Mahindra JINMA20-30A Tractor ops n maintenanceManual

What's Included?

Fast Download Speeds

Online & Offline Access

Access PDF Contents & Bookmarks

Full Search Facility

Print one or all pages of your manual

JINMA SERIES TRACTOR

OPERATION MANUAL

JINMA-200

JINMA-204

JINMA-250

JINMA-254

JINMA-300A

JINMA-304A

MAHINDRA YUEDA

(YANCHENG) TRACTOR CO.,LTD.

1

Preface

Jinma series wheeled tractors ( 、 、 、 、 JM-200 JM-204 JM-250 JM-254 M-

、 ) 300A JM-304A are small four wheel tractors of new type , which are developed

according to the increasingly rising demands of dometic and overseas agricultural

machinery for small new wheeled tractors . The tractors have the characteristics of

saving energy , high efficiency , varied purpose ,beautiful appearance . If you buy

them , you will get satisfactory economic profit from them .

Jinma series wheeled tractors respectively adopt vertical and energy saving

, , diesel engine of 20 25 30Hp as their power ;they employ direct gears transmission

between engine and transmission system . Jinma tractors have many types for you to

choose . They not only have single stage clutch and dual stage clutch types , but also

have two wheel and four wheel drive types .They also have creeper device for you to

choose if you want your tractors to conduct ditching operation . They have perfect

hydraulic suspension system in performance , wide thread driving tyres of good

adhesive force and low pressure and reliable (crankpin type and circulating ball type)

but also have hydraulic steering gear , the users can choose either of them . The

products are featured by their favourable power ,relatively hight traction force ,

compact contruction , high transmission efficiency ,easy operation , convenient repair

and maintenance ,economical oil consupmtion ,easy attachment of implements and

good compreshensive usage .

In order to help the customers master the Jinma series tractors' operation ,

adjustment and maintenance , and prolong their service life , make the best possible

use of them and obtain ideal economic profit ,we compile the operation manual ,With

regard to the operation and repair and maintenace , Please consult the operation

manuals of the diesel engines .

With the development of science and technology and varying in requirement of

customers , the tractors are subject to improvements and perfection in their in their

constructions which will be written about in next editions of the manual . Therefore ,

users of tractors are required to pay attention to where the manual differs from the

actual tractors .

2

Precautions

1. Drivers should read the operation manual carefully and be familiar with the

performance, operation and maintenance of the tractor. Otherwise we will not be

responsible for any quality problems caused by improper operation.

2. Never fill the fuel tank with unfiltered or un-precipitated fuel.

3. New tractors must undergo running according to the regulations before they are

put into use.

4. It is prohibited to turn sharply with one-side braking while tractor runs at high

speed in order to avoid overturning or parts damage.

5. Bolts or nuts of wheel disc and of other important parts should be checked

regularly and be tightened if they are loose.

6. During transferring the tractor with a mounted implement, it is not allowed to

drive the tractor at high speed in order to avoid damaging hydraulic lift system and

suspension system.

℃ 7. After operation at the area of below 0 in winter, the water should be drained

out at idle speed in order not to freeze and damage the tractor parts (not including anti-

icing fluid).

1

CONTENTS

…………………………………………………………………………………………… Preface (1)

……………………………………………………………………………………… Precautions (2)

Ⅰ ……………………………………………………………… Chapter Main Specifications (1)

Ⅱ …………………………………………………………… Chapter Operating the Tractor (5)

………………………………………………………………… 1.Fuel and lubricating oil (5)

…………………………………………………………………………………… 2.Water (6)

…………………………………………………………… 3.Running-in of unused tractor (6)

……………………………………………………………… 4.Controls and instruments (8)

………………………………………………… 5.Control and operation of the tractor (10)

……………………………………… 6.Control and operation of the working devices (14)

…………………………………………………… 7.Use of the electrical equipment (16)

Ⅲ ………………………………………… Chapter Technical Maintenance of the Tractor (19)

……………………………………………………………………… 1.Shift maintenance (19)

