2001-2006 Chrysler PT Cruiser Service & Repair Manual

What's Included?

Fast Download Speeds

Offline Viewing

Access Contents & Bookmarks

Full Search Facility

Print one or all pages of your manual

GROUP TAB LOCATOR

Introduction

0

Lubrication & Maintenance

2

Suspension

3

Differential & Driveline

5

Brakes

6

Clutch

7

Cooling

8A

Audio/Video

8B

Chime/Buzzer

8E

Electronic Control Modules

8F

Engine Systems

8G

Heated Systems

8H

Horn

8I

Ignition Control

8J

Instrument Cluster

8L

Lamps

8M

Message Systems

8N

Power Systems

8O

Restraints

8P

Speed Control

8Q

Vehicle Theft Security

8R

Wipers/Washers

8T

Navigation/Telecommunication

8W

Wiring

9

Engine

11

Exhaust System and Turbocharger

13

Frame & Bumpers

14

Fuel System

19

Steering

21

Transaxle

22

Tires/Wheels

23

Body

24

Heating & Air Conditioning

25

Emissions Control

Component and System Index

Service Manual Comment Forms (Rear of Manual)

INTRODUCTION

TABLE OF CONTENTS

page page

BODY CODE PLATE

DESCRIPTION .......................... 1

FASTENER IDENTIFICATION

DESCRIPTION .......................... 2

FASTENER USAGE

DESCRIPTION

FASTENER USAGE ..................... 5

THREADED HOLE REPAIR ............... 5

INTERNATIONAL SYMBOLS

DESCRIPTION .......................... 5

METRIC SYSTEM

DESCRIPTION .......................... 5

TORQUE REFERENCES

DESCRIPTION .......................... 8

VEHICLE IDENTIFICATION NUMBER

DESCRIPTION - VEHICLE IDENTIFICATION

NUMBER ............................. 9

VEHICLE CERTIFICATION LABEL

DESCRIPTION ......................... 11

E-MARK LABEL

DESCRIPTION ......................... 11

VECI LABEL

DESCRIPTION ......................... 11

MANUFACTURER PLATE

DESCRIPTION ......................... 11

BODY CODE PLATE

DESCRIPTION

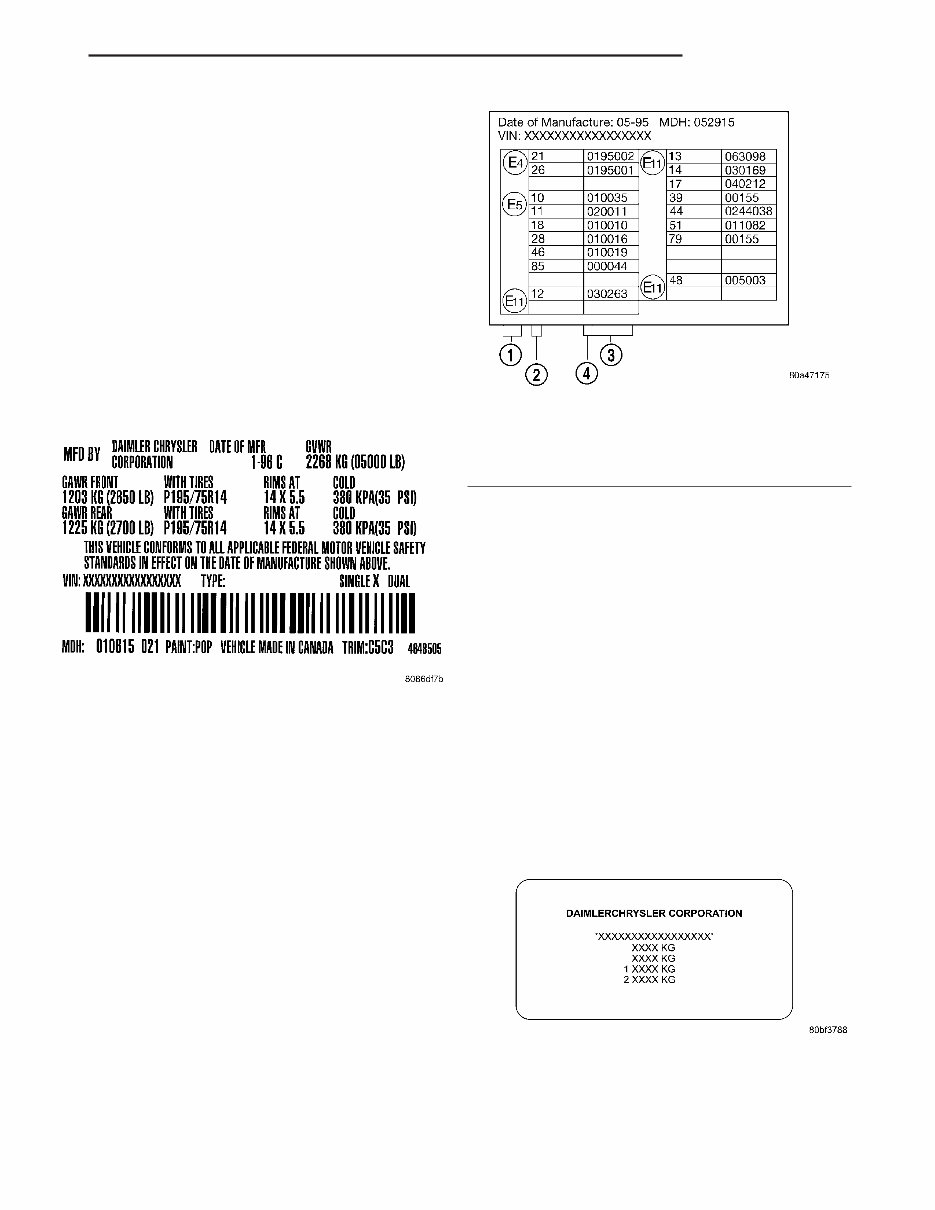

The Body Code Plate (Fig. 1) is located in the

engine compartment on the plenum behind the right

side struttower (Fig. 2). There are seven lines of

information on the body code plate. Lines 4, 5, 6, and

7 are not used to define service information. Informa-

tion reads from leftto right, starting with line 3 in

the center of the plate to line 1 atthe bottom of the

plate.

