GENERAL INFORMATION

Introduction - F10

INTRODUCTION

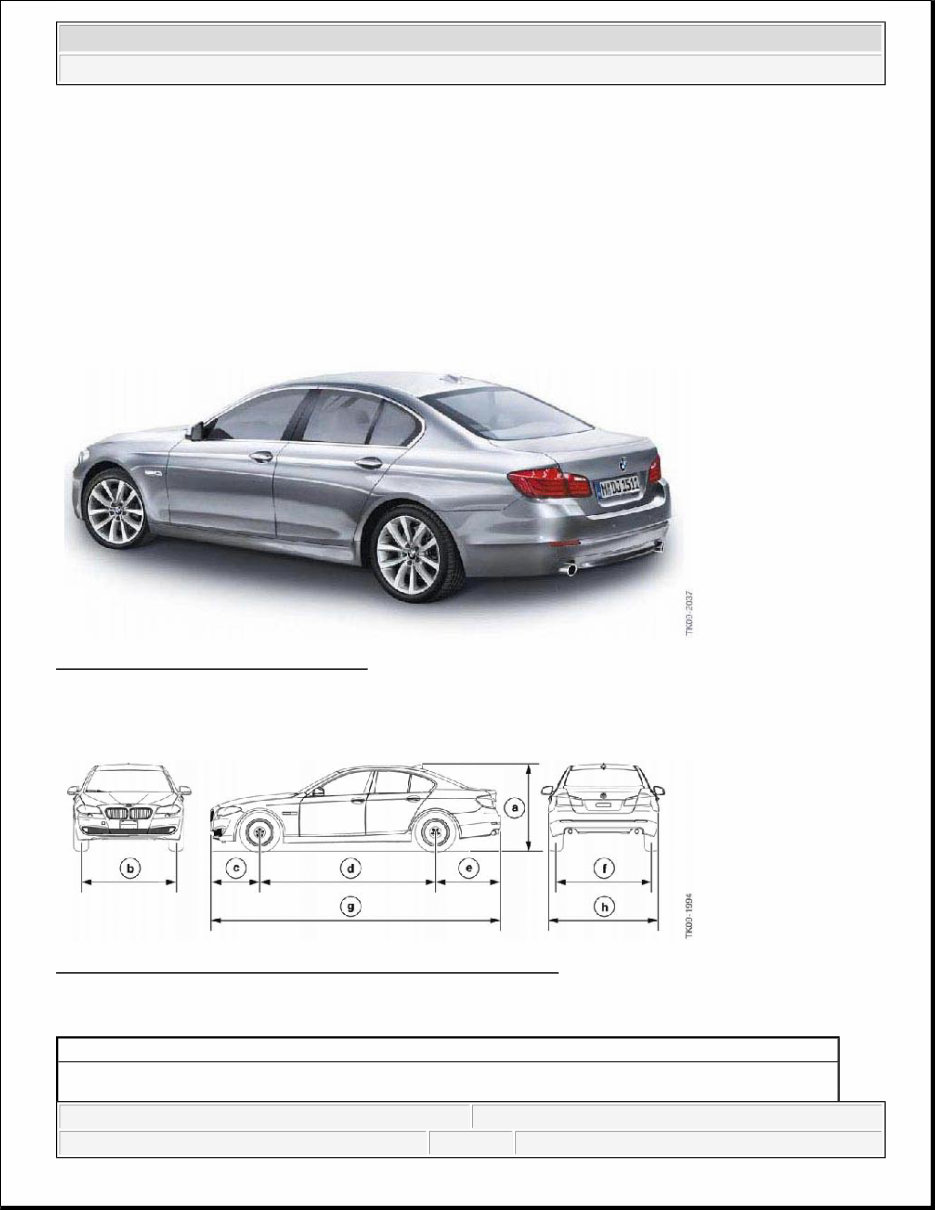

1.1. THE NEW BMW 5 SERIES SALOON

The F10 5 Series was introduced in to the US market in March of 2010. The vehicle is available in 528i, 535i

and 550i models.

Fig. 1: Identifying BMW 5 Series Sedan

Courtesy of BMW OF NORTH AMERICA, INC.

