2005-2010 ASTON MARTIN DB9 Workshop / Repair / Service Manual

What's Included?

Fast Download Speeds

Online & Offline Access

Access PDF Contents & Bookmarks

Full Search Facility

Print one or all pages of your manual

Workshop Manual

Issue 2

DB9

Aston Martin Lagonda Limited

Banbury Road, Gaydon, WARWICK, Warwickshire,

England, MK16 9AN

Telephone: (01926) 644700 Fax: (01926) 644733

Aston Martin are constantly seeking to improve the specification, design and production of their vehicles and alterations

take place accordingly. While every effort has been made to ensure the accuracy of this Manual, it should not be regarded

as an infallible guide to current specifications of any particular vehicle.

All rights reserved. No part of this publication may be reproduced, stored in a retrieval system or transmitted, in any form,

electronic, mechanical, photocopying, recording or other means without prior written permission from Aston Martin

Lagonda Limited.

The manufacturer reserves the right to vary specifications without notice in accordance with its policy of continual product

improvement.

Produced by the Technical Publications Department

Aston Martin Lagonda Limited

Issue 2 - February 2005 Part No. 4G43-43-10032

Issue 2 February 2005 Workshop Manual I-I-III

DB9 Workshop Manual

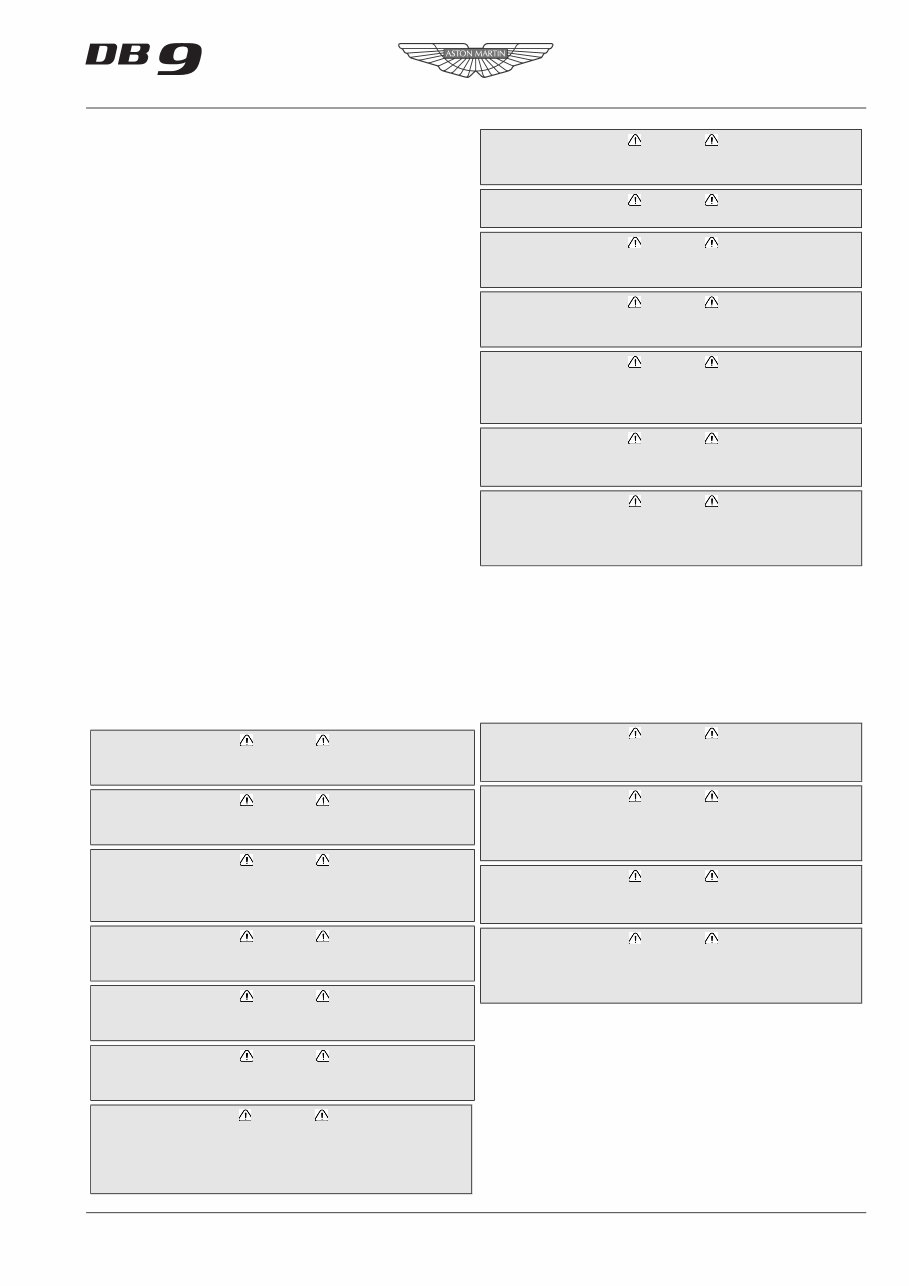

Contents

Introduction

Welcome ............................................................... i-i-iv

Safety Precautions ................................................... i-i-v

Lifting and Jacking ................................................. i-i-vii

Vehicle Recovery ..................................................i-i-viii

Vehicle Identification Number ............................... i-i-ix

Body System (01.00)