BODYCODE PLATE LINE2

DIGITS 1, 2, AND 3

Paint procedure

DIGIT 4

Open Space

DIGITS 5THROUGH 7

Primary paint

(Refer to 23 - BODY/PAINT - SPECIFICATIONS)

for Body Color Codes.

DIGIT 8 AND 9

Open Space

DIGITS 10 THROUGH 12

Secondary Paint

DIGIT 13 AND 14

Open Space

DIGITS 15 THROUGH 18

Interior Trim Code

DIGIT 19

Open Space

Fig. 1 BODY CODE PLATE

1 - PRIMARY PAINT

2 - SECONDARY PAINT

3 - VINYL ROOF

4 - VEHICLE ORDER NUMBER

5 - CAR LINE SHELL

6 - PAINT PROCEDURE

7 - ENGINE

8 - TRIM

9 - TRANSMISSION

10 - MARKET

11 - VIN

PT INTRODUCTION 1

VEHICLE CERTIFICATION

LABEL

DESCRIPTION

A vehicle certification labelis attached to the rear

shutface of the driver’s door (Fig.4). This labelindi-

cates date of manufacture (month and year), Gross

V ehicle Weight Rating (GVWR), Gross Axle Weight

Rating (GA WR) front, Gross Axle Weight Rating

(GA WR) rear and the V ehicle Identification Number

(VIN). The Month, Day and Hour of manufacture is

also included.

All communications or inquiries regarding the

vehicle should include the Month-Day-Hour and

V ehicle Identification Number .

E-MARK LABEL

DESCRIPTION

An E-mark Label (Fig. 5) is located on the rear

shut face of the driver’s door . The label contains the

following information:

• Date of Manufacture

• Month-Day-Hour (MDH)

• V ehicle Identification Number (VIN)

• Country Codes

• Regulation Number

• Regulation Amendment Number

• Approval Number

VECI LABEL

DESCRIPTION

All models have a V ehicle Emission Control Infor-

mation (VECI) Label. Chrysler permanently attaches

the label in the engine compartment. It cannot be

removed without defacing information anddestroying

the label.

The label contains the vehicle’s emission specifica-

tions and vacuum hose routings. All hoses must be

connected and routed according to the label.

MANUFACTURER PLATE

DESCRIPTION

The Manufacturer Plate (Fig. 6) is located in the

engine compartment on the passenger side rear cor-

ner of the hood. The plate contains five lines of infor-

mation:

1. V ehicle Identification Number (VIN)

2. Gross V ehicle Mass (GVM)

3. Gross Train Mass (GTM)

4. Gross Front Axle Rating (GFAR)

5. Gross Rear Axle Rating (GRAR)

Fig. 4 VEHICLE CERTIFICATION LABEL - TYPICAL

Fig. 5 E-MARK LABEL

1 - COUNTRY CODE

2 - REGULATION NUMBER

3 - APPROVAL NUMBER

4 - AMENDMENT NUMBER

Fig. 6 MANUFACTURER PLATE

PT INTRODUCTION 11

• Association des Constructeurs Européens d’

Automobiles (European Automobile Manufacturers

Association) (ACEA)

API CERTIFICATION AND LICENSE SYMBOL

Use an engine oil that is API Certified (Fig.2) and

Licensed to display the certification mark. MOPAR

provides engine oils that meet or exceed, Material

Standard MS-6395 requirement.

SAE VISCOSITY

SAE 5W-20 and SAE 5W-30 engine oils are rec-

ommended for all operating temperatures.

These engine oils are designed to improve low

temperaturestarting and vehicle fuel economy .

Referto theengine oil filler cap forthe pre-

ferred engine oilviscositygrade for each vehi-

cle (Fig. 3). SAE viscositygrades are used to specify

the correct viscosity oil for an engine. Use only Multi-

Viscosity oils such as SAE 5W-20 or 5W-30. These

are specified with a dualSAE viscositygrade which

indicates the cold (5W) to hot (20, 30) temperature

performance range of the oil.

ACEA CATEGORIES

For countries that use the ACEA European Oil

Categories for service fill oils, use engine oils that

meet the requirements of ACEAA1/B1, A2/B2, or

A3/B3.

CONTAINER IDENTIFICATION

The Engine Oil Certification Mark was developed

and trademarked by the API to refer customers to

thoseengine oils preferred by the automobile manu-

facturers. Thissymbol means thatthe oil has been

certified and licensed by the American Petroleum

Institute (API). This certification mark will only be

found on the front of the oil containers (Fig.4). Those

oils that do not display the “Mark” on the front of the

container should not be used.

DiamlerChrysler only recommends API Certified

engine oils that meetthe requirements of Material

Standard MS-6395. Use Mopar or an equivalent oil

meeting the specification MS-6395.

SYNTHETIC ENGINE OILS

There are a number of engine oils being promoted

as either syntheticor semi-synthetic. If you chose to

use such a product, use only those oils that are cer-

tified by the American Petroleum Institute (API) to

display the “Certification Mark” and show SAE vis-

cosity grade recommended for each vehicle. Follow

the service schedule that describes your driving type.

ENGINE OIL ADDITIVES/SUPPLEMENTS

The manufacturer does notrecommend the addi-

tion of any engine oil additives/supplements to the

specified engine oil. Engine oil additives/supplements

should not be used to enhance engine oil perfor-

mance. Engine oil additives/supplementsshould not

be used to extend engine oil change intervals. No

additive is known to be safe for engine durability and

can degradeemission components. Additives can con-

tain undesirable materials that harm the long term

durability of engines and emission systems by:

• Increasing the level of Phosphorus and Sulfur in

theengine oil. The API Certified Engine Oils control

the Phosphorus and Sulfur contents of the oil to lev-

els that reduce the contamination effect on the vehi-

cles emission control system.

• Altering the viscosity characteristics of the

engine oil so that it no longer meets the require-

ments of the specified viscositygrade.

• Creating potential for an undesirable additive

compatibility interaction in the engine crankcase.

