Massey Ferguson MF365 Tractor OEM Service & Repair Manual

What's Included?

Fast Download Speeds

Online & Offline Access

Access PDF Contents & Bookmarks

Full Search Facility

Print one or all pages of your manual

Masse

y

hr3uson

300 Series

Tractor

Workshop Manual

Publication No 1856 558 MS

Published by:

Mass Ferguson (United Kingd) Limited,

Banner Lane,

Covent

CV4 9GF

Published by:

300 SERIES TRACR RHOP MANUAL

•

•

Stion No

1

2

3

4

5

6

7

8

I

Publication No 1856 558 MB

CONTENTS

Description

INTRODUCTION ANO SAFE

SPECIFICATIONS

SPLIING THE TRACTOR - CAB MODELS

ENGINE D

COOLING SYSTEM

FUEL AND AIR SYSTEM

CLUTCHES

GEARBOXES

REAR AXLE, BRAKES AND DIFFERENTIAL

Mass Ferguson (Unit Kingd) Limited,

Banner Lane,

Covent

CV49GF

Fgu a w su ol 1 AGCO pu@ion

300 SERIES TRACTOR WORKSHOP MANUAL

First edition 1986

Second edition 1987

Third edition 1988

Fourth edition 1989

Fifth edition 1990

Sixth edition 1991

Seventh edition 1994

Eighth edition 1996

Published by:

Massey Ferguson (United Kingdom) Limited,

Banner Lane.

Coventry

CV49GF

Massey Ferguson is a wholly owned subsidiary 01 tne AGeD Corporation

1

INTRODUCTION AND SAFETY

Introduction

The purpose of this manual is to assist Dealers and

Distributors in the efficient repair and maintenance of

Massey-Ferguson farm machinery. Carrying out the

procedures as delailed, together with the use of special

tools where appropriate, will enable the operations to be

completed withinJhe time stated in the repair time

schedule.

To assist with locating information, each division of the

manual is precedM by a contents page listing the

operations. Each instruction within an operation has a

sequence number, and to complete the operation in the

minimum time it is essential that these instructions are

performed in numerical sequence commencing at 1

unless otherwise stated. When applicable, these

sequence numbers identify the components in the

appropriate illustration. Where an operation requires the

use of a special tOOl, the tool number is quoted under the

operation heading and is repeated in, or following, the

instruction involving its use.

Indexing

For convenience the manual is divided into parts and

sections, each page bearing a part and section number.

The sections are $ubdivided into numbered operations.

Example: 7A-01 would be Section 7, Part A, Operation

01. This simplifies cross referencing and enables the

subject to be found easily.

Definition of Terms

The operation Clescriptions generally used throughout

the schedules may be defined as follows:-

Removal and Refitment

- Remove and refit an original part or assembly, or a

new part or assembly which does not involve

additional operations or time.

Install

- Install a part or component not previously fitted eg

accessories.

Overhaul

- Remove a part or assembly, dismantle, inspect and

recondition, re-assemble, and re-install making all

necessary adjustments.

Disassembly and Reassembly

- The term indicates the orderly taking apart of an

asssembly into indMduai parts and into the

original assembly.

Adjust

- Make necessary adjustments to restore specified

setting or performance.

Check

- Ascertains if a setting or condition is within limits of

acceptability, either as defined in the manufacturers

specifications or, wihere a dimension is not

specified, in the judgement of the mechanic. The

checking of fixings, eg nuts and bolts, includes

tightening to the specified torque figures listed in this

Manual.

Servicing

- All technical work to maintain the machine in working

order.

M-F 300 Series

Special Tools

Where the use of a special tool is specified in an

operation the tool number will be shown under the

operation heading and also following the instruction

requiring its use.

The use of the special tools mentioned in the text

contributes to a safe, efficient and profitable repair. Some

operations are impracticable without their use, eg the

refitment of the differential unit. Distributors and Dealers

are therefore urged to check their tools against the list

provided. Where necessary, tools may be ordered from:

V L Churchill & Co Ltd, London Road, Daventry,

Northants, England, NN11 4NF. Telephone 0327 704461.

For further details refer to the special tool catalogue for

this range of tractorS, Publication Reference A1038.

