2003-2010 BMW 5 Series E60 E61 Service & Repair Manual

What's Included?

Fast Download Speeds

Online & Offline Access

Access PDF Contents & Bookmarks

Full Search Facility

Print one or all pages of your manual

Important Safety Notice i i

Foreword i v

Index rea r of manual

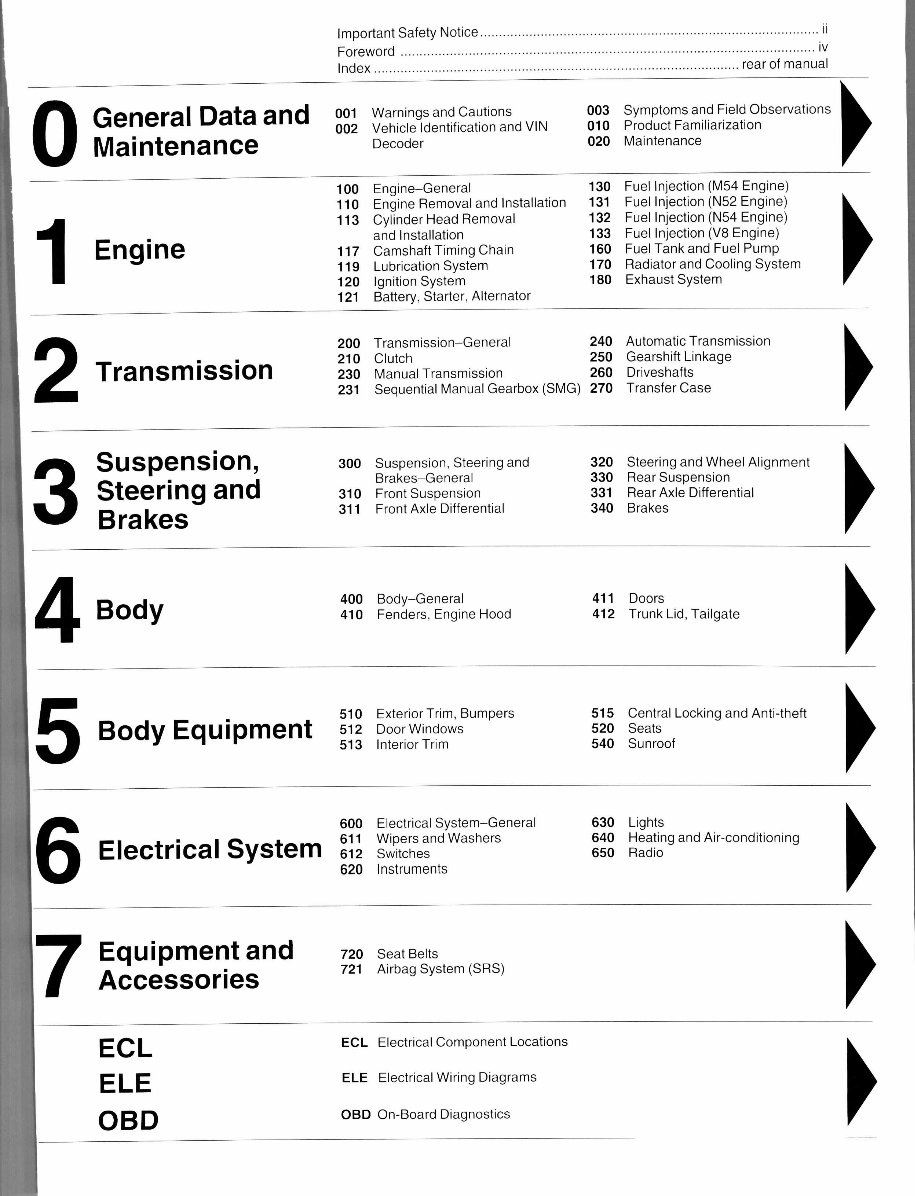

0

General Data and

Maintenance

001 Warning s and Cautions 00 3

002 Vehicl e Identification and VIN 01 0

Decoder 02 0

Symptoms and Field Observations

Product Familiarization

Maintenance

1

Engine

100 Engine-Genera l 13 0

110 Engin e Removal and Installation 13 1

113 Cylinde r Head Removal 13 2

and Installation 13 3

117 Camshaf t Timing Chain 16 0

119 Lubricatio n System 17 0

120 Ignitio n System 18 0

121 Battery , Starter, Alternator

Fuel Injection (M54 Engine)

Fuel Injection (N52 Engine)

Fuel Injection (N54 Engine)

Fuel Injection (V8 Engine)