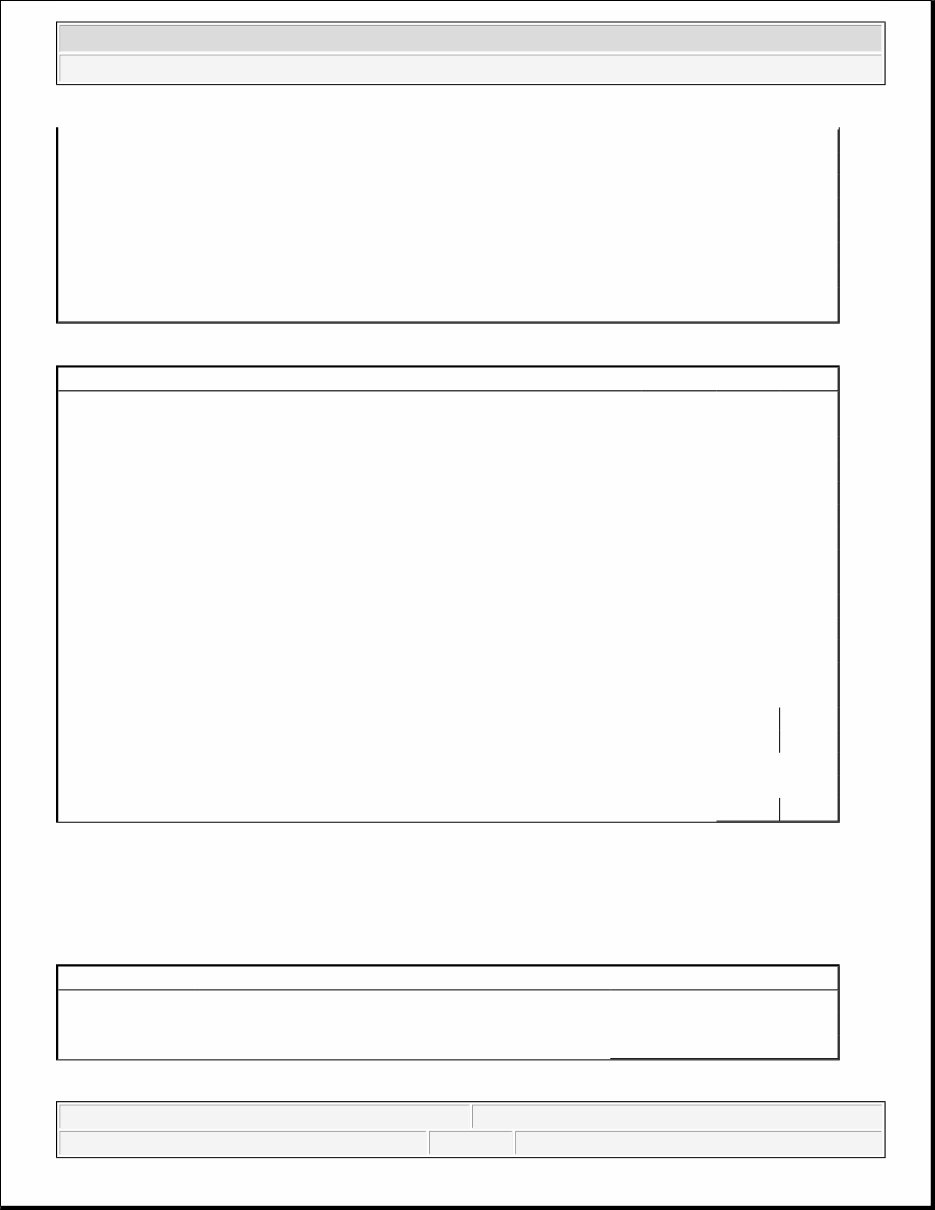

1.1.1. Dimensions

Fig. 2: Identifying Exterior Dimensions Of BMW 5 Series Sedan

Courtesy of BMW OF NORTH AMERICA, INC.

INDEX EXPLANATION CHART

Index Explanation

a

Vehicle height, empty (1464 mm)

(1)

2011 -2015 BMW 5

CARMANUALSUSA

Saturday, September 05, 2015 9:08:10 AM Page 1 © 2011 Mitchell Repair Information Company, LLC.

COMPARISON OF F10 WITH E60

Weight and payload

Refer to the following table for the weight and payload of the F10 with automatic transmission according to the

German Standardization Institute (DIN).