Repairs and Replacements

When service parts are required it is essential that only

genuine Massey-Ferguson replacements are used.

Attention is particularly drawn to the following points

concerning repairs and the fitting of replacement parts

and accessories.

Safety features embodied in the tractor may be

impaired if other than genuine parts are fitted.

In cerfain territories, legislation prohibits the fitting of

parts not to the tractor manufacturers specification ..

Torque wrench setting figures given in the Workshop

Manual rilust be strictly adhered to. Locking devices

wihere specified must be fitted. If the efficiency of a

locking device is impaired during removal it must be

renewed.

The tractor warranty may be invalidated by the fitting of

other than genuine Massey-Ferguson parts. All Massey-

Ferguson replacements have the full backing of the

manufacturers warranty. Massey-Ferguson Distributors

and Dealers are obliged to supply only genuine service

parts.

Repair of the Tractor

Follow these important points:

TROUBLE-SHOOT AND CLEAN TRACTOR BEFORE

DISASSEMBLY.

If possible, make a complete diagnosis to determine

extent of repair required. Take precautions, as

necessary, to prevent dirt or other foreign material

entering hydraulic, fuel and air systems.

DO NOT MIX PARTS.

Make particular note of special parts which should not

be interchanged.

DURING DISASSEMBLY, CLEAN PARTS THOROUGHLY

AND INSPECT THEM FOR WEAR, DAMAGE, ETC.

LABEL PARTS. PROTECT PRECISION OR MACHINED

SURFACES.

Issue 3

2 _.

ilNTRODUCTION AND SAFETY

Repair Time Schedule

The operations listed in the Repair Time Schedule refer

to those descril:led in this manual. The time set against

each operation in the schedule is established by

performing the actual operations on standard machines

using special tools where applicable. The Repair Time

Schedule for use with this manual is issued as a separate

publication.

Note: Repair Time Schedules are issued to Massey·

Ferguson Distributors and Dealers only and are not for

general circulation.

Amendments

Under normal conditions revised pages are issued

canying the same number as the existing pages

requiring amendment. The new pages are inserted in

place of the existing ones. The old pages should then be

destroyed.

The issue number is printed on the bottom of each

page, eg Issue 1,2 or 3 etc.

In some cases aditional pages or completely new

sections may be issued. These pages are to be inserted

immediately following the page carrying the next lowest

page number, or section number as appropriate.

. Where new pages are required to be positioned

between existing pages, the new page numbers will

contain a suffix letter ··Example:· New page number

7A·16a. This page is inserted after existing page number

7A·16 and before page number 7A·17. Correspondingly

a further new page numbered 7 A·16b would be

positioned after 7 A·l6a but before 7A·17.

To ensure that a record of amendments to this manual

is readily available, the list of amendments will be

re-issued with each set of revised pages, quoting the

amendment number, date of issue, appropriate

instrucitons and revised page numbers.

Note: Service Bulletins and Amendment Sheets are

issued to the Massey·Ferguson Distributors and Dealers

only and are not for general circulation. .

A

Safety Precautions

Make sure thai all personnel are in a safe position

before starting the engine, or operating ANY of the

controls.

Always stop the engine before leaving the operator's

platform.

Wait for all moving parts to stop COMPLETELY before

starting any work on the tractor.

Before starting service procedures ... attached

equipment should be resting on the ground and all

hydraulic control levers operated back and forth several

times with the engine stopped.

If it becomes necessary to go under a raised

attachment (eg loader) to perform adjustments etc, safety

stands must be used to support the attachment.

Make sure the battery earth cables are disconnected

before working on the electical system.

M·F 300 Series

Keep hands, feet and clothing a safe distance away

from moving belts, pulleys and other moving parts ...

and make sure all safety shields are installed.

Be extra careful when performing any checks,

inspection, adjustments or tests that require operating

the engine, the hydraulic controls, or with the machine in

motion.

Make sure dependable jacks of adequate lifting

capacity and suitable stands (or wooden blocking) are

used to securely block up the machine when removing

any of the wheels or axles.

Before any attempt is made to disconnect or remove

any hydrauliC component, make sure the hydraulic

pressure within the system is relieved ... and the engine

is stopped.

