2010-2011 Cadillac SRX Service & Repair Manual

What's Included?

Fast Download Speeds

Online & Offline Access

Access PDF Contents & Bookmarks

Full Search Facility

Print one or all pages of your manual

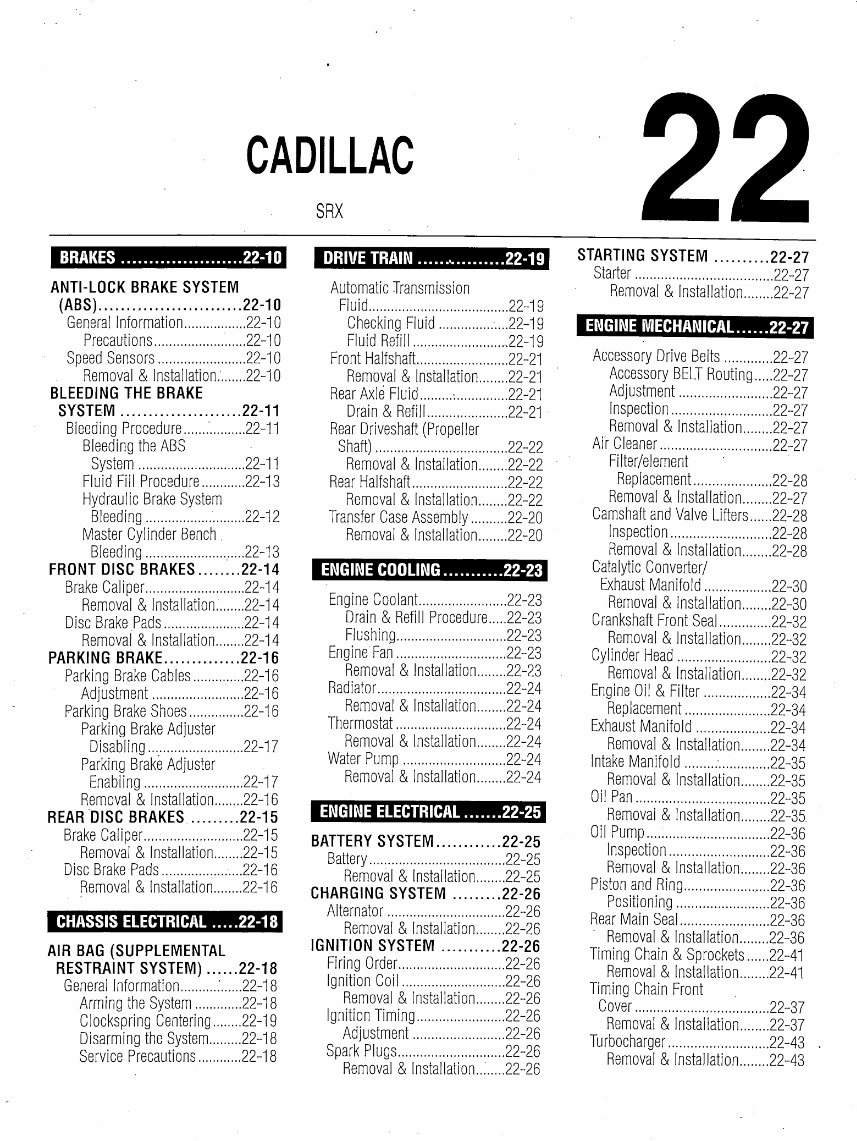

CADILLAC

SRX

BRAKES 22-10 • DRIVE TRAIN 22-19

ANTI-LOCK BRAKE SYSTEM

(ABS) 22-10

General Information 22-10

Precautions 22-10

Speed Sensors 22-10

Removal & Installation: 22-10

BLEEDING THE BRAKE

SYSTEM 22-11

Bleeding Procedure .". 22-11

Bleeding the ABS

System 22-11

Fluid Fill Procedure 22-13

Hydraulic Brake System

Bleeding 22-12

Master Cylinder Bench.

Bleeding 22-13

FRONT DISC BRAKES 22-14

Brake Caliper 22-14

Removal & Installation. 22-14

Disc Brake Pads 22-14

Removal & Installation 22-14

PARKING BRAKE 22-16

Parking Brake Cables 22-16

Adjustment 22-16

Parking Brake Shoes 22-16

Parking Brake Adjuster

Disabling... 22-17

Parking Brake Adjuster

Enabling :22-17

Removal & Installation 22-16

REAR DISC BRAKES 22-15

Brake Caliper..... 22-15

Removal & Installation 22-15

Disc Brake Pads ....22-16

Removal & Installation 22-16

CHASSIS ELECTRICAL 22-18

AIR BAG (SUPPLEMENTAL

RESTRAINT SYSTEM) 22-18

General Information .' 22-18

Arming the System 22-18

Clockspring Centering 22-19

Disarming the System 22-18

Service Precautions 22-18

Automatic Transmission

Fluid 22-19

Checking Fluid ....22-19

Fluid Refill .22-19

Front Halfshaft 22-21

Removal & Installation 22-21

Rear Axle Fluid -. 22-21

Drain & Refill 22-21

Rear Driveshaft (Propeller

Shaft) 22-22

Removal & Installation 22-22

Rear Halfshaft 22-22

Removal & Installation 22-22

Transfer Case Assembly 22-20

Removal & Installation 22-20

ENGINE COOLING 22-23

Engine Coolant 22-23

Drain & Refill Procedure 22-23

Flushing 22-23

Engine Fan 22-23

Removal & Installation 22-23

Radiator 22-24

Removal & Installation 22-24

Thermostat 22-24

Removal & Installation 22-24

Water Pump 22-24

Removal & Installation 22-24

ENGINE ELECTRICAL 22-25

BATTERY SYSTEM 22-25

Battery 22-25

Removal & Installation 22-25

CHARGING SYSTEM 22-26

Alternator 22-26

Removal & Installation 22-26

IGNITION SYSTEM 22-26

Firing Order 22-26

Ignition Coil 22-26

Removal & Installation 22-26

Ignition Timing 22-26

Adjustment 22-26

SparkPlugs 22-26

Removal & Installation...' 22-26

STARTING SYSTEM 22-27

Starter 22-27

Removal & Installation 22-27

ENGINE MECHANICAL 22-27

Accessory Drive Belts 22-27

Accessory BELT Routing 22-27

Adjustment 22-27

Inspection 22-27

Removal & Installation 22-27

Air Cleaner 22-27

Filter/element

Replacement 22-28

Removal & Installation 22-27

Camshaft and Valve Lifters 22-28

Inspection 22-28

Removal & Installation 22-28

Catalytic Converter/

Exhaust Manifold 22-30

.Removal & Installation 22-30

Crankshaft Front Seal 22-32

Removal & Installation 22-32

Cylinder Head 22-32

Removal & Installation 22-32

Engine Oil & Filter 22-34

Replacement 22-34

Exhaust Manifold 22-34

Removal & Installation 22-34

Intake Manifold • 22-35

Removal & Installation 22-35

Oil Pan 22-35

Removal & Installation 22-35.