WEIGHT AND PAYLOAD OF F10

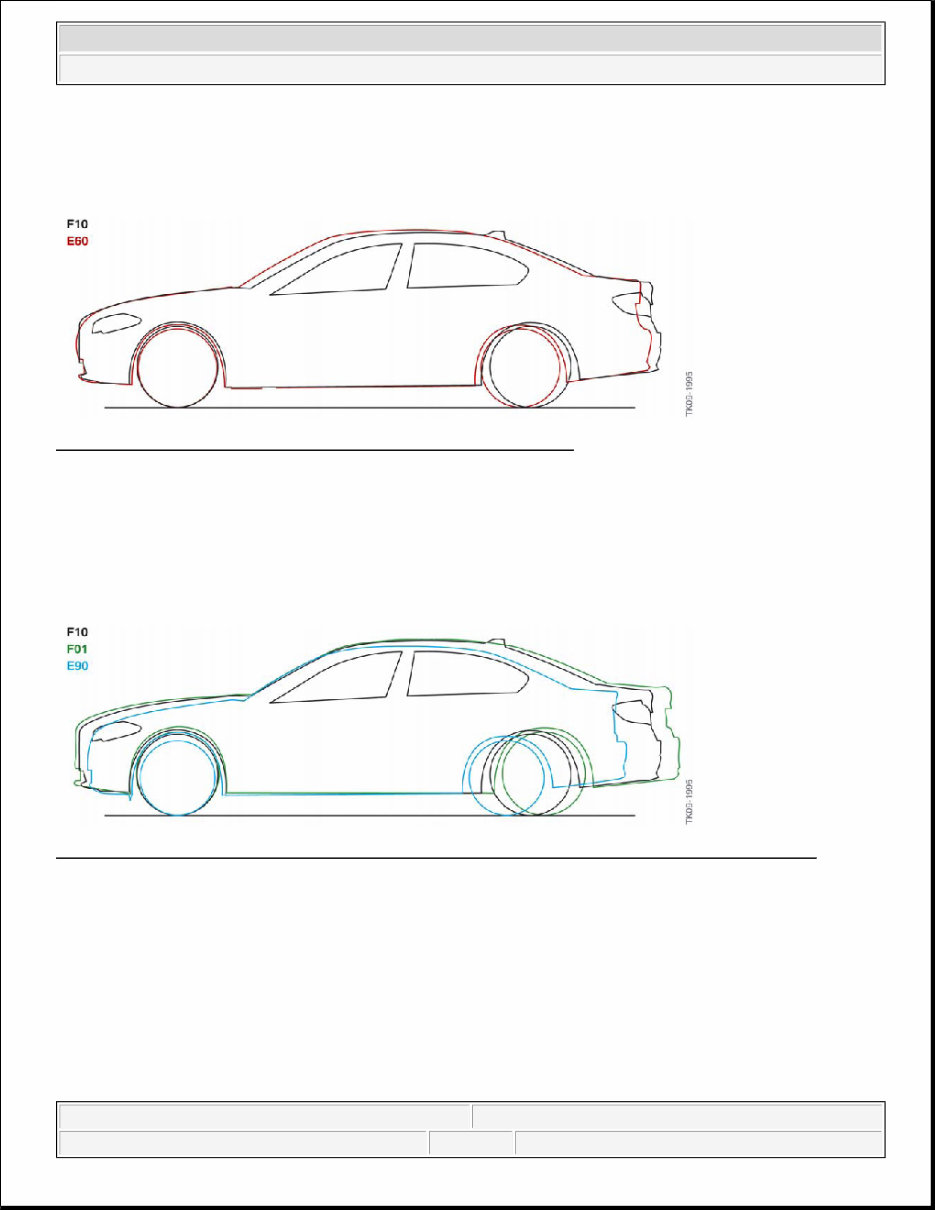

1.1.2. Silhouette comparison

b Track width of basic wheels, front (1600 mm)

c Overhang, front (832 mm)

d Wheelbase(2968mm)

e Overhang, rear (1099 mm)

f Track width of basic wheels, rear (1627 mm)

g Vehicle length (4899 mm)

h Vehicle width without exterior mirrors (1860 mm)

(1)

With roof-mounted antenna: 1475 mm.

F10 E60

Vehicle height, empty [mm] 1464 1467

Track width, front [mm] 1600 1558

Overhang, front [mm] 832 856

Wheelbase [mm] 2968 2888

Overhang, rear [mm] 1099 1111

Track width, rear [mm] 1627 1582

Vehicle length [mm] 4899 4855

Vehicle width without exterior mirrors [mm] 1860 1846

Vehicle width over exterior mirrors [mm] 2094 2030

Turning circle (at vehicle curb weight) [m] 11.95 11.4

Shoulder room, front [mm] 1480 1455

Shoulder room, rear [mm] 1427 1454

Elbow room, front [mm] 1518 1485

Elbow room, rear [mm] 1485 1496

Maximum headroom, front (without slide/tilt sunroof) [mm] 1028 1028

Maximum headroom, front (with slide/tilt sunroof) [mm] 992 992

Maximum headroom, rear (without slide/tilt sunroof) [mm] 973 967

Maximum headroom, rear (with slide/tilt sunroof) [mm] 965 955

Luggage compartment capacity [liters] 520 520

Vehicle Vehicle curb weight (DIN) Payload

F10 528i 1730 kg/3814 lb 480 kg/1058 lb

F10 535i 1855 kg/4090 lb 480 kg/1058 lb

F10 550i 1985 kg/4376 lb 450 kg 992 lb

2011 BMW 535xi

GENERAL INFORMATION Introduction - F10

CARMANUALSUSA

Saturday, September 05, 2015 9:08:06 AM Page 2 © 2011 Mitchell Repair Information Company, LLC.

F10

E60

Fig. 3: F10 Silhouette Comparison With BMW 5 Series Sedan E60

Courtesy of BMW OF NORTH AMERICA, INC.

F10

F01

E90

Fig. 4: F10 Silhouette Comparison With BMW 7 Series Sedan F01 And BMW 3 Series Sedan E90

Courtesy of BMW OF NORTH AMERICA, INC.