Carry out the repair procedures in a 'common sense"

manner. Safety procedures cannot be over-emphasised

when working on, or around machinery ... especially

when working on engine driven andlor hydraulically

actuated equipment.

Safety also depends upon the skill of the serviceman in

the use of tools and other workshop equipment while

performing the recommended service procedures.

Warning

WARNING

CONTAINS

ASBESTOS

Breathing asbestos

dust is dangerous

to health

Follow safetv

instructions

TL898

Some components on the tractor, such as gaskets

and friction surfaces (brake linings, Clutch Dnings, etc.),

may contain asbestos. Breathing asbestos dust is

dangerous to your health. When service operations are

to be undertaken on parts containing asbestos, the

essential precautions listed below must be observed:

'Work out of doors or in well ventilated area

• Dust found on the tractor or produCed during work on

the tractor must be removed by extraction and NOT by

blOwing.

"Dust waste should be dampened, placed in a sealed

container and marked to ensure safe disposal.

"If any cutting, drilling etc. is attempted on materials

containing asbestos, the item must be dampened and

only hand tools or low speed power tools used •.

Issue 3

e-

•

•

•

3

INTRODUCTION AND SAFETY

Roll Over Protective Structures (ROPS) and/or Safety Frames and Cabs

ALWAYS observe the following

points - these are IMPORTANT.

TIGHTEN ALL BOLTS progressively

and evenly to their recommended

torques.

Install all bolts which project

through inside edges and/or

faces of frames, or cab so that

threaded end of bolt (ie nut

side) is outside frame.

Use only bolts and other

hardware supplied with ROPS

(or cab frame) ... do not

substiMe these fasteners.

Use a flat washer over slotted

holes.

Use lockwasher to secure nuts

... except self-locking type

nut.

DO NOT do any of the following.

Drill the frame structure to

accept equipment such as extra

mirrors or flashing indicators.

Weld anything to the frame.

Straighten a bent frame.

Interchange components with

other frame structures even of

identical type.

Modify the frame structure in

any way without prior approval

of Massey-Ferguson.

Attach other implements, or

fittings to Tractor by means

of the frame structure (or its

attachment points) unless such

attachments are approved by

Massey-Ferguson.

PERSONAL INJURY MAY RESULT IF THESE PRECAUTIONS ARE NOT FOLLOWED.

Look for this symbol to point out important safety precautions. It means - ATTENTION! BECOME ALERT! YOUR

SAFETY IS INVOLVED.

Fluids

Fluids escaping from a very small hole can be almost

invisible, they can penetrate the skin causing serious

injury. Keep hands and body away from pin holes and

nozzles which eject fluids under high pressure. When

checking for leaks always use a piece of cardboard or

wood, never use your hands to find a pressure lead.

If ANY fluid is injected into the skin. it must be attended to

by a doctor immediately.

M-F 300 Series

All fluids must be handled with care. If you are injured by

or swallow any fluid seek medical attention immediately

and show the label on the product.

Take note of the following instructions when handling

fluids:

Antifreeze

When handling antifreeze observe the following safety

precautions:

Warning: It is very important that you read the label on

the container before you add antifreeze to the cooling

system. The safety precautions are as follows:

1. Keep locked up and out of reach of children.

2. Keep only in the original container.

3.

4. protective clothing and gloves.

5. Harmful by inhalation and if swallowed.

6. If swallowed, seek medical advice immediately and

show the label or container.

If you have any queries please contact the supplier.

Issue 3

4

INTRODUCTION AND SAFETY

Engine and transmission oils

Waming: When changing oil is important you follow

some basic rules on personal hygiene, these are as

follows:

1. Before changing the oil use a barrier cream

on your hands

2. Wear protective clothing, overalls, PVC gloves etc.

3. Wash off with soap and water any diny oil which you

come into contact as soon as soon as you have

finished changing the oil.

4. Contaminated clothing must be removed and cleaned.

Prolonged contact with diny oil may affect your health and

is important you follow the above instructions.

TlB94

Starting fluid

Handle starting fluid safely. Starting fluid must only be

used when an ether-start aid is fitted as original equipment

by the manufacturer or when installed by a Dealer as an

accessory. In cases oftractors being fitted with glow plugs

or Thermostart, these MUST be removed prior to

installation of an ether-starting aid.

