KUBOTA B4200 COMPACT Tractor RC44 42 MOWER Workshop Service Manual

What's Included?

Fast Download Speeds

Online & Offline Access

Access PDF Contents & Bookmarks

Full Search Facility

Print one or all pages of your manual

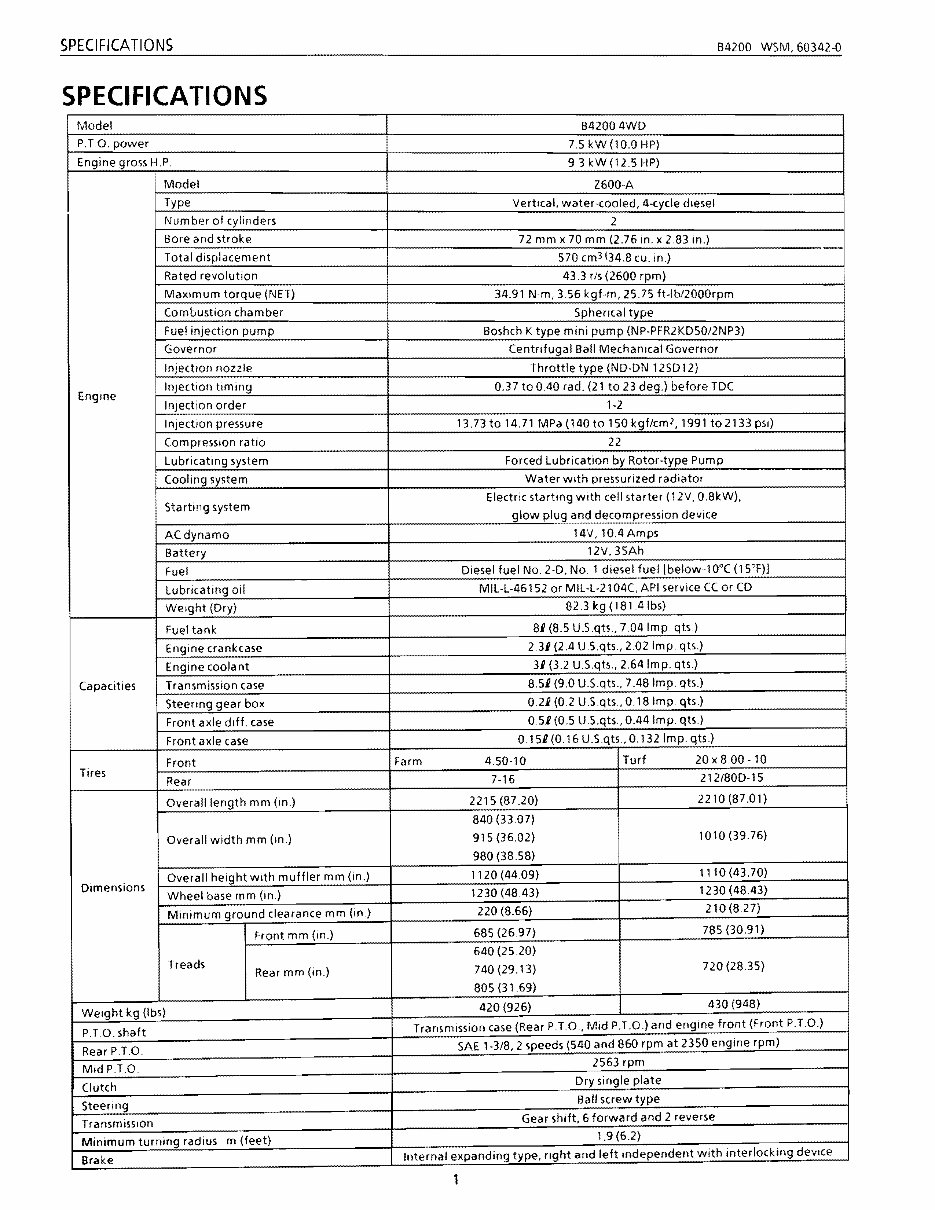

SPECIFICATIOI\JS 84200 WSM,60342-0

SPECIFICATIONS

Model 842004WO

P.T.O. power 7.5 kW (10.0 HP)

Engine gross H.P. 9.3 kW (125 HP)

Model Z600-A

Type Vertical. water-cooled, 4-cycle diesel

Number of cylinders 2

Bore and stroke 72 mm x 70 mm (2.76 In. x 2.83 In.)

Total displacement 570 cm

3

(34.8 cu. In.)

Rated revolution 43.3 rls (2600 rpm)

Maximum torque (NET) 34.91 N·m, 3.56 kgf-m, 25.75 ft-lbl2000rpm

Combustion chamber SpherICal type

Fuel injection pump Boshch K type mini pump (NP-PFR2KD50/2NP3)

Governor Centrifugal Ball MechanICal Governor

Injection nozzle Throttle type (NO-ON 125012)

Engine

Injection timing 0.37 to 0.40 rad. (21 to 23 deg.) before TDC

Injection order 1-2

Injection pressure 13.73 to 14.71 MPa (140 to 150 kgflcm2, 1991 to 2133 pSI)

Compression ratio 22

Lubricating system Forced Lubrication by Rotor-type Pump

Cooling system Water With pressurized radiator

Starting system

Electric starting with cell starter (12V, 0.8kW),

glow plug and decompression deVICe

ACdynamo

14V.10.4Amps

12V.35Ah

Fuel

Diesel fuel No. 2-0, No.1 diesel fuellbelow-1 O°C (15°F)j

Lubricating oil

MIL-L-461 52 or MIL-L-21 04C. API service CC or CD

weight (Dry)

823 kg (181.4Ibs)

Fuel tank

81 (8.5 U.S.qts .• 7.04Imp. qts.)

Engine crankcase

2.31 (2.4 U.S.qts., 2.02 Imp. qts.)

Engine coolant

31 (3.2 U.S.qts., 2.64Imp. qts.)

Capacities Transmission case

8.51 (9.0 U5.qts., 7 .48Imp. qts.)

Steering gear box

0.21 (0.2 U.S.qts .• 0.18 Imp. qts.)

Front axle dlff. case

0.51 (0.5 U.S.qts .• 0.44 Imp. qts.)

Front axle case

0.151 (0.16 U.S.qts .• 0.132 Imp. qts.)

Front I Farm 4.50-10 Turf 20x8.00-10

Tires

Rear

7-16

212/800-15

Overall length mm (in)

2215 (87.20)

2210 (87.01)

840 (3307)

Overall width mm (In)

915 (36.02)

1010 (39.76)

980 (38.58)

Overall height With muffler mm (in.)

