McCormick CX - CX50 CX60 CX70/75 CX80/85 CX90/95 CX100/105 Tractor Factory Service Repair Manual - IMPROVED -

What's Included?

Fast Download Speeds

Online & Offline Access

Access PDF Contents & Bookmarks

Full Search Facility

Print one or all pages of your manual

Intentionally blank

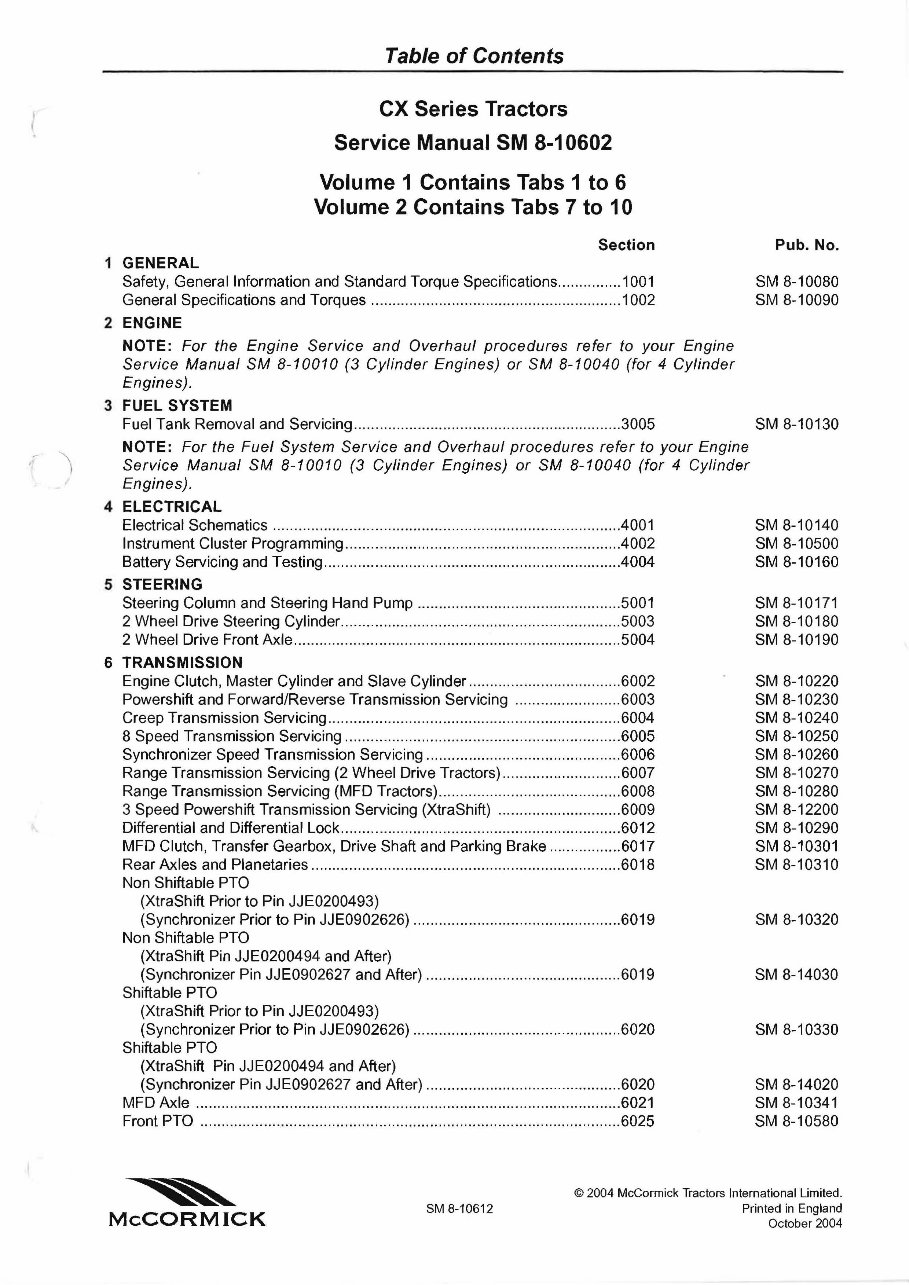

1 GENERAL

Table of Contents

CX Series Tractors

Service Manual SM 8-10602

Volume 1 Contains Tabs 1 to 6

Volume 2 Contains Tabs 7 to 10

Section

Safety, General Information and Standard Torque Specifications ......... ..... . 1001

