IH International Harvester 674 Repair Service Manual

What's Included?

Fast Download Speeds

Online & Offline Access

Access PDF Contents & Bookmarks

Full Search Facility

Print one or all pages of your manual

INTERNATIONAL

HARVESTER

Models H454 H464 m484 W574 H 584 H674

SHOP MANUAL

Engine serial number is stamped on left side of engine crankcase on all nondiesel series. Engine serial

number is stamped on right side of engine crankcase on all diesel series.

Tractor serial number is stamped on name plate attached to left side of speed transmission housing on

Models 454, 464, 574 and 674 or on the right rear side of front axle support on Models 484 and 584.

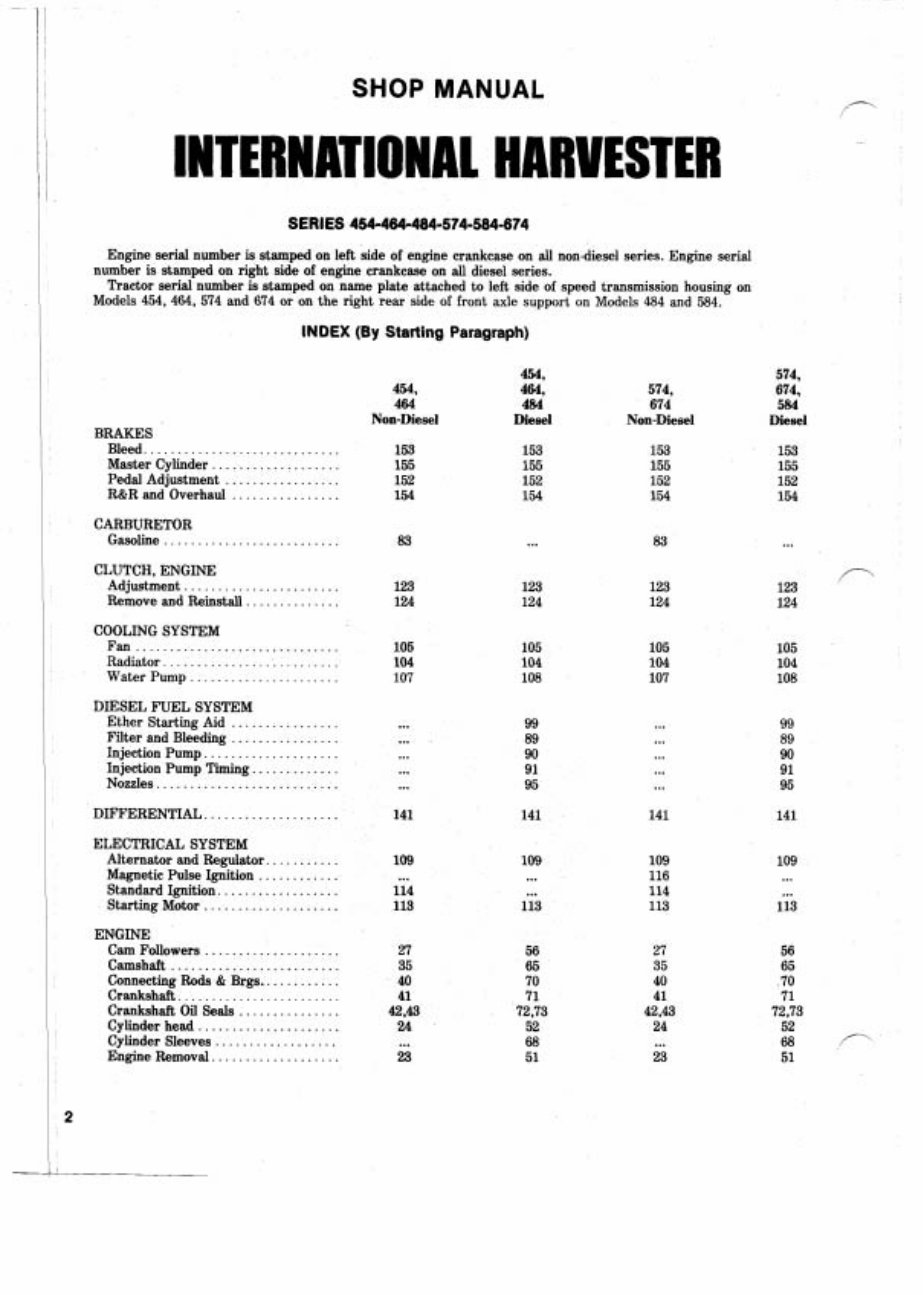

INDEX (By Starting Paragraph)

454,

464, 574,

484 674

Diesel Non-Diesel

574,

674,

584

Diesel

454,

464

Non-Diesel

BRAKES

Bleed. ............................ 153

Master Cylinder ................... 155

Pedal Adjustment ................. 152

R&R and Overhaul ................ 154

CARBURETOR

Gasoline ...............

CLUTCH, ENGINE

Adjustment ....................... 123 123 123

Remove and Reinstall. ............. 124 124 124

COOLING SYSTEM

Fan ..............................

Radiator ..........................

Water Pump ......................

DIESEL FUEL SYSTEM

Ether Starting Aid ................ ... 99 ...

Filter and Bleeding ................ ... 89 ...

Injection Pump. ................... ... 90 ...

Injection Pump Timing. ............ ... 91 ...

Nozzles ........................... ... 95 ...

DIFFERENTIAL ....................

ELECTRICAL SYSTEM

Alternator and Regulator. ..........

Magnetic Pulse Ignition ............

Standard Ignition. .................

Starting Motor ....................

ENGINE

Cam Followers ....................

......................... Camshaft

Connecting Rods & Brgs.. ..........

Crankshaft ........................

Crankshaft Oil Seals ...............

Cylinder head .....................

Cylinder Sleeves ..................

Engine Removal. ..................