Warning: It is very important that you read the label on

the can before using, the safety precautions are as follows:

1. Startingfiuid gives off a heavy flammable vapour.

2. DO NOT smoke.

3. DO NOT use nearfireorfiame.

M-F 300 Series

4. Keep away from sources of ignition, store in a cool

place.

5. The container is pressuried, DO NOT expose to heat

or puncture, even ij empty.

6. Keep out ot reach of children.

7. Avoid contact the skin and eyes.

8. Hannful by inhalation and ij swallowed.

9. If swallowed or had oontact with the eyes seek medical

advice immediately and show the label or oontainer.

Brake fluid

Warning: It is very important that the following safety

precautions are observed in relation to bralke fluid:

1. Keep only in the original oontainer.

2. Keep out ot reach of children.

3. Do not mix with other liquids or oils, keep the container

tightly closed.

4. Avoid contact with the skin and eyes.

5. Wear protective clothing and gloves.

6. In the event of eye contact, wash immecfl8lely with

oopious quantities of water then seek medical advice.

7. In the event of skin oontact, thoroughly wash the

affected parts, remove any contaminated clothing,

and apply a conditioning cream ij the skin has a

tendency towards dryness.

8. Hswallowed, do not induce vomiting, seek medical

advice, show label oroontainer.

9. Keep brake system mineral oil clean, contamination

with dust or other materials may resutt in brake failure

or costly repair.

10. Mineral brake oil is NOT COMPATIBLE with rubber

oomponents of other brake systems.

Issue 3

•

•

•

•

.'