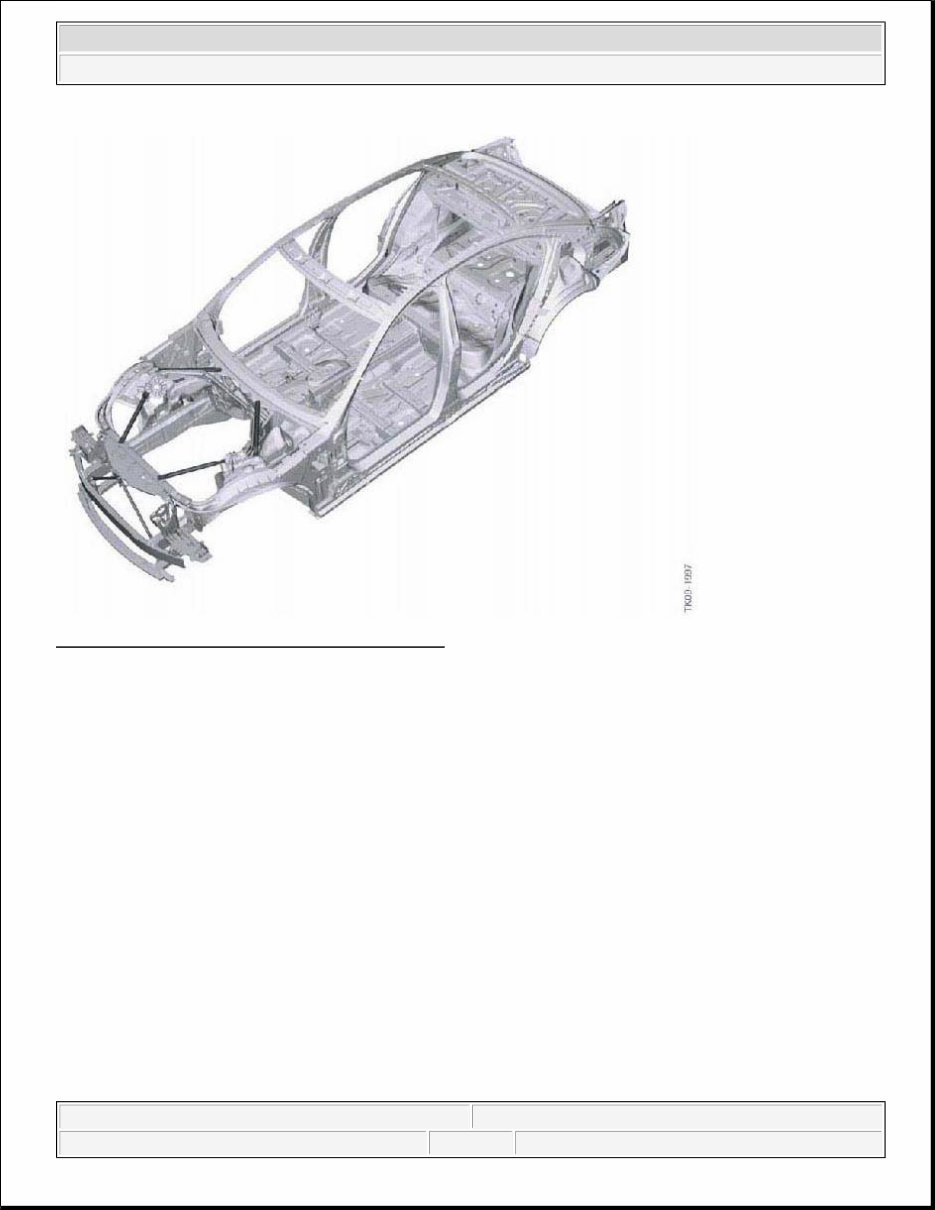

BODY

2.1. BODYSHELL

2011 BMW 535xi

GENERAL INFORMATION Introduction - F10

CARMANUALSUSA

Saturday, September 05, 2015 9:08:06 AM Page 3 © 2011 Mitchell Repair Information Company, LLC.