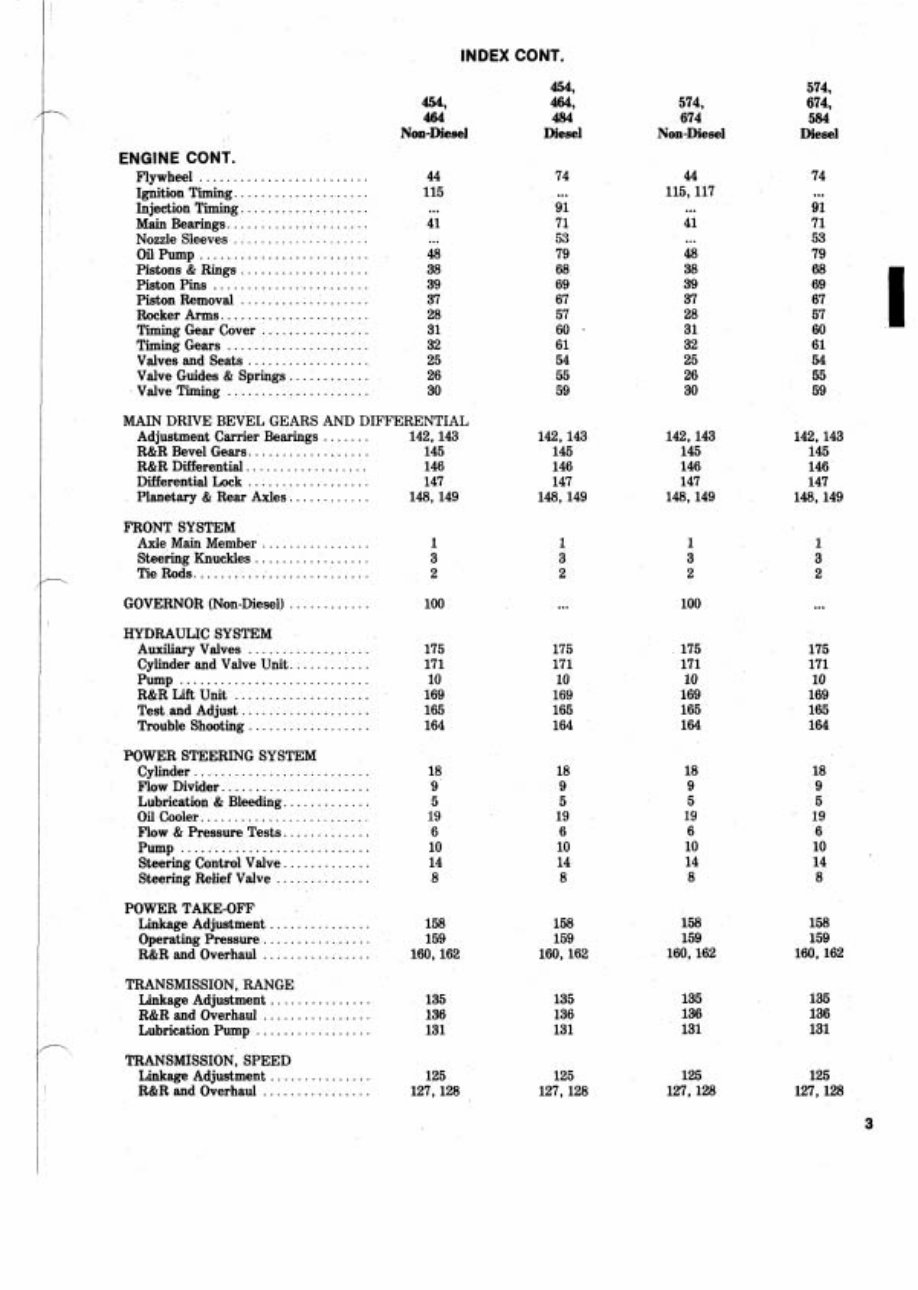

INDEX CONT .

454.

454. 464.

464 484

Non-Diesel Diesel

574.

674.

584

Diesel

574.

674

Non-Diesel

ENGINE CONT .

Flywheel .........................

Ignition Timing ....................

Injection Timing ...................

Main Bearings .....................

Nozzle Sleeves ....................

......................... Oil Pump

................... Pistons & Rings

Piston Pins .......................

................... Piston Removal

Rocker Arms ......................

................ Timing Gear Cover

Timing Gears .....................

Valves and Seats ..................

Valve Guides & Springs ............

Valve Timing .....................

MAIN DRIVE BEVEL GEARS AND DIFFERENTIAL

Adjustment Carrier Bearings ....... 142.143

R&R Bevel Gears .................. 145

R&R Differential .................. 146

Differential Lock .................. 147

Planetary & Rear Axles ............ 148. 149

FRONT SYSTEM

Axle Main Member ................ 1

Steering Knuckles ................. 3

Tie Rods .......................... 2

GOVERNOR (Non-Diesel) ............ 100

HYDRAULIC SYSTEM

.................. Auxiliary Valves

Cylinder and Valve Unit ............

Pump ............................

R&R Lift Unit ....................

Test and Adjust ...................

Trouble Shooting ..................

POWER STEERING SYSTEM

Cylinder ..........................

Flow Divider ......................

............. Lubrication & Bleeding

......................... Oil Cooler

Flow & Pressure Tests .............

Pump ............................