Body Structure (01.01) .......................................... 1-1-3

Front End System (01.02) ...................................... 1-2-1

Body Closures (01.03) ........................................... 1-3-1

Interior Trim (01.05) ............................................. 1-4-1

Exterior Trim (01.08) ............................................. 1-5-1

Mirrors (01.09) ...................................................... 1-6-1

Seating (01.10) ...................................................... 1-7-1

Glass, Frame and Mechanism (01.11) .................... 1-8-1

Instrument Panel (IP) (01.12) ................................. 1-9-1

Handles and Lock Mechanisms (01.14) ............... 1-10-1

Wipers and Washer System (01.16) ..................... 1-11-1

Bumpers (01.19) ................................................. 1-12-1

Restraining Devices (01.20) ................................. 1-13-1

Frame and Mounting (02.00)

Subframes (02.03) ................................................. 2-1-2

Engine System (03.00)

Engine Assembly (03.00) ....................................... 3-1-3

Engine Structure (03.01) ........................................ 3-2-1

Lubrication System (03.02) .................................... 3-3-1

Cooling System (03.03) ......................................... 3-4-1

Fuel Charging System (03.04) ................................ 3-5-1

Accessory Drive System (03.05) ............................. 3-6-1

Engine Cranking System (03.06) ............................ 3-7-1

Ignition System (03.07) ......................................... 3-8-1

Emission Control (03.08) ....................................... 3-9-1

Valve Train (03.09) ............................................. 3-10-1

Engine Sealing (03.10) ......................................... 3-11-1

Power Conversion (03.11) ................................... 3-12-1

Air Charging (03.12) ............................................ 3-13-1

Evaporative Emissions (03.13) ............................. 3-14-1

Engine Management System (03.14) .................... 3-15-1

Throttle Control (03.16) ...................................... 3-16-1

Suspension (04.00)

Road Wheel Alignment (04.00) ............................. 4-1-2

Front Suspension (04.01)....................................... 4-2-1

Rear Suspension (04.02)........................................ 4-3-1

Road Wheels and Tyres (04.04) ............................ 4-4-1

Driveline (05.00)

Driveshaft (05.01) ................................................. 5-1-2

Rear Drive System (05.02) .................................... 5-2-1

Halfshafts (05.05) .................................................. 5-3-1

Brake System (06.00)

Description ........................................................... 6-1-2

Front Disc Brake (06.03) ....................................... 6-2-1

Rear Disc Brakes (06.04) ....................................... 6-3-1

Hand Brake (06.05) .............................................. 6-4-1

Brake Actuation System (06.06) ............................ 6-5-1

Power Brake System (06.09) ................................. 6-6-1

Transmission (07.00)

Automatic Transmission (07.01) ............................ 7-1-2

Transmission Cooling (07.02) ................................ 7-2-1

Manual Transmission (07.03) ................................ 7-3-1

Automatic Control System (07.05) ......................... 7-4-1

Clutch (08.00)

Clutch Controls (08.02) ......................................... 8-2-1

Exhaust (09.00)

Exhaust Overview ................................................. 9-1-2

Silencer Assembly (09.01) ..................................... 9-1-3

Pipes and Supports (09.03) ................................... 9-2-1

Fuel (10.00)

Fuel Tank and Lines (10.01) ................................ 10-1-2

Steering (11.00)

Steering Gear (11.01) .......................................... 11-1-2

Power Steering (11.02)........................................ 11-2-1

Steering Column (11.04) ..................................... 11-3-1

Steering Column Switches (11.05) ....................... 11-4-1

Steering Wheel (11.06) ....................................... 11-5-1

Climate Control (12.00)

Body Ventilation system (12.01) .......................... 12-1-3

Heater System (12.02) ........................................ 12-2-1

Air Conditioning (A/C) System (12.03) ................. 12-3-1

A/C Control System (12.04) ................................. 12-4-1

Information, Gauge and Warning (13.00)

Instrument Cluster (13.01) .................................. 13-1-2

Power Supply (14.00)

Battery System (14.01) ........................................ 14-1-2

Alternator and Regulator System (14.02) ............. 14-2-1

I-I-IV Workshop Manual Issue 2 February 2005

Vehicle Entertainment (15.00)

Audio System ..................................................... 15-1-1

Vacuum Distribution (16.00)

Body Vacuum System (16.01) ............................. 16-1-1

Lighting (17.00)

Front Lights (17.01) ............................................ 17-1-2

Interior Lighting (17.02) ...................................... 17-2-1

Rear Lights (17.03) ............................................. 17-3-1

Lighting Mechanisms (17.04) .............................. 17-4-1

Electric Distribution/Electronic Control (18.00)

