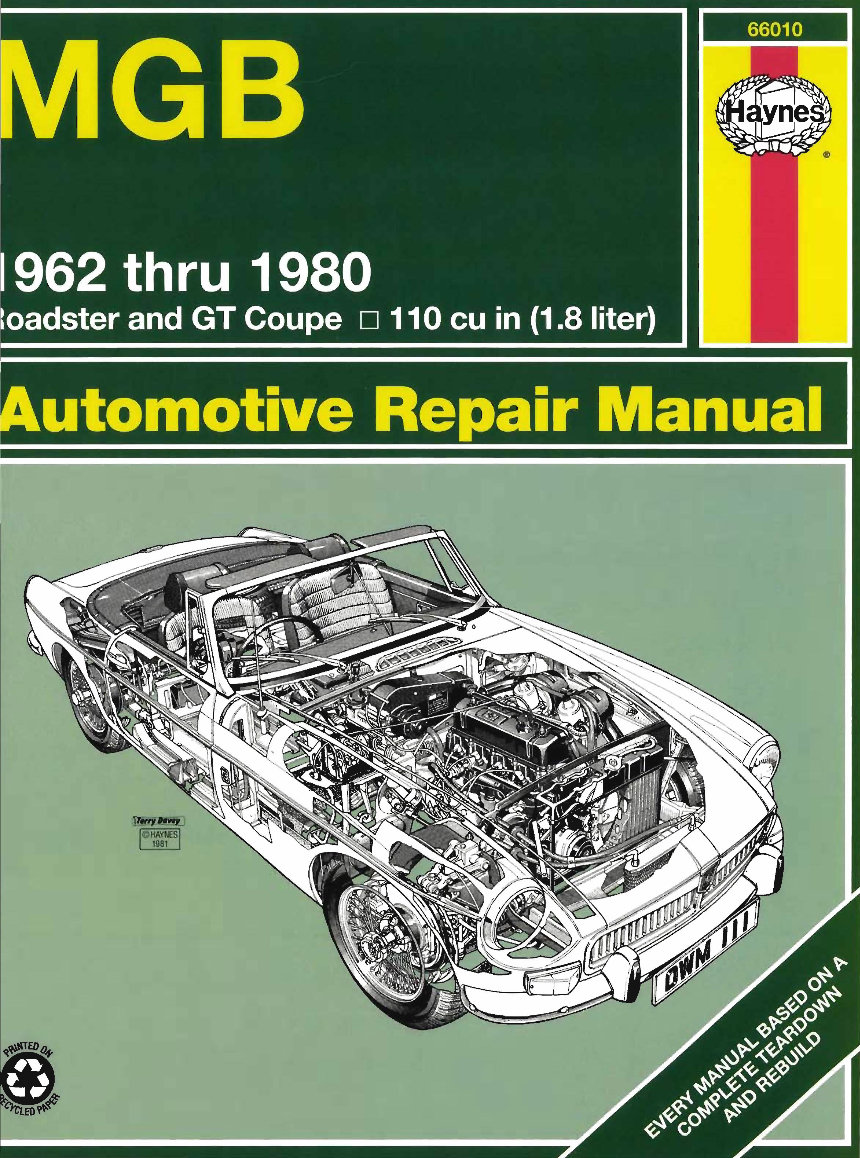

1962-1980 MG MGB Service & Repair Manual

What's Included?

Fast Download Speeds

Online & Offline Access

Access PDF Contents & Bookmarks

Full Search Facility

Print one or all pages of your manual

66010

utomotive Repair Manual

MGB

Automotive

Repair

Manual

John Fowler

Models covered

All models of the MGB Roadster and GT Coupe

with 1798 cc (110 cu in) engine

Does not cover MGB GT \i8

ISBN 0 85696 6231

HR1"n~~!'I North America, Inc. 1981,1987,1989

Wilh permission from J. H. Haynes & Co. Lid.

All rights reserved. No part of this book may be reproduced or transmitted in any form or by

any means, electrical or mechanical, including photocopying, recording or information

storage or retrieval system, without permission in writing from the copyright

Printed in the USA

(6/=4 - 66010)

Haynes Publishing Group

Sparkford Nr Yeovil

Somerset BA22 7 JJ England

Haynes North America, Inc

861 Lawrence Drive

Newbury Park

California 91320 USA

1

Acknowledgements

Thanks are due to the Champion Sparking Plug Company Limited who

supplied the illustrations sAowing spark plug conditions, to Holt Lloyd

Limited who supplied the illustrations showing bodywork repair, and

to Duckhams Oils who provided lubrication data. Thanks are also due

to Rover cars for supplying technical information. The Section in Chapter

10 dealing with the suppression of electrical interference was originated

by Mr. I. P. Davey and was first published in Motor magazine.

