Massey Ferguson 1010 & 1020 Tractor Service & Repair Manual

What's Included?

Fast Download Speeds

Online & Offline Access

Access PDF Contents & Bookmarks

Full Search Facility

Print one or all pages of your manual

SHOP MANUAL

MASSEY-FERGUSON

MODELS 1010 AND 1020

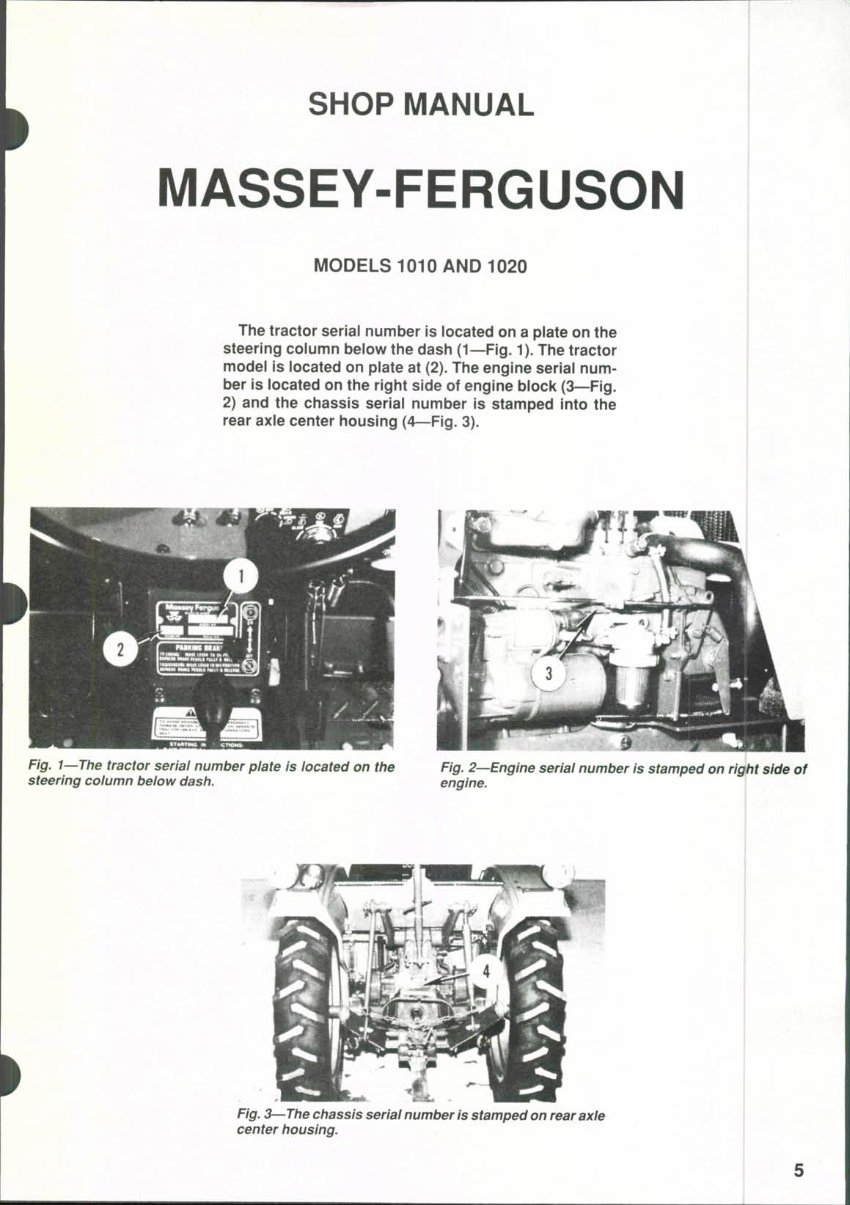

The tractor serial number is located on a plate on the

steering column below the dash (1—Fig. 1). The tractor

model is located on plate at (2). The engine serial num-

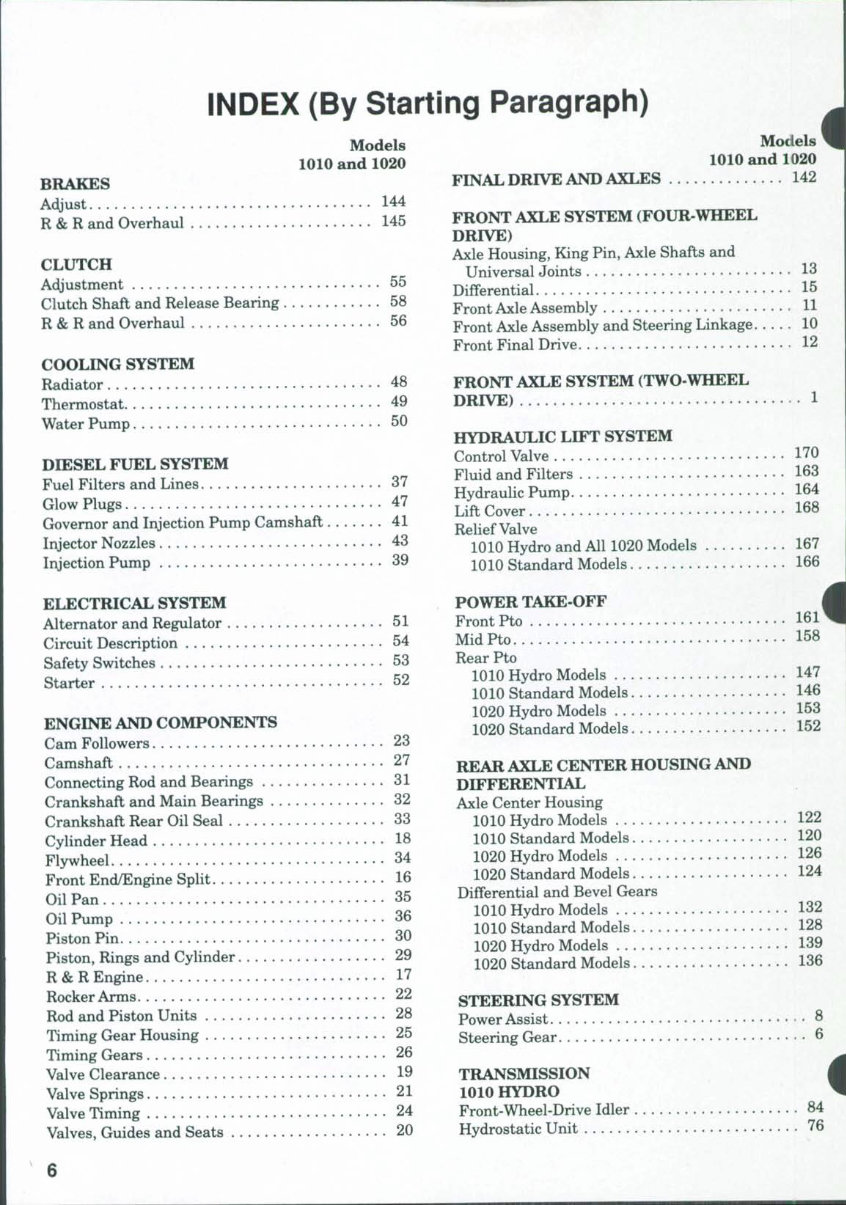

ber is located on the right side of engine block (3—Fig,

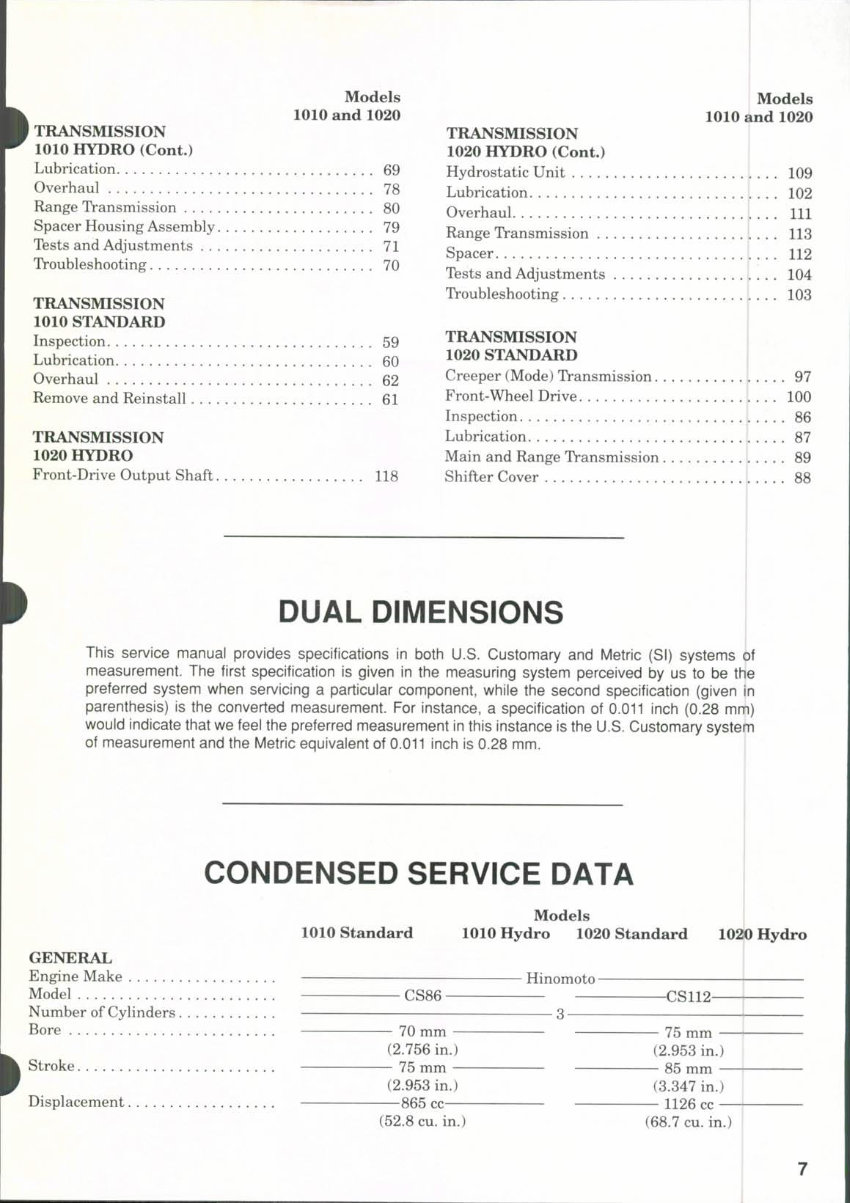

2) and the chassis serial number is stamped into the

rear axle center housing (4—Fig. 3).

Fig, I—The tractor serial number plate Is located on the Fig. 2—Englne serial number Is stamped on right side of

steering column below dash. engine.

Fig. 3—The chassis serial number Is stamped on rear axle

center housing.

INDEX (By Starting Paragraph)

Models