General Specifications and Torques ..... .. .. .................................................. 1002

2 ENGINE

NOTE: For the Engine Service and Overhaul procedures refer to your Engine

Service Manual SM 8-10010 (3 Cylinder Engines) or SM 8-10040 (for 4 Cylinder

Engines).

3 FUEL SYSTEM

Fuel Tank Removal and Servicing .... ....... ... ... ......................... .. .. .......... ....... 3005

NOTE: For the Fuel System Service and Overhaul procedures refer to your Engine

Service Manual SM 8-10010 (3 Cylinder Engines) or SM 8-10040 (for 4 Cylinder

Engines).

4 ELECTRICAL

Electrical Schematics .. ............................................................................... . 4001

Instrument Cluster Programming ................................................................ .4002

Battery Servicing and Testing .. .................. .. ........................ ....................... .4004

5 STEERING

Steering Column and Steering Hand Pump .... .. ........ .. ... ..... .. ... .. ... ... ... ... ..... 5001

2 Wheel Drive Steering Cytinder. ... ...... ..... .... ................ ........ ..................... ..5003

2 Wheel Drive Front Axle ...... ....... ................. .. ... .................... .................. .... 5004

6 TRANSMISSION

Engine Clutch, Master Cylinder and Slave Cylinder ...... ... .. ................. .. .... ..6002

Powershift and Forward/Reverse Transmission Servicing ..... ..... .. ... .... .. .... 6003

Creep Transmission Servicing .... ......... ..... ... ..................... .. ......................... 6004

8 Speed Transmission Servicing ....................... ..................... .................. ... 6005

Synchronizer Speed Transmission Servicing ..................... ....................... .. 6006

Range Transmission Servicing (2 Wheel Drive Tractors) .. .. ........................ 6007

Range Transmission Servicing (MFD Tractors) ... ......... ........ ... ..... .. ............. 6008

3 Speed Powershift Transmission Servicing (XtraShift) .... ....... ..... ........... .. 6009

Differential and Differential Lock .............. .. ....................... .................... .. ..... 6012

MFD Clutch, Transfer Gearbox, Drive Shaft and Parking Brake .................6017

Rear Axles and Planetaries ........................................... .. .................. ... .. ..... 6018

Non Shiftable PTO

(XtraShift Prior to Pin JJE0200493)

(Synchronizer Prior to Pin JJE0902626) ....................... .. .... ..... ........... .. .. 6019

Non Shiftable PTO

(XtraShift Pin JJE0200494 and After)

(Synchronizer Pin JJE0902627 and After) .... .... .. ........ .. ......... .... ............. 6019

Shiftable PTO

(XtraShift Prior to Pin JJE0200493)

(Synchronizer Prior to Pin JJE0902626) .................. ..... ..................... .. ... 6020

Shiftable PTO

(XtraShift Pin JJE0200494 and After)

(Synchronizer Pin JJE0902627 and After) .............................................. 6020

MFD Axle .............................. .... ............... .. ................................................. 6021

Front PTO ...... .. ................. ... .. .... ............ .. ... .................. .. .. ................. ......... 6025

Pub. No.

SM 8-10080

SM 8-10090

SM 8-10130

SM 8-10140

SM 8-10500

SM 8-10160

SM 8-10171

SM 8-10180

SM 8-10190

SM 8-10220

SM 8-10230

SM 8-10240

SM 8-10250

SM 8-10260

SM 8-10270

SM 8-10280

SM 8-12200

SM 8-10290

SM 8-10301

SM 8-10310

SM 8-10320

SM 8-14030

SM 8-10330

SM 8-14020

SM 8-10341

SM 8-10580

~

© 2004 McCormick Tractors International Limited.

