Massey Ferguson 50 & 65 Tractor Service & Repair Manual

What's Included?

Fast Download Speeds

Online & Offline Access

Access PDF Contents & Bookmarks

Full Search Facility

Print one or all pages of your manual

MASSEY -FERGUSON

GROUP IV - SECTION A - PART 2

PART2. FRONT AXLE ASSEMBLIES

MF 50 AND 65 TRACTORS

INDEX

Page

Servicing the Wide FrontAxle Assemblies. . . . . . .. 1

Servicing the Si~gle Wheel Front Axle. ......... 7

Servicing the TwinWheel Front Axle........... 8

SERVICINGMF 50 &65 MULTI-PUR

POSE, STANDARD, HI-ARCH,AND

UTILITY FRONT AXLE ASSEMBLIES

Similiarities between front axle assemblies

of the Multi-Purpose, Standard, Hi-Arch and

Utility description permit servicing procedures

of these assemblies to be combined and dis-

cussed as one.

Single wheel front axle assemblies and twin

wheel front axle assemblies each deserve sepa-

rate discussions of servicing procedures. The

procedures concerning axles of this type will

include servicing the front pedestal and support

assemblies.

Consult the Parts Book for information re-

garding the inter-change features of parts.

REMOVING FRONT AXLE AS A UNIT

Front axle assemblies of this description

are removed as a unit when complete dis-

assembly is not necessary.

Support the tractor with front wheel slightly

touching the ground, refer to Fig. 1, and remove:

1. Lower grill panel.

2. Lower steering arm, No.3, from pedestal

shaft.

3. Thrust plate, No. 20, and shims from end

of front pivot pin.

4. Front pivot support.

5. Front axle assembly by rolling the unit

forward and out from tractor (a floor jack

supporting the front axle center member facili-

tates easy handling when following this pro-

cedure). See Fig. 5.

Install the assembly as a unit by reversing

the procedures for removing.

REMOVING FRONT AXLE TO DISASSEMBLE

When front axles of this description are to

be completely disassembled, remove the as-

semblies as follows:

1. Slightly loosen the wheel lug nuts.

2. Support tractor with front wheels clearing

the ground.

3. . Remove:

a. Front wheels.

b. Lower grill panel.

c. Grease fittings.

d. Tie rods ends, Nos. 1 and 9, from

spindle steering arms, Nos. 10 and 27. Fig. 1.

e. Tie rods end No.6, from main steer-

ing arm, No.3.

f. Main steering arm from pedestal shaft.

g. Both R.H. and L.H. axle extension as-

semblies, Nos. 15 and 25, Fig. 1, (if so equip-

ped).

h. Pivot thrust plate, No. 20, and shims,

No. 21.

NOTE: Save the shims.