© Haynes North America, Inc. 1981,1987,1989

With permission from J. H. Haynes & Co. Ltd.

A book in the Haynes Automotive Repair Manual Series

Printed in the USA

All rights reserved. No part of this book may be reproduced or

transmitted in any form or by any means, electronic or mechanical,

including photocopying, recording or by any information storage or

retrieval system, without permission in writing from the copyright

holder.

ISBN 0 85696 623 1

Whilst every care is taken to ensure that the information in this

manual is correct. no liability. can be accepted by the authors or

publishers for loss, damage or injury caused by any errors in, or omis-

sions from, the information given.

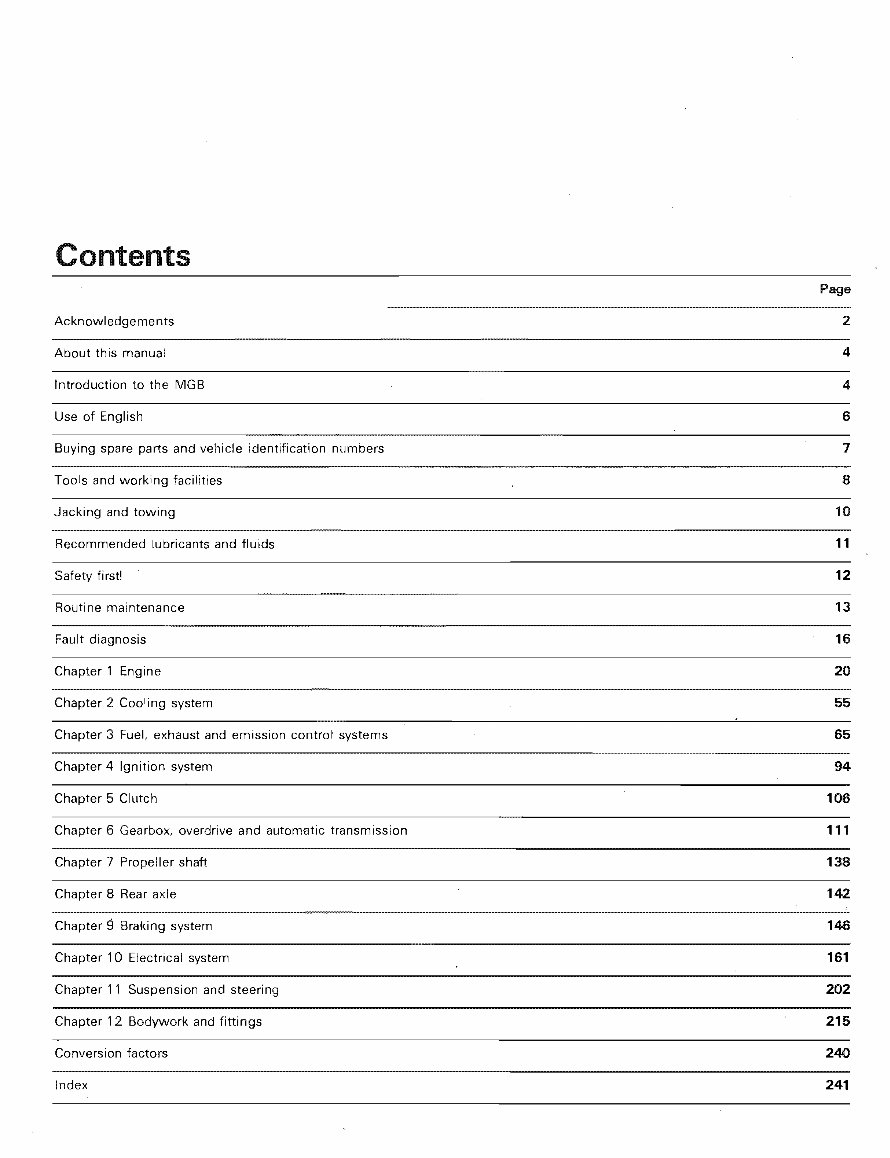

Contents

Page

Acknowledgements 2

About this manual 4

Introduction to the MGB 4

Use of English 6

Buying spare parts and vehicle identification numbers 7

Tools and working facilities 8

Jacking and towing 10

Recommended lubricants and fluids 11

Safety first! 12

Routine maintenance 13

Fault diagnosis 16

Chapter 1 Engine 20

Chapter 2 Cooling system 55

Chapter 3 Fuel, exhaust and emission control systems 65

Chapter 4 Ignition system 94

Chapter 5 Clutch 106

Chapter 6 Gearbox, overdrive and automatic transmission 111

Chapter 7 Propeller shaft 138

Chapter 8 Rear axle 142

Chapter:3 Braking system 146

Chapter 10 Electrical system 161

Chapter 11 Suspension and steering 202

Chapter 12 Bodywork and fittings 215

Conversion factors 240

Index 241

About this manual

Its aim

The aim of this manual is to help you get the best value from your car. It

can do so in several ways. It can help you decide what work must be

done (even should you choose to get it done by a garage), provide

information on routine maintenance and servicing, and give a logical

course of action and diagnosis when random faults occur. However, it is

hoped that you will use the manual by tackling the work yourself. On

simpler jobs it may even be quicker than booking the car into a garage'

and going there twice to leave and collect it Perhaps most important, a

lot of money can be saved by avoiding the costs the garage must charge

to cover its labour and overheads.

The manual has drawings and descriptions to show the function of the

various components so that their layout can be understood. Then the

tasks are described and photographed in a step-by-step sequence so

that even a novice can do the work.

Its arrangement

The manual is divided into twelve Chapters, each covering a logical

sub-division of the vehicle. The Chapters are each divided into Sections,

numbered with single figures, eg 5; and the Sections into paragraphs (or

sub-sections), with decimal numbers following on from the Section they

are in, eg 5.1, 5.2, 5.3 etc.

