MASSEY FERGUSON MF255 MF265 MF270 MF275 MF290 Shop Manual

What's Included?

Fast Download Speeds

Online & Offline Access

Access PDF Contents & Bookmarks

Full Search Facility

Print one or all pages of your manual

Information and Instructions

This shop manual contains several sections each covering a specific group of

wheel type tractors. The Tab Index on the preceding page can be used to locate

the section pertaining to each group of tractors. Each section contains the

necessary specifications and the brief but terse procedural data needed by a

mechanic when repairing a tractor on which he has had no previous actual

experience.

Within each section, the material is arranged in a systematic order beginning with

an index, which is followed immediately by a Table of Condensed Service

Specifications. These specifications include dimensions, fits, clearances and

timing instructions. Next in order of arrangement is the procedures paragraphs.

In the procedures paragraphs, the order of presentation starts with the front axle

system and steering and proceeding toward the rear axle. The last paragraphs

are devoted to the power take-off and power lift systems. Interspersed where

needed are additional tabular specifications pertaining to wear limits, torqueing,

etc.

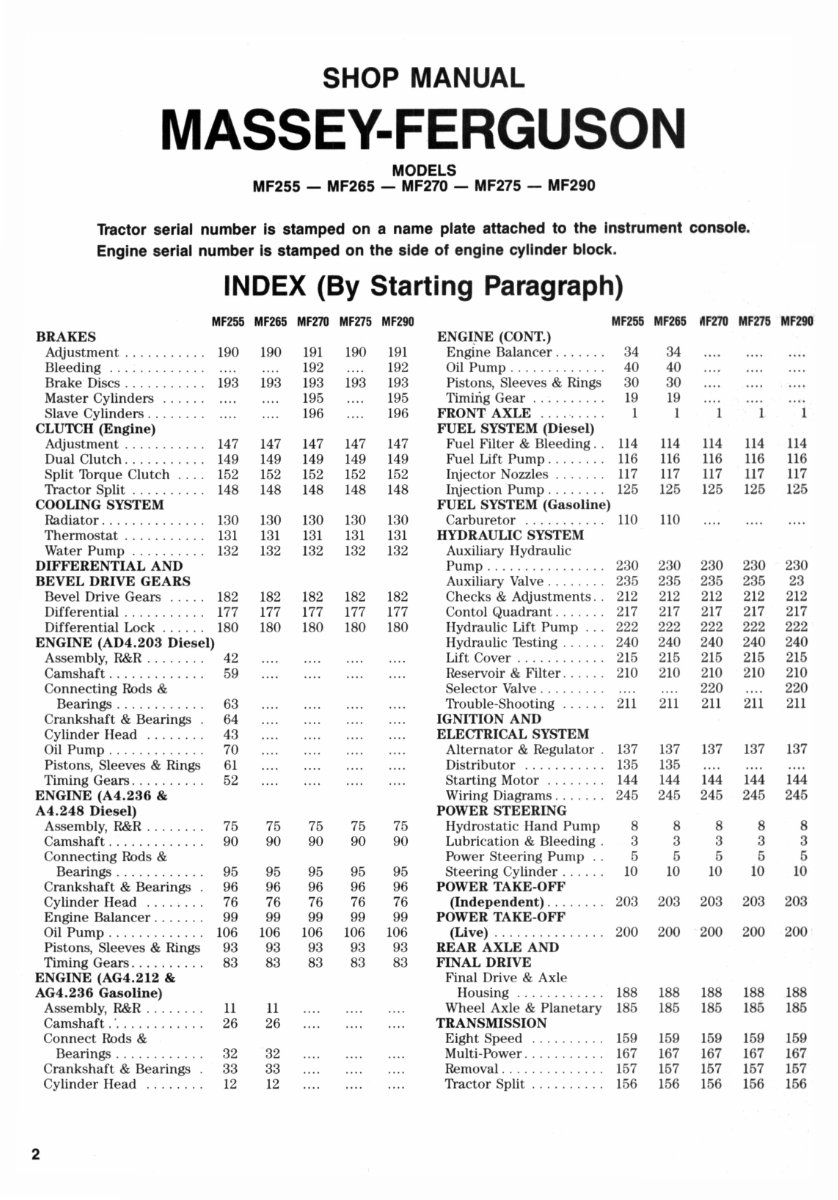

HOW TO USE THE INDEX

Suppose you want to know the procedure for R&R (remove and reinstall) of the

engine camshaft. Your first step is to look in the index under the main heading of

ENGINE until you find the entry “Camshaft.” Now read to the right where under

the column covering the tractor you are repairing, you will find a number that

indicates the beginning paragraph pertaining to the camshaft. To locate this

wanted paragraph in the manual, turn the pages until the running index

appearing on the top outside corner of each page contains the number you are

seeking. In this paragraph you will find the information concerning the removal of

the camshaft.

SHOP MANUAL

MASSEY-FERGUSON

MODELS

MF255 - MF265 - MF270 - MF275 - MF290

Tractor serial number Is stamped on a name plate attached to the Instrument console.

Engine serial number Is stamped on the side of engine cylinder block.

INDEX (By Starting Paragraph)

MF255 MF265 MF210 MFZ75 MF290 MF255 MF265 I'IF21O MF275 MF290

BRAKES ENGI~ (CONT.)

Adjustment .. ...... .. . 190 190 191 190 191 Engine Balancer . . . .... 34 34

Bleeding ......... .. .. 192 192 Oil Pump ...... .. .. . .. 40 40

Brake Discs . . . . . . . . . . . 193 193 193 193 193 Pistons, Sleeves & Rings 30 30

Master Cylinders .. ... . 195 195 Timing Gear ........ .. 19 19

Slave Cylinders ........ 196 196 FRONT AXLE ....... .. 1 1 1 1 1

CLUTCH (Engine) FUEL SYSTEM (Diesel)

Adjustment ... ... .. ... 147 147 147 147 147 Fuel Filter & Bleeding . . ll4 ll4 ll4 ll4 ll4

Dual Clutch .. ......... 149 149 149 149 149 Fuel Lift Pump .. ...... ll6 ll6 ll6 ll6 ll6

Split Thrque Clutch .... 152 152 152 152 152 II\i ector Nozzles ....... ll7 ll7 117 ll7 ll7

Tractor Split ... . ...... 148 148 148 148 148 II\iection Pump ... ..... 125 125 125 125 125

COOLING SYSTEM FUEL SYSTEM (Gasoline)

Radiator .............. 130 130 130 130 1 30 Carburetor ........... llO 110

Thermostat ........... 131 131 131 131 131 HYDRAULIC SYSTEM

Water Pump . ......... 132 132 132 1 32 132 Auxiliary Hydraulic

DIFFERENTIAL AND Pump ........ . ....... 230 230 230 230 230

BEVEL DRIVE GEARS Auxiliary Valve ........ 235 235 235 235 23

Bevel Drive Gears ..... 182 182 182 182 182 Checks & Adjustments .. 212 212 212 212 212

Differential ........... 177 177 177 177 177 Contol Quadrant ....... 217 217 217 217 217

Differential Lock .. ... . 1 80 180 180 180 180 Hydraulic Lift Pump ... 222 222 222 222 222

ENGINE (AD4.203 Diesel) Hydraulic 'Jesting .. . ... 240 240 240 240 240

Assembly, R&R ..... . .. 42 Lift Cover ......... ... 215 215 215 215 215

Camshaft ... ... . ...... 59 Reservoir & Filter ...... 210 210 210 210 210

Connecting Rods & Selector Valve ......... 220 220

Bearings ............ 63 Trouble-Shooting ...... 2ll 2ll 2ll 2ll 2ll

Crankshaft & Bearings . 64 IGNITION AND

Cylinder Head ... . .... 43 ELECfRICAL SYSTEM

Oil Pump ............. 70 Alternator & Regulator . 137 137 137 137 137

Pistons, Sleeves & Rings 61 Distributor ........... 135 135

Timing Gears . .. .. .. . .. 52 Starting Motor ........ 144 144 144 144 144

ENGINE (A4.236 & Wiring Diagrams .. ..... 245 245 245 245 245

A4.248 Diesel) POWER STEERING

Assembly, R&R ........ 75 75 75 75 75 Hydrostatic Hand Pump 8 8 8 8 8

Camshaft ............. 90 90 90 90 90 Lubrication & Bleeding . 3 3 3 3 3

Connecting Rods & Power Steering Pump .. 5 5 5 5 5

Bearings .. ........ .. 95 95 95 95 95 Steering Cylinder ...... 10 10 10 10 10

Crankshaft & Bearings . 96 96 96 96 96 POWER TAKE-OFF

Cylinder Head . ... .. .. 76 76 76 76 76 (Independent) .. ...... 203 203 203 203 203

Engine Balancer ... . ... 99 99 99 99 99 POWER TAKE-OFF

Oil Pump ...... . ...... 106 106 106 106 106 (Live) .... . ...... . .. . 200 200 200 200 200