1120 (4409)

1110 (43.70)

Dimensions

Wheel base mm (in.)

1230 (4843)

1230 (4843)

Minimum ground clearance mm (in.)

220 (8.66)

210(827)

Front mm (in.)

685 (2697)

785 (30.91)

640 (2520)

Treads

Rear mm (in.)

740 (29.13)

720 (2835)

805 (3169)

Weight kg (Ibs)

420 (926)

430(948)

PTO. shaft

Transmission case (Rear P.T.O, Mid P.T.O.) and engine front (Front P.T.O.)

Rear P.T.O.

SAE 1-318.2 speeds (540 and 860 rpm at 2350 engine rpm)

Mid PT.O

2563 rpm

Clutch

Dry single plate

Steering

Ball screw type

TransmiSSion

Gear shift. 6 forward and 2 reverse

Minimum turning radius m (feet)

1.9 (6.2)

Brake

Internal expanding type, right and left independent with interlocking

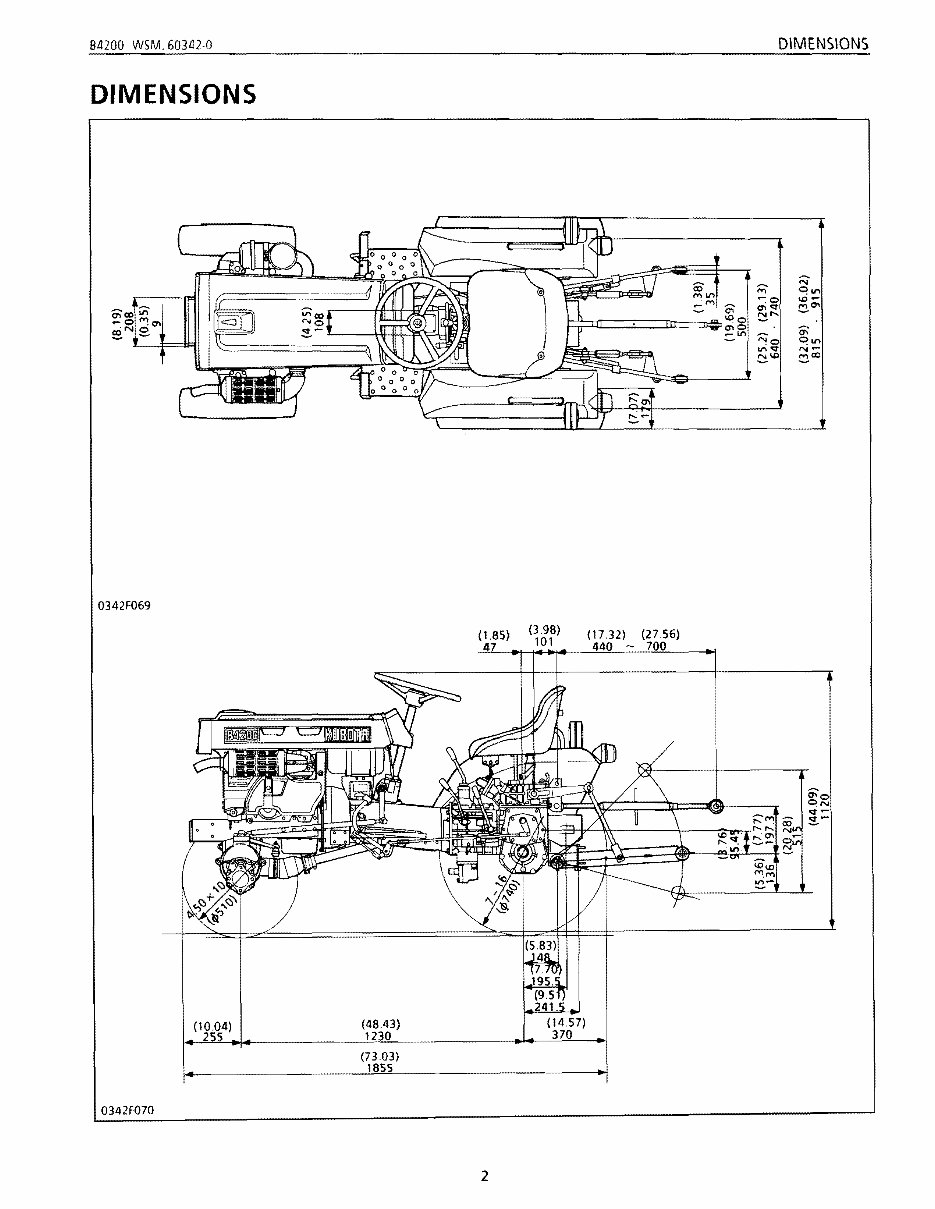

84200 WSM,60342-0 DIMENSIONS

DIMENSIONS

N

M C>

\0

-

ai

!::1

Ci\

~

-

Ci\

~

N

C>

on

~ '" !::1

0342F069

(3.98)

(1.85) (1732) (2756)

101

47 440 - 700

(1004)

255

(48.43)

1230

(7303)