McCORMICK

8M 8-10612 Printed in England

October 2004

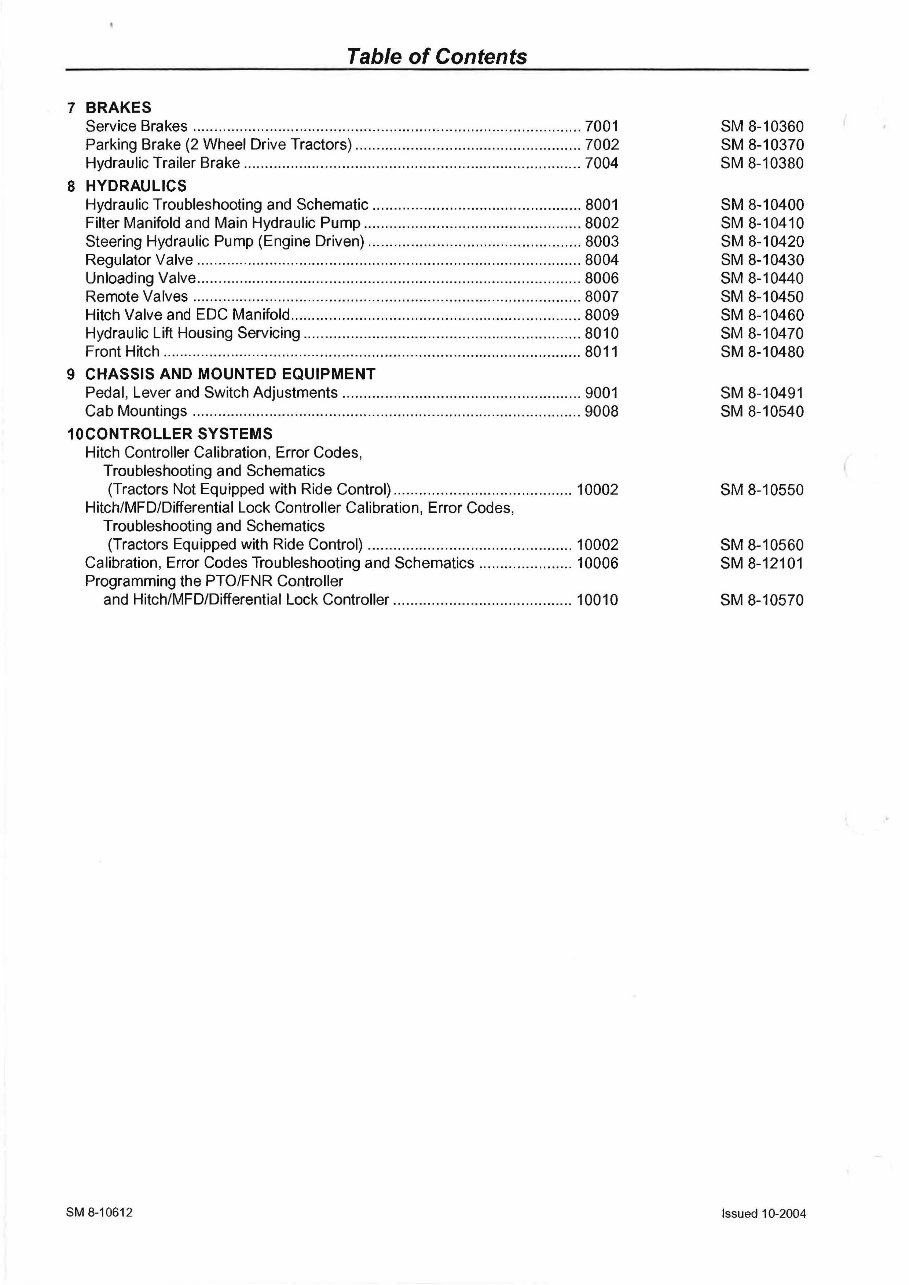

Table of Contents

7 BRAKES

Service Brakes ........ ......... ... ................ .. .............................................. .. ..... 7001