Pistons, Sleeves & Rings 93 93 93 93 93 REAR AXLE AND

Timing Gears .......... 83 83 83 83 83 FINAL DRIVE

ENGINE (AG4.212 & Final Drive & Axle

AG4.236 Gasoline) Housing ............ 188 188 188 188 188

Assembly, R&R .... . ... II 11 Wheel Axle & Planetary 185 185 185 185 185

Cams haft .' .......... .. 26 26 TRANSMISSION

Connect Rods & Eight Speed .......... 159 159 159 159 159

Bearings ...... . ..... 32 32 Multi-Power ........... 167 167 167 167 167

Crankshaft & Bearings . 33 33 Removal .............. 157 157 157 157 157

Cylinder Head . .... .. . 12 12 Tractor Split .......... 156 156 156 156 156

2

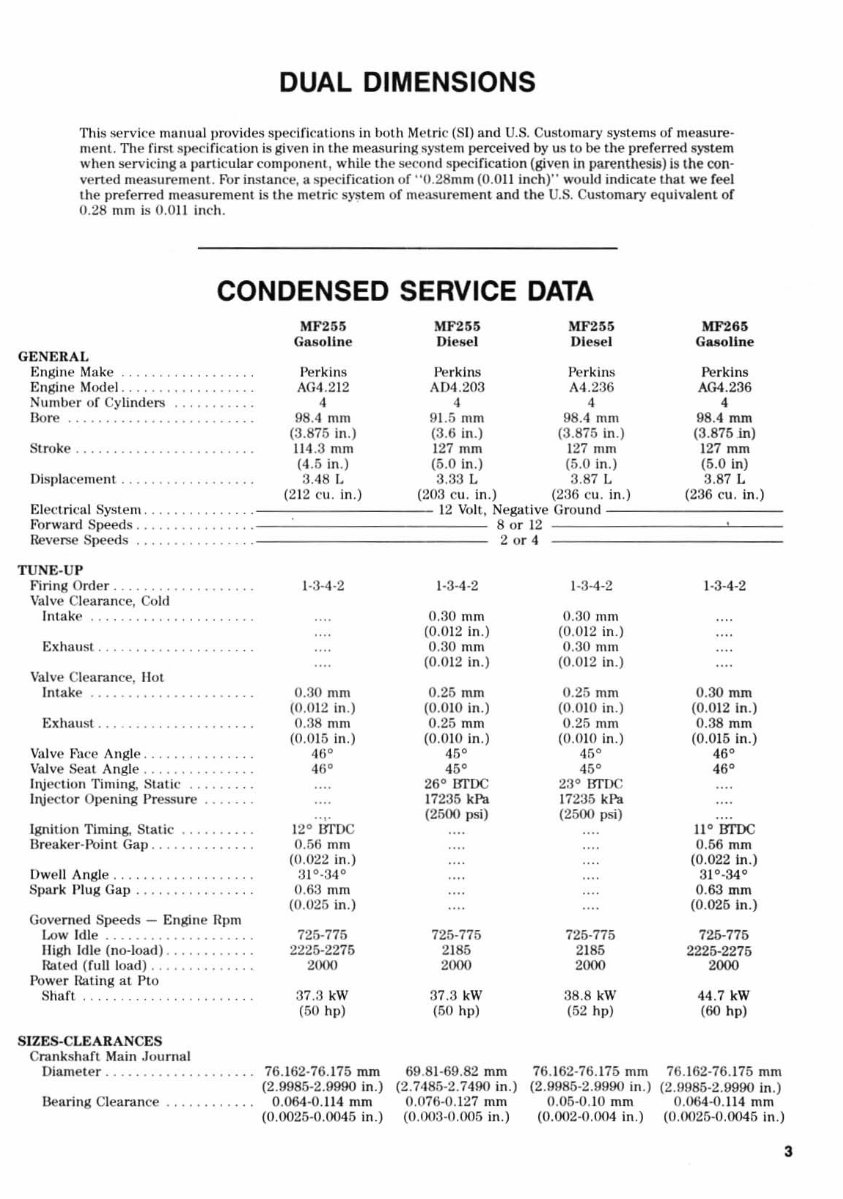

DUAL DIMENSIONS

TIllS service manual provides specifica ti ons in both Metric (81) and U.S. Customary systems of measure-

ment . The first specific ation is given in the measuring system perceived by us LO be the preferred system

when servicing a particular component, while the ~cond specifi cation (given in parenthesis) is the con-

ve rt ed measurement. For instanc~, a specification of ··O.28mm (0. 011 inch )" would indicate that we feel

t.he preferred measurement is the metri c syste m of meas urement and the U.S. Customary e<luivalenL of

0.28 mm is 0.0 11 inch.

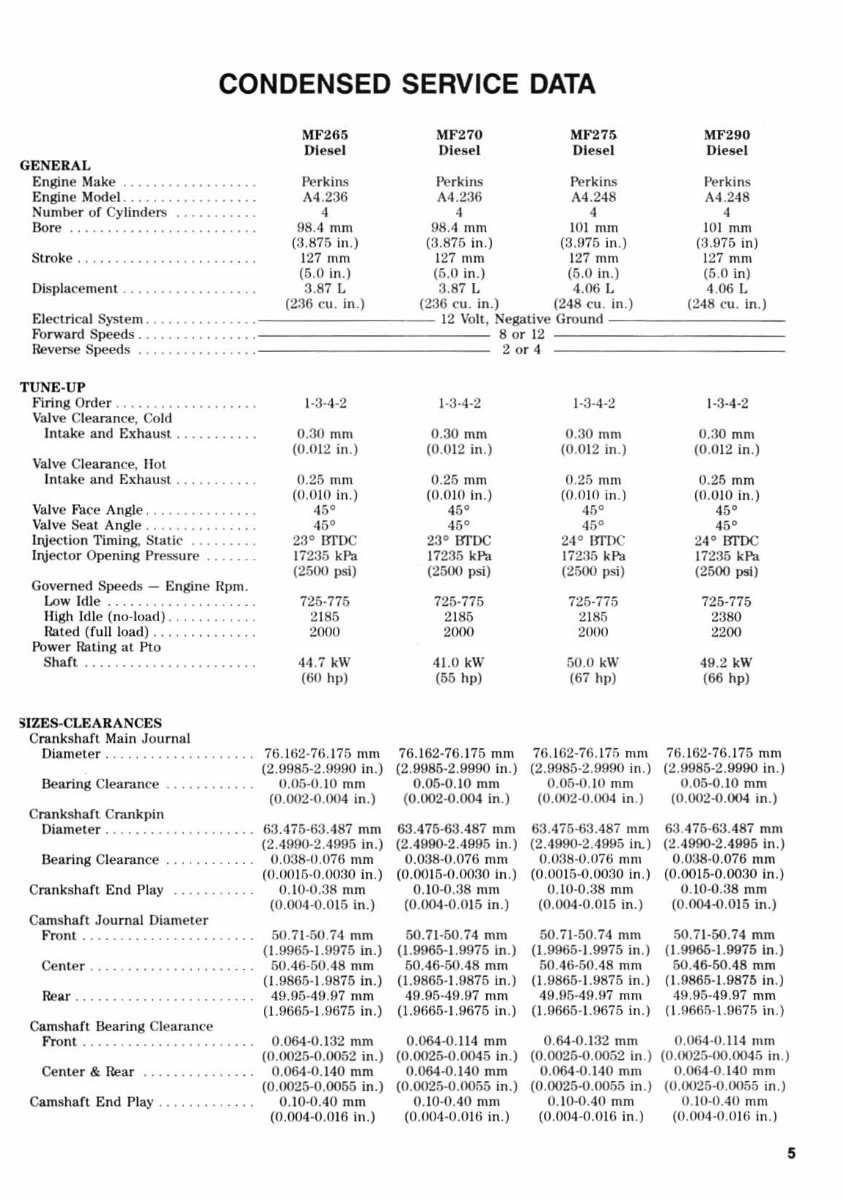

CONDENSED SERVICE DATA

GENERAL

Engine Make ....... .

En gine Model. .

Numbe r of Cylind ers

l10re ....

Stroke ....... .

Displacement .......... •..

El cc lr i(: lIi System ....... , ..

Forward Speeds ... .

Reve~ Speeds

TUNE -U P

l- lri ng Order ......... .

Va lve Clearance, Cold

Intake

Exhaust .

Va lve Cleara nce, 1I 0t

Intake ............... .

Exhaust ... ..

Va lve Face Angle . . ..... .

Va lve Seat Angle ......... .

Injection Timi ng, Stat ic

Il\iector Opening Pressu re ..

Ignition Timing, St atic .... .

Breaker-lloinl Gap ........ .

Dwe ll Angle ............. .

Spark Plug Gap . .... .

Governed Speeds - Engine npm

Low Id le ......... .... . .

IIigh Idle (no-load) ....... .

Rated (rull load) ..... .

'lower Rating at Pto

Shaft . . . ........ .. .... .

SIZES-C LEARANCES

Crankshaft M ain Jountal

Diameter ............ .

Hearing Clearance .....