Wiring and Circuit Protection (18.01) ................. 18-1-2

Vehicle Control System (18.08) .......................... 18-2-1

Electronic Features (19.00)

Active Anti-Theft System (19.01) ......................... 19-1-2

Appendix & Glossary

Diagnostic Ports................................................... 20-1-2

Fluids/Capacities.................................................. 20-1-3

Abbreviations ...................................................... 20-1-3

Terms .................................................................. 20-1-3

Special Tools - Pictorial Index .............................. 20-1-4

Specialist Tool Operation .................................... 20-1-8

Maintenance Schedules ..................................... 20-1-11

Torque Figures .................................................. 20-1-14

Torque Conversion Tables ................................. 20-1-31

Issue 2 February 2005 Workshop Manual I-I-V

Introduction

Contents

Welcome................................................................ I-I-VI

Chapters ................................................................ I-VI

Chapter Navigation ................................................ I-VI

Numbering ............................................................ I-VI

Special Tools.......................................................... I-VI

Location References............................................... I-VI

Warnings, Cautions and Notes .............................. I-VI

Repairs and Replacements .................................... I-VI

Safety Precautions ................................................ I-I-VII

Battery Disconnection .......................................... I-VII

Air Conditioning (A/C) System.............................. I-VII

Chemical Handling and Storage ........................... I-VII

Electrical Equipment ............................................. I-VII

Exhaust Fumes ..................................................... I-VIII

Fire Precautions ................................................... I-VIII

Tools and Equipment........................................... I-VIII

Used Engine Oil ................................................... I-VIII

Health Protection Precautions ............................. I-VIII

Environmental Protection .................................... I-VIII

Lifting and Jacking ................................................. I-I-IX

Safety ..................................................................... I-IX

Jacking Points ........................................................ I-IX

Stands ................................................................. I-IX

Workshop Hoist..................................................... I-IX

Vehicle Recovery .................................................... I-I-X

General .................................................................... I-X

Transporting ............................................................ I-X

Suspended Towing ................................................. I-X

Front Suspended Tow........................................... I-X

Rear Suspended Tow ............................................ I-X

Towing an Automatic Vehicle ................................. I-X

Towing Regulations ................................................. I-X

Towing by Another Vehicle ..................................... I-X

Push-start ................................................................ I-X

Identification Numbers ......................................... I-I-XI

Vehicle Identification Number (VIN) ...................... I-XI

VIN Number Location............................................ I-XI

Engine Number..................................................... I-XII

Gearbox Number.................................................. I-XII

Automatic Gearbox............................................... I-XII

Manual Gearbox ................................................... I-XII

Welcome

Introduction

I-I-VI Workshop Manual Issue 2 February 2005

Introduction

Welcome

This Workshop Manual is part of a suite of technical manuals

provided for DB9. Other technical manuals include:

• Parts manual

• OBDII Diagnostic manual

• Man hour schedules

Chapters

The DB9 suite of manuals incorporate a new chapter

structure.

Each chapter in this workshop manual is associated with a 4

digit number, i.e. Transmission (07.00). Each chapter is then

further broken into sections, i.e. Automatic Transmission

(07.01).

Chapter Navigation

Example 1:

Previous workshop manuals would have Steering and

Suspension together in one chapter. The new structure now

places Steering and Suspension into their own chapters.

Road wheels are also now included in Suspension.

Example 2:

Fuel, emissions and exhaust is now in three different

chapters. Fuel has its own chapter and includes all fuel

aspects up to the fuel rails (Fuel rails and fuel injection now

come under Engine System). Exhaust, not including

manifolds, has its own chapter and Emissions now come

under the Engine system.

When required references are made out to other chapters.

Numbering

Chapters and sections within chapters are numbered using

the system detailed above. All technical manuals for this

vehicle use the same numbering system. When carrying out

a procedure, the relevant parts illustration and spare parts list

can be found using the same numbering system.

To avoid excessive repetition, each procedure is fully

detailed once in its appropriate chapter. In any other

location where this procedure is required, it is referenced by

its title and chapter / page number.

Special Tools

Where special service tools are required to perform an

operation, the tool number is recorded at the point of use

within the procedure. Where the operation of a special

service tool is complicated or not obvious, refer to the

Appendix and Glossary for detailed operation procedures. A

pictorial list of special service tools available for this vehicle

can also be found in the Appendix and Glossary.

Location References

References to left, right, front or

rear of the vehicle or of a

component are referenced from

sitting in the drivers seat facing

forward. Any such references to

assemblies removed from the

vehicle are to the normal

orientation of the assembly when

installed in the vehicle.

Warnings, Cautions

and Notes

The following Warnings, Cautions

and Notes are used within this workshop manual to call your

attention to specific types of information.