Parking Brake (2 Wheel Drive Tractors) .... ............ ............ ...... ........ .. .... .. ... 7002

Hydraulic Trailer Brake ................................ .. .. .............. ............................. 7004

8 HYDRAULICS

Hydraulic Troubleshooting and Schematic ...... .. ............ .. .......... .. ...... .. ....... 8001

Filter Manifold and Main Hydraulic Pump .. .. .. .. .. .. .. ........ ........ .. .. ........ .. ....... 8002

Steering Hydraulic Pump (Engine Driven) .................. .. .............................. 8003

Regulator Valve .. ... ........... ... ........... ... .. ..... .. ....... ............. ........ .. .... ... ......... .. 8004

Unloading Valve ... .. ................ .. .... . .. ........ ..... .... .. ................................ .... ..... 8006

Remote Valves ...................... ..................... .. ... .. .......... .. ...... ... ....... .. ......... .. 8007

Hitch Valve and EDC Manifold .................................................................... 8009

Hydraulic Lift Housing Servicing ........... .. ...... ... .......................... .. . ... .. ......... 8010

Front Hitch ......................... . .. .. ............. .. ........... ... .......... .. .... .. ....... ....... ..... .. 8011

9 CHASSIS AND MOUNTED EQUIPMENT

Pedal, Lever and Switch Adjustments .. ....... .. .... .. .......................... .. .. .. .... .. . 9001

Cab Mountings ... ... .. ... .... .. ... .. ... ......... .. .......... ........ ..... .... . .. .... .. .. ................. 9008

10CONTROLLER SYSTEMS

Hitch Controller Calibration, Error Codes,

Troubleshooting and Schematics

(Tractors Not Equipped with Ride Control) ................. .. ........... ....... ..... 10002

Hitch/MFD/Differential Lock Controller Calibration, Error Codes,

Troubleshooting and Schematics

(Tractors Equipped with Ride Control) ....... ............. .. .......................... 10002

Calibration, Error Codes Troubleshooting and Schematics ......... ..... ........ 10006

Programming the PTO/FNR Controller

and Hitch/MFD/Differential Lock Controller .. .. .... .. ................................ 10010

8M 8-10612

SM 8-10360

SM 8-10370

SM 8-10380

SM 8-10400

SM 8-10410

SM 8-10420

SM 8-10430

SM 8-10440

SM 8-10450

SM 8-10460

SM 8-10470

SM 8-10480

SM 8-10491

SM 8-10540

SM 8-10550

SM 8-10560

SM 8-12101

SM 8-10570

Issued 10-2004

Section

1001

SAFETY, GENERAL INFORMATION

AND STANDARD TORQUE SPECIFICATIONS

~

McCORMICK

© 2001 McCormick Tractors International Limited.

SM 8-10080 March 2001

2 SECT/ON 1001

TABLE OF CONTENTS

SAFETY ..................... .. .................... ........ .... ........................... .. ............ .............................. ........... .. ...... ...... .. .... ...... 3

GENERAL INFORMATION

Cleaning .......................................................................................................................... .. ............ .................... ... 5

Inspection .. ............... .. ........... ... ... ........................................ .................. ............... .. ..................................... ... ..... . 5

Bearings ... ... .................. .... ..... .. ..... .... ... ... ..... .. . .. .. .... .. ........................................... ...... .... ..... ......... ...... .... ... ... ... ..... 5

Needle Bearings ...... ... ....... .. ... ... .. ........................ ... .... ...... ....... ......... .. .......... .. .. .. .............................................. ... 5

Gears ................................................................................. .................. .. .............. ........... ... ...... .... .. .. ... .......... ... .... 5

Oil Seals, O-Rings And Gaskets ... ...... .. ... .. ........ .. ... ......................................... ... ............ ... .. .. ... .. ................ . .. ... ... 5

Shafts ... ......... ...... .. .. .. ..... ...... ................ ... ... .. ........... ...... ... .... .. ........ ....... .......... ..... ....... .... .... ....... ... .............. .. .... . .. 5