Fuel Tank and Fuel Pump

Radiator and Cooling System

Exhaust System

2

Transmission

200 Transmission-Genera l 24 0

210 Clutc h 25 0

230 Manua l Transmission 26 0

231 Sequentia l Manual Gearbox (SMG) 27 0

Automatic Transmission

Gearshift Linkag e

Driveshafts

Transfer Case

3

Suspension,

Steering and

Brakes

300 Suspension , Steering and

Brakes-General

310 Fron t Suspension

311 Fron t Axle Differential

320 Steerin g and Wheel Alignment

330 Rea r Suspension

331 Rea r Axle Differential

340 Brake s

4

Body

400 Body-Genera l

410 Fenders , Engine Hood

411 Door s

412 Trun k Lid, Tailgate

5

Body Equipment

510 Exterio r Trim, Bumpers

512 Doo r Windows

513 Interio r Trim

515 Centra l Locking and Anti-theft

520 Seat s

540 Sunroo f

6

Electrical System

600 Electrica l System-General

611 Wiper s and Washers

612 Switche s

620 Instrument s

630 Light s

640 Heatin g and Air-conditioning

650 Radi o

7

Equipment an d

Accessories

720 Sea t Belts

721 Airba g System (SRS)

ECL

ELE

OBD

ECL Electrica l Component Locations

ELE Electrica l Wiring Diagrams

OBD On-Boar d Diagnostics

001-1

001 Warnings and Caution s

PLEASE REA D THES E WARNING S AND CAUTION S

BEFORE PROCEEDIN G WIT H MAINTENANC E AN D REPAI R WORK .

WARNINGS—

See also CAUTIONS

• Rea d the important safet y notic e on the copyright page a t the

beginning of the book .

• Som e repairs may be beyond your capability. If you lack the skills,

tools and equipment o r a suitable workplace for any procedure

described in this manual, we suggest you leave such repair s to

an authorized BM W dealer service department or other qualified

shop.

• I f any procedure, tightenin g torque , wear limit, specification or

data presented in this manua l doe s not appear to be appropriate

for a specific application, contac t the publisher or the vehicle

manufacturer for clarification before using the informatio n in

question.

• D o not reuse an y fasteners that are worn or deformed. Man y

fasteners are designed to be used only once and become

unreliable and may fail when used a second time. This includes ,

but is not limited to, nuts, bolts, washers, self-locking nuts or

bolts, circlips and cotte r pins . Replace these fasteners with new

parts.

• D o not work under a lifted car unless i t is solidly supporte d on

stands designe d fo r the purpose. Do not support a car on cinder

blocks, hollow tile s or other prop s that may crumble unde r

continuous load . Do not work unde r a car that is supported solely

by a jack. Do not work unde r the car while the engine is running.

• I f you are going to work under a car on the ground, mak e sure

that the ground is level. Block the wheels to keep the car from

rolling. Disconnec t th e battery negative (-) termina l to prevent

others from starting the car while you are unde r it.

• D o not run the engin e unles s th e work area is well ventilated.

Carbon monoxide kills.

• Remov e rings , bracelet s and other jewelry so that they canno t

cause electrical shorts, get caught in running machinery, or be

crushed by heavy parts .

• Tie long hai r behin d you r head . Do not wear a necktie, a scarf,

loose clothing, or a necklace when you work near machine tool s

or runnin g engines. If your hair, clothing, or jewelry were to ge t

caught i n the machinery , sever e injury could result .

Do not attempt to work on your car i f you d o no t feel well. You

increase the dange r of injury to yourself and other s i f you ar e

tired, upset or have taken medication or any other substance tha t

may keep you from being fully alert.

Illuminate your work area adequately but safely. Use a portabl e

safety light for working inside or under the car. Make sure the bul b

is enclosed b y a wire cage. The ho t filament of an accidentall y

broken bul b ca n ignite spilled fuel, vapors or oil.

Catch draining fuel , oil, or brake fluid in suitable containers . Do

not use food or beverage containers that might mislead someon e

into drinking from them. Store flammable fluids away from fire

hazards. Wip e up spills at once, but do not store the oil y rags ,

which can ignit e and burn spontaneously.

Observe good workshop practices. Wear goggles whe n you

operate machine tool s or work with battery acid. Wea r glove s or

other protective clothing whenever the job requires working with

harmful substances .

Greases, lubricants and other automotive chemicals contain toxic

substances, many of which are absorbed directly throug h the

skin. Rea d the manufacturer's instructions and warning s

carefully. Use hand and eye protection. Avoid direct skin contact.