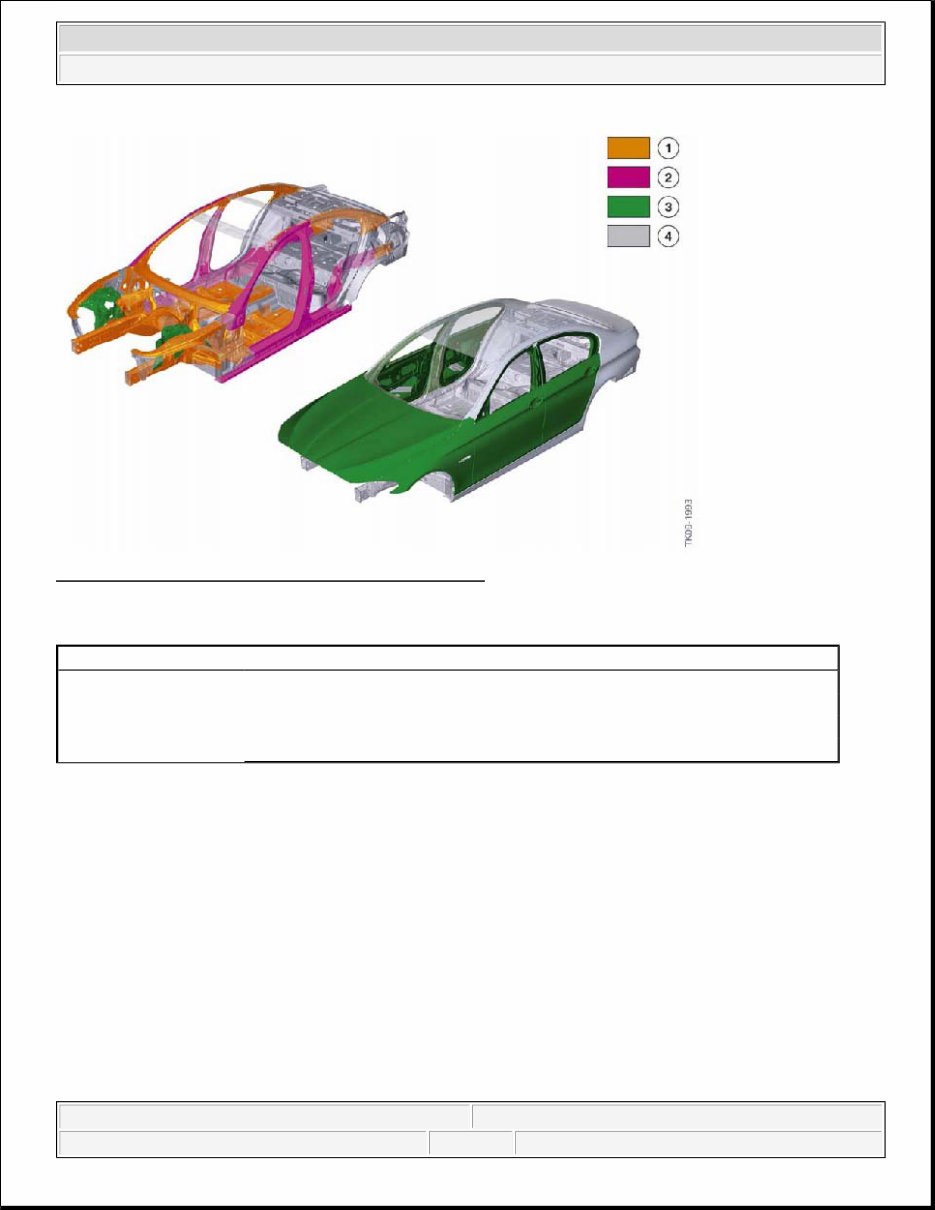

Fig. 5: Identifying F10 Bodyshell (Body In White)

Courtesy of BMW OF NORTH AMERICA, INC.

2.1.1. Introduction

As with other models, the use of lightweight materials was a major requirement in the F10 design. This involves

the intelligent deployment of increased-strength multiphase steels and super high strength (press hardened)

steels. In the F10, the average strength of the body materials has increased by 55% compared to the E60.

The lightweight materials contribute significantly to the overall reduction in vehicle weight, and in combination

with the rigidity of the body structure.

The lightweight materials used on the F10 body structure contribute directly to its:

Driving Dynamics

Reduction of fuel consumption

Reduction of CO2 emissions

Passive safety

Weight saving features of the F10 bodyshell

Strut towers are made of die-cast aluminum

2011 BMW 535xi

GENERAL INFORMATION Introduction - F10

CARMANUALSUSA

Saturday, September 05, 2015 9:08:06 AM Page 4 © 2011 Mitchell Repair Information Company, LLC.

High proportion of multiphase steels (20 % of the body skeleton weight)

High proportion of hot-formed steels (14 % of the body skeleton weight)

The die-cast aluminum strut towers reinforce the front section by ensuring the necessary rigidity that the

component design requires to withstand the loads. Compared to a conventional steel-shell structure, the more

compact design has significantly reduced the installation space and the weight in the front section. This

p rovides a more uniform axle-load distribution, among other benefits.

The increased-strength multiphase steels and super high strength hot-formed steels combine low weight with

maximum strength for the safety passenger cell, thus contributing significantly to passive safety.

For hot-formed steels, an innovative further development known as passive corrosion protection is used.

Previously, no suitable hot-formed sheet metal materials with cathodic corrosion protection had been available

on the market. With the development of press-hardening, a method is now available that enables mass

p roduction of galvanized hot-formed components. The components fabricated in this way can be used in the wet

area without corrosion of the base material. There is no need for additional corrosion protection measures for

this steel.

2.1.2. Materials

A modern vehicle body has to fulfill many different requirements. Despite small exterior dimensions, it is to

p rovide the largest possible passenger compartment. In the event of an accident, it must provide the passengers

with the best possible protection. All assemblies, such as the engine and transmission, are supported by the body

against the torque they generate. Futhermore, the body must have high static and, above all, dynamic rigidity to

guarantee the excellent driving characteristics typical of BMW vehicles.

In addition, the supporting structure of the vehicle must have high fatigue strength and be able to be repaired

with reasonable effort and cost in the event of an accident.

To fulfill all these requirements, BMW applies a manufacturing strategy that produces each part from the

material that is best suited for its function.

The two terms "aluminum" and "steel" are only the generic terms for the wide variety of alloys used in the

construction of the body.

These different allo y s have quite different properties.

2011 BMW 535xi

GENERAL INFORMATION Introduction - F10

CARMANUALSUSA

Saturday, September 05, 2015 9:08:06 AM Page 5 © 2011 Mitchell Repair Information Company, LLC.

Fig. 6: Identifying F10 Material Qualities Of Bodyshell

Courtesy of BMW OF NORTH AMERICA, INC.

INDEX EXPLANATION CHART

Multiphase steels are steels with a structure that consists of multiple phases. Advanced-strength multiphase

steels with a yield strength R

p0.2

of 300 to 600 MPa include, for example, dual-phase steels and TRIP steels.

Advanced-strength multiphase steels with a yield strength R

p0.2

over 600 MPa include, for example, complex-

p hase steels and martensite-phase steels.

The hot-formed manganese-boron steels are ultra-high-strength steels with a yield strength

Rp0.

2 of over 900

MPa.

