Same Dorado S & V 70 75 90 100 Tractor Full Service & Repair Manual

What's Included?

Fast Download Speeds

Online & Offline Access

Access PDF Contents & Bookmarks

Full Search Facility

Print one or all pages of your manual

00-1

INTRODUCTION

The purpose of this workshop manual is to provide instruction for repair technicians and

a practical guide to improving the quality of repairs.

This manual enables repair technicians to acquire a thorough knowledge of the

machine, indicating the correct methods for fault diagnosis, for working in safety and for

accurate dimensional checks and visual inspections. The instructions also indicate the

products to use, the tightening torques and the adjustment data.

The technical material contained in this manual is reserved to Authorised Dealers and

Service Centres who will be duly informed of any technical changes to the machines in

question through the issue of documents regarding modifications, updates and

supplements for optional equipment.

All technicians and their colleagues are expressly forbidden from reproducing any part

of this manual in any form or from communicating the contents to third parties without

the express written permission of the Manufacturer, who remains the sole owner of this

document with all rights reserved in accordance with applicable laws.

INTRODUCTION

00-3

GENERAL SAFETY RULES

SAFETY NOTES

To ensure that machines entrusted to Authorised Service Centres for repair or overhaul continue

to function correctly, it is very important that all repair work is carried out in the prescribed manner.

The procedures for checks and repairs indicated in this manual are safe and effective.

Some of the operations described require the use of special tools and equipment: these tools

have been designed for a specific purpose and may ordered directly from the Manufacturers.

DO NOT USE MAKESHIFT TOOLS; not only is there is risk of personal injury, but such tools are

rarely suited to the purpose for which they are used.

To prevent injury to operators, the symbols and are used in this manual to indicate the

safety precautions required. The warnings accompanying these symbols must always be

adhered to carefully.

In potentially hazardous situations, always give priority to personal safety and take the necessary

actions to eliminate the danger.

GENERAL SAFETY RULES

1 - Even if you have a thorough knowledge of the machine as regards its

components, operation and controls, always take particular care when

carrying out the following operations. Remember that the machine you are

working on is in need of repair or overhaul and consequently may not

always behave as expected.

2 - Before starting work, clean the machine thoroughly to remove all mud,

dust and road dirt. Also clean the cab to remove all traces of oil, snow and

ice from the access steps and grab rails.

3 - When climbing up to or down from the cab, always ensure you maintain

three points of contact at a time (foot or handholds) in order to keep your

balance and prevent accidental falls.

4 - Always take special care when carrying out fault diagnosis operations;

these operations often require two persons, who must never stand in front

of the wheels when the engine is running.

5 - When carrying out checks and repairs, wear close-fitting clothing, safety

goggles and protective gloves that are suitable for the task (cleaning,

draining fluids, repairs).

When working near moving parts, long hair should be gathered up and

secured safely under a cap to prevent the risk of entanglement and sever

injury.

6 - Do not allow anyone who is not directly involved in the work to come near

the machine; ensure that they remain at a safe distance.

7 - Keep well clear of moving parts; when the engine is running, some moving

parts are not easily visible and therefore present a risk of entanglement,

even if protected by safety guards.

8 - Ensure that the area is well ventilated before starting the engine in order to

avoid the formation of dangerous concentrations of toxic gases; always

connect suitable fume extraction equipment to the exhaust pipe.

00-4

9 - Under no circumstances start the engine with the safety guards removed;

all repair and adjustment operations must be carried out with the engine

stopped.

10 - Do not top up fuel, oil or coolant levels when the engine is running.

11 - Never smoke and ensure there are no naked flames nearby when topping

up fuel or oil. Always remove the battery from the machine before

recharging.

12 - Before checking or removing the battery, stop the engine and remove the

key from the starter switch.

13 - Remove the battery and recharge in a well-ventilated area where the

temperature exceeds 0°C.

14 - When checking or recharging the battery, do not smoke or allow naked

flames in the vicinity as the hydrogen gas given off by the battery is highly

explosive.

15 - The liquid (electrolyte) contained in the battery is very harmful if it comes

into contact with the skin and the eyes; for this reason, always wear gloves

and safety goggles with side shields when checking or topping up the

battery.

Should any electrolyte accidentally come into contact with your skin, wash

the affected parts immediately with copious amounts of water. If

electrolyte comes into contact with your clothing, this should be removed

as soon as possible.