1010 and 1020

BRAKES

Adjust 144

R & R and Overhaul 145

CLUTCH

Adjustment 55

Clutch Shaft and Release Bearing 58

R & R and Overhaul 56

COOLING SYSTEM

Radiator 48

Thermostat 49

Water Pump 50

DIESEL FUEL SYSTEM

Fuel Filters and Lines 37

Glow Plugs 47

Governor and Injection Pump Camshaft . 41

Injector Nozzles 43

Injection Pump 39

ELECTRICAL SYSTEM

Alternator and Regulator 51

Circuit Description 54

Safety Switches 53

Starter 52

ENGINE AND COMPONENTS

Cam Followers 23

Camshaft 27

Connecting Rod and Bearings 31

Crankshaft and Main Bearings 32

Crankshaft Rear Oil Seal 33

Cylinder Head 18

Flywheel 34

Front End/Engine Split 16

Oil Pan 35

Oil Pump 36

Piston Pin 30

Piston, Rings and Cylinder 29

R & R Engine 17

Rocker Arms 22

Rod and Piston Units 28

Timing Gear Housing 25

Timing Gears 26

Valve Clearance 19

Valve Springs 21

Valve Timing 24

Valves, Guides and Seats 20

Models

1010 and 1020

FINALDRIVE AND AXLES 142

FRONT AXLE SYSTEM (FOUR-WHEEL

DRIVE)