Fig. 2 API Certification Mark

Fig. 3 5W-30 Oil Filler Cap

Fig. 4 API Certification Mark

0 - 2 LUBRICATION & MAINTENANCE PT

FLUID TYPES (Continued)

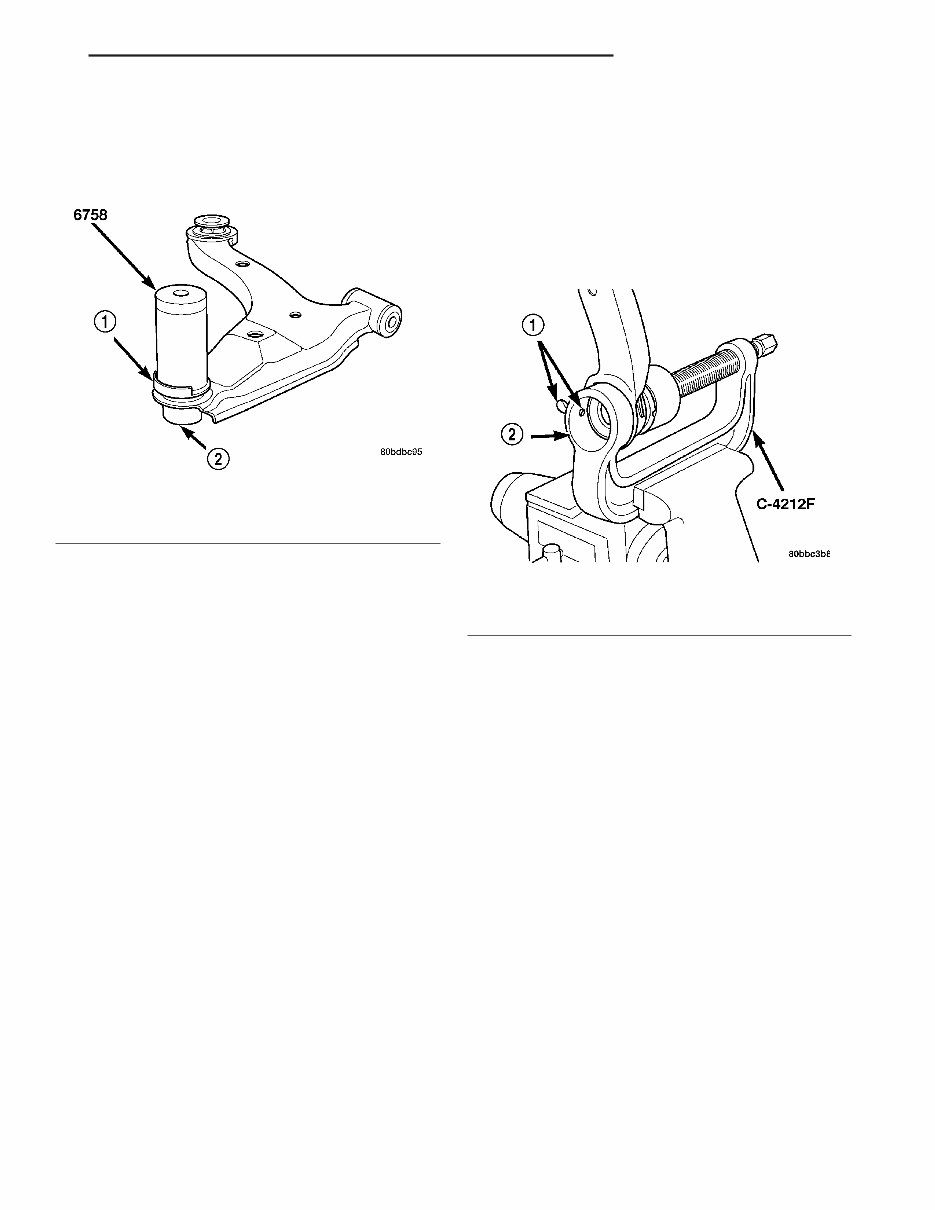

CAUTION: When installing the sealing boot on the

ball joint, position the upward lip on the outside

perimeter of the seal boot outward, away from the

control arm once installed (Fig. 32). It is there to

help shield heat from the sealing boot.

(6) Place a new ball joint seal boot over the ball

joint stud. The upward lip located on the outside

perimeter of the seal boot must point outward away

from the control arm once installed (Fig. 32). Start

the sealing boot over the sides of the ball joint by

hand.

(7) Position the Installer , Special T ool 6758, over

the sealing boot outer diameter asshown (Fig. 32).

By hand, apply pressure to the top of the Installer

until the seal boot is pressed squarely down against

the top surface of lower control arm.

(8) Remove the tool.

(9) If not already installed, install standard zirc-

type grease fitting in ball joint.

CAUTION: It is important to lubricate the ball joint

before installation of steering knuckle to allow

proper venting when the seal is filled. If the ball

joint is lubricated after installation to knuckle, dam-

age to the seal can occur.

(10) Using a hand-operatedpump grease gun, fill

the ball joint seal boot with Mopar Multi-Mileage

Lube or equivalent until grease pushes out past ball

joint stem. Wipe off overfill.

(11) Remove standard zirc-type grease fitting and

install headless grease fitting from original ball joint

to prevent future lubricating. See above Caution. Be

sure to properly cleanheadless grease fitting

priorto installation.

(12) Install the lower control arm. (Refer to 2 -

SUSPENSION/FRONT/LOWER CONTROL ARM -

INSTALLATION).

ASSEMBL Y - LOWER CONTROL ARM (REAR

ISOLATOR BUSHING)

(1) Back the Ball Joint Press, Special T ool

C-4212F , set screw outward so it does not extend out

into the cup area (Fig. 33).

(2) Startthe isolator bushing into the bottom of

the lower control arm bushing bore by hand. Position

the bushing so the voids in the rubber are aligned in

relationship to the ball joint asshown (Fig. 34). Place

the larger void toward the ball joint.

(3) Install the Installer , Special T ool 9356-1, on the

tip of the Ball Joint Press screw drive.

(4) Place the lower control arm upper flange

against the cup area of the Ball Joint Press and

tighten the screw-drive until the Installer contacts

the outer circumference of the bushing (Fig. 35).