MF265

Gaso li ne

P erki ns

AG4 .212

4

98.4 mm

(3.875 in.)

114 .3 mm

(4 .5 in .)

3.48 L

(2 12 cu. in.)

1-3- 4 -2

0.30 mm

(0 .012 in .)

0.38 mm

(0 .0 15 in .)

46°

46°

.. ,.

12° BTDC

0.56 mm

(0.022 in .)

31 °· 34 °

0.63 mm

(0.025 in.)

725-775

2225·2275

2000

37 .3 kW

(50 hpl

76.162-76. 175 mm

(2 .9985·2.9990 in.)

0.064·0. 114 mm

(0.0025-0.0045 in.)

MF265 MF255

Diese l Diese l

Perkins P erki ns

, \D4 .203 M .236

4 4

9 1. 5 mm 98.4 mm

(3.6 in.) (3.875 in.)

127 mm 127 mm

(5.0 in .) (5.0 in.)

3. 33 L 3.87 L

(203 cu. in .) (236 cu. in .)

12 Volt . Negat ive Grou nd

8 or 12

2 or 4

1-3-4 -2

0.30 mm

(0.0 12 in .)

0.30 mm

(0.012 in.)

0.25 mm

(0.010 in.)

0.25 mm

(0.010 in.)

46'

45 '

26° BTOC

17235 kPa

(2500 psi)

725-775

21 85

2000

37.3 kW

(50 hll)

69.81-69.82 mm

(2.7485·2.7490 in .)

0.076-0.127 mm

(0.003-0.005 in.)

1 -3 -4-2

0.30 mill

(0.012 in.)

0.30 mm

(0.012 in .)

0.25 mm

(0.010 in.)

0.25 mm

(0.010 in.)

45°

45'

23° ErrDC

17235 kPa

(2500 psi)

725-775

21 85

2000

38 .8 kW

(52 hll)

76.162-76.175 mm

(2.9985-2.9990 in.)

0.05-0.10 mm

(0.002-0.004 in.)

MF26,

Gasoline

Pe rkins

AG4.236

4

98.4 mm

(3.875 in)

127 mm

(5.0 In)

3.87 L

(236 cu. in .)

1-3-4-2

0. 30 mm

(0.012 in.)

0.38 mm

(0.015 in.)

46 '

46'

1l

0

1JI1X;

0.56 mm

(0.022 In.)

31°_34°

0.63 mm

(0.025 in.)

726-776

2225-2276

2000

44 .7 kW

(60 hp j

76.162-76. 175 mm

(2.0985-2.9990 in .)

O.064-0. 114 mm

(0.0025-0.0045 in.)

3

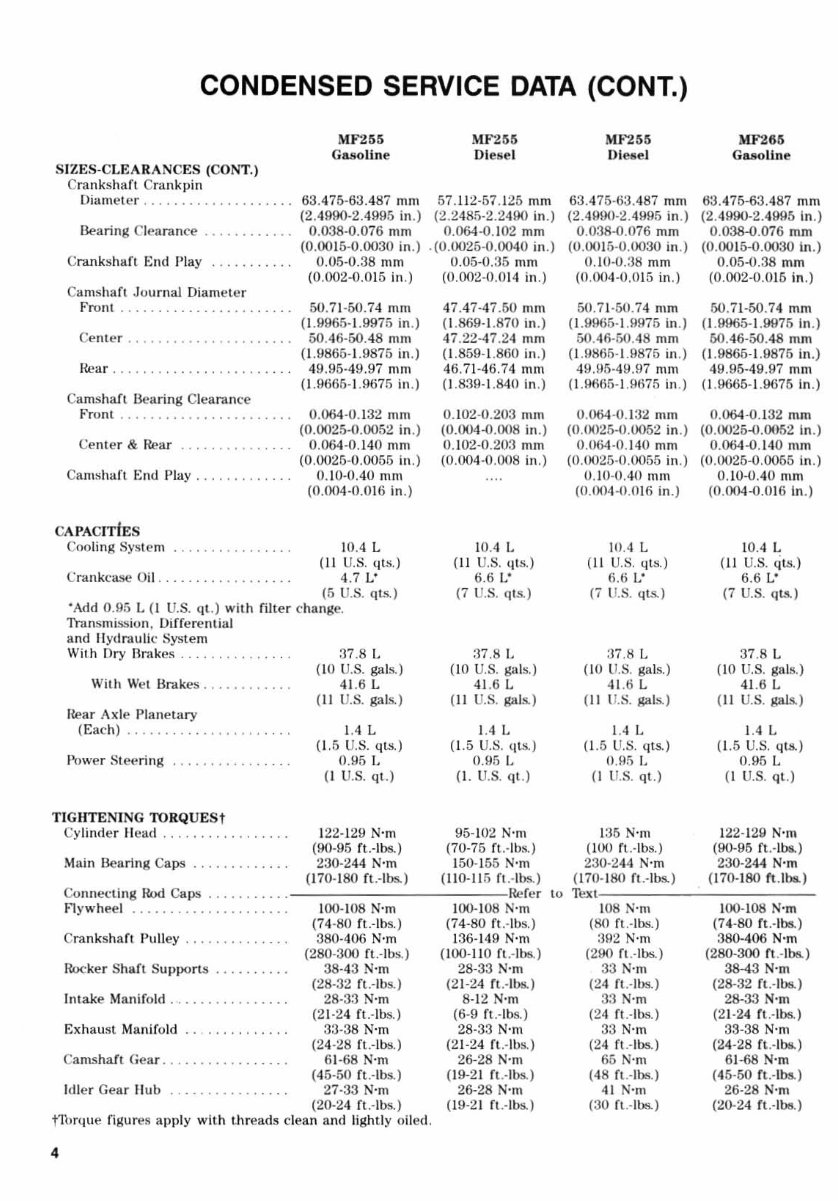

CONDENSED SERVICE DATA (CONT.)

MF255 MF'l55

MF2.'

GasoUne Di ese l Dl etlel

SIZES-CLEARANCES (CONT.)

Crank s hafl Crank pi n

Diameter ... .......... 63.475-63.487 mill 57. 112 -57.125 mm 63.475 -63.487 mm

(2.4990-2.4995 in .) (2.2485-2.2490 in.) (2.4900-2 . 4995 in .)

Bearing Cl earance ....... ... 0.038-0.076 mm 0.064 -0 .102 mm 0.038-0.076 mm

(0.0015-0.0030 in .) .(0.0025-0.0040 in.) (0. 001 5-0.0030 in .)

C nmkshaft End Play 0.05-0.38 mill

(0.002-0.015 in.)

Ca ms haft Journal Diameter

Front .... 50 .71 -50.74 mm

(I .9965-1.9975 in .)

Center .. 50.46-50.48 mm

( 1. 9865- 1. 9875 ill .)

H ea r . . . ............... 49 .95·49,97 mm

( 1. 9665-1.9675 in .)

Camshaft Bearing C1 (!ard. n ce

Front ......... ........... 0.064-0. 132 mill

(0.0025-0.0052 in .)

Ce nl er & Rear ........... 0.064-0.140 mOl

(0,0025-0,0055 in.)

Camshaft End Play 0. 1O-0 AO m ill

(0.004-0.016 ill .)

CA PACITiES

Cooling System lOA L

(II U.S. qts ,)

Cr"mkcase Oil .. . 4.7 L'

(5 U.S. qls. )

'Add 0 .95 L {I U.S. (11.) with riller c hange.

Transmission, Differentilll

and lI ydraulic System

With Dry Rrakes ...... .

With Wei Br-.:tkes .. , .. ... .

Hear Axle Plane t ary

(Eac h) .... . ..... . ...... .. .

Power Steering ....

:)7 .8 L

(10 U.S. gals.)

41.6 L

(II U.S. gals. )

IA L

(1.5 U.S. qts.)

0.95 L

(J U.S. ql .)

TIGHTENING TO RQUESt

Cy linder Head, ..... . . .

Main Bearing Caps . , ....

Connect ing Hod Ca ps .. .

flywhe el ................ _ .. .

Crankshaft Pulley , .

Rocker Shllft Su pports .....

In take Manifold ..

Exhaust Manifold

Ca mshafl Gear ....

hile r Gear Hub

122- 12 9 N·m

(90-95 ft.-Ibs.)

230-2 44 N·m

(l70-ISO ft.-lbs.)

100-108 N-m

(74-80 ft.-Ibs.)

380-406 N·m

(2SO-3OO ft.-Ibs.)

38-43 N-m

(2S-32 ft.-IllS.)

28 - 33 N·m

(2 1-24 fl.-Ills.)

33-38 N·m

(24- 28 ft.-Ibs.)

61-68 N'm

(45- 50 ft .- Ibs.)

27-33 N·m

(20-24 fl.-Its.)

f1brque figures apply with Ulreads clean and light ly oiled.

4

0.05-0. 35 mm

(0.002-0. 014 in .)

47.47-47.60 mill

( 1. 869-1.870 in.)

47 .22-47.24 mm

( 1. 859- 1. 860 in . )

46.71 -46 .74 mm

(1 .839-1.840 in .)