Disconnect the battery negativ e (-) termina l whenever yo u work

on the fuel system or the electrical system. D o not smoke or work

near heaters or other fire hazards . Kee p an approved fir e

extinguisher handy .

Friction materials (such as brake pads and shoes or clutch discs)

contain asbestos fibers or other friction materials . D o not create

dust by grinding, sanding , or by cleaning wit h compressed air.

Avoid breathing dust . Breathing any friction material dus t ca n

lead to serious diseases and may result in death.

Batteries give off explosive hydrogen gas during charging. Keep

sparks, lighted matche s an d open flame away from the top of the

battery. If hydrogen gas escaping from the cap vents is ignited, it

may ignite gas trapped in the cells and cause the battery to

explode.

The air-conditioning system is filled with chemical refrigerant ,

which is hazardous. Mak e sure the system is serviced only by a

trained technician using approved refrigerant recovery/recyclin g

equipment, trained in related safety precautions, and familiar with

regulations governing the discharge and disposal of automotive

chemical refrigerants.

Continued on next page

• Thoroughl y read each procedur e and the WARNINGS and

CXcXCxzcxz

001-2 Warning s and Cautions

WARNINGS (continued )

• D o not expose any par t o f the A/C system to high temperature s

such as open flame. Excessiv e heat increase s syste m pressure

and may cause th e system to burst.

• Som e aerosol tire inflators are highly flammable. Be extremely

cautious when repairin g a tire that may have been inflate d usin g

an aerosol tire inflator. Keep sparks, open flame or other sources

of ignition away from the tire repai r area. Inflat e and deflate the

tire at least four times befor e breaking th e bead from the rim .

Completely remov e the tire from the ri m before attempting an y

repair.

• Car s covered by this manua l ar e equipped wit h a supplementa l

restraint system (SRS ) that automaticall y deploy s airbag s an d

pyrotechnic seat bel t tensioner s in case o f a frontal or side

impact. These ar e explosive devices. Handle d improperly or

without adequate safeguards , the y can be accidently activate d

and cause seriou s injury .

• Th e ignition system produce s hig h voltage s tha t can be fatal.

Avoid contact with exposed terminals an d us e extreme car e

when working on a car with the engine runnin g o r the ignitio n

switched ON.

• Plac e jack stands only at locations specified by the manufacturer.

The vehicle lifting jack supplied with the vehicle is intended for tire

changes only . Use a heavy duty floor jack to lif t vehicle before

installing jack stands . See 020 Maintenance.

• Batter y acid (electrolyte) can cause sever e burns. Flus h contact

area with water, then seek medica l attention .

• Aeroso l cleaners and solvents may contain hazardou s or deadly

vapors and are highly flammable . Us e only i n a well ventilated

area. Do not use on hot surfaces (engines , brakes , etc.).

• Du e to risk of personal injury , be sure the engine is cold before

beginning work on the cooling system .

CAUTIONS—

See also WARNINGS

• I f you lack the skills, tools and equipment, o r a suitable workshop

for any procedure described in this manual, leave such repairs to

an authorized BMW dealer or other qualified shop.

• BM W is constantly improving it s cars and sometimes these

changes, bot h in parts and specifications, are made applicable to

earlier models . Any part numbers liste d in this manua l ar e for

reference only. Check with your authorized BMW dealer parts

department for the latest information.

• Befor e starting a job, mak e certai n tha t you hav e the necessary

tools and parts on hand. Read all the instructions thoroughly, and

do not attempt shortcuts. Use tools appropriate t o the work and

use only replacement parts meeting BMW specifications.

• Us e pneumatic an d electric tools onl y to loosen threade d parts

and fasteners. Do not use these tool s to tighten fasteners,

especially on light alloy parts . Us e a torque wrench to tighten

fasteners to the tightening torqu e specification listed.

Be mindful of the environment an d ecology. Before you drain the

crankcase, fin d out the prope r wa y to dispose of the oil. D o not

pour oil onto the ground , dow n a drain, or into a stream, pon d or

lake. Dispos e of waste in accordance wit h federal, state an d

local laws .

The control module for the anti-lock brak e system (ABS) canno t

withstand temperatures from a paint-drying booth or a heat lam p

in excess of 203° F (95° C). D o not subject to temperatures in

excess of 185°F (85° C) for more than two hours .

Before doing an y electrical welding on cars equipped with ABS,

disconnect the battery negativ e (- ) termina l (groun d strap) and

the ABS control modul e connector .

Make sur e ignition is switched OFF befor e disconnecting battery.

Label batter y cables befor e disconnecting. On some models ,

battery cables are not color coded .

