1994-1998 Audi Cabriolet Service & Repair Manual

What's Included?

Fast Download Speeds

Online & Offline Access

Access PDF Contents & Bookmarks

Full Search Facility

Print one or all pages of your manual

A/C COMPRESSOR REFRIGERANT OIL CHECKING

1994 A/C Compressor Refrigerant Oil Checking

REFRIGERANT OIL

Only NEW, moisture-free refrigerant oil should be used in the air conditioning system. This oil is highly refined

and dehydrated so moisture content is less than 10 parts per million. The oil container must be tightly closed at

all times when not in use, or moisture from the air will be absorbed into the refrigerant oil.

SERVICING PRECAUTIONS

DISCHARGING SYSTEM

Discharge A/C system using approved refrigerant recovery/recycling equipment. Always follow

recovery/recycling equipment manufacturer's instructions. After refrigerant recovery process is completed, the

amount of compressor oil removed must be measured and the same amount added to A/C system.

DISCONNECTING LINES & FITTINGS

After system is discharged, carefully clean area around all fittings to be opened. Always use 2 wrenches when

tightening or loosening fittings. Some refrigerant lines are connected with a coupling. Special tools may be

required to disconnect lines. Cap or plug all openings as soon as lines are removed. DO NOT remove caps until

connections of lines and fittings are completed.

CONNECTING LINES & FITTINGS

Always use a new gasket or "O" ring when connecting lines or fittings. Coat "O" ring with refrigerant oil and

ensure it is not twisted during installation. Always use 2 wrenches to prevent damage to lines and fittings.

PLACING SYSTEM IN OPERATION

After component service or replacement has been completed and all connections have been made, evacuate

system thoroughly with a vacuum pump. Charge system with proper amount of refrigerant and perform leak

test. See REFRIGERANT OIL & REFRIGERANT SPECIFICATIONS TABLE in the A/C COMPRESSOR

SERVICING article for system capacities. Check all fittings that have been opened. After system has been leak

tested, check system performance.

NOTE: For COMPRESSOR APPLICATION and REFRIGERANT OIL & REFRIGERANT

SPECIFICATIONS tables, see the A/C COMPRESSOR SERVICING article in the

AIR CONDITIONING & HEAT section. DO NOT exceed A/C system refrigerant oil

capacity when servicing system.

