White 2-135 & 2-155 Tractors Complete Workshop Service Repair Manual

What's Included?

Fast Download Speeds

Online & Offline Access

Access PDF Contents & Bookmarks

Full Search Facility

Print one or all pages of your manual

SHOP MANUAL

MODELS

2-135 2-155

INDEX (BY STARTING PARAGRAPH)

BRAKES

Bleeding

Adjustment

Brake valve

Overhaul

CLUTCH

Engine clutch adjustment.

Engine clutch R&R

Engine clutch overhaul ...

COOLING SYSTEM

Water pump

Radiator

Thermostat

DIESEL SYSTEM

Fuel filler

Water separator

Fuel system bleeding ....

Governor adjust

Nozzles, testing

Nozzles, R&R

Nozzles, overhaul

Injection pump, R&R ....

Injection pump, timing ...

Trouble shooting

Turbocharger

DIFFERENTIAL

Overhaul

Remove and reinstall ....

ELECTRICAL

Alternator

Regulator

Starting motor —

ENGINE

Assembly, R&R

Cam followers

Camshaft

Connecting rod bearings .

Crankshaft and bearings .

Cylinder head

Flywheel

Front oil seal

Main bearings

Oil cooler

Oil pump

Pistons

Piston pins

Piston and rod removal..

Piston rings

Rear oil seal

Relief valve, oil pressure

Model

2-135

116

117

119

120

73

74

75

68

67

69

48

49

50

62

53

52

58

61

60

47

66A

110

108

70

70

72

18

26

31

37

38

20

41

39

38

45

42

33

36

32

33

40

44

Model

2-155

116

117

119

120

73

74

75

68

67

69

48

49

50

62

53

52

58

61

60

47

66A

no

108

70

70

72

18

26

31

37

38

20

41

39

38

45

42

33

36

32

33

40

44

INDEX CONT.

Model

2-135

ENGINE CONT.

Rocker arms 27

Tappets 26

Timing gear cover 29

Timing gears 30

Valve guides 21

Valve springs 25

Valve timing 28

Valves and valve seats 21

FINAL DRIVE

Rear axle 112

Axle carrier 112

Planetary 112

Differential 108

Wheel axle shaft 112

FRONT SYSTEM

Front axle member 1

Front carrier 3

Pivot pin 1

Spindle (knuckle) 2

Tie rods & toe-in 4

HYDRAUL SHIFT 79

LIFT SYSTEM, HYDRAULIC

Draft control spring, adjust 189

Draft input shaft 181

Drain and refill 150

Hitch control lever 180

Hydraulic housing 177

Lubrication and maintenance 149

Cylinder and piston 185

Manifold 184

Oil cooler 191

Oil filter 153

Filter head 154

Pump 171

Pressure relief valve 164

Quick check 137

Remote cylinders 200

Remote valves 192

Rockshaft 178

Servo valve 182

System adjustments 159

Testing 139

Trouble shooting 126

POWER STEERING 6

POWER TAKE-OFF

Control valve 122

Clutch overhaul 124

PTO unit. R&R 123

TRANSMISSION

Bevel pinion shaft 104

Countershaft 102

Input shaft lOO

Lubrication system 91

Park lock latch 107

Reverse idler 106

Shifter rails & forks 99

Top cover 98

Model

2-155

27

26

29

30

21

25

28

21

112

112

112

108

112

1

3

1

2

4

79

189

181

150

180

177

149

185

184

191

153

154

171

164

137

200

192

178

182

159

139

126

6

122

124

123

104

102

100

91

107

106

99

98

CONDENSED SERVICE DATA

Model

2-135

Model

2-155

Own

6

478

Yes

Dry

7

Neg.

4.56x4.00

-1-5-3-6-24-

Own

6

478

Yes

Dry

7

Neg.

GENERAL

Engine Make

Number of Cylinders

Bore & Stroke-Inches

Displacement-Cu. In.

Cylinders Sleeved

Cylinder Sleeves—Type

Main Bearings, Number of

Battery Terminal Grounded

TUNE-UP

Firing Order

Valve Tappet Gap-Inlet (Cold) 0.010 0.010

Valve Tappet Gap-Exhaust (Cold) 0.025 0.025

Compression At Cranking Speed (PSI) .. 300-350 Nominal

Max. Allowable Variation 25 psi

Timing Mark Location Vib. dampener

Timing (Static) 20° BTDC

Engine Low Idle RPM 775-825

Engine High Idle RPM 2370-2420

Engine Rated RPM 2200

SIZES—CAPACITIES—CLEARANCES

(Sizes and Clearances are in Inches)

Crankshaft Journal Diameter 3.6210-3.6220-

Crankpin Diameter 2.9970-2.9980"

Camshaft Journal Diameter

No. 1 (Front) 2.4285-2.4295

No 2 2.3660-2.3670

No 3 2.3035-2.3045

No! 4 1.9910-1.9920

Main Bearings, Diameter Clearance 0.0018-0.0048

Rod Bearing, Diameter Clearance 0.0014-0.0044

Cooling System—Quarts *31

Crankcase Oil—Quarts (Including

Filter) 22

Transmission, Final Drive and

Hydraulic System—Gallons 23

Hydraul-Shift—Quarts 37?

•Including cab heater.

775-825

2370-2420

2200

*31

22

23

3V2

FRONT AXLE

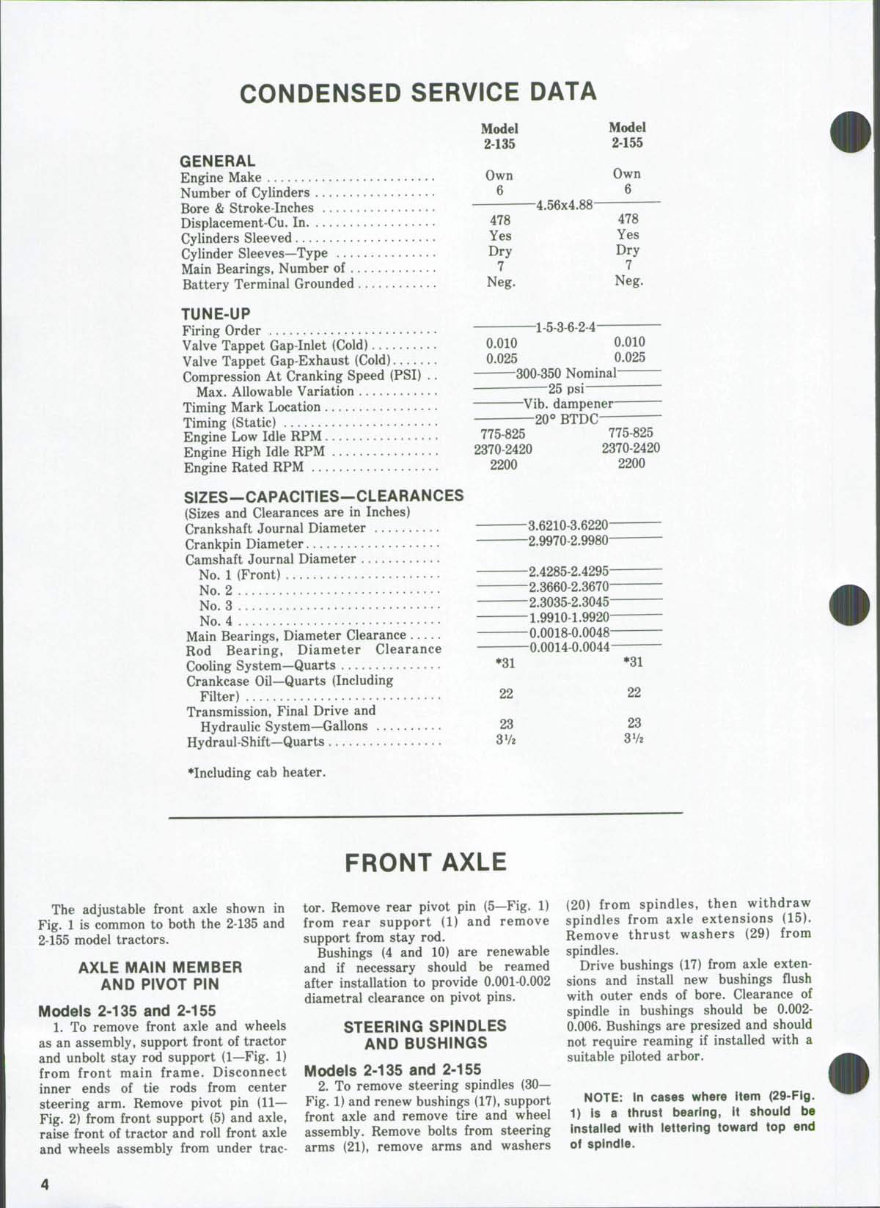

The adjustable front axle shown in

Fig. 1 is common to both the 2-135 and

2-155 model tractors.