............. Steering Control Valve

.............. Steering Relief Valve

POWER TAKE-OFF

............... Linkage Adjustment 158

................ Operating Pressure 159

R&R and Overhaul ................ 160. 162

TRANSMISSION. RANGE

Linkage Adjustment ............... 135

R&R and Overhaul ................ 136

Lubrication Pump ................. 131

TRANSMISSION. SPEED

Linkage Adjustment ............... 125

R&R and Overhaul ................ 127. 128

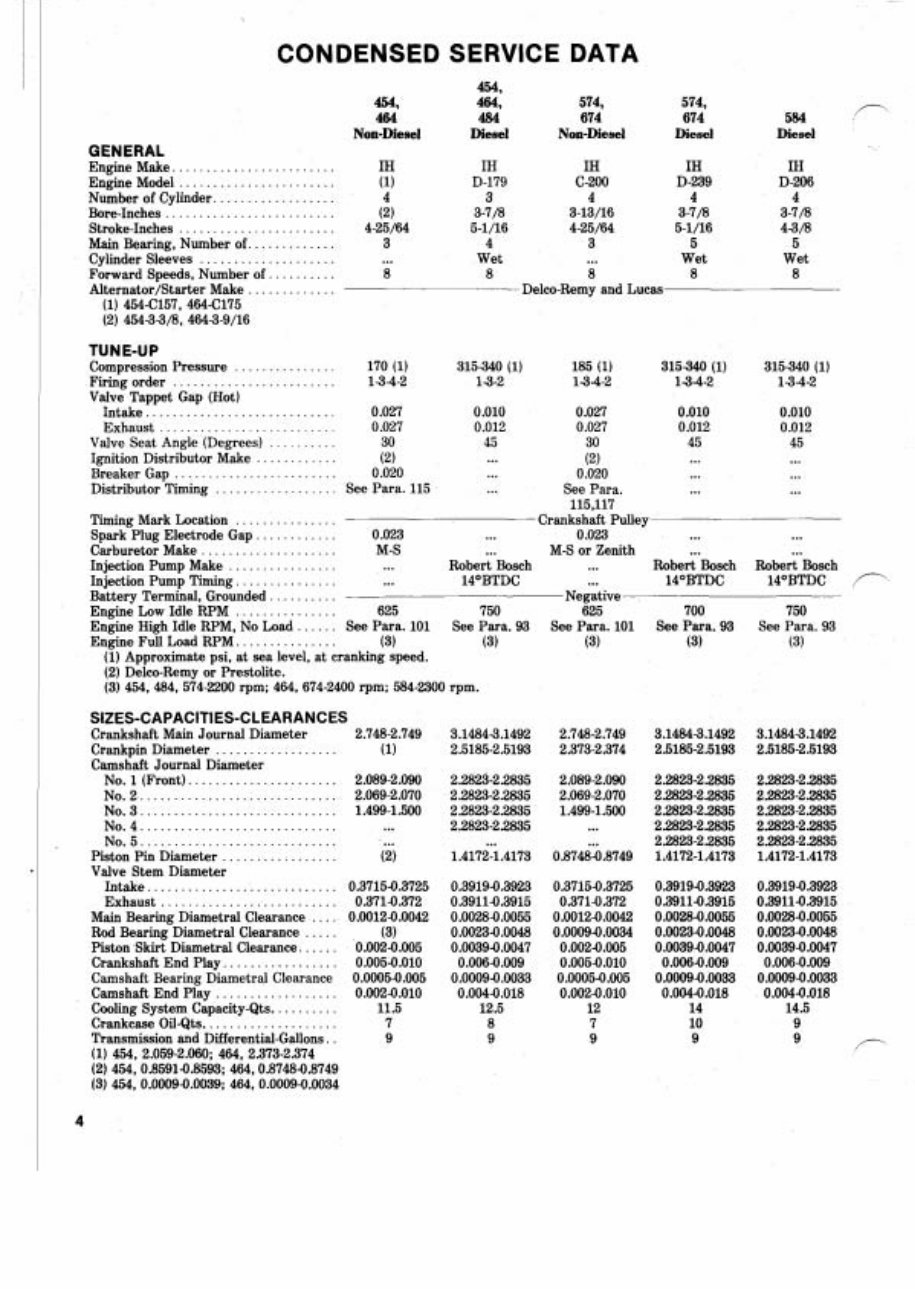

CONDENSED SERVICE DATA

GENERAL

Engine Make. .......................