……………………………………………………………… 2.First class maintenance (19)

……………………………………………………………… 3.Second class maintenance (20)

……………………………………………………………… 4.Third class maintenance (20)

……………………………………………………………… 5.Fourth class maintenance (20)

………………………………………………………………… 6.Maintenance in winter (21)

……………………………………………… 7.Maintenance for storage of a long time (21)

Ⅳ …………………………………………………………… Chapter Adjustment of Tractor (22)

…………………………………………………………………… 1.Adjustment of clutch (22)

……………………………………………………………… 2.Adjustment of main drive (24)

……………………………………………………… 3.Adjustment of differential lock (27)

…………………………………………………………………… 4.Adjustment of brake (28)

……………………………………………………………… 5.Adjustment of front axle (30)

………………………………………………………… 6.Adjustment of front drive axle (31)

…………………………………………………………… 7.Adjustment of wheel tread (33)

……………………………………………………… 8.Adjustment of steering gear (34)

…………………………… 9.Construction and adjustment of hydraulic hitch system (39)

………………………………… 10.Use and adjustment of air brake device of trailer (46)

Ⅴ …………………………… Chapter Main Troubles of Tractors and Trouble Shooting (49)

………………………………………………………………………………… 1.Engine (49)

………………………………………………………………… 2.Transmission system (51)

2

………………………………………………………………………………… 3.Brake (52)

…………………………………………………… 4.Steering gear and walking system (53)

…………………………………………………………… 5.Hydraulic hitch system (54)

…………………………………………………………………… 6.Electrical system (55)

…………………………………………………………………… 7.Electrical system (56)

Ⅵ ………………………………………………………………………… Chapter Appendix (59)

……………………………………………… 1.Wiring diagram of the electrical system (59)

…………………………………………………… 2.Accessaries for customers to order (59)

3.Distribution diagram of rolling bearing

……………………………………… and transmission system of JM series tractors (61)

………… 4.Specifications and distributions of oil seals in JM series tractor's chassis (63)

…………………………………………………………………… 5.Sizes of hitch system (65)

………………………………………… 6.OECD approval No. of JM series tractors (67)