Service Parts ............ ... ........... ............................ .. .... ........ ............... .... ........... ... .............................. ..................... 5

Lubrication .. ............. ... ................ ........... ... .. .............. ............... ........... .... .................................... ... ........... ........... 5

STANDARD TORQUE DATA FOR NUTS AND BOLTS

Chart 1 (Plain Nuts/Bolts) ........ .. ........... ... ............ ... .......................... ... ................................................................ 6

Chart 2 (Phosphate Coated Nuts/Bolts) ... ............. ... .......................... .. ....................................... .. .. .. .... ...... .. .. ..... 6

Chart 3 (Zinc or Cadmium Plated Nuts/Bolts) ...... .. ......................... .. .. .. .............. .. ............................................... 7

8M 8-10080 Issued 03-2001

SECTION 1001 3

SAFETY

This symbol means A TTENT/ON! BECOME ALERT! YOUR SAFETY

IS INVOL VED. The message that follows the symbol contains

A important information about safety. Carefully read the message.

Make sure you fully understand the causes of possible injury or

death.

To prevent injury always follow the Warning,

Caution and Danger notes in this section and

throughout the manual.

Put a warning tag as shown below on the key for the

key switch when carrying out servicing or repairs to

the tractor. Warning tags (publication number 2-1000)

are available from your McCormick dealer.

DO NOT OPERATE

NE PAS UTILISER

NICHT BETREIBEN

NO UTILIZAR

I

2·1000

H:A""~ "

VUlIII,tIlol' IMN'OIr

~

McCORMICK

WARNING: Read the operators manual to

A familiarize yourself with the correct

control functions.

WARNING: Operate the machine and

*' equipment controls from the seat

~ position only. Any other method could

result in serious injury.

*' WARNING: This is one a man machine, no

~ riders aI/owed.

SM 8-10080

WARNING: Before starting engine, study

Operator's Manual safety messages.

Read all safety signs on machine. Clear

the area of other persons. Learn and

practice safe use of controls before

*' operating.

~ It is your responsibility to understand and

follow manufacturers instructions on

machine operation, service, and to

observe pertinent laws and regulations.

Operator's and Service Manuals may be

obtained from you McCormick dealer.

WARNING: If you wear clothing that is too

loose or do not use the correct safety

equipment for your job, you can be

A injured. Always wear clothing that will not

~ catch on objects. Extra safety equipment

• that can be required includes hard hat,

safety shoes, ear protection, eye or face

protection, heavy gloves and reflector

clothing.

WARNING: When working in the area of

1,\ the fan belt with the engine running, avoid

l.llloose clothing if possible, and use

extreme caution.

WARNING: When doing checks and tests

*- on the equipment hydraulics, follow the

~ procedures as they are written. DO NOT

change the procedure.

WARNING: When putting the hydraulic

cylinders on this machine through the

A necessary cycles to check operation or to

remove air from a circuit, make sure all

people are out of the way.

1,\ WARNING: Use insulated gloves or

l.ll mittens when working with hot parts.

Iss ued 03-2001

4 SECT/ON 1001

CAUTION: Lower all attachments to the

J,\ ground or use stands to safely support

~ the attachments before you do any

maintenance or service.

CAUTION: Pin sized and smaller streams

of hydraulic oil under pressure can

penetrate the skin and result in serious

infection. If hydraulic oil under pressure

does penetrate the skin, seek medical

J,\ treatment immediately. Maintain all hoses

~ and tubes in good condition. Make sure

all connections are tight. Make a

replacement of any tube or hose that is

damaged or thought to be damaged. DO

NOT use your hand to check for leaks,

use a piece of cardboard or wood.

CAUTION: When removing hardened pins

such as a pivot pin, or a hardened shah,

A use a soh ~ead (brass or bronze) hammer

or use a drtver made from brass or bronze

and a steel head hammer.