1

MASSEY -FERGUSON

FRONT AXL E & STEERING

GROUP IV - SECTION A- PART 2

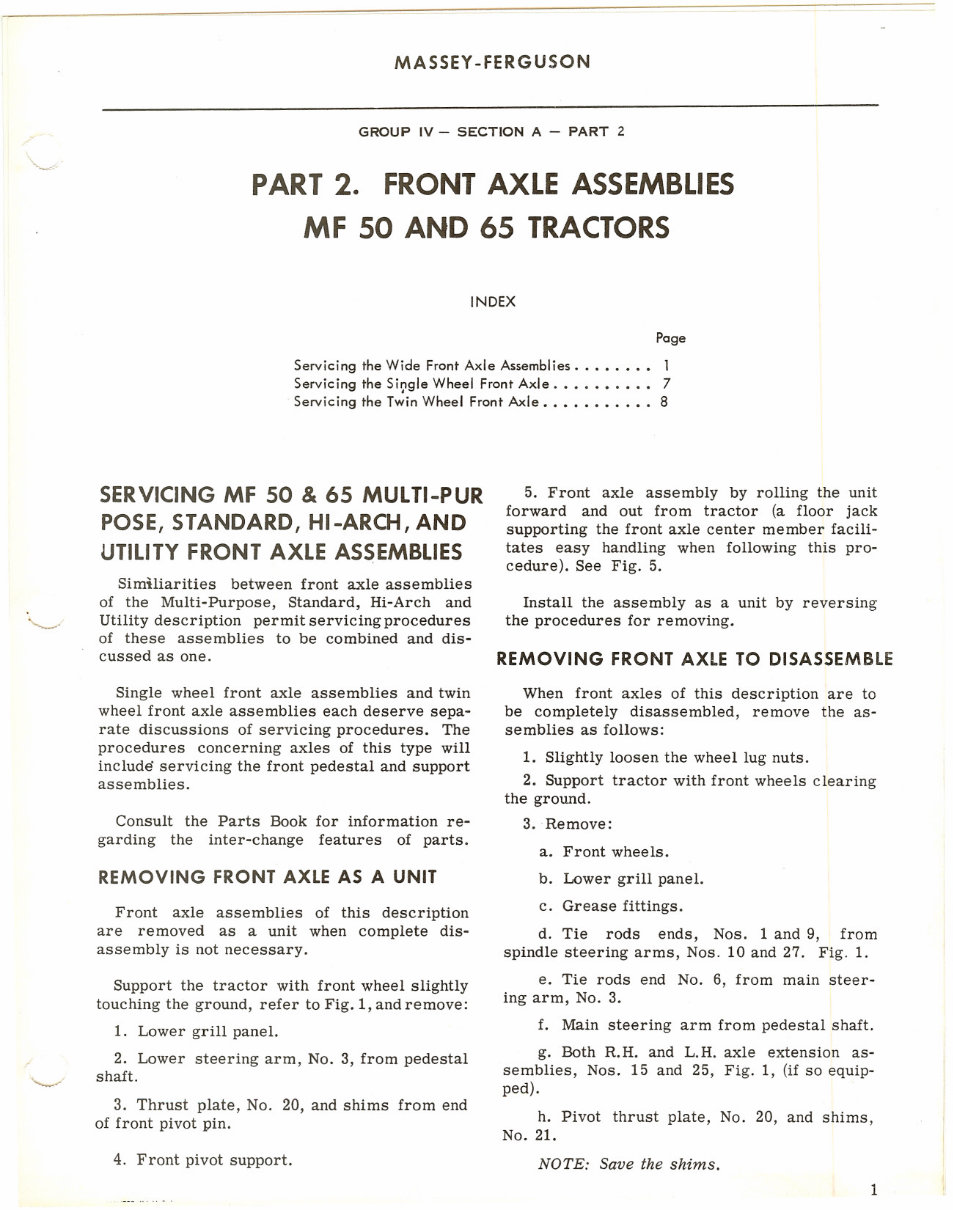

Fig. 3 _ MF 65 Utility Front Axle Assembly Nomenclature.