Axle Housing, King Pin, Axle Shafts and

Universal Joints 13

Differential 15

Front Axle Assembly H

Front Axle Assembly and Steering Linkage 10

Front Final Drive 12

FRONT AXLE SYSTEM (TWO-WHEEL

DRIVE) 1

HYDRAULIC LIFT SYSTEM

Control Valve 170

Fluid and Filters 163

Hydraulic Pump 164

Lift Cover 168

Relief Valve

1010 Hydro and All 1020 Models 167

1010 Standard Models 166

POWER TAKE-OFF i

Front Pto 161^

MidPto 158

Rear Pto

1010 Hydro Models 147

1010 Standard Models 146

1020 Hydro Models 153

1020 Standard Models 152

REAR AXLE CENTER HOUSING AND

DIFFERENTIAL

Axle Center Housing

1010 Hydro Models 122

1010 Standard Models 120

1020 Hydro Models 126

1020 Standard Models 124

Differential and Bevel Gears

1010 Hydro Models 132

1010 Standard Models 128

1020 Hydro Models 139

1020 Standard Models 136

STEERING SYSTEM

Power Assist 8

Steering Gear 6

TRANSMISSION

1010 HYDRO

Front-Wheel-Drive Idler 84

Hydrostatic Unit 76

Models

1010 and 1020

TRANSMISSION

1010 HYDRO (Cont.)

Lubrication 69

Overhaul 78

Range Transmission 80

Spacer Housing Assembly 79

Tests and Adjustments 71

Troubleshooting 70

TRANSMISSION

1010 STANDARD

Inspection 59

Lubrication 60

Overhaul 62

Remove and Reinstall 61

TRANSMISSION

1020 HYDRO

Front-Drive Output Shaft 118

Models

1010 and 1020

TRANSMISSION

1020 HYDRO (Cont.)

Hydrostatic Unit 109

Lubrication 102

Overhaul , 111

Range Transmission 113

Spacer 112

Tests and Adjustments 104

Troubleshooting 103

TRANSMISSION

1020 STANDARD

Creeper (Mode) Transmission 97

Front-Wheel Drive 100

Inspection. 86

Lubrication 87

Main and Range Transmission 89

Shifter Cover 88

DUAL DIMENSIONS

This service manual provides specifications in both U.S. Customary and Metric (SI) systems of

measurement. The first specification is given in the measuring system perceived by us to be the

preferred system when servicing a particular component, while the second specification (given in

parenthesis) is the converted measurement. For instance, a specification of 0.011 inch (0.28 mm)

would indicate that we feel the preferred measurement in this instance is the U.S. Customary system

of measurement and the Metric equivalent of 0.011 inch is 0.28 mm.

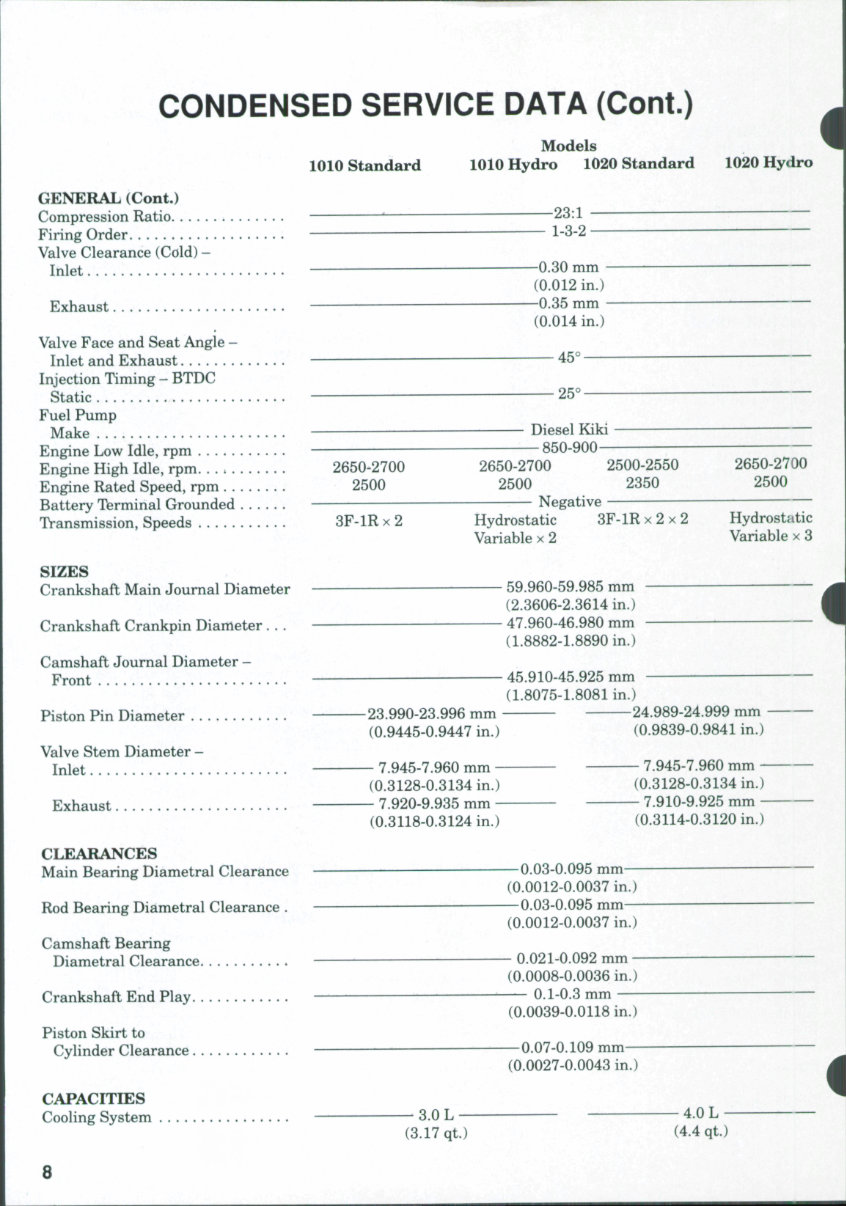

CONDENSED SERVICE DATA

1010 standard

Models

1010 Hydro 1020 Standard 1020 Hydro

GENERAL

Engine Make

Model

Number of Cylinders.

Bore

Stroke

Displacement

Hinomoto -

CS86 • -CS112-

— 70 mm —

(2.756 in.)

— 75 mm —

(2.953 in.)

865 cc

(52.8 cu. in.)

— 75 mm —

(2.953 in.)

— 85 mm —

(3.347 in.)

— 1126 cc —

(68.7 cu. in.)

CONDENSED SERVICE DATA (Cont.)

Models

1010 Standard 1010 Hydro 1020 Standard 1020 Hydro

i

GENERAL (Cont.)

Compression Ratio " 23:1 —

Firing Order ~" 1-3-2 —

Valve Clearance (Cold) -

Inlet ' —0.30 mm ——

(0.012 in.)

Exhaust —0.35 mm

(0.014 in.)