1855

0342F070

2

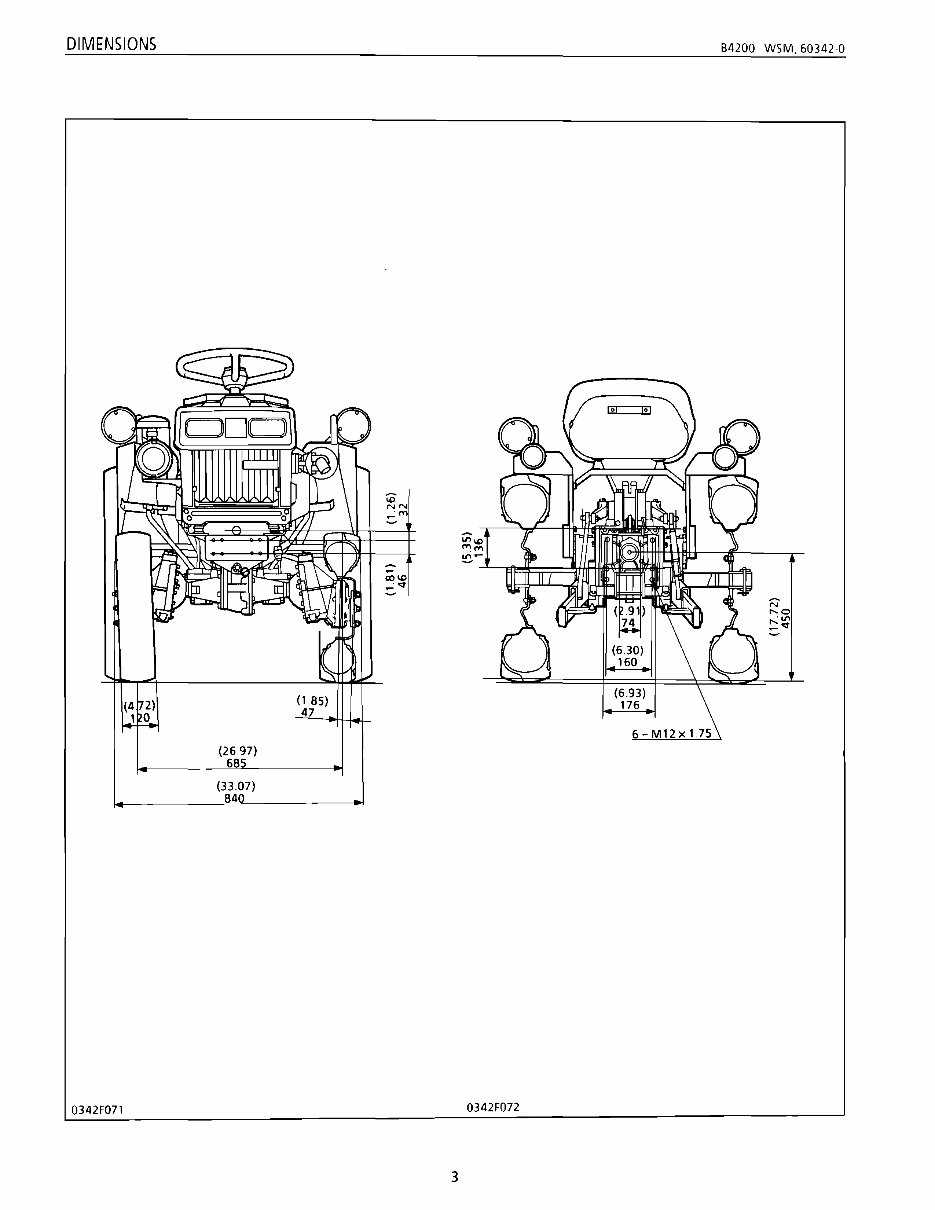

DIMENSIONS

B4200 WSM,60342-0

(630)

160

(6.93)

176

6-M12x1.75

(2697)

685

(33.07)

840

0342F072

0342F071

3

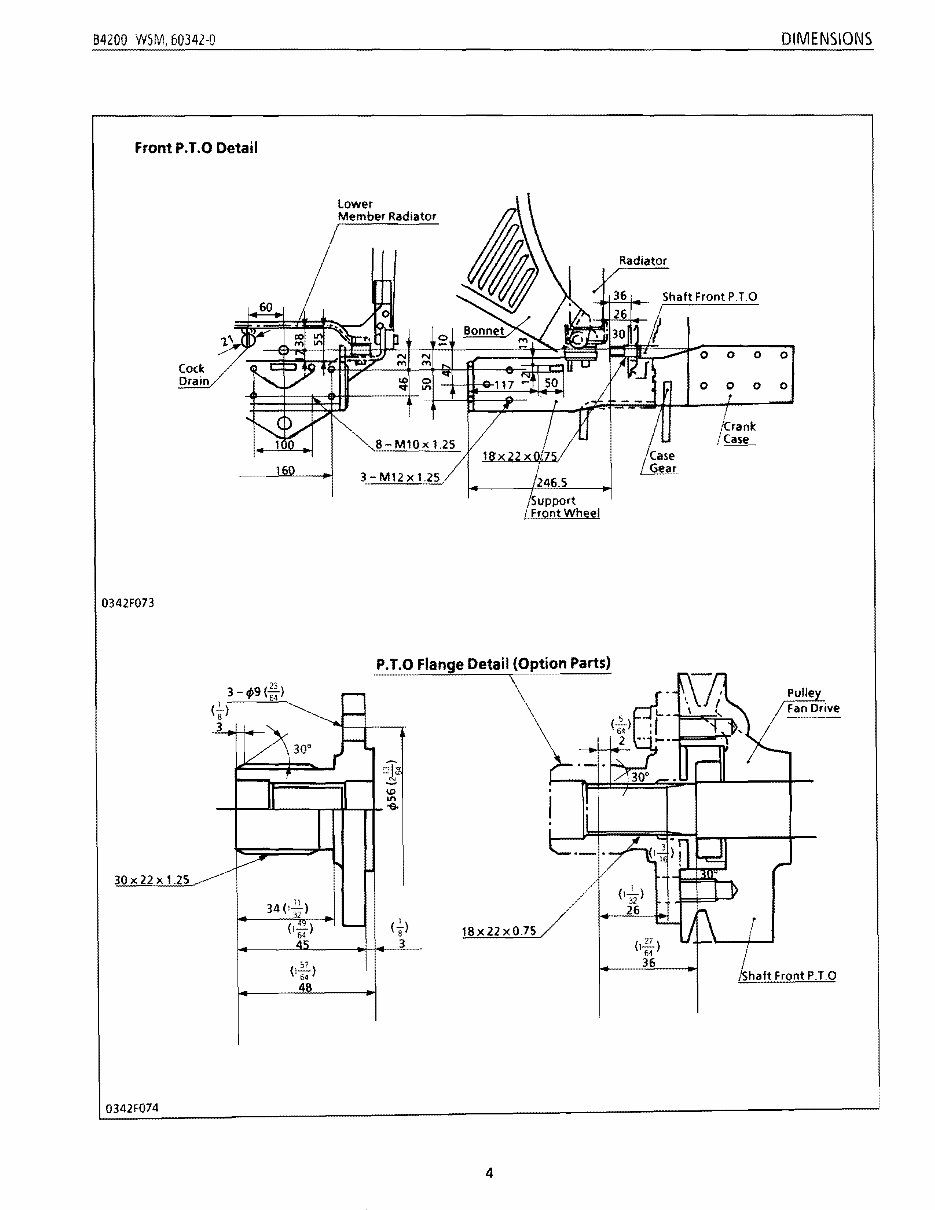

64200 W5M,60342-0 DIMENSIONS

Front P.T.O Detail

Cock

Drain

16

lower

Member Radiator

o 0 0 0

o 0

8 M10x 1.25

3 - M12 x 1.25

0342F073

P.T.O Flange Detail (Option Parts)

3-+9(-£)

(~)

8

3

30x22 x 1.25

34 (1..!..!..)