Make sure the bushing flange sits squarely in the

step built into the Installer .

(5) Using hand tools, slowly tighten the screw-

drive until the bushing bottoms in the lower control

arm bushing bore. Do not overtighten the screw-

drive; damage to the bushing, arm or tool can result.

(6) Back off the screw-drive and remove the con-

trol arm from the Ball Joint Press.

(7) Install the lower control arm on the vehicle.

(Refer to 2 - SUSPENSION/FRONT/LOWER CON-

TROL ARM - INSTALLATION)

Fig. 32 Seal Boot Installation

1 - SEAL BOOT UPWARD LIP

2 - BALL JOINT

Fig. 33 Set Screw Backed Outward

1 - SET SCREW

2 - CUP AREA

PT FRONT SUSPENSION 2 - 17

LOWER CONTROL ARM (Continued)

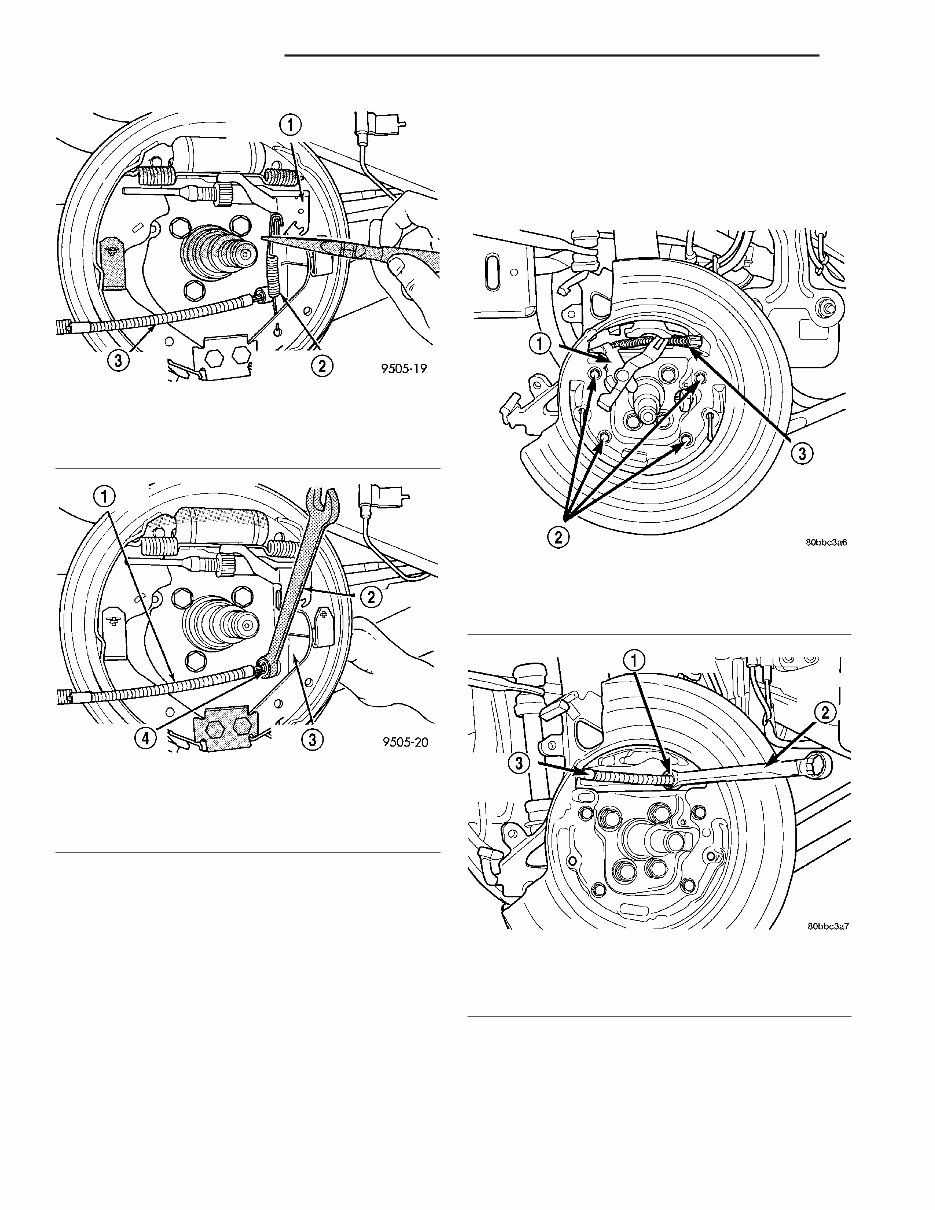

(16) T o remove the parking brake cable from the

disc brake adapter on vehicles equipped with rear

disc brakes:

(a) Remove the parking brake actuating lever

from the parking brake cable (Fig. 11).

(b) Remove the parking brake cable from the

rear disc brake adapter . The parking brake cable

can be removed from the disc brake adapter using

a

1

/2 inch offset box wrench to compress the locking

fingers on the parking brake cable retainer (Fig.

12).

Fig. 9 Actuating Spring

1 - BRAKE SHOE ADJUSTMENT LEVER

2 - ADJUSTMENT LEVER ACTUATING SPRING

3 - PARK BRAKE CABLE

Fig. 10 Parking Brake Cable Removal

1 - PARK BRAKE CABLE

2 - 1/2 WRENCH

3 - REAR BRAKE SUPPORT PLATE

4 - PARK BRAKE CABLE RETAINER

Fig. 11 Parking Brake Actuator Lever

1 - SHOE ACTUATOR LEVER

2 - SHIELD MOUNTING SCREWS

3 - REAR PARKING BRAKE CABLE

Fig. 12 Parking Brake Cable Removal

1 - CABLE RETAINER

2 - OFFSET BOX WRENCH

3 - PARKING BRAKE CABLE

2 - 32 REARSUSPENSION PT

AXLE - FRONT WHEEL DRIVE REAR (Continued)

(4) On vehicles equipped with rear disc brakes:

(a) Remove the boltssecuring the disc brake flex

hose to the axle trailing arm.