AXLE MAIN MEMBER

AND PIVOT PIN

Models 2-135 and 2-155

1. To remove front axle and wheels

as an assembly, support front of tractor

and unbolt stay rod support (1—Fig. 1)

from front main frame. Disconnect

inner ends of tie rods from center

steering arm. Remove pivot pin (11—

Fig. 2) from front support (5) and axle,

raise front of tractor and roll front axle

and wheels assembly from under trac-

tor. Remove rear pivot pin (5—Fig. 1)

from rear support (1) and remove

support from stay rod.

Bushings (4 and 10) are renewable

and if necessary should be reamed

after installation to provide 0.001-0.002

diametral clearance on pivot pins.

STEERING SPINDLES

AND BUSHINGS

Models 2-135 and 2-155

2. To remove steering spindles (30—

Fig. 1) and renew bushings (17), support

front axle and remove tire and wheel

assembly. Remove bolts from steering

arms (21), remove arms and washers

(20) from spindles, then withdraw

spindles from axle extensions (15).

Remove thrust washers (29) from

spindles.

Drive bushings (17) from axle exten-

sions and install new bushings flush

witb outer ends of bore. Clearance of

spindle in bushings should be 0.002-

0.006. Bushings are presized and should

not require reaming if installed with a

suitable piloted arbor.

NOTE: In cases where item (29-Fig.

1) is a thrust bearing, it should be

installed with lettering toward top end

of spindle.

2-135, 2-155

FRONT AXLE CARRIER

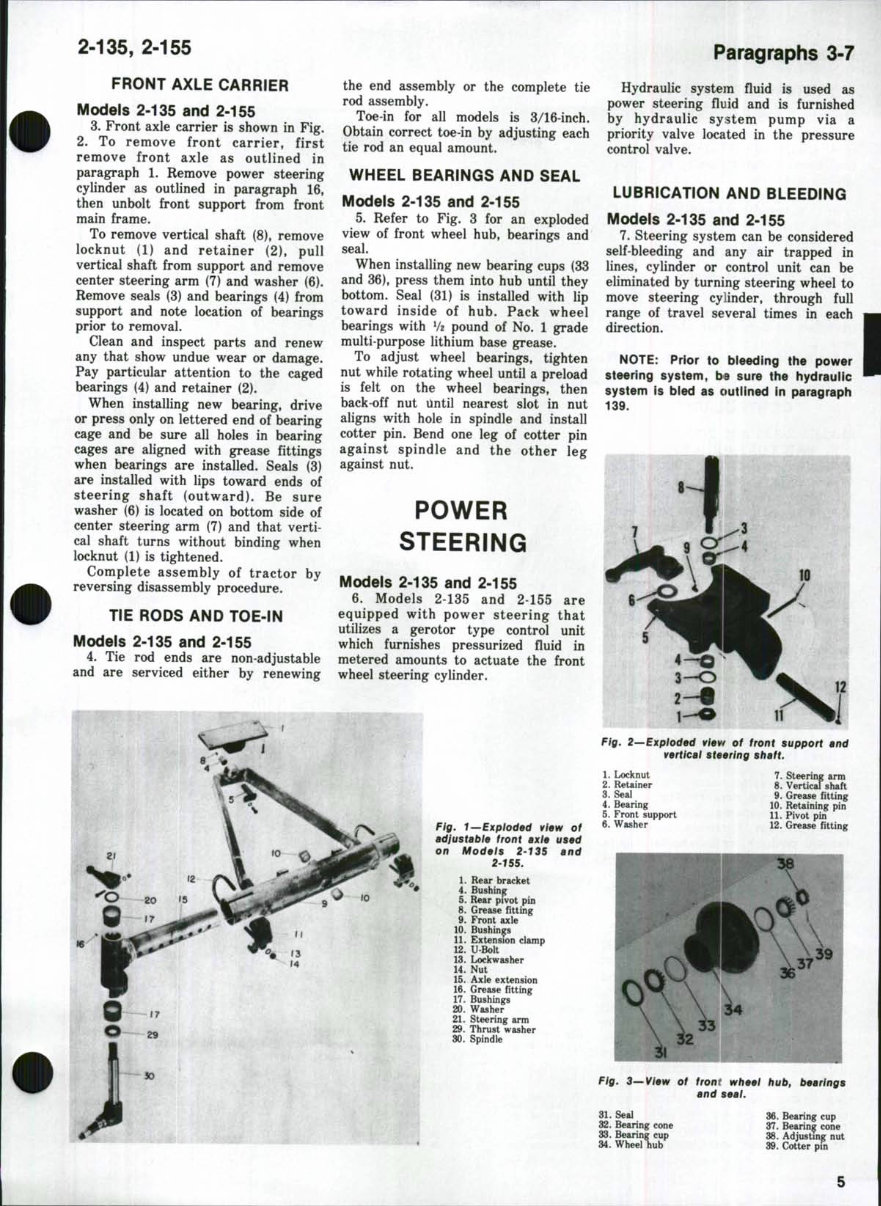

Models 2-135 and 2-155

3. Front axle carrier is shown in Fig.

2. To remove front carrier, first

remove front axle as outlined in

paragraph 1, Remove power steering

cylinder as outlined in paragraph 16,

then unbolt front support from front

main frame.

To remove vertical shaft (8), remove

locknut (1) and retainer (2), pull

vertical shaft from support and remove

center steering arm (7) and washer (6).

Remove seals (3) and bearings (4) from

support and note location of bearings

prior to removal

Clean and inspect parts and renew

any that show undue wear or damage.

Pay particular attention to the caged

bearings (4) and retainer (2).

When installing new bearing, drive

or press only on lettered end of bearing

cage and be sure all holes in bearing

cages are aligned with grease fittings

when bearings are installed. Seals (3)

are installed with lips toward ends of

steering shaft (outward). Be sure

washer (6) is located on bottom side of

center steering arm (7) and that verti-

cal shaft turns without binding when

locknut (1) is tightened.

Complete assembly of tractor by

reversing disassembly procedure.

TIE RODS AND TOE-IN

Models 2-135 and 2-155

4. Tie rod ends are non-adjustable

and are serviced either by renewing

the end assembly or the complete tie

rod assembly.

Toe-in for all models is 3/16-inch.

Obtain correct toe-in by adjusting each

tie rod an equal amount.

WHEEL BEARINGS AND SEAL

Models 2-135 and 2-155

5. Refer to Fig. 3 for an exploded

view of front wheel hub, bearings and

seal.

When installing new bearing cups (33

and 36), press them into hub until they

bottom. Seal (31) is installed with lip

toward inside of hub. Pack wheel

bearings with V2 pound of No. 1 grade

multi-purpose lithium base grease.

To adjust wheel bearings, tighten

nut while rotating wheel until a preload

is felt on the wheel bearings, then

back-off nut Until nearest slot in nut

aligns with hole in spindle and install

cotter pin. Bend one leg of cotter pin

against spindle and the other leg

against nut.

POWER

STEERING

Models 2-135 and 2-155

6. Models 2-135 and 2-155 are

equipped with power steering that

utilizes a gerotor type control unit

which furnishes pressurized fluid in

metered amounts to actuate the front

wheel steering cylinder.

Fig, 1—Exploded view of

adjustable front axle used

on Models 2-135 and

2-155.

I. Rear bracket

4. Bushing

5. Rear pivot pin

8. Grease fitting

9. Front axle

10. Bushings

11. Extension clamp

12. U Bolt

13. Lock washer

14. Nut

15. Axle extension

16. Grease fitting

17. Bushings

20. Washer

21. Steering arm

29. Thrust washer

30. Spindle

Paragraphs 3-7

Hydraulic system fluid is used as

power steering fluid and is furnished

by hydraulic system pump via a

priority valve located in the pressure

control valve.

LUBRICATION AND BLEEDING

Models 2-135 and 2-155

7. Steering system can be considered

self-bleeding and any air trapped in

lines, cylinder or control unit can be

eliminated by turning steering wheel to

move steering cylinder, through full

range of travel several times in each

direction.

NOTE: Prior to bleeding the power

steering system, be sure the hydrauiic

system is bied as outlined in paragraph

139.

3-O

Fig, 2—Exploded vievf of front support and

vertical steering shaft.