0.102-0.203 mm

(0.004-0.008 in.)

0. 10·.2-0 .203 mill

(0. OO4 -0.008 in.)

lOA L

(J I U.S . qLS. )

6.6 I:

(7 U.S. (lIS.)

:]7.8 ].

(10 U.S. gals.)

41 .6 L

(II U.S. gal s..)

1.4 L

( 1. 5 U.S. ti ts.,

0.95 L

(J. U.S. (II. )

95-102 N·m

(70-75 ft .- Ibs.)

150- 155 N·m

(l1O-1l 5 fl.-I bs.)

Refer

lOO- IOS N·m

(74-80 fl.-Ibs.)

136-149 N·m

(100-110 fl. -Ibs. )

2S-33 N·m

(21-24 rt .- Ibs..)

8-12 N·m

(6-9 rl.-Ibs.)

2S-33 N'm

(21-24 ft.-lbs.)

26-28 N'm

(19-2 1 f t. -Ibs.)

26-28 N· m

(19-2 1 ft. -Ibs.)

0. 10-0.38 mm

(0.004-0.015 in.)

50.71·50.74 mm

( 1. 9965-1.1)975 In .)

5OA6-50 .48 mm

(1.9865· 1. 9875 in.)

49JJ5 - 49 .97 mm

(1.9605- 1. 9675 in.)

0. 064 -0. 132 mm

(0.0025-0.0052 in .)

0.064-0.140 mm

(0.0025-0.0055 in.)

O. lO-OAO mm

(0.004-0.0 16 in .)

iliA L

(II U.S. qLS.)

6.6 L'

(7 U.S. qts. )

: 17 .8 L

( 10 U.S. gals.)

41.6 L

(II I1.S. gal s..)

1.4 L

(1.5 U.S, (Its.)

0. 95 I.

(l U.S. ql .)

135 N·m

(lOU rl.·lbs.)

230-24'1 N·m

(170-180 fl. -Ibs. )

to Text

lOS N'm

(SO fl. -Ibs. )

392 N·m

(290 fl.-Ibs.)

33 N·m

(24 ft .· lbs. )

33 N- m

(24 fl.-Ibs.)

33 N·m

(2 4 ft .- Ibs. )

65 N· m

(48 ft.-Ills.)

41 N·m

(30 fl .- Ibs. )

MF26.

Gasoline

63.475-63.487 mm

(2.4990-2.4995 in .)

0.038-0.076 mm

(0.0015-0.0030 in.)

0.05-0.38 rnm

(0.002-0.015 in .)

50. 71 -50. 74 mm

(1.9965-1.9976 In.)

6O A6-50.48 mm

(1.9865-1.9876 Ill .)

411 .95-49.97 mm

(1.9665-1.9675 In.)

0.064-0.132 mm

(0.0025-0.0052 In.)

0.064-0. 14 0 mm

(0.0025-0.0056 in .)

0 .10-0040 mm

(0.004-0.016 in .)

lOA L

( ll U.S. qts.)

6.6 L'

(7 U.S. qtA)

37.8 L

(10 U.S. gals.)

41.6 L

(J I U.S. gals.)

1.4 L

(1.5 U.S. qts.)

0.95 L

(I U.S. ql .)

122- 1 29 N·m

(90-95 ft.-Ibs.)

230-244 N·m

(l70-ISO ft.JbIl.)

100- lOS N·m

(74-80 (t .- Ibs.)

381HOO N·m

(280-300 ft .- I bs..)

38-43 N-m

(28-32 rt.-Ilwl)

28-33 N'm

(2 1-2 4 ft ,- Ibs.)

33-38 N·m

(24-28 (t .- II>8. )

61-68 N-m

(45-60 rt .- Ibs.)

26-28 N·nl

(:l0-24 (t .- lbe.)

CONDENSED SERVICE DATA

G ENE R AL

Engine Make .............. • • ..

Engine Model .. . ........ .

Number of Cy lind ers ....... .

Bore . .... .. ..... .

Stroke ..

Disp l acement .. .... .......... .

MF265

Olese l

Perkins

A4 .236

4

98 .4 mm

(3.875 in .)

127 mm

(5.0 in.)

3.87 L

(236 Cll . in.)

MF270

Diese l

Pe rkins

A4 .236

4

MF275

Diese l

Perki ns

A4 .248

4

98 .4 mm IOJ mm

(3.875 in.) (3.975 in .)

127 mm 127 mill

(5.0 in .) (5.0 in.)

3.87 L 4.06 L

(236 cu. in.) (248 cu. in.)

MF290

Diesel

Perki ns

A4 .248

4

IOlmm

(3.975 in )

127 mm

(5.0 in)

4.06 L

(248 cu. in .)

E I e<: lric a1 System ...... ..... .. .. ===========~ ' 2~V~ol~t , NegatiVe;~ro~un~d~==========

Fo rwa rd Speed s. . . . . . . •• . . . . . 8 or 12

Reverse S) >eeds . . . . . . . . . . 2 or 4

T UNE·UP

Firing Order . ......... . .. •..

Va lve Clearance, Co ld

Intake and Exhaust ....

Val ve Clearance, Hot

Intake and Exhaust .. .. .. . . . . .

Va lve Face Angle . ...... .

Va lve Sea t Angle. . . . . . ... .

bijection Timing, Stat ic ........ .

lrijector Opening Pressure .... .

Governed Speeds - Engine Hpm.

Low Idl e. . ... . . . . . .. .

High I dle (no-load) ..

Rated (fu ll load) . .. . ..... . . . .

Power Rating at Pto

Shart . . . . . . . . . . . . . .. . . .. . . .

~IZES-CLEARANCES

Crankshart Main Journal

Diameter.

Bearing Clearance

Cranks hart Crankpin

Diamete r. . . ........ .

Bearing Clearance

Crankshart End Play

Cams hart Journal Diam e te r

Front ....... ... ............ .

Center .

Rear . .

Camshart Bearing Cle arance

Front

Ce nt er & Rear

Cams haft End Play ...... . . .

1-3-'1-2

0. 30 mm

(0.012 in.)

0.25 mm

(0.0 10 in .)

45°

45

0

23° IJrDC

17235 kPa

(2500 I >si)

725-775

2 185

2000

44.7 kW

(60 hpj

76. 162·76.175 mm

(2.9985·2.9990 in.)

0.05-0. 10 mm

(0.002·0.004 in .)

63.475·63.487 mm

(2 .4990·2.4995 in.)

0.038-0.076 mm

(0.0015·0.0030 in .)

0.10-0.38 mm

(0.004-0.015 in.)

50.71 ·50.74 mm

(1.9965- 1. 9975 in.)

50.46-50.48 mm

(1.9865- 1. 9875 in .)

49.95-49.97 mm

(1.9665- 1. 9675 in.)

0.064-0. 132 mm

(0.0025.0.0052 in .)

0.064-0. 14 0 mm

(0.0025·0.0055 in.)

0. 10·0.40 mm

(0.004-0.016 in .)

1-3·4-2

0.30 mm

(0. 0I2 in .)

0.25 mm

(0.010 In .)

45°

23 ° BTDC

17 235 kPa

(2500 psi)

725-775

2 185

2000

41 .0 kW

(55 hll)

76.162 -76. 17 5 mm

(2.0085-2.9990 in.)

0.05·0. 10 mm

(0.002.0.004 in .)

63.475·63.487 mm

(2.4900-2.4995 in.)

0.038 ·0 .076 mm

(0 .0015·0.0030 in.)

0.10-0.38 mm

(0.004·0.015 in.)

50.71-50.74 mm

(1.9965· 1. 9975 in .)

50.46-50.48 mm

(1.9865- 1. 9875 in .)

49.05-49.97 mm

(1.0fi65- J.9675 in .)

0.064·0. 114 mm

(0.0025-0.0045 in.)

0.064-0.140 mm

(0.0025-0.0055 in.)

0.10-0.40 mm

(0.004-0.0 16 in .)

1-3-4-2

0.30 mm

(0.012 in.)

0 .25 mm

(0 .010 in.)

45°

45

0

24 ° IJroc

17235 kPa

(2500 I>si)

725-775

2 185

2000

50.0 kW

(67 hi»

76. 162-76. 17 5 mm

(2.9985-2.9990 in .)

0.05-0. 10 mm

(0.002-0.004 in.)

63.475-63.487 mm

(2.4990-2.4995 in.)

0.038-0.076 mill

(0.001 5-0.0030 in .)

0.10-0.:38 mm

(0.004-0.015 in.)

50. 71 -50.74 mm

( 1. 9965- 1. 9975 in .)

50.46-50.48 mm

(1.9865-1.9875 in .)

49.95-49.97 mm

(}'9665-1.9675 in .)

0.64-0.132 mm

(0.0025-0.0052 in .)

0.064-0. 14 0 mm

(0.0025-0.0055 in.)

0. 10-0.40 mm

(0.004-0.016 in .)

1 -3- 4-2

0.30 mm

(0.012 in .)

0.25 mm

(0.010 in .)