Valve Face and Seat Angle -

Inlet and Exhaust ^ — 45°—

Injection Timing - BTDC

Static 25° -—

Fuel Pump

Make — Diesel Kiki —

Engine Low Idle, rpm ' 850-900 -

Engine High Idle, rpm 2650-2700 2650-2700 2500-2550 2650-2700

Engine Rated Speed, rpm 2500 2500 2350 2500

Battery Terminal Grounded Negative

Transmission, Speeds 3F-1R x 2 Hydrostatic 3F-1R x 2 x 2 Hydrostatic

Variable x 2 Variable x 3

SIZES

Crankshaft Main Journal Diameter • 59.960-59.985 mm

(2.3606-2.3614 in.)

Crankshaft Crankpin Diameter . . . 47.960-46.980 mm

(1.8882-1.8890 in.)

Camshaft Journal Diameter -

Front 45.910-45.925 mm

(1.8075-1.8081 in.)

Piston Pin Diameter 23.990-23.996 mm 24.989-24.999 mm

(0.9445-0.9447 in.) (0.9839-0.9841 in.)

Valve Stem Diameter -

Inlet 7.945-7.960 mm 7.945-7.960 mm

(0.3128-0.3134 in.) (0.3128-0.3134 in.)

Exhaust 7.920-9.935 mm 7.910-9.925 mm

(0.3118-0.3124 in.) (0.3114-0.3120 in.)

CLEARANCES

Main Bearing Diametral Clearance —^0.03-0,095 mm

(0.0012-0.0037 in.)

Rod Bearing Diametral Clearance . — 0.03-0.095 mm

(0.0012-0.0037 in.)

Camshaft Bearing

Diametral Clearance 0.021-0.092 mm

(0.0008-0.0036 in.)

Crankshaft End Play — 0.1-0.3 mm

(0.0039-0.0118 in.)

Piston Skirt to

Cylinder Clearance 0.07-0.109 mm

(0.0027-0.0043 in.)

CAPACITIES

Coohng System 3.0 L 4.0 L

(3.17 qt.) (4.4 qt.)

8

CONDENSED SERVICE DATA (Cont.)

Models

1010 Standard 1010 Hydro 1020 Standard 1020 Hydro

CAPACITIES (Cont.)

Crankcase With Filter 2.5 L* 3.0 L 3.7 L

(2.64 qt.*) (3.2 qt.) (4.0 qt.)

Transmission 17 L 23 L 26 L

(4.5 gal.) (6.08 gal.) (6.9 gal.)

Front Drive Axle Hubs

(Each Side) — 0.4 L

(0.42 qt.)

Front Drive Axle Housing 1,5 L

(1.6 qt.)

* Later models with two drain plugs - 3.0 L (3.2 qt.).

9

Paragraphs 1-3

MASSEY-FERGUSON

FRONT AXLE SYSTEM

(TWO-WHEEL DRIVE)

FRONT AXLE ASSEMBLY AND

STEERING LINKAGE

Two-Wheel-Drive Models

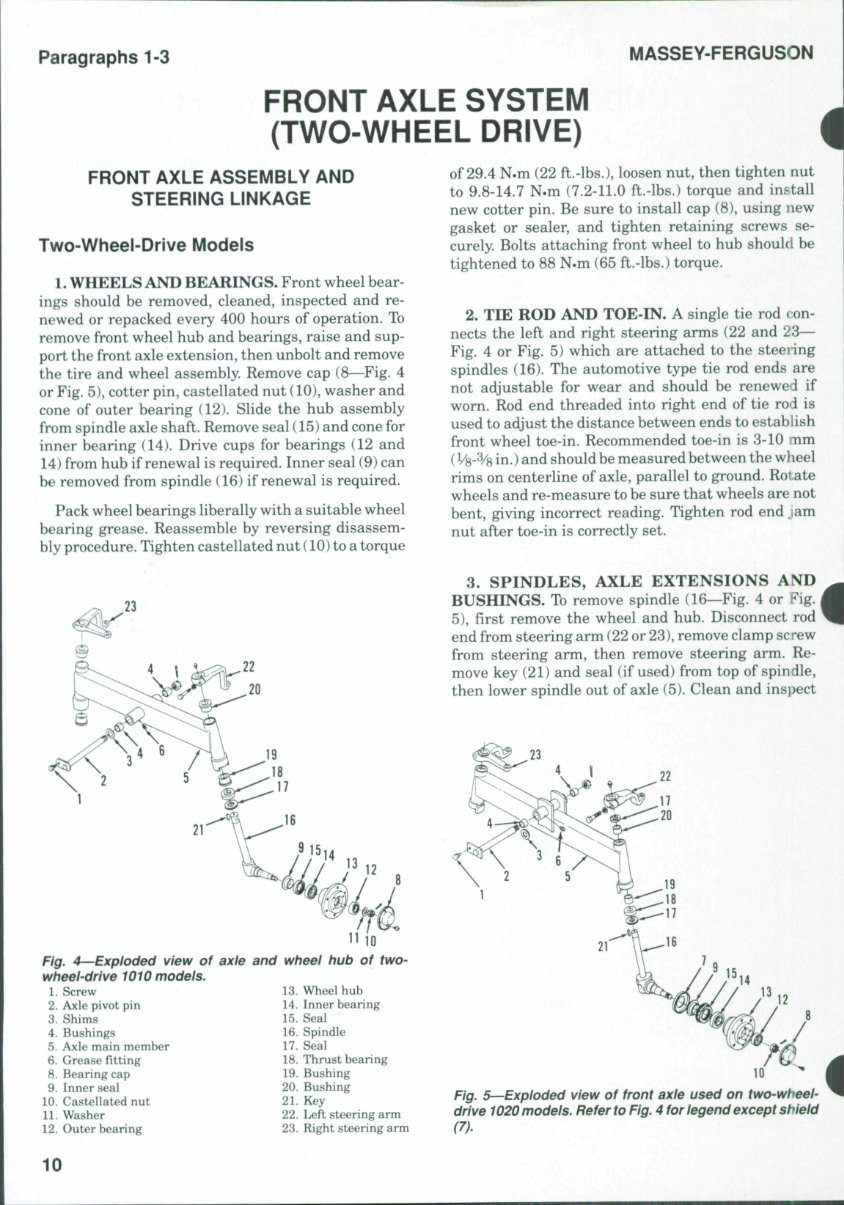

1. WHEELS AND BEARINGS. Front wheel bear-

ings should be removed, cleaned, inspected and re-

newed or repacked every 400 hours of operation. To

remove front wheel hub and bearings, raise and sup-

port the front axle extension, then unbolt and remove

the tire and wheel assembly. Remove cap (8—Fig. 4

or Fig. 5), cotter pin, castellated nut (10), washer and

cone of outer bearing (12). Slide the hub assembly

from spindle axle shaft. Remove seal (15) and cone for

inner bearing (14). Drive cups for bearings (12 and

14) from hub if renewal is required. Inner seal (9) can

be removed from spindle (16) if renewal is required.