Warnings

Cautions

Notes

Repairs and Replacements

Where replacement parts are required, it is essential that

only genuine Aston Martin parts are used. Your attention is

drawn to the following points concerning repairs and the

fitting of genuine Aston Martin parts and accessories:

• Safety features embodied in the vehicle may be impaired

if other than genuine Aston Martin parts are installed. In

certain territories, legislation prohibits the installation of

parts which are not produced to the manufacturers

specification

• Adhere to torque wrench settings given in this manual

• Locking devices, where specified, must be installed. If the

efficiency of a locking device is impaired during removal,

it must be renewed

• The vehicle warranty may be invalidated by the

installation of other than genuine Aston Martin parts

03. 02.

System, i.e. Engine system

Subsystem, i.e. Engine lubrication system

Warning

Identifies procedures which must be followed precisely

to help avoid the risk of personal injury.

Caution

Provided to indicate procedures which must be followed

precisely to reduce the possibility of damage to the

vehicle.

Provided to indicate procedures which will help to avoid

difficulties in the operation of the vehicle.

Safety Precautions

Introduction

Issue 2 February 2005 Workshop Manual I-I-VII

Safety Precautions

All service workshops are a source of potential danger and

repair work should only be performed by technically trained

staff following procedures detailed in this manual. A safety

conscious approach to the performance of all service

procedures must be observed at all times. Statutory

requirements governing all aspects of health and safety at

work including directives for the proper use of materials and

equipment must be implemented.

The following headings highlight particular safety

precautions which should be observed (The list is not

intended to be exhaustive).

Battery Disconnection

Where a procedure requires the vehicle battery to be

physically disconnected (disconnect the vehicle battery

earth (Negative) lead), the following items will have to be

reset or re-learnt on connection:

• Seats memory

• Radio pre-sets

• DTCs will be lost

Air Conditioning (A/C) System

Do not break into the A/C refrigeration system until the

refrigerant has been evacuated using the procedure detailed

in this manual. Do not disconnect any A/C refrigerant system

pipes unless trained and instructed to do so. The refrigerant

used can cause blindness if allowed to contact your eyes.

Chemical Handling and Storage

Chemicals used in the servicing of motor vehicles include

acids, adhesives, antifreeze, brake fluids, coolants, grease,

oil, paint, resin and solvents. Exposure to certain chemicals

through direct contact or inhalation can be fatal.

Potential hazards may also be present through the incorrect

use, storage and handling of chemicals causing a fire risk.

Electrical Equipment

Warning

Strictly adhere to handling and safety information found

on containers and labels.

Warning

Do not store chemicals in unlabelled or incorrectly

labelled containers.

Warning

Containers used for storing chemicals should not be left

open; there is a risk of spilling, or evaporation of fumes

which may be inflammable or toxic.

Warning

Do not mix chemicals unless instructed to do so,

following manufacturers guidelines.

Warning

Do not inhale chemical materials to determine identity,

they may be toxic.

Warning

Do not use petrol, kerosene, diesel fuel, gas oil,

thinners or solvents for washing skin.

Warning

Chemicals based on solvents such as paint should not

be sprayed in a confined space; work areas used for

such operations should be well ventilated and fume

extraction equipment should be utilised.

Warning

Containers whose capacity is over 25 litres (5 gallons)

require a bund wall in order to contain spillages.

Warning

Avoid splashing the skin, eyes and clothing.

Warning

Ensure that adequate ventilation is provided when

volatile de-greasing agents are being used.

Warning

Clean chemicals from the skin and clothing as soon as

possible after soiling.

Warning

Wear protective clothing such as goggles, non porous

gloves and apron when handling battery acid and other

corrosive and toxic substances.

Warning

Do not smoke in the vicinity of volatile de-greasing

agents.

Warning

Fume extraction equipment must be in operation when

solvents are used e.g. trichloroethane, white spirit,

SBP3, methylene chloride, perchloroethylene.

Warning

Ensure that electrical equipment is in safe working

order before use.

Warning

Inspect power leads of all mains electrical equipment

for damage and security, and check that it is properly

earthed.

Warning

Ensure that electrical equipment is protected by a fuse

of the correct current rating.

Warning

Disconnect the battery before commencing repair

operations to the electrical system, fuel system and

engine or when working beneath the vehicle.

Safety Precautions

Introduction

I-I-VIII Workshop Manual Issue 2 February 2005

Exhaust Fumes

Engines must only be run where there is fume extraction

equipment in operation or where there is adequate

ventilation.

Fire Precautions

Tools and Equipment

Use the recommended service tool where instructed to do

so.

Used Engine Oil

Adequate means of skin protection and washing facilities

should be provided.

Health Protection Precautions

• Wear protective clothing, including impervious gloves

where practicable.

• Do not put oily rags in pockets.

• Avoid contaminating clothes with oil.

• Overalls must be cleaned regularly. Discard un-washable

clothes and oil impregnated footwear.

• First aid treatment should be obtained immediately for

open cuts or wounds.

• Use barrier creams, apply before each work period to help

the removal of oil from the skin.