Disconnecting th e battery may erase fault code(s) stored in control

module memory. Usin g special BMW diagnostic equipment, check

for fault codes prior to disconnecting th e batter y cables. If the

malfunction indicator light (MIL) is illuminated, see OBD On-Boar d

Diagnostics at the bac k of this manual. (This light may be

identified as the Check Engin e ligh t or the Service Engin e Soon

light.) I f any othe r syste m fault s ar e detecte d (indicated by a n

illuminated warning light), see an authorized BM W dealer .

If a normal or rapid charger is used to charge battery, disconnec t

the battery remov e it from the vehicle in order to avoid damagin g

the vehicle.

Do not quick-charge the batter y (fo r boost starting) for longe r

than one minute . Wai t at least on e minut e befor e boosting the

battery a second time .

Connect an d disconnect a battery charger only with the battery

charger switched OFF.

Sealed or "maintenance free " batteries shoul d be slow-charged

only, at an amperage rat e that is approximately 10 % of the

battery's ampere-hour (Ah ) rating .

Do not allow battery charging voltag e to exceed 16.5 volts. If the

battery begins producin g ga s o r boiling violently, reduce the

charging rate . Boosting a sulfated battery a t a high charging rat e

can cause an explosion.

Do not use steel fasteners on engine components mad e of

aluminum-magnesium alloy . Use aluminum fasteners only. Test

fasteners for aluminum compositio n wit h magnet.

Replace aluminu m bolt s each time they are loosened. Follo w

torque instructions, including angl e of rotation specifications,

when installin g aluminum fasteners .