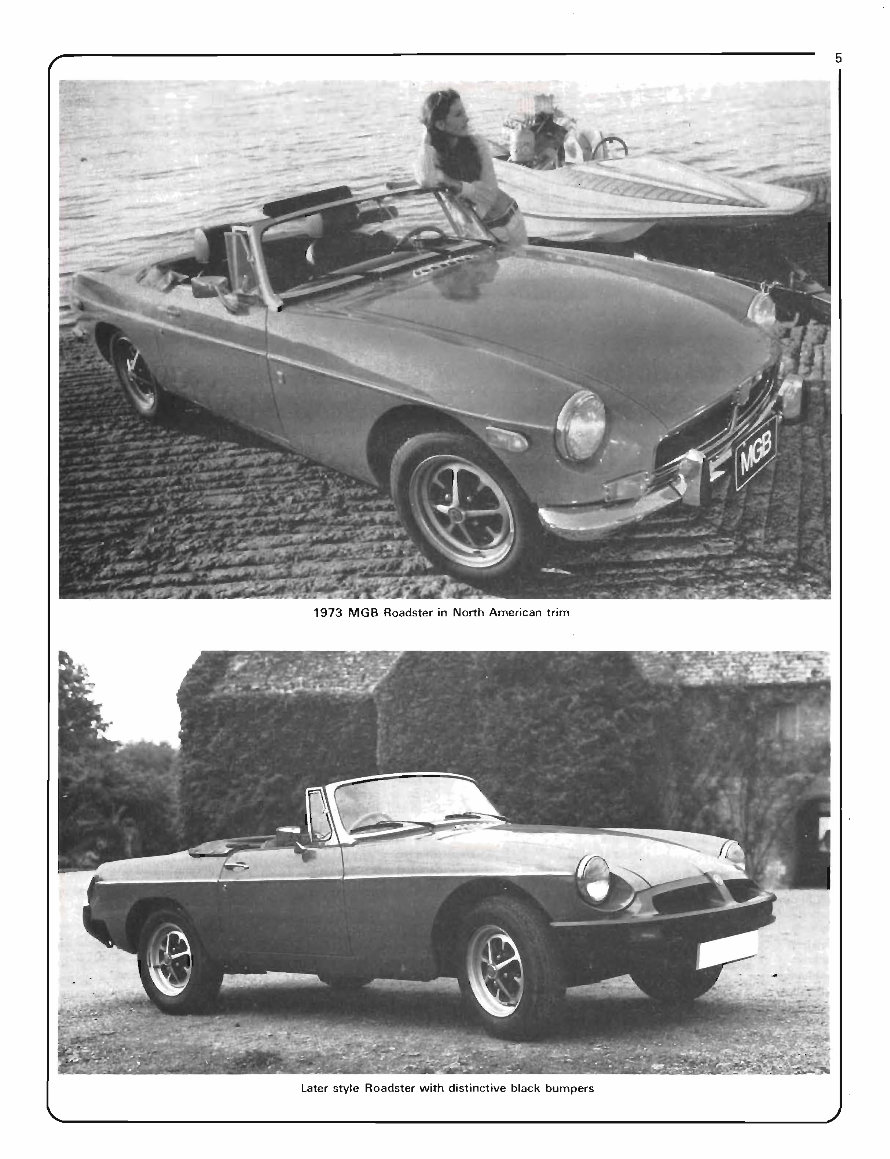

Introduction to the MGB

Since first introduced, the MGB had undergone many modifications

as a result of development, and in order to comply with regulations

which have come into force in certain territories.

The engine, of straightforward design, began as a three-main

bearing unit, but a five-main bearing version was subsequently

developed.

The transmission system is available in various versions, and can be

a four-speed manual gearbox, a four-speed manual gearbox with

overdrive, or an automatic gearbox.

Independent front suspension is employed, together with rubber-

mounted semi-elliptical springs at the rear.

It is freely illustrated, especially in those parts where there is a detailed

sequence of operations to be carried out. There are two forms of

illustration: figures and photographs. The figures are numbered in

sequence with decimal numbers, according to their position in the

Chapter - eg Fig. 6.4 is the fourth drawing/illustration in Chapter 6.

Photographs carry the same number (either individually or in related

groups) as the Section or sub-section to which they relate.

There is an alphabetical index at the back of the manual as well as a

contents list at the front. Each Chapter is also preceded by its own

individual contents list

References to the 'left' or 'right' of the vehicle are in the sense of a

person in the driver's seat facing forwards.

Unless otherwise stated, nuts and bolts are removed by tuming anti-

clockwise, and tightened by turning clockwise.

Vehicle manufacturers continually make changes to specifications

and recommendations, and these when notified are incorporated into

our manuals at the earliest opportunity.

Whilst every care is taken to ensure that the information in this

manual is COlTect. no liability can be accepted by the authors or

publishers for loss. damage or injury caused by any elTors in, or

omissions from. the information given.

Depending upon the model, a three-quarter floating or semi-floating

rear axle is fined, driven by a propeller shaft and universal joints.

A hydraulically-operated diaphragm spring clutch is fined to all

models which employ manual transmission.

Disc front brakes and drum rear brakes are fined, hydraulically

operated. Servo assistance, and a tandem brake master cylinder, are

fined as appropriate to certain veh icles. The cable-operated handbrake

is applied to the rear wheels only.

Vehicles manufactured for certain territories are fined with exhaust

emission control systems, in order that the amount of poisonous exhaust

gases being released afe reduced to tl=1e permined level.