1. Tie Rod End

2. Spindle Steering Arm

3. Felt Dust Seol

4. Spindle Bushing

5. Spindle Bushing

6. Thrust Bearing

7. Woodruff Key

8. Spindle Assembly

9. Tie Rod Assembly

10. Nut

11. Dust Seal

12. Front Axle Assembly

13. Main Steering Arm

14. Dust Seal

15. Nut

16. Dust Seal

17. Tie Rod Assembly

18. Nut

19. Spindle Steering Arm

20. Dust Seal

21. Felt Dust Seal

22. Spindle Bushing

23. Spindle Bushing

24. Thrust Bearing

25. Woodruff Key

26. Spindle Assembly

27. Pivot Support Assembly

28. Pivot Bushing

29. Shim Pock

30. Thrust Plate

4

GROUP IV - SECTION A - PART 2

MASSEY -FERGUSON

MF 50 & 65 FRONT AXLE & STEERING

1. Tie Rod End

2. Tie Rod Assembly

3. Main Steering Arm

4. DustSeal

5. Nut

6. DustSeal

7. Tie RodAssembly

8. SpindleSteeringArm

9. Nut

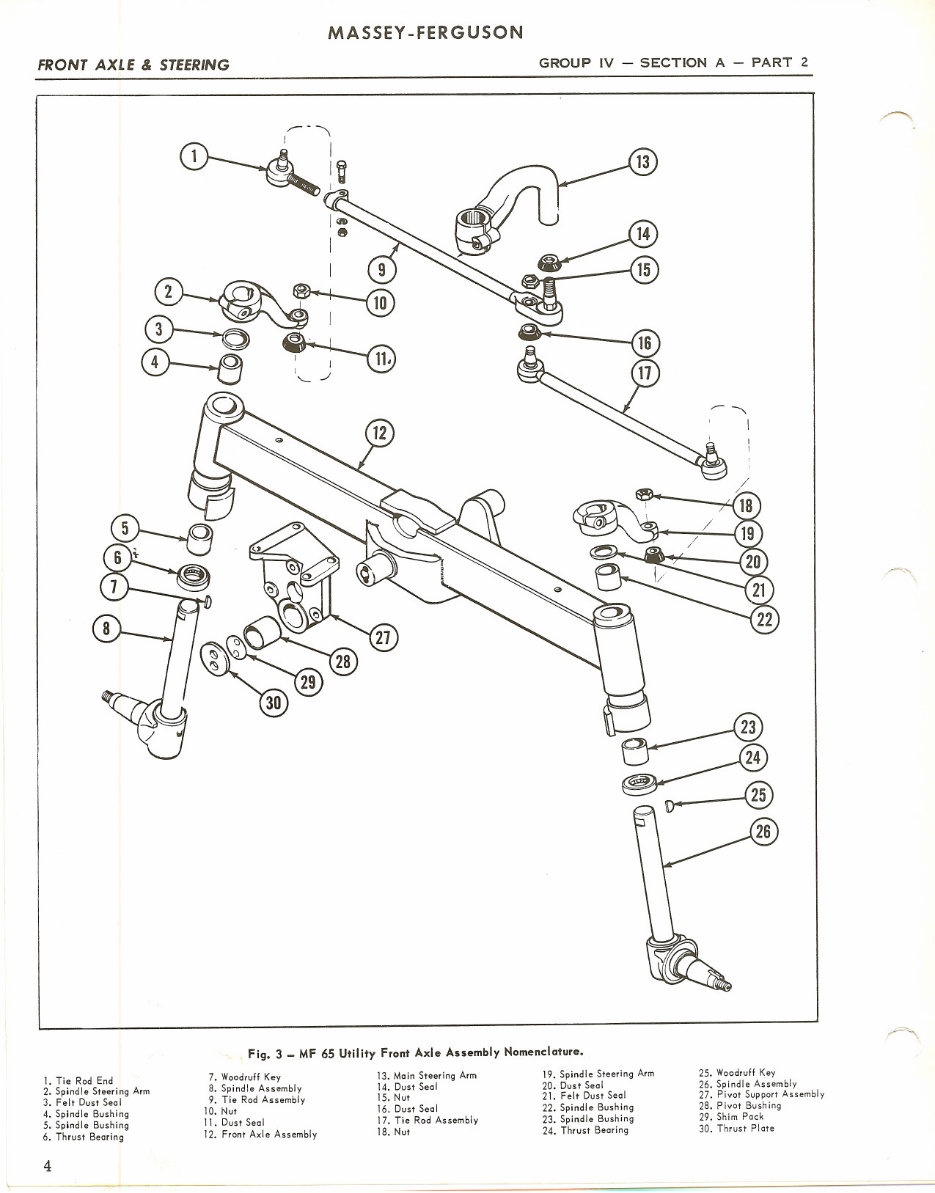

Fig. 4 - MF 50 Multi-Purpose Front Axle Assembly Nomenclature

10. Dust Seal 19. Nut

11. Dust Seal 20. Spindle Steering Arm

12. Spindle Bushing 21. Dust Seal

13. Grease Fitting 22. Du..t Seal

14. Spindle Bushing 23. Spindle Bushing

15. Thrust Bearing 24. Grease Fitting

16. WoodruffKey 25. Spindle Bushing

17. Spindle Assembly 26. Thrust Bearing

18. Front Axle 27. WoodruffKey

28. Spindle Assembly

29. Thrust Plate

30. Shim Pock

31. Pivot Bushing

32. Grease Fitting

33. Axle Support Assembly

entering through grease fitting hole, to

drill a spot in the bore 1/64" deep.

When installing the bushing, line up the

grease holes and insert a long punch to

stake bushing into drill spot.

Replacement pivot bushings are pre-sized

and do not require reaming when installed

carefully with the proper tool.

Spindle bu~hings are renewable but require

sizing after installation.

