Massey Ferguson MF 175 Service & Repair Manual

What's Included?

Fast Download Speeds

Online & Offline Access

Access PDF Contents & Bookmarks

Full Search Facility

Print one or all pages of your manual

MF 165 TCTOR SERVICE MANUAL

DESCRIPTION PART

Front Axle and Steering • • • • • • • • • • • • • • • • • • • " • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • 1

Continental Gas Engine

• • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • 2

Perkins Gas Engine • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • 3

Perk ins AD4-203 Diesel Engine • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • •

4

Dual Clutch • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • 5

Split Torque Clutch • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • 5

6 Speed Standard Transmission.............. • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • 6

8 Speed Standard Transmission ......... • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • 7

Multi-Power Transmission........ • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • 8

Differential, Pinion and Rear Axle. • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • 9

Power Take-off • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • 9

Internal Hydraulic System • • • � . . . . . . . • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • 10

MASSEY-FERGU SON

GROUP IV - SETION A - PART 12

PART 12--FRONT AXLE AND STEERING-

MF 150, 165 AND 175 TRACTORS

I NDEX

Page

E NGI NE-DRIVE N STEE RI NG PUMP-

DIESEL MODEL . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2

Fi I I i ng The Reservo

·

i r . . . . . • . . . . . . . . . . . . . . . . . 2

Removing The Pump . . • . • . • . . . . . . . . . • • . . . . . . 2

I nsta l l i ng The Pum p . . . . • . . . • . . . . . • . • . . . . • . • 2

Servi ci ng The Pump-MF 150 . . . • . . . . • . . . . . . . 3

Disassembly • • • • • • . • . • • • • • • • . . . • . • • . • • • . 3

Inspection • . • • . • • • • • • • • • • • • • • • . • • • . . • • . . 3

Reassembly . . . . . . . . • • • . . . . •. . . . . . . . . . . • . . . 3

Servici ng The Pump-MF 165 and MF 175 • • • • . . 4

Disassembly • • • • • • • • • • • • • • • • • • • . • • • • • • • • • 4

I' nspecti on . • • • • • • • • • • • • • • • • • • • • • • • • • • • • • 5

Reassembly • • • • • • • • • • • • • • • • • • • • . • • • • • • • • • 6

ENGINE-DRIVE N STE ERI NG PUMP-

GASOLI NEOD EL • • . • • • . . . • • • • . . . . • . • . • . . . 6

Fil l i ng The Reservo ir . . • • . . • • • • . • • • • • • . • • . • . 6

Removal . • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • 6

Disassembly . . • • • • • • . • • • • • . • • • • • • • • • • • • • • • • 6

Inspection . • • • • . • . . • • • • • • • • • • • • . • • . • • • • • • • 7

Reassemb I y . . • • • • • • • . • • • • • • • • • • . • . • • • • • • • • • 7

Installation . • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • 8

HYDRAULIC CYL I N DER A N D VALVE . • • • • . • . • • .

Removal . • • . • • . . . . . • • . . • • . • • • • . • • • • . • • . • . •

MF 165 a nd MF 175 Row Crop Models . • • . . • .

MF 150 Row Crop and MF 150 and MF 1A

Dual Tricy cle Models . • • • • . . • . . . • . • • . • . . •

Disassembly-Contro l Va l ve • . • • . • . . • . • • • • . • . .

Insפcti on-Contro l Va l ve . • • • . • • . • • • • • • . . • • o

Reassemb l y-Contro l Va l ve • . • . • • . • . • • • • • • • .. •

D isassem bly-Cy l i nder . • • • • . • • . • . • • . • • • • • • • •

I nspection-Cylinder · · · · · · · · · � · · · · · · · · · · · · ·

Reassemb I y :Cy I i nder . • • • • • • • • • . • • . • • • . • • • •

I I

"

I nsta at i on :· • • • • • • • • • . • • • • • • • • • . • • . . • • • • • . .

8

8

8

10

10

1 1

1 1

11

12

12

12

MF 1A and MF 175 Row Crop Models . • • • • • . 12

: MF 150 Row Crop and F 150 and

MF 165. Dua l Tricycle Models • • • • • • • • • • • • • • 13

PEDESTAL SHAFT . • • • • • • • • • • • • • • • • • • • • • • • • • • • 13

MF 165 and MF 175 Row Crop Models . • • • • • • . • 13

Remove I • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • 1 3, 14

Inspection • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • 14

Page

Instal lation . . . . . . . . . . . • • . . . . . . . • . . . . . • . 14

MF 150 Row Crop and MF 150 a nd

MF 165 Dual Tricycle Models . . . . . • . . . • . . . . . 15

Remo va l . • • • • • • • • • • • • . • • . • • • • . • . • • . • • . � 15

Disassembly . . . • • • . • . . . . . . • . . . • . . . . . . . . . 15

I nspection . . . • • . • • . • • • • . • • . • • • • • � • • . . . . 16

Reassembly . . • • . • . . • . • • • • . . . • . . • • . • . . • . • 16

I nstal lation . . . • • • . . . . • • • . • • . . • • . • o . . . . . . 16

SERVIC I NG THE STE ERI NG GEAR HOUSI NG . . • 17

Prerations For Servicing Steeri ng

Gear Housi ng • • • • • • • • • • • • o • • • • • • • • • • • • • • • o 17

Completi ng Tractor Reassembly . • • • . • • • • • . . . • 19

Disassembl i ng The S.teeri ng Gear Housi ng . • • • . 21

Reassembl i ng The Steer ing Gear Housing . • . . . 21

SERVIC I NG THE FRON T AXLE . . • • . . o . . . . . . . . . 22

MF 150 Row Crop Model s • • . • . • • . • • • • • • . • . • 22

Removal . • • . • • • • • • • • • • • • • . . • • • • • • • • • • . • 22

I ns pect i o n . • • • • • . • • • , • • • • • • . • • • • • • . • • • • • 23

Instal lation . • . • • . • • • • • • • • • • • • • • • • •. • • • • . • 23

MF 165 and MF 175 Row Crop Model s . .. • • • o . . 23

Removal and Insta l lation . . • . • . . . . • • • . . . . . 23,24

Dua Tricycle Models . . . . . • • • . . . • • . • • • • • • • • 25

Removal . • . • . • • • . • • • • • • • • . • • . • . • • . • . . .