(b) Remove the disc brake caliper guide pin

bolts, then the caliper from the disc brake adapter

(Fig. 27).

(c) Hang the caliper out of the way using a wire

hanger or bungee cord.

(d) Remove the brake rotor from the rear hub

and bearing.

(5) Remove the dust cap from the rear hub and

bearing (Fig. 26).

(6) Remove the hub and bearing retaining nut

from the spindle, then remove the hub and bearing

(Fig. 26).

(7) Remove the two bolts on each axle trailing arm

securing the parking brake cable and routing brack-

ets to the axle trailing arm (Fig. 28).

(8) On vehicles equipped with antilock brakes,

remove the bolt securing the wheel speed sensor to

the disc brake adapter (Fig. 29). Remove the sensor

from the adapter .

(9) Remove the four boltssecuring the brake shoe

support plate (drum brakes)or disc brake adapter ,

and spindle to the axle (Fig. 26).

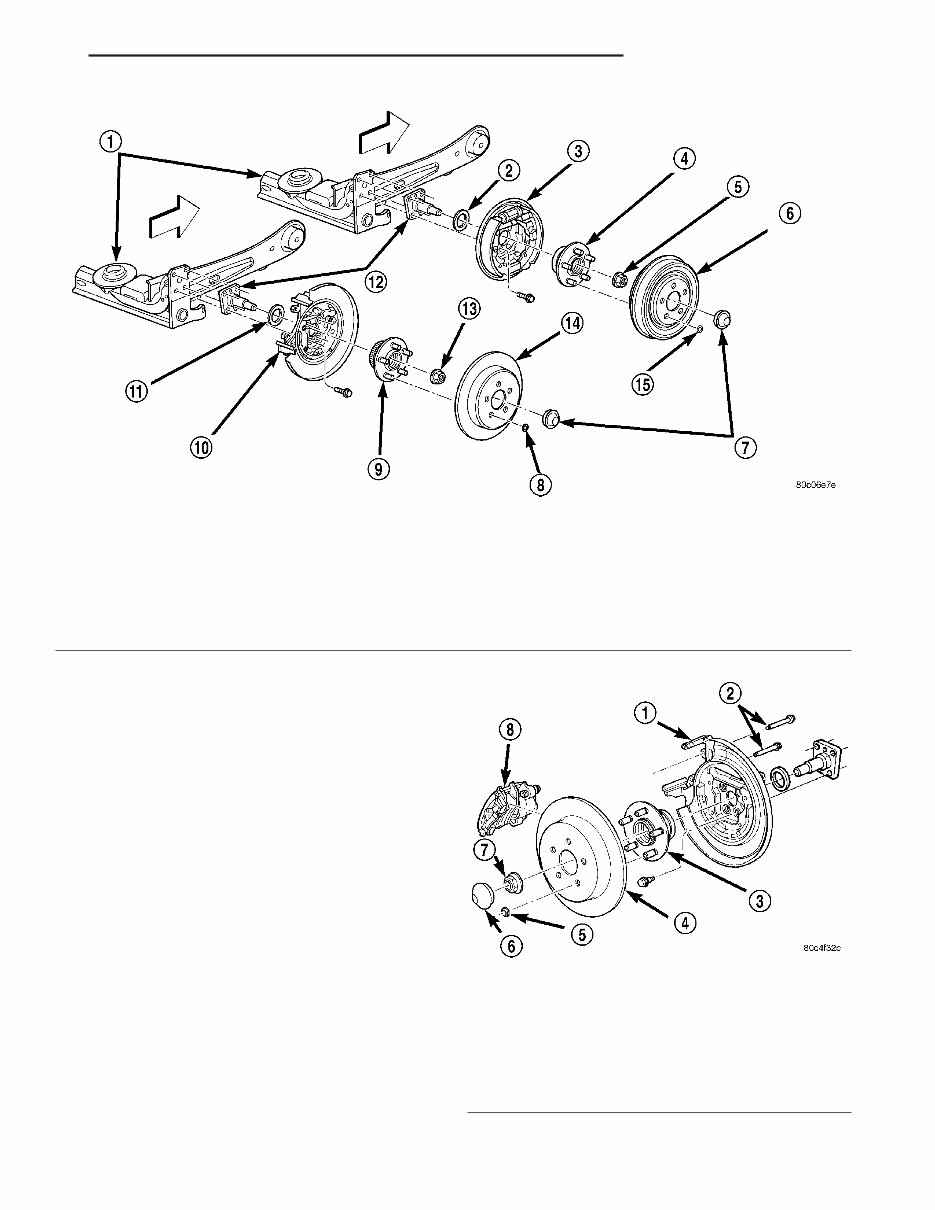

Fig. 26 Rear Brake Mounting To Axle

1 - AXLE

2 - SEAL

3 - DRUM BRAKE WITH SUPPORT PLATE

4 - HUB AND BEARING

5 - HUB NUT

6 - BRAKE DRUM

7 - DUST CAP

8 - RETAINER CLIP

9 - HUB AND BEARING

10 - DISC BRAKE ADAPTER

11 - SEAL

12 - SPINDLE

13 - HUB NUT

14 - BRAKE ROTOR

15 - RETAINER CLIP

Fig. 27 Rear Disc Brakes

1 - DISC BRAKE ADAPTER

2 - GUIDE PIN BOLTS

3 - HUB AND BEARING

4 - BRAKE ROTOR

5 - RETAINER CLIP

6 - DUST CAP

7 - NUT

8 - DISC BRAKE CALIPER

PT REARSUSPENSION 2 - 43

SPINDLE (Continued)

DIAGNOSIS AND TESTING - SUSPENSION ANDSTEERING

CONDITION POSSIBLE CAUSES POTENTIAL CORRECTIONS

Front End Whine On Turns 1. Defective Wheel Bearing 1. Replace Wheel Bearing

2. Incorrect Wheel Alignment 2. Check And Reset Wheel Alignment

3. Worn Tires 3. Replace Tires

Front End Growl Or

Grinding On Turns

1. Defective Wheel Bearing 1. Replace Wheel Bearing

2. Engine Mount Grounding

Against Frame Or Body Of Vehicle.