<&0

45

0

24° BTDC

17235 kP'd.

(2500 psI)

725-775

2380

2200

49.2 kW

(66 hpj

76 . 162- 76.175 mOl

(2 .9985-2.9990 in .)

0.05-0. 10 mOl

(O.0()2.o.004 in.)

63.475-63.487 mm

(2 .4990·2 .4 995 in.)

0.038-0.076 mm

(0.0015-0.0030 in .)

0.10-0.38 mm

(0.004-0 .015 in .)

50.71-50.74 mm

(1.9960-1.9975 In .)

50.46-50.48 mm

(1.9865-1.9875 in .)

49.95-49.97 mm

( 1. 9665- 1. 9675 in .)

0.064-0. 114 mm

(O.0025-lXUX)45 in .)

0 .064 -0 .140 mOl

(0.0025-0.0055 in.)

0. 10-0040 mm

(0.004-0.016 in .)

5

Paragraphs '-2 MASSEY - FERGUSON

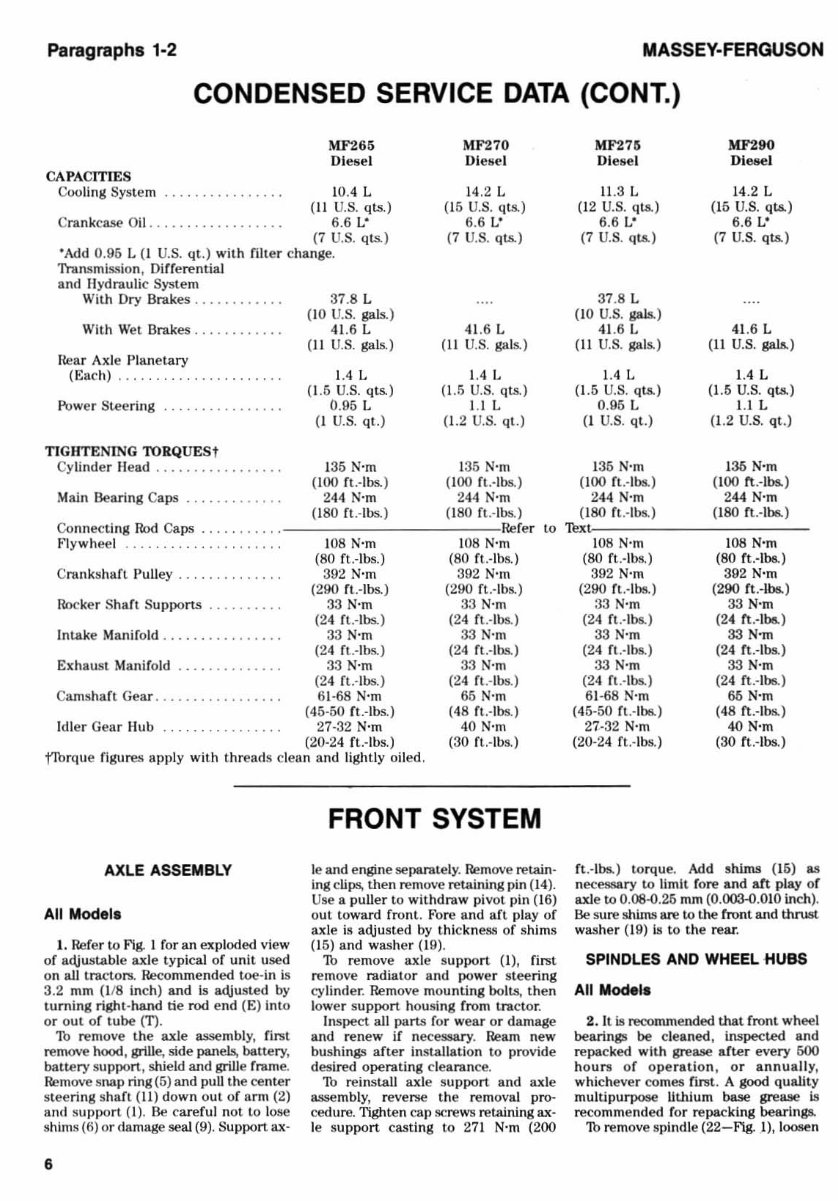

CONDENSED SERVICE DATA (CONT_)

~IF265 MF270

Diese l Di eIJe l

CAPACITIES

Cooling System . . . . . . . . . . . . . . . . lOA L 14.2 L

( 11 U.S. qts.) (I6 U.S. qts.)

Crankc ase Oil .. ........ ..... ... 6 .6 L" 6.6 L"

(7 U. S. qts.) (7 U.S. qts.)

·Add 0.96 L (1 U.S. qt.) with filler change.

Tnmsmission, Differential

and HydrauliC System

With Dry Brakes ............ 37 .8 L

(10 U.S. _)

With W et Brakes .. ........ . 41.6 L 41.6 L

(11 U.S. gals.) (I I U.S. gals.)

near Ax le Planetary

(Each) .... . .. ... . ..... ...... 1.4 L 1.4 L

(1.5 U.S. qts.) (1.5 U.S. qts.)

Power Sleering ........ 0.95 L LlL

(I U.S. qt.) (1.2 U.S. qt.)

TIGHTENING roRQUES t

Cylinder Head ................. 135 N'm 1 35 N'm

(100 rt .-Ibs.) (100 rt .- Ibs.)

Main Bearing Caps ... ..... 244 N'm 244 N-m

(180 rt .- Ibs.) (180 ft .-Ibs. )

Co nnecting Rod Caps .. . Refer lO

Flywheel 108 N-m 108 N'm

(80 ft..-Ibs.) (80 ft.-Ihs.)

Crankshaft Pulley . .. 392 N'm 392 N'm

(290 ft.-Ibs.) (290 ft .- Ibs.)

Rocker Shaft Supports .. 33 N-m 33 N'm

(24 ft .- Ibs. ) (24 ft.-Ibs.)

Intake Manifold ..... 33 N'm 33 N'm

(24 ft.-lbs.) (24 rt .- Ibs.)

Exhaust Manifold .. .......... .. 33 N'm 33 N'm

(24 ft.-lbs. ) (24 rt .- Ibs.)

Camsh art Gear .. 61 -68 N'm 55 N'm

(45-50 ft.-Ibs.) (48 fl .-lbs.)

Id ler Gear Hub 27-32 N'm 40 N'm

(20-24 ft .-l bs.) (30 ft.-Ibs.)

f!b rque figures apply with th reads clea n and lightly o il ed .

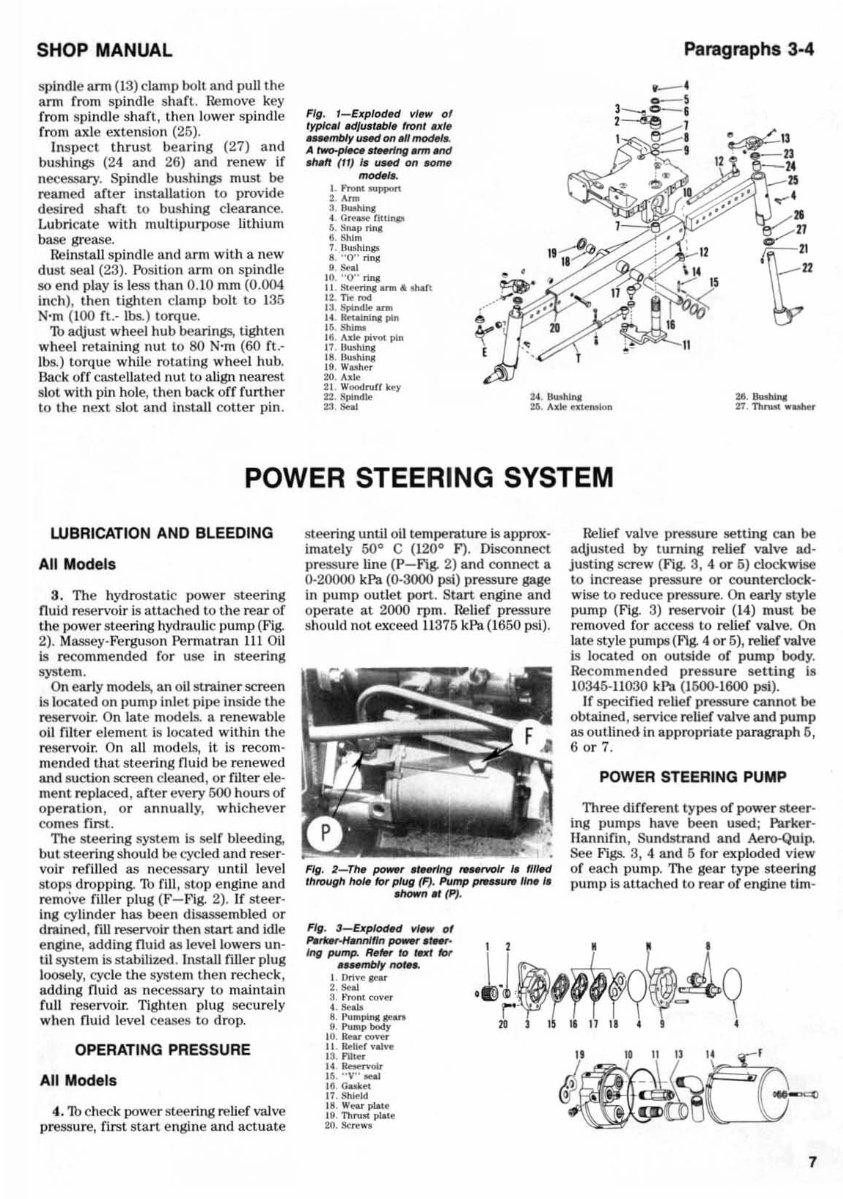

AXLE ASSEMBLY

All Model,

1. Refer to Fig. I for an exploded view

of adjus table axle typical of unit used

on all tractors. Recommended toe -in Is

3.2 mm (l /8 inch) and Is adjusted by

tu rning right- hand tie rod end (El into

or out of tube (n .