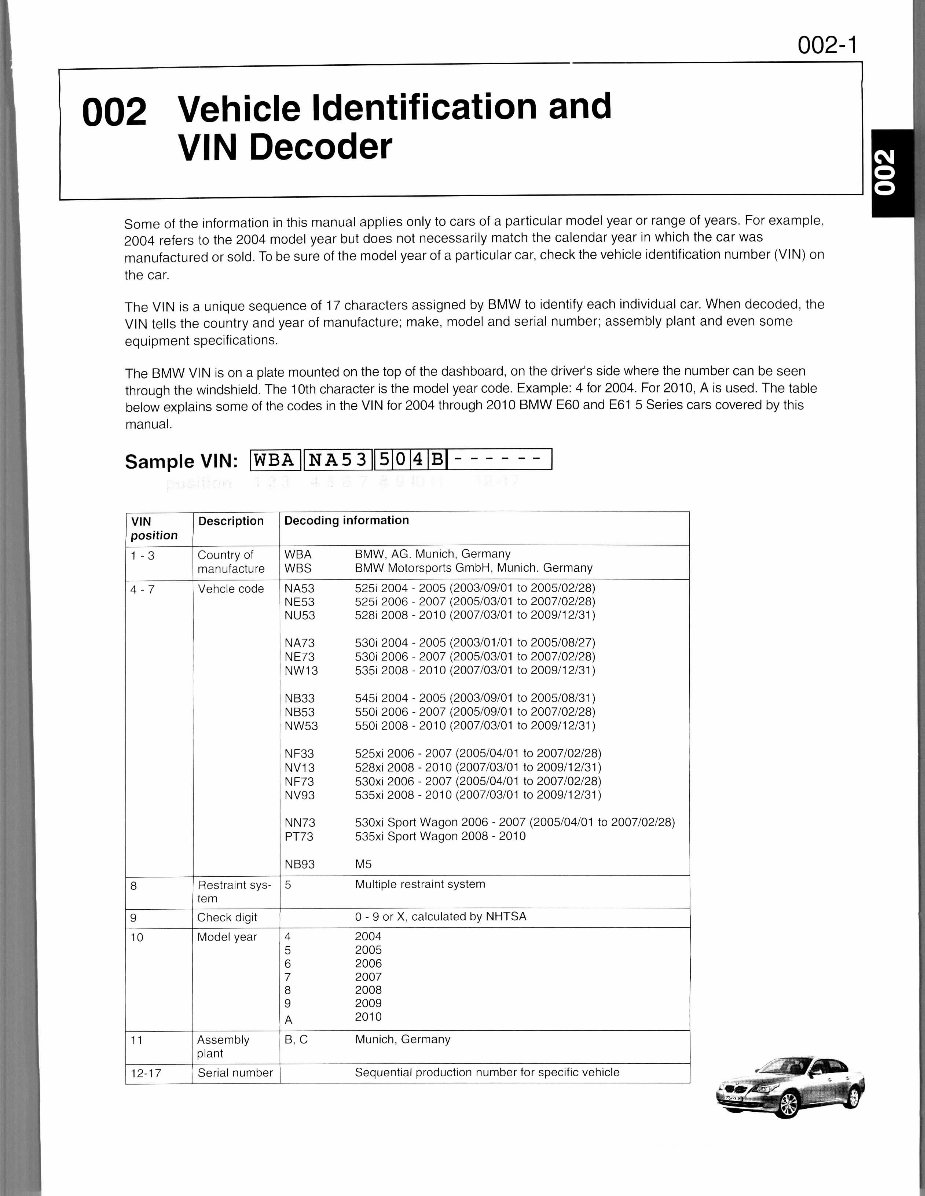

002-1

002 Vehicl e Identification and

VIN Decode r

Some o f the informatio n in this manual applie s onl y to cars of a particular model year or range of years. For example,

2004 refers to the 2004 model year but does not necessarily matc h the calendar yea r in which the car was

manufactured or sold. To be sure of the model year of a particular car, check the vehicle identification number (VIN) on

the car.

The VI N i s a unique sequence of 17 characters assigned by BMW to identify each individual car. When decoded, the

VIN tells the country and year of manufacture; make, mode l and serial number; assembl y plant an d even some

equipment specifications.

The BM W VI N i s on a plate mounted on the top of the dashboard, on the driver's side where the number can be seen

through the windshield. The 10t h character is the model year code. Example: 4 for 2004. For 2010, A is used. The tabl e

below explains some of the codes in the VIN for 2004 through 2010 BMW E6 0 and E6 1 5 Series cars covered by this

manual.

Sample VIN: [WBA||NA53||5|0|4|B|

VIN

position

1 -3

4-7

8

9

10

11

12-17

Description

Country of

manufacture

Vehcle code

Restraint sys-

tem

Check digit

Model year

Assembly

plant

Serial number

Decoding

WBA

WBS

NA53

NE53

NU53

NA73

NE73

NW13

NB33

NB53

NW53

NF33

NV13

NF73

NV93

NN73

PT73

NB93

5

information

BMW, AC. Munich, Germany

BMW Motorsports GmbH, Munich. Germany

525i 2004 - 2005 (2003/09/0 1 to 2005/02/28)

525i 2006 - 2007 (2005/03/01 to 2007/02/28 )

528i 2008 - 201 0 (2007/03/01 to 2009/1 2/31 )

530i 200 4 - 2005 (2003/01/0 1 to 2005/08/27 )

530i 2006 - 2007 (2005/03/01 to 2007/02/28 )

535i 2008 - 2010 (2007/03/01 to 2009/12/31)

545i 2004 - 2005 (2003/09/01 to 2005/08/31)

550i 2006 - 2007 (2005/09/0 1 to 2007/02/28)

550i 2008 - 2010 (2007/03/01 to 2009/12/31)

525xi 2006 - 2007 (2005/04/0 1 to 2007/02/28 )

528xi 2008 - 2010 (2007/03/01 to 2009/12/31)

530xi 2006 - 2007 (2005/04/01 to 2007/02/28)

535xi 2008 - 2010 (2007/03/01 to 2009/12/31)

530xi Spor t Wagon 200 6 - 2007 (2005/04/01 to 2007/02/28)

535xi Sport Wagon 2008 - 201 0

M5

Multiple restraint system

0 - 9 or X, calculated by NHTS A

4

5

6

7

8

9

A

B, C

2004

2005

2006

2007

2008

2009

2010

Munich, Germany

Sequential production number for specific vehicle

003-1

003 Symptom s and Field Observations

GENERAL 003- 1

0 GENERA L DAT A AN D MAINTENANCE 003- 2

1 ENGIN E 003- 5

2 TRANSMISSIO N 003-1 2

3 SUSPENSION , STEERIN G AN D BRAKES. . 003-1 4

4 BOD Y

5 BOD Y EQUIPMEN T

6 ELECTRICA L SYSTE M

7 EQUIPMEN T AND ACCESSORIES .

003-17

003-18

003-19

003-24

GENERAL

This repair group includes a list of symptoms, field observations, and

suggested fixes for common problem s and issues found on BMW 5

Series (E60, E61) vehicles.

The information is organized by sections that correspond t o th e

layout of the repair manual. Additional information (when available)

can be found in the repair group associated with the specifi c issue :

• 0 Genera l Dat a and Maintenance

• 1 Engin e

• 2 Transmission

• 3 Suspension , Steering and Brakes

• 4 Bod y

• 5 Bod y Equipmen t

• 6 Electrica l System

• 7 Equipmen t and Accessories

This information was developed from varied sources, rangin g from

professional BMW technician feedback to manufacturer-issue d

technical service bulletins (TSBs). The content is intended to

complement the repair information found in this repai r manual .