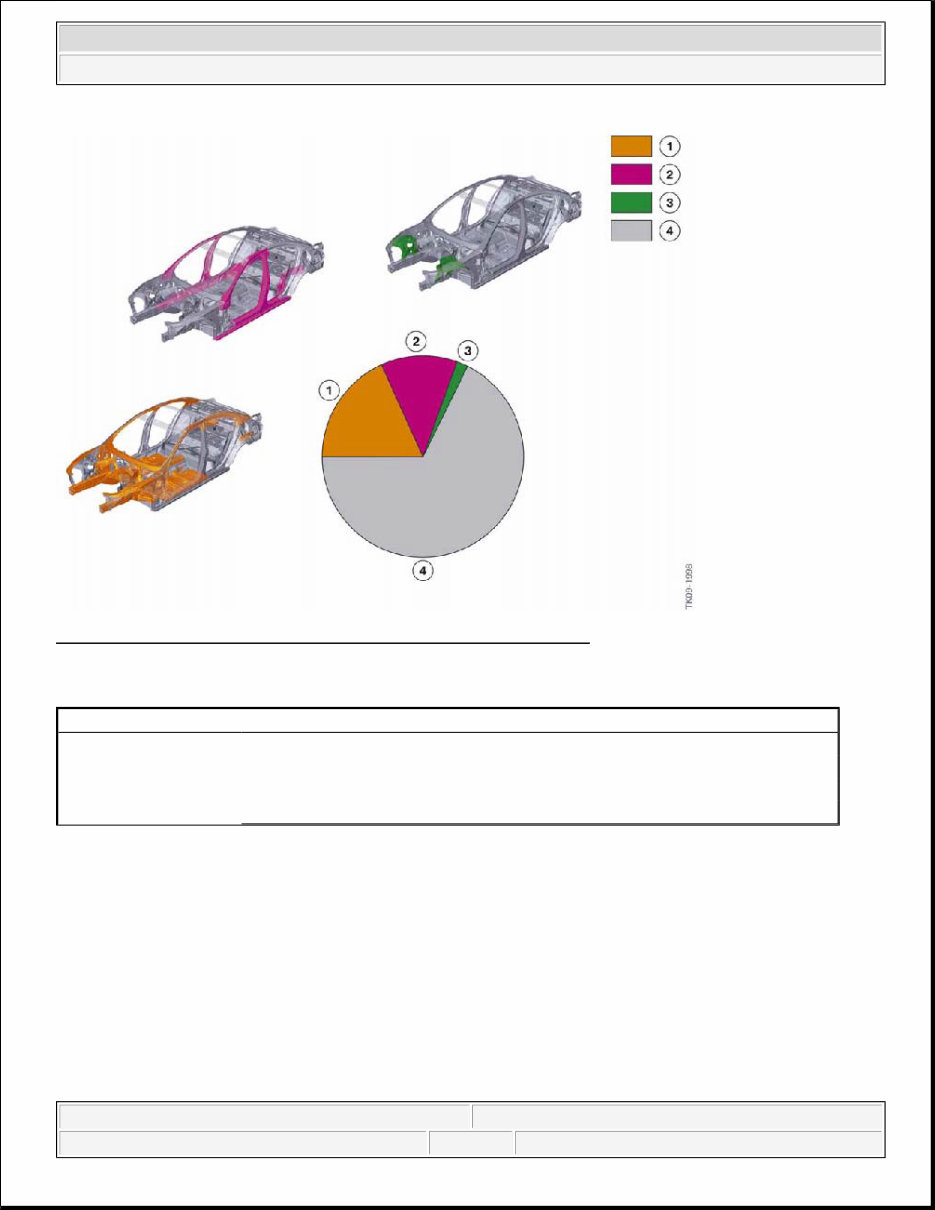

Weight proportions

The proportion of advanced-strength multiphase steels, super high strength hot-formed steels and aluminum is

increasing. These measures decrease the vehicle weight while still guaranteeing maximum strength of the

b od y shell.

Index Explanation

1 Multiphase steels (> 300 MPa)

2 Hot-formed steels (> 900 MPa)

3 Aluminum

4 Other steels (< 300 MPa)

2011 BMW 535xi

GENERAL INFORMATION Introduction - F10

CARMANUALSUSA

Saturday, September 05, 2015 9:08:06 AM Page 6 © 2011 Mitchell Repair Information Company, LLC.

Fig. 7: Identifying F10 Bodyshell, Distribution Of Material Qualities

Courtesy of BMW OF NORTH AMERICA, INC.

INDEX EXPLANATION CHART

2.1.3. Corrosion protection and tightness

In order to optimize anti-corrosion protection, the body of the F10 is constructed primarily from galvanized

sheet metal and aluminum or aluminum sandwich sheet metals. Welding, adhesive bonding and riveting are the

assembly techniques used.

The overlaps of the panels are designed to minimize the joint surfaces, to prevent bondline corrosion. The

p enetration of water into the body structure is prevented in the design engineering of the vehicle by adhering

and sealing the joint surfaces.

In particularly critical areas, expanding foam parts are used to seal the body cavities against moisture. Doubled

up sheets in wet zones are double-sealed and, if necessar y , the y are also treated with wax to ensure a water ti g ht

Index Explanation

1 Multiphase steels (> 300 MPa), proportion 20%

2 Hot-formed steels (> 900 MPa), proportion 12%

3 Aluminum, proportion 2%

4 Other steels (< 300 MPa), proportion 66 %

2011 BMW 535xi

GENERAL INFORMATION Introduction - F10

CARMANUALSUSA

Saturday, September 05, 2015 9:08:06 AM Page 7 © 2011 Mitchell Repair Information Company, LLC.

seal.