• Wash with soap and water to ensure all oil is removed.

Preparations containing lanolin replace the natural skin

oils which have been removed.

• Do not use petrol, kerosene, diesel fuel, gas oil, thinners

or solvents for washing skin.

• If skin disorders develop, obtain medical advice.

• Where practicable, degrease components prior to

handling.

• Where there is a risk of eye contact, eye protection should

be worn. In addition, an eye wash facility should be

provided.

Environmental Protection

It is illegal to pour used oil on the ground, down sewers or

drains, or into water courses. The burning of used engine oil

in small space heaters or boilers is not recommended unless

emission control equipment is installed; in case of doubt,

contact the Local Authority for advice on disposal facilities.

Warning

Do not breathe exhaust fumes. Exhaust fumes contain

carbon monoxide. Carbon monoxide is a dangerous

gas, which is colourless and odourless and can cause

unconsciousness and may be fatal. Never start or leave

the engine running in an enclosed, unventilated area.

Warning

Avoid skin contact with all exhaust system and engine

components, engine fluids and escaping steam. They

may be hot and will burn you.

Warning

Ensure that a suitable form of fire extinguisher is

conveniently located near the work area.

Warning

Keep oils, solvents and combustible materials away

from naked flames and other sources of ignition.

Warning

Ensure that NO SMOKING signs are posted around

areas where combustible materials and vapour may be

present and ensure that the warnings are strictly

observed.

Warning

Ensure that dry sand is available to soak up any spillage

of fuel or other flammable solutions.

Warning

Fume extraction equipment must be available and in

full working order to remove combustible and toxic

vapours.

Warning

All personnel should be aware of the fire drill

procedures and precautions.

Warning

Do not leave tools, equipment, spilt oil, etc. around or

on the work area.

Warning

Ensure that tools and equipment used are in good

condition; do not use damaged or defective tools or

equipment.

Caution

Do not apply heat in an attempt to free stiff nuts or

fittings; as well as causing damage to protective

coatings, the stray heat may damage electronic

equipment, harnesses and brake lines.

Warning

Prolonged and repeated contact with used engine oils

can cause serious skin disorders, including dermatitis

and cancer. Avoid excessive contact, wash thoroughly

after contact.

In addition, observe all laws regarding the disposal of

waste oil and toxic fluids.

Warning

Prolonged and repeated contact with used engine oils

can cause serious skin disorders, including dermatitis

and cancer. Avoid excessive contact, wash thoroughly

after contact.