Oil Pump..... 22-36

Inspection 22-36

Removal & Installation 22-36

Piston and Ring ,...22-36

Positioning 22-36

Rear Main Seal 22-36

' Removal & Installation 22-36

Timing Chain & Sprockets 22-41

Removal & Installation 22-41

Timing Chain Front

Cover 22-37

Removal & Installation..: 22-37

Turbocharger 22-43

Removal & Installation 22-43

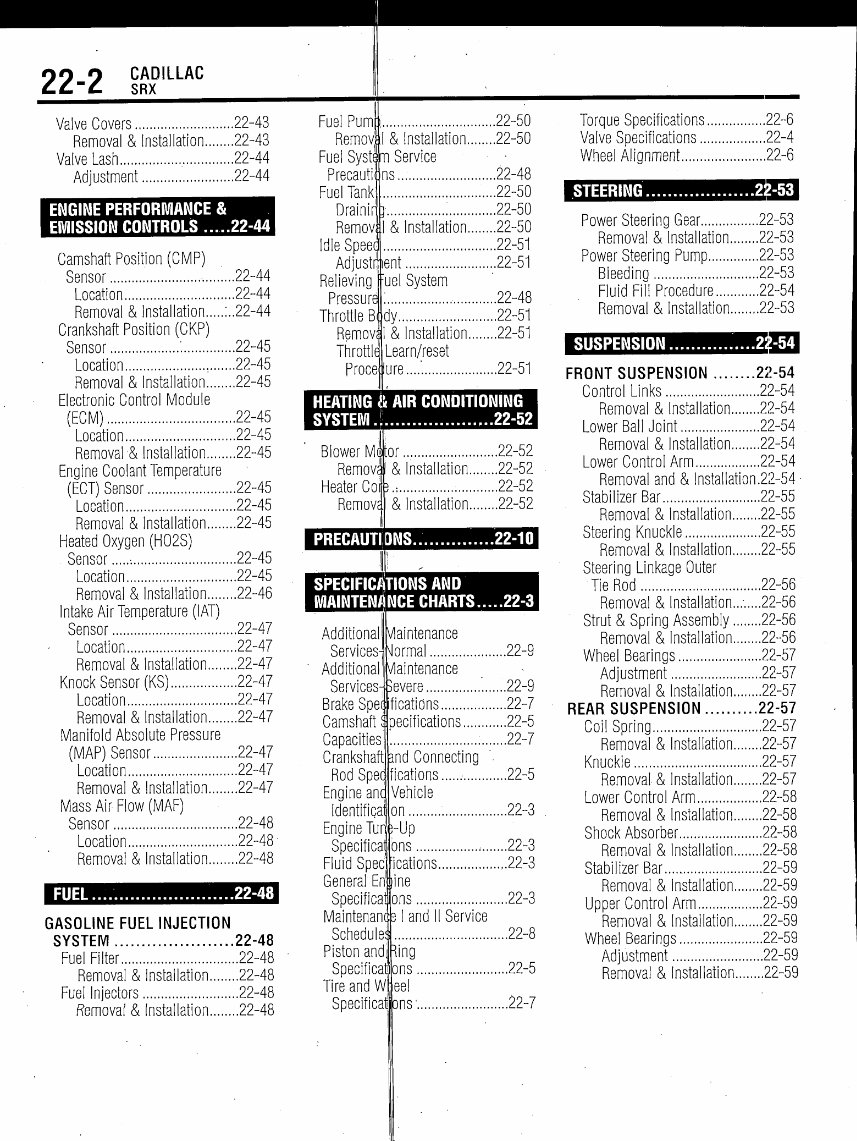

22-2

CADILLAC

SRX

Valve Covers 22-43

Removal & Installation 22-43

Valve Lash 22-44

Adjustment 22-44

ENGINE PERFORMANCE &

EMISSION CONTROLS .....22-44

Camshaft Position (CMP)

Sensor 22-44

Location 22-44

Removal & Installation :..22-44

Crankshaft Position (CKP)

Sensor : 22-45

Location 22-45

Removal & Installation 22-45

Electronic Control Module

(ECM) 22-45

Location 22-45

Removal & Installation 22-45

Engine Coolant Temperature

(ECT) Sensor 22-45

Location 22-45

Removal & Installation 22-45

Heated Oxygen (H02S)

Sensor -. 22-45

Location 22-45

Removal & Installation 22-46

Intake Air Temperature (IAT)

Sensor 22-47

Location 22-47

Removal & Installation 22-47

Knock Sensor (KS) 22-47

Location 22-47

Removal & Installation 22-47

Manifold Absolute Pressure

(MAP) Sensor 22-47

Location 22-47

Removal & Installation 22-47

Mass Air Flow (MAF)

Sensor 22-48

Location 22-48

Removal & Installation 22-48

FUEL.... .....22-48

GASOLINE FUEL INJECTION

SYSTEM 22-48

Fuel Filter 22-48

Removal & Installation 22-48

Fuel Injectors 22-48

Removaf & Installation 22-48

Tl

Fuel Pum

Remov

Fuel Syst

Precauti!

Fuel Tank

Drainir

Remov

Idle Speec

Adjustment

Relieving

Pressure

Throttle B

Remov

Throttle1

Proce

22-50

& Installation 22-50

Service

ns... 22-48

22-50

22-50

& Installation 22-50

22-51

22-51

uel System

22-48

dy 22-51

& Installation 22-51

Learn/reset

ure....'. 22-51

HEATING & AIR CONDITIONING

SYSTEM.! 22-52

Blower

Remove

Heater Coj

RemovE

.or 22-52

& Installation 22-52

i, 22-52

& Installation 22-52

PRECAUTIONS.. 22-10

SPECIFICATIONS AND

MAINTENANCE CHARTS 22-3

Additional

Services^

Additional

Services-

Brake Spei

Camshaft:

Capacities

Crankshaft

Rod Spec

Engine anc

Identifica

Engine Tur

Specificai

Fluid Speci

General En'

Maintenam

Schedule:

Piston and

Specificat

Tire and

Specificai

Maintenance

ormal 22-9

/laintenance

evere '. 22-9

ications 22-7

pecifications 22-5

22-7

.nd Connecting '

ications • 22-5

Vehicle

on..., 22-3

-Up

ons 22-3

ications 22-3

ine

Specificat ons 22-3

and II Service

{ing

ons.

eel

ons1.