CAUTION: When using a hammer to

remove and install pivot pins or separate

parts using compressed air or using a

A grinder, wear eye protection that

• completely encloses the eyes (approved

goggles or other approved eye

protectors).

CAUTION: Use suitable floor (service)

J,\ jacks or chain hoist to raise wheels or

~ tracks off the floor. Always block machine

in place with suitable safety stands.

SM 8-10080

CAUTION: When servlcmg or repairing

the machine. Keep the shop floor and

J,\ operator's compartment and steps free of

£ll oil, water, grease, tools, etc. Use oi/

absorbing material and or shop cloths as

required. Use safe practices at all times.

CAUTION: Some components of this

J,\ machine are very heavy. Use suitable

L:..l. lihing equipment or additional help as

instructed in this Service Manual.

DANGER: Engine exhaust fumes can

cause death. If it is necessary to start the

J,\ engine in a closed place, remove the

£ll exhaust fumes from the area with an

exhaust pipe extension. Open the doors

and get outside air into the area.

DANGER: When the battery electrolyte is

frozen, the battery can explode if (1), you

try to charge the battery, or (2), you try to

J,\ jump start and run the engine. To prevent

L:..l. that battery electrolyte from freezing, try

to keep the battery at full charge. If you do

not follow these instructions, you or

others in the area can be injured.

DANGER: Batteries contain acid and

explosive gas. Explosions can result from

sparks, flames or wrong cable

*" connections. To connect the jumper

L:..l. cables correctly to the battery of this

machine see the Operator's Manual.

Fai/ure to follow these instructions can

cause serious injury or death.

Issued 03-2001

SECTION 1001 5

GENERAL INFORMATION

Cleaning

Clean all metal parts except bearings, in mineral

spirits or by steam cleaning. Do not use caustic

soda for steam cleaning. After cleaning dry and put

oil on all parts. Clean oil passages with compressed

air. Clean bearings in kerosene, dry the bearings

completely and put oil on the bearings.

Inspection

Check all parts when the parts are disassembled.

Replace all parts that have wear or damage. Small

scoring or grooves can be removed with a hone or

crocus cloth. Complete visual inspection for

indications of wear, pitting and the replacement of

parts necessary will prevent early failures.

Bearings

Check bearings for easy action. If bearings have a

loose fit or rough action replace the bearing. Wash

bearings with a good solvent or kerosene and

permit to air dry. DO NOT DRY BEARINGS WITH

COMPRESSED AIR.

Needle Bearings

Before you press needle bearings in a bore always

remove any metal protrusions in the bore or edge of

the bore. Before you press bearings into position

put petroleum jelly on the inside and outside

diameter of the bearings.

SM 8-10080

Gears

Check all gears for wear and damage. Replace

gears that have wear or damage.

Oil Seals, O-Rings And Gaskets

Always install new oil seals, o-rings and gaskets.

Put petroleum jelly on seals and o-rings.

Shafts

Check all shafts that have wear or damage. Check

the bearing and oil seal surfaces of the shafts for

damage.

Service Parts

Always install genuine McCormick service parts,

when ordering refer to the Parts Catalog for the

correct part number of the genuine McCormick

replacement items. Failures due to the use of other

than genuine McCormick replacement parts are not

covered by warranty.

Lubrication

Only use the oils and lubricants specified in the

Operators or Service Manual. Failures due to the

use of non specified oils and lubricants are not

covered by warranty.