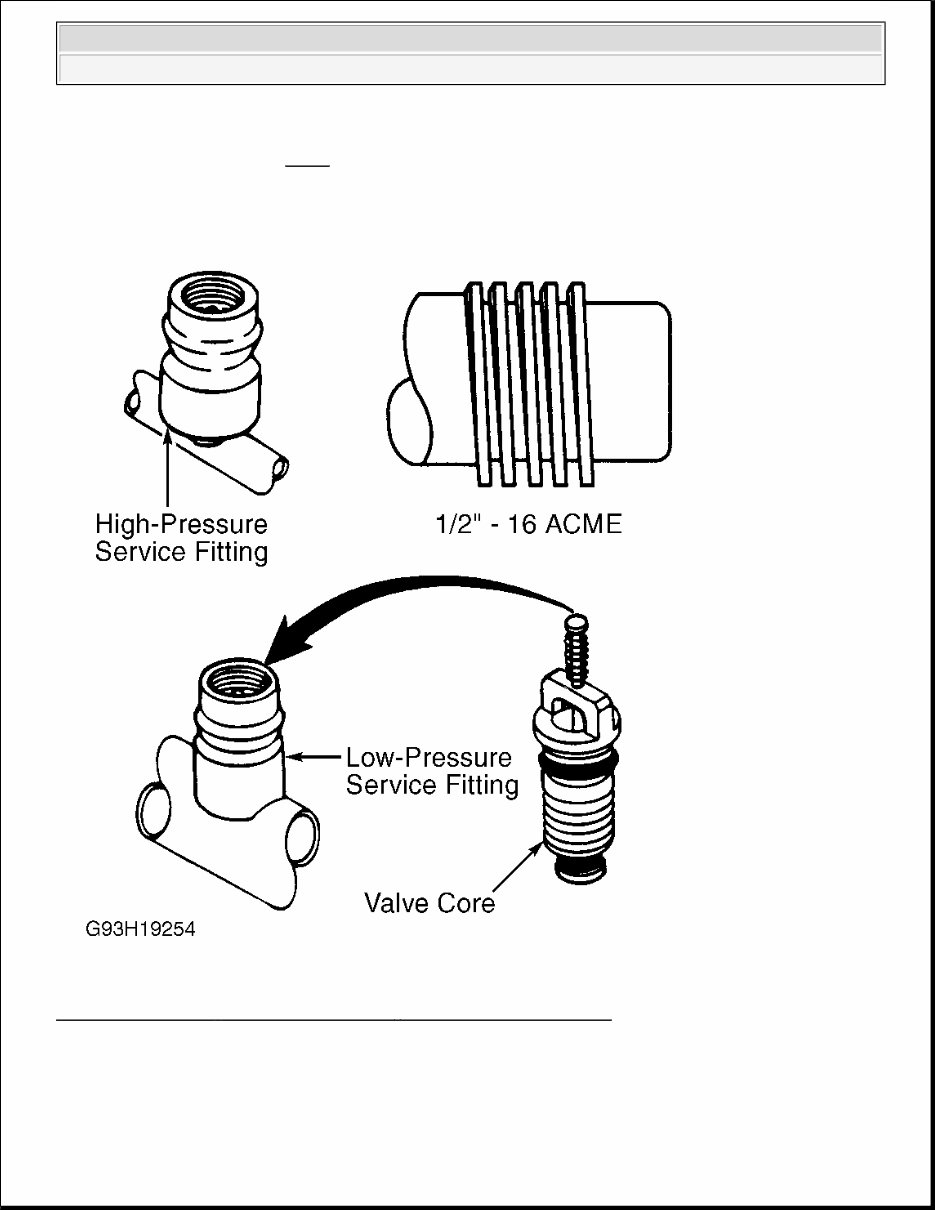

NOTE: All R-134a based systems use 1/2"-16 ACME threaded fittings. Ensure all

replacement parts match the connections of the system being worked on.

1994 Audi Cabriolet

A/C COMPRESSOR REFRIGERANT OIL CHECKING 1994 A/C Compressor Refrigerant Oil Checking A/C COMPRESSOR REFRIGERANT OIL CHECKING 1994 A/C Compressor Refrigerant Oil Checking

CHECKING COMPRESSOR OIL

ZEXEL - 6-CYLINDER

1. The use of refrigerant recovery/recycling is recommended by manufacturer. After refrigerant recovery

process is completed, the amount of compressor oil removed must be measured and the same amount

added to A/C system.

2. Add one ounce of refrigerant oil when replacing accumulator. When replacing condenser, add amount

drained from condenser plus 1/3 ounce of refrigerant oil. When replacing evaporator, add amount drained

from evaporator plus 2/3 ounce of refrigerant oil.