Ⅰ

Chapter Main Specifications

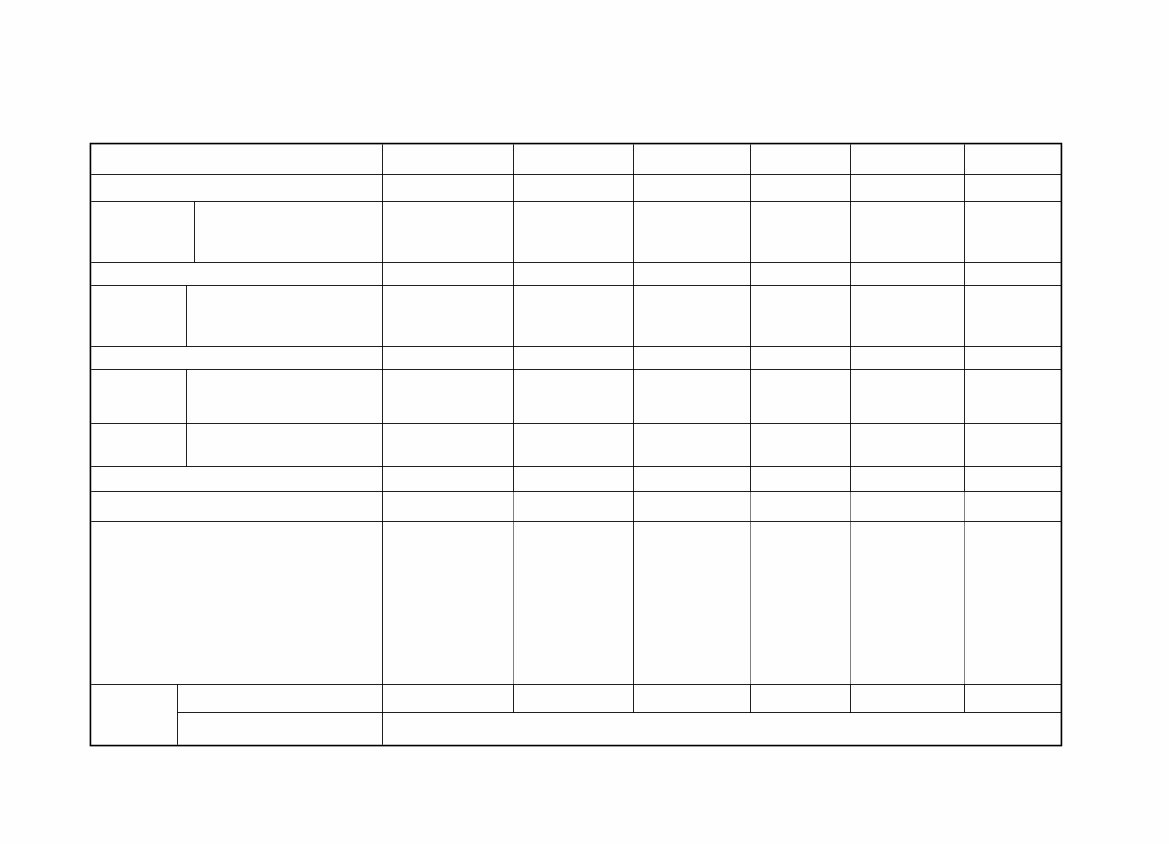

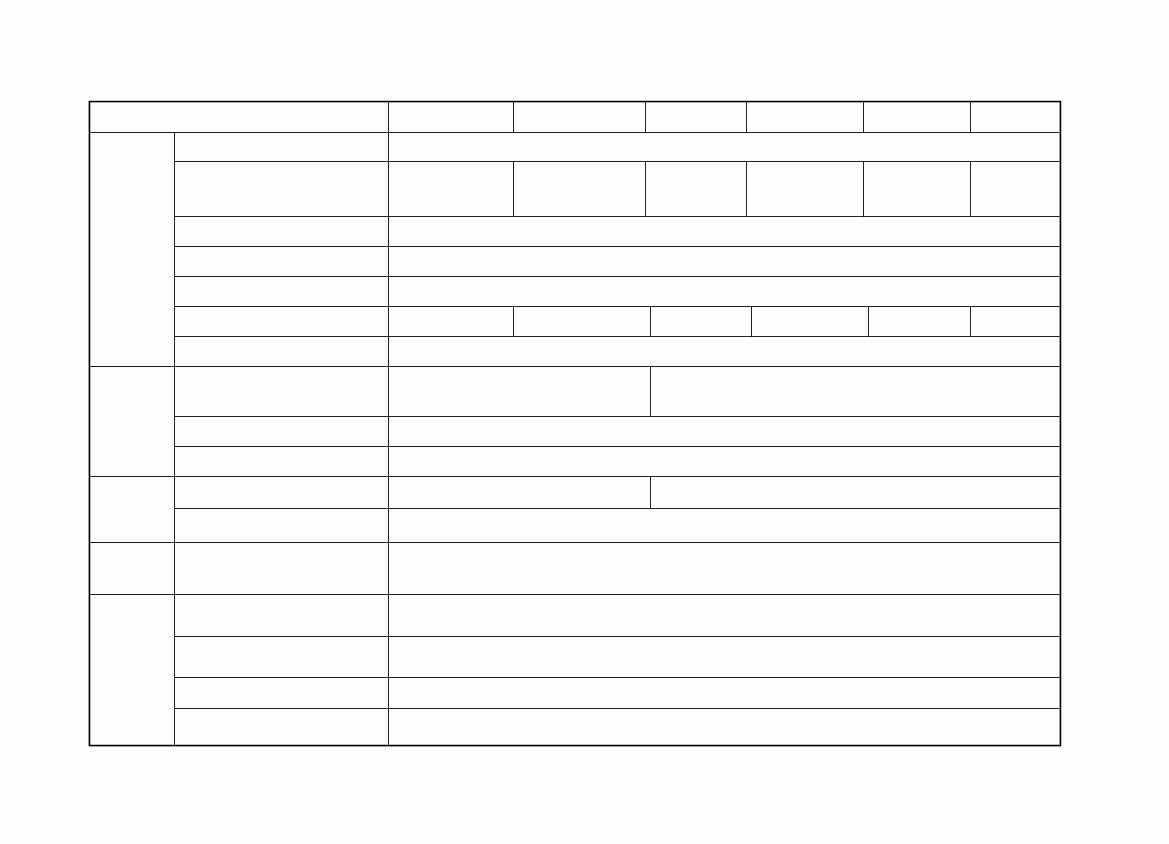

Model JM-200 JM-204 JM-250 JM-254 JM300A JM304A

Type × 4 2wheeled × 4 4wheeled × 4 2wheeled × 4 4wheeled × 4 2wheeled × 4 4wheeled

Overall

dimen-sions

(mm)

Length

Width(without ballast)

Heitht(to steering wheel)

3080

1250/1410

1910

3080

1250/1410

1910

3080

1280/1440

1930

3080

1280/1440

1930

3200

1280/1440

1930

3200

1280/1440

1930

Wheel base (mm) 1465 1510/1560 1587.5 1588

Wheel tread

(mm)

Front wheel

Rear wheel

1070 -1270

1040-1200

950 / 1050

1040-1200

1070 -1270

1040-1200

950 / 1050

1040-1200

1070 -1270

1040-1200

1050

1040-1200

Ground clearance (mm) 330 275 340 340

Turning radius

(m)

With one-side braking

without braking

± 2.4 0.2

± 2.8 0.2

± 2.8 0.2

± 3.0 0.2

± 2.75 0.2

± 3.0 0.2

± 2.8 0.2

± 3.0 0.2

± 2.75 0.2

± 3.0 0.2

± 2.8 0.2

± 3.0 0.2

Weight

(kg)