25

Disassembly............................. 25

Reassemb I y • • • • • • • • • • • • • • • • • • • . • • • • • • • • •

25

l n-s ta I I at ion • • • • • • • • • • • • • • • • • • • • • • • • • • • • 26

ADJ USTME NTS • • . • . • • • . . • • • • . • • . . . . • • . . • • • . . 26

Toe-In • • • • • • • • • . - . . . . . . . . . . . . . . . . . . . . . . . 26

Drag Link • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • 26

Steering Axl e Wheel Bearings-Row Crop Models 27

Ste edng Axle Wheel Bearings-

Dual Tricycle Models . • • • • • • • • • • • • • • • • . • • • • 27

Axle Pivot Pin End-Play- MF 150 • • • • • • • • • • • 27

Axle Pivot Pin End-P iay-MF 1A and MF 175 • 27

Steering Gear Housing • • • • • • • • • • • • • • • . .

·

• • • • 28

Steering Valve • • • • • • • • • • • • • • • • • • • • • • • • • • • • 28

SPECIF ICATIONS • • • • • • • • • • • • • • • • • • • • • • • • • • • 29

TRO UBLE-SHOOTING . . . . . . ... . . . . . . . . . . . . . >

This Part of the Mual contains the recommended removal, overhaul and installa-

tion procedures at should be ten when servicing the steering system on the MF

150, 165 and 175 Tractors.

termine the possible cause of any malfuncon by consulting the "Trouble-Shoot-

ing" Section of is Manual befe any attempt is made to repair the system. Follow-

ing this practic will result in more accurate· maintenance, of the stee· rtng system d

will aid in-preventing uecessary repairs.

Printed in U.S.A.

1

.

.

M A S S E Y - F E R G U S O N

MF 150, 165 & 175 TRACTORS

ENGINE-

DRIVEN ST EERING PUMP-

Diesel Mode

l

FILLING THE RESERVOIR

1. Position front wheels in a straight for-

ward directi0n and shut off engine.

2. Remove fil ler plug and fill reservoi r with

oil conforming to MF Specification M-1110 un-

til oil level is even with the filler opening.

3. Replace filler plug, start engine and

operate s teering wheel in both directions to

insure the entire system is filled.

4. Position front wheels in a straight for-

ward direction and shut off engine.

5. Repeat these operations until the oil level

remains even with the fil ler opening.

REMOVING THE PUMP

1. Position front wheels in a straight for-

ward direction and shut off engine .

2. sconne ct hydra u 1 i c lines, remove

mounting bolts, remove pump from Tractor

and plug ports d lines.

3. Remove pump mounting gasket from tim -

ing gear housing (or mounting surface of pump)

and thoroughly clean the mounting surfa ces.