Pack wheel bearings liberally with a suitable wheel

bearing grease. Reassemble by reversing disassem-

bly procedure. Tighten castellated nut (10) to a torque

Fig. 4—Exploded view of axle

wheel-drive 1010 models.

and wheel hub of two-

1. Screw

2. Axle pivot pin

3. Shims

4. Bushings

5. Axle main member

6. Grease fitting

8. Bearing cap

9. Inner seal

10. Castellated nut

11. Washer

12. Outer hearing

13. Wheel huh

14. Inner hearing

15. Seal

16. Spindle

17. Seal

18. Thrust bearing

19. Bushing

20. Bushing

21. Key

22. Left steering arm

23. Right steering arm

of 29.4 N.m (22 ft.-lbs.), loosen nut, then tighten nut

to 9.8-14.7 N.m (7.2-11.0 ft.-lbs.) torque and install

new cotter pin. Be sure to install cap (8), using new

gasket or sealer, and tighten retaining screws se-

curely. Bolts attaching front wheel to hub should be

tightened to 88 N.m (65 ft.-lbs.) torque.

2. TIE ROD AND TOE-IN. A single tie rod t on-

nects the left and right steering arms (22 and 23—

Fig. 4 or Fig. 5) which are attached to the steering

spindles (16). The automotive type tie rod ends are

not adjustable for wear and should be renewed if

worn. Rod end threaded into right end of tie rod is

used to adjust the distance between ends to establish

front wheel toe-in. Recommended toe-in is 3-10 mm

(V8-% in.) and should be measured between the wheel

rims on centerline of axle, parallel to ground. Roi ate

wheels and re-measure to be sure that wheels are not

bent, giving incorrect reading. Tighten rod end jam

nut after toe-in is correctly set.

3. SPINDLES, AXLE EXTENSIONS AND

BUSHINGS. To remove spindle (16—Fig. 4 or Fig. |

5), first remove the wheel and hub. Disconnect rod

end from steering arm (22 or 23), remove clamp screw

from steering arm, then remove steering arm. Re-

move key (21) and seal (if used) from top of spindle,

then lower spindle out of axle (5). Clean and inspect

Flg^ 5—Exploded view of front axie used on two-wheel-

drlve 1020 models. Refer to Fig. 4 for legend except shield

10

MODELS 1010 & 1020

Paragraphs 4-5

parts for wear or other damage and renew as neces-

sary.

Spindle bushings (19 and 20) should not require

reaming after pressing into position in axle (5). Be

sure that hole in spindle for grease fitting is clean and

open before assembling.

When reassembling, install thrust bearing (18) so

that numbered side of bearing is facing upward. In-

stall seal (17) and insert spindle through axle. Install

upper seal (if so equipped) and key (21), then locate

steering arm on top of spindle. Tighten steering arm

retaining clamp screw to 88 N.m (65 ft.-lbs.) torque.

Bolts attaching front wheel to hub should be tight-

ened to 88 N.m (65 ft.-lbs.) torque. Balance of reas-

sembly is the reverse of disassembly. Refer to

paragraph 2 for toe-in adjustment.

4. AXLE CENTER MEMBER, PIVOT PIN AND

BUSHINGS. To remove front axle assembly, first

remove any front mounted equipment, guards,

weights and weight frame. Raise front of tractor in

such a way that it will not interfere with the removal

of the axle. Remove the front wheels. Disconnect

steering hoses if equipped with power steering and

cover openings to prevent the entry of dirt. On all

models, disconnect drag link from right steering arm.

Support the axle with a suitable jack to prevent

tipping while permitting the axle to be lowered and

|moved safely. Remove axle pivot pin (2—Fig. 4 or Fig.

r5), carefully lower the axle assembly and roll axle

from under tractor.

Check axle pivot bushings (4) and renew if neces-

sary. Bushings are pressed into bore of axle and

should be installed flush with bore. Split in bushing

should be 45° from top of axle bore. It should not be

necessary to ream bushings after installation.

Reverse removal procedure when assembling. Axle

end play should be 0-0.3 mm (0-0.012 in.) for 1010

models; 0-0.4 mm (0-0.016 in.) for 1020 models. Push

the axle toward rear on pivot pin, then measure axle

end play with a feeler gauge. Shims (3) are available

in various thicknesses for adjusting end play. Make

sure that pin retaining screw (1) at front is tight and

that pin retaining nut at rear is snug, but not over-

tightened. Install cotter pin through pin and castel-

lated nut. Refer to paragraphs 2 and 3 for additional

torque values and assembly notes.

5. FRONT SUPPORT, The front axle and radiator

must be removed before unbolting the front axle

support from engine. The front axle, the front support

and the remainder of the tractor must each be sup-

ported separately while removing, while separated

and while assembling. Be sure that sufficient equip-

ment is available before beginning.

Remove any front mounted equipment, guards,

weights and weight frame. Unplug lights, then re-

move hood and grille assembly. Remove the battery,

drain cooling system, disconnect radiator hoses and

remove radiator assembly. Refer to paragraph 4 and

remove axle assembly. Remove the front pto, if so

equipped. On all models, attach a hoist or other

supporting device to front support, then remove the

five retaining screws from each side and separate the

front support from engine.

Reattach front support to engine by reversing the

removal procedure. Apply "Loctite 271" or equivalent

to the ten screws attaching front support and frame

to sides of engine. Complete assembly by reversing

the removal procedure.