1. Locknut 7. Steering arm

2. ReUiner 8. Vertical shaft

3. Seal 9. Grease fitting

4. Bearing 10. ReUining pin

5. Front support 11. Pivot pin

6. Washer 12. Grease fitting

Fig, 3—View of front wheel hub, bearings

and seal.

31. Seal

32. Bearing cone

33. Bearing cup

34. Wheel hub

36. Bearing cup

37. Bearing cone

38. Adjusting nut

39. Cotter pin

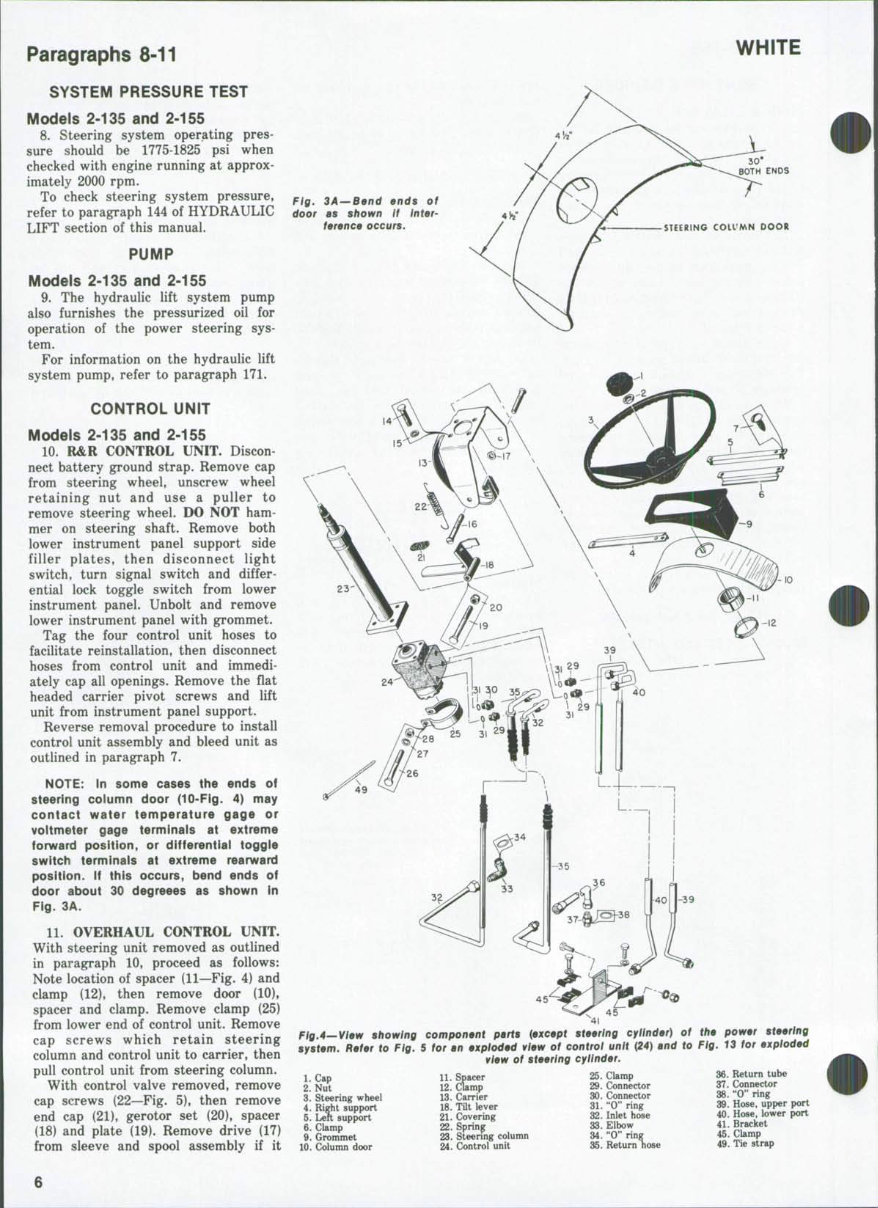

Paragraphs 8-11

WHITE

SYSTEM PRESSURE TEST

Models 2-135 and 2-155

8. Steering system operating pres-

sure should be 1775-1825 psi when

checked with engine running at approx-

imately 2000 rpm.

To check steering system pressure,

refer to paragraph 144 of HYDRAULIC

LIFT section of this manual.

PUMP

Models 2-135 and 2-155

9. The hydraulic lift system pump

also furnishes the pressurized oil for

operation of the power steering sys-

tem.

For information on the hydraulic lift

system pump, refer to paragraph 171.

CONTROL UNIT

Models 2-135 and 2-155

10. R&R CONTROL UNIT. Discon-

nect battery ground strap. Remove cap

from steering wheel, unscrew wheel

retaining nut and use a puller to

remove steering wheel. DO NOT ham-

mer on steering shaft. Remove both

lower instrument panel support side

filler plates, then disconnect light

switch, turn signal switch and differ-

ential lock toggle switch from lower

instrument panel. Unbolt and remove

lower instrument panel with grommet.

Tag the four control unit hoses to

facilitate reinstallation, then disconnect

hoses from control unit and immedi-

ately cap all openings. Remove the flat

headed carrier pivot screws and lift

unit from instrument panel support.

Reverse removal procedure to install

control unit assembly and bleed unit as

outlined in paragraph 7.

NOTE: In some cases the ends of

steering column door (10-Flg. 4) may

contact water temperature gage or

voltmeter gage terminals at extreme

forward position, or differential toggle

switch terminals at extreme rearward

position. If this occurs, bend ends of

door about 30 degreees as shown In

Fig. 3A.

11. OVERHAUL CONTROL UNIT.

With steering unit removed as outlined

in paragraph 10, proceed as follows:

Note location of spacer (11—Fig. 4) and

clamp (12), then remove door (10).

spacer and clamp. Remove clamp (25)

from lower end of control unit. Remove

cap screws which retain steering

column and control unit to carrier, then

pull control unit from steering column.

With control valve removed, remove

cap screws (22—Fig. 5), then remove

end cap (21). gerotor set (20). spacer

(18) and plate (19). Remove drive (17)

from sleeve and spool assembly if it

Fig. 3A — Bend ends of

door as shown if inter-

ference occurs. STEERING COIVMN DOOR

. 45

41

Fig,4—View showing component parts {axcapt stearing cylindar) of

system. Rafar to Fig. 5 for an axplodad view of control unit {24) and to

vlaw of staering cylinder.