•

5

INTRODUCTION AND SAFETY

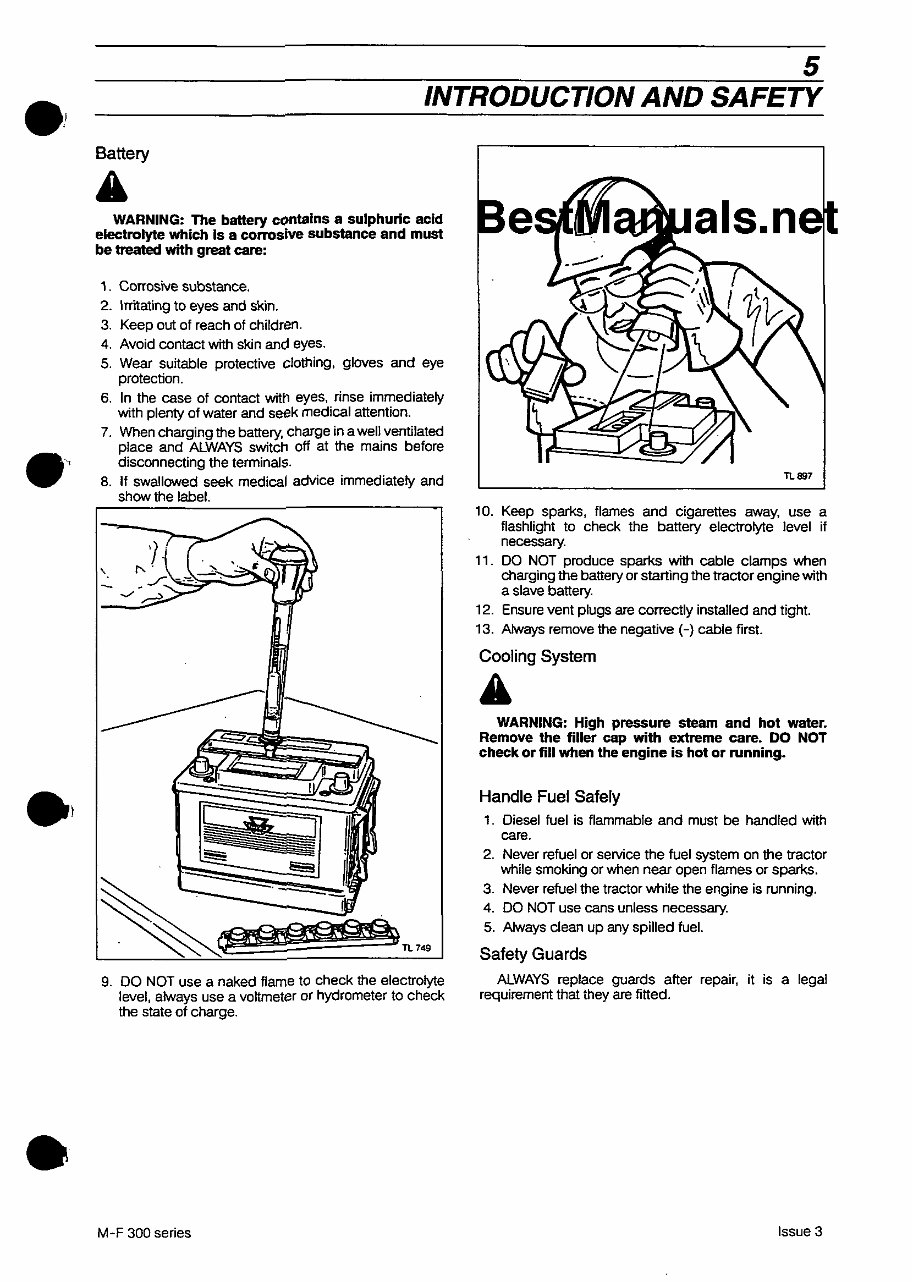

Battery

A

WARNING: The battery contains a sulphuric acid

electrolyte which Is a conosive substance and must

be treated with great care:

1. Corrosive substance.

2. Irritating to eyes and skin.

3. Keep out of reach of children.

4. Avoid contact with skin and eyes.

5. Wear suitable protective clothing, gloves and eye

protection.

6. In the case of contact with eyes, rinse immediately

with plenty of water and seek medical attention.

7. When charging the battery, charge in a well ventilated

place and ALWAYS switch off at the mains before

disconnecting the terminals.

8. If swallowed seek medical advice immediately and

show the label.

9. DO NOT use a naked flame to check the electrolyte

level, always use a vohmeter or hydrometer to check

the state of charge .

M-F 300 series

TL897

10. Keep sparks, flames and Cigarettes away, use a

flashlight to check the battery electrolyte level if

necessary.

11. DO NOT produce sparks with cable clamps when

charging the battery or starting the tractor engine with

a slave battery.

12. Ensure vent plugs are correctly installed and tight.

13. Always remove the negative H cable first.

Cooling System

WARNING: High pressure steam and hot water.

Remove the filler cap with extreme care. DO NOT

check or fill when the engine is hot or running.

Handle Fuel Safely

1. Diesel fuel is flammable and must be handled with

care.

2. Never refuel or service the fuel system on the tractor

while smoking or when near open flames or sparks.

3. Never refuel the tractor while the engine is running.

4. DO NOT use cans unless necessary.

5. Always clean up any spilled fuel.

Safety Guards

ALWAYS replace guards after repair, it is a legal

requirement that they are fitted.