If necessary, the overlaps of the panels in dry zones are sealed to prevent dust from getting inside.

Corrosion-critical material pairing is avoided. The combinations of material substrates and joining methods

were chosen with meticulous care in order to avoid corrosion risks.

Coating process

In the painting process, the bodyshell is dipped and:

Alkaline-cleaned

Phosphated (roughening the surface for better adhesion)

Cathodic-dip coated (anticorrosion coating that coats the insides of all body cavities).

The organic paint coat is then baked on.

Furthermore, the body is sealed with PVC and protected by filler, topcoat and clear coat paints on the outer

skin.

Critical parts of the body of the F10 are specially treated with cavity preservation sealant.

The objectives are:

Three years without any visible corrosion whatsoever

Twelve years without rust penetration

High level of protection against water and dust intrusion.

2.1.4. Front section

Regarding the repair of the F10 front section, compared to the F01, there are no major changes.

As on previous vehicles, bod y struts are used to increase the ri g idit y of the front section.

2011 BMW 535xi

GENERAL INFORMATION Introduction - F10

CARMANUALSUSA

Saturday, September 05, 2015 9:08:06 AM Page 8 © 2011 Mitchell Repair Information Company, LLC.

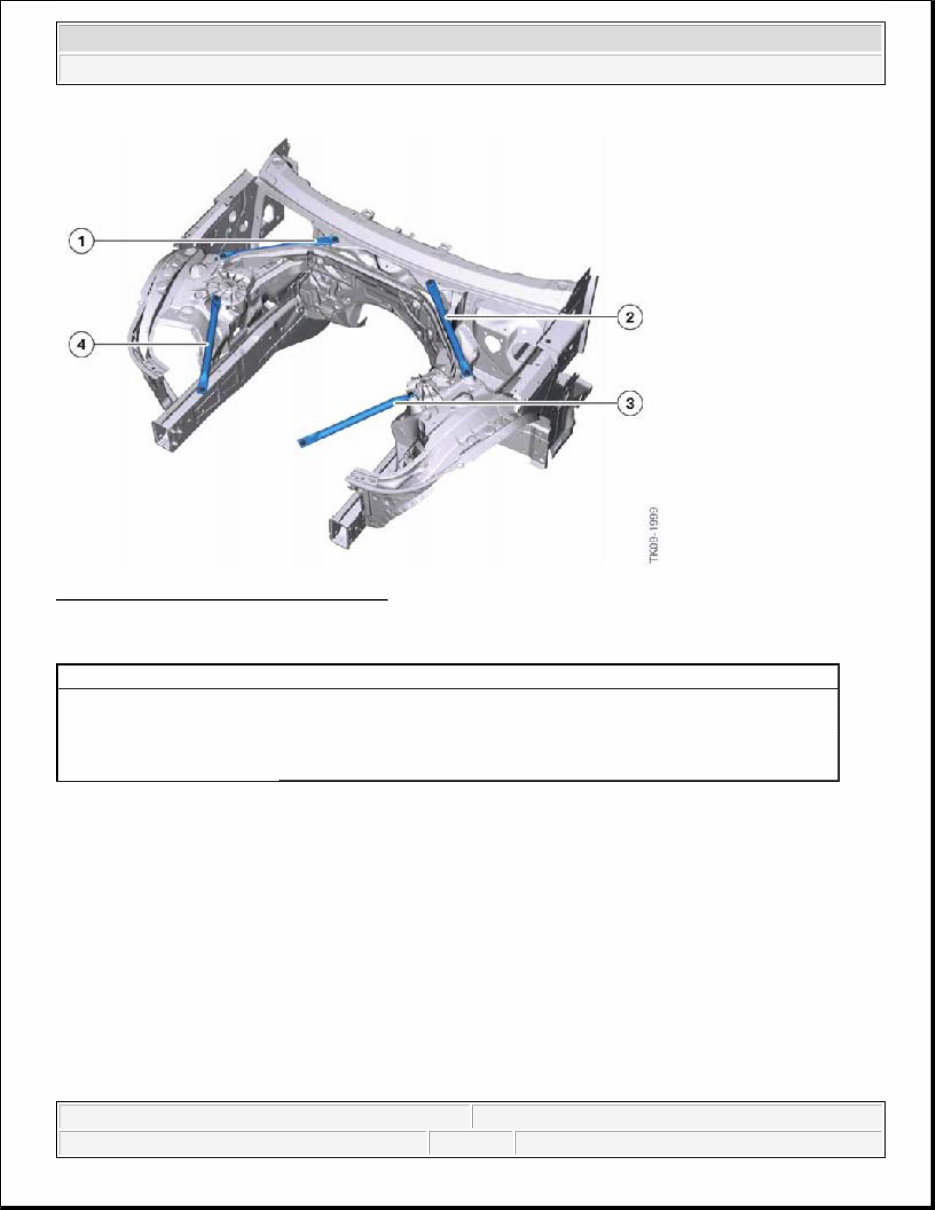

Fig. 8: Identifying F10 Front Body Section

Courtesy of BMW OF NORTH AMERICA, INC.