Engine Model .......................

................. Number of Cylinder.

Bore-Inches .........................

Stroke-Inches .......................

Main Bearing. Number of. ............

.................... Cylinder Sleeves

Forward Speeds, Number of. .........

............. Alternator/Starter Make

(1) 454-C157, 4644175

(2) 45433/8, 4643-9/16

454,

464

Non-Diesel

454,

464,

484

Diesel

IH

D-179

3

3-7/8

5-1/16

4

Wet

8

574,

674

Non-Diesel

IH

C-200

4

3-13/16

4-25/64

3

...

8

Delco-Remy and Lucas

574,

674

Diesel

IH

D-239

4

3-7/8

5-1/16

5

Wet

8

TUNE-UP

Compression Pressure ............... 170 (1) 315340 (1) 185 (1) 315340 (1)

Firing order ........................ 134-2 13-2 13-4-2 13-4-2

Valve Tappet Gap (Hot)

Intake ............................ 0.027 0.010 0.027 0.010

Exhaust ..................... 0.027 0.012 0.027 0.012

Valve Seat Angle (Degrees) ....... 30 45 30 45

............ ... Ignition Distributor Make (2) (2) ...

........................ Breaker Gap 0.020 ... 0.020 ...

Distributor Timing .................. See Para. 115 ... See Para. ...

115,117

Timing Mark Location ............... Crankshaft Pulley

Spark Plug Electrode Gap. ........... 0.023 ... 0.023 ...

Carburetor Make .................... M-S ... M-S or Zenith ...

Injection Pump Make ................ ... Robert Bosch ... Robert Bosch

Injection Pump Timing. .............. ... 14OBTDC ... 14OBTDC

Battery Terminal, Grounded .......... Negative

Engine Low Idle RPM ............... 625 750 625 700

Engine High Idle RPM, No Load ...... See Para. 101 See Para. 93 See Para. 101 See Para. 93

Engine Full Load RPM. .............. (3) (3) (3) (3)

(1) Approximate psi, at sea level, at cranking speed.

(2) Delco-Remy or Prestolite.

(3) 454,484, 574-2200 rpm; 464.674-2400 rpm; 584-2300 rpm.

SIZES-CAPACITIES-CLEARANCES

Crankshaft Main Journal Diameter 2.748-2.749

.................. Crankpin Diameter (1)

Camshaft Journal Diameter

No. 1 (Front) ...................... 2.089-2.090

NO. 2 ............................. 2.069-2.070

NO. 3 ............................. 1.499-1.500

No.4 ............................. ...

No.5 ............................. ...

Piston Pin Diameter ................. (2)

Valve Stem Diameter

Intake ............................ 0.37154.3725

Exhaust .......................... 0.3714.372

Main Bearing Diametral Clearance .... 0.00124.0042

Rod Bearing Diametral Clearance ..... (3)

Piston Skirt Diametral Clearance. ..... 0.0024.005

Crankshaft End Play. ................ 0.0054.010

Camshaft Bearing Diametral Clearance 0.00054.005

Camshaft End Play .................. 0.0024.010

Cooling System Capacity-Qts. ......... 11.5

Crankcase Oil-Qts. ................... 7

Transmission and Differential-Gallons . . 9

(1) 454, 2.059-2.060; 464, 2.373-2.374

(2) 454,0.8591-0.8593; 464,0.87484.8749

(3) 454, 0.00094.0039; 464, 0.00094.0034

584

P

Diesel

IH

D-206

4

3-7/8

43/8

5

Wet

8

...