5

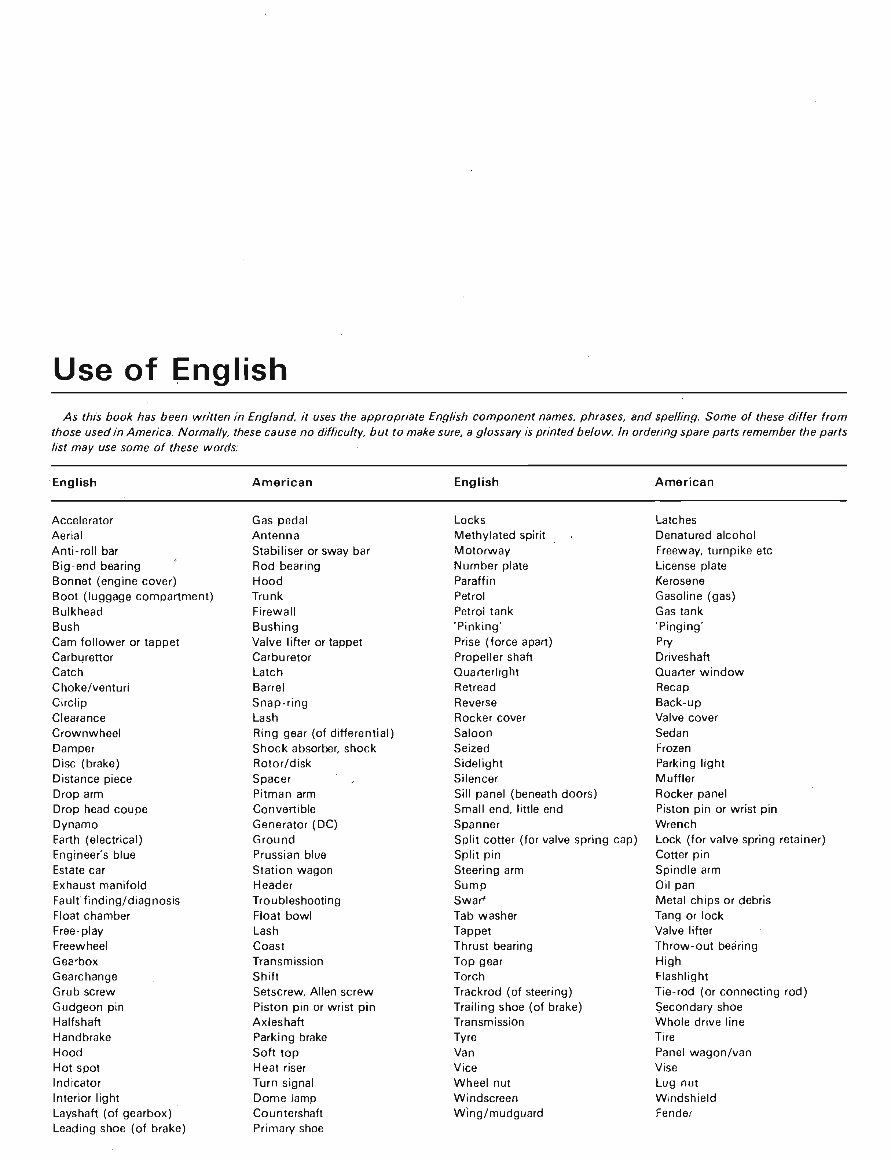

Use of English

As this book has been written in England. it uses the appropriate English component names, phrases, and spelling. Some of these differ from

those used in America. Normally, these cause no difficulty, but to make sure, a glossary is printed below. In ordering spare parts remember the parts

list may use some of these words:

. English American English American

Accelerator Gas pedal Locks Latches

Aerial Antenna Methylated spirit Denatured alcohol

Anti-roll bar Stabiliser or sway bar Motorway Freeway, turnpike etc

Big-end bearing Rod bearing Number plate License plate

Bonnet (engine cover) Hood Paraffin Kerosene

Boot (luggage compartment) Trunk Petrol Gasoline (gas)

Bulkhead Firewall Petrol tank Gas tank

Bush Bushing 'Pinking' 'Pinging'

Cam follower or tappet Valve lifter or tappet Prise (force apart) Pry

Carburettor Carburetor Propeller shaft Driveshaft

Catch Latch Quarterlight Quarter window

Choke/venturi Barrel Retread Recap

Circlip Snap-ring Reverse Back-up

Clearance Lash Rocker cover Valve cover

Crownwheel Ring gear (of differential) Saloon Sedan

Damper Shock absorber, shock Seized Frozen

Disc (brake) Rotor/disk Sidelight Parking light

Distance piece Spacer Silencer Muffler

Drop arm Pitman arm Sill panel (beneath doors) Rocker panel

Drop head coupe Convertible Small end, little end Piston pin or wrist pin

Dynamo Generator (DC) Spanner Wrench

Earth (electrical) Ground Split cotter (for valve spring cap) Lock (for valve spring retainer)

Engineer's blue Prussian blue Split pin Cotter pin

Estate car Station wagon Steering arm Spindle arm

Exhaust manifold Header Sump Oil pan

Fault finding/diagnosis Troubleshooting Swar' Metal chips or debris

Float chamber Float bowl Tab washer Tang or lock

Free-play Lash Tappet Valve lifter

Freewheel Coast Thrust bearing Throw-out bearing

Gee'box Transmission Top gear High

Gearchange Shift Torch Flashlight

Grub screw Setscrew, Allen screw Trackrod (of steering) Tie-rod (or connecting rod)