Th remove the axle assemb ly, first

remove hood , grille, side panels, battery,

battery support, shield and grille frame.

Remove s nap ring (6) and pull the center

s teering s haft (Il) down ou t of arm (2)

and s upport (I) . Be care ful not to lose

shims (6) or damage seal (9). Su pport ax-

6

FRONT SYSTEM

Ie and engine separately. Remove retain-

Ing cli ps, then remove retaining pin (14).

Use a puller to wit hdraw pivot pin (I6)

o ut toward front. Fore and aft play of

axle is adjusted by th ic kness of shims

(15) and was h er (19).

1b remove axle support (1), fi rst

remove radiat or and power stee ring

cy linder . Remove mounting bolts. the n

lower support housing from tractor.

Inspect all parts for wear or damage

and renew if necessary. Ream new

bushings after installati on to provide

des ired operati ng clearance.

1b reinstall axle s upport and axle

asse mbl y, reverse the removal pro-

cedure. Tighten cap screws retaining ax-

le support casti ng to 271 N- m (200

MF276 MF290

Di ese l Di esel

11 .3 L 14.2 L

(12 U.S. q18.) (16 U.S. q18.)

6.6 L· 6.6 L·

(7 U.S. qt.s.) (7 U.S. qts.)

37 .8 L

(10 U.S._)

41.6 L 41.6 L

(11 U.S. gals.) (II U.S._)

1.4 L 1.4 L

(1.5 U.S. ql8.) (l.f) U.S. qts.)

0.95 L LlL

(1 U. S. qt.) (1 .2 U.S. qt .)

135 N'm 1 36 N'm

(100 ft.-Ibs.) ( 100 tt .- Ibs.)

244 N'm 244 N-m

(180 ft .- Ibs.) (180 rt .-Ibs.. )

'!>xl

108 N-m lOS N'm

(SO ft.-lbs.) (80 ft.-Ibs..)

392 N'm 392 N'm

(290 ft.-Ibs.) (290 rt .-lbs.)

33 N'm 33 N'm

(24 ft.-Ibs.) (24 fl .·lbo.)

33 N-m 33N ...

(24 rt.-lbs.) (24 Ct.-Ibs.)

33 N'm 33 N'm

(24 ft.-Ibs.) (24 ft. -Ibs.)

6 1-68 N'm 66 N'm

(45-50 fl. -Ibs.) (48 n .- Ibs.)

27-32 N'm 40 N'm

(20-24 fl.-Ibs.) (30 fl.·ll>o.)

ft .- lbs.) to rque. Add shims (16) as

necessary to limit f ore and aft play of

axle to 0.08-0.26 mm (0.003-0.010 inch).

Be sure shims are to the front and thrust.

was h er (19) ill to t he rear.

SPINDLES AND WHEEL HUBS

All Model.

2. It is recommended that front wheel

bearings be clea ned , inspected and

repac ked with grease arter every 600

hours of ope rati on, or annually,

wh icheve r comes first. A good quality

multipurpose llthlum base grease is

recommended ror repacking bearings.

1b remove spindle (22-F'\g. .1) , loosen

SHOP MANUAL

spindle arm (13) clamp bolt and pull the

ann from spindle shaft. I re-move key

from spindle sh aft , then lower spindle

from axle extension (25).

Inspect t hru st bearing (27) and

bushings (24 and 26) and renew if

necessary. Spindle bushings must be

reamed after installation to provide

desired shaft to bushing clearance.

Lubricate with multipurpose lithium

base grease.

Reinstall spindle and arm w it h a new

dust sea l (23). Position ar m on s pindle

so end play is Jess than 0. 10 mm (0.004

inch) , then lighten clamp bolt to 135

N'm (100 f t. - \bs. ) torque.

1b adjust wheel hub bearings, tight en

wh eel retaining nut to 80 N- m (60 f t. -

Jbs.) torque while rotating wh ee l hub.

Back off castellated nul to align nearest

slot with pin hole, then back off furth er

to the next sl ot and install cotte r pin.

Fig. I_Exp /od" vl.w of

typic.' Idju. ttlbl. Iron' .xt.

_mbIy lINd 0If .U mocHI ..

A ~.r..rlng_and

wf'l (H) I. uud on .am.

..... ,.

I. fmnt ... ppon

2. Arm

' .........

4. a"'MefitUnp

t. . Snap ring

II. SIIl m

7 n ... hlnp

8. "0" ring

... "

10. "0 " nn,

II Steomng ...... " "".'1

12 n.. rod

'3. Spindle.,...

14. ~pln

It.. ShImI

18 Ad!: pi vot pin

L 7 llIah.I"lI

18 . Hulhl ng

Ig. Wuher

2<1. A" I/:

21 Wood ruff k~

U . Spindle

" .. "

Paragraphs 3·4

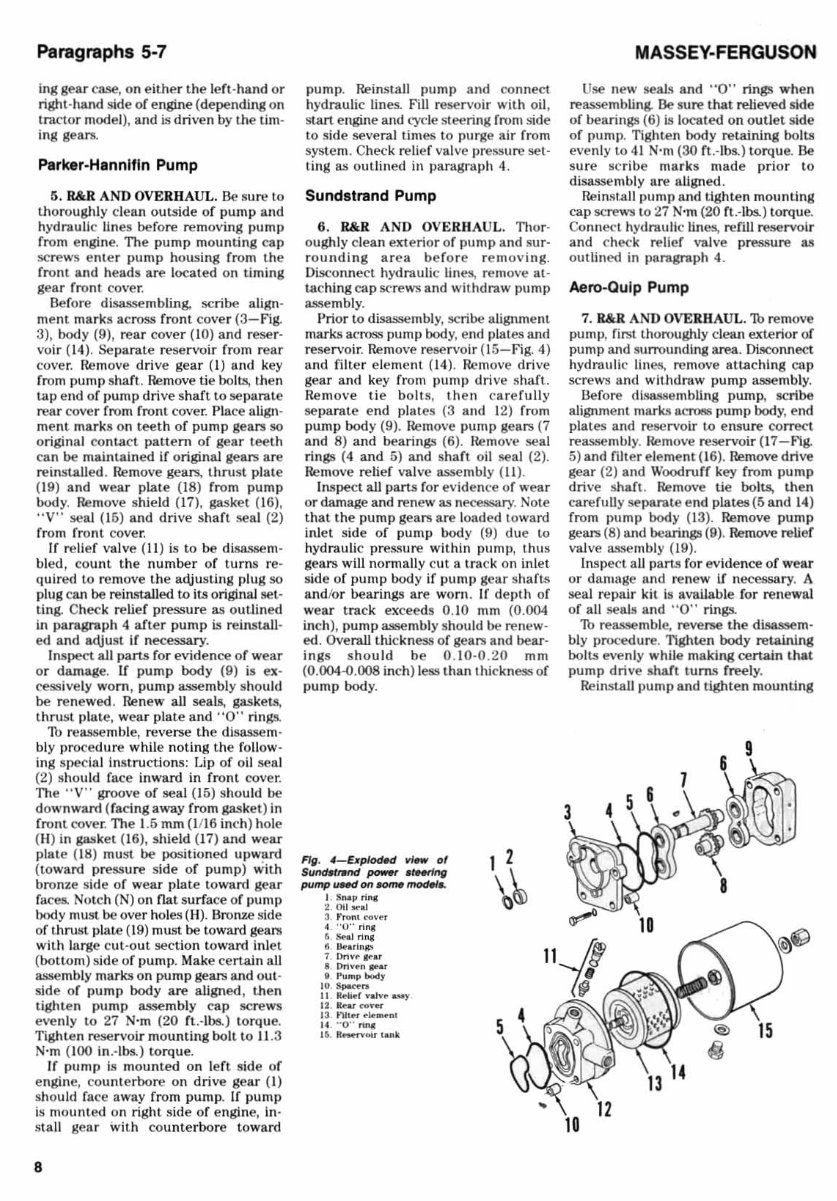

POWER STEERING SYSTEM

WBRICATION AND BLEEDING

All Models

3. TIle hydrostatic power steering

fluid reservoir is attached to the rear or

the power stee ring hydraulic pump (Fig.