Construcional weight

Min.working weight

1040

1160

1140

1270

1040

1060

1140

1270

1170

1290

1270

1400

( ) Rated traction force N 4000 4800 5200 5980 5200 5980

( ) Normal speed km/h six six six six eight eight

: Forward 1 st

2nd

3rd

4th

5th

6th

7th

8th

: Reverse 1st

2nd

1.99 0.37

3.94 0.73

6.57 1.22

9.21 1.72

18.2 3.39

30.36 5.66

1.58 0.29

7.3 1.36

1.68 0.31

3.31 0.62

5.52 1.03

7.75 1.45

15.3 2.85

25.5 4.76

1.33 0.29

6.15 1.15

2.06 0.38

4.07 0.76

6.79 1.27

9.52 1.78

18.8 3.51

31.4 5.85

1.63 0.30

7.55 1.41

1.73 0.32

3.42 0.64

5.71 1.06

8.01 1.49

15.8 2.59

26.4 4.92

1.37 0.26

6.35 1.18

2.12

3.24

5.08

7.00

9.82

14.97

23.49

32.38

2.79

13.52

1.77

2.69

4.23

5.83

8.18

12.46

19.56

26.96

2.32

11.25

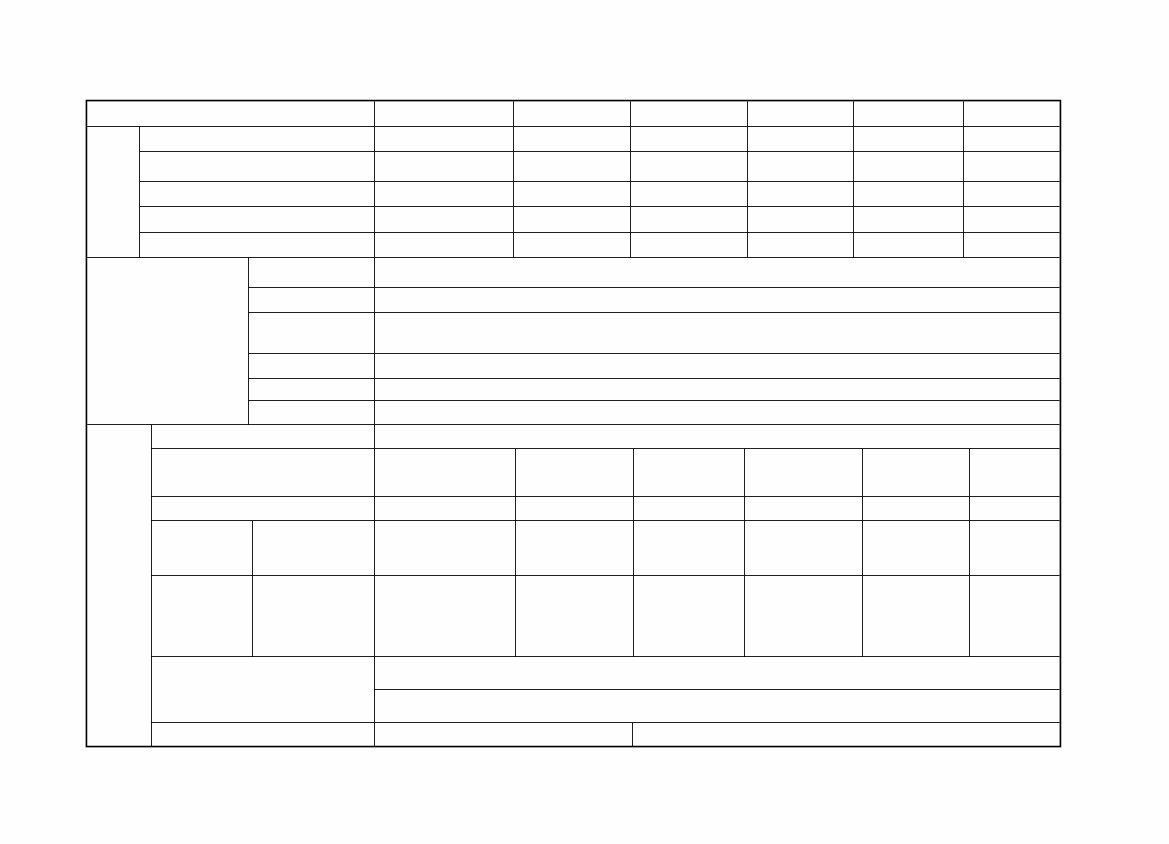

Engine

Model LL380 LL380 KM385 KM385 ZN390T ZN390T

Type 3 cylinder ,vertical ,water - cooled , 4-stroke

1

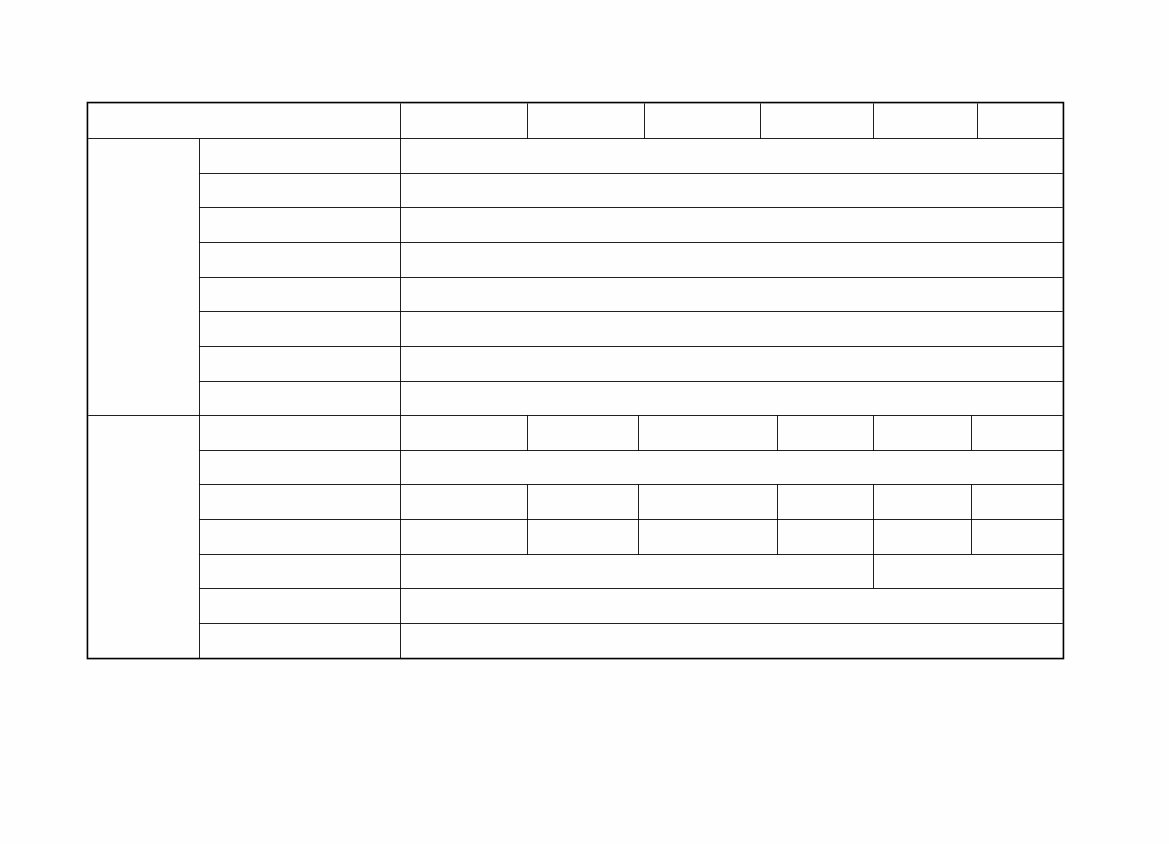

Model JM-200 JM-204 JM-250 JM-254 JM300A JM304A

Engine

12-hour power(kW)/rated speed r.p.m 14.7 14.7 18.4 18.4 22.1 22.1

× Bore Stroke(mm) × 80 90 × 80 90 × 85 90 × 85 90 × 90 95 × 90 95

Fuel consumption (g/kw·h) ≤ 245 ≤ 245 ≤ 245 ≤ 245 ≤ 255 ≤ 255

Oil consumption (g/kw·h) ≤ 2.0 ≤ 2.0 ≤ 2.0 ≤ 2.0 ≤ 2.72 ≤ 2.72

Net weight (kg) 250 250 250 250 230 230

Transmission

Clutch Single disc,dry-friction constant mesh OR Dual stage ,gear operation