Gudgeon pin Piston pin or wrist pin Trailing shoe (of brake) $econdary shoe

Halfshaft Axleshaft Transmission Whole drive line

Handbrake Parking brake Tyre Tire

Hood Soft top Van Panel wagon/van

Hot spot Heat riser Vice Vise

Indicator Turn signal Wheel nut Lug nut

Interior light Dome lamp Windscreen Windshield

Layshaft (of gearbox) Countershaft Wing/mudguard Fender

Leading shoe (of brake) Primary shoe

Buying spare parts

and vehicle identification numbers

Buying spare parls

Replacement parts are available from many sources, which generally

fall into one of two categories - authorized dealer parts departments and

independent retail auto parts stores. Our advice conceming these parts

is as follows:

Retail auto parts stores: Good auto parts stores will stock frequently

needed components which wear out relatively fast, such as clutch compo-

nents, exhaust systems, brake parts, tune-up parts, etc. These stores of-

ten supply new or reconditioned parts on an exchange basis, which can

save a considerabre amount 01 money. Discount auto parts stores are 01-

ten very good places to buy materials and parts needed for general vehicle

maintenance such as oil, grease, filters, spark plugs, belts, tOUCh-Up paint,

bulbs, etc. They also usually sell tools and general accessories, have con-

venient hours, charge lower prices and can often be found notlar from

home.

Authorized dealer parts department: This is the best source for parts

which are unique to the vehicle and not generally available elsewhere

(such as major engine parts, transmission parts, trim pieces, etc.).

Warranty information: If the vehicle is still covered under warranty, be

sure that any replacement parts purchased - regardless of the source-

do not invalidate the warranty!

To be sure 01 obtaining the correct parts, have engine and chassis

numbers available and, if possible, take the old parts along for positive

identification.

Vehicle identification numbers

Modifications are a continuing and unpublished process in vehicle

manufacture quite apart from major model changes. Spare parts manuals

and lists are compiled upon a numerical basis, the individual vehicle num-

bers being essential to correct identification of the component required.

The position of the numbers concerned has varied, but the following list

gives some guidance.

The car will have an identification plate, normally found on the inside

of one of the wing panels, under the hood.

The car number is preceded by three letters and one figure:

a) The letter G standing for MG

b) The letter H for the Leyland type of engine

c) Either N for two-seater Tourer or D for the GT Coupe

d) A type serial number, eg 3, 4 or 5

Thus in 1972 the Tourer was GHN5, and the GT GHD5.

The car commission number will probably be found on the hood lock

platform.

The engine number is stamped on a plate secured to the right side of

the engine block, or alternatively may be stamped directly upon the block.

The engine number starts with the figures 18. This signifies the 1798

cc engine. This used to be lollowed by the letter G lor MG and a second

letter lor the type serial. Thus the 18GB followed the 18GA when five main

bearings were introduced. This series went through to 18GH. This group

of the number had after it a second group giving the type of gearbox:

a) U for standard

b) RU for overdrive

c) We-All synchromesh box

d) RWe-AII synchromesh with overdrive

e) Rc-Automatic gearbox

The engine number/first group is now always 18V and the second

group a three figure and one letter serial. Thus in October 1972 the home

market was 18V/582F, Europe 18V/581Y and North America 18V/672Z.

The engine prefix is followed by one letter, H for high compression ratio

and L for low, and then the serial number.

The gearbox numberis stamped on the casing of the unit, as is the rear

axle number.