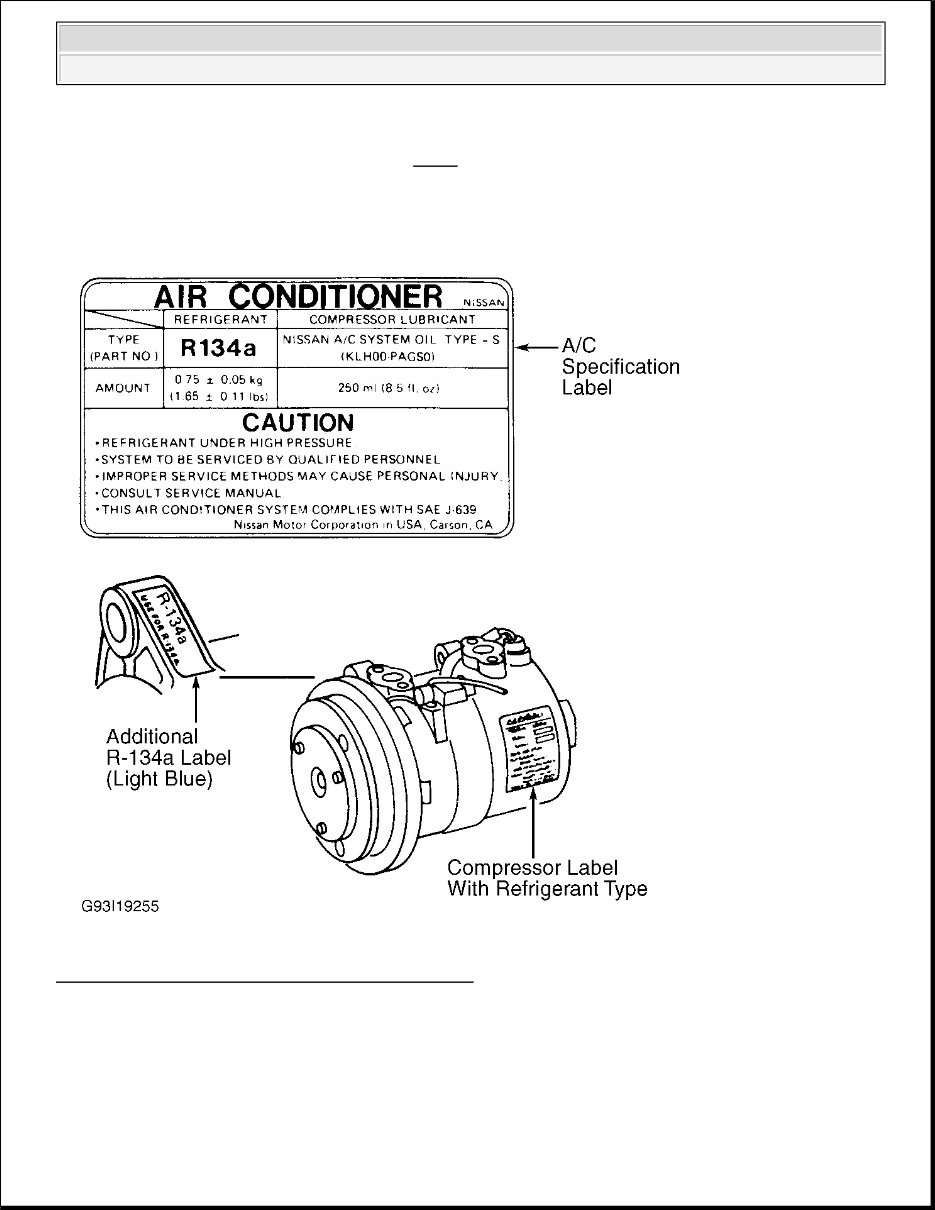

NOTE: Most compressors are pre-charged with a fixed amount of refrigerant (shipping)

oil. Drain compressor oil from new compressor and add refrigerant oil to new

compressor according to amount removed from old compressor. Always refer

to underhood A/C specification label or A/C compressor label while servicing

A/C system.

1994 Audi Cabriolet

A/C COMPRESSOR REFRIGERANT OIL CHECKING 1994 A/C Compressor Refrigerant Oil Checking