Issued 03-2001

6 SECTION 1001

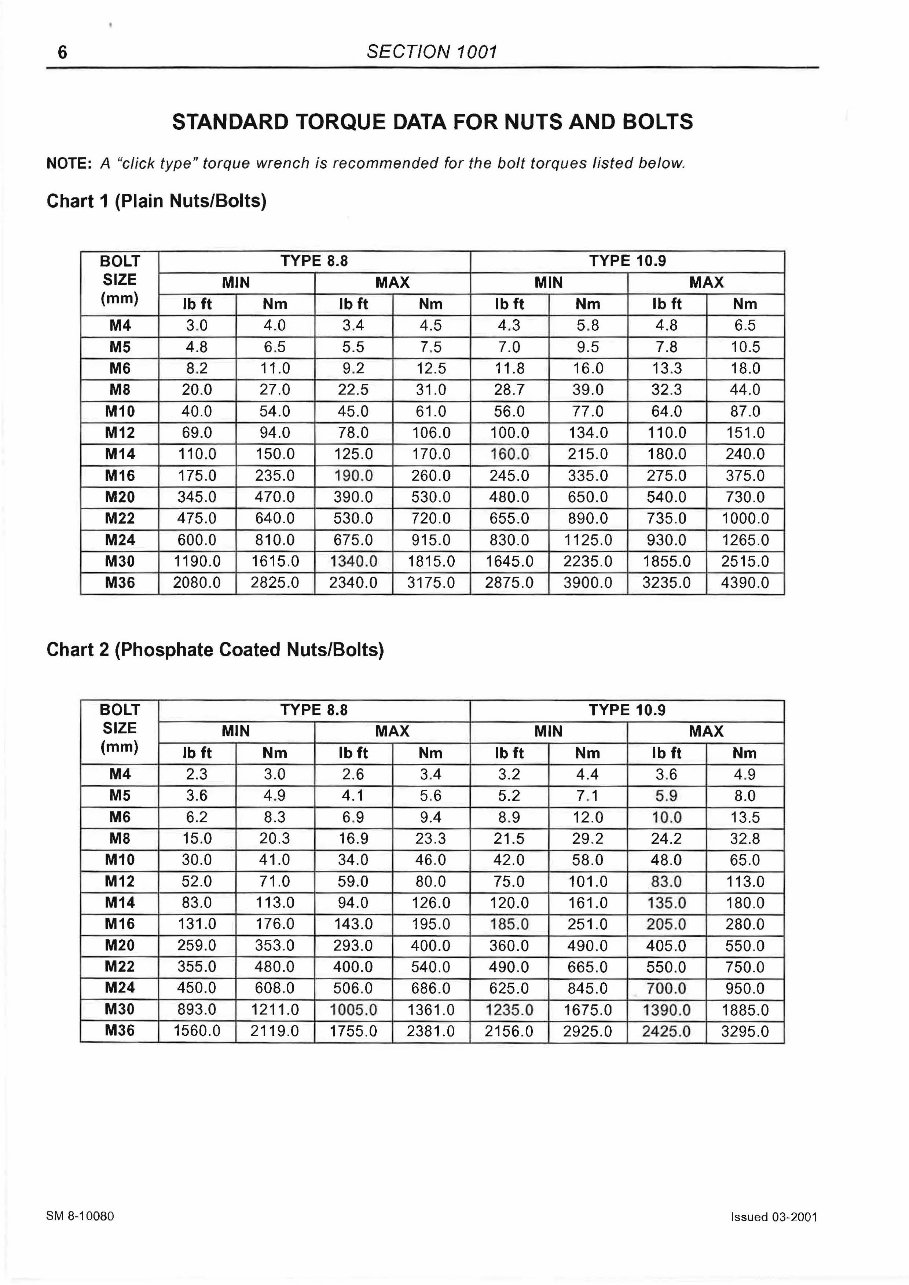

STANDARD TORQUE DATA FOR NUTS AND BOLTS

NOTE: A "click type" torque wrench is recommended for the bolt torques listed below.

Chart 1 (Plain Nuts/Bolts)

BOLT TYPE 8.8 TYPE 10.9

SIZE

MIN MAX MIN MAX

(mm)