2

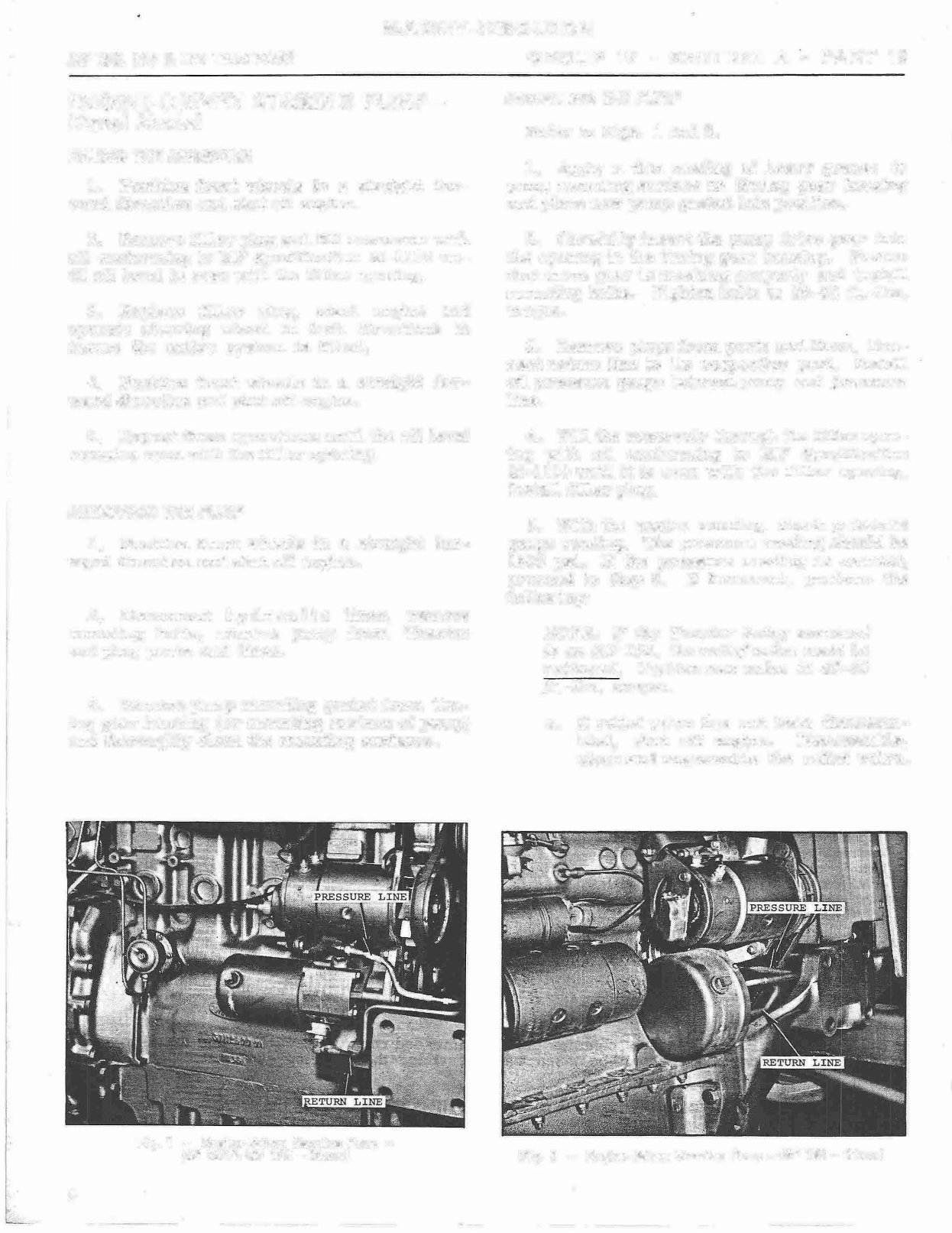

Fig. 1 - Engine-Driven Steering Pump -

MF 1 65 & MF 17 5 - Diesel

GROUP IV - SECTION A - PART 12

INSTALLING THE PUMP

Refer to Figs. 1 and 2.

1. Apply a thin coating of heavy grease to

pump mounting surface on timing gea r housing

and place new pump gasket into position.

2. Carefully inse rt the pump drive gea r into

the opening in the timing gear housing. Ensure

that drive gear is meshing properly and install

mounting bolts. Tighten bolts to 28-32 ft.-lbs .

torque.

3. Remove plugs from po rts and lines. Con-

nect return lihe to its respective po rt. stal l

oil pressure gauge between pump and pressure

line.

4. Fill the rese rvoi r through the fille r open-

ing with oil conforming to MF Specification

M-1110 unl it is even with the filler opening.

stall filler plug.

5. Wi the engine running, check p ressure

gauge reading. The pressure reading shoul d be

1500 psi. the pressure reading is co rrect,

proceed to Step 6. incorrect, perform the

following:

NOTE: the Tractor being serviced

is an MF 150, the relief valve must be

replaced. Tighten new valve to 40-50

ſt. -lbs . torque.

a. relief valve has not been sassem-

bled, shut off eng�ne. sassemble,

, clean and reassemble the relief valve.

Fig. 2 - Engine-Driven Steering Pump - MF 1 50 - Diesel

M A S S E Y - F E RG U S ON

GROUP IV - SE. CTION A - PART 12

FRONT AXLE & STEERNG

FILTER

SPRING

Fig. 3 - Disassembling the Steer ing Pump - MF 150 - Diesel

Run engine and adjust plug until reading

is cor rect.

b. relief valve has been disassembled,

adjust plug until pressure reading ts

correct.

6. Shut off engine, remove pressure· gauge

and connect line.

7. stl new Welch plug (if applicable).

8. Remove filler plug d refill the reser-

voir to maintain the fluid level even with th�

filler opening. Replace filler plug.

SERVICING THE PUMP-MF l50

Disassmbly

·

1. Remove the four retaining screws, Fig.

3, and remove the reservoir.

NOTE: At this time, the filter, filter

•

spri and reservoir '�0 "-ring may be

removed.

Printed in U.S.A.

_ 2. Place drive ger, Fig. 4, between t wo

blocks of wood in a vise. Remove nut fr om

shaft.

3. Remov e drive gear and key.

4. Remove pump from vise and remove the

capscrews securing back cover, Fig. 4, to

housing.

NOTE: Place an identifying mark on

back cover and on h ousing t o ensure

proper reass embly.

5. Remove the o gears from the housing.

6. Using a brass welding rod, remove dia-

phragm, Nylatron gasket , protecto r gasket d

"V" seal, Fig. 4.

7. poppet assembly is t o be rem oved, re-

move poppet s eat, bl d spring; Fig. 4.

NOTE: Count the number of

made when removing th e s eat.

must be ins talled Wfh the same

ber of tus.

turns

This

num-

8. The relief valve has been pre-set by the

manufacture r to open at 1500 psi and should not

be removed unless a malfunction o£ the valve

has been eerienced. The valve should then

be removed and replaced wi a new one.

Tighten valve to 40-50 ft.-lbs. torque.

NOTE: Relief valve is serviced as an

assembly onl y.

1. Replace filter element, "0" -rings, gas-

kets, diaphragm, "V" seal and j nut with new

parts.

2. spect facing surfaces of cov er plat e d

housing f or scoring and rough surfaces.

3. spect drive gear sht for broken key-

way and _ for excessive wear in b earing areas.

4. spect gears for nicked or b oken teeth.

Reassembly

Refer to Fig. 4.

1. poppet . assembly has been removed,

reinstall into its proper place in housing. (See

Fig. 3.)

3

MASSEY-FERGU SON

MF 150, 165 & l75 TRACTORS GROUP IV - SECTION A - PART 12

POPPET SEAT

�

�- POPPET BALL

DRIVE GEAR

I POPPET SPRING

�

0

t

SPRING

F\ LTER

RESERVOl

"0"-RING

FILTER

IDLER GEAR

, / KE

T

T T '