A/C COMPRESSOR SERVICING

1994 A/C Compressor Servicing

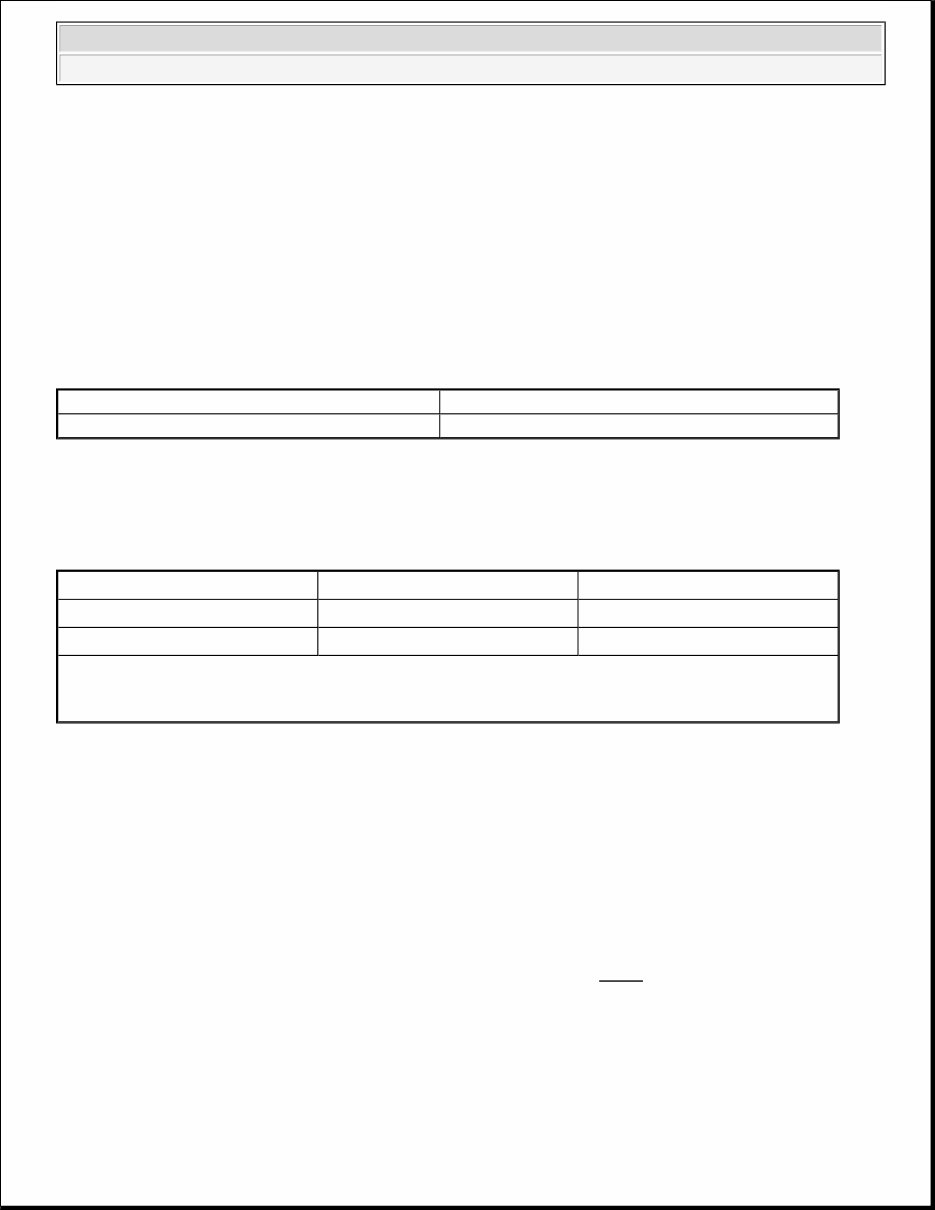

COMPRESSOR APPLICATION

COMPRESSOR APPLICATION

A/C COMPRESSOR REFRIGERANT SPECIFICATIONS

REFRIGERANT OIL & REFRIGERANT CAPACITY

REFRIGERANT OIL & R-134a REFRIGERANT CAPACITY

ZEXEL 6-CYLINDER

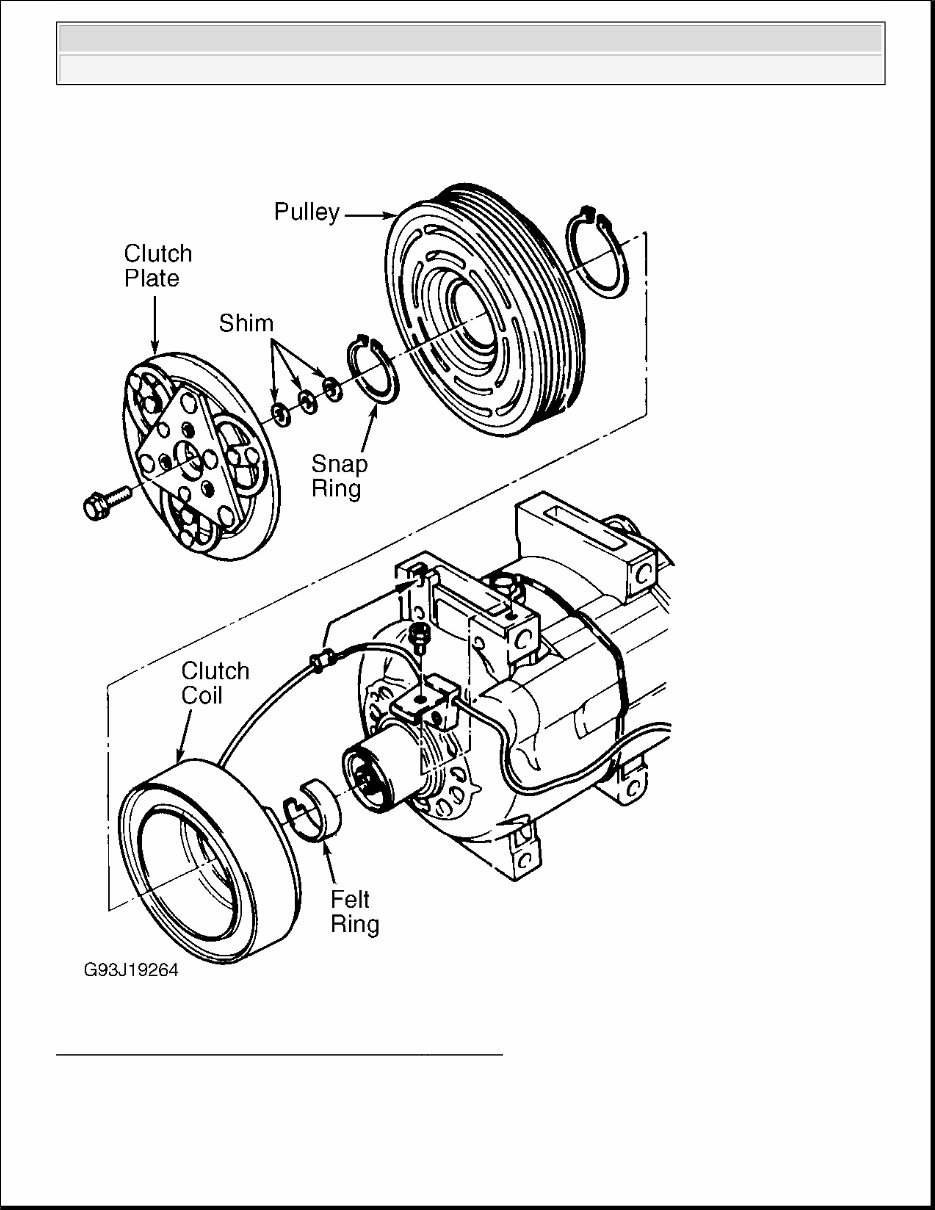

CLUTCH COIL & BEARING

Removal

1. Using Spanner Wrench (44-4), hold clutch hub stationary and remove shaft bolt. Remove clutch plate and

shim(s) using Puller (VAG 1719) and Spanner Wrench (3212). See Fig. 1 . Remove snap ring.

2. Place Spacer (VAG 1719/1) in center of pulley cavity. Attach Puller (US 1078) to outer diameter of

pulley and remove pulley. Remove snap ring, bearing, and clutch coil as necessary.

Installation

NOTE: Due to late changes, always refer to underhood A/C specification label in engine

compartment or A/C compressor label while servicing A/C system. If A/C

Specification label and specifications in this article differ, always use label

specifications.

Application Compressor

All Models Zexel 6-Cyl.

Application

(1)

Oil Ounces Refrigerant Ounces

Cabriolet & 90

(2)

7.8-9.2

23.0-24.8

100

(2)

7.8-9.2

21.0-22.8

(1)

Total system capacity, unless otherwise noted.

(2)

Use Polyalkylene Glycol (PAG) oil.

NOTE: Due to variety of clutch and shaft seal configurations, obtain appropriate A/C

compressor service tools for compressor being serviced.

1994 Audi Cabriolet

A/C COMPRESSOR SERVICING 1994 A/C Compressor Servicing

1994 Audi Cabriolet

A/C COMPRESSOR SERVICING 1994 A/C Compressor Servicing

Ensure clutch coil lug fits into hole on compressor housing. Using Installer (VAG 1719/2), press on pulley and

install snap ring. Install shim(s) and clutch plate. Tighten shaft bolt to 11 ft. lbs. (15 N.m). Using feeler gauge,

ensure air gap between pulley and clutch disc is .012-.024" (.30-.60 mm). If clearance is incorrect, add or

remove shim(s) as necessary.