Ib ft Nm Ib ft Nm Ib ft Nm Ib ft Nm

M4 3.0 4.0 3.4 4.5 4.3 5.8 4 .8 6.5

M5 4 .8 6 .5 5.5 7.5 7.0 9.5 7 .8 10.5

M6 8.2 11.0 9.2 12.5 11.8 16.0 13.3 18.0

M8 20.0 27 .0 22.5 31 .0 28.7 39.0 32.3 44.0

M10 40.0 54.0 45.0 61.0 56.0 77.0 64.0 87.0

M12 69 .0 94.0 78.0 106.0 100.0 134.0 110.0 151 .0

M14 110.0 150.0 125.0 170.0 160.0 215.0 180.0 240.0

M16 175.0 235.0 190.0 260.0 245.0 335.0 275.0 375.0

M20 345.0 470.0 390.0 530.0 480.0 650 .0 540 .0 730.0

M22 475.0 640.0 530.0 720 .0 655.0 890.0 735.0 1000.0

M24 600.0 810.0 675.0 915.0 830.0 1125 .0 930.0 1265.0

M30 1190.0 1615.0 1340 .0 1815.0 1645.0 2235.0 1855.0 2515.0

M36 2080.0 2825.0 2340.0 3175.0 2875.0 3900 .0 3235.0 4390.0

Chart 2 (Phosphate Coated Nuts/Bolts)

BOLT TYPE 8.8 TYPE 10.9

SIZE

MIN MAX MIN MAX

(mm)

Ib ft Nm Ib ft Nm Ib ft Nm Ib ft Nm

M4 2.3 3 .0 2.6 3.4 3.2 4.4 3.6 4.9

M5 3.6 4 .9 4.1 5.6 5.2 7.1 5.9 8.0

M6 6.2 8.3 6.9 9.4 8.9 12.0 10.0 13 .5

M8 15 .0 20.3 16.9 23 .3 21.5 29.2 24.2 32.8

M10 30 .0 41.0 34.0 46 .0 42.0 58 .0 48 .0 65.0

M12 52.0 71.0 59.0 80 .0 75.0 101.0 83.0 113.0

M14 83.0 113.0 94 .0 126.0 120.0 161.0 135.0 180.0

M16 131 .0 176.0 143.0 195.0 185. 0 251.0 205.0 280.0

M20 259.0 353.0 293.0 400.0 360.0 490.0 405.0 550.0

M22 355.0 480.0 400.0 540.0 490.0 665.0 550 .0 750.0

M24 450.0 608.0 506.0 686 .0 625.0 845.0 70 0 .0 950.0

M30 893.0 1211.0 1005.0 1361 .0 1235.0 1675.0 1390.0 1885.0

M36 1560.0 2119.0 1755.0 2381.0 2156.0 2925.0 2425.0 3295.0

8M 8-10080 Issued 03-2001

You're Reading a Preview

What's Included?

Fast Download Speeds

Online & Offline Access

Access PDF Contents & Bookmarks

Full Search Facility

Print one or all pages of your manual

$50.99

Viewed 14 Times Today

Loading...

Secure transaction

What's Included?

Fast Download Speeds

Online & Offline Access

Access PDF Contents & Bookmarks

Full Search Facility

Print one or all pages of your manual

$50.99

- This comprehensive factory service manual for the McCormick CX Series Tractor Dealer includes detailed instructions, diagrams, and manufacturer specifications for maintaining and servicing the following tractors: CX50, CX60, CX70, CX75, CX80, CX85, CX90, CX95, CX100, and CX105.

- The manual is bookmarked and searchable, allowing for quick navigation to identify service repair procedures.

- It features detailed illustrations, exploded diagrams, drawings, and photos to guide users through the service repair procedures.

- Instant access with no waiting time, available in English language and compatible with all versions of Windows, Mac, iOS, BB, Android, etc.

- The manual covers various sections including General, Electrical, Steering, Transmission, Brakes, Hydraulics, Chassis and Mounted Equipment, and Controller Systems.

- It does not include information on the engine or fuel system, and users are advised to refer to their Engine Service Manual for related procedures.

- The manual is in an easy-to-read file format, viewable on any computer, and can be zoomed and printed as needed.

- Technical details and step-by-step instructions are included, making it useful for both professional mechanics and DIY enthusiasts.

For optimal viewing, the documents may require the newest version of Acrobat Reader. If there are any issues, upgrading to the latest version of Adobe Acrobat Reader is recommended. For any additional manuals needed, feel free to email us as we have thousands available.