.22-5

.22-7

Torque Specifications 22-6

Valve Specifications 22-4

Wheel Alignment 22-6

STEERING 22-53

Power Steering Gear 22-53

Removal & Installation 22-53

Power Steering Pump 22-53

Bleeding 22-53

Fluid Fill Procedure 22-54

Removal & Installation 22-53

SUSPENSION 22-54

FRONT SUSPENSION 22-54

Control Links 22-54

Removal & Installation 22-54

Lower BallJoint 22-54

Removal & Installation 22-54

Lower Control Arm 22-54

Removal and & lnstallation.22-54

Stabilizer Bar 22-55

Removal & Installation 22-55

Steering Knuckle 22-55

Removal & Installation 22-55

Steering Linkage Outer

Tie Rod 22-56

Removal & Installation...- 22-56

Strut & Spring Assembly 22-56

Removal & Installation 22-56

Wheel Bearings 22-57

Adjustment 22-57

Removal & Installation 22-57

REAR SUSPENSION 22-57

Coil Spring 22-57

Removal & Installation 22-57

Knuckle 22-57

Removal & Installation 22-57

Lower Control Arm 22-58

Removal & Installation 22-58

Shock Absorber 22-58

Removal & Installation 22-58

Stabilizer Bar 22-59

Removal & Installation 22-59

Upper Control Arm 22-59

Removal & Installation 22-59

Wheel Bearings 22-59

Adjustment 22-59

Removal & Installation 22-59

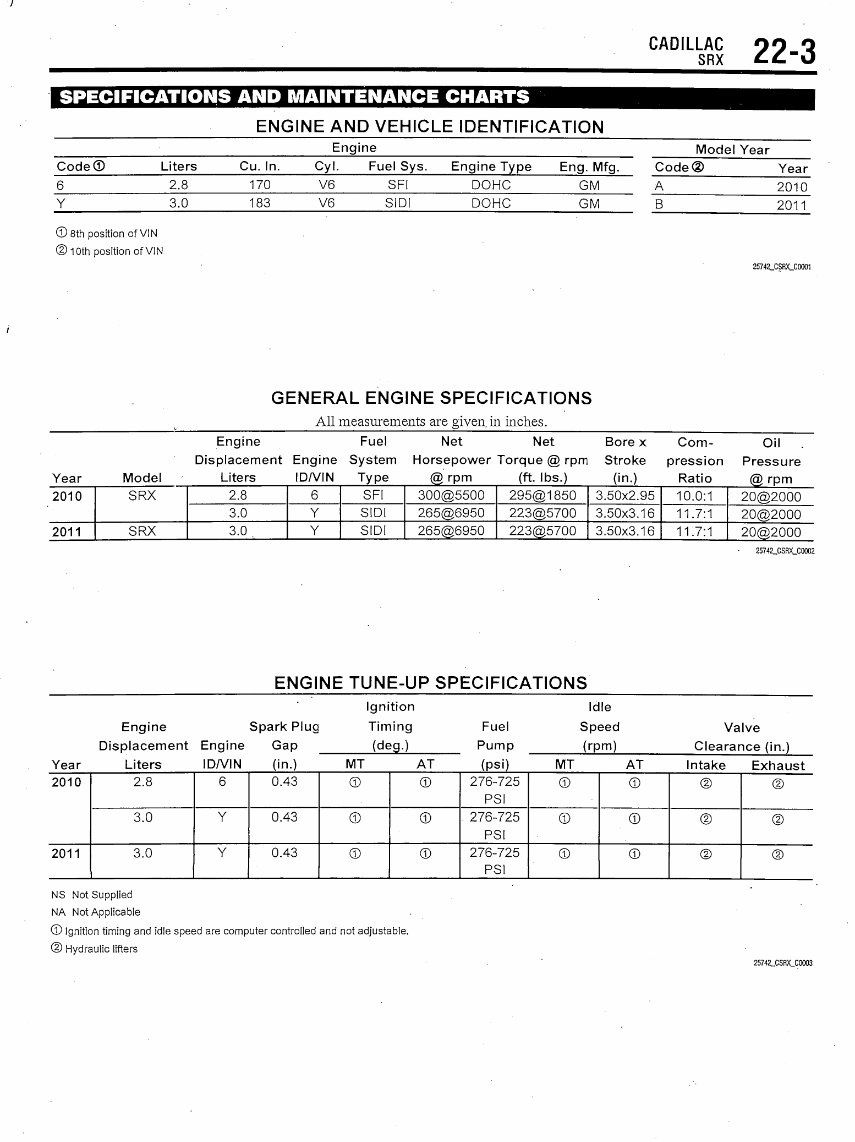

CADILLAC

SRX 22-3

ENGINE AND VEHICLE IDENTIFICATION

Engine

Model Year

Code© Liters Cu. In. Cyl. Fuel Sys. Engine Type Eng. Mfg. Code® Year

6 170 V6 SFI DOHC GM A 2010

Y 3.0 183 V6 SIDI DOHC GM 2011

©8th position of VIN

© 10th position of VIN

25742_CSRX_C0001

GENERAL ENGINE SPECIFICATIONS

All measurements are given, in inches.

Engine Fuel Net Net Bore x Com- Oil

Displacement Engine System Horsepower Torque @ rpm Stroke pression Pressure

Year Model Liters ID/VIN Type @ rpm (ft. Ibs.) (in.) Ratio @ rpm

2010

2011

SRX

SRX

2.8

3.0

3.0

6

Y

Y

SFI

SIDI

SIDI

300@5500

265@6950

265@6950

295@1850

223@5700

223@5700

3.50x2.95

3.50x3.16

3.50x3.16

10.0:1

11.7:1

11.7:1

20@2000

20@2000

20@2000

25742_CSRX_C0002

ENGINE TUNE-UP SPECIFICATIONS

Ignition Idle

Engine Spark Plug Timing Fuel Speed Valve

Displacement Engine Gap

Year Liters IDA/IN (in.)

2010

2011

2.8

3.0

3.0

6

Y

Y

0.43

0.43

0.43

(deg.)

MT AT

©

©

©

©

©

©

Pump

(psi)

276-725

PSI

276-725

PSI

276-725

PSI

(rpm) Clearance (in.)

MT AT Intake Exhaust

©

©

©

©

©

©

©

©

©

©

©

©

NS Not Supplied

NA Not Applicable

© Ignition timing and idle speed are computer controlled and not adjustable.

@ Hydraulic lifters

25742_CSRX_C0003

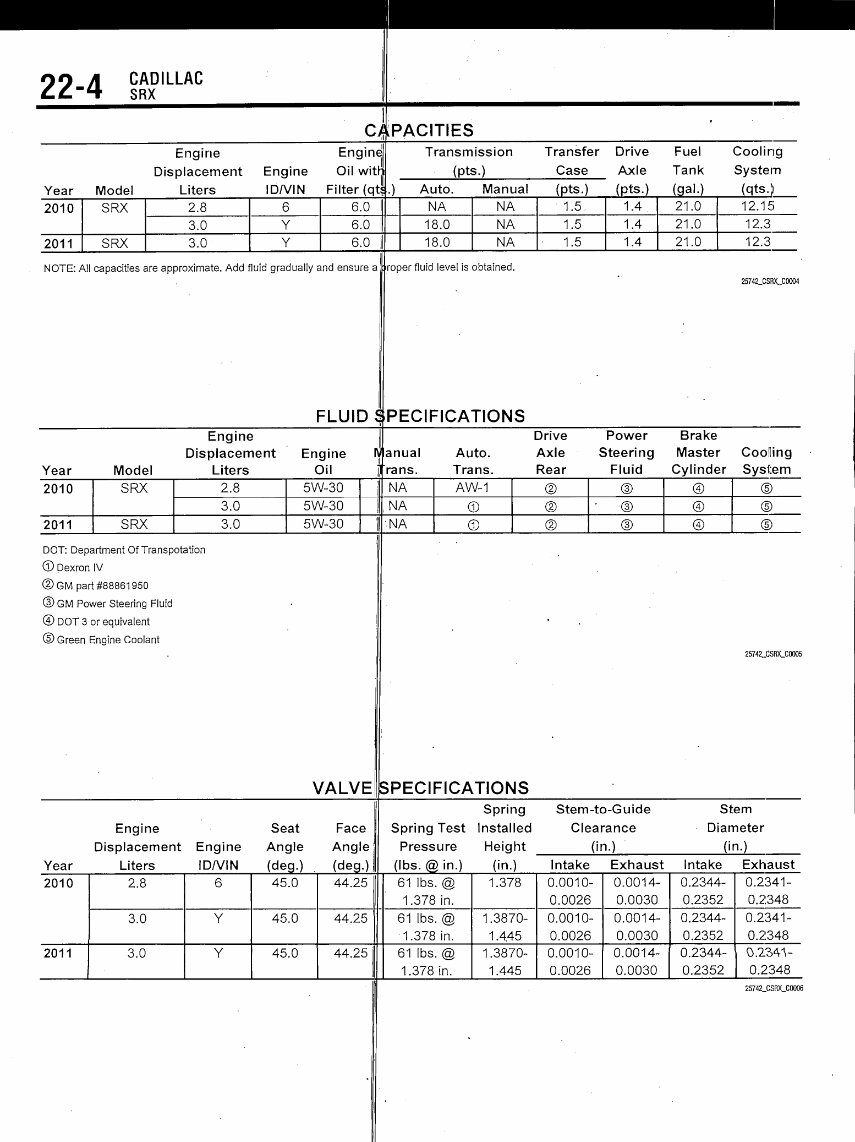

22-4

CADILLAC

SRX

C)

Engine Engine

Displacement Engine Oil with

Year Model Liters IDA/IN Filter (qt

2010 SF

2011 SF

RX 2.8 f

3.0 N

RX 3.0

3 6.0

< 6.0

{ 6.0 t

NOTE: All capacitiesare approximate. Add fluid gradually and ensure a

PACITIES

Transmission Transfer Drive Fuel Cooling

(pts.) Case Axle Tank System

.) Auto. Manual (pts.)