Lifting and Jacking

Introduction

Issue 2 February 2005 Workshop Manual I-I-IX

Lifting and Jacking

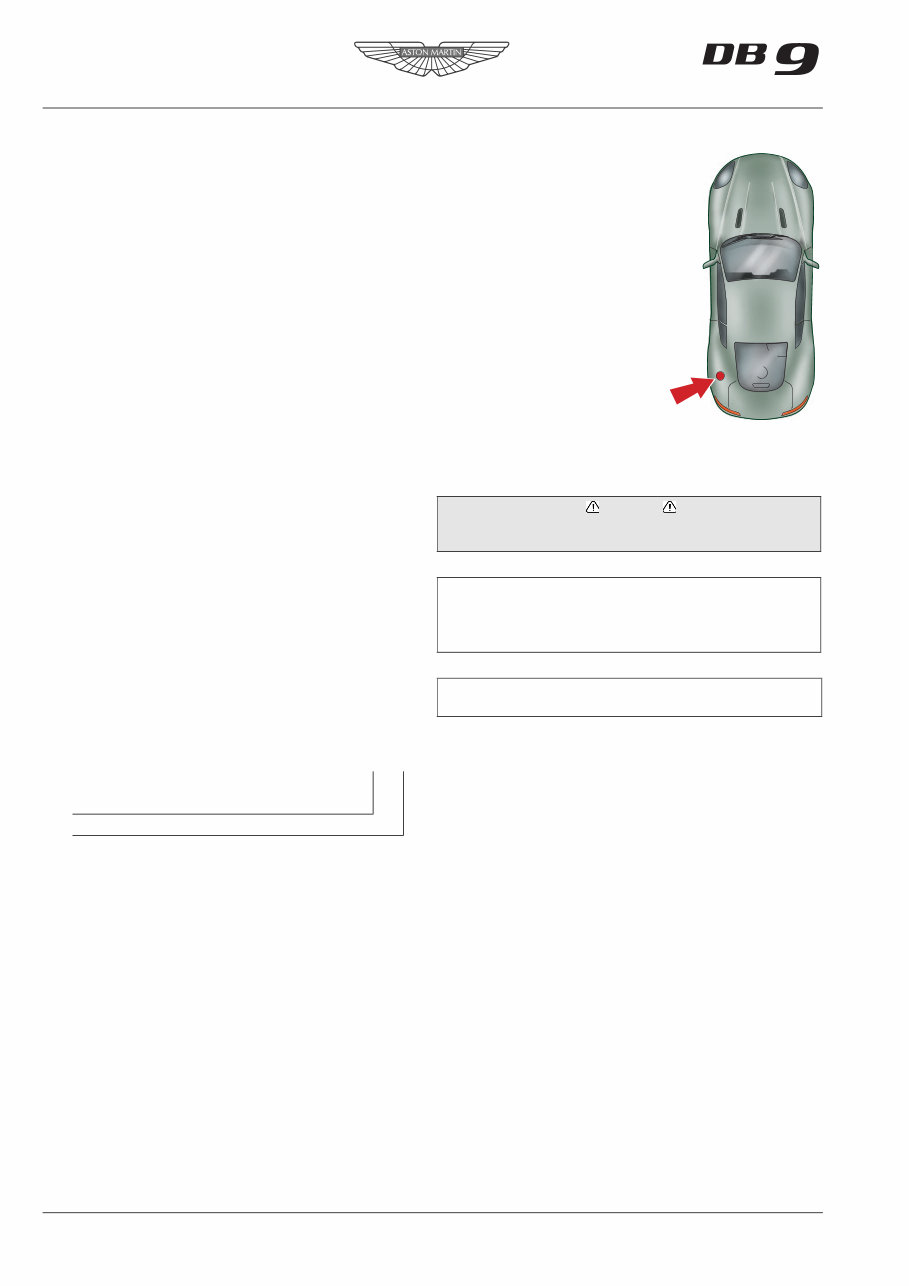

Safety

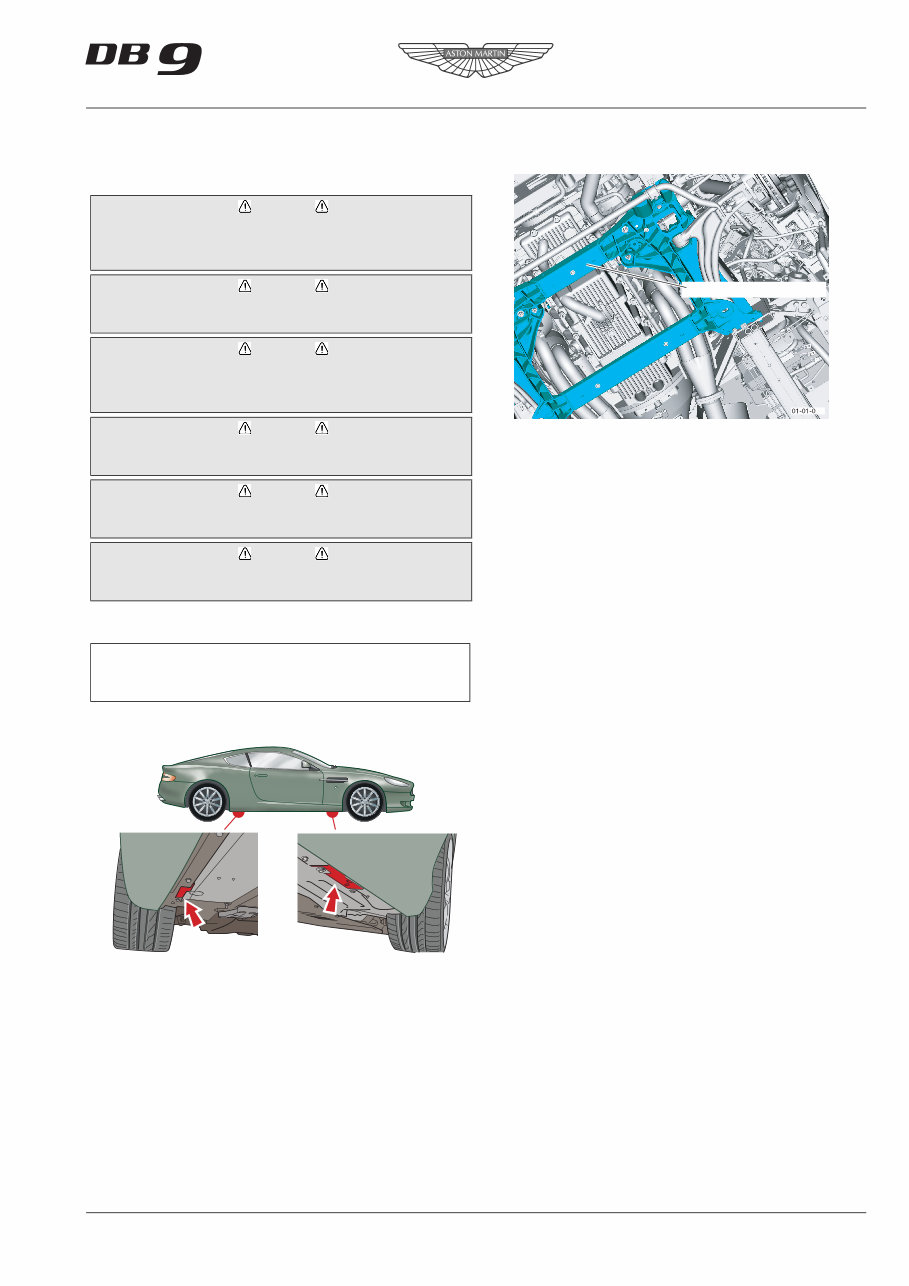

Jacking Points

This vehicle jacking points are at positions shown.