In case of accidental ingestion of electrolyte, drink copious amounts of

water, milk or vegetable oil and take antacids such as magnesium,

bicarbonate, etc.. and seek medical attention immediately.

16 - Before working on the electrical systems, always disconnect the battery

terminals.

IMPORTANT!

Always disconnect the negative terminal (--) first and then the positive

terminal (+); when re-connecting the battery on completion of the work,

first connect the positive terminal (+) and then the negative (--).

17 - Before carrying out any arc welding, on the tractor, always disconnect the

battery terminals and unplug all the connectors of the electronic control

units and the alternator.

18 - When topping up lubricants, always wear suitable protective gloves.

19 - Do not wear clothing contaminated by engine or hydraulic oil; prolonged

contact with the skin can be harmful and may cause allergic reactions.

20 - Used engine oil and hydraulic oil must be disposed of in a proper manner;

recover used lubricants and dispose of them in accordance with the

applicable regulations.

21 - Before carrying out any work on the hydraulic or pneumatic systems,

discharge all residual pressure from the circuits.

22 - Before carrying out any work on the hydraulic system or engine, allow the

oil and engine coolant to cool down.

GENERAL SAFETY RULES

00-5

23 - When removing and refitting certain assemblies, it will be necessary to

support the machine; use stands, jacks or blocks capable of supporting

the weight and arrange them in a triangular pattern to prevent the machine

from overturning.

24 - To lift heavy components, use a hoist or crane.

Check that wire ropes, chains or fibre slings are not worn and that hooks

are not damaged.

25 - Always use lifting equipment of suitable capacity for the weight of the

components to be removed. Ensure lifting equipment is attached

correctly.

26 - When lifting or supporting an assembly or component, manoeuvre the

parts slowly and carefully to avoid oscillation or collision with other

components.

27 - Never work on components suspended from a hoist or crane.

28 - When removing the retaining bolts of a component that could fall, always

leave two opposing bolts in place for safety; these bolts should only be

removed when the component has been securely attached to a hoist or

when supporting blocks have been put in position.

29 - Any oil or fuel spilled during removal or dismantling operations should be

cleaned up as soon as possible to prevent the risk of slipping and fire.

30 - When refitting electrical wiring looms and wires, ensure that they are

properly secured with their original retaining straps or brackets to prevent

the possibility of damage caused by vibration.

31 - Never insert your fingers or hands to check the alignment between fixing

holes in components; always use a suitable dowel of soft material.

32 - When refitting assemblies or components, always use the specified

tightening torques; the tightening torques indicated in the paragraphs

regarding assembly/refitting operations have been determined through

experimentation and must be scrupulously adhered to.

33 - When refitting parts that are subject to vibration or that rotate at high

speed, take particular care when carrying final installation checks.

GENERAL SAFETY RULES

00-6

SAFETY PRECAUTIONS FOR REMOVAL AND REFITTINGOPERATIONS

★ When removing or refitting parts, always take the following safety

precautions.

1. PRECAUTIONS FOR REMOVAL OPERATIONS

• Unless otherwise indicated, lower the working equipment until it rests on

the ground.

• After disconnecting hydraulic and fuel system pipes, always fit plugs to the

open ends of the pipes to prevent ingress of impurities.

• Before removing a cylinder, fully retract the piston and secure it in this

position using a retaining strap.

• Use containers of sufficient capacity when draining oil, coolant or fuel.

• Before removing a part from the machine, check for alignment markings

indicating the correct assembly position. If necessary, make new markings

to ensure correct assembly.

• When unplugging electrical connectors, always grip the connectors firmly

to avoid pulling on the wires.

• Where necessary, label wires and pipes before removal to avoid confusion

when reconnecting.

• Check the number and thickness of any shims removed and keep them

together in a safe place.

• To lift the machine or any of its main components, use lifting equipment of

suitable capacity.

• When using eyebolts for lifting tractor components, first check that they

are not deformed or damaged, screw them fully home and then turn the

bolt so that the eye is aligned with the lifting hook.

• Before removing a part, clean the surrounding area and, after removing the

part, cover it to prevent the ingress of dirt and dust.

2. PRECAUTIONS FOR REFITTING OPERATIONS

• Tighten nuts and bolts to the specified tightening torques.