2). Massey-Ferguson Permatran 1lI Oil

is recommended ror use in stee ri ng

system.

On early models, an 011 strainer screen

Is located on pump Inl et pipe ins id e the

reservoir. On late models. a renewable

oil rnter element is located within the

reservoir. On a ll mod els, it is recom-

mended that stee ring fluid be renewed

and suction screen cleaned, or £ilter ele-

ment replaced, after every 500 hours or

operati on , or an nua ll y, whichever

comes £irst.

The st ee ring system Is selr bleeding,

but steering should be cycled and reser-

voir rerilled as necessary u nt il level

stops dropping. 1b £ill , stoll engine and

remove filler plug (F- Fig. 2). If st eer-

ing cy li nder has been disassembled or

drained, fill reservoir then start and idle

engine, adding fluid as level lowers un-

t il s)'8tem is stabilized. Install £iller plug

loosely, cycle the sys tem then recheck,

adding fluid as ne<:essa ry to maintain

rull reservoir. Tighten plug securely

when fluid level ceases to drop.

OPERATING PRESSURE

All Models

4. 1b che<:k power steering relief valve

pressure, fiJ~t start engine and actuate

steering until oil temperature is approx-

imately 50

0

C (120

0

F). Disconnect

pressure line ( P-Flg. 2) and conne<:t a

0-20000 kPa (0·3000 psi) pressure gage

in pump outlet port. Start engine and

operate at 2000 rpm. Relief pressure

should not exceed I L375 kPa (1650 psi).

FIg. 2-TII. ~r ., Hrlng , .... ,-voIr I. fII!«I

'"roug" hot. lor plug (F). Pump ",. .. U,.. /1M I.

MIown lit (P).

Relief valve pressure setting can be

adjusted by turning relier valve ad·

justing screw (Fig. 3, 4 or 5) clockwise

to increase pressure or cou nt erclock·

wise to reduce pressure. On early style

pump (Fig. 3) reservoir (1 4) must be

removed for access to relief valve. On

late style pum ps (Ag. 4 or 6), relief valve

is located on outs id e of pump body.

Recommended press ure setting Is

10345-11030 kPa (1600- 1 600 psi).

If specified reli er pressure can not be

obtained, service relief valve and pump

as outlined in ap llropriate paragraph 6,

6 or 7.

POWER STEERING PUMP

Three different types of power s teer·

ing pumps have been used ; Parker·

Hann ifin, Sundstrand and Aero-Qulp.

See Figs. 3, 4 and 5 f or exploded view

or each pump. The gear type stee ring

pump is attached to rear of engine tlm-

Fig. 3-uplad" vf_ of

h~-tNNllfin ~ .~.

In, pump. R.,., 10 ,..., It:N

.... mblyno, ...

L Ori~!: &e&r

2. Stoal

3. fmn. (O~~r

4. SOW

I. Pumplna: "' ...

e. Pump body

10. Rear (O~.,

II IIo:lIer ~~

13 . Fliu-r

,, -

I t. . " V" JoH.I

1II 0 .... e<

17 . Sh~ld

II. WKr ""'f

III. Thrust pIa.e

2fl. Ikn: ....