DIAPHRAGM

NYLATRON GASKET1

PROTECTOR GASKET

& ''V" SEAL

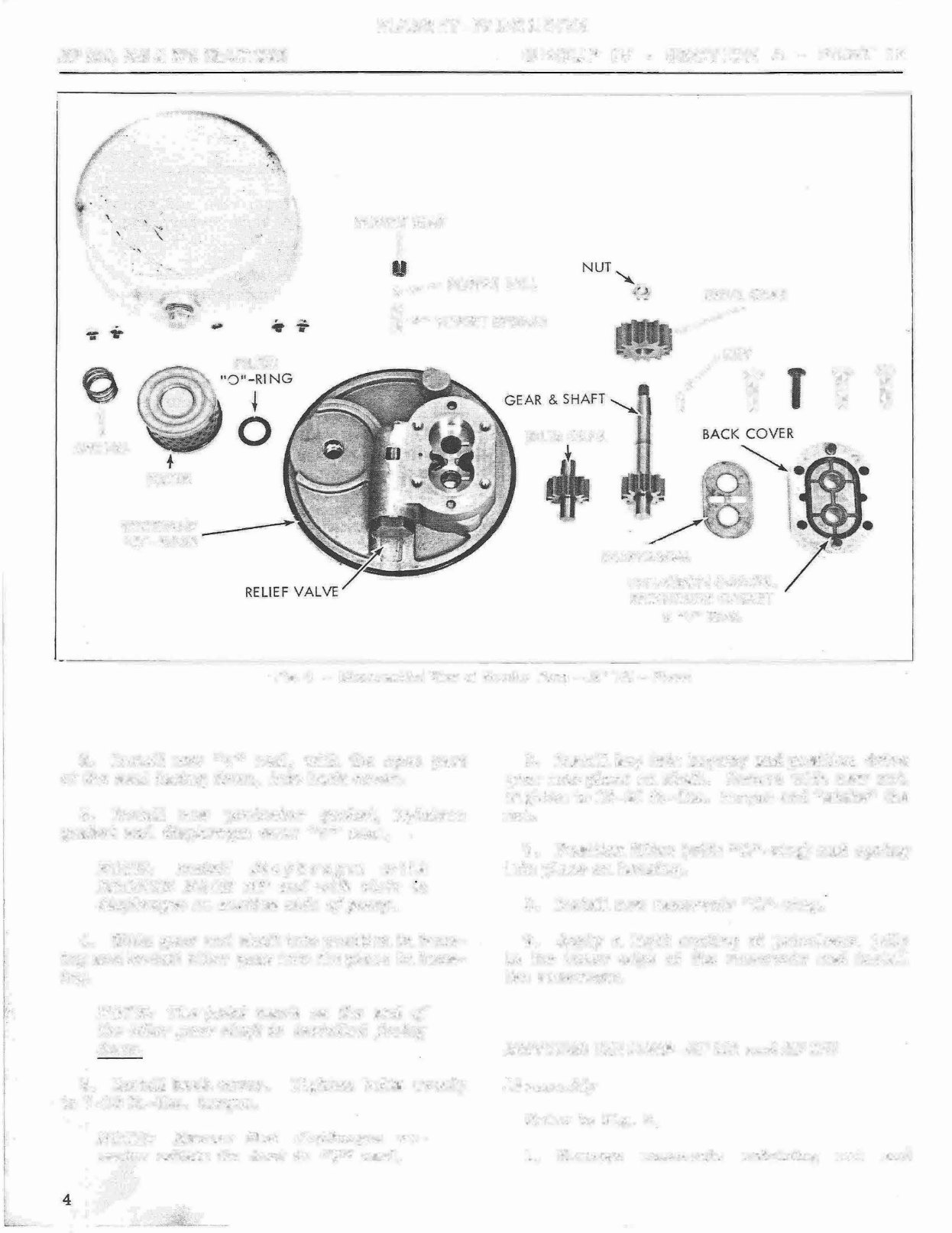

Fig. 4 - Oisa· ssembled View of Steering Pump - MF 1 2 - Diesel

2. stall new "V" seal, with the open part

of the seal facing down, into back cover.

3. stl new protector gasket, Nylatron

gasket d diaphragm over "V" seal.

NOTE: Ins ta ll diaphragm with

BRONZE FACE UP and with slots z

diaphragm on suction side of pump.

4. Slide gear and sht into position in hous-

ing and instl i dler gear into its place in hous-

ing.

NOTE: The paint mark on the end of

the idl er gear shaſt s installed facing

down .

5. stl back cover. Tighten bolts evenly

7-10 ft.-lbs . orque.

4

NOTE: Ensure that diaphragm re-

mains ithin ts seat in "V seal.

6o tall key into keyway and poSit ion drive

gear into place on sht. Secure with new nut.

Tighten to 15-20 ft.-lbs. torque and '·'stake" the

nut.

7. Posion filter (with "0'' - ring) d spring

into place on housing.

8. stall new reservoir "0" -ring.

9. Apply a light . coating of petroleu jelly

to the inner edge of the rese rvoir and install

te reseroi r.

SERVICING THE PUMP-MF 165 and MF 175

Disassembly

Refer to Fig. 5.