32

18x22xO.75

0342F074

4

DIMENSIONS 84200 60342-0

(2}2)

64

61.5

(1..2.- )

( 1..:2.) (~)

(:2)

7

64

64 32

2B

315 17

(:2)

2.5

o

N

-

(~)

64

Ml0x 1.25

I/>B.3

(Metric)

Direction of R .... t",tir,n

Clockwise from Rear

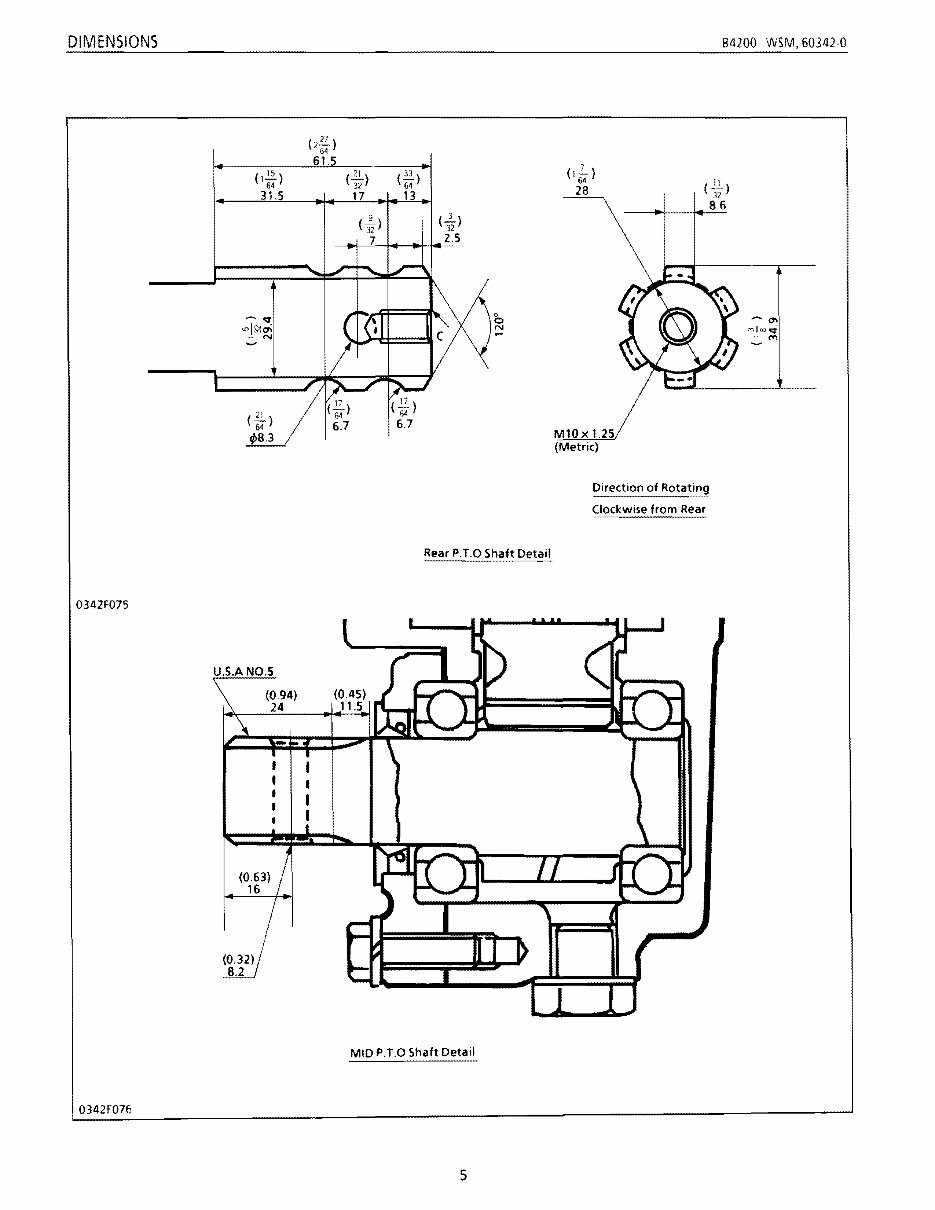

Rear P.T.O Shaft Detail

0342F075

(0.32)