2. Check For Motor Mount Hitting Frame

Rail And Reposition Engine As Required

3. Worn Or Broken C/V Joint 3. Replace C/V Joint

4. Loose Wheel Lug Nuts 4. Verify Wheel Lug Nut Torque

5. Incorrect Wheel Alignment 5. Check And Reset Wheel Alignment

6. Worn Tires 6. Replace Tires

Front End Clunk Or Snap

On Turns

1. Loose Wheel Lug Nuts 1. Verify Wheel Lug Nut Torque

2. Worn Or Broken C/V Joint 2. Replace C/V Joint

3. Worn Or Loose Tie Rod Or Ball

Joint

3. Tighten Or Replace Tie Rod End Or Ball

Joint

4. Worn Control Arm Bushing 4. Replace Control Arm Bushing

5. Loose Sway Bar Or Upper Strut

Attachment

5. Tighten Sway Bar Or Upper Strut

Attachment To Specified Torque

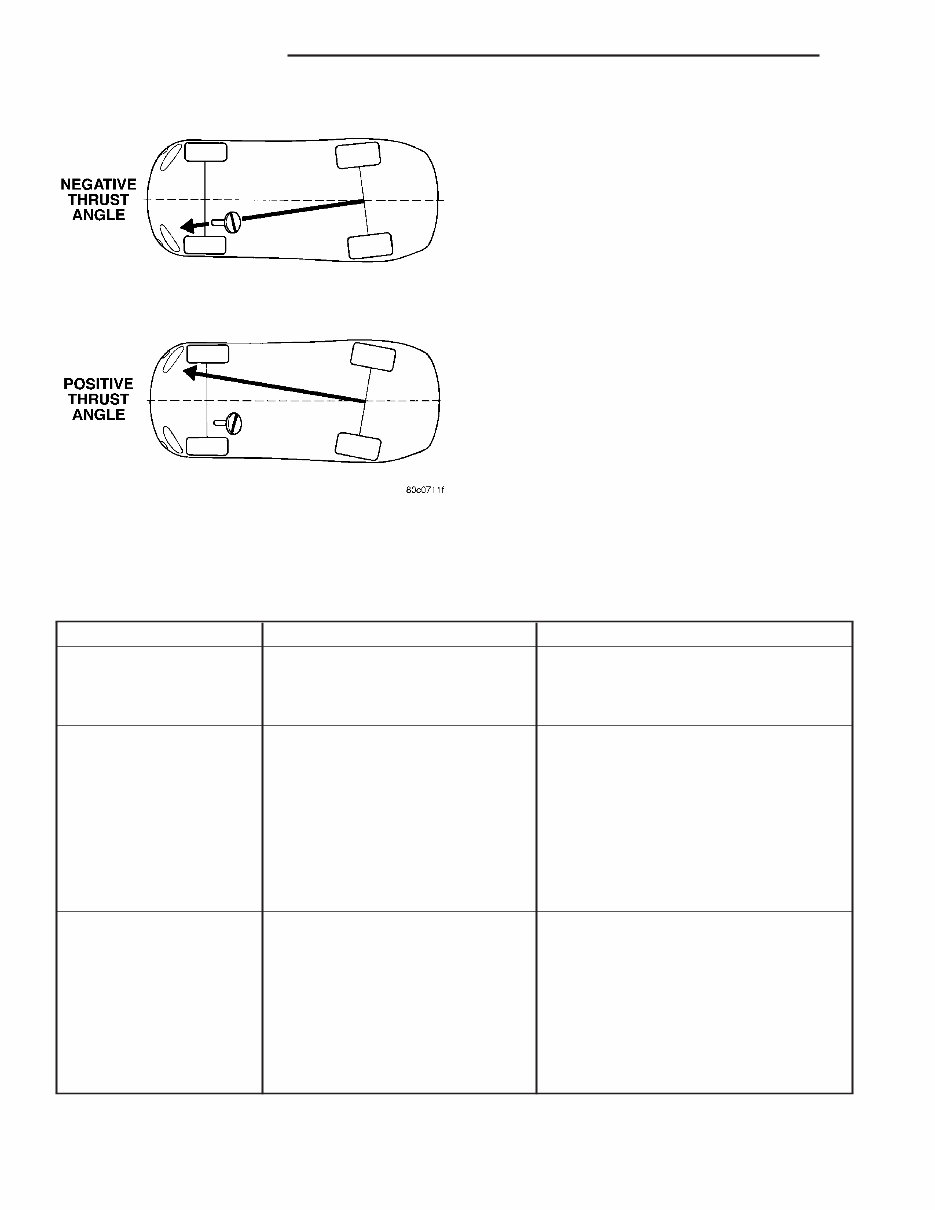

Fig. 6 Thrust Angle

2 - 56 WHEEL ALIGNMENT PT

WHEEL ALIGNMENT (Continued)