1. Cap

2. Nut

3. Steering wheel

4. Right support

5. Lett support

6. Clamp

9. Grommet

10. Column door

11. Spacer

12. Clamp

13. Carrier

18. TUt lever

21. Covering

22. Spring

23. Steering column

24. Control unit

25. Clamp

29. Connector

30. Connector

31. "0" ring

32. Inlet hose

33. Elbow

34. "0" ring

35. Return hose

the power steering

Fig, 13 for exploded

36. Return tube

37. Connector

38. "0" ring

39. Hose, upper port

40. Hose, lower port

41. Bracket

45. Clamp

49. Tie strap

6

2-135, 2-155

2Z

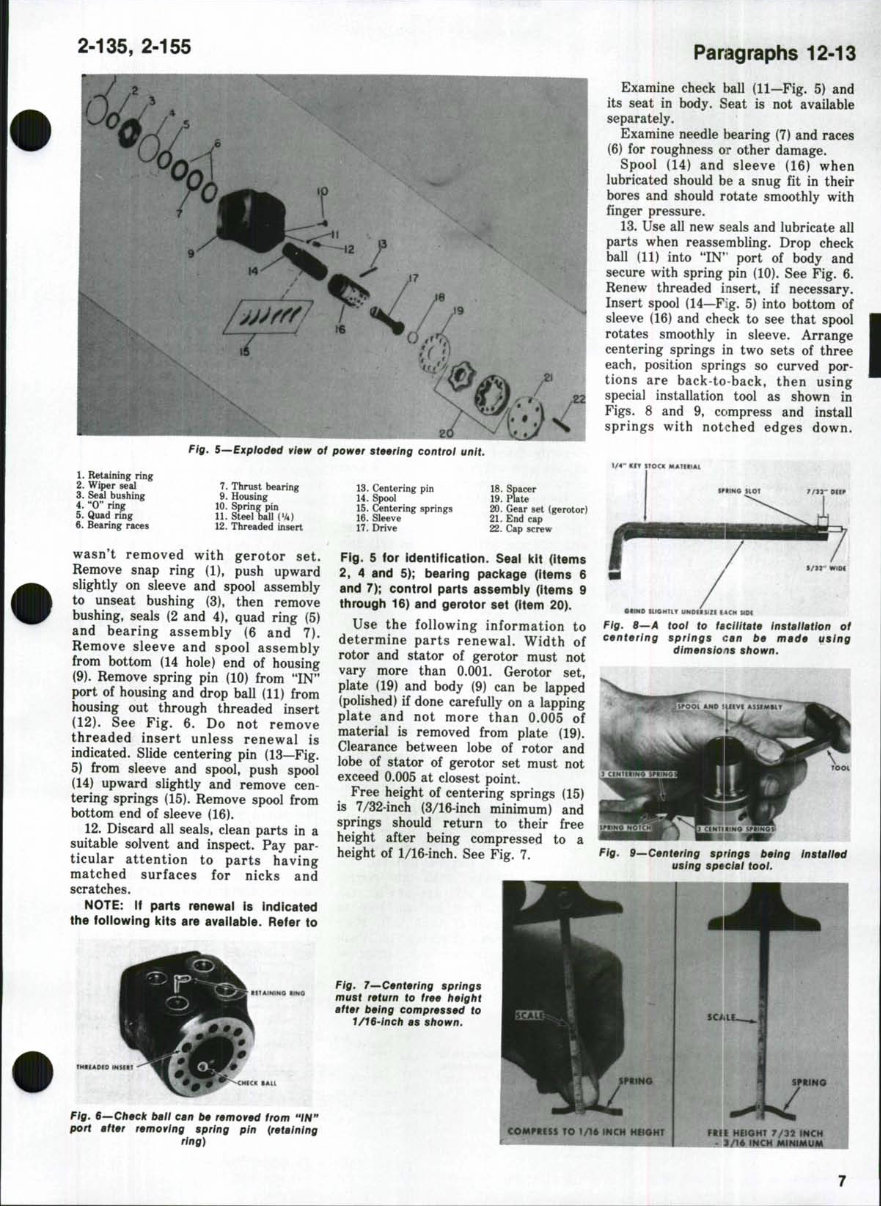

Fig, S—Exploded view of power steering control unit

1. Retaining rin?

2. Wiper seal

3. Seal bushing

4. "0" ring

5. Quad ring

6. Bearing races

7. Thrust bearing

9. Housing

10. Spring pin

11. Steet ball(V4)

12. Threaded insert

13. Centering pin

14. Spool

15. Centeri

16. Sleeve

17. Drive

ng springs

18. Spacer

19. Plate

20. Gear set {gerotor)

21. End cap

22. Cap screw

wasn't removed with gerotor set.

Remove snap ring (1), push upward

slightly on sleeve and spool assembly

to unseat bushing (3), then remove

bushing, seals (2 and 4), quad ring (5)

and bearing assembly (6 and 7).

Remove sleeve and spool assembly

from bottom (14 hole) end of housing

(9). Remove spring pin (10) from "IN"

port of housing and drop ball (11) from

housing out through threaded insert

(12). See Fig. 6. Do not remove

threaded insert unless renewal is

indicated. Slide centering pin (13—Fig.

5) from sleeve and spool, push spool

(14) upward slightly and remove cen-

tering springs (15). Remove spool from

bottom end of sleeve (16).

12. Discard all seals, clean parts in a

suitable solvent and inspect. Pay par-

ticular attention to parts having

matched surfaces for nicks and

scratches.

NOTE: If parts renewal is indicated

the foUowing kits are availabie. Refer to

Fig. 5 for identification. Seal kit (items

2. 4 and 5); bearing package (items 6

and 7); control parts assembly (items 9

through 16) and gerotor set (item 20).

Use the following information to

determine parts renewal. Width of

rotor and stator of gerotor must not

vary more than 0.001. Gerotor set.

plate (19) and body (9) can be lapped

(polished) if done carefully on a lapping

plate and not more than 0.005 of

material is removed from plate (19).

Clearance between lobe of rotor and

lobe of stator of gerotor set must not

exceed 0.005 at closest point.

Free height of centering springs (15)

is 7/32-inch (3/16-inch minimum) and

springs should return to their free

height after being compressed to a

height of 1/16-inch. See Fig. 7.

Paragraphs 12-13

Examine check ball (11—Fig. 5) and

its seat in body. Seat is not available

separately.

Examine needle bearing (7) and races

(6) for roughness OP other damage.

Spool (14) and sleeve (16) when

lubricated should be a snug fit in their

bores and should rotate smoothly with

finger pressure.

13. Use all new seals and lubricate all

parts when reassembling. Drop check

ball (11) into "IN" port of body and

secure with spring pin (10). See Fig. 6.

Renew threaded insert, if necessary.

Insert spool (14—Fig. 5) into bottom of

sleeve (16) and check to see that spool

rotates smoothly in sleeve. Arrange

centering springs in two sets of three

each, position springs so curved por-

tions are back-to-back, then using

special installation tool as shown in

Figs. 8 and 9, compress and install

springs with notched edges down.

1/4" KiY STOCK MAflKtAL

• HMD aiCHTlT UNDf'l»ZI lACH

Fig, 8—A tool to faciiitate installation of

centering springs can be made using

shown.

Fig. 9—Centering springs being

using special tool.

Installed

tlTAININO UMO

Fig. 7—Centering springs

must return to free height

after being compressed to

T/T6-/ncA as shown.

Fig. $^Check ball can be removed from "IH"

port after removing spring pin {retaining

ring)

TO 1/16 INCH HEIGHT

SC/iLE

FREE HEIGHT 7/32 INCH

• 3/16 INCH MtNIMUM

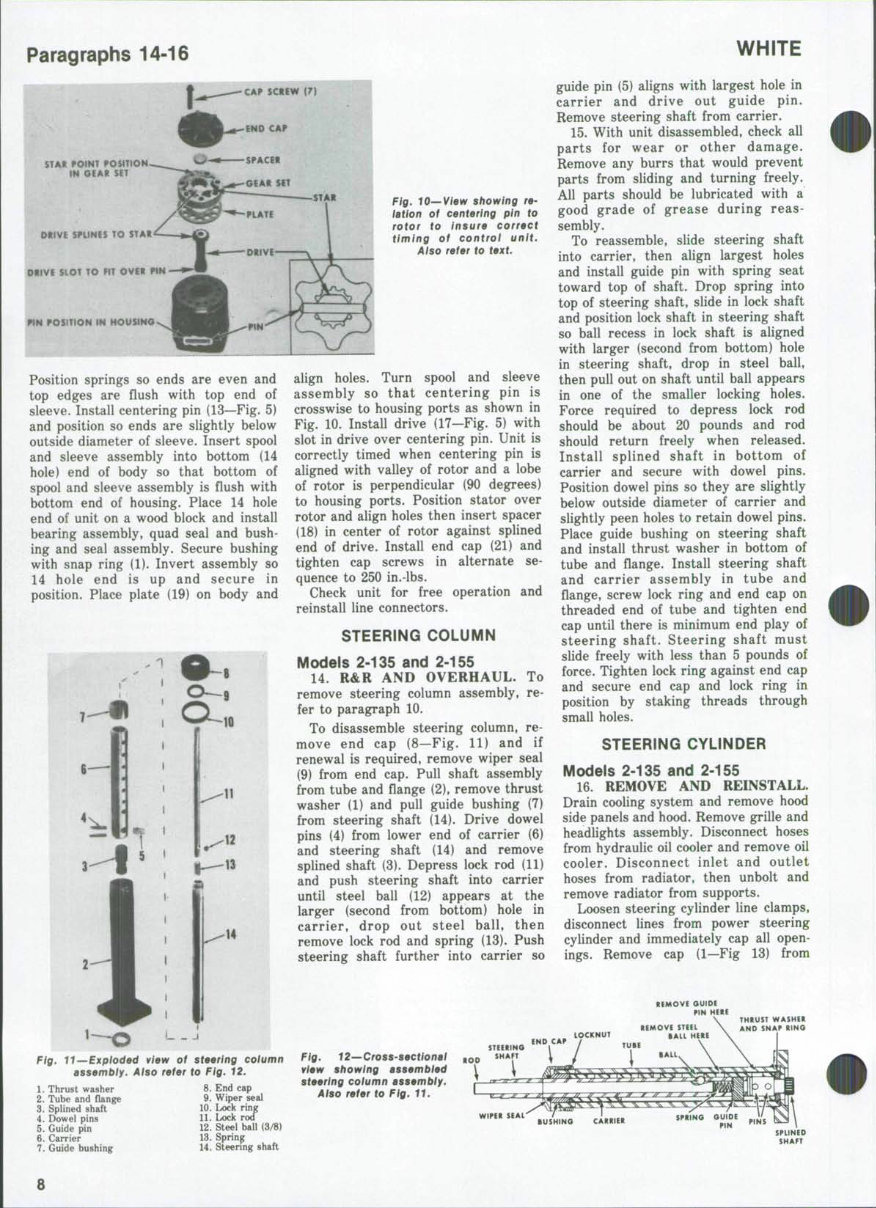

Paragraphs 14-16

f

STAR POINT POSITION

m a f AK SET

DItlVE SniNES TO STAR

&t)VE SLOT TO m OVER P%H

PtN POSITION IN HOUSING

Position springs so ends are even and

top edges are flush with top end of

sleeve. Install centering pin (13—Fig. 5)