NA NA 1.5

18.0 NA 1.5

18.0 NA • 1.5

roper fluid level is obtained.

(pts.) (gal.) (qts.)

1.4 21.0 12.15

1.4 21.0 12.3

1.4 21.0 12.3

25742_CSRX_C0004

FLUID SPECIFICATIONS

Engine II Drive Power Brake

Displacement Engine lyjanual Auto. Axle Steering Master Cooling

Year Model Liters Oil

2010

2011

SRX

SRX

2.8

3.0

3.0

5W-30

5W-30

5W-30

Trans. Trans. Rear Fluid Cylinder System

NA

[NA

II'-NA

AW-1

®

©

©

©

©

®

• ©

©

©

©

©

©

©

©

DOT: Department Of Transpotation

© Dexron IV

©GM part #88861950

© GM Power Steering Fluid

©DOTS or equivalent

© Green Engine Coolant

25742_CSRX_C0005

VALVE

Engine Seat Face

Displacement Engine Angle Angle;

Year Liters IDA/IN (deg.) (deg.)

2010

2011

2.8

3.0

3.0

6

Y

Y

45.0

45.0

45.0

44.25

44.25 '

44.25

SPECIFICATIONS

Spring

Spring Test Installed

Pressure Height

(Ibs. @ in.) (in.)

61 Ibs. @

1.378 in.

61 Ibs. @

•1.378 in.

61 Ibs. @

1.378 in.

1.378

1.3870-

1 .4,45

1.3870-

1.445

Stem-to-Guide Stem

Clearance Diameter

(in.) (in.)

Intake Exhaust Intake Exhaust

0.0010-

0.0026

0.0010-

0.0026

0.0010-

0.0026

0.0014-

0.0030

0.0014-

0.0030

0.0014-

0.0030

0.2344-

0.2352

0.2344-

0.2352

0.2344-

0.2352

0.2341-

0.2.348

0.2341-

0.2348

0.234V

0.2348

25742_CSRX_C0006

CADILLAC

SRX 22-5

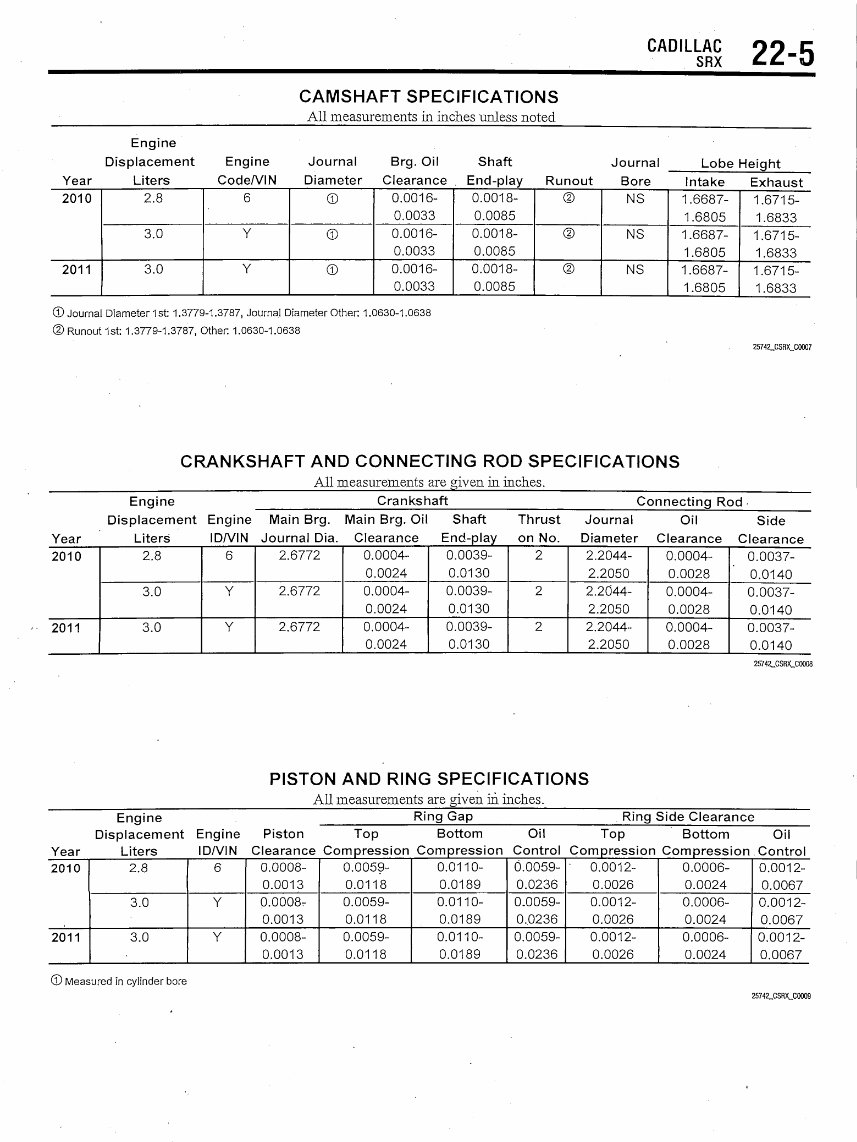

CAMSHAFT SPECIFICATIONS

All measurements in inches unless noted

Engine

Displacement Engine Journal Brg. Oil Shaft Journal

Year Liters Code/VIN Diameter Clearance . End-play Runout Bore

2010

2011

2.8

3.0

3.0

6

Y

Y

©

©

©

0.0016-

0.0033

0.0016-

0.0033

0.0016-

0.0033

0.0018-

0.0085

0.0018-

0.0085

0.0018-

0.0085

©

©

©

NS

NS

NS

Lobe Height

Intake Exhaust

1 .6687-

1.6805

1.6687-

1.6805

1.6687-

1.6805

1.6715-

1.6833

1.6715-

1.6833

1.6715-

1.6833

©Journal Diameter 1st: 1.3779-1.3787, Journal Diameter Other: 1.0630-1.0638

© Runout 1st: 1.3779-1.3787, Other. 1.0630-1.0638

25742_CSRX_C0007

CRANKSHAFT AND CONNECTING ROD SPECIFICATIONS

All measurements are given in inches.