• When refitting flexible pipes and wires, take care not to twist or tangle

them.

• Always fit new seals, O-rings, cotter pins and safety stop rings on

reassembly; make sure that the ends of the cotter pins are separated and

bent back so that the pin cannot be withdrawn from the hole.

• Ensure that circlips are correctly installed in their seatings.

• Always fit new seals, O-rings, cotter pins and safety stop rings; ensure that

cotter pins are bent over so that they cannot work loose.

SAFETY PRECAUTIONS FOR REMOVAL AND REFITTING OPERATIONS

00-7

• When applying sealant, first clean the surface removing all traces of oil and

grease and check for dirt or indentations, then apply the sealant evenly

making sure that it forms a continuous film around any fixing holes.

• Clean all parts, removing dirt, oxidisation, carbon deposits, burrs and

indentations.

• Coat all moving parts with a thin film of engine oil.

• When reconnecting electrical connectors, first remove all traces of oil, dust

and water from the inside of the connector and then push the two halves

together firmly; only apply the force necessary to clip the two halves

together.

• Bolt down flanged fittings evenly, tightening the bolts gradually in a

crosswise pattern.

3. PRECAUTIONS TO BE TAKEN ON COMPLETION OF REMOVAL/REFITTING OPERATIONS

• If coolant has been drained from the engine, refit the drain plug and add

new coolant to the correct level. Start the engine to circulate the coolant

and then check the level again and top up.

• After removing hydraulic components, top up the hydraulic oil to the

specified level. Start the engine to circulate the oil in the hydraulic circuits

and then recheck the level and top up as necessary.

• After having removed a variable displacement pump, connect the drain

pipe and fill the pump casing with oil through the filler hole provided.

• Grease stub axle housings, cylinder pivot mountings and drive shafts

thoroughly after assembly.