and position so ends are slightly below

outside diameter of sleeve. Insert spool

and sleeve assembly into bottom (14

hole) end of body so that bottom of

spool and sleeve assembly is flush with

bottom end of housing. Place 14 hole

end of unit on a wood block and install

bearing assembly, quad seal and bush-

ing and seal assembly. Secure bushing

with snap ring (1). Invert assembly so

14 hole end is up and secure in

position. Place plate (19) on body and

Fig. 10—Viaw showing ra-

lation of centering pin to

rotor to insure corract

timing of controi unit.

Aiso refer to taxt.

-12

align holes. Turn spool and sleeve

assembly so that centering pin is

crosswise to housing ports as shown in

Fig. 10. Install drive (17—Fig. 5) with

slot in drive over centering pin. Unit is

correctly timed when centering pin is

aligned with valley of rotor and a lobe

of rotor is perpendicular (90 degrees)

to housing ports. Position stator over

rotor and align holes then insert spacer

(18) in center of rotor against spiined

end of drive. Install end cap (21) and

tighten cap screws in alternate se-

quence to 250 in.-lbs.

Check unit for free operation and

reinstall line connectors.

STEERING COLUMN

Models 2-135 and 2-155

14. R&R AND OVERHAUL. To

remove steering column assembly, re-

fer to paragraph 10.

To disassemble steering column, re-

move end cap (8—Fig. 11) and if

renewal is required, remove wiper seal

(9) from end cap. Pull shaft assembly

from tube and flange (2), remove thrust

washer (1) and pull guide bushing (7)

from steering shaft (14). Drive dowel

pins (4) from lower end of carrier (6)

and steering shaft (14) and remove

spiined shaft (3). Depress lock rod (11)

and push steering shaft into carrier

until steel ball (12) appears at the

larger (second from bottom) hole in

carrier, drop out steel ball, then

remove lock rod and spring (13). Push

steering shaft further into carrier so

1. Thrust washer

2. Tube and flange

3. Spiined shaft

4. Dowel pins

5. Guide pin

6. Carrier

7. Guide bushing

8. End cap

9. Wiper seal

10. Lock ring

11. Lock ro<r

12. Steel ball (3/8)

13. Spring

14. Steering shaft

WHITE

guide pin (5) aligns with largest hole in

carrier and drive out guide pin.

Remove steering shaft from carrier.

15. With unit disassembled, check all

parts for wear or other damage.

Remove any burrs that would prevent

parts from sliding and turning freely.

All parts should be lubricated with a

good grade of grease during reas-

sembly.

To reassemble, slide steering shaft

into carrier, then align largest holes

and install guide pin with spring seat

toward top of shaft. Drop spring into

top of steering shaft, slide in lock shaft

and position lock shaft in steering shaft

so ball recess in lock shaft is aligned

with larger (second from bottom) hole

in steering shaft, drop in steel ball,

then pull out on shaft until ball appears

in one of the smaller locking holes.

Force required to depress lock rod

should be about 20 pounds and rod

should return freely when released.

Install spiined shaft in bottom of

carrier and secure with dowel pins.

Position dowel pins so they are slightly

below outside diameter of carrier and

slightly peen holes to retain dowel pins.

Place guide bushing on steering shaft

and install thrust washer in bottom of

tube and flange. Install steering shaft

and carrier assembly in tube and

flange, screw lock ring and end cap on

threaded end of tube and tighten end

cap until there is minimum end play of

steering shaft. Steering shaft must

slide freely with less than 5 pounds of

force. Tighten lock ring against end cap

and secure end cap and lock ring in

position by staking threads through

small holes.

STEERING CYLINDER

Models 2-135 and 2-155

16. REMOVE AND REINSTALL.

Drain cooling system and remove hood

side panels and hood. Remove grille and

headlights assembly. Disconnect hoses

from hydraulic oil cooler and remove oil

cooler. Disconnect inlet and outlet

hoses from radiator, then unbolt and

remove radiator from supports.

Loosen steering cylinder line clamps,

disconnect lines from power steering

cylinder and immediately cap all open-

ings. Remove cap (1—Fig 13) from

REMOVE GUIDE

HERE

THRUST WASHER

AND SNAP RING

Fig. 11—Exploded viaw of staaring column

assembly. Also refer to Fig, 12.

Fig. 12—CrosS'S»ctional

viaw showing assambtad

staaring column assambly.

Also rafar to Fig. 11.

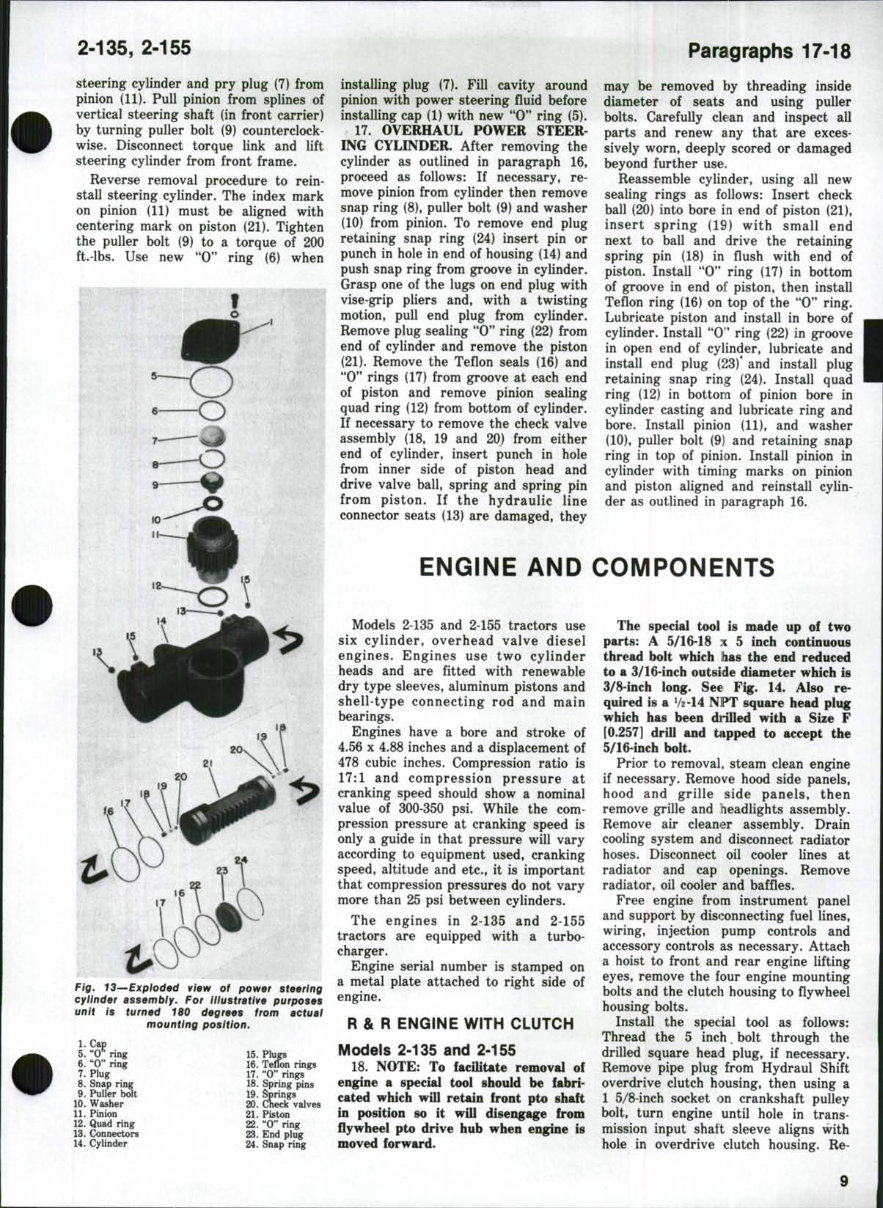

2-135, 2-155

Paragraphs 17-18

steering cylinder and pry plug (7) from

pinion (11). Pull pinion from splines of

vertical steering shaft (in front carrier)

by turning puller bolt (9) counterclock-

wise. Disconnect torque link and lift

steering cylinder from front frame.