Paragraphs 6-8

MASSEY-FERGUSON

STEERING SYSTEM

STEERING GEAR

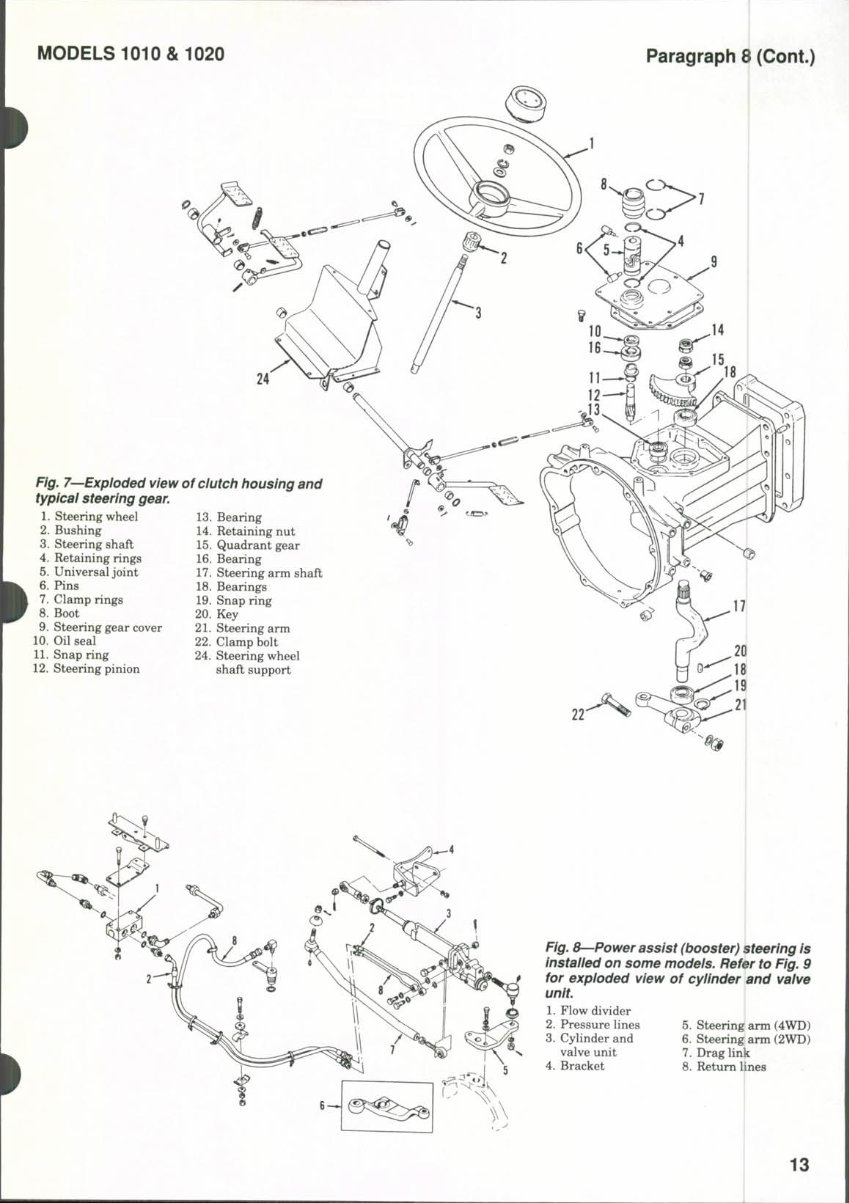

All Models

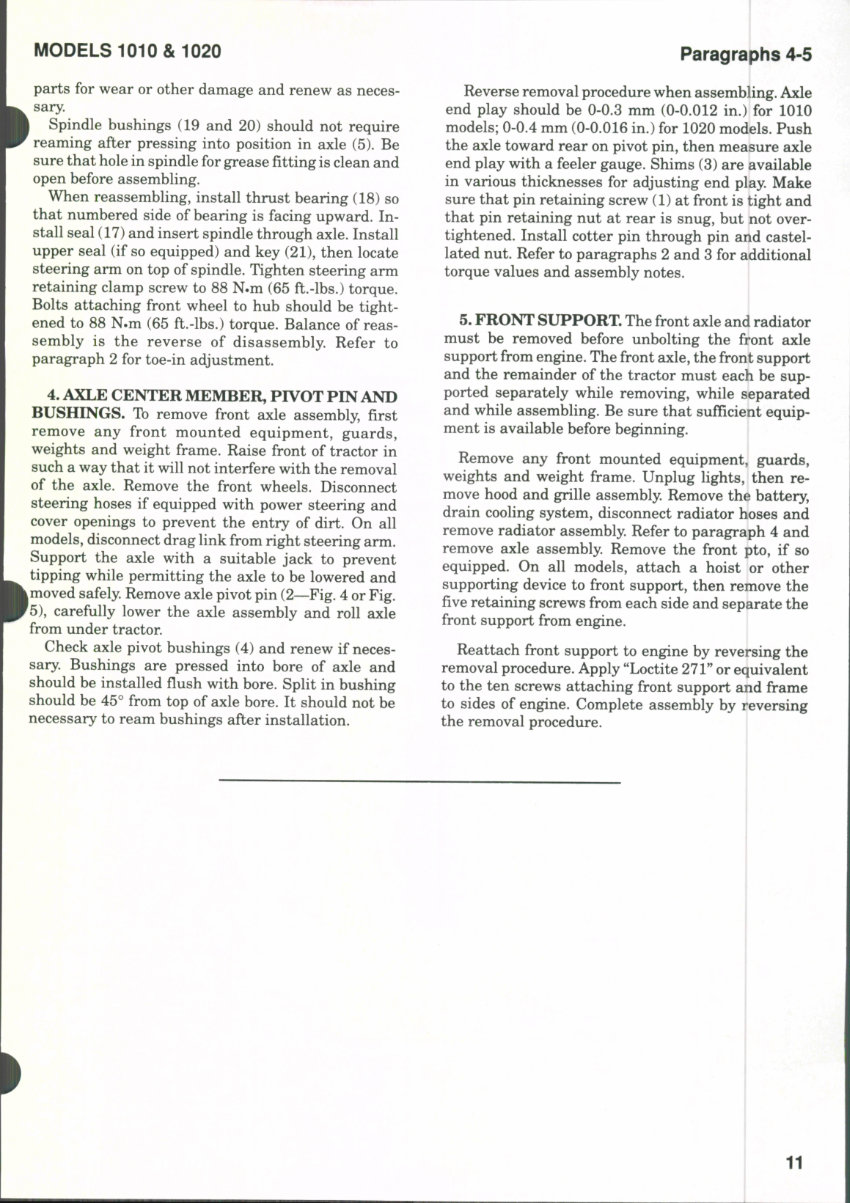

6. A cross section drawing of the manual steering

gear assembly is shown in Fig 6. Note that the steer-

ing gears are contained within a cavity in the top of

the clutch housing and that the steering shaft ex-

tends through the clutch housing. The steering ratio

is 10:1 for all 1010 models and 13:1 for all 1020

models. Some differences will be noticed, including

the number of teeth on gears (12 and 15—Fig, 7) and

shaft (17) may be straight on some models.