B.2

0342F076

MID P.T.O Shaft Detail

5

84200 WSM,60342-0

S.G GENERAL

m GENERAL

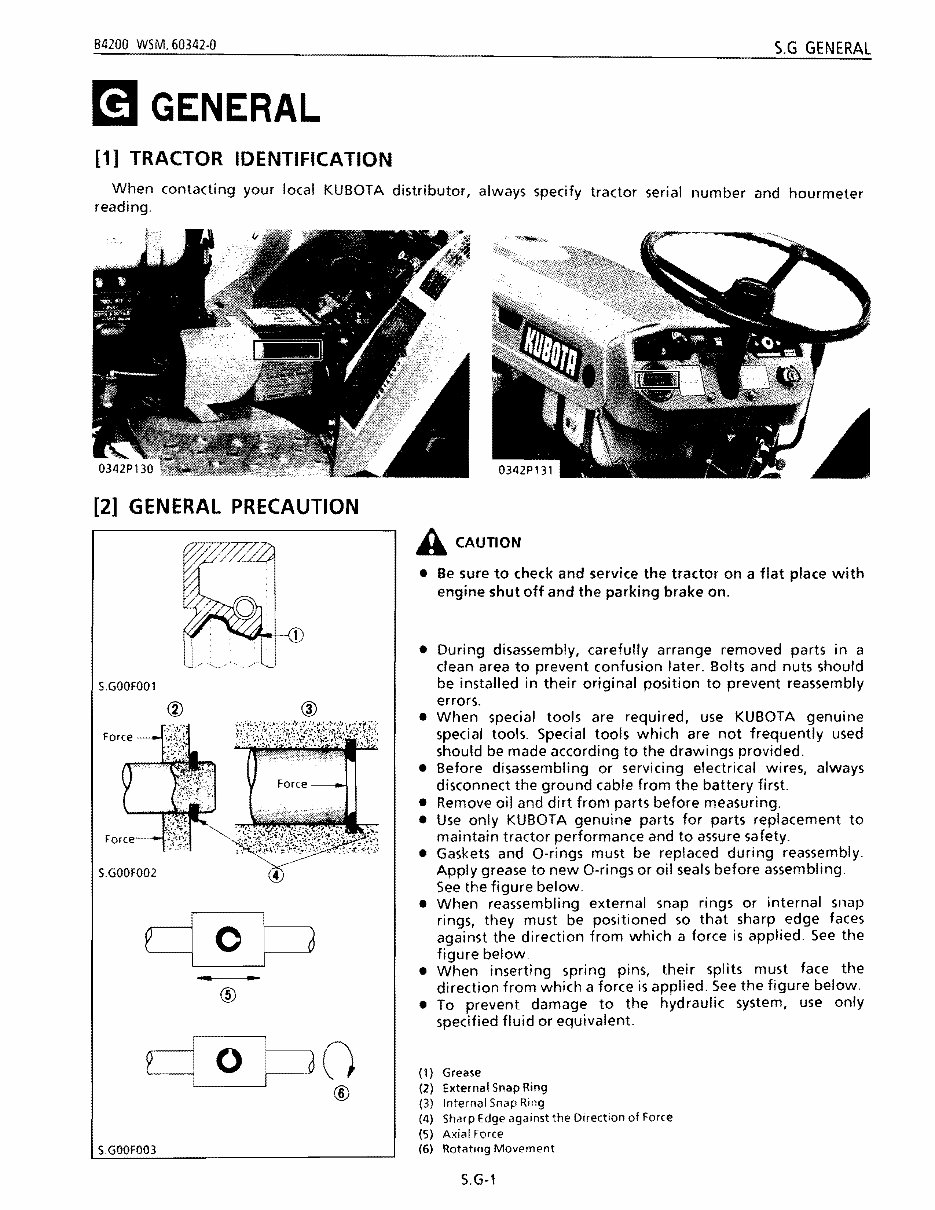

[1] TRACTOR IDENTIFICATION

When contacting your local KUBOTA distributor, always specify tractor serial number and hourmeter

reading.

[2] GENERAL PRECAUTION

S.GOOF001

@

S.GOOF002

- ..

S.GOOF003

A CAUTION

• Be sure to check and service the tractor on a flat place with

engine shut off and the parking brake on.

• During disassembly, carefully arrange removed parts in a

dean area to prevent confusion later. Bolts and nuts should

be installed in their original position to prevent reassembly

errors.

• When special tools are required, use KUBOTA genuine

special tools. Special tools which are not frequently used

should be made according to the drawings provided.

• Before disassembling or servicing electrical wires, always

disconnect the ground cable from the battery first.

• Remove oil and dirt from parts before measuring.

• Use only KUBOTA genuine parts for parts replacement to

maintain tractor performance and to assure safety.

• Gaskets and O-rings must be replaced during reassembly.

Apply grease to new O-rings or oil seals before assembling.

See the figure below.

• When reassembling external snap rings or internal snap

rings, they must be positioned so that sharp edge faces

against the direction from which a force is applied. See the

figure below

• When inserting spring pins, their splits must face the

direction from which a force is applied. See the figure below.

• To prevent damage to the hydraulic system, use only

specified fluid or equivalent.

(1) Grease

(2) External Snap Ring

(3) Internal Snap Ring

(4) Sharp Edge against the Direction of Force

(5) Axial Force

(6) Rotating Movement

S.G-1

S.G GENERAL

84200 WSM,60342-O

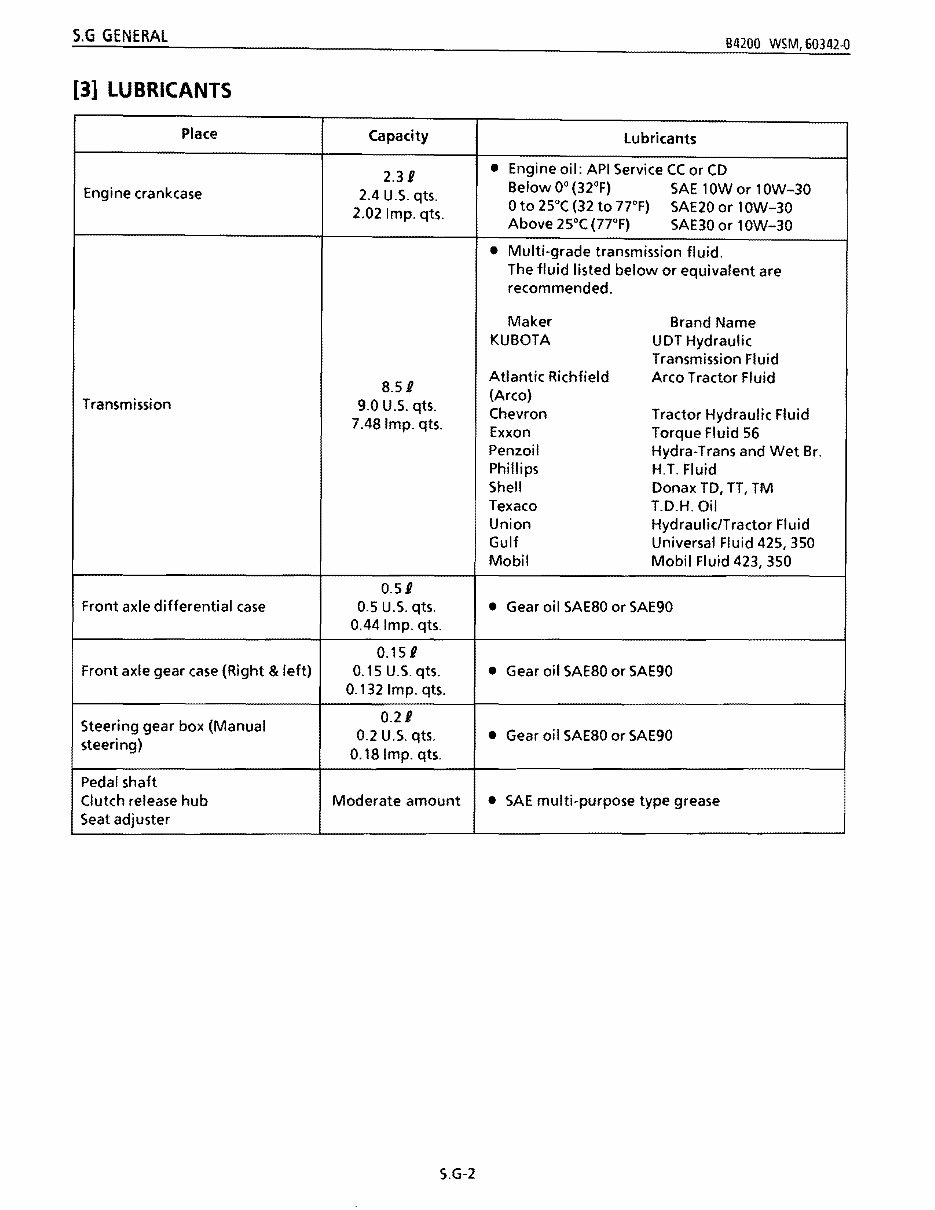

[3] LUBRICANTS

Place

Capacity

lubricants

• Engine oil: API Service CC or CO

2.31

Below 0° (32°F) SAE 1 OW or 10W-30

Engine crankcase

2.4 U.S. qts.

oto 25°C (32 to 77°F) SAE20 or 10W-30

2.02 Imp. qts.

Above 25°C (77°F) SAE30 or 10W-30

• Multi-grade transmission fluid.