The vehicle may also be jacked with the jack placed on the

front subframe, front crossmember.

Always use a jack with a rubber contact pad. Avoid the use

of jacks with sharp contact pads which could damage the

vehicle floor pan Always chock the opposite road wheels as

well as applying the handbrake when using a hydraulic jack.

To prevent body distortion, avoid single point or one side

jacking with the tunnel shear panel removed.

To avoid any danger of bodywork damage when using a

hydraulic jack, the vehicle must only be lifted at the jacking

points.

Stands

When carrying out work (other than a wheel change) which

requires a wheel to be raised, a stand must be used, located

at the jacking point, to provide a secure support for the

vehicle.

Workshop Hoist

Use of a workshop hoist is recommended for all operations

where vehicles must be raised. Follow manufacturers

instructions. If using an adjustable arm type, ensure lifting

pads are correctly positioned at the four jacking points

before lifting.

Warning

Recommended procedures for lifting, jacking and

towing must be strictly observed to ensure personal

safety.

Warning

Always use a vehicle hoist, ramp or pit for working

beneath the vehicle in preference to jacking.

Warning

Never rely on a jack to support a car independently,

use axle stands or blocks carefully placed at jacking

points to provide rigid support.

Warning

When working beneath a vehicle, chock wheels as well

as applying handbrake.

Warning

Ensure vehicle is standing on firm, level ground before

jacking or lifting.

Warning

Check lifting equipment has adequate capacity for load

being lifted and is in full working order.

Caution

Do not jack the vehicle on the lower suspension arms

(front or rear).

Front Crossmember

Vehicle Recovery

Introduction

I-I-X Workshop Manual Issue 2 February 2005

Vehicle Recovery

General

The preferred method of vehicle recovery is by a flat bed,

covered, transporter.

The towing eye is primarily for emergency use when towing

for short distances, e.g. removing vehicle if it is causing an

obstruction or winching vehicle onto a flatbed transporter.

If moving this vehicle in such a situation, install the towing

eye to the bracket, which is located behind the registration

number plate.

Transporting

If vehicle is to be transported on a trailer or flat bed

transporter the handbrake must be applied and the road

wheels must be chocked.