Gear box ( + )× ( )× Supr gear 3 1 2 compound , or supr gear 4+1 2compound Creeper can b chosen

Intermediate drive × 1 2 spiral bevel gear

Differential Closed with 2 planetary bevel gears

Diffierential lock Claw type

Final drive Internally meshed single spur cylindrical gear

Walk

and

operatin

g system

Frame type Frameless rigid connection

Front axle type

inverted U pipe

balancing arm

side bevel gear

drive

inverted U pipe

balancing arm

side bevel gear

drive

inverted U pipe

balancing arm

side bevel

gear drive

Pendulum angle of front axle ° 12 ° 8 ° 12 ° 8 ° 12 ° 8

Tyres

Front wheel

Rear wheel

4.00-16

8.3-24

6.00-12

8.3-24

5.00-15

9.5-24

6.00-16

9.5-24

5.00-15

9.5-24

6.00-16

9.5-24

Tire infation

( pressure kPa)

: Front wheel

: Rear wheel

( ) in field

( ) transportation

200-250

100-120

120-140

180-200

100-120

120-140

200-250

100-120

120-140

180-200

100-120

120-140

200-250

100-120

120-140

180-200

100-120

120-140

Steering gear

sphere worm steering

Hydraulic steering gear may be chosen for all models

Brake Foot - controlled shoes type Disc type

2

Model JM-200 JM-204 JM-250 JM-254 JM300A JM304A

Hydraulic

systems

Type Half remote

Hydraulic pump

CBN-E306

gear pump

CBN-E306 / 314

gear pump

CBN-E306

gear pump

CBN-E306 / 314

gear pump

CBN-E310

gear pump

CBN-E310

gear pump

Hydraulic cylinder

× Horizontal single− acting type63 100(mm)