The fluid listed below or equivalent are

recommended.

Maker Brand Name

KUBOTA UOT Hydraulic

Transmission Fluid

Atlantic Richfield Arco Tractor Fluid

8.51

(Arco)

Transmission 9.0 U.S. qts.

Chevron Tractor Hydraulic Fluid

7.48 Imp. qts.

Exxon Torque Fluid 56

Penzoil Hydra-Trans and Wet Br.

Phillips H.T. Fluid

Shell Oonax TO, TT, TM

Texaco T.O.H. Oil

Union Hydraulic/Tractor Fluid

Gulf Universal Fluid 425, 350

Mobil Mobil Fluid 423, 350

0.51

Front axle differential case 0.5 U.S. qts. • Gear oil SAE80 or SAE90

0.44 Imp. qts.

0.151

Front axle gear case (Right & left) 0.15 U.S. qts. • Gear oil SAE80 or SAE90

0.132 Imp. qts.

0.21

Steering gear box (Manual

0.2 U.S. qts. • Gear oil SAE80 or SAE90

steering)

0.18 Imp. qts.

Pedal shaft

Clutch release hub Moderate amount • SAE mUlti-purpose type grease

Seat adjuster

S.G-2

B4200 WSM.60342-0

S.G GENERAL

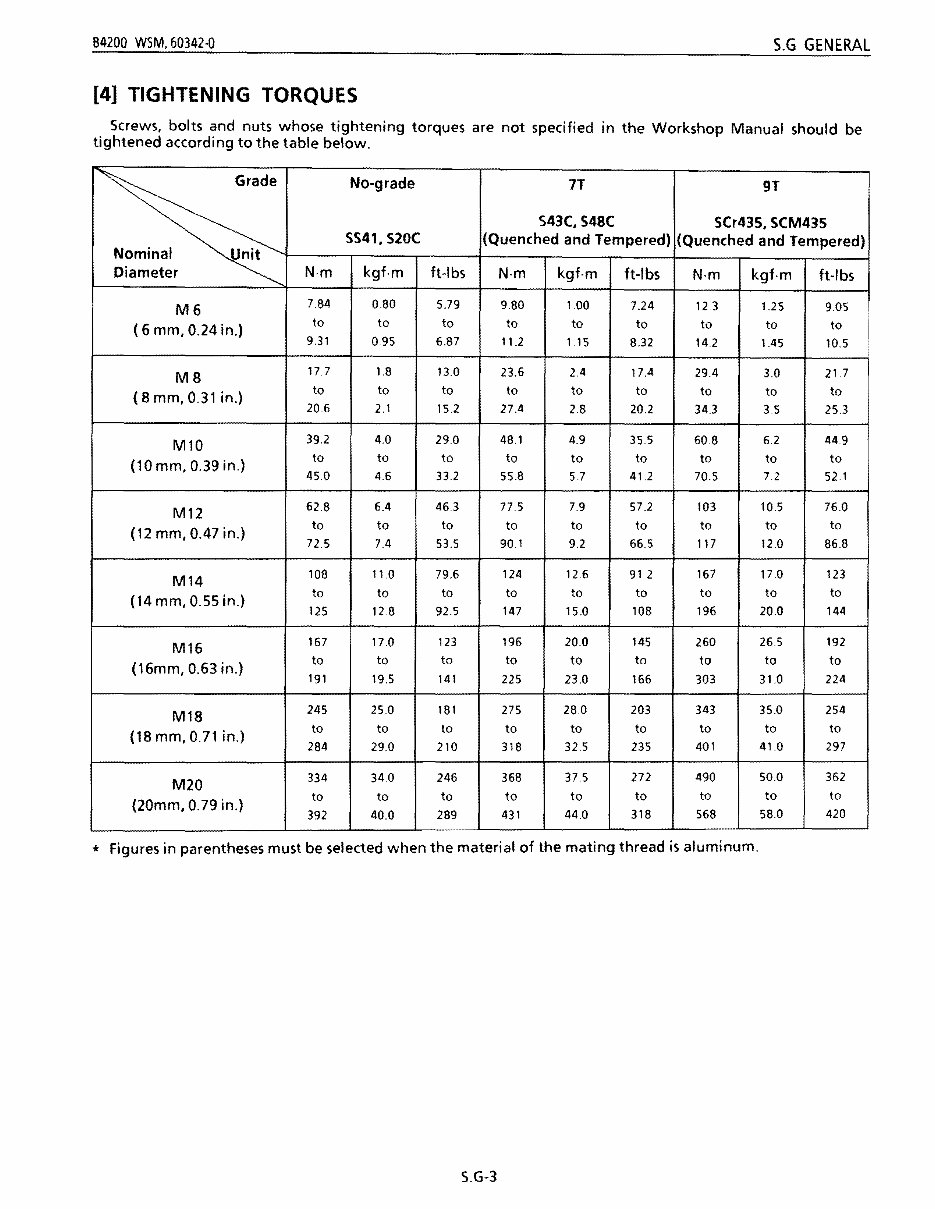

[4] TIGHTENING TORQUES

Screws, bolts and nuts whose tightening torques are not specified in the Workshop Manual should be

tightened according to the table below.

Grade

No-grade 7T

9T

S43C.S48C SCr435, SCM435

SS41,S20C

(Quenched and Tempered) (Quenched and Tempered)

Nominal Unit

Diameter N·m kgf·m ft-Ibs N·m kgf·m ft-Ibs N·m kgf.m ft-Ibs

M6

7.84 0.80 5.79 980 100 7.24 12.3 1.25 9.05

( 6 mm, 0.24 in.)

to to to to to to to to to

9.31 0.95 6.87 11.2 1.15 8.32 14.2 145 10.5

M8

17.7 1.8 130 23.6 24 17.4 29.4 3.0 21.7

(8 mm, 0.31 in.)

to to to to to to to to to

20.6 2.1 15.2 27.4 2.8 20.2 34.3 3.5 25.3

M10

39.2 4.0 29.0 48.1 4.9 35.5 60.8 6.2 44.9

(10 mm, 0.39 in.)

to to to to to to to to to

45.0 4.6 33.2 55.8 5.7 41.2 70.5 7.2 52.1

M12

62.8 6.4 46.3 77.5 7.9 57.2 103 10.5 76.0

(12 mm, 0.47 in.)

to to to to to to to to to

72.5 7.4 535 90.1 9.2 66.5 117 12.0 868

M14

108 11.0 79.6 124 12.6 91.2 167 17.0 123

(14 mm, 0.55 in.)

to to to to to to to to to

125 12.8 92.5 147 15.0 108 196 20.0 144

M16

167 17.0 123 196 20.0 145 260 26.5 192

(16mm, 0.63 in.)

to to to to to to to to to

191 19.5 141 225 23.0 166 303 31.0 224

M18

245 25.0 181 275 28.0 203 343 35.0 254

(18 mm, 0.71 in.)

to to to to to to to to to

284 29.0 210 318 32.5 235 401 41.0 297

M20

334 34.0 246 368 37.5 272 490 50.0 362

to to to to to to to to to

(20mm, 0.79 in.)