5

FRONT AXLE & STEERING

MASSEY -FERGUSON

GROUP IV - SECTION A - PART 2

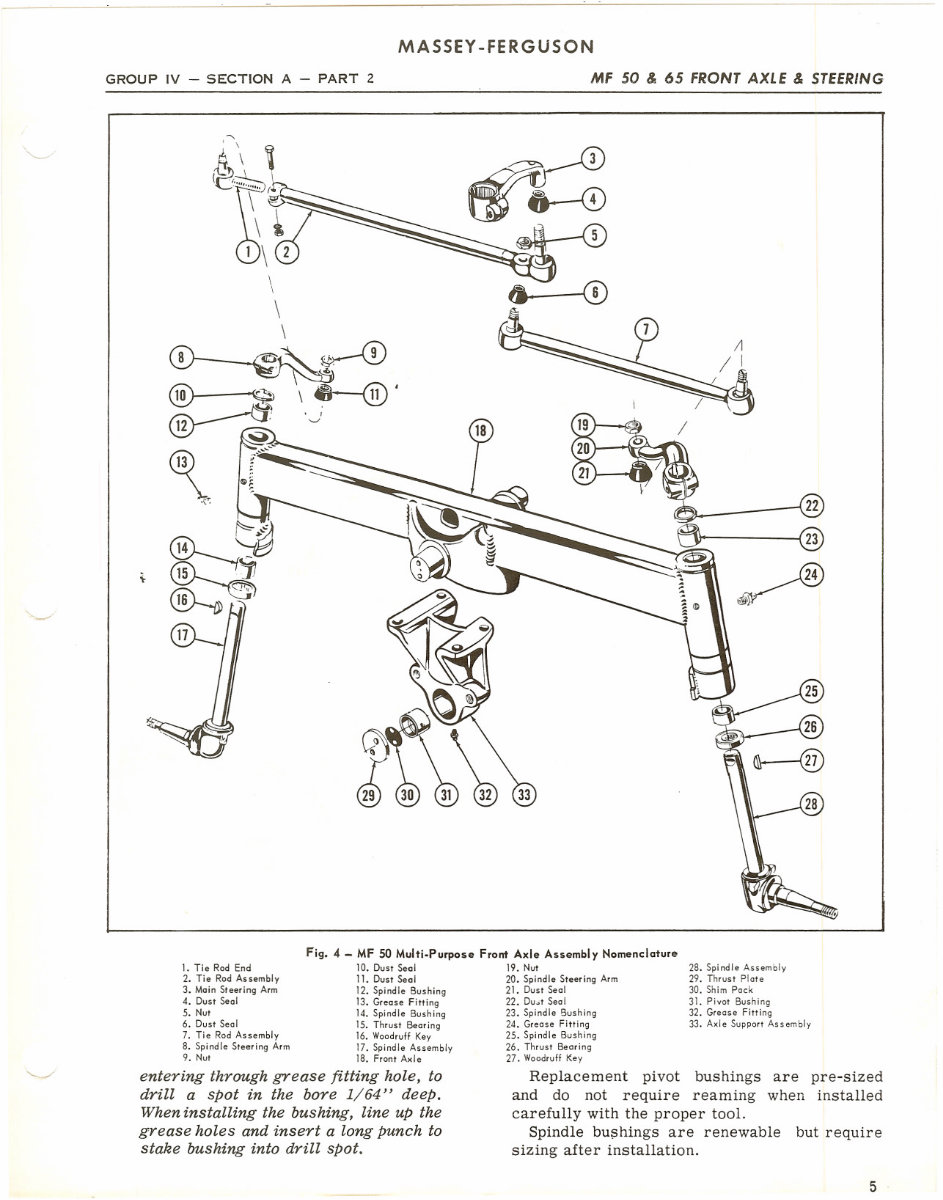

Fig. 5 - Removing Wide Front Axle.Assembly.

Tie rod ends are not adjustable for wear.

Recommen~ed toe-in adjustment is 0-1/4 inch.

End-play adjustment is 0.002-0.008 inch be-

tween support housing front face and front

pivot bracket rear face.

ASSEMBLING THE AXLE

1. Install: (Refer to Fig. 1).

a. Bearing, No. 17, to spindle, No. 19.

b. Spindle bushings, Nos. 14 & 16, and ream

to size.

c. Spindle through axle spindle tube, No. 15.

d. Dust seal, No. 13.

e. Woodruff key, No. 18, to spindle.

f. Spindle steering arm, No. 10, to spindle.

g. Tighten spindle, bolt arm clamp.

h. Repeat procedure for spindle assembly

on other side.

INSTALLING THE AXLE

1. Install: (Refer to Fig. 1).

a. Rear pivot bushing, making certain

grease holes are in alignment.

b. Axle main center-member, No. 24, by

carefully inserting the rear pivot pin of center-

member into support casting pivot pin bore.

6

c. Steering arm, No.3, onto pedestal shaft

and tighten clamp.

d. Front pivot bushing, No. 22, in front

pivot bracket, No. 23.

e. Front pivot bracket to front pivot pin

and attach to support casting.

f. Tie rods, No.6, to main steering arm,

No.3.

g. Axle extensions, Nos. 15 and 25, to main

center-member.

h. Tie rods Nos. 1 and 9, to spindle stee-ring

arms Nos. 10 and 27.

i. Shims, No. 21, (which are available in

0.002,0.005 and 0.010 inch thickness) to the end

of front pivot pin and secure with thrust plate,

No. 20.

NOTE: End-Play shuuld be 0.002-0.008

inch between Pivot bracket and center-

member.

j. Wheels.

k. Lower grill panel.

1. Grease fittings.

2. Lubricate all grease fittings.

3. Adjust toe-in 0-1/4 inch.

....

~_~7

~

.