Reverse removal procedure to rein-

stall steering cylinder. The index mark

on pinion (11) must be aligned with

centering mark on piston (21). Tighten

the puller bolt (9) to a torque of 200

ft.-lbs. Use new "0" ring (6) when

Fig, 13—Exploded view of power steering

cylinder assembly. For illustrative purposes

unit is turned 180 degrees from actual

mounting position.

1. Cap

5. "O'^ ring

6. "0" ring

7. Plug

8. Snap ring

9. Puller bolt

10. Washer

11. Pinion

12. Quad ring

13. Connectors

14. CyUnder

15. Plugs

16. Teflon rings

17. "0" rings

18. Spring pins

19. Springs

20. Check valves

21. Piston

22. "0" ring

23. End plug

24. Snap ring

installing plug (7). Fill cavity around

pinion with power steering fluid before

installing cap (1) with new "0" ring (5).

17. OVERHAUL POWER STEER-

ING CYLINDER. After removing the

cylinder as outlined in paragraph 16,

proceed as follows: If necessary, re-

move pinion from cylinder then remove

snap ring (8), puller bolt (9) and washer

(10) from pinion. To remove end plug

retaining snap ring (24) insert pin or

punch in hole in end of housing (14) and

push snap ring from groove in cylinder.

Grasp one of the lugs on end plug with

vise-grip pliers and, with a twisting

motion, pull end plug from cylinder.

Remove plug sealing "0" ring (22) from

end of cylinder and remove the piston

(21). Remove the Teflon seals (16) and

"0" rings (17) from groove at each end

of piston and remove pinion sealing

quad ring (12) from bottom of cylinder.

If necessary to remove the check valve

assembly (18, 19 and 20) from either

end of cylinder, insert punch in hole

from inner side of piston head and

drive valve ball, spring and spring pin

from piston. If the hydraulic line

connector seats (13) are damaged, they

may be removed by threading inside

diameter of seats and using puller

bolts. Carefully clean and inspect all

parts and renew any that are exces-

sively worn, deeply scored or damaged

beyond further use.

Reassemble cylinder, using all new

sealing rings as follows: Insert check

ball (20) into bore in end of piston (21),

insert spring (19) with small end

next to ball and drive the retaining

spring pin (18) in flush with end of

piston. Install "0" ring (17) in bottom

of groove in end of piston, then install

Teflon ring (16) on top of the "0" ring.

Lubricate piston and install in bore of

cylinder. Install "0* ring (22) in groove

in open end of cylinder, lubricate and

install end plug (23)* and install plug

retaining snap ring (24). Install quad

ring (12) in bottom of pinion bore in

cylinder casting and lubricate ring and

bore. Install pinion (11), and washer

(10), puller bolt (9) and retaining snap

ring in top of pinion. Install pinion in

cylinder with timing marks on pinion

and piston aligned and reinstall cylin-

der as outlined in paragraph 16.

ENGINE AND COMPONENTS

Models 2435 and 2-155 tractors use

six cylinder, overhead valve diesel

engines. Engines use two cylinder

heads and are fitted with renewable

dry type sleeves, aluminum pistons and

shell-type connecting rod and main

bearings.

Engines have a bore and stroke of

4.56 X 4.88 inches and a displacement of

478 cubic inches. Compression ratio is

17:1 and compression pressure at

cranking speed should show a nominal

value of 300-350 psi. While the com-

pression pressure at cranking speed is

only a guide in that pressure will vary

according to equipment used, cranking

speed, altitude and etc., it is important

that compression pressures do not vary

more than 25 psi between cylinders.

The engines in 2-135 and 2-155

tractors are equipped with a turbo-

charger.

Engine serial number is stamped on

a metal plate attached to right side of

engine.

R & R ENGINE WITH CLUTCH

Models 2-135 and 2-155

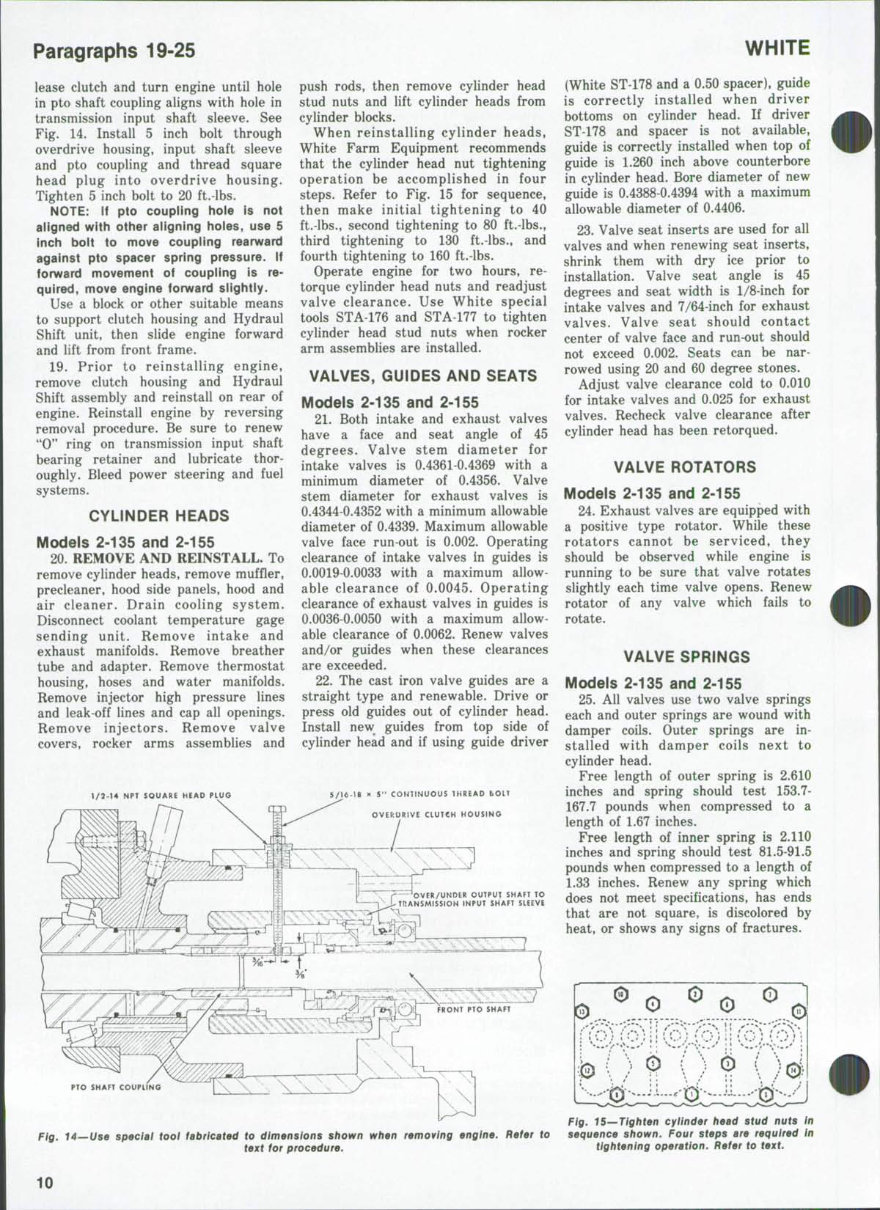

18. NOTE: To facilitate removal of

engine a special tool should be fabri-

cated which will retain front pto shaft

in position so it will disengage from

flywheel pto drive hub when engine is

moved forward.

The special tool is made up of two

parts: A 5/16-18 x 5 inch continuous

thread bolt which has the end reduced

to a 3/16-inch outside diameter which is

a/8-inch long. See Fig. 14. Also re-

quired is a 72-14 NPT square head plug

which has been di*iUed with a Size F

[0.257] drill and tupped to accept the

5/16-inch bolt.

Prior to removal, steam clean engine

if necessary. Remove hood side panels,

hood and grille side panels, then

remove grille and headlights assembly.

Remove air cleaner assembly. Drain

cooling system and disconnect radiator

hoses. Disconnect oil cooler lines at

radiator and cap openings. Remove

radiator, oil cooler and baffles.