Engine

Displacement Engine

Year Liters ID/VIN

2010

2011

2.8

3.0

3.0

6

Y

Y

Crankshaft Connecting Rod

Main Brg. Main Brg. Oil Shaft Thrust Journal Oil Side

Journal Dia. Clearance End-play on No. Diameter Clearance Clearance

2.6772

2.6772

2.6772

0.0004-

0.0024

0.0004-

0.0024

0.0004-

0.0024

0.0039-

0.0130

0.0039-

0.0130

0.0039-

0.0130

2

2

2

2.2044-

2.2050

2.2044-

2.2050

2.2044-

2.2050

0.0004-

0.0028

0.0004-

0.0028

0.0004-

0.0028

0.0037-

0.0140

0.0037-

0.0140

0.0037-

0.0140

25742_CSRX_C0008

PISTON AND RING SPECIFICATIONS

All measurements are alven in inches.

Engine

Displacement

Year Liters

Ring Gap Ring Side Clearance

Engine Piston Top Bottom Oil Top Bottom Oil

ID/VIN Clearance Compression Compression Control Compression Compression Control

2010

2011

2.8

3.0

3.0

6

Y

Y

0.0008-

0.0013

0.0008-

0.0013

0.0008-

0.0013

0.0059-

0.0118

0.0059-

0.0118

0.0059-

0.0118

0.0110-

0.0189

0.0110-

0.0189

0.0110-

0.0189

0.0059-

0.0236

0.0059-

0,0236

0.0059-

0.0236

' 0.0012-

0.0026

0.0012-

0.0026

0.0012-

0.0026

0.0006-

0.0024

0.0006-

0.0024

0.0006-

0.0024

0.0012-

0.0067

0.0012-

0.0067

0.0012-

0.0067

© Measured in cylinder bore

25742_CSRX_C0009

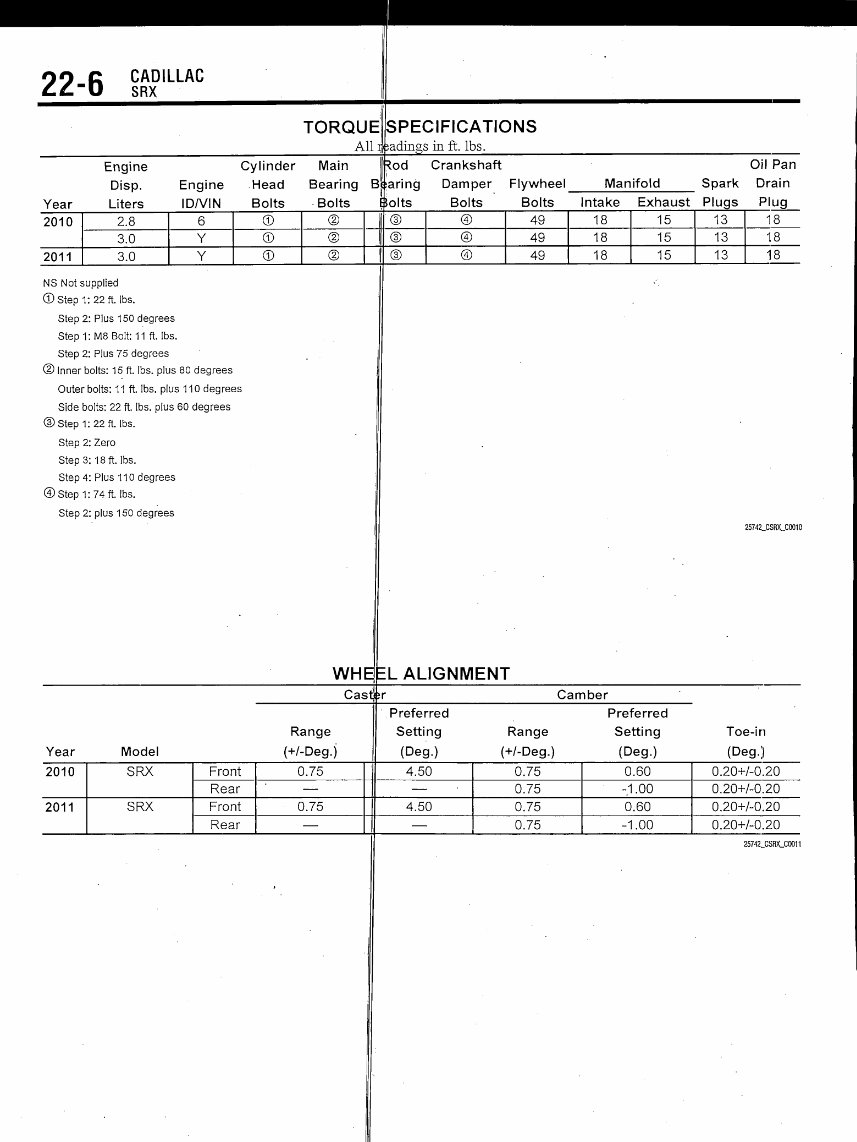

99 c CADILLAC

££"

Year

2010

2011

U SRX

Engine

Disp.

Liters

2.8

3.0

3.0

Engine

IDA/IN

6

Y

Y

Cylinder

Head

Bolts

©

©

©

TORQUE

All*

Main

Bearing

Bolts

©

©

©

B

.

SPECIFICATIONS

;adings in ft. Ibs.

^od Crankshaft

taring Damper

$olts Bolts

|© ©

© ©

(I © ©

NS Not supplied

©Step 1:22 ft. Ibs.

Step 2: Plus 150 degrees

Step 1:M8 Bolt: 11 ft. Ibs.

Stpn 9- Pln<; 75 dpnrpps

Flywheel Manifold

Oil Pan

Spark Drain

Bolts Intake Exhaust Plugs Plug

49 18

49 18

49 18

5 13 18

5 13 18

5 13 18

@ Inner bolts: 15 ft. Ibs. plus 80 degrees

Outer bolts: 11 ft. Ibs. plus 110 degrees

Side bolts: 22 ft. Ibs. plus 60 degrees

©Step 1:22ft. Ibs.

Step 2: Zero

Step 3:18 ft. Ibs.

Step 4: Plus 110 degrees

©Step 1:74 ft. Ibs.

Step 2: plus 150 degrees

25742_CSRX_C0010

WHEEL ALIGNMENT

Cast Camber

Range

Year Model (+/-Deg.j

2010

2011

SRX

SRX

Front

Rear

Front

Rear

0.75

—

0.75

—

[

Preferred Preferred

Setting Range Setting Toe-in

(Deg.) (+/-Deg.) (Deg.) (Deg.)