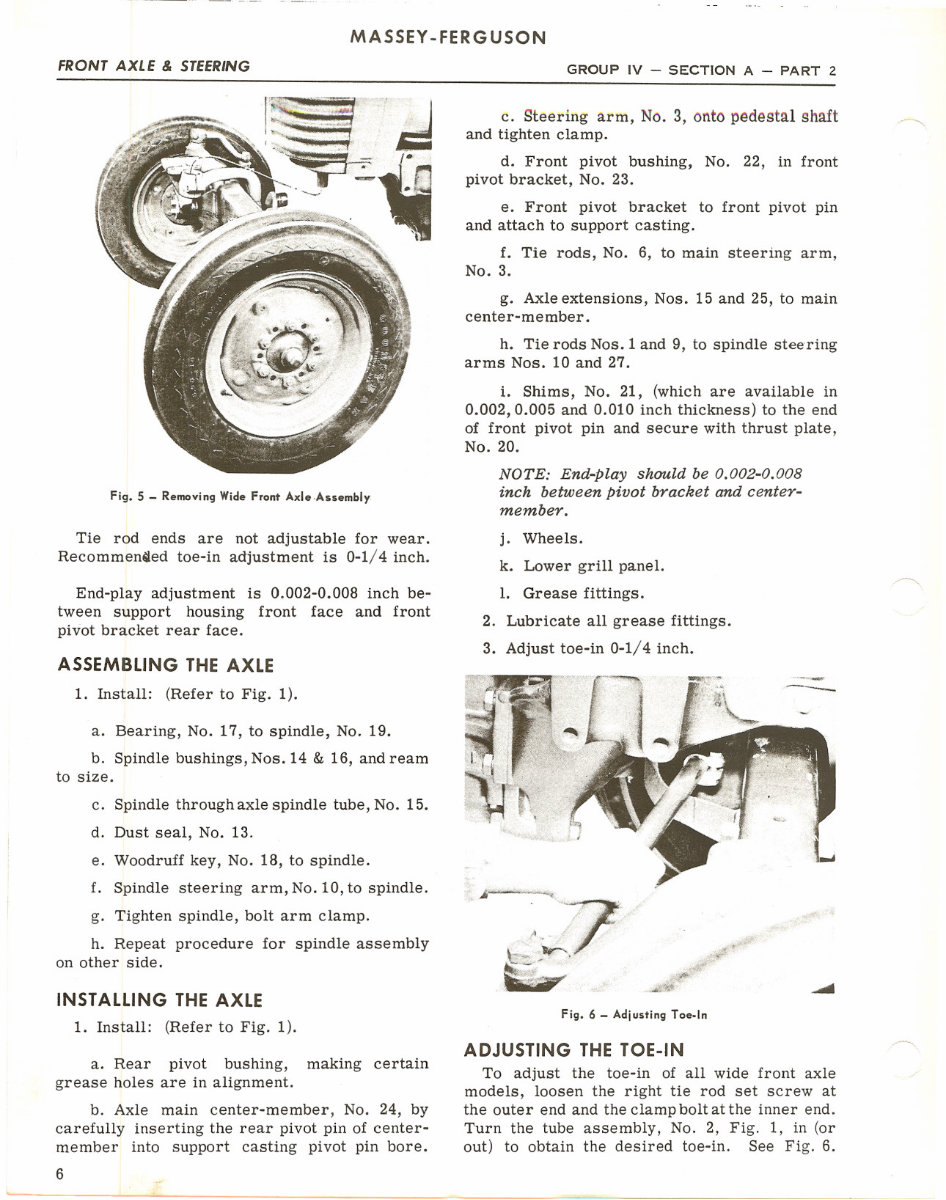

Fig. 6 - Adjusting Toe-In

ADJUSTING THE TOE-IN

To adjust the toe-in of all wide front axle

models, loosen the right tie rod set screw at

the outer end and the clamp bolt at the inner end.

Turn the tube assembly, No.2, Fig. 1, in (or

out) to obtain the desired toe-in. See Fig. 6.