Issue 3

6

INTRODUCTION AND SAFETY

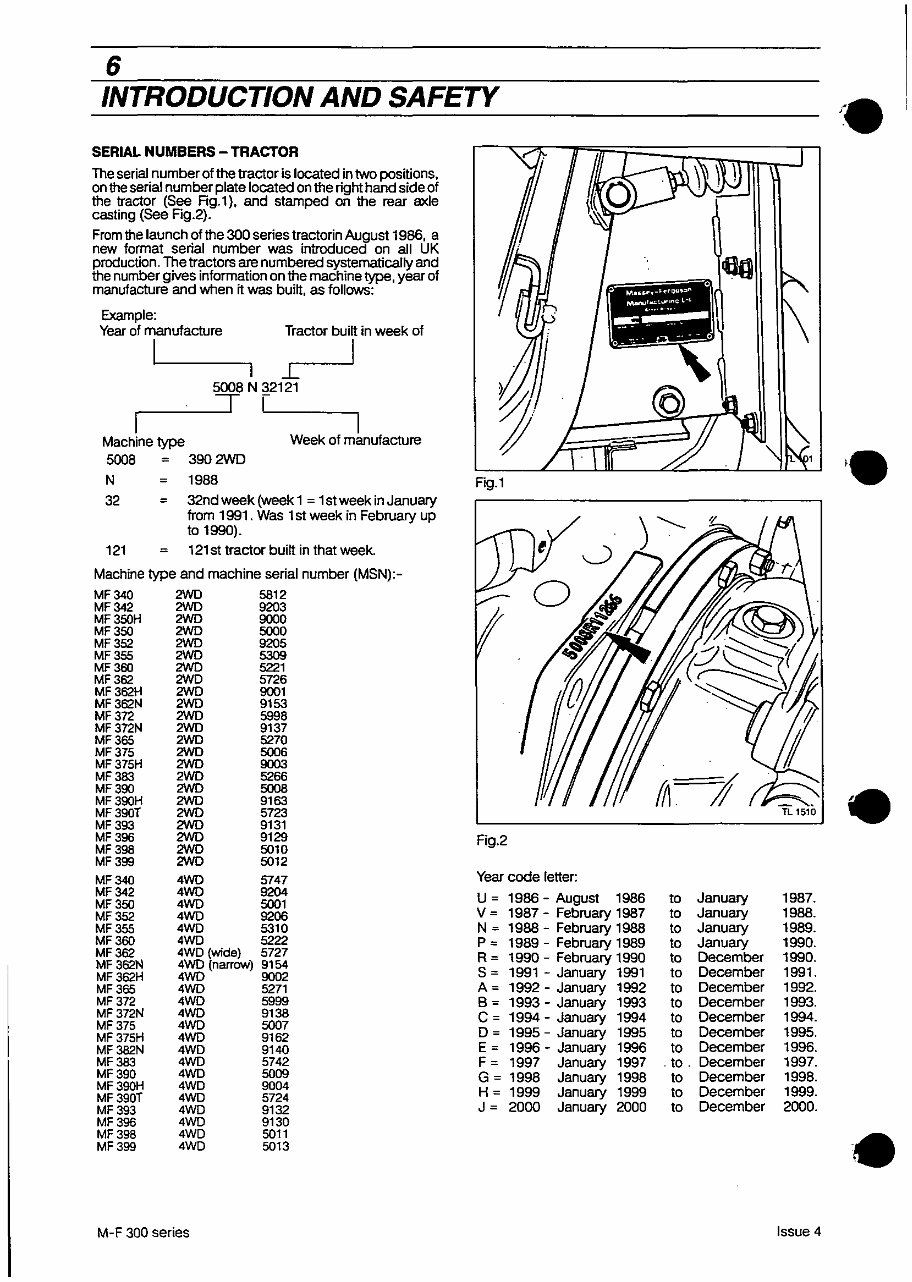

SERIAL NUMBERS - TRACTOR

The serial number of the tractor is located in two posnions.

on the serial number plate located on the right hand side of

the tractor (See Rg.1). and stamped on the rear axle

casting (See Fig.2).

From the launch of the 300 series tractorin August 1986. a

new format serial number was introduced on all UK

production. The tractors are numbered systematically and

the number gives information on the machine type. year of

manufacture and when n was buitt. as follows:

Example:

Vear of manufacture Tractor buitt in week of

I I

'----'1

5008 N 32121

.---__ "T--' LI __ ---,

I

Machine type

Week of manufacture

5008 = 390 2WD

N 1988

32 = 32nd week (week 1 = 1 st week in January

from 1991 . Was 1 st week in February up

to 1990).

121 121 st tractor buitt in that week.