.1~'fffly' ~q

~~~CG--

7

Paragraphs 5-7

ing gear case, on eith er t he l erl-hand or

right -hand side of engine (depe nding on

tractor model ), and is driven by the tim-

ing gears.

Pa rker·Hannlfln Pump

5. R&R. AND OVERH AUL . Be sure to

thoroughly clean outside of p ump and

hydra ulic lin es before removing p ump

from engine. The pump mounting cap

screws enter pump housing from the

front and heads a re located on liming

gear fronl cover.

Before disassembling. scribe align-

ment marks across front cover (3-fig.

3), body (9), rear cover (10) and r eser·

voir (14). Separate reservoir from rear

cover. Remove drive gear (1) and key

from pump shaft. Remove tie bol ts, then

l ap end of pump dri ve shaft to separate

rear cover from front cover. Place align-

ment ma rk s on t eet h of p um p geal'S SO

original contact pattern of gear teeth

can be maintained if original gears are

reinstalled. Remove gear.i, thrust pla te

(19) a nd wear plate (18) from pump

body. Remove shield (1 7 ), gasket (16),

"V" sea l (16) and drive shaft seal (2)

from front cover.

If relief valve (II) is to be dl sasse m·

bled, count the number of turns reo

quired to remove the adjus ting plug so

plug can be reinstalled to its original set·

ting. Ch eck relief pressure as out lined

in l>aragraph 4 after pump is reinstall-

ed and adjust if necessary.

Inspect all pans for evidence of wear

or damage. II pump body (9) is ex-

cessively worn , pump assembly sh ou ld

be rene wed . Renew all seals, gaskets.

thrust plate, wea r plate and "0" rings.

Th reassemb le, reverse the djsassem·

bly procedure while not ing the fo ll ow -

in g special ins tru ctions: Lip of o il sea l

(2) should face inward in f ront cover.

The "V" groove of seal (15) should be

d ownward (facing away from gasket) in

front cove r. The 1.5 mm (I116 inch) hole

(H) in gasket (I6), shield (17) and wear

p late (18) must be positioned upward

( toward pressu re side of pump) wit h

bronze side of we ar plate toward gear

faces. Notch ( N) on nat surface of pump

body must be over holes (H). Bronze side

of thrust I)late (\9) must be toward gears

wit h large c ut·o ut section toward I nl et

(botto m) side of pump. Make certain all

assembly marks on pump gears and out·

side of pump body are aligned, then

tighten pump assembly cap screws

evenly to 27 N-m (20 ft.·lhs.) torque.

Tighten reservoir mounting bo lt to 11 .3

N'm (1 00 in .· lbs.) to rqu e.

If pump is mou n ted on lef t side of

engin e, count erbore on drive gear (I)

should fa ce away from pump. If pump

is mounted on righl side of engine, in·

stall gea r with cou nterbore toward

8

pump. Reinstall pump a nd connect

hydraulic lines. F'ill reservoir with oil,

start engine and (:ycle steering from si de

lo side several times to purge air from

system. Chec k relief valve pressure sel-

ling as outlined in paragrap h 4.

Sundatrand Pump

6. R&R AND OVERHAUL. Thor-

oughly clean exterio r of puml) a nd s ur·

ro unding ar ea be fore re moving .

Disconnect hydnlUlic Iin~ remove at ·

tachlng ca p screws and withdraw pump

asse mbl y.

Prior to disassembly, scribe alignment

marks acfOS.'iI pump body, end plates and

reservo ir. Remove rese rvoir (l5- F ig. 4)

and filter element (14). Remove d ri ve

gear an d key from pump drive shaft.

Re mo ve tie boil S, then care full y

separate end plates (3 and 12) from

pump body (9). Remove puml) gears (7

and 8) and bearings (6). rt emo\'e seal

rings (4 and 5) and shaft oil seal (2).

Remove relief valve asse mbly ( II) .

Inspect all pans for evide n ce of wear

or damage and renew as necessary. Note

t hat the pum p gears are load ed loward

inl et side of pump body (9) due to

hydraulic pressure withIn l)IIml), thus

gears will nonnall y c ut a trac k on in lei

side of pump body if p ump gear sha f ts

and/or bearings are worn . If de plh of

wear track exceeds 0. 10 mm (0.004

inch ), pump assemb ly should be renew'

ed . Overall thickness or gesr.li a nd bear·

i ngs s hould be 0. 10 -0.20 mm

(0.004"'().008 inch) less thanlhi ck nessof

pump body.

Fig. 4- E$pkxHd ",,- 0'

Su,,",~nd power ~

pump lINd on _ f1tO<HI ..

I. S ... p "n,

2.01 1..,0.1

3. ,."", <"<>v~.

4. ·· 0·· rln.

6. Se.J ring

8. ~ •• In",

7. DrI~~ ... r

S Dnv~n ... .

I p.., ... pbody

IO. ~

II 1It"lifl' nJve 0.00)'

12. II .... covet

13 . ",er .,Ioo .. .,n,

14 ··0 ·· nNI

". R-.vDl' ,ank

1 1

\ ~

MASSEY-FERGUSON

Use new seal<! and "0" rings when

reassembling. Be s ure that relieved side

of bea rings (6) Is located on outle t side

of pump. TIghten body retaining bolts

even ly to 41 N-m (30 ft .- Ibs.) torq u e. Be

su re scr Ibe ma r ks made prior to

disassembly are a li gned.

Rein.'ItaJl pump and tighten mou nting

cap screws to 27 N'm (20 rt.-lbs.) torque.

Connect hydmullc lines, refill reservoir

and check relief valve press u re as

oUllined in paragraph 4.

Aero· Qu lp Pump

7. R&R AND OVERHAUL. 1b remove

pump, first thoroughly clean exterior of

pump and surrounding area. Oi~nnect

hydraulic lines, re move au . ac hlng ca p

screws and withdraw pu mp assembl y.

Uefore dlSi\S8emhling pump, scribe

alignmelll mark. 'I acr086 pump body, end

plates and reservoir to ensure correct

reassembly. Remove reservoir ( 17 -flg.

5) and filter el eme nt (16). Remove drive

gear (2) and Woodruff key from pump

drive shaft. Remove tie bolts, th en

care fully !leparate end plates (5 and 14 )

from pump body (13). Remove pump

gears (8) a.nd bearings (9). Remove relief

valve assemb ly (19).

Inspect a ll parts for evid ence of wear

or damage and rene w If necessary. A

seal repair kit Is available fo r renewal

of all seals and ' '0·· rings.

1b reassemble, reverse. the disassem-

bly procedure. Tighten body retaining

bolts even ly while makifl8 certain that

pump drive s haft tums freely.

Reinstall pump and tighten mou nting

SHOP MANUAL

ca p screws to 27 N-m (20 ft .· lbs). Con-

nect hydraulic lines. refill reservoir and

check re lief valve ] )res..o;u re as out lin ed

in paragraph 4.

HYDROSTATIC HAND PUMP

Early Models

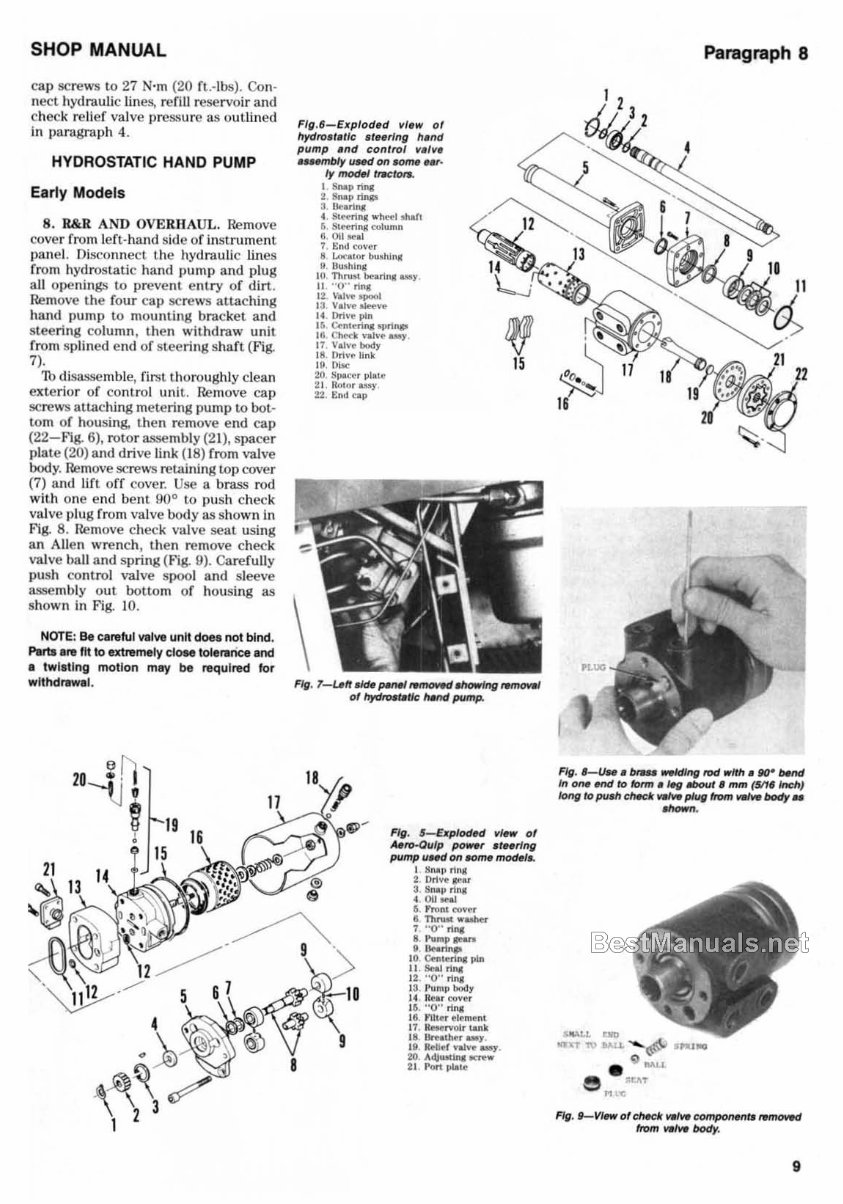

8. R&R AND OVERHAUL. Remove

cover from l eft- hand si de of inSl mmcnt

pane l. Disconnect the hydra uli c li nes

from hydros tat ic hand pump and pl ug

all ope nings to prevent e nl ry of dirt.

Remove the fou r cap screws attaching

hand pump to mounting bracket and

stee ring column, then withdraw unit

from splin ed end of stee ring sha ft (Fig.

7).

Th di sasse mble, fi rs t thoroughly clean

exterior of co nt rol uni t. Remove ca l)

screws attach ing metering pump to bot-

tom of housing. then remove end cap

(22-F'ig. 6), rotor assembly (21 ), spacer

plate (20) and d ri ve link (18) from va lve

body. Remove screws retaining top cover

(7) a nd lift off cover. Use a brass rod

with one end be nt 90

0

to push ch ec k

valve plug fro m valve body as shown in

F'ig. 8. Remove check va lve seal using

an Allen wrench , then re move check

valve ball and s pring ( 1- 1g. 9). Carefully

push control valve spool and sleeve

assembly o ut bottom of housing as

sh ow n in F'ig. 10.

NOTE: Be ca .. fu l ..... lve uni t does not bind.

PIIrtsa .. lit 10 extremely CiON tolenlrice and

• twill Ing motion may be required lor

wttlHtrawal.

FIII .6-Ellplod.d vl.w of

hydro" .IIc ,' .. rlnll h.nd

pump .nd con l rol v .,v •

• uembly uNd on ~ Hr'

I)' model t,.;ton.

\

1 Snoop rinC

2. Snoop rInp

3 lIe.n,..

t. S<H11ns ... h,...1 shall

5. S<H11ng cullimn

6. OII ... al

7. End COY"'"

8 u",a • .,.. ""'hili!!

9 U ... hlns

10 . Thrust burln' .... y

II "0" rI,..

12. '·. hoe .......

13 Valve oWve

I( Driv-e pin ,

16 Cenc"""'"""""-

16. C~k VJOl""_

17 Valve body

\8. !)rive Unk 15

19. !li te

20 8~u. pl. ce

21 Roc". uoy

2:2. t:nd cap

Fig. 1-Len ekIe pen« tMIOWd "-'"II rwnoveI

of hydtoer.tk tt.ttd pump.

Fig. S-&pIodH1 view of

MfOoOulp po,,"r " .. rlttg

pump uNd on .om. model ..

I Snail",..

2 OrIve Ie'"

3. Snap rI"I

"" ... 5 ",o,n .,.,..., r

8 ThnIIt""""r

7 "o·· .u.,

Il"ulllp~

. .... , ....

10 Cenc...u..; pin

II . SeAl oiII!L

12 ··O·' rI..,

13. !' lImp body

14 IIev <:<tv","

1&. "0" rinC

18. ntuo- ~"'~I

11 . ~"'oIrt.&l\k

II . Bre.ther _yo

19 IWILft .... Iv-e_.

20. A~...u.., ICf"eW

2 1. Pon place

Paragraph 8

I

FIg • • _U ... bfae weldlrlfl twJ"lth. fNr 0Md

In _ end /0 foro! • ,. .txHI1 • mm (SIt. Inch}

IonfI /0 pull! ctt.et ~ plug I'rom *"- body ..

....... .

FIg. f-V"" o'cMck"""'~~1"MIOWd

from VII ..... body .

9

You're Reading a Preview

What's Included?

Fast Download Speeds

Online & Offline Access

Access PDF Contents & Bookmarks

Full Search Facility

Print one or all pages of your manual

$52.99

Viewed 70 Times Today

Loading...

Secure transaction

What's Included?

Fast Download Speeds

Online & Offline Access

Access PDF Contents & Bookmarks

Full Search Facility

Print one or all pages of your manual

$52.99

This manual is suitable for both first-time owners and amateur enthusiasts, as well as professional technicians. It is designed in an easy-to-read format and provides all the necessary information to perform procedures accurately. Keeping this service manual accessible and referring to it regularly is recommended. Regular and preventive maintenance outlined in the manual can help save time and money by preventing premature failure and unnecessary repairs.

- BRAKES

- CLUTCH

- COOLING SYSTEM

- DIESEL FUEL SYSTEM

- DIFFERENTIAL

- DIFFERENTIAL LOCK

- ELECTRICAL SYSTEM

- ENGINE

- FINAL DRIVE

- FRONT SYSTEM

- HYDRAULIC SYSTEM

- POWER TAKE-OFF

- TRANSMISSION

File Format: PDF

Compatibility: All Versions of Windows & Mac

Language: English

Requirements: Adobe Reader