4.50

—

4.50

—

0.75

0.75

0.75

0.75

0.60

-1.00

0.60

-1.00

0.20+/-0.20

0.20+/-0.20

0.20+/-0.20

0.20+/-0.20

25742_CSRX_C0011

22-8

CADILLAC

SRX

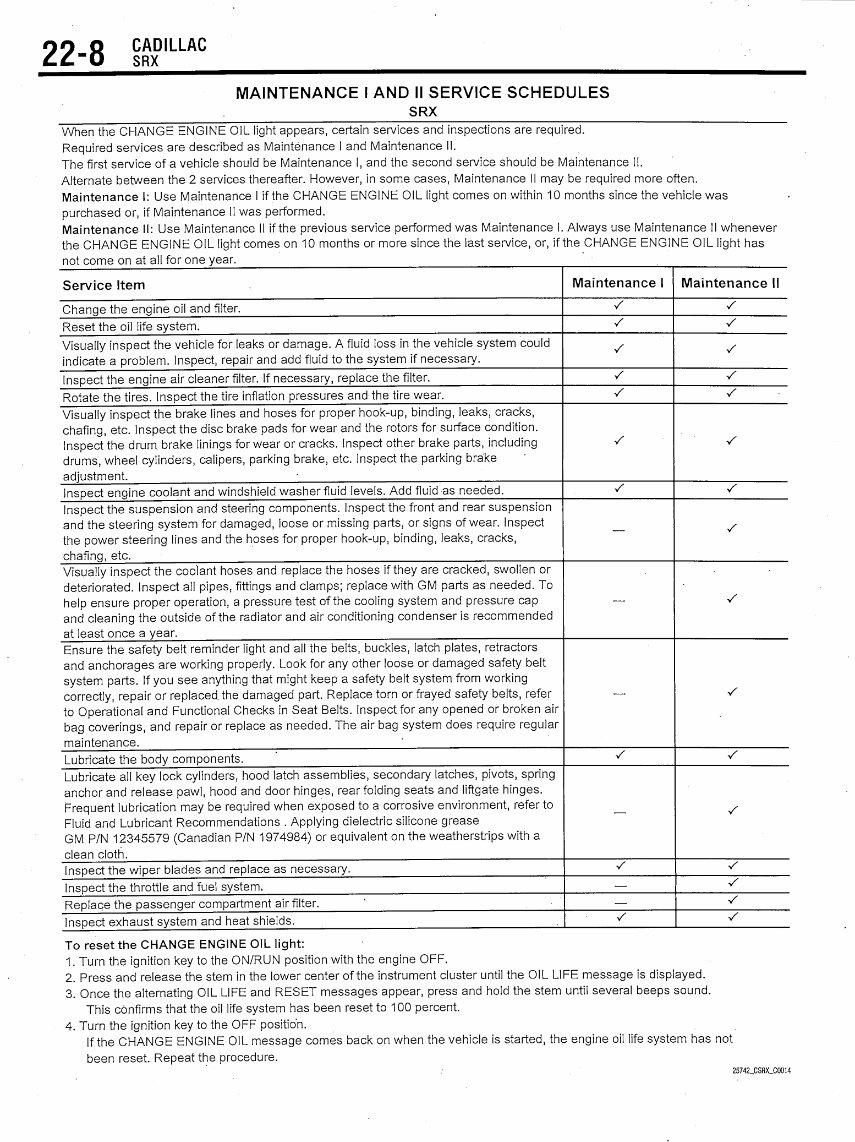

MAINTENANCE I AND II SERVICE SCHEDULES

SRX

When the CHANGE ENGINE OIL light appears, certain services and inspections are required.

Required services are described as Maintenance I and Maintenance II.

The first service of a vehicle should be Maintenance I, and the second service should be Maintenance II.

Alternate between the 2 services thereafter. However, in some cases, Maintenance II may be required more often.

Maintenance I: Use Maintenance I if the CHANGE ENGINE OIL light comes on within 10 months since the vehicle was

purchased or, if Maintenance II was performed.

Maintenance II: Use Maintenance II if the previous service performed was Maintenance I. Always use Maintenance II whenever

the CHANGE ENGINE OIL light comes on 10 months or more since the last service, or, if the CHANGE ENGINE OIL light has

not come on at all for one year.

Service Item

Change the engine oil and filter.

Reset the oil life system.

Visually inspect the vehicle for leaks or damage. A fluid loss in the vehicle system could

indicate a problem. Inspect, repair and add fluid to the system if necessary.

Inspect the engine air cleaner filter. If necessary, replace the filter.

Rotate the tires. Inspect the tire inflation pressures and the tire wear.

Visually inspect the brake lines and hoses for proper hook-up, binding, leaks, cracks,

chafing, etc. Inspect the disc brake pads for wear and the rotors for surface condition.

Inspect the drum, brake linings for wear or cracks. Inspect other brake parts, including

drums, wheel cylinders, calipers, parking brake, etc. Inspect the parking brake

adjustment.

Inspect engine coolant and windshield washer fluid levels. Add fluid as needed.

Inspect the suspension and steering components. Inspect the front and rear suspension

and the steering system for damaged, loose or missing parts, or signs of wear. Inspect

the power steering lines and the hoses for proper hook-up, binding, leaks, cracks,

chafing, etc.

Visually inspect the coolant hoses and replace the hoses if they are cracked, swollen or

deteriorated. Inspect all pipes, fittings and clamps; replace with GM parts as needed. To

help ensure proper operation, a pressure test of the cooling system and pressure cap

and cleaning the outside of the radiator and air conditioning condenser is recommended

at least once a year.

Ensure the safety belt reminder light and all the belts, buckles, latch plates, retractors

and anchorages are working properly. Look for any other loose or damaged safety belt

system parts. If you see anything that might keep a safety belt system from working

correctly, repair or replaced, the damaged part. Replace torn or frayed safety belts, refer

to Operational and Functional Checks in Seat Belts. Inspect for any opened or broken air

bag coverings, and repair or replace as needed. The air bag system does require regular

maintenance.

Lubricate the body components.

Lubricate all key lock cylinders, hood latch assemblies, secondary latches, pivots, spring

anchor and release pawl, hood and door hinges, rear folding seats and liftgate hinges.

Frequent lubrication may be required when exposed to a corrosive environment, refer to

Fluid and Lubricant Recommendations . Applying dielectric silicone grease

GM P/N 12345579 (Canadian P/N 1974984) or equivalent on the weatherstrips with a

clean cloth.

Inspect the wiper blades and replace as necessary.

Inspect the throttle and fuel system.

Replace the passenger compartment air filter. ' . • '

Inspect exhaust system and heat shields.

Maintenance I

S

V

V

•/

•/

V

•/

—

—

—

•/

—

•/

—

—

s

Maintenance II

S

•s

V

s

s

•/

•S

-/

V

V

•/

V

V

•S

s

V

To reset the CHANGE ENGINE OIL light:

1. Turn the ignition key to the ON/RUN position with the engine OFF.

2. Press and release the stem in the lower center of the instrument cluster until the OIL LIFE message is displayed.

3. Once the alternating OIL LIFE and RESET messages appear, press and hold the stem until several beeps sound.

This confirms that the oil life system has been reset to 100 percent.

4. Turn the ignition key to the OFF position.

If the CHANGE ENGINE OIL message comes back on when the vehicle is started, the engine oil life system has not

been reset. Repeat the procedure.