CAUTION—

• The information contained in this section is inherently dated

material. It was applicable and relevant at the time this manual

went to press. A/ways check BMW factory repair information at

www.bmwtechinfo.com or the publisher's website at

www. com for information that may

supersede any information included in this section.

003-2 Symptom s and Fiel d Observations

0 GENERA L DAT A AND MAINTENANCE

Topic Notes

Exiting a vehicle tha t is double-

locked from the outsid e

Never lock a vehicle from outside the car with an someone insid e the

car!

In the unlikely that someon e get s double-locke d insid e th e car , the

person insid e the car can exit the vehicle using the following 2-step

procedure:

• Pres s the central unloc k butto n to disable "double-lock" .

• Pul l the door handl e twic e to open door .

NOTE—

• For vehicles with the factory alarm, opening the door will

activate the alarm.

Additional

information

(when available)

Engine oil , toppin g up

Replacing spark plugs, servic e ti p

Oil residu e ma y collect on the cylinder hea d cove r near th e oi l filler

cap a few days afte r topping u p or refilling the engine oil .

When oi l i s added, th e filler cap is laid partially upsid e down . In this

position, engine oil seeps into the area of the oil cap that is not seale d

by the gasket. When the cap is reinstalled, the oil leaks fro m the

unsealed are a onto the cylinder head cove r surface.

If investigating an oil leak in this area, confirm that it is not oil from the

cap.

020

When servicing spark plugs, a standard socket may fit too tightly into

the spar k plu g bor e i n the cylinder head . If this i s the case , remov e

the hea t shield insid e plu g hole (arrow) before servicing spark plugs .

020

Special tool for spark plu g removal ) Th e N5 4 engine use s a new design spar k plu g from Bosch tha t

consists of a 12m m thread (compared to the 14m m design on the

N52) an d a 12-point hex. The plug require s a special too l (BM W

special tool part no . 83 30 0 495 560). The specia l socke t i s a thin-

wall design to facilitate acces s i n the confined are a o f the N5 4

cylinder head . 020

Symptoms and Field Observations 003- 3

0 GENERA L DAT A AN D MAINTENANCE (CONTINUED )

CD

§

CM

2

o

•a

o

Topic

Engine oil level, checking after oil

change - dynamic chec k

(engine running)

V8 engine A/C belt removin g and

installing.

A/C belt installatio n tool

Notes

Always perform the dynamic oil level measurement (approx . 5

minutes driving time) after an oil change. The oil level could be

misinterpreted as the oil level last stored is initially displayed after an

oil change.

NOTE—

• There is no oil level initially stored after replacing or

reprogramming the engine control unit ("Oil level below min" is

displayed). The correct oil level is indicated after running the

engine for approx. 5 minutes.

- Star t engine.

- Select on-board computer function - OIL usin g rocker switch. Press

BC switch in once. Oil level check begins . A clock symbol (arrow)

may appear while the leve l measurement is running.

NOTE—

• The clock symbol appears for up to 50 seconds after starting

the engine when there is no measured value or the last stored

value is not within the tolerance range of the currently

measured oil level.

Additional

information

(when available)

On the V8 engines, there is no tensioner on the A/C belt. To install a

new belt, a special tool (BMW part # 90 88 6 641 040) is required to

guide the belt onto the pulley.

When installing a new battery, it must be "registered" to the

vehicle to notify the vehicle power management software

(engine electronics and intelligent battery sensor) that a new

battery was fitted. This operatio n require s a BMW scan tool.

Without new battery registration, various electrical problems as

well odd electrical system behavior can occur.

020

020

121

003-4 Symptom s and Field Observations

0 GENERA L DAT A AND MAINTENANCE (CONTINUED )

Topic

No communication wit h BMW sca n

tool on DCAN . __

plug

Notes

Additional

information

(when available)

Intelligent battery sensor (IBS) ,

service precaution s

When performing diagnosis o n a vehicle with the BMW scan tool, the

message "Connec t diagnostic connecto r and switch ON ignitio n

(Terminal 15)! " is displayed .

• D-CA N failure in vehicle.

Before diagnosing D-CA N in the vehicle, try communicating wit h

another vehicle . If communication cannot be established on othe r

vehicle, try a different scan tool. If communication resume s o n the

other vehicle, us e the following steps to diagnose DCAN .