OPERATION

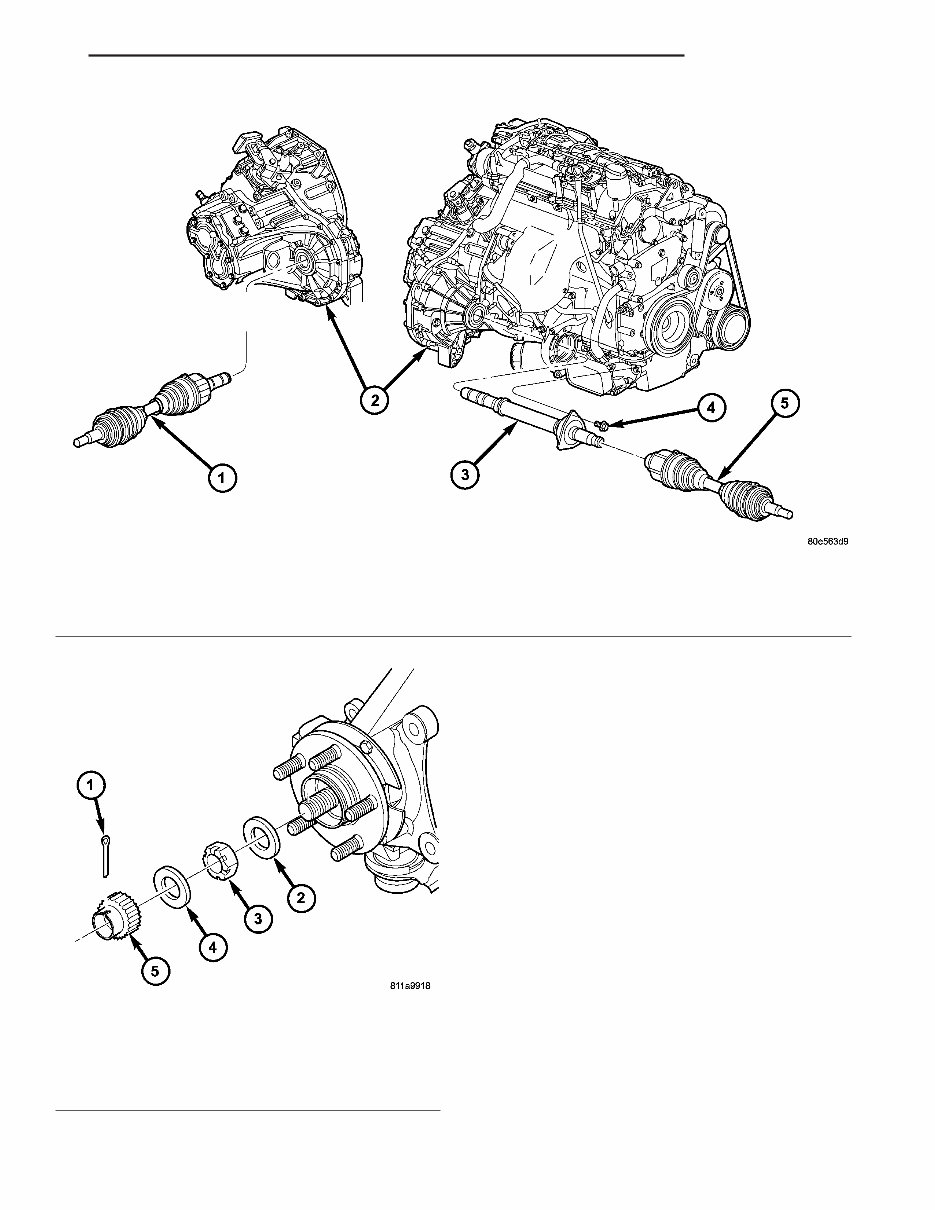

Halfshaft assemblies are designed to transmit

power from the transaxle to the front wheels, while

allowing for powertrain and suspension flex.

DIAGNOSIS AND TESTING - HALFSHAFT

DIAGNOSIS

VEHICLEINSPECTION

(1) Check for grease in the vicinity of the inboard

tripod joint and outboard C/V joint; this is a sign of

inner or outer joint seal boot or seal boot clampdam-

age.

NOISEAND/OR VIBRATION IN TURNS

Aclicking noise and/or a vibration in turns could

be caused by one of the following conditions:

(1) Loose hub nut. Using a click-style torque

wrench, torque hub nutto 244 N·m (180 ft. lbs.).

(2) Damaged outer C/V or inner tripod joint seal

boot or seal boot clamps, which is evident by the

presence of grease slung outward from the joint. This

will result in the loss and/or contamination of the

joint grease, resulting in inadequate lubrication of

the joint.

Fig. 2 Halfshaft and Intermediate Shaft (2.2L TD Shown—2.4L Turbo Similar)

1 - HALFSHAFT (LH)

2 - TRANSAXLE

3 - INTERMEDIATE SHAFT

4 - BOLT (3)

5 - HALFSHAFT (RH)

Fig. 3 Halfshaft Retaining Hardware

1 - COTTER KEY

2 - WASHER

3 - HUB NUT

4 - SPRING WASHER

5 - NUT LOCK

PT HALF SHAFT 3 - 3

HALF SHAFT (Continued)

(3) Noise may also be caused by another compo-

nent of the vehicle coming in contact with the half-

shafts.

CLUNKING NOISE DURING ACCELERATION

This noise may be a result of one of the following

conditions:

(1) A torn seal boot on the inner or outer joint of

the halfshaft assembly , which is evident by the pres-

ence of grease slung outward from the joint. This will

result in the loss and/or contamination of the joint

grease, resulting in inadequate lubrication of the

joint.

(2)A loose or missing clamp on the inner or outer

joint of the halfshaft assembly . This may be accom-

panied by the visible loss of grease.

(3)A damaged or wornhalfshaft C/V joint. Isolate

the noise toone side of the vehicle. Replace only the

affected side. Replacing bothhalfshafts is not neces-

sary .

SHUDDER OR VIBRATION DURING ACCELERATION

(1)A worn or damaged halfshaft inner tripod joint.

Isolate the condition to one side of the vehicle.

Replace only the affected side. Replacing bothhalf-

shafts is not necessary .

(2)A sticking tripod joint spider assembly (inner

tripod joint only). Isolate the condition toone side of

the vehicle. Replace only the affected side. Replacing

bothhalfshafts is not necessary .

(3) Improper wheel balance.

VIBRATION AT HIGHWAY SPEEDS

(1) Foreign material (mud, etc.) packed on the

backside of the wheel(s).

(2) Out of balance fronttires or wheels.

(3) Improper tire and/or wheel runout.