INDEX EXPLANATION CHART

2.1.5. Side frame

Index Explanation

1 Rear right strut

2 Rear left strut

3 Front left strut

4 Front right strut

NOTE: When installing and dismantling the struts, it is mandatory to observe the repair

instructions!

2011 BMW 535xi

GENERAL INFORMATION Introduction - F10

CARMANUALSUSA

Saturday, September 05, 2015 9:08:06 AM Page 9 © 2011 Mitchell Repair Information Company, LLC.

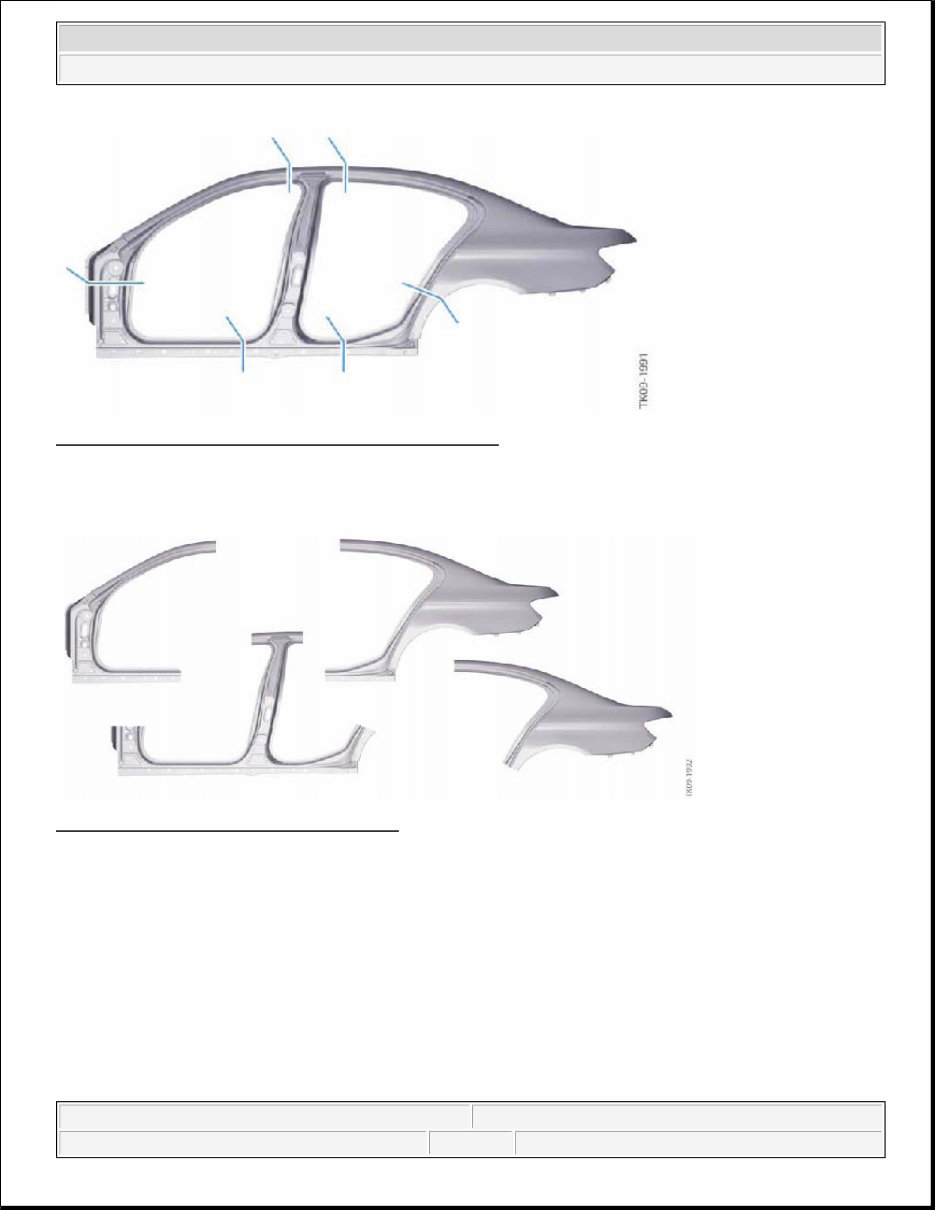

Fig. 9: Identifying F10 Separation Points On Side Frame

Courtesy of BMW OF NORTH AMERICA, INC.

When performing a body repair, the separation points listed above should be used where possible.

Fig. 10: Identifying F10 Spare Part Sections

Courtesy of BMW OF NORTH AMERICA, INC.

The rear side panel is welded to the bodyshell at the factory. However, if it needs to be replaced in the field, the

rear side panel is to be bonded and riveted.

2.1.6. Roof

The roof is welded to the bodyshell at the factory. However, if it needs to be replaced in the field, the roof is to

be bonded and riveted.

2.1.7. Rear Section

Re g ardin g the repair of the F10 rear section, compared to the F01, there are no ma j or chan g es.

2011 BMW 535xi

GENERAL INFORMATION Introduction - F10

CARMANUALSUSA

Saturday, September 05, 2015 9:08:06 AM Page 10 © 2011 Mitchell Repair Information Company, LLC.

You're Reading a Preview

What's Included?

Lifetime Access

Access PDF Contents & Bookmarks

Print one or all pages of your manual