1. Remove reservoi r reaining nut d

MA S S E Y -FERGUSON

GROUP IV - SECTION A - PART 12

FRONT AXLE & S TEERING

F i g . 5

-

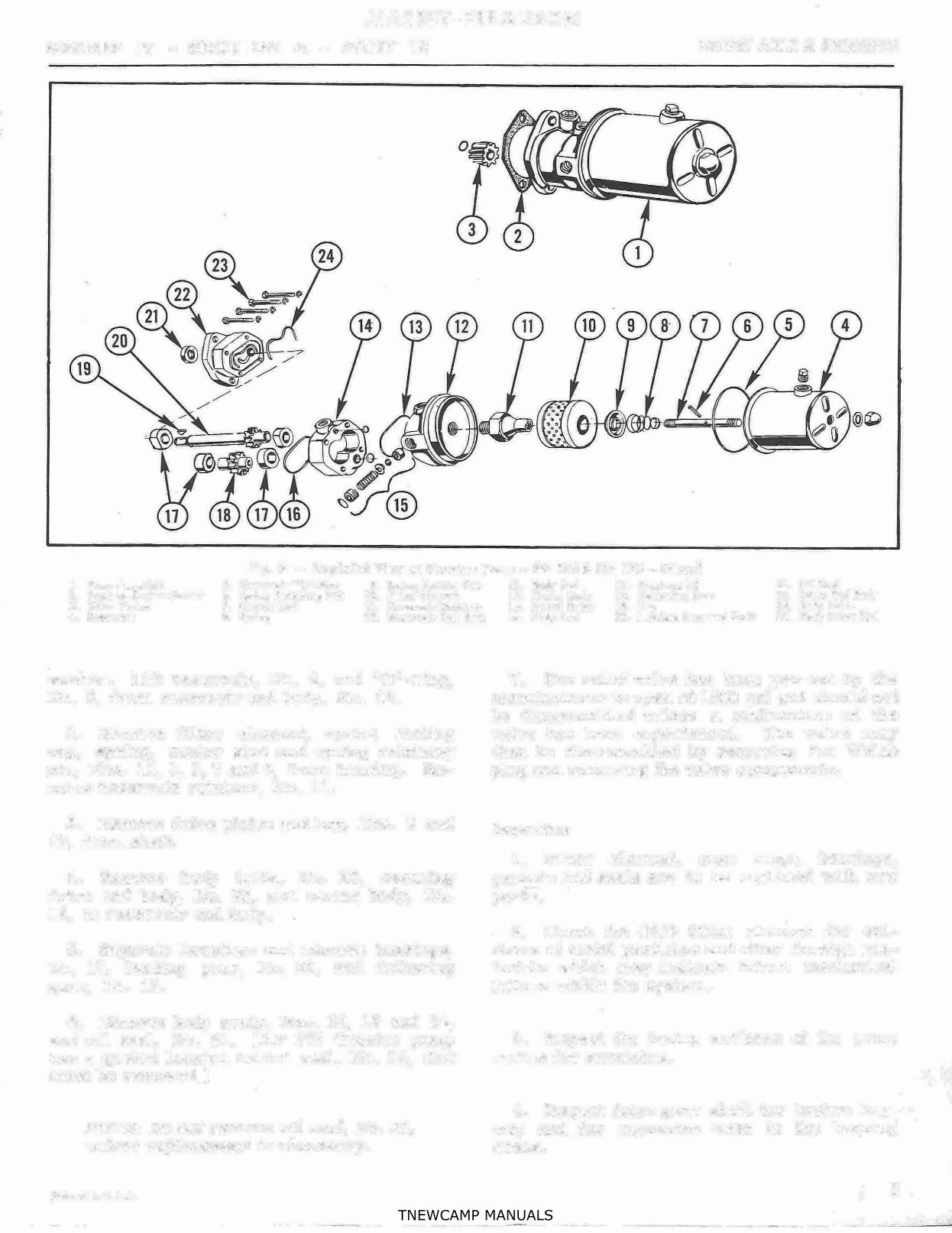

Exploded View of Steer ing Pump - MF 165 & MF 175 - D iesel

1. Pump As sembly 5. Reservoi r "0"-Ring

9. Spring Seating Cup

2. Pump-to -Engine Gasket 6. Spring Reta ining Pin 1 0. Filter E lement

3. Drive Pin ion

7. Center Stu d 11. Reservoi r Retaine r

4. Reservoir 8. Spring 12. Reservoi r End Body

washer. Lift reservoir, No. 4, and "0" -ring,

No. 5, from reservoir end bo dy, No. 12.

2. Remove filter element, spring seang

cup,

.

spring, center stud and , spring retaining

pin, Nos. 10, 9, 8, 7 and 6, from housing. Re-

move reservoi r retainer, No. 11 .

3 . Remove drive pinion and key, Nos. 3 d

19, from shaft.

4. Remove body bolts, No. 23, securing

drive end body, No. 22, and center body, No.

14, to reservoir end body.

5. Separate housings and remove bearings,

No. 17 , leading gear, No. 20, and following

gear, No. 18.

6. Remove body seals, Nos. 13, 16 and 24,

and oil se, No. 21. (MF 175 Tracr pump

has a gasket located behind seal, No. 24, that

must be removed. )

NOTE: Do not remove oil seal, No. 21,

unless replacement is necessary.

P rinte d in U.S .A.

13. Body Se ol 17. Bearings (4) 21. Oil Sea l

1 4. Center Body 18. Fol lowing Gear 22. Drive End Body

15. Reli ef Va l v e 19. K 23. Body Bolts

16. Body Seal 20. Leadig Gear and Shaft 24. Body Front Seal

7 . The relief valve has been pre-set by the

manufacturer to open a t 1500 psi and shoul d not

be disassembled unless a malfunction of the

vve has been eerienced. The valve may

then be disassembled by removing the Welch

plug d removing the valve components.

Inspection

1. Filter element, snap rings, bearings,

gaskets and ses are to be replaced with new

parts.

2. Check the OLD filter elem

.

ent for evi-

dence of metal p articles and o ther foreign ma-

terials which may indicate fure mechical

failure within the system.

3. spect the facing surfaces of e pump

bodies for scratches.

4. spect drive gear sht for broken key-

wa

y and for excessive wear in the be�ring

areas.

5

MA S S E Y -FERGUS · ON

MF 150, 165 & 175 TRACTORS

Reassembly

Refer to Fig. S.

1. Apply a light coating of Permatex #3

form-a-gasket to bore of le ad gear shaft se al

in drive end body, No. 22. Press new seal i nto

position (flush to surface of bore) d stake in

three places.

NOTE: Omit this procedure if seal

was not removed.

2. stl new ses, Nos. 13, 16 nd 24.

NOTE: MF 1 75 is being serviced,

a new gasket must be installed behind

seal, No. 24.

3. stal l new bearings, No . 17 , leading

gear, No . 20, and fol lowing gear, No. . 18.

Place pump bodies, Nos. 22, 14 and 12, in

their proper sequence and install bolts, No. 23.