GROUP IV - SECTION A - PART 2

MASSEY-FERGUSON

MF 50 & 65 FRONT AXLE & STEERING

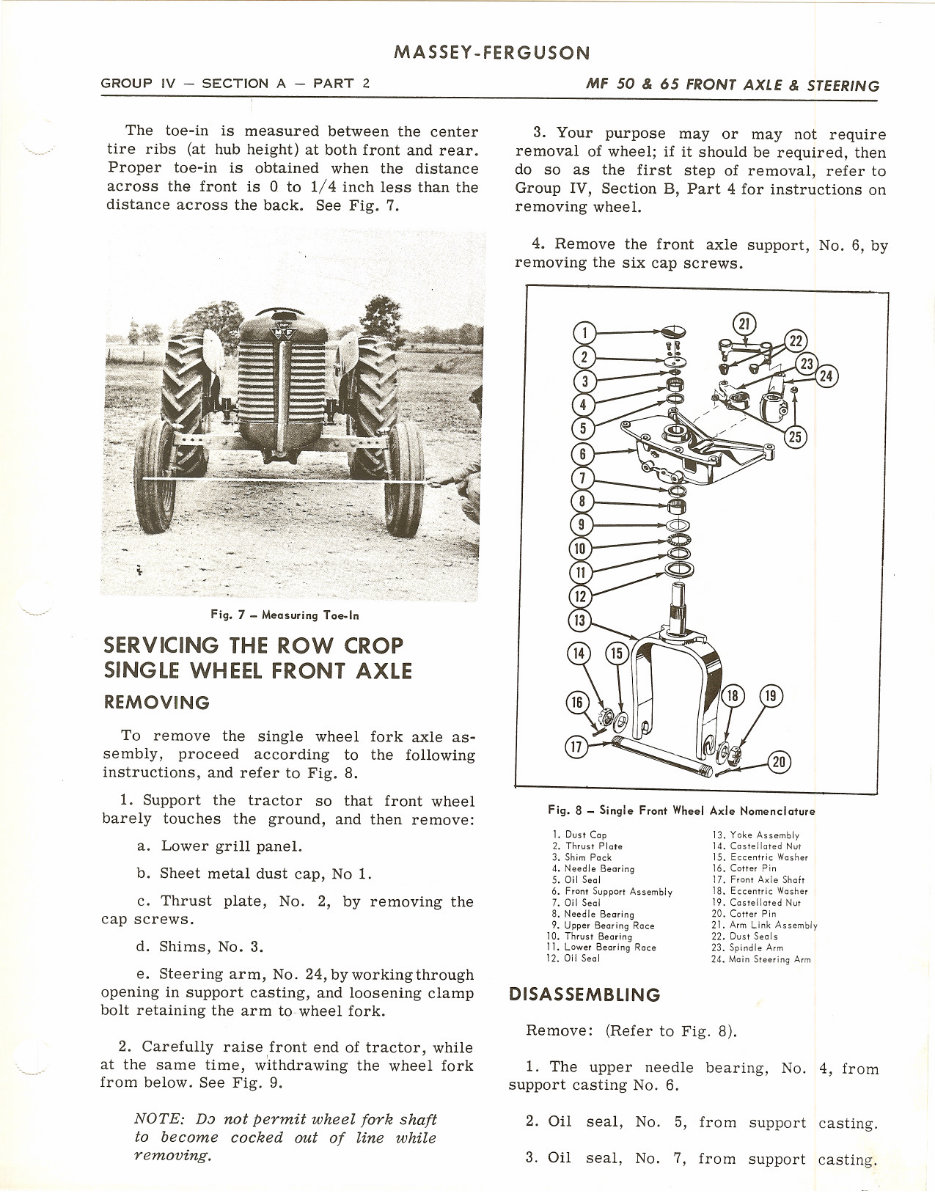

The toe-in is measured between the center

tire ribs (at hub height) at both front and rear.

Proper toe-in is obtained when the distance

across the front is 0 to 1/4 inch less than the

distance across the back. See Fig. 7.