1994 Audi Cabriolet

A/C COMPRESSOR SERVICING 1994 A/C Compressor Servicing

Fig. 1: Exploded View Of Compressor (Zexel 6 - Cylinder)

Courtesy of AUDI OF AMERICA, INC.

1994 Audi Cabriolet

A/C COMPRESSOR SERVICING 1994 A/C Compressor Servicing

A/C SYSTEM GENERAL SERVICING

1994 A/C System General Servicing

USING R-12 & R-134A REFRIGERANT

HANDLING/SAFETY PRECAUTIONS

1. Always work in a well-ventilated, clean area. Refrigerant R-134a is colorless and is invisible as a gas.

Refrigerant (R-12 or R-134a) is heavier than oxygen and will displace oxygen in a confined area. Avoid

breathing refrigerant vapors. Exposure may irritate eyes, nose and throat.

2. The system's high pressure can cause severe injury to eyes and skin if a hose were to burst. Always wear

eye protection when working around A/C system and refrigerant. If necessary, wear rubber gloves or

other protective clothing.

3. Refrigerant evaporates quickly when exposed to atmosphere, freezing anything it contacts. If liquid

refrigerant contacts eyes or skin, DO NOT rub eyes or skin. Immediately flush affected area with cool

water for 15 minutes and consult a doctor or hospital.

4. Never use R-134a in combination with compressed air for leak testing. Pressurized R-134a in the

presence of oxygen (air concentrations greater than 60% by volume) may form a combustible mixture.

DO NOT introduce compressed air into R-134a containers (full or empty), A/C system components or

service equipment.

5. DO NOT expose A/C system components to high temperatures, steam cleaning for example, as excessive

heat will cause refrigerant/system pressure to increase. Never expose refrigerant directly to open flame. If

refrigerant needs to be warmed, place bottom of refrigerant tank in warm water. Water temperature

MUST NOT exceed 125°F (52°C).

6. Use care when handling refrigerant containers. DO NOT drop, strike, puncture or incinerate containers.

Use Department Of Transportation (DOT) approved, DOT 4BW or DOT 4BA refrigerant containers.

7. Never overfill refrigerant containers. The safe filling level of a refrigerant container MUST NOT exceed

60% of the container's gross weight rating. Store refrigerant containers at temperature less than 125°F

(52°C).

8. R-12 refrigerant (Freon) will be sold and stored in White containers, while R-134a refrigerant will be sold

and stored in 30 or 50-pound Light Blue containers.

9. R-12 and R-134a refrigerants must never be mixed, as their desiccants and lubricants are not compatible.

If the refrigerants are mixed, system cross-contamination or A/C system component failure may occur.

Always use separate servicing and refrigerant recovery/recycling equipment.

10. Follow equipment manufacturer instructions of all service equipment to be used. The Material Safety

Data Sheet (MSDS), provided by refrigerant manufacturer/suppliers, contains valuable information

regarding the safe handling of R-12 or R-134a refrigerants.

IDENTIFYING R-134A SYSTEMS & COMPONENTS

To prevent refrigerant cross-contamination, use following methods to identify R-134a based systems and

components.

Fittings & "O" Rings

1994 Audi Cabriolet

A/C SYSTEM GENERAL SERVICING 1994 A/C System General Servicing

1994 Audi Cabriolet

A/C SYSTEM GENERAL SERVICING 1994 A/C System General Servicing

All R-134a based A/C systems use 1/2" - 16ACME threaded fittings (identifiable by square threads) and quick-

connect service couplings. See Fig. 1 . Besides the use of these fittings, most manufacturers will use Green

colored "O" rings in R-134a systems.

Fig. 1: Identifying R - 134a Fittings & Quick - Connect Service Couplings

Courtesy of AUDI OF AMERICA, INC.

Underhood A/C Specification Labels

1994 Audi Cabriolet

A/C SYSTEM GENERAL SERVICING 1994 A/C System General Servicing

Most R-134a based systems will be identified through the use of Green or Light Blue underhood labels, or with

R-134a refrigerant clearly printed on labels. See Fig. 2 . Some manufacturers will identify R-12 based systems

with White, Red, Silver or Gold underhood labels. Before servicing an A/C system, always determine which

refrigerant is being used.