25742_CSRX_C0014

^^^^^^^^^^^^^^^^^^-^—

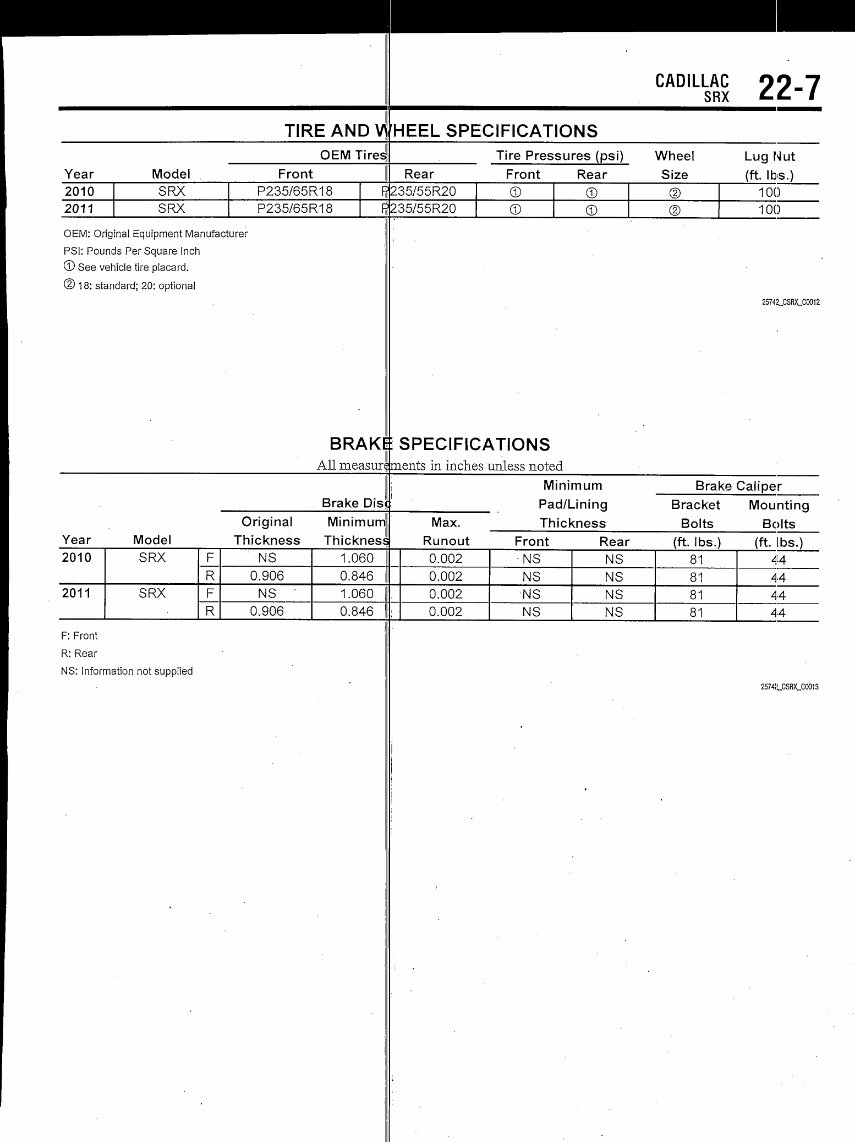

TIRE AND V

OEM Tires

Year Model Front

2010 SRX P235/65R18 f}

2011 SRX P235/65R18 ff

OEM: Original Equipment Manufacturer

PSl: Pounds Per Square Inch

© See vehicle tire placard.

@ 1 8: standard; 20: optional

BRAKl

All measun

Brake Dis

Original Minimum

Year Model Thickness Thickness

2010 SRX F NS 1.060

R 0.906 0.846

2011 SRX F NS 1.060

R 0.906 0.846

F: Front

R: Rear

NS: Information not supplied

CADILLAC 99 7

SRX "" /

HEEL SPECIFICATIONS

Tire Pressures (psi) Wheel Lug Nut

Rear Front Rear Size (ft. Ibs.)

235/55R20 © © © 100

235/55R20 © © © 100

25742_CSRX_C0012

i SPECIFICATIONS

merits in inches unless noted

i Minimum Brake Caliper

Pad/Lining Bracket Mounting

Max. Thickness Bolts Bolts

Runout Front Rear (ft. Ibs.) (ft. Ibs.)

0.002 -NS NS 81 44

0.002 NS NS 81 44

0.002 NS NS 81 44

; 0.002 NS NS 81 44

2574!LCSRX_C0013

CADILLAC

SRX

22-9

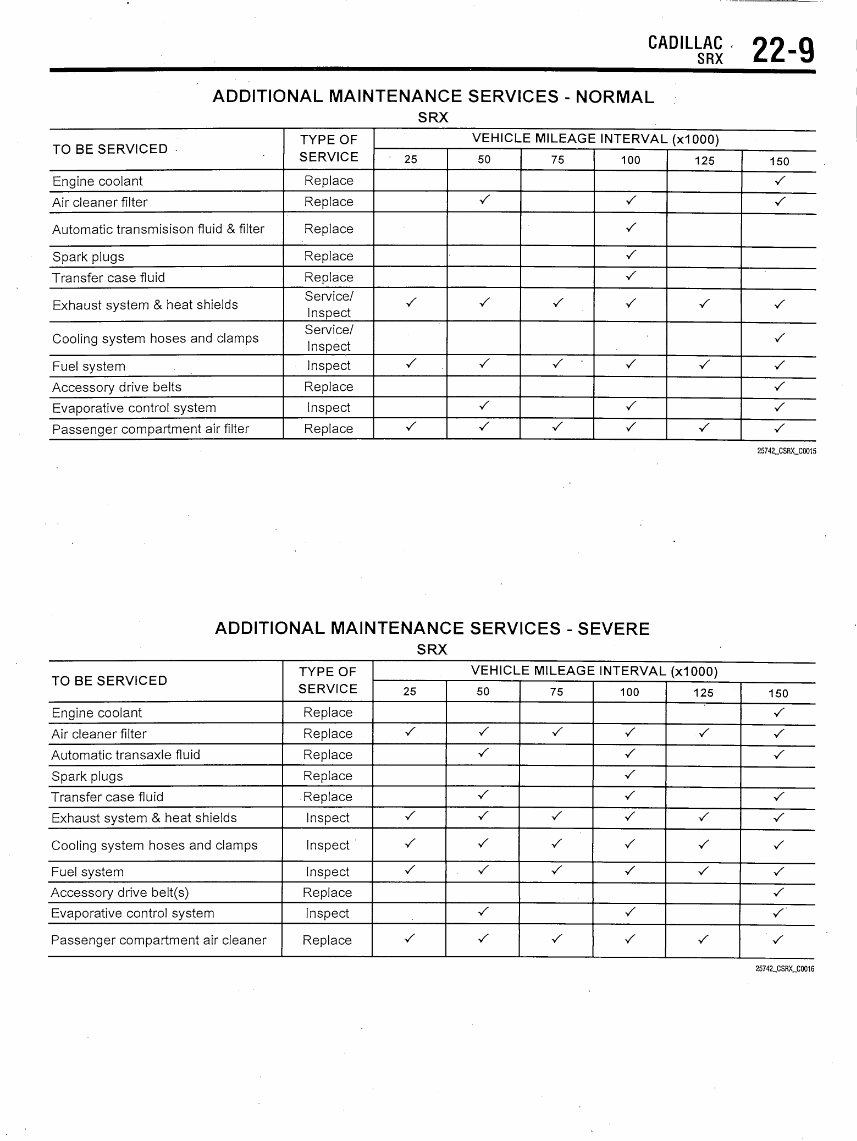

ADDITIONAL MAINTENANCE SERVICES - NORMAL

SRX

TO BE SERVICED

Engine coolant

Air cleaner filter

Automatic transmisison fluid & filter

Spark plugs

Transfer case fluid

Exhaust system & heat shields

Cooling system hoses and clamps

Fuel system

Accessory drive belts

Evaporative control system

Passenger compartment air filter

TYPE OF

SERVICE

Replace

Replace

Replace

Replace

Replace

Service/

Inspect

Service/

Inspect

Inspect

Replace

Inspect

Replace

VEHICLE MILEAGE INTERVAL (x1 000)

25

•/

S

•/

50

s

•/

s

•/

•/

75

•/

S •

•/

100

^

•/

s

s

s

•/

s

V

125

V

•/

•/

150

Y

S

V

S

•/

S

S

•/

25742_CSRX_C0015

ADDITIONAL MAINTENANCE SERVICES - SEVERE

SRX

TO BE SERVICED

Engine coolant

Air cleaner filter

Automatic transaxle fluid

Spark plugs

Transfer case fluid

Exhaust system & heat shields

Cooling system hoses and clamps

Fuel system

Accessory drive belt(s)

Evaporative control system

Passenger compartment air cleaner

TYPE OF

SERVICE

Replace

Replace

Replace

Replace

Replace

Inspect

Inspect

Inspect

Replace

Inspect

Replace

VEHICLE MILEAGE INTERVAL (xlOOO)

25

•/

S

•/

•s

•/

50

•/

S

•/

V

•/

•/

•/

s

75

S

S

-/

S

•/

100

•/

•/

•/

•/

s

s

•/

s

•/

125

V

V

•/

S

•/

150

•/

V

V

s

•/

s

s

•s

•/

•s

25742_CSRX_C0016

22-10 CADILLAC

SRX

PRECAUTIONS

Before servicing any vehicle, please be

sure to read all of the following precautions,

which deal with personal safety, prevention

of component damage, and important points

to take into consideration when servicing a

motor vehicle:

• Never open, service or drain the radia-

tor, or cooling system when the engine is

hot; serious burns can occur from the steam

and hot coolant.