Machine type and machine serial number (MSN):-

MF340 2WO 5812

MF342 2WO 9203

MF350H 2WO 9000

MF350 2WO 5000

MF352 2WO 9205

MF355 2WO 5309

MF360 2WO 5221

MF362 2WO 5726

MF362H 2WD 9001

MF362N 2WO 9153

MF372 2WO 5998

MF372N 2WO 9137

MF365 2WO 5270

MF375 2WO 5006

MF375H 2WO 9003

MF3B3 2WD 5266

MF390 2WO 5008

MF390H 2WO 9163

MF390T 2WO 5723

MF393 2WO 9131

MF396 2WO 9129

MF398 2WO 5010

MF399 2WO 5012

MF340 4WD 5747

MF342 4WD 9204

MF350 4WD 5001

MF352 4WD 9206

MF355 4WD 5310

MF360 4WD 5222

MF362 4WD (wide) 5727

MF362N 4WD (narrow) 9154

MF352H 4WD 9002

MF365 4WD 5271

MF372 4WD 5999

MF372N 4WD 9138

MF375 4WD 5007

MF375H 4WD 9162

MF362N 4WD 9140

MF383 4WD 5742

MF390 4WD 5009

MF390H 4WD 9004

MF390T 4WD 5724

MF393 4WD 9132

MF396 4WD 9130

MF398 4WD 5011

MF399 4WD 5013

M-F 300 series

Fig.2

Vear code letter:

U = 1986 - August 1986

V = 1987 - February 1987

N = 1988 - February 1988

P = 1989 - February 1989

R = 1990 - February 1990

S = 1991 - January 1991

A = 1992 - January 1992

B = 1993 - January 1993

C = 1994 - January 1994

D = 1995 - January 1995

E = 1996 - January 1996

F = 1997 January 1997

G = 1998 January 1998

H = 1999 January 1999

J = 2000 January 2000

'.

ffI

=;f

•

to January 1987.

to January 1988.

to January 1989.

to January 1990.

to December 1990.

to December 1991.

to December 1992.

to December 1993.

to December 1994.

to December 1995.

to December 1996.

. to . December 1997.

to December 1998.

to December 1999.

to December 2000.

•

Issue 4

•

',-- ..