392 40.0 289 431 44.0 318 568 58.0 420

* Figures in parentheses must be selected when the material of the mating thread is aluminum.

S.G-3

S.G GENERAL

B4200 WSM.60342-O

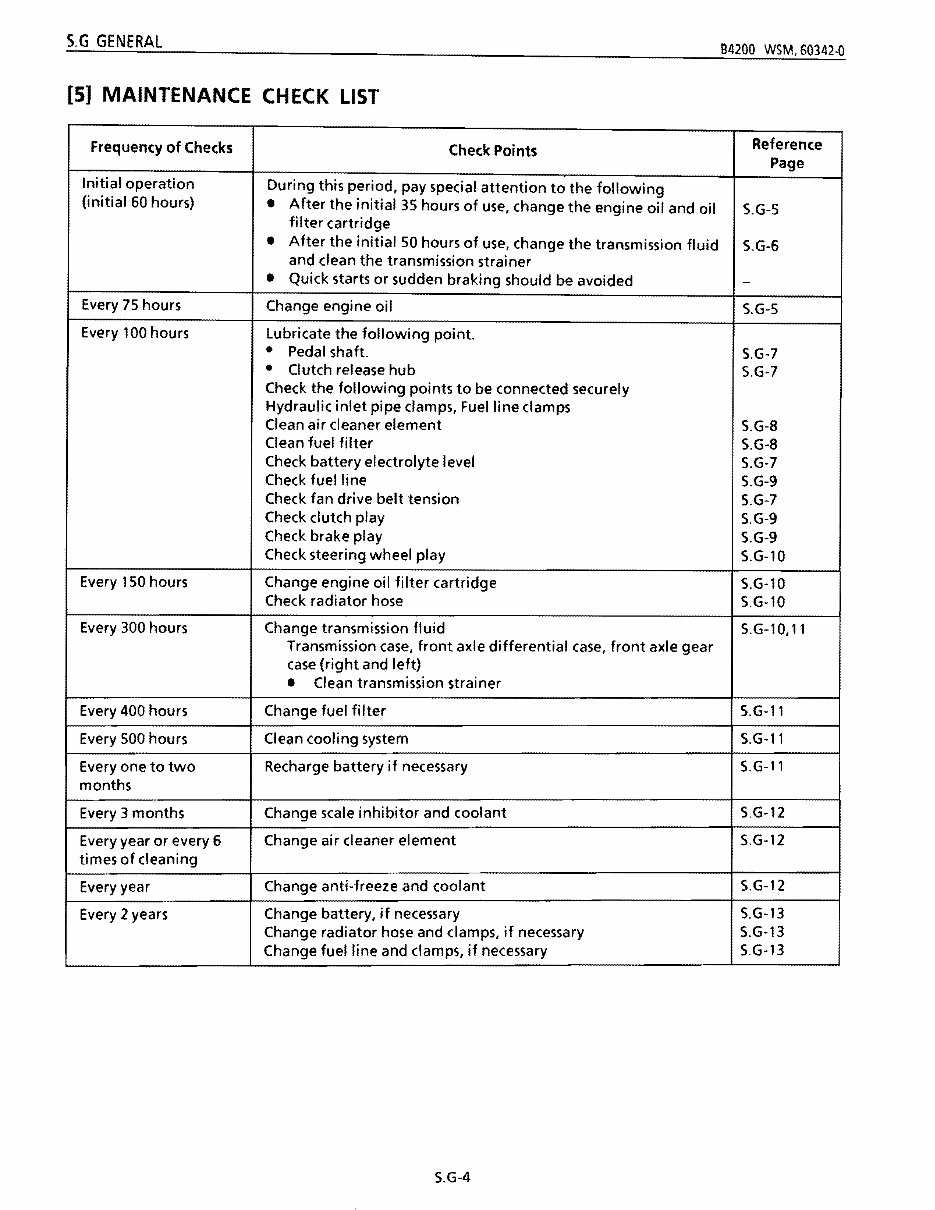

[5] MAINTENANCE CH ECK LIST

Reference

Frequency of Checks

Check Points

Page

Initial operation

During this period, pay special attention to the following

(initial 60 hours)

• After the initial 35 hours of use, change the engine oil and oil

S.G-5

filter cartridge

•

After the initial 50 hours of use, change the transmission fluid

S.G-6

and dean the transmission strainer

•

Quick starts or sudden braking should be avoided

-

Every 75 hours Change engine oil

S.G-5

Every 100 hours Lubricate the following point.

• Pedal shaft.

S.G-7

• Clutch release hub

S.G-7

Check the following points to be connected securely

Hydraulic inlet pipe clamps, Fuel line damps

Clean air cleaner element S.G-8

Clean fuel filter S.G-8

Check battery electrolyte level S.G-7

Check fuel line S.G-9

Check fan drive belt tension S.G-7

Check clutch play S.G-9

Check brake play S.G-9

Check steering wheel play S.G-l0

Every 150 hours Change engine oil filter cartridge S.G-l0

Check radiator hose S.G-l0

Every 300 hours Change transmission fluid S.G-l0,11

Transmission case, front axle differential case, front axle gear

case (right and left)