Fig. 7 - Measuring Toe-In

SERVICING THE ROW CROP

SINGLE WHEEL FRONT AXLE

REMOVING

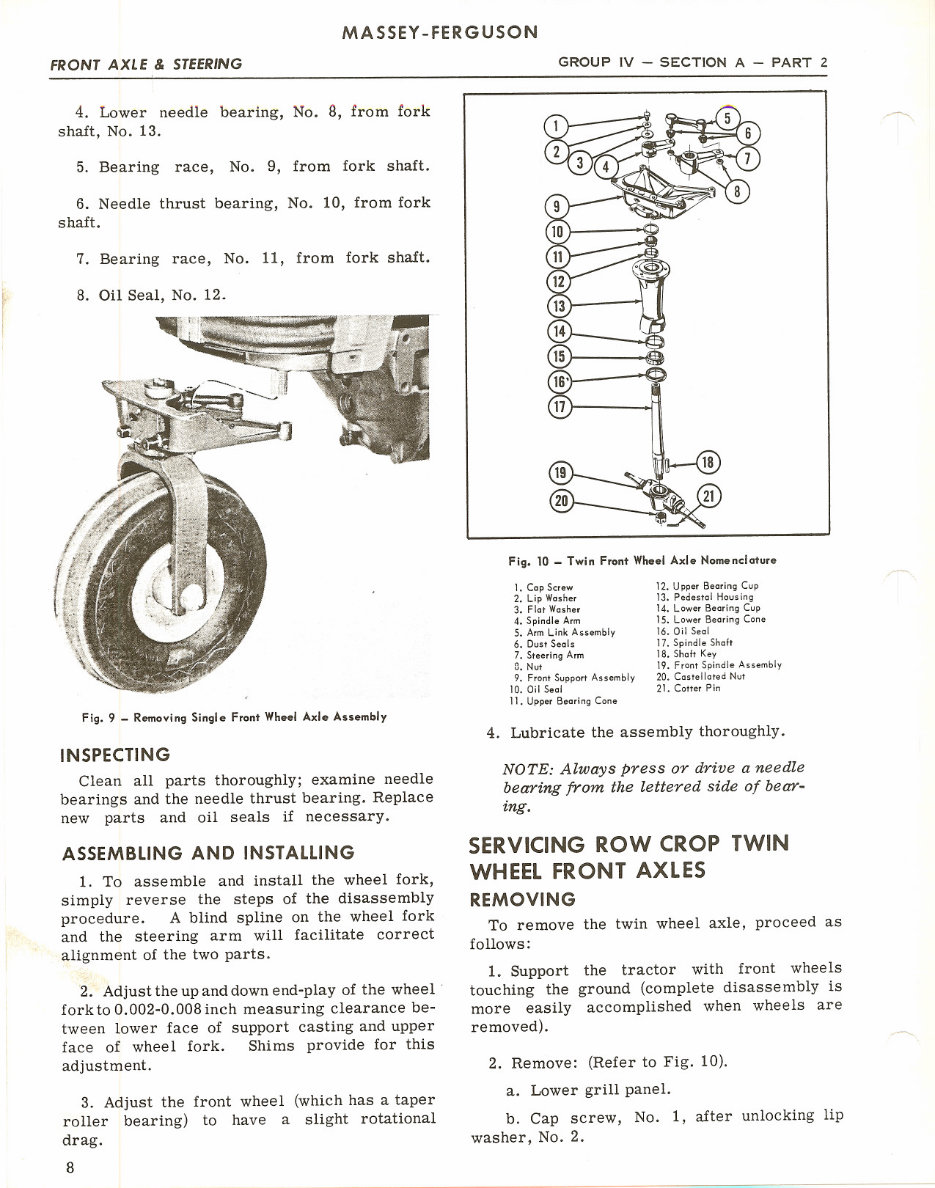

To remove the single wheel fork axle as-

sembly, proceed according to the following

instructions, and refer to Fig. 8.

1. Support the tractor so that front wheel

barely touches the ground, and then remove:

a. Lower grill panel.

b. Sheet metal dust cap, No 1.

c. Thrust plate, No.2, by removing the

cap screws.

d. Shims, No.3.

e. Steering arm, No. 24, by working through

opening in support casting, and loosening clamp

bolt retaining the arm to wheel fork.

2. Carefully raise front end of tractor, while

at the same time, withdrawing the wheel fork

from below. See Fig. 9.

NOTE: D:J not permit wheel fork shaft

to become cocked out of line while

removing.

3. Your purpose mayor may not require

removal of wheel; if it should be required, then

do so as the first step of removal, refer to

Group IV, Section B, Part 4 for instructions on

removing wheel.

4. Remove the front axle support, No.6, by

removing the six cap screws.

Fig. 8 - Single Front WheelAxle Nomenclature

1. Dust Cap

2. Thrust Plate

3. Shim Pack

4. Needle Bearing

5. Oil Seal

6. Front Support Assembly

7. Oil Seal

8. Needle Bearing

9. Upper Bearing Race

10. Thrust Bearing

11. Lower Bearing Race

12. Oil Seal

13. Yoke Assembly

14. Castellated Nut

15. Eccentric Washer

16. Cotter Pin

17. Front Axle Shaft

18. Eccentric Washer

19. Castellated Nut

20. Cotter Pin

21. Arm Link Assembly

22. Dust Seals

23. Spindle Arm

24. Main Steering Arm

DISASSEMBLING

Remove: (Refer to Fig. 8).

1. The upper needle bearing, No.4, from

support casting No.6.

2. Oil seal, No.5, from support casting.

3. Oil seal, No.7, from support casting.

FRONT AXLE & STEERING

MASSEY -FERGUSON

GROUP IV - SECTION A - PART 2

4. Lower needle bearing, No.8, from fork

shalt, No. 13.

5. Bearing race, No.9, from fork shaft.

6. Needle thrust bearing, No. 10, from fork

shaft.

