet Clean around the drain plug

nertng, then refit and tighten the plug,

if II the fitter is also to be renewed, move the

pontainer into position under the oil filter. On

^models the filler is located on the front

:•& ot the cylinder block

1 Uwxj an oil filter removal tool if necessary.

MKken the filter initially, then unscrew it by

■ line the rest of the way (see illustrations) If

any O il remains in the old titter, empty it into

T4container

I Use a clean rag to remove all oil, dirt and

!*uOfle from the filter sealing area on the

mg^e Check the old filter to make sure that

M rubber sealing ring hasn't sluck to the

Vgre W it has, carefully remove it

10 Apply a light coating ol engine oil to the

M ing nng on the new filter, then screw it

onto the engine. Tighten the (liter firmly

bt hand only do not use any tools. If

fMtessary refit the splash guard under the

tapme

It Remove the old oil and all tools from

under the car. then lower the car lo the

ground (it applicable!.

12 Remove the dipstick, then unscrew the oil

tt« cap from the cylinder head cover. Fill the

mpr-t- using the correct grade and type of oil

Bee Wee*/K checks) An oil can spout or

linnet may help to reduce spillage. Pour in

kalf the specified quantity of oil first, then wart

a few minutes for the oil to fall to the sump.

Continue adding oil a small quantity at a time

urtt the level is up to the tower mark on the

Opstick Adding approximately 1.5 litres will

bring the level up to the upper mark on the

dpstick Refit the filler cap.

13 Start the engine and run it tor a few

minutes, check for leaks around the oil filter

seal and the sump dram plug There may be a

delay ot a few seconds before the oil pressure

nming, light goes out when the engine is firsl

tuned, as the oil circulates through the

3.81) .. . then unscrew it by hand the rest

of the way

engine oil galleries and the new oil fitter (where

fitted) before the pressure buiMs up.

14 Switch off the engine, and wait a few

minutes for the oil to settle in the sump once

more. With the new oil circulated and the filter

completely full, recheck the level on the

dipstick, and add more oil as necessary

15 Dispose ot the used engine oil safely, with

reference to Genera/ Repair Procedures.

4 Automatic transmission fluid

renewal 'iy

S i

1 T ake the vehicle on a short rim, to warm the

transmission up to normal operating

temperature,

2 Park the car on level ground, then switch off

the ignition and apply the parking brake firmly.

For Improved access, chock the rear wheels

then jack up the front of the car and support it

securely on axle stands (see Jacking and

Vehicle Support) When refilling and checking

the fluid level, the car must be towered to the

ground, and level, to ensure accuracy.

3 Remove the dipstick, then position a

suitable container under the transmission. The

transmission unit has one drain plug, located

at the bottom of the differential housing.

A

Warning: It the fluid is hot, take

precautions against scalding.

4 Unscrew the drain plug, and allow the fluid

to drain completely into the container. Clean

the dram plug, being especially careful to wipe

any metallic particles off the magnetic Insert.

Discard the original sealing washers: these

should be renewed whenever they are

disturbed.

5 When the fluid has finished draining, clean

the drain plug threads and those of the

transmission casing. Fit a new sealing washer

to the drain plug, and refit the plug to the

transmission, tightening ft securely. If the

car was raised for the draining operation,

now lower it lo the ground. Make sure that

the car is level (Iront-to-rear and side-to-

SKJe)

6 Refilling the transmission is an awkward

operation, adding the specified type of fluid to

the transmission a little at a time via the

dipstick tube. Alternatively, use the filler cap

(breather) having cleaned around the area

first. Use a funnel with a fine-mesh gauze, to

avoid spillage, and to ensure that no foreign

matter enters the transmission, Allow pJenty ot

time for the fluid level to settle properly

7 Once the level is up to the MAX mark on the

dipstick, refit the dipstick. Start the engine,

and allow It to idle for a lew minutes In P, then

recheck the level, topping-up if necessary

Take the car on a short run to fully distribute

the new fluid around the transmission, then

recheck the fluid level.

5 Clutch pedal height check -

models with cable-operated ,

clutch ^

t The clutch adjustment Is checked by

measuring the dutch pedal travel, If a new

cable has been fitted, settle it in position by

depressing the clutch pedal at least thirty

times.

2 Ensure that there are no obstructions

beneath the clutch pedal then measure the

distance (L1) from the centre of the clutch

pedal pad to the base of the steering wheel

with the pedal in the at-resl position. Depress

the clutch pedal fully to the floor, and measure

the distance (L 2) from the centre ot the clutch

pedal pad to the base of the steering wheel

(see Illustration)

3 Subtract the first measurement from the

second to obtain the clutch pedal travel. If this

is not with the range given in the

Specifications at the start of this Chapter,

adjust the clutch as follows,

4 The clutch cable is ad|usted by means of

the adjuster nut on the transmission end of

the cable. Access to the locknut is

limited and. if required, the air cleaner

duct or housing component can be

removed or disconnected to improve access

(refer to Chapter 4A). Access can be further

LI Pedal height at rest

L2 Pedal height tulfy depressed

X Clutch pedal travel

ia *8 Every 9000 miles - petrol models

1 Locknut

2 Ad/ustment nut

3 Clutch release

arm

6 Hose and fluid leak check

*

impoved by removing the battery and

its holder (refer to Chapter 5A) (see

Illustration)

5 Working in the engine compartment,

slacken the locknut from the end of the clutch

cable Adjust the position of the adiuster nut.

then depress the clutch pedal ten times and

re-measure the clutch pedal travel. Repeat

this procedure until the clutch pedal travel is

as specified.