Distributor Slide valve regulating type

Safety valve Direct-acting type

× Rated lifting capacity (N mm) × 3600 610 × 3900 610 × 4200 610 × 4200 610 × 5000 610 × 5000 610

Safety valve release pressure(MPa) ~+ 16 ( 0 1.6 )

Suspension

mechanism

Connection type of implements rear mounted - point hitch category 0 Ⅰ rear mounted - point hitch category

Upper link-hole diameter(mm)

× φ19.5 44

Lower link-hole diameter(mm)

× φ22.5 35

Traction

device

Traction ground clearance(mm) 470 495

Traction pin diameter(mm) Φ20

Power-take-

off

Rear P.T.O shaft , Nonindepender 540r/min or semi-independent 540r/min dual speed(540r/min ,1000r/min)can be chosen

Electrical

equipments

and gauges

System 12V ,negative pole connected with iron , single phase circuit

Starter 、 12V 2.5kW or 3.0kW

Generator 14V 350W

Battery 6-Q(A)-80,80A·h

3

Model JM-200 JM-204 JM-250 JM-254 JM300A JM304A

Electrical

equipments

and gauges

Ammeter + ( ) -30~0~ 30 A

Oil pressure gauge ( ) 12V 0~0.5 MPa

Water temperature gauge ℃ 12V (40~100)

pressure gauge 0~1.0 MPa

Head lamp ND118-80T , 20/8W 12V

Rear light WD115-2 , 20/8W.12V

Direction light FT12 , 8W.12V

Electric horn DL87-12

Main filling

capacity (L)

Fuel tank 19 19 19 19 24 24

Engine oil sump 5

Front drive axle ─ 4.5 / 6 ── 6 ── 6

Transmission box 11 14 11 14 11 14

Lifter 9 14

Steering gear 0.4

Cooling water 10 or 12

4

5

Ⅱ Chapter Operating the Tractor

1.Fuel and lubricating oil

1) For fuel and lubricating oil for the tractor see Table 2-1.