7. R&R AND OVERHAUL. To service steering

gear, it is necessary to remove the steering wheel,

instrument panel cover and fuel tank. Disconnect

brake and clutch rods from pedals and pedal cross

Fig. &^Cross section drawing of steering gear typicai of

ali modeis. Refer to Fig. 7 for exploded view.

shaft, then unbolt and remove the steering wheel

shaft support (24—Fig. 7). Remove clamp rings- (7)

and slide boot (8) up to uncover universal joint. Re-

move lower retaining ring (4) and use a punch to d rive

lower pin (6) from universal joint, then separate

universal joint (5) from pinion shaft (12). Notice that

pins (6) are stepped and must be removed toward

larger end. Remove screws attaching cover (9) to

transmission housing, then remove cover, leaving

pinion shaft (12) in transmission housing. Pinion

shaft (12) and quadrant gear (15) can be removed

together after removing retaining nut (14). Steering

arm shaft (17) can be removed after splitting tractor

between engine and clutch housing, then removing

the engine clutch shaft.

When reassembling, front wheels must be straight

ahead and steering pinion (12) must be in center of

teeth on quadrant gear (15). Tighten nut (14) to 59-78

N.m (43-58 ft.-lbs.) torque. If tab lockwasher is in-

stalled under nut (14), flat side of nut should be

toward top and tab of washer should be bent up to

lock retaining nut. Some models may be equij^ped

with self-locking nut or two special nuts. Fill gear

cavity half full with multi-purpose lithium ])ase

grease. Nut for clamp bolt (22) retaining steering arm

(21) to lower end of shaft should be tightened to 78-90

N.m (57-68 ft.-lbs.) torque. The steering arm (21) o

some models is retained with a nut threaded to shaft

similar to the type (14) at upper end. The larger

retaining nut should be tightened to 98-117 N.m

(72-87 ft.-lbs.) torque.

POWER ASSIST

Models So Equipped

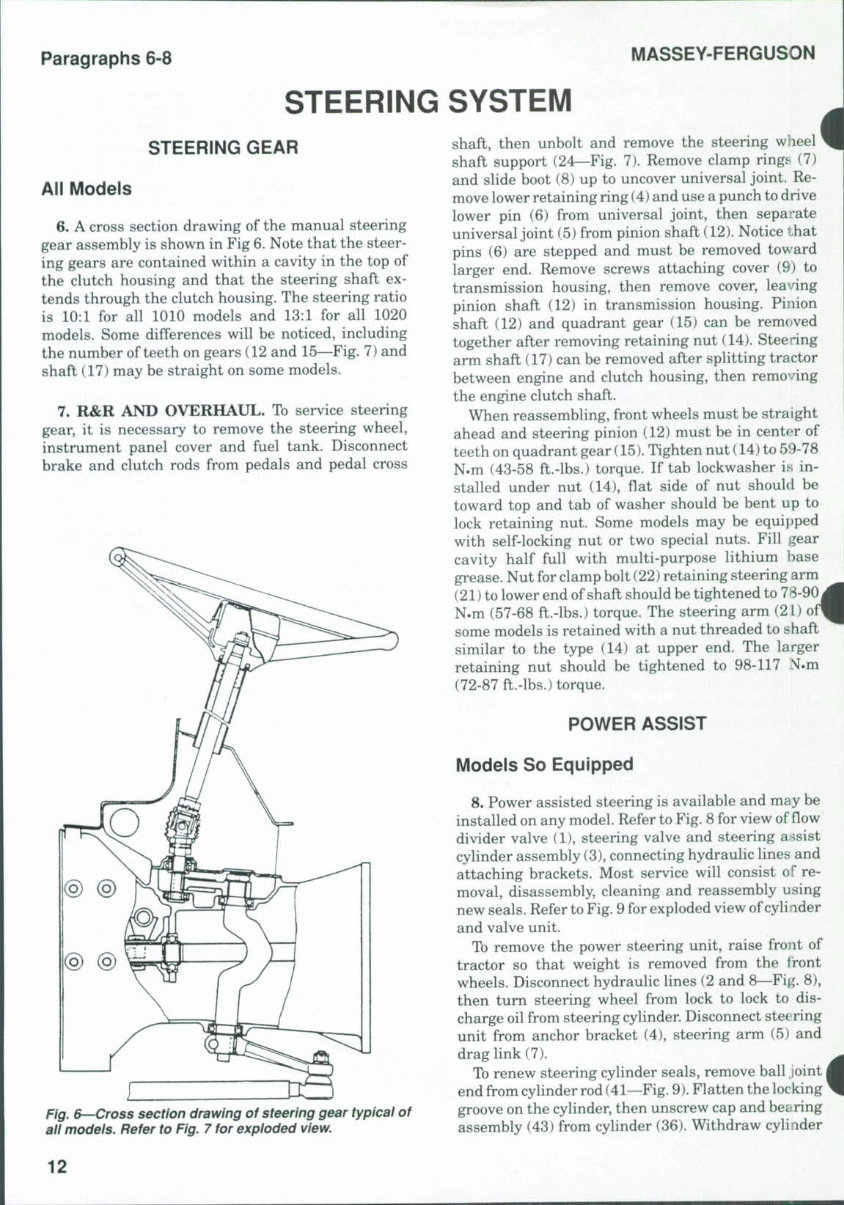

8. Power assisted steering is available and may be

installed on any model. Refer to Fig. 8 for view of flow

divider valve (1), steering valve and steering assist

cyhnder assembly (3), connecting hydraulic lines and

attaching brackets. Most service will consist of re-

moval, disassembly, cleaning and reassembly using

new seals. Refer to Fig. 9 for exploded view of cylinder

and valve unit.

To remove the power steering unit, raise front of

tractor so that weight is removed from the lront

wheels. Disconnect hydraulic lines (2 and 8—Fig. 8),

then tum steering wheel from lock to lock to dis-

charge oil from steering cylinder. Disconnect steering

unit from anchor bracket (4), steering arm (5) and

drag link (7).

To renew steering cylinder seals, remove ball joint |

end from cylinder rod (41—Fig. 9). Flatten the locking

groove on the cylinder, then unscrew cap and bearing

assembly (43) from cylinder (36). Withdraw cylinder

12

MODELS 1010 & 1020

Paragraph 8 (Cont.)

Fig. 7^Expioded view of dutch housing and

typicai steering gear.

1. Steering wheel

2. Bushing

3. Steering shaft

4. Retaining rings

5. Universal joint

6. Pins

7. Clamp rings

8. Boot

9. Steering gear cover

10. Oil seal

11. Snap ring

12. Steering pinion

13. Bearing

14. Retaining nut

15. Quadrant gear

16. Bearing

17. Steering arm shaft

18. Bearings

19. Snap ring

20. Key

21. Steering arm

22. Clamp bolt

24. Steering wheel

shaft support

22'

Fig. 8—Power assist (booster) steering is

instaiied on some models. Refer to Fig. 9

for expioded view of cyiinder and vaive

unit.