6 Once the adjuster nut is correctly

positioned, and the pedal travel is correctly

set. securely tighten the cable locknut. Where

necessary, refit any disturbed air cleaner

duct/housing components (see Chapter 4A).

1 Visually inspect the engine joint faces,

gaskets and seals for any signs of water or oil

leaks. Pay particular attention to the areas

around the cylinder head cover, cylinder head,

oil filter and sump )oint faces. Bear in mind

that, over a period of time, some very slight

seepage from these areas is to be expected -

what you are really looking for is any

indication of a serious leak. Should a leak be

found, renew the offending gasket or oil seal

by referring to the appropriate Chapters in this

manual.

2 Also check the security and condition of all

the engine-related pipes and hoses, and all

hydraulic and braking system pipes and

hoses (see illustration) Ensure that all cable

ties or securing dips are m place, and in good

condition Clips which are broken or missing

can lead to chafing of the hoses, pipes or

wiring, which could cause more serious

problems In the future.

3 Carefully check the radiator hoses and

heater hoses along their entire length . Renew

any hose which Is cracked, swollen or

deteriorated Cracks will show up better if the

hose is squeezed Pay close attention to the

hose clips that secure the hoses to the

6.2 Check the hydraulic fluid pipes for

leaks

cooling system components. Hose clips can

pinch and puncture hoses, resulting in cooling

system leaks If the cnmped-type hose clips

are used, it may be a good idea to replace

them with standard womvdrive clips

4 Inspect all the cooling system components

(hoses, joint faces, etc) for leaks (see Haynes

Hint)

5 Where any problems are found on system

components, renew the component or gasket

with reference to Chapter 3.

6 With the vehicle raised, inspect the fuel

tank and tiller neck lor punctures, cracks and

other damage The connection between the

filler neck and tank is especially critical.

Sometimes a rubber filler neck or connecting

hose will leak due to loose retaining damps or

deteriorated rubber

7 Carefully check all rubber hoses and metal

fuel lines leading away from the fuel tank.

Check for loose connections, deteriorated

hoses, cnmped lines, and other damage Pay

particular attention to the vent pipes and

hoses, which often loop up around the filler

neck and can become blocked or crimped.

Follow the lines to the front of the vehicle,

carefully inspecting them all the way Renew

damaged sections as necessary Similarly,

whilst the vehicle is raised, take the

opportunity to Inspect all underbody brake

fluid pipes and hoses

8 From within the engine compartment.

HAYNES

A leak in the cooling system will usualIf

show up as white or rust-coloured

deposits on the area adjoining the leak

7.

check the security of all fuel, vacuum an|

brake hose attachments and pipe unions. *1

inspect all hoses for kinks, chafing m

deterioration.

9 Check the condition of the power steentfl

fluid pipes and hoses and. where applicatHa|

the automatic transmission fluid cooler p i M

and hoses. ■

6

I

7 Steering and suspension ^

check £|j

I

I securJ

king

Suspension and steering check

1 Raise the front ot the vehicle, and

support it on axle stands (see Jacking

Vehicle Support) i

2 Visually inspect the balljoint dust covofl

and the steering gear gaiters for splits, chafing

or deterioration (see illustrations) Any wea |

of these components will cause loss a

lubricant, together with dirt and water entrjJ

resulting in rapid deterioration of the balltoirfl

or steering gear

3 Check the hydraulic fluid hoses and pip

for chafing or deterioration, and the pipe I

hose unions for fluid leaks. Also check

signs of fluid leakage under pressure from t

steering gear rubber gaiters, which wc

7.2a Inspect the ball)oint dust

covers...

7.2b . . . and the steering gear

gaiters

You're Reading a Preview

What's Included?

Fast Download Speeds

Online & Offline Access

Access PDF Contents & Bookmarks

Full Search Facility

Print one or all pages of your manual

$31.99

Viewed 49 Times Today

Loading...

Secure transaction

What's Included?

Fast Download Speeds

Online & Offline Access

Access PDF Contents & Bookmarks

Full Search Facility

Print one or all pages of your manual

$31.99

Get access to a comprehensive service/repair manual for the Citroen XM, featuring detailed instructions and step-by-step diagrams for all workshop procedures. This manual is an invaluable resource for both professional mechanics and DIY enthusiasts, providing all the necessary information to keep your Citroen XM running smoothly.

The manual is available in PDF format, allowing for easy printing of information and notes for reference.

It is suitable for the following models:

- Citroen XM

Product Details:

- File Format: PDF

- Compatible: All Versions of Windows & Mac

- Language: English

- Printable: Without any restriction

- Delivery: Link will appear on the checkout page after payment is complete

- Requirements: Adobe Reader

Obtaining the manual is simple. Upon completing the purchase, you can instantly download it, saving both time and money. There's no need to pay extra costs or wait for delivery.