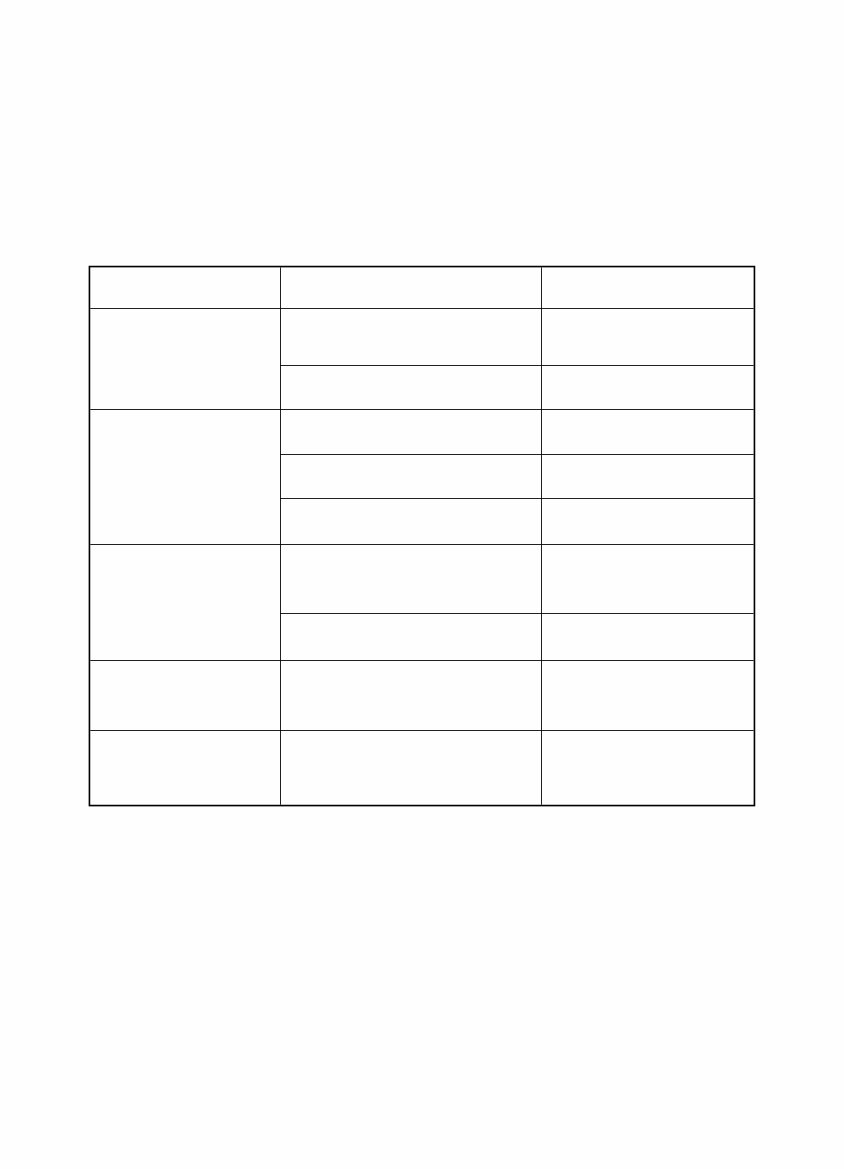

Table 2-1 Fuel and lubricating oil for the tractor

2) Cautions for filling fuel

Using clear diesel fuel is an important factor to prevent troubles in engine and

prolong the engine's service life. The followings should be observed during filling fuel:

A. Fuel must be deposited for over 48 hours before fuel tank is filled with it. Fuel at

the bottom should not be poured into the fuel tank.

B. Filter fuel when filling fuel tank with it.

C. Fuel filling devices must be kept clean.

D. Fuel tank and fuel filter should be cleaned regularly, and deposited fuel should be

drained out.

Component Season and ambient temperature Oil specification

Fuel tank

Summer (ambient temp. above10

℃ )

No.0, -10 light diesel fuel

GB252-87

℃ Winter (ambient temp. below10 )

No. -20 light diesel fuel

GB252-87

Engine sump

Lifter

Oil pan of air cleaner

Injection pump

Hydraulic steering gear

℃ Ambient temp. below 0

No. 20 diesel engine oil

GB5323-85

℃ Ambient temp. at 0-25

No. 30 diesel engine oil

GB5323-85

℃ Ambient temp. above 25

No. 40 diesel engine oil

GB5323-85

Transmission box

Transfer case Front drive

axle Mechanical steering

gear

Summer (ambient temp. above10

℃ )

No. 40 diesel engine oil

GB5323-85

℃ Winter (ambient temp. below10 )

No. 30 diesel engine oil

GB5323-85

Grease nipple Without consideration of season

No. ZFG2 calcium base

compound grease

ZBE 36003-88

Bearing 60203Generator

and starter

Without consideration of season

No. ZFG2 compound

calcium base grease ZBE

36003-88

You're Reading a Preview

What's Included?

Fast Download Speeds

Online & Offline Access

Access PDF Contents & Bookmarks

Full Search Facility

Print one or all pages of your manual

$30.99

Viewed 45 Times Today

Loading...

Secure transaction

What's Included?

Fast Download Speeds

Online & Offline Access

Access PDF Contents & Bookmarks

Full Search Facility

Print one or all pages of your manual

$30.99

The Mahindra JINMA20-30A Tractor operation and maintenance manual is a comprehensive guide spanning 73 pages. It is available in PDF format, making it compatible with all versions of Windows, Mac, and Linux operating systems. This manual is designed to be easily printable and offers instant high-speed access. The only requirement for accessing this manual is having Adobe Reader installed on your device.