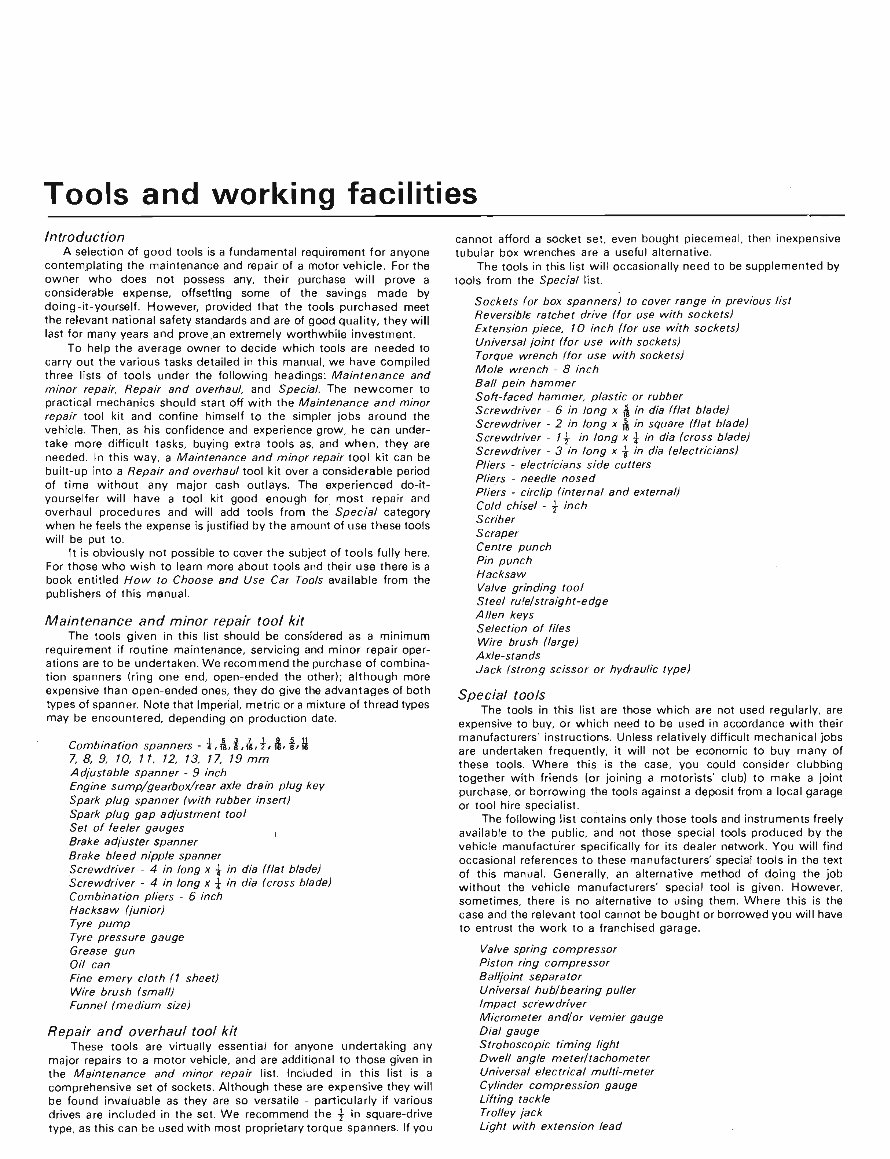

Tools and working facilities

Introduction

A selection of good tools is a fundamental requirement for anyone

contemplating the maintenance and repair of a motor vehicle. For the

owner who does not possess any, their purchase will prove a

considerable expense, offsettmg some of the savings made by

doing-it-yourself. However, provided that the tools purchased meet

the relevant national safety standards and are of good quality, they will

last for many years and prove,an extremely worthwhile investment.

To help the average owner to decide which tools are needed to

carry out the various tasks detailed in this manual, we have compiled

three lists of tools under the following headings: Maintenance and

minor repair, Repair and overhaul, and Special. The newcomer to

practical mechanics should start off with the Maintenance and minor

repair tool kit and confine himself to the simpler jobs around the

vehicle. Then, as his confidence and experience grow, he can under-

take more difficult tasks, buying extra tools as, and when, they are

needed. In this way, a Maintenance and minor repair tool kit can be

built-up into a Repair and overhaul tool kit over a considerable period

of time without any major cash outlays. The experienced do-it-

yourselfer will have a tool kit good enough for most repair and

overhaul procedures and will add tools from the Special category

when he feels the expense is justified by the amount of use these tools

will be put to.

It is obviously not possible to cover the subject of tools fully here.

For those who wish to learn more about tools and their use there is a

book entitled How to Choose and Use Car Tools available from the

publishers of this manual.

Maintenance and minor repair tool kit

The tools given in this list should be considered as a minimum

requirement if routine maintenance, servicing and minor repair oper-

ations are to be undertaken. We recommend the purchase of combina-

tion spanners Iring one end, open-ended the other); although more

expensive than open-ended ones, they do give the advantages of both

types of spanner. Note that Imperial, metric or a mixture of thread types

may be encountered, depending on production date.