•

7

INTRODUCTION AND SAFETY

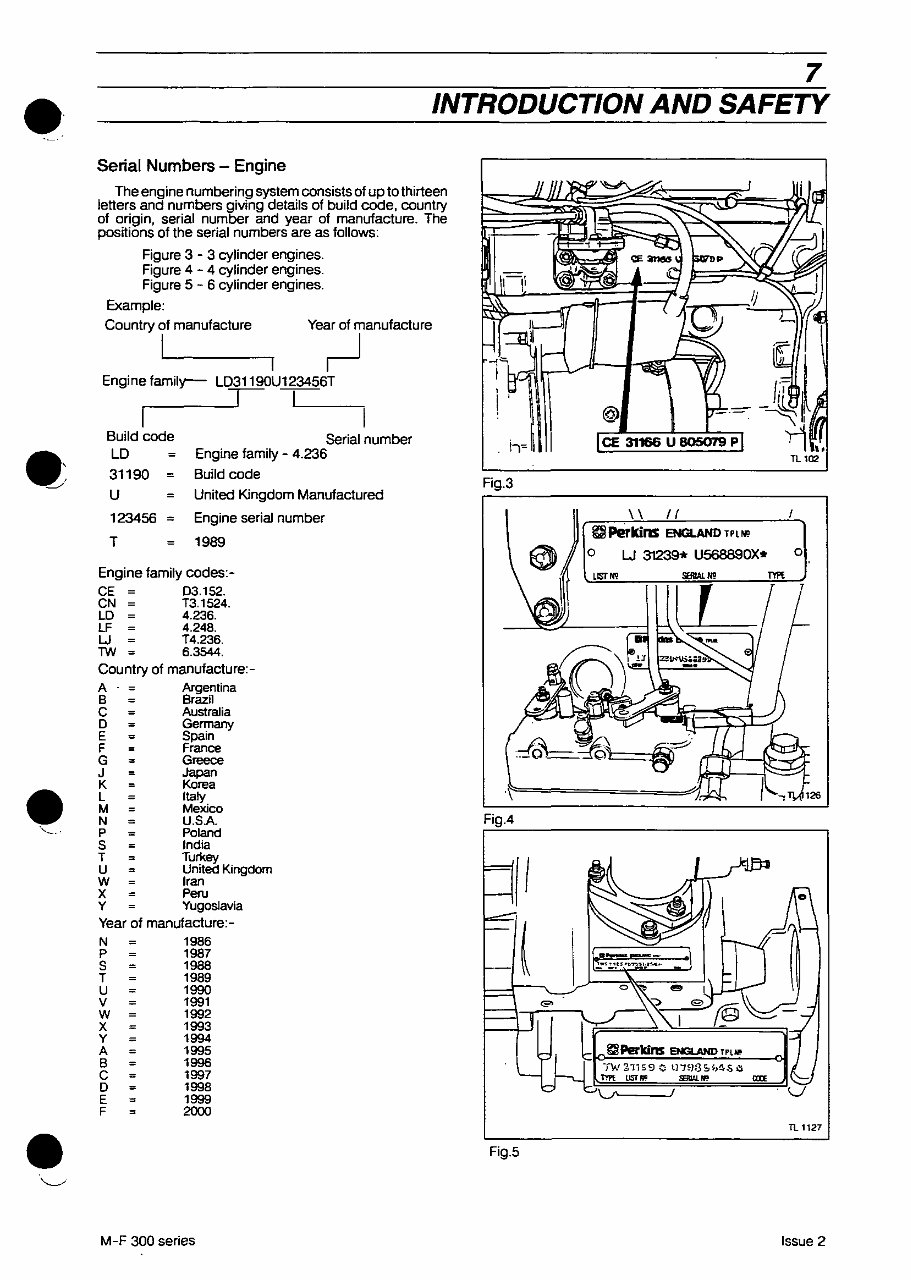

Serial Numbers - Engine

The engine numbering system consists of up to thirteen

letters and numbers giving details of build code, country

of origin, serial number and year of manufacture. The

postlions of the serial numbers are as follows:

Figure 3 - 3 cylinder engines.

Figure 4 - 4 cylinder engines.

Figure 5 - 6 cylinder engines.

Example:

Country of manufacture Year of manufacture

I I

L----_--., I

Engine family-- LD31190UI23456T

Build code

LD

31190

U

Serial number

Engine family - 4.236

Build code

United Kingdom Manufactured

123456 = Engine serial number

T 1989

Engine family codes:-

CE 03.152.

CN T3.1524.

LD 4.236.

LF 4.248.

W T4.236.

TW 6.3544.

Country of manufacture:-

A Argentina

B Brazil

C Australia

o

E Spain

F France

G

J Japan

K Korea

L Italy

M

N U.SA

P Poland

S India

T Tur1<ey

U United Kingdom

W Iran

X Peru

y

Year of manufacture:-

N 1986

P 1967

S 1988

T 1989

U 19!XJ

V 1991

W 1992

X 1993

Y 1994

A 1995

B 1996

C 1997

o 1998

E 1999

F 2000

M-F 300 series

IL-;

II \

'; l

__ I-' 11

@ --

CE 31166 U B05079 P , , ..

TLl02

Fig.3

\\ 1/

gj!Perkins ENGLAND TPUO

o W 31239* U568890X*

o

LJSr"

""'" "

-' [

Fig.4

ENGI.AHD

-rw 2.115 9 0 S f.,4S 1)

T'!'PE USTfIIC !EIIAi."'-' au

TL 1127

Fig.5

Issue 2

You're Reading a Preview

What's Included?

Fast Download Speeds

Online & Offline Access

Access PDF Contents & Bookmarks

Full Search Facility

Print one or all pages of your manual

$39.99

Viewed 10 Times Today

Loading...

Secure transaction

What's Included?

Fast Download Speeds

Online & Offline Access

Access PDF Contents & Bookmarks

Full Search Facility

Print one or all pages of your manual

$39.99

- Get the comprehensive Massey Ferguson MF365 Tractor Service & Repair Manual for all your troubleshooting and replacement needs.

- Includes step-by-step instructions, clear images, and exploded-view illustrations for easy understanding.

- Essential for both professional mechanics and DIY enthusiasts to maintain and service the tractor.

- Regular maintenance is crucial for the durability of your tractor, and this manual provides the manufacturer's recommended troubleshooting charts and replacement procedures.

- Save on repairs, reduce downtimes, and keep your tractor running smoothly with the help of this manual.

- Convenient digital format allows easy access, search, and bookmarking on various electronic devices.

- Printable for those who prefer a physical copy.

- Language: English

- Compatibility: Works on various electronic devices including PC, Mac, Android, and Apple devices.

- Requirements: Adobe Reader (free)

Please note: This is a comprehensive repair manual that provides all the necessary procedures for servicing and maintaining your tractor.