Fig. 2: Underhood A/C Specification Labels (Typical)

Courtesy of NISSAN MOTOR CO., U.S.A.

Other Means Of Identification

Refrigerant R-134a, when viewed through a sight glass, may have a "milky" appearance due to the mixture of

1994 Audi Cabriolet

A/C SYSTEM GENERAL SERVICING 1994 A/C System General Servicing

charged A/C system,most R-134a systems have no sight glass.

Audi models use Green bands/labels on condenser, refrigerant lines, receiver-drier and expansion valve.

REFRIGERANT OILS

Refrigerant R-12 based systems use mineral oil, while R-134a systems use synthetic/Polyalkylene Glycol

(PAG) oils. Using a mineral oil based lubricant with R-134a will result in A/C compressor failure due to lack of

proper lubrication.

SERVICE EQUIPMENT

Because R-134a is not interchangeable with R-12, separate sets of hoses, manifold gauge set and

recovery/recycling equipment are required to service vehicles. This is necessary to avoid cross-contaminating

and damaging system.

All equipment used to service systems using R-134a must meet SAE standard J1991. The service hoses on the

manifold gauge set must have manual (turn wheel) or automatic back-flow valves at the service port connector

ends. This will prevent refrigerant from being released into the atmosphere.

For identification purposes, R-134a service hoses must have a Black stripe along its length and be clearly

labeled SAE J2196/R-134a. The low pressure test hose is Blue with a Black stripe. The high pressure test hose

is Red with a Black stripe, and the center test hose is Yellow with a Black stripe.

R-134a manifold gauge sets can be identified by one or all of the following: Labeled FOR USE WITH R-134a

on set, labeled HFC-134 or R-134a on gauge face, or by a Light Blue color on gauge face. In addition,

pressure/temperature scales on R-134a gauge sets are different from R-12 manifold gauge sets.

SYSTEM SERVICE VALVES

SCHRADER-TYPE VALVES

Schrader valve is similar in construction and operation to a tire valve. When a test gauge hose with built-in

valve core depressor is attached, Schrader stem is pushed inward to the open position and allows system

pressure to reach gauge.

NOTE: Use ONLY the specified oil for the appropriate system or A/C compressor.

Always check the underhood A/C specification label or A/C compressor label

before adding refrigerant oil to A/C compressor/system. See Fig. 2 .

NOTE: Synthetic/PAG oils absorb moisture very rapidly, 2.3-5.6% by weight, as

compared to a mineral oil absorption rate of .005% by weight.

NOTE: Although similar in construction and operation to a tire valve, NEVER replace a

Schrader-type valve with a tire valve.

1994 Audi Cabriolet

A/C SYSTEM GENERAL SERVICING 1994 A/C System General Servicing

You're Reading a Preview

What's Included?

Fast Download Speeds

Online & Offline Access

Access PDF Contents & Bookmarks

Full Search Facility

Print one or all pages of your manual

$41.99

Viewed 30 Times Today

Loading...

Secure transaction

What's Included?

Fast Download Speeds

Online & Offline Access

Access PDF Contents & Bookmarks

Full Search Facility

Print one or all pages of your manual

$41.99

Thank you for considering this comprehensive Service & Repair Workshop Manual for the 1994-1998 Audi Cabriolet.

This manual is an invaluable resource, covering all Service & Repair Procedures with easy-to-follow step-by-step instructions and illustrations. It is designed to help both professional mechanics and DIY enthusiasts save significant costs on repairs.

Upon acquisition, this manual becomes your permanent asset, allowing you to print specific pages, chapters, or the entire manual. It is also compatible with tablets and smartphones for easy access.

Models Covered:

- All Models/Engines/Trim/Transmissions Types

Contents:

- Comprehensive coverage of all repair procedures from A-Z

- Inclusive of every repair and service procedure

Computer Requirements:

- Compatible with All PC & MAC Computers, tablets, and mobile phones

- Requires Adobe Reader, which is commonly pre-installed or can be downloaded for free

Delivery:

- Instant delivery via email to the address provided during checkout

- Payment accepted through Visa, MasterCard, or PayPal

Customer satisfaction is guaranteed with this manual.