— Disconnec t vehicl e powe r supply / charger (if connected) .

— Disconnec t battery.

— Chec k resistanc e of D-CAN circuit across OBD socke t Pi n 6

(D_CAN_H) an d Pi n 1 4 (D_CAN__L). A good D-CA N measure s

60 ohms. The D-CAN circui t is fitted with two 12 0 ohm terminal

resistors. One is fitted in wiring near OBD socket. The secon d is

fitted in gateway module of vehicle (KG M or SGM) .

— If resistance reading is 0 ohms, the D-CA N wires are shorte d

together. Check circui t for shorts as per wiring diagram.

— If resistance reading is Mega ohms , the D-CA N wiring ha s a n

open circuit. Check circuit for opens as per wiring diagram .

— If resistance reading is 12 0 ohms, on e o f terminal resistor s is

faulty. Check resistanc e of both resistor s for an open circui t and

replace as necessary .

The Intelligen t Battery Senso r (IBS ) is an electronic devic e

connected directly to the negative battery terminal.The IBS is very

sensitive to mechanical stres s and strain. Particular attention shoul d

be paid to the following points:

• D o not make any additional connections at the negative terminal of

the battery .

• Do not modify the battery groun d cable.

• D o not make any connections between the IBS and the senso r

screw.

• D o not use force when disconnectin g the ground terminal from the

battery.

• Neve r pul l on the ground cable.

• D o not use the IB S as a pivot poin t to lever off the ground terminal .

• D o not use the connections o f the IB S as a lever.

• Us e only a torque wrench as described in the repair manua l during

installation.

• Do not release or tighten the sensor screw .

NOTE—

•A replacemen t IBS includes the ground cable. The groun d

cable als o serves as a heat dissipate r for the IBS .

020, 600

121

Symptoms and Field Observations 003- 5

1 ENGIN E

Topic

Engine knoc k fault code s

Diagnosing electri c cooling fan

E-box water ingres s

No crank, no start

Notes

Engine knoc k fault codes indicat e tha t the engin e is knocking .

Detonation or knock i s an erratic form of combustion that can cause

head gasket failure as well as other engine damage. Prolonge d or

heavy detonation can be very damaging. Th e hammer-lik e shock

waves created by detonation subject the hea d gasket, piston, rings,

spark plug and rod bearings to severe overloading. As a first remedy,

try highe r octan e hig h detergent fuel or switch brands . I f the faults

codes continue to return, contact your authorized BMW dealer.

Additional

information

(when available)