7. Bearing race, No. 11, from fork shaft.

8. Oil Seal, No. 12.

Fig. 9 - RemovingSingle Front Wheel Axle Assembly

INSPECTING

Clean all parts thoroughly; examine needle

bearings and the needle thrust bearing. Replace

new parts and oil seals if necessary.

ASSEMBLING AND INSTALLING

1. To assemble and install the wheel fork,

simply reverse the steps of the disassembly

procedure. A blind spline on the wheel fork

and the steering arm will facilitate correct

alignment of the two parts.

2. Adjust the up and down end-play of the wheel.

fork to 0.002-0.008 inch measuring clearance be-

tween lower face of support casting and upper

face of wheel fork. Shims provide for this

adjustment.

3. Adjust the front wheel (which has a taper

roller bearing) to have a slight rotational

drag.

8

Fig. 10 - Twin Front Wheel Axle Nomenclature

1. Cap Screw

2. Lip Washer

3. Flat Washer

4. Spindle Arm

5. Arm Link Assembly

6. Dust Seals

7. Steering Arm

D. Nut

9. Front Support Assembly

10. Oil Seal

11. Upper Bearing Cone

12. Upper Bearing Cup

13. Pedestal Housing

14. Lower Bearing Cup

15. Lower Bearing Cone

16. Oil Seal

17. Spindle Shalt

18. Shalt Key

19. Front Spindle Assembly

20. Castellated Nut

21. Cotter Pin

4. Lubricate the assembly thoroughly.

NOTE: Always press or drive a needle

bearing from the lettered side of bear-

ing.

SERVICING ROW CROP TWIN

WHEEL FRONT AXLES

REMOVING

To remove the twin wheel axle, proceed as

follows:

1. Support the tractor with front wheels

touching the ground (complete disassembly is

more easily accomplished when wheels are

removed).

2. Remove: (Refer to Fig. 10).

a. Lower grill panel.

b. Cap screw, No.1, after unlocking lip

washer, No.2.

GROUP IV - SECTION A - PART 2

MASSEY -FERGUSON

MF 50 & 65 FRONT AXLE & STEERING

c. Flat washer, No.3.

d. Steering arm, No.7, working through

support casting.

3. Carefully raise tractor, and at the same

time, withdraw from below, the spindle shaft,

No. 17, axle ,No. 19, and wheels as an assembly.

(See Fig. 11).

4. Remove:

a. Lower pedestal assembly, No. 13, from

support casting, No.9.

b. Front axle support, No.9.

Fig. 11 - RemovingTwin Front Wheel Axle Assembly

DISASSEMBLING

Remove: (Refer to Fig. 10)

1. Oil seals, Nos. 10 and 16, from pedestal,

No. 13.

2. Upper and lower bearing cones, Nos.11 and

15, from pedestal.

3. Upper and lower bearing cups, Nos. 12 and

14, from pedestal.

4. Cotter pin and castellated nut, No. 20, from

spindle shaft, No. 17.

5. Axle, No. 19 and key, No. 18, from spindle

shaft.

INSPECTION

Clean all parts thoroughly and examine for

wear. Replace new parts and oil seals if neces-

sary.

ASSEMBLING AND INSTALLING

1. Reverse the disassembly procedures and

tighten cap screw No.1, Fig. 10 until all end-

play is removed from spindle, leaving a slight

drag on the bearings.

2. Blind splines on the lower spindle shaft

in the steering arm provide for a correct

installation.

See Group IV, Section B, Part 4 for wheel

and hub information.

NOTE: When assembling, install new

oil seals, and lightly grease the sealing

surfaces. Rotate the shaft as it passes

through seals.

3. Lubricate the assembly thoroughly.

,

You're Reading a Preview

What's Included?

Fast Download Speeds

Online & Offline Access

Access PDF Contents & Bookmarks

Full Search Facility

Print one or all pages of your manual

$37.99

Viewed 12 Times Today

Loading...

Secure transaction

What's Included?

Fast Download Speeds

Online & Offline Access

Access PDF Contents & Bookmarks

Full Search Facility

Print one or all pages of your manual

$37.99

Massey Ferguson 50 & 65 Tractor Service & Repair Manual is a comprehensive resource that includes:

- General info and service tools

- Maintenance, hydraulics and linkage

- Troubleshooting

- Engine, G-176, GB176, 4A203, AD4203 ENGINES, GAS AND DIESEL

- Transmission including multipower and dual clutch info

- Fuel system and carb

- Lubrication system

- Electrical system and magneto

- Valve adjustment

- Steering system, front end standard hi-arch & utility front axle

- Suspension/brakes/ pto shaft assembly, diff and rear axle

- Body/fenders/lights and implements

- Over 360 pages of essential information

This manual is a valuable resource for both professional mechanics and DIY enthusiasts.