1. Flow divider

2. Pressure lines

3. Cylinder and

valve unit

4. Bracket

I

5. Steering arm (4WD)

6. Steering arm (2WD)

7. Drag link

8. Return lines

13

Paragraph 8 (Cont.)

MASSEY-FERGUSON

IS

14

26

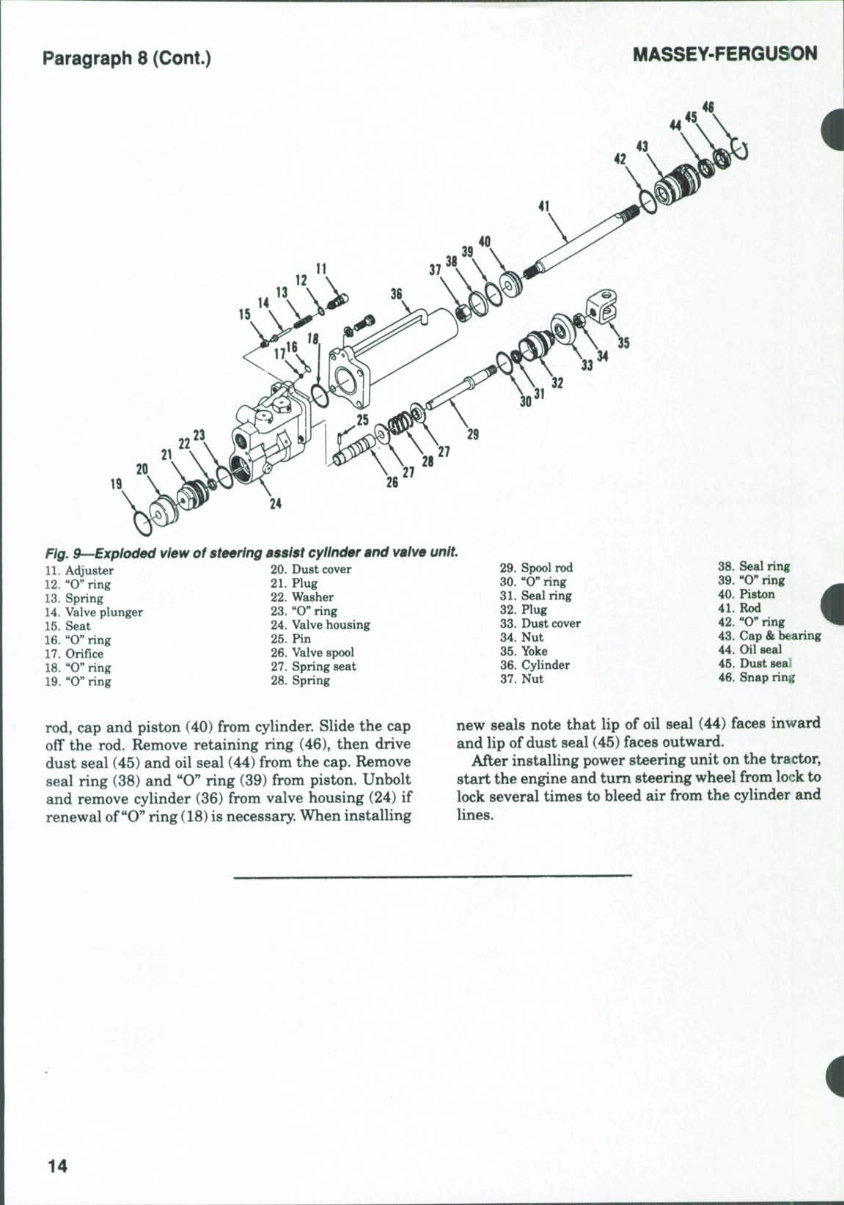

Fig. 9-~Explod0d view of steering BBSist cylinder and valve unit,

11. AcUuster 20. Dust cover 29. Spool rod

12. "O" ring 21. Plug 30. "0" ring

13. Spring 22. Washer 31. Seal ring

14. Valve plunger 23. "O" ring 32. Plug

15. Seat 24. Valve housing 33. Dust cover

16. "O" ring 25. Pin 34. Nut

17. Orifice 26. Valve spool 35. Yoke

18. "O" ring 27. Spring seat 36. Cylinder

19. "O" ring 28. Spring 37. Nut

38. Seal ring

39. "O" ring

40. Piston i

41. Rod I

42. "O" ring ^

43. Cap & bearing

44. Oil seal

45. Dust seal

46. Snap ring

rod, cap and piston (40) from cylinder. Slide the cap

off the rod. Remove retaining ring (46), then drive

dust seal (45) and oil seal (44) from the cap. Remove

seal ring (38) and "O" ring (39) from piston. Unbolt

and remove cylinder (36) from valve housing (24) if

renewal of "O" ring (18) is necessary. When installing

new seals note that lip of oil seal (44) faces inward

and lip of dust seal (45) faces outward.

After installing power steering unit on the tractor,

start the engine and tum steering wheel from lock to

lock several times to bleed air from the cylinder and

lines.

14

You're Reading a Preview

What's Included?

Fast Download Speeds

Online & Offline Access

Access PDF Contents & Bookmarks

Full Search Facility

Print one or all pages of your manual

$52.99

Viewed 71 Times Today

Loading...

Secure transaction

What's Included?

Fast Download Speeds

Online & Offline Access

Access PDF Contents & Bookmarks

Full Search Facility

Print one or all pages of your manual

$52.99

This manual is suitable for both first-time owners and amateur enthusiasts, as well as professional technicians. It is designed in an easy-to-read format and provides comprehensive information necessary for accurate procedure execution. It is recommended to keep this service manual accessible and refer to it regularly. Adhering to routine and preventive maintenance outlined in the manual will contribute to time and cost savings by averting premature failure and unnecessary repairs.

- BRAKES

- CLUTCH

- COOLING SYSTEM

- DIESEL FUEL SYSTEM

- DIFFERENTIAL

- DIFFERENTIAL LOCK

- ELECTRICAL SYSTEM

- ENGINE

- FINAL DRIVE

- FRONT SYSTEM

- HYDRAULIC SYSTEM

- POWER TAKE-OFF

- TRANSMISSION

File Format: PDF

Compatibility: All Versions of Windows & Mac

Language: English

Requirements: Adobe Reader