• Observe all applicable safety precau-

tions when working around fuel. Whenever

servicing the fuel system, always work in a

well-ventilated area. Do not allow fuel spray

or vapors to come in contact with a spark,

open flame, or excessive heat (a hot drop

light, for example). Keep a dry chemical fire

extinguisher near the work area. Always

keep fuel in a container specifically

designed for fuel storage; also, always

properly seal fuel containers to avoid the

possibility of fire or explosion. Refer to the

additional fuel system precautions later in

this section.

• Fuel injection systems often remain

pressurized, even after the engine has been

turned OFF. The fuel system pressure must,

be relieved before disconnecting any fuel

lines. Failure to do so may result in fire

and/or personal injury.

• Brake fluid often contains polyglycol

ethers and polyglycols. Avoid contact with

the eyes and wash your hands thoroughly

after handling brake fluid. If you do get

brake fluid in your eyes, flush your eyes

with clean, running water for 15 minutes.

If eye irritation persists, or if you have taken

GENERAL INFORMATION

PRECAUTIONS

• Certain components within the ABS '

system are not intended to be serviced or

repaired individually.

• Do not use rubber hoses or other parts

not specifically specified for and ABS sys-

tem. When using repair kits, replace all

parts included in the kit. Partial or incorrect

repair may lead to functional problems and

require the replacement of components.

• Lubricate rubber parts with clean,

fresh brake fluid to ease assembly. Do not

use shop air to clean parts; damage to rub-

ber components may result.

• Use only DOT 3 brake fluid from an

unopened container.

• If any hydraulic component or line is

:e n

brake fluid in]

medical assis'

• The EP/^

with used enc

of skin disord

should make!

exposure to u

gloves slioulc

Wash your ha

skin areas as

sure to used e

waterless nan

• All new

with an air ba

a Supplement

Supplemental'

tern. The syst

performing se

components,

panel compor

Failure to

dures could re

deployment,

unnecessary

• Always v

working with,

When carrying a

sure the bag

away from yoi

deployed air

face the bag a

from the surfa

motion of the

deployed. Refe

system precai

• Clean, h

sealed contair

rnally, IMMEDIATELY seek

nee.

warns that prolonged contact

ne oil may cause a number

rs, including cancer. You

very effort to minimize your

ed engine oil. Protective

be worn when changing oil.

ds and any other exposed

oon as possible after expo-

igine oil. Soap and water, or

cleaner should be used,

ehicles are now equipped

system, often referred to as

Restraint System (SRS) or

nflatable Restraint (SIR) sys-

must be disabled before

vice on or around system

:eeririg column, instrument

fits, wiring and sensors.

N safety and disabling proce-

sult in accidental air bag

personal injury and

/stem repairs,

ear safety goggles when

r around, the air bag system.

non-deployed air bag, be

trim cover are pointed

• body. When placing anon-

ig on a work surface, always

d trim cover upward, away

e. This will reduce the

nodule if it is accidentally

'to the additional air bag

ions later in this section.

;h quality brake fluid from a

r is essential to the safe and

aid

proper operation of the brake system. You

should always buy the correct type of brake

fluid' for your vehicle. If the brake fluid

becomes contaminated, completely flush the

system with new fluid. Never reuse any

brake fluid. Any brake fluid that is removed

from the system should be discarded. Also,,

do not allow any brake fluid to come in con-

tact with a painted surface; it will damage

the paint.

• Never operate the engine without the

proper amount and type of engine oil; doing

so WILL result in severe engine damage.

• Timing belt maintenance is extremely

important. Many models utilize an

interference-type, non-freewheeling engine.

If the timing belt breaks, the valves in the

cylinder head may strike the pistons, caus-

ing potentially serious (also time-consum-

ing and expensive) engine damage. Refer to

the maintenance interval charts for therec-

ommended replacement interval for the tim-

• ing belt, and to the timing belt section for

belt replacement and inspection.

• Disconnecting the negative battery

cable on some vehicles may interfere with

the functions of the on-board computer sys-

tem^) and may require the computer to

undergo a relearning process once the

negative battery cable is reconnected.

• When servicing drum brakes, only dis-

assemble and assemble one side at a time,

leaving the remaining side intact for refer-

ence.

• .Only an MVAC-trained, EPA-certified

automotive technician should service the air

conditioning system or its components.

ANTI-LOCK BRAKE SYSTEM (A^S)

removed or re

bleed the entiij

• A clean r

clean the resei

before removing

amount of dirt

fice and impai

repairs

oughly cleane

to clean comp

components to

substance

includes used

• TheAntH

laced, it may be necessary to

system.

pair area is essential. Always

/oir and cap thoroughly

the cap. The slightest

n the fluid may plug an ori-

•the system function. Perform

after components have been thor-

use only denatured alcohol

nents. Do not allow ABS

come into contact with any

mineral oil; this

;hop rags.

.ock control unit is a micro-

processor simj ar to other computer units in

the vehicle. Erj ;ure that the ignition switch

is OFF before emoving or installing con-

troller harnessi s. Avoid static electricity dis-

charge at or ne.br the controller.

con aming

• If any arc welding is to be done on

the vehicle, the control unit should be

unplugged before welding operations

begin.

SPEED SENSORS

REMOVAL & INSTALLATION

Front

See Figure 1.

1. Before servicing the vehicle, refer to

the Precautions Section.

2. Raise and support the vehicle.

3. Remove the tire and wheel assembly.

4. Remove the wheel speed sensor bolt.

5. Clean the wheel speed sensor

mounting area on the suspension knuckle of

any accumulated dirt and debris.

You're Reading a Preview

What's Included?

Fast Download Speeds

Online & Offline Access

Access PDF Contents & Bookmarks

Full Search Facility

Print one or all pages of your manual

$33.99

Viewed 28 Times Today

Loading...

Secure transaction

What's Included?

Fast Download Speeds

Online & Offline Access

Access PDF Contents & Bookmarks

Full Search Facility

Print one or all pages of your manual

$33.99

The SRX 2010-2011 Service Repair Manual covers a comprehensive range of repairs, including brakes, wiring, engine, and transmission. It is an invaluable resource for both professional mechanics and DIY enthusiasts.

By utilizing this manual, you can avoid expensive hourly labor costs and mark-up fees on parts. It enables you to take control of your car repairs and save money by purchasing your own parts.

Whether you are looking to perform routine maintenance or tackle more complex repairs, this manual provides the necessary guidance and instructions to empower you to make your own repairs.