Combination spanners - t.;\. t .~. t.;\. t. M

7, 8. 9, 10. 11. 12, 13, 17, 19 mm

Adjustable spanner - 9 inch

Engine sump/gearbox/rear axle drain plug key

Spark plug spanner (with rubber insert)

Spark plug gap adjustment tool

Set of feeler gauges

Brake adjuster spanner

Brake bleed nipple spanner

Screwdriver - 4 in long x t in dia (flat blade)

Screwdriver - 4 in long x t in dia (cross blade)

Combination pliers - 6 inch

Hacksaw (junior)

Tyre pump

Tyre pressure gauge

Grease gun

Oil can

Fine emery cloth (1 sheet)

Wire brush (small)

Funnel (medium size)

Repair and overhaul tool kit

These tools are virtually essential for anyone undertaking any

major repairs to a motor vehicle, and are additional to those given in

the Maintenance and minor repair list. Included in this list is a

comprehensive set of sockets. Although these are expensive they will

be found invaluable as they are so versatile - particularly if various

drives are included in the set. We recommend the t in square-drive

type, as this can be used with most proprietary torque spanners. If you

cannot afford a socket set. even bought piecemeal, then inexpensive

tubular box wrenches are a useful alternative.

The tools in this list will occasionally need to be supplemented by

tools from the Special list.

Sockets (or box spanners) to cover range in previous list

Reversibl€ ratchet drive (for use with sockets)

Extension piece, 10 inch (for use with sockets)

Universal joint (for use with sockets)

Torque wrench (for use with sockets)

Mole wrench - 8 inch

Ball pein hammer

Soft-faced hammer, plastic or rubber

Screwdriver - 6 in long x ;\ in dia (flat blade)

Screwdriver - 2 in long x ;\ in square (flat blade)

Screwdriver - 1 t in long x t in dia (cross blade)

Screwdriver - 3 in long x t in dia (electricians)

Pliers - electricians side cutters

Pliers - needle nosed

Pliers - circlip (internal and external)

Cold chisel - t inch

Scriber

Scraper

Centre punch

Pin punch

Hacksaw

Valve grinding tool

Steel rule/straight-edge

Allen keys

Selection of files

Wire brush (large)

Axle-stands

Jack (strong scissor or hydraulic type)

Special tools

The tools in this list are those which are not used regularly, are

expensive to buy, or which need to be used in accordance with their

manufacturers' instructions. Unless relatively difficult mechanical jobs

are undertaken frequently, it will not be economic to buy many of

these tools. Where this is the case, you could consider clubbing

together with friends lor joining a motorists' club) to make a joint

purchase, or borrowing the tools against a deposit from a local garage

or tool hire specialist.

The following list contains only those tools and instruments freely

available to the public, and not those special tools produced by the

vehicle manufactu'rer specifically for its dealer network. You will find

occasional references to these manufacturers' special tools in the text

of this manual. Generally, an alternative method of doing the job

without the vehicle manufacturers' special tool is given. However,

sometimes, there is no alternative to using them. Where this is the

case and the relevant tool cannot be bought or borrowed you will have

to entrust the work to a franchised garage.

Valve spring compressor

Piston ring compressor

Balljoint separator

Universal hub/bearing puller

Impact screwdriver

Micrometer and/or vernier gauge

Dial gauge

Stroboscopic timing light

Dwell angle meter/tachometer

Universal electrical multi-meter

Cylinder compression gauge

Lifting tackle

Trolley jack

Light with extension lead

You're Reading a Preview

What's Included?

Fast Download Speeds

Online & Offline Access

Access PDF Contents & Bookmarks

Full Search Facility

Print one or all pages of your manual

$31.99

Viewed 51 Times Today

Loading...

Secure transaction

What's Included?

Fast Download Speeds

Online & Offline Access

Access PDF Contents & Bookmarks

Full Search Facility

Print one or all pages of your manual

$31.99

- The 1962-1980 MG MGB Service & Repair Manual is a comprehensive resource for fixing vehicle issues, providing troubleshooting and replacement procedures, step-by-step instructions, and clear images.

- Regular maintenance is essential for the durability of your vehicle, and this manual equips both professional mechanics and DIY enthusiasts with the necessary manufacturer-recommended information.

- With the manual's detailed troubleshooting charts and replacement procedures, you can save on repairs, enhance your vehicle's reliability, and minimize visits to the repair shop.

- Featuring step-by-step instructions, exploded-view illustrations, and clear images, this manual offers convenient access to specific information without the hassle of traditional bound manuals.

- It is available in .pdf format, allowing for easy accessibility and printing if a physical copy is preferred. The manual is compatible with various electronic devices and requires Adobe Reader for access.