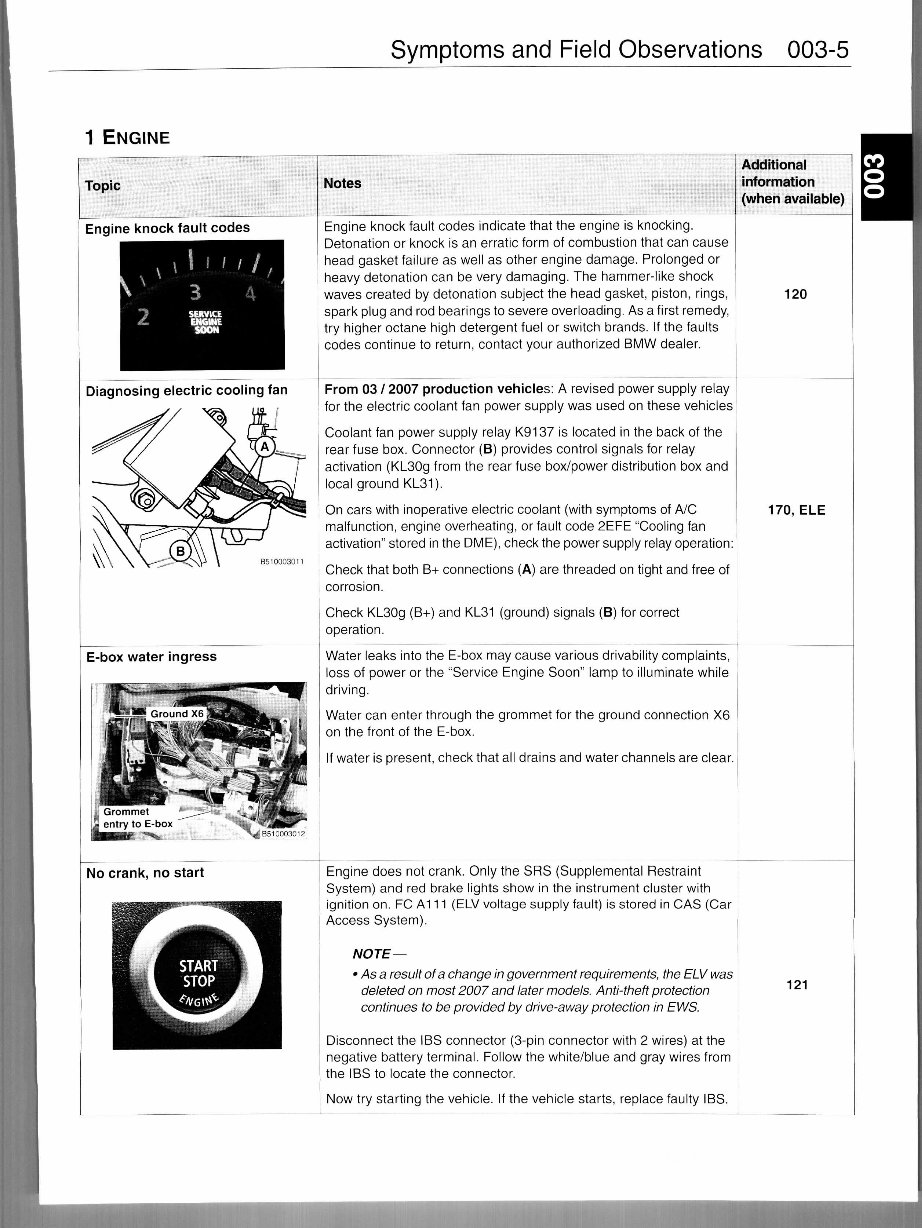

From 03 / 2007 production vehicles : A revised power supply rela y

for the electric coolant fan power supply was use d on these vehicle s

Coolant fa n powe r supply rela y K9137 is located i n the bac k of the

rear fuse box. Connector (B ) provides control signals for rela y

activation (KLSO g from the rea r fuse box/power distribution box and

local ground KL31).

On cars with inoperative electri c coolant (wit h symptoms of A/C

malfunction, engine overheating, or fault code 2EFE "Cooling fan

activation" stored in the DME), check the power supply relay operation:

Check that both B+ connections (A) are threaded on tight and free of

corrosion.

Check KLSO g (B+) an d KL31 (ground ) signals (B) for correc t

operation.

Water leak s into the E-box may cause variou s drivability complaints,

loss of power or the "Service Engine Soon " lam p to illuminate while

driving.

Water can enter through the grommet for the ground connection X6

on the front of the E-box.

If water is present, check that all drains and water channels are clear.

Engine doe s not crank. Only the SRS (Supplemental Restraint

System) an d re d brake lights show i n the instrumen t cluster with

ignition on. FC A111 (ELV voltage supply fault) is stored in CAS (Ca r

Access System).

NOTE—

•Asa result of a change in government requirements, the ELV was

deleted on most 2007 and later models. Anti-theft protection

continues to be provided by drive-away protection in EWS.

Disconnect th e IB S connector (3-pi n connecto r with 2 wires) at the

negative battery terminal. Follo w the white/blue and gray wires from

the IB S to locate the connector .

Now try startin g the vehicle. I f the vehicle starts, replace faulty IBS .

120

170, EL E

121

You're Reading a Preview

What's Included?

Fast Download Speeds

Online & Offline Access

Access PDF Contents & Bookmarks

Full Search Facility

Print one or all pages of your manual

$31.99

Viewed 87 Times Today

Loading...

Secure transaction

What's Included?

Fast Download Speeds

Online & Offline Access

Access PDF Contents & Bookmarks

Full Search Facility

Print one or all pages of your manual

$31.99

The BMW 5 Series E60 E61 2003-2010 Factory Service Repair Manual is a comprehensive guide suitable for both professional mechanics and DIY enthusiasts. It covers the BMW 5 Series models from 2003 to 2010, including the E60 and E61 variations, providing step-by-step instructions and illustrations for proper maintenance, repair, and servicing.

Key features of this Factory Service Repair Manual:

- Detailed information on engine, transmission, suspension, electrical system, and more

- Comprehensive instructions for routine maintenance tasks, such as oil changes and brake pad replacement

- Troubleshooting and diagnostic procedures for identifying and resolving common issues

- Detailed wiring diagrams, exploded views, and technical specifications for easy reference

- Written and designed by BMW experts to ensure accuracy and reliability

Whether you are a DIY enthusiast or a professional technician, this Factory Service Repair Manual is an indispensable tool for ensuring the longevity and performance of your BMW 5 Series. Invest in this manual today and unleash the full potential of your vehicle.