4. stl drive pinion and key, Nos. 3 and

19, onto sht, No. 20.

5. sll reservoir retainer, No. 11. Po-

sition filter element, No. 10, spring seating

cup, No .• 9, spring, No. 8, and spring retning

pin, No. 6, in place on center sd, No. 7, and

install stud into reseoir retner, No. 11.

6. stall new "0"-ring, No. 5, and positio n

reservoir onto reservoir end body. stl re-

taining nut and washer.

7. the relief valve assembly, No. 15, has

been removed, reinstall the assembly;. less the

Welch plug. (Final adjustment is to be made

during test. )

8. Rotate the drive gear by hand check

for freedom of movement. The pp should

have a ce

·

rfaih amount of drag but should rotate

freely ter a shor t period of rning.

ENGIN E-DRIVEN STEE RING

PUMP-Gasoline Model

FILLING THE RESERVOIR

l. Posion front wheels in a straight for-

ward direcon d shut off engine.

2. Re

.

move reservoir cover and fill reser-

voir wi oil coorming to MF ecification

6

GROUP IV - SE· CTION A - PART 12

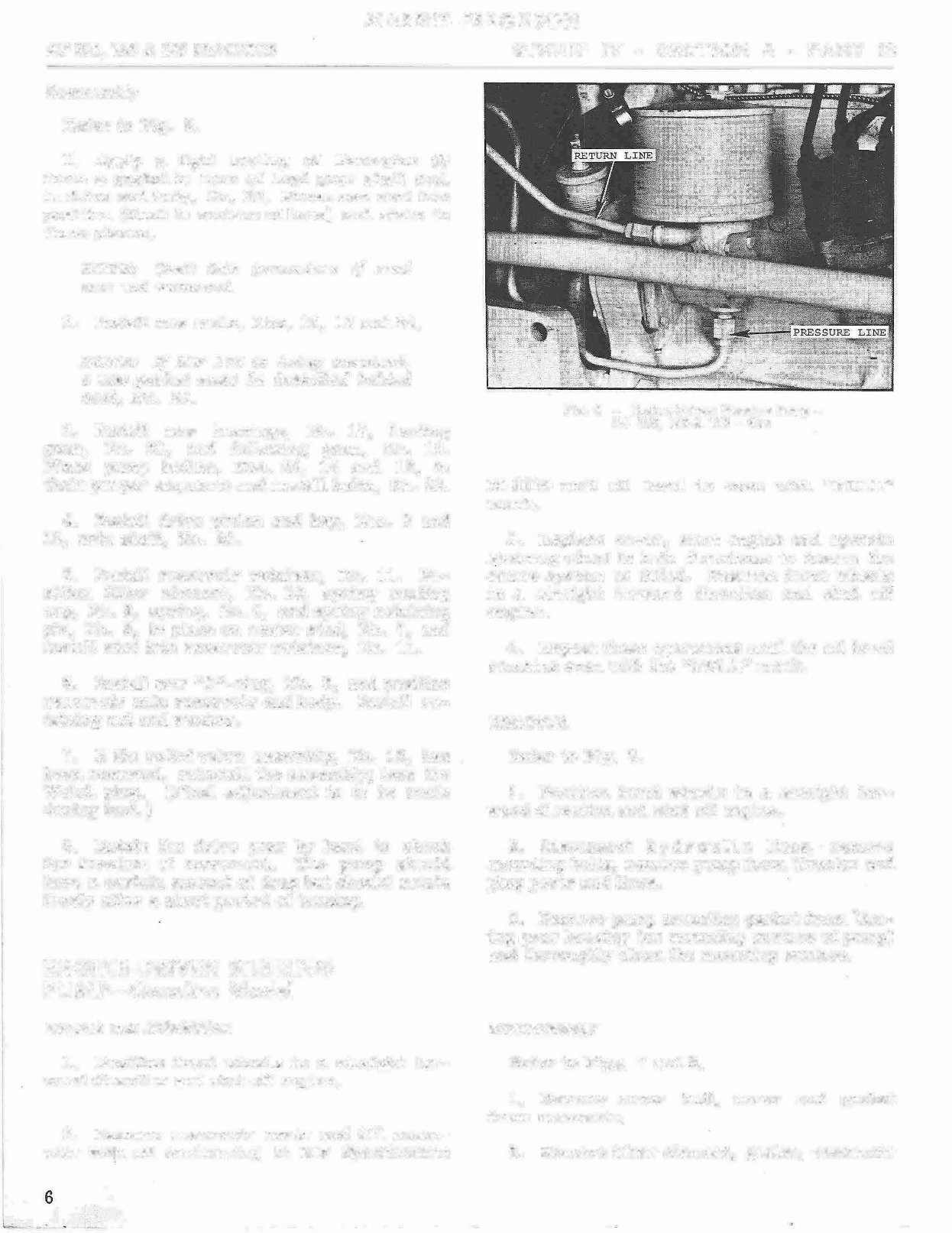

Fig. 6 - Engine-Driv- en Steering Pp -

M F 1 50, 16 5 & 17 5 - Ga s

M�11l 0 until oil leve l is even with "FULL''

mark.

3. Replace cover, start engine d operate

steering wheel in both recons insure the

entire system is filled. Posit ion front wheels

in a straight forward direction and shut off-

engine.

4. Repeat these operations until the oil level

remains even with the "FULL" mark.

REMOVAL

Refer to Fig. 6.

1. Position fro nt wheels in a strght for-

ward direction and shut off engine.

2. Disconnect h y d r u 1 i c lines,

·

remove

mounting bol ts, r

·

emove pump from Tractor and

plug ports d lines.

3. Remove pump m- ounting gasket from 'm-

ing gear hous ing (or mounting surface of pump)

and thoroughly cle the mounting surface.