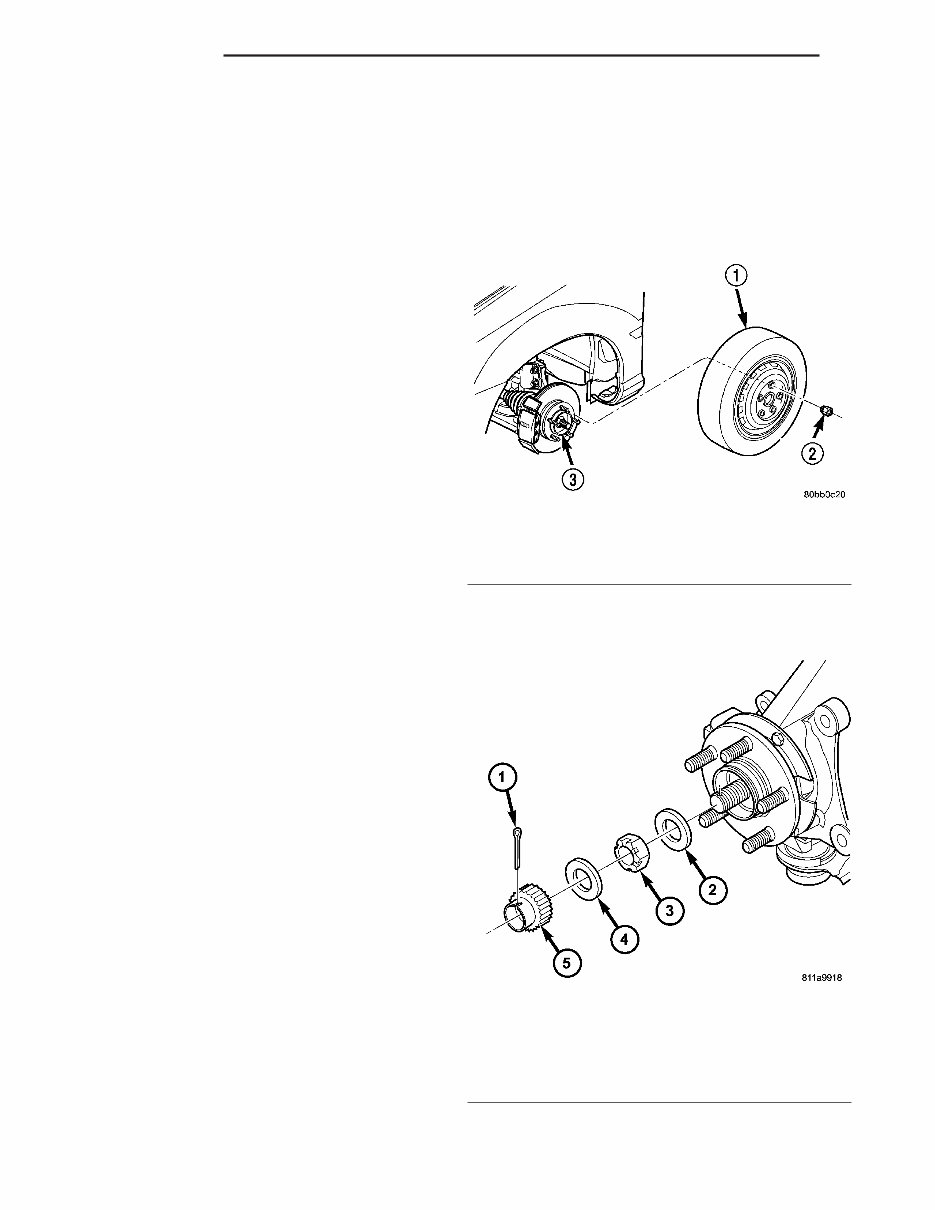

REMOVAL

REMOVAL—EXCEPT DIESEL AND TURBO

MODELS

CAUTION: Boot sealing is vital to retain special

lubricants and to prevent foreign contaminants

from entering the C/V joint. Mishandling, such as

allowing the assemblies to dangle unsupported, or

pulling or pushing the ends can cut boots or dam-

age C/V joints. During removal and installation pro-

cedures, always support both ends of the halfshaft

to prevent damage.

CAUTION: The halfshaft, when installed, acts as a

bolt and secures the front hub/bearing assembly. If

vehicle is to be supported or moved on its wheels

with a halfshaft removed, install a PROPER–SIZED

BOLT AND NUT through front hub. Tighten bolt and

nut to 244 N·m (180 ft. lbs.). This will ensure that

the hub bearing cannot loosen.

(1) Disconnect battery negative cable.

(2) Place transaxle in gatedpark.

(3) Raise vehicle onhoist.

(4) Remove wheel and tire assembly (Fig.4).

(5) Remove the cotter pin, nut lock, and spring

washer , and hub nut from theend of the outer C/V

joint stub axle (Fig.5).

Fig. 4 Wheel and Tire Removal

1 - WHEEL/TIRE ASSY.

2 - LUG NUT (5)

3 - HUB

Fig. 5 Halfshaft Retaining Hardware

1 - COTTER KEY

2 - WASHER

3 - HUB NUT

4 - SPRING WASHER

5 - NUT LOCK

3 - 4 HALF SHAFT PT

HALF SHAFT (Continued)

You're Reading a Preview

What's Included?

Fast Download Speeds

Offline Viewing

Access Contents & Bookmarks

Full Search Facility

Print one or all pages of your manual

$35.99

Viewed 35 Times Today

Loading...

Secure transaction

What's Included?

Fast Download Speeds

Offline Viewing

Access Contents & Bookmarks

Full Search Facility

Print one or all pages of your manual

$35.99

The 2001-2006 Chrysler PT Cruiser Service & Repair Manual is a comprehensive guide for owners of Chrysler PT Cruisers manufactured between 2001 and 2006. This manual provides detailed instructions on maintenance, service, and repair procedures, allowing owners to keep their PT Cruisers in optimal condition.

Key Features of the 2001-2006 Chrysler PT Cruiser Service & Repair Manual:

- Complete coverage of all PT Cruiser models produced from 2001 to 2006

- Step-by-step instructions for vehicle maintenance tasks, including oil changes, filter replacements, and tire rotations

- Detailed diagrams and illustrations to aid in understanding and performing repairs

- Comprehensive troubleshooting guides for addressing common issues and diagnosing problems

- Repair procedures for various components and systems, such as the engine, electrical system, suspension, and brakes

- Specifications and tightening torques for important parts and fasteners

- Easy-to-follow format with clear explanations and helpful tips

- Written by experienced automotive experts

With the 2001-2006 Chrysler PT Cruiser Service & Repair Manual, owners can take control of their vehicle's maintenance and repairs, saving time and money by avoiding costly trips to the mechanic. Whether you are a DIY enthusiast or a professional mechanic, this manual is an essential resource for keeping your PT Cruiser running smoothly and efficiently.