SAFETY PRECAUTIONS FOR REMOVAL AND REFITTING OPERATIONS

00-8

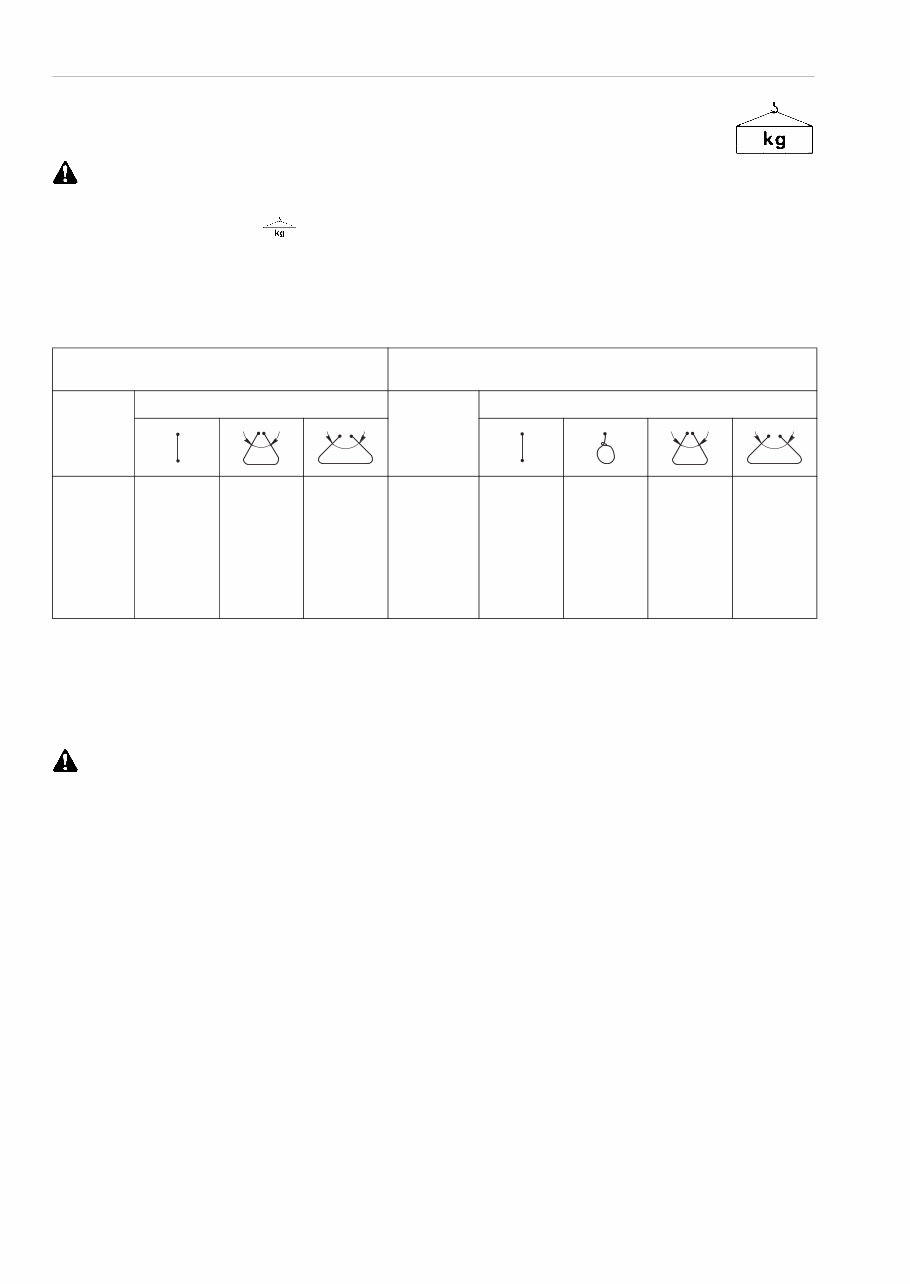

LIFTING INSTRUCTIONS

Components weighing over 25 kg or of significant size must be supported and removed using suitable lifting

equipment with wire rope or polyester slings.

In the paragraphs regarding removal and refitting operations, the weight of the component or assembly to be lifted is

indicated with the symbol

WIRE ROPES - SLINGS

• Use wire ropes or polyester slings of suitable capacity for the parts to be lifted, referring to the following tables:

NOTE. Lifting capacities are calculated with a safety coefficient.

• The lifting hook should be attached to the central part of the rope or sling; if the hook is attached near the ends of the

rope/sling, this could cause the load to slip during lifting.

• Never lift a heavy load using a single rope; always use two or more symmetrically arranged ropes.

Suspension of a load from a single rope could cause the load to start rotating and consequently cause the rope

strands to untwist or the load to slip; this could lead to serious injury.

• Never lift a heavy load when the two branches of the ropes form a wide angle.

The permitted load (kg) decreases in inverse proportion to the angle of suspension; the table below indicates how the

permitted load varies according to the angle of suspension for two Ø 10 mm ropes each with a load capacity of 1000

kg.

WIRE ROPES

(standard twisted «S» or «Z» type)

POLYESTER SLINGS

(eye-and-eye - simple loop)

Ø rope

mm

Capacity (kg)

Width

(mm)

Capacity (kg)

8

10

12

14

16

18

650

1000

1450

2000

2600

3300

620

1740

2500

3460

4500

5710

500

1420

2050

2820

3670

4660

25

50

62

75

100

150

500

1000

1250

1400

2000

2500

400

800

1000

1120

1600

2000

860

1730

2160

2420

3460

4330

700

1410

1760

1980

2820

3530

60° 90° 60° 90°

You're Reading a Preview

What's Included?

Fast Download Speeds

Online & Offline Access

Access PDF Contents & Bookmarks

Full Search Facility

Print one or all pages of your manual

$39.99

Viewed 10 Times Today

Loading...

Secure transaction

What's Included?

Fast Download Speeds

Online & Offline Access

Access PDF Contents & Bookmarks

Full Search Facility

Print one or all pages of your manual

$39.99

This is a comprehensive factory service repair workshop manual for the Same Dorado S & V 70 75 90 100 Tractor. It is available for instant access on your computer, tablet, or smartphone without any extra fees or expiry dates.

The manual is designed for professional mechanics and technicians, as well as DIY enthusiasts. It covers all repair, servicing, and troubleshooting procedures with detailed photos, diagrams, step-by-step instructions, and highly detailed exploded diagrams to guide you through each job.

- Printing: You have the option to print out a single page or the entire manual as per your requirement.

- Multi-Device Usage: The manual can be used on multiple computers without any limitations.

- Full Version: This is the full manual without any trial periods or limitations, and it can be used for life.

- Compatibility: It is fully compatible with Windows and MAC computers.

Thank you for considering this manual. Click the button to access it now.