Free engine from instrument panel

and support by disconnecting fuel lines,

wiring, injection pump controls and

accessory controls as necessary. Attach

a hoist to front and rear engine lifting

eyes, remove the four engine mounting

bolts and the clutch housing to flywheel

housing bolts.

Install the special tool as follows:

Thread the 5 inch. bolt through the

drilled square head plug, if necessary.

Remove pipe plug from Hydraul Shift

overdrive clutch housing, then using a

1 5/8-inch socket on crankshaft pulley

bolt, turn engine until hole in trans-

mission input shaft sleeve aligns with

hole in overdrive clutch housing. Re-

9

Paragraphs 19-25

lease clutch and turn engine until hole

in pto shaft coupling aligns with hole in

transmission input shaft sleeve. See

Fig. 14. Install 5 inch bolt through

overdrive housing, input shaft sleeve

and pto coupling and thread square

head plug into overdrive housing.

Tighten 5 inch bolt to 20 ft.-lbs.

NOTE: if pto coupiing hoie is not

aiigned with other aiigning hoies, use 5

inch boit to move coupiing rearward

against pto spacer spring pressure, if

forward movement of coupiing is re-

quired, move engine forward siightiy.

Use a block or other suitable means

to support clutch housing and Hydraul

Shift unit, then slide engine forward

and lift from front frame.

19. Prior to reinstalling engine,

remove clutch housing and Hydraul

Shift assembly and reinstall on rear of

engine. Reinstall engine by reversing

removal procedure. Be sure to renew

"0" ring on transmission input shaft

bearing retainer and lubricate thor-

oughly. Bleed power steering and fuel

systems.

CYLINDER HEADS

Models 2-135 and 2-155

20. REMOVE AND REINSTALL. To

remove cylinder heads, remove muffler,

precleaner, hood side panels, hood and

air cleaner. Drain cooling system.

Disconnect coolant temperature gage

sending unit. Remove intake and

exhaust manifolds. Remove breather

tube and adapter. Remove thermostat

housing, hoses and water manifolds.

Remove injector high pressure lines

and leak-off lines and cap all openings.

Remove injectors. Remove valve

covers, rocker arms assemblies and

1/2-M NPT SQUARE HEAD PLUG

push rods, then remove cylinder head

stud nuts and lift cylinder heads from

cylinder blocks.

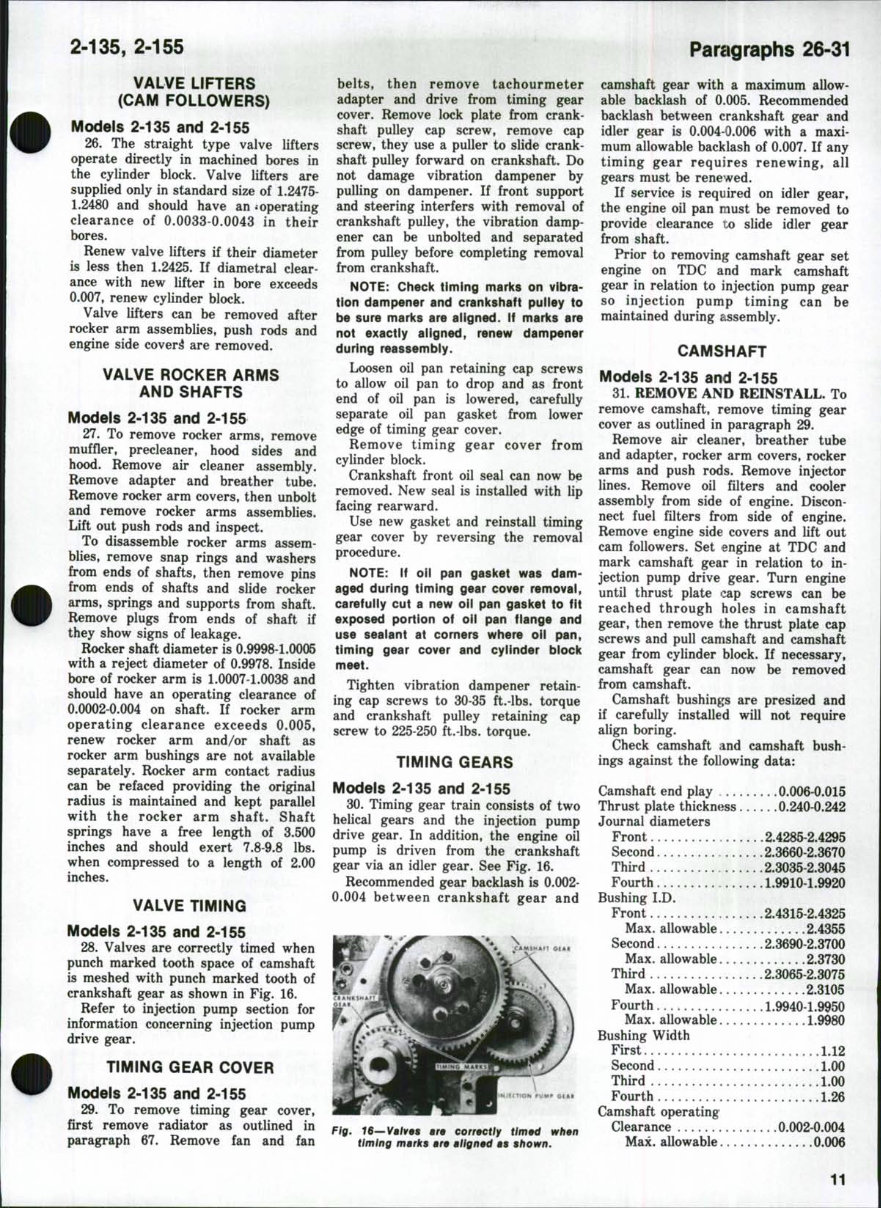

When reinstalling cylinder heads.

White Farm Equipment recommends

that the cylinder head nut tightening

operation be accomplished in four

steps. Refer to Fig. 15 for sequence,

then make initial tightening to 40

ft.-lbs., second tightening to 80 ft.-lbs.,

third tightening to 130 ft.-lbs., and

fourth tightening to 160 ft.-lbs.

Operate engine for two hours, re-

torque cylinder head nuts and readjust

valve clearance. Use White special

tools STA-176 and STA-177 to tighten

cylinder head stud nuts when rocker

arm assemblies are installed.

VALVES, GUIDES AND SEATS

Models 2-135 and 2-155

21. Both intake and exhaust valves

have a face and seat angle of 45

degrees. Valve stem diameter for

intake valves is 0.4361-0.4369 with a

minimum diameter of 0.4356. Valve

stem diameter for exhaust valves is

0.4344-0.4352 with a minimum allowable

diameter of 0.4339. Maximum allowable

valve face run-out is 0.002. Operating

clearance of intake valves in guides is

0.0019-0.0033 with a maximum allow-

able clearance of 0.0045. Operating

clearance of exhaust valves in guides is

0.0036-0.0050 with a maximum allow-

able clearance of 0.0062. Renew valves

and/or guides when these clearances

are exceeded.

22. The cast iron valve guides are a

straight type and renewable. Drive or

press old guides out of cylinder head.

Install new guides from top side of

cylinder head and if using guide driver

5/16-18 ^ 5" CONTINUOUS 1HREAD t>OlT

OVEfcURIVE CLUTCH HOUSING

' "' /^- -'OVER/UNDER OUTPUT SHAfT TO

|M-TRANSMISSION INPUT SHAFT SIECVE

WHITE

(White ST-178 and a 0.50 spacer), guide

is correctly installed when driver

bottoms on cylinder head. If driver

ST-178 and spacer is not available,

guide is correctly installed when top of

guide is 1.260 inch above counterbore

in cylinder head. Bore diameter of new

guide is 0.4388-0.4394 with a maximum

allowable diameter of 0.4406.

23. Valve seat inserts are used for all

valves and when renewing seat inserts,

shrink them with dry ice prior to

installation. Valve seat angle is 45

degrees and seat width is 1/8-inch for

intake valves and 7/64-inch for exhaust

valves. Valve seat should contact

center of valve face and run-out should

not exceed 0.002. Seats can be nar-

rowed using 20 and 60 degree stones.

Adjust valve clearance cold to 0.010

for intake valves and 0.025 for exhaust

valves. Recheck valve clearance after

cylinder head has been retorqued.

VALVE ROTATORS

Models 2-135 and 2-155

24. Exhaust valves are equipped with

a positive type rotator. While these

rotators cannot be serviced, they

should be observed while engine is

running to be sure that valve rotates

slightly each time valve opens. Renew

rotator of any valve which fails to

rotate.