DISASSEMBLY

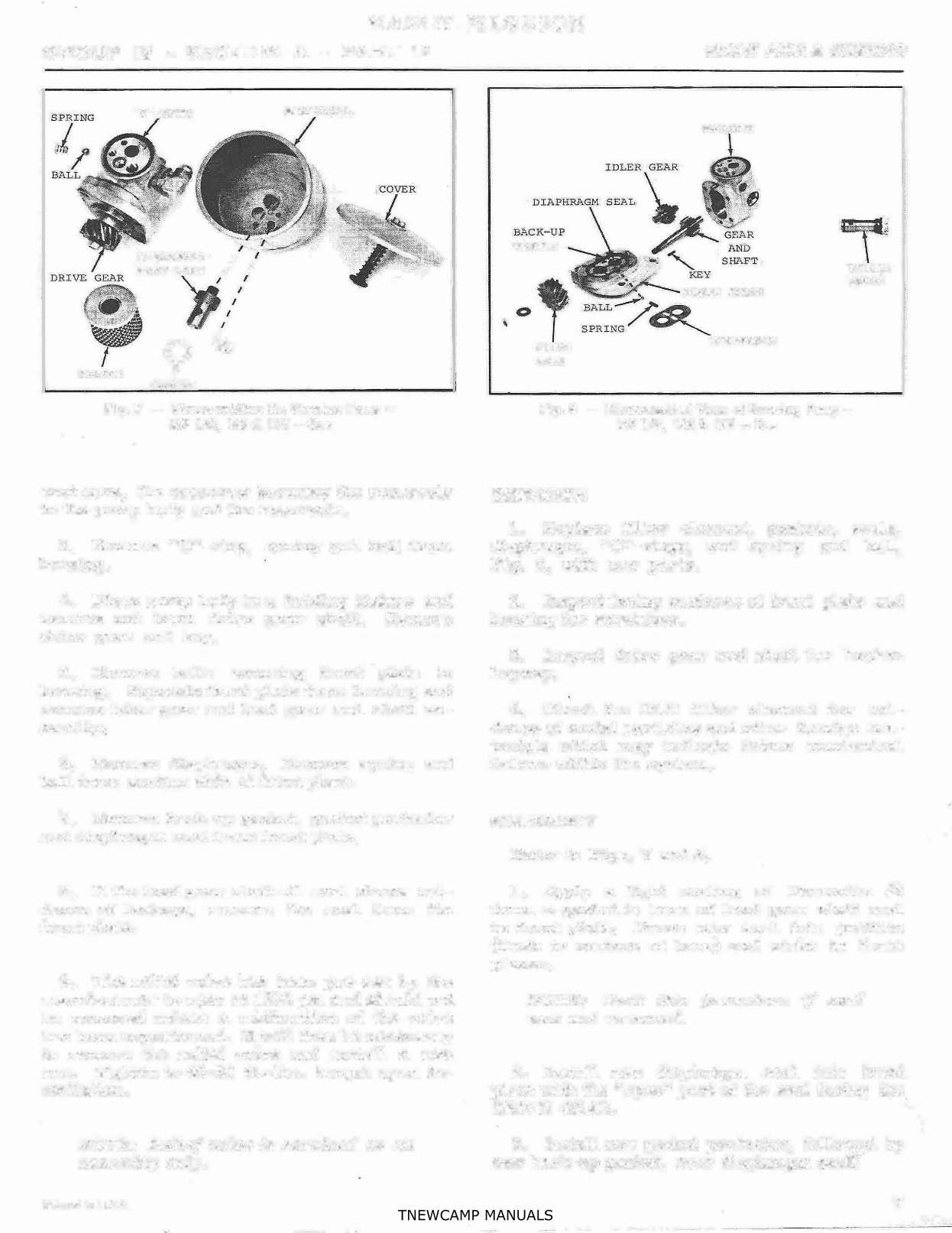

Refer to Figs. 7 d 8.

1. Remove cover bolt, cover d gasket

from reservoir.

2. Remove filter element, gasket, reservoi r

MASSEY-FER · GUSON

GROUP IV - SECTION A - PART 12 FRONT AXLE & STE

·

ERING

FI_LTER

"0"-RING'

SERVOIR J

SEAT •CORE /

I/,

0

t

Gl�ST

RESERVOIR

I

Fig. 7 - DisQssembling the Steering Pump -

M 150, 165 & 175-

·

Gas

seat core, the capscrew securing the reservoir

to the pump body and t he reservoir.

3. Remove "0"-ring, spring d hl from

housing.

4. Plac· e pump body in a holding fixture d

remove nut from drive . gear sht. Remove

drive gear and key.

5 . Remove bolts securing front plate to

housing. Separate front plate from housing and

remove idler gear and lead gear d shaft as-

embly.

6. Remove diaphragm. Remove spring and

bl from suction side of front plate.

7 . Remove back-up gasket, gasket protector

and diaphragm seal from f ront plate.

B. the lead gear s ht oil seal shows evi-

dence of leakage, remove the se from e

front plate.

9. The relief valve has been pre-set by the

m anuf acturer to open at 1500 psi and hould not

be removed unless a malfunction of e valve

has been eerienced. It will then be necssary

to remove the relief vve and ins tall a new

one. Tighten to 40-50 ft. -lbs. torque upon in-

sl laon.

NOTE: Relief valve is servied as an

assembly an.Zy .

Printed in U.S.A.

GAST

DRIVE

GEAR

HOUSING

FRONT P.TE

BA- LL

�

�

SPRING/ �

DIAPH�GH

REli�F

VAL

Fig. 8 - Di sssebled View of Steering Pump -

MF 150� 165 & 17 5 - Gas

INSPECTIO N

1. Replace filter e lement, gaskets, ses,

diaphragm, "0" -Fings, and spring and ball,

Fig. 8, with new par ts.

2. spect facing surface s of front plate and

housing for scratches.