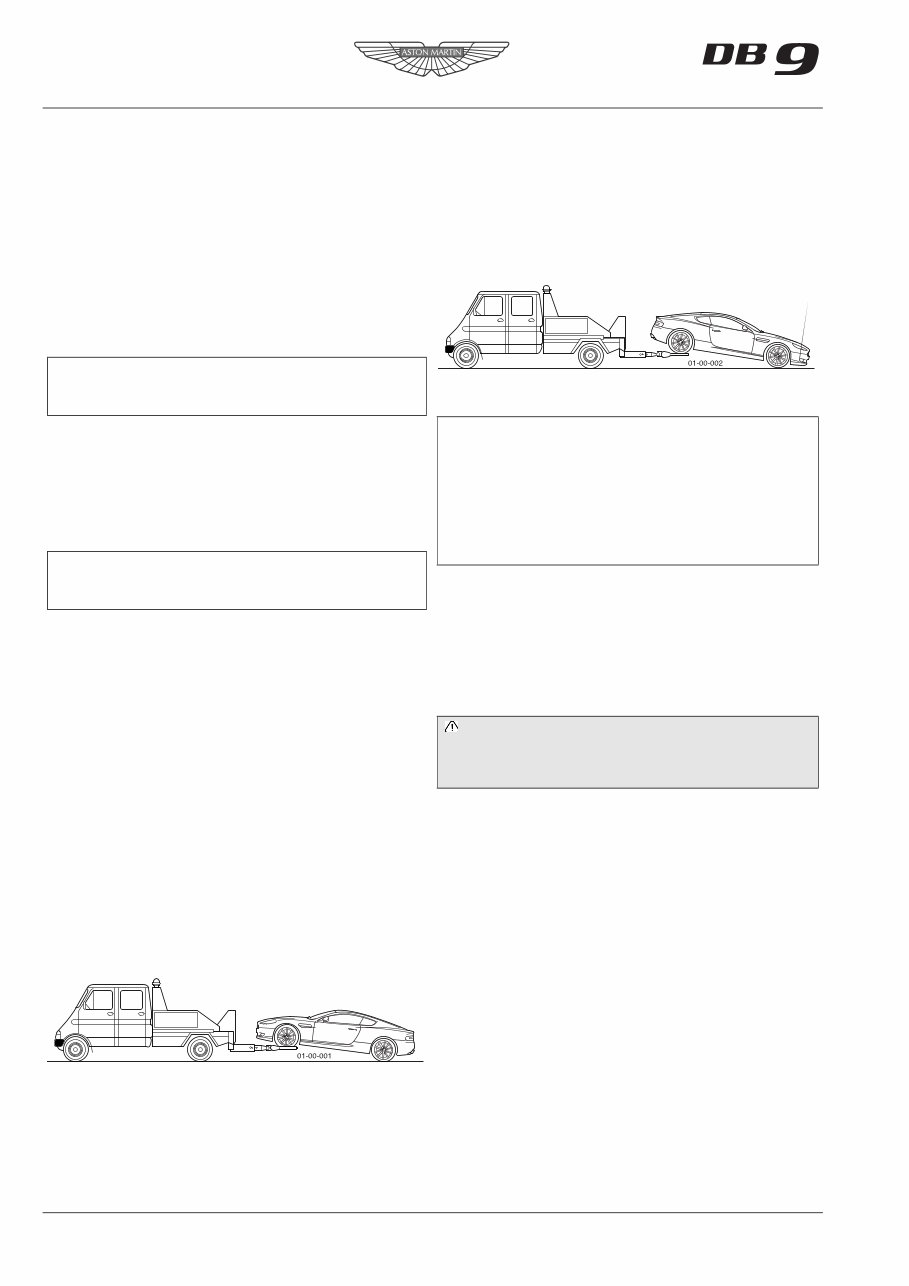

Suspended Towing

Take care when using 'spectacle frame' type towing

equipment that the towing device is well clear of front or

rear apron. Body damage may occur if vehicle passes over

uneven road surfaces.

Ensure the recovery team follow the following towing

instructions:

Front Suspended Tow

Automatic Transmission Only

1. Switch the ignition ‘On’.

2. Pull back twice on both paddles, simultaneously, to force

the gearbox into ‘Neutral’.

Switch the ignition ‘Off’ within three seconds.

Manual and Automatic Transmissions

3. Remove the ignition key from the ignition.

4. Raise the vehicle using a 'spectacle frame' type lifting

device with a cradle positioned under each front wheel as

indicated below.

Rear Suspended Tow

1. Set the steering in the ‘straight ahead’ position.

2. Remove the ignition key from the ignition. Ensure the

steering is locked in the straight ahead position.

3. Raise the vehicle using a 'spectacle frame' style lifting

device where a cradle is positioned under each rear

wheel as indicated below.

Towing an Automatic Vehicle

Towing Regulations

In certain countries the registration number plate of the

towing vehicle and an ‘ON TOW’ sign or warning triangle

must be displayed in a prominent position at the rear of

vehicle being towed.

Towing by Another Vehicle

This vehicle may be towed short distances by another

vehicle provided that a speed of 48 km/h (30 mph) is not

exceeded. Ensure that the towed vehicle gear selection is in

‘Neutral’ (manual) or position ‘N’ (automatic), the ignition

key turned to position ‘II’ (to release steering lock and to

render the horn, indicators and brake lights operational).

Push-start

Vehicle’s installed with automatic transmissions cannot be

started by push-starting.

Caution

Take care to protect the paint work when installing the

towing eye. Ensure the towing eye is tight.

Caution

Do not tow with ‘sling’ type equipment, damage to

bodywork will result.

Caution

This vehicle installed with an automatic transmission

can be towed on its driven wheels at not more than 70

km/h road speed and for a maximum

distance of 500 km.

The selector lever must be in Neutral (N).

If the above speed and distance limits are exceeded, the

automatic transmission will be severely damaged.

Ward the brake booster will become ineffective after

a few applications of the brakes. Be prepared for

relatively heavy steering and the need for greatly

increased brake pedal pressure.

You're Reading a Preview

What's Included?

Fast Download Speeds

Online & Offline Access

Access PDF Contents & Bookmarks

Full Search Facility

Print one or all pages of your manual

$48.99

Viewed 52 Times Today

Loading...

Secure transaction

What's Included?

Fast Download Speeds

Online & Offline Access

Access PDF Contents & Bookmarks

Full Search Facility

Print one or all pages of your manual

$48.99

This workshop manual is an essential resource for owners of the Aston Martin DB9. From routine maintenance to complex engine repairs, this manual has the potential to save you a significant amount of money. It is the official maintenance and service workshop manual used by technicians and is suitable for both professional mechanics and DIY enthusiasts.

- Engine

- Lubrication

- Cooling

- Ignition

- Throttle

- Fuel System

- Clutch

- Exhaust

- Suspension

- Steering

- Transmission - Automatic & Manual

- Braking System

- Hand Brake

- Driveline

- Body

- Exterior Trim

- Interior Trim

- Seating

- Mirrors

- Instrument Panel

- Washer & Wiper System

- Frame & Mounting

- Wheels & Tyres

- Climate Control

- Air Conditioning & Heat

- Power Supply

- Gauges

It offers the best value and is the most comprehensive manual available for the Aston Martin DB9.