VALVE SPRINGS

Models 2-135 and 2-155

25. All valves use two valve springs

each and outer springs are wound with

damper coils. Outer springs are in-

stalled with damper coils next to

cylinder head.

Free length of outer spring is 2.610

inches and spring should test 153.7-

167.7 pounds when compressed to a

length of 1.67 inches.

Free length of inner spring is 2.110

inches and spring should test 81.5-91.5

pounds when compressed to a length of

1.33 inches. Renew any spring which

does not meet specifications, has ends

that are not square, is discolored by

heat, or shows any signs of fractures.

PTO SHAFT COUPIING

4—Use special tool fabricated to dimensions shown when removing angina. Rafer to

taxt for procadura.

Fig. IS—Tighten cylinder head stud nuts In

sequence shown. Four steps are required In

tightening operation. Refer to text.

10

2-135, 2-155

Paragraphs 26-31

VALVE LIFTERS

(CAM FOLLOWERS)

Models 2-135 and 2-155

26. The straight type valve lifters

operate directly in machined bores in

the cylinder block. Valve lifters are

supplied only in standard size of 1.2475-

1.2480 and should have an -operating

clearance of 0.0033-0.0043 in their

bores.

Renew valve lifters if their diameter

is less then 1.2425. If diametral clear-

ance with new lifter in bore exceeds

0.007, renew cylinder block.

Valve lifters can be removed after

rocker arm assemblies, push rods and

engine side covert are removed.

VALVE ROCKER ARMS

AND SHAFTS

Models 2-135 and 2-155

27. To remove rocker arms, remove

muffler, precleaner, hood sides and

hood. Remove air cleaner assembly.

Remove adapter and breather tube.

Remove rocker arm covers, then unbolt

and remove rocker arms assemblies.

Lift out push rods and inspect.

To disassemble rocker arms assem-

blies, remove snap rings and washers

from ends of shafts, then remove pins

from ends of shafts and slide rocker

arms, springs and supports from shaft.

Remove plugs from ends of shaft if

they show signs of leakage.

Rocker shaft diameter is 0.9998-1.0005

with a reject diameter of 0.9978. Inside

bore of rocker arm is 1.0007-1.0038 and

should have an operating clearance of

0.0002-0.004 on shaft. If rocker arm

operating clearance exceeds 0.005,

renew rocker arm and/or shaft as

rocker arm bushings are not available

separately. Rocker arm contact radius

can be refaced providing the original

radius is maintained and kept parallel

with the rocker arm shaft. Shaft

springs have a free length of 3.500

inches and should exert 7.8-9.8 lbs.

when compressed to a length of 2.00

inches.

VALVE TIMING

Models 2-135 and 2-155

28. Valves are correctly timed when

punch marked tooth space of camshaft

is meshed with punch marked tooth of

crankshaft gear as shown in Fig. 16.

Refer to injection pump section for

information concerning injection pump

drive gear.

TIMING GEAR COVER

Models 2-135 and 2-155

29. To remove timing gear cover,

first remove radiator as outlined in

paragraph 67. Remove fan and fan

belts, then remove tachourmeter

adapter and drive from timing gear

cover. Remove lock plate from crank-

shaft pulley cap screw, remove cap

screw, they use a puller to slide crank-

shaft pulley forward on crankshaft. Do

not damage vibration dampener by

pulling on dampener. If front support

and steering interfers with removal of

crankshaft pulley, the vibration damp-

ener can be unbolted and separated

from pulley before completing removal

from crankshaft.

NOTE: Check timing marks on vibra-

tion dampener and crankshaft puiley to

be sure marks are aligned, if marks are

not exactly aligned, renew dampener

during reassembly.

Loosen oil pan retaining cap screws

to allow oil pan to drop and as front

end of oil pan is lowered, carefully

separate oil pan gasket from lower

edge of timing gear cover.

Remove timing gear cover from

cylinder block.

Crankshaft front oil seal can now be

removed. New seal is installed with lip

facing rearward.

Use new gasket and reinstall timing

gear cover by reversing the removal

procedure.

NOTE: If oil pan gasket was dam-

aged during timing gear cover removal,

carefully cut a new oil pan gasket to fit

exposed portion of oii pan flange and

use sealant at comers where oil pan,

timing gear cover and cyiinder block

meet.

Tighten vibration dampener retain-

ing cap screws to 30-35 ft.-lbs. torque

and crankshaft pulley retaining cap

screw to 225-250 ft.-lbs. torque.

TIMING GEARS

Models 2-135 and 2-155

30. Timing gear train consists of two

helical gears and the injection pump

drive gear. In addition, the engine oil

pump is driven from the crankshaft

gear via an idler gear. See Fig. 16.

Recommended gear backlash is 0.002-

0.004 between crankshaft gear and

\

Fig. IS—Valves are correctly ffm«d when

timing marks are aligned as shown.

camshaft gear with a maximum allow-

able backlash of 0.005. Recommended

backlash between crankshaft gear and

idler gear is 0.004-0.006 with a maxi-

mum allowable backlash of 0.007. If any

timing gear requires renewing, all

gears must be renewed.

If service is required on idler gear,

the engine oil pan must be removed to

provide clearance to slide idler gear

from shaft.

Prior to removing camshaft gear set

engine on TDC and mark camshaft

gear in relation to injection pump gear

so injection pump timing can be

maintained during assembly.

CAMSHAFT

Models 2-135 and 2-155

31. REMOVE AND REINSTALL. To

remove camshaft, remove timing gear

cover as outlined in paragraph 29.

Remove air cleaner, breather tube

and adapter, rocker arm covers, rocker

arms and push rods. Remove injector

lines. Remove oil filters and cooler

assembly from side of engine. Discon-

nect fuel filters from side of engine.

Remove engine side covers and lift out

cam followers. Set engine at TDC and

mark camshaft gear in relation to in-

jection pump drive gear. Turn engine

until thrust plate <:^p screws can be

reached through holes in camshaft

gear, then remove the thrust plate cap

screws and pull camshaft and camshaft

gear from cylinder block. If necessary,

camshaft gear can now be removed

from camshaft.

Camshaft bushings are presized and

if carefully installed will not require

align boring.

Check camshaft and camshaft bush-

ings against the following data:

Camshaft end play 0.006-0.015

Thrust plate thickness 0.240-0.242

Journal diameters

Front 2.4285-2.4295

Second 2.3660-2.3670

Third 2.3035-2.3045

Fourth 1.9910-1.9920

Bushing I.D.

Front 2.4315-2.4325

Max. allowable 2.4355

Second 2.3690-2.3700

Max. allowable 2.3730

Third 2.3065-2.3075

Max. allowable 2.3105

Fourth 1.9940-1.9950

Max. allowable 1.9980

Bushing Width

First 1.12

Second 1.00

Third .1.00

Fourth 1.26

Camshaft operating

Clearance 0.002-0.004

Max. allowable 0.006

11

You're Reading a Preview

What's Included?

Fast Download Speeds

Online & Offline Access

Access PDF Contents & Bookmarks

Full Search Facility

Print one or all pages of your manual

$41.99

Viewed 69 Times Today

Loading...

Secure transaction

What's Included?

Fast Download Speeds

Online & Offline Access

Access PDF Contents & Bookmarks

Full Search Facility

Print one or all pages of your manual

$41.99

Thank you for considering this comprehensive Service Repair Workshop Manual for the White 2-135 & 2-155 Tractors.

This manual is an invaluable resource, covering every Service & Repair Procedure necessary for professional mechanics and DIY enthusiasts alike.

With easy-to-follow step-by-step instructions and detailed pictures, this manual empowers you to save significant costs by performing your own repairs.

Upon purchase, this manual becomes your permanent asset, allowing you to print specific pages, chapters, or the entire document. It is also compatible with tablets and smartphones for convenient access.

MODELS COVERED:

- All Models/Engines/Trim/Transmissions Types Are Covered

CONTENTS:

- This high-quality Service Repair Workshop Manual encompasses all repair procedures from A to Z, ensuring that every repair and service procedure is comprehensively addressed.

COMPUTER REQUIREMENTS:

- This downloadable Manual is compatible with all PC & MAC Computers, tablets, and mobile phones. It only requires adobe reader, which is typically pre-installed on most computers or can be downloaded for free.

INSTANT DELIVERY:

- Upon payment confirmation via Visa, MasterCard, or PayPal, the manual will be instantly emailed to the address provided during checkout.

Customer Satisfaction Guaranteed.