3. spect drive gear an d shaft for broken

keyway.

4. Check the OLD filter e lement for evi-

dence of meal p articles and other foreign ma-

terials wnich may incate fur e mechanical

failure within the sy stem.

REAS SEMBLY

Refer to Figs. 7 d 8 .

1. Apply a light coating of Permatex #3

form-a-gasket to bore of lead gear shaft seal

in front plate. Press new seal into posion

( flush to surface of bore ) and stake in three

places.

NOTE·: Omit this procedure if s ea l

was not removed.

2.. stall new diaphragm se into front

plate wi th the "open" par t of the se facing the

ORNE GEAR.

3. stall new gasket protector, fo l lowed by

new back-up gasket, over diaphragm seal :

7

MASSEY-FERGUSON

MF 150, 165 & 175 TRACTORS

4. Drop new ball and new spring into hole on

sctian side of front plate and place new dia-

phragm on top of gasket.

NOTE: The two notches in diaphragm

rnust go on suction side of pump and

bronze side of diaphragm 1nust face

upward.

5. stall lead gear and sht into front plate

d place ier gea r into front plate with paint-

ed (or marked) end of shaft tow ard the DRE

GEAR.

6. Install front plate. Tighten bolts evenly

to 7 -10 ft. -lbs. torque.

NOTE: Ensure that diaphragm re-

nwins within its groove in front pla te.

7. stall new "0" -ring, Fig. 7, bal l and

spring.

B. stal l reservoir seat core and gasket

onto reservoir. Fasten reservoi r onto housing

with caps crew and w asher. Tighten core and

capscrew to 10-15 ft. -lbs. torque.

9. stall key into its groove and sl ide drive

gear over shaft. Instal l nut and washer. Tight-

en to 15-20 f t.-lbs . torque.

10. Rotate the drive gear by hand to check

for freedom of movement. The pump should

have a certain amount of drag but should rotate

f _ reely after a short period of turning.

INSTALLATION

Refer to Fig. 6 .

1 . Apply a thin coating of heavy grease to

pump mounti ng surface of timin g gear housing

d place new pump gasket into pos ition.

2 . Carefully inse rt the pump drive gear into

e opening in e timing gear housing. Ensure

that drive gea r is meshing prope rly d install

mounting bolts. Tighten to 30-35 ft.-lbs.

torque.

3. Remove plugs from ports and lin es. Con-

nect rern li ne to its r espective port. Tighten

to 20-30 f t.-lbs. torque. sl l oi l pressure

gauge bee en pump d pressure line.

4. stl new fil ter elment ad fill rese r-

voir w i oil coorming to MF ecification

8

GROUP IV - SECTION A - PA RT 12

M-1110 until oi l level is even with the "FULL"

mark. Install reservoir cover.

5. Start engine a nd turn steering wheel to

extreme left and right. Shut off engine and re-

check oil level. It must remain at the "FULL"

m ark.

6. With engine running, che ck pressure

gauge reading. The pressure reading should be

1500 psi. the pressure reang is correct

proceed to Step 7. incorrect, remove the

relief valve and i nstal l a new one. Tighten

valve to 40-50 ft. -lbs. torque .

7. Shut off engine and remove pressure

gauge. Connect pressure line. Tighten to 20-

30 ft.-lbs . torque.

8. Remove reservoir cover to check for

correct fluid leve l. Maintain fluid leve l even

with "FULL" mark. Replace reservoir cover.

HYDRAULIC CYLINDER AND VALVE

REMOVAL

MF 165 and M

.

F 175 Row Crop Models

Two different pes of stee ring arrangements

are used on the MF 165 and MF 17 5 Tractors

having e Row Crop front axle. Therefore the

removal, instlaon and adjustment proce-

dures of e cylinder and vve wil l dfer. Re-

fer to Figs. 9 and 1 1, which show these o

steering arrangeme nts and follow the approp ri-

ate procedures fo r the Trac tor being se rviced.

ARR ANGE.MENT AS SHOWN IN FIG . 9

Refer to Figs. 9 d 10.

1. Remove grille door, gril le d side

panels.

2. sconnect hoses, Nos. 2 and 3 . Plug

ports.

3. Remove cotter pin and clevis pin, No. 5,

securing ste ering arm link,

·

No 4, to the upper

steering arm, No. 9.

4. sconnect drag li nk, No. 8, and remove

snap ring, No. 11.

5. Remove upper arm from pedestal shaft.

You're Reading a Preview

What's Included?

Fast Download Speeds

Online & Offline Access

Access PDF Contents & Bookmarks

Full Search Facility

Print one or all pages of your manual

$39.99

Viewed 16 Times Today

Loading...

Secure transaction

What's Included?

Fast Download Speeds

Online & Offline Access

Access PDF Contents & Bookmarks

Full Search Facility

Print one or all pages of your manual

$39.99

Massey Ferguson MF 175 Service & Repair Manual

When it comes to fixing problems on your tractor, this repair manual provides a comprehensive, step-by-step approach. It includes troubleshooting and replacement procedures, along with clear images and exploded-view illustrations, making it useful for both professional mechanics and DIY enthusiasts.

Regular maintenance is essential for the durability of your tractor. Over time, certain parts will wear out and require replacement. A good tractor repair manual offers manufacturer-recommended troubleshooting charts and replacement procedures, enabling you to save on repairs, reduce downtimes, and maintain your tractor effectively.

Please note:

- This is not a generic repair manual. It contains every troubleshooting and replacement procedure provided by the manufacturer, including step-by-step instructions, exploded-view illustrations, and clear images.

- No need to flip through hundreds of pages to find specific information. It is easily accessible and searchable, making it more convenient than a traditional bound manual.

- Printable: Yes

- Language: English

- Compatibility: Compatible with various electronic devices, including PC, Mac computers, Android and Apple smartphones, and tablets.

- Requirements: Adobe Reader (free)