•

Clean transmission strainer

Every 400 hours Change fuel filter S.G-ll

Every 500 hours Clean cooling system S.G-l1

S.G-l1

months

Recharge battery if necessary Everyone to two

Change scale inhibitor and coolant S.G-12 Every 3 months

S.G-12

times of deaning

Change air cleaner element Every year or every 6

S.G-12 Change anti-freeze and coolant Every year

S.G-13

Change radiator hose and clamps, if necessary

Change battery, if necessary Every 2 years

S.G-13

Change fuel line and clamps, if necessary S.G-13

S.G-4

84200 WSM,60342·0

S.G GENERAL

[6] CHECK AND MAINTENANCE

(1) Check Points of Initial 35 Hours

:==\\

~~~\ ~ ~Ii~

~:9 (9 --

-----

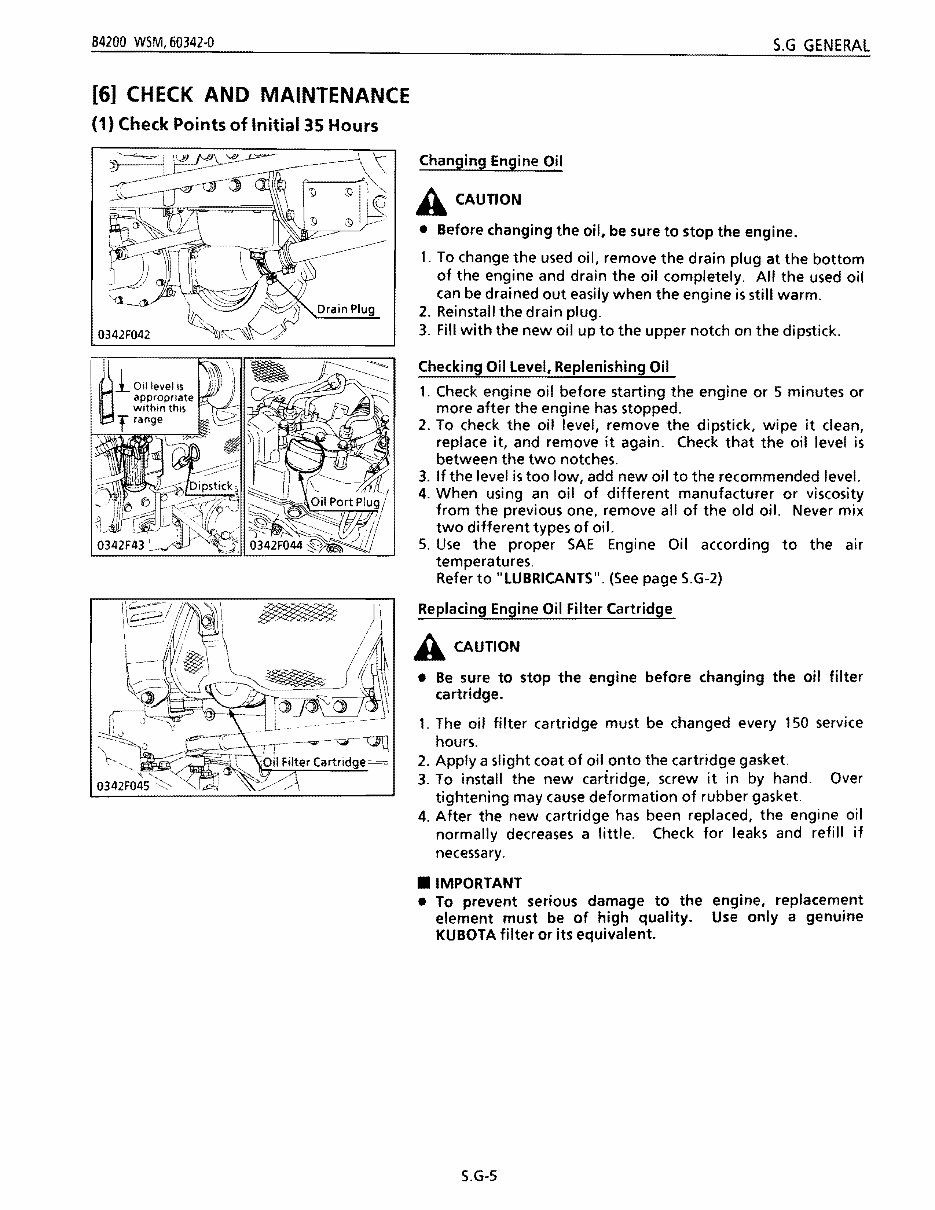

Changing Engine Oil

.A CAUTION

• Before changing the oil, be sure to stop the engine.

1. To change the used oil, remove the drain plug at the bottom

of the engine and drain the oil completely. All the used oil

can be drained out easily when the engine is still warm.

2. Reinstall the drain plug.

3. Fill with the new oil up to the upper notch on the dipstick.

Checking Oil Level, Replenishing Oil

1. Check engine oil before starting the engine or 5 minutes or

more after the engine has stopped.

2. To check the oil level, remove the dipstick, wipe it clean,

replace it, and remove it again. Check that the oil level is

between the two notches.

3. If the level is too low, add new oil to the recommended level.

4. When using an oil of different manufacturer or viscosity

from the previous one, remove all of the old oil. Never mix

two different types of oil.

5. Use the proper SAE Engine Oil according to the air

temperatures.

Refer to "LUBRICANTS". (See page S.G-2)

Replacing Engine Oil Filter Cartridge

A CAUTION

• Be sure to stop the engine before changing the oil filter

cartridge.

1. The oil filter cartridge must be changed every 150 service

hours.

2. Apply a slight coat of oil onto the cartridge gasket.

3. To install the new cartridge, screw it in by hand. Over

tightening may cause deformation of rubber gasket.

4. After the new cartridge has been replaced, the engine oil

normally decreases a little.

necessary .

Check for leaks and refill if

• IMPORTANT

• To prevent serious damage to the engine. replacement

element must be of high quality. Use only a genuine

KUBOTA filter or its equivalent.

S.G-5

You're Reading a Preview

What's Included?

Fast Download Speeds

Online & Offline Access

Access PDF Contents & Bookmarks

Full Search Facility

Print one or all pages of your manual

$40.99

Viewed 12 Times Today

Loading...

Secure transaction

What's Included?

Fast Download Speeds

Online & Offline Access

Access PDF Contents & Bookmarks

Full Search Facility

Print one or all pages of your manual

$40.99

The Workshop Service Manual provides detailed servicing instructions for Kubota equipment, offering step-by-step information on repair, servicing, preventative maintenance, and troubleshooting procedures. This comprehensive manual includes 217 pages with photos, illustrations, and clear instructions to guide you through the repair process.

- Engine

- Clutch

- Transmission

- Rear Axle

- Brakes

- Front Axle

- Steering

- Hydraulic

- Electrical

Additionally, it covers the RC44-42 Series Mower. Please note that Adobe Reader 9.0 or newer is recommended for viewing this manual. You can access the current version of Adobe Reader for free at get.adobe.com. Satisfaction Guaranteed!