Robert Bosch

14OBTDC f-'

750

See Para. 93

(3)

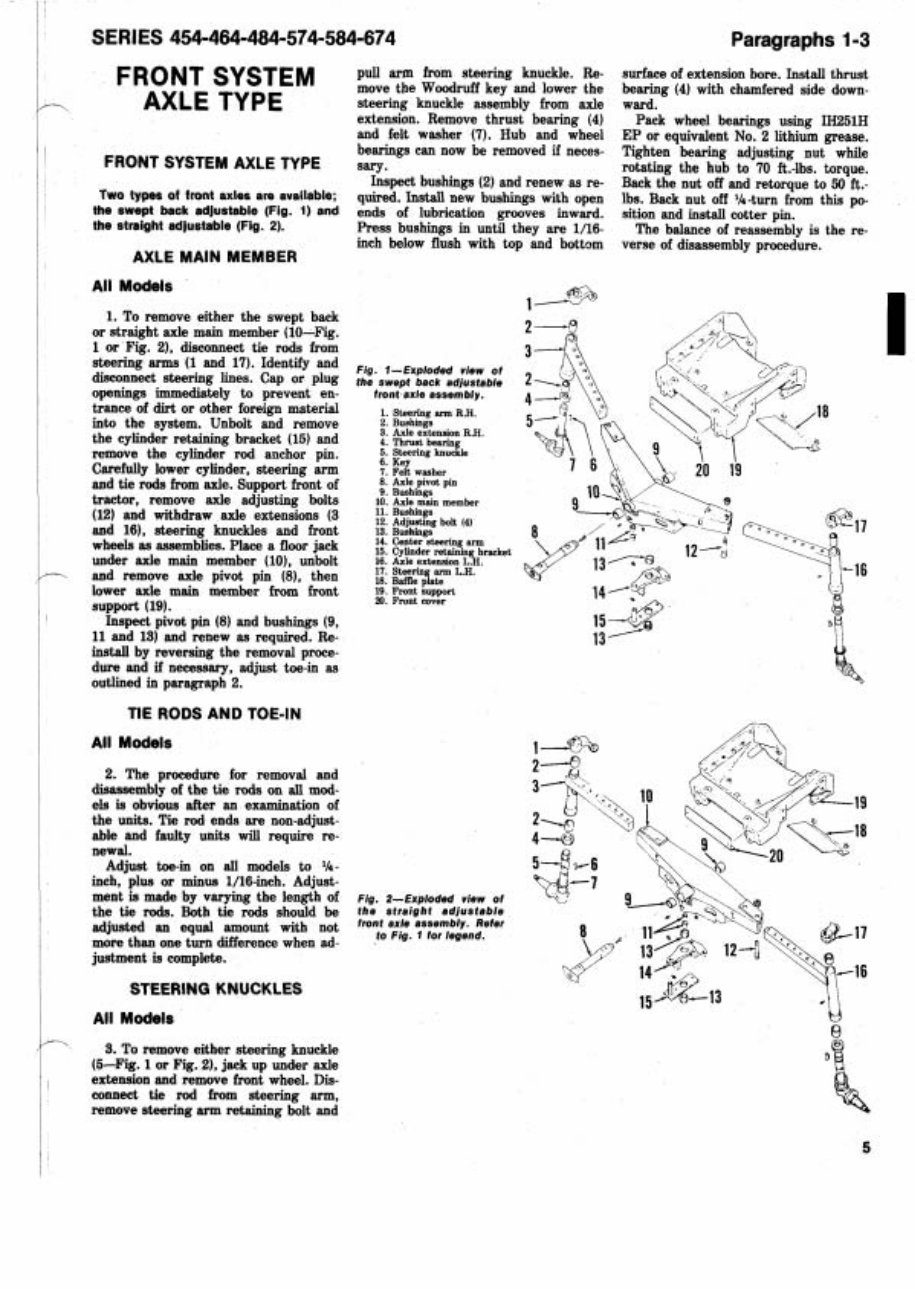

Paragraphs 1-3

pull arm from steering knuckle. Re-

Ro SYSTEM move the Woodruff key and lower the

AXLE TYPE

steering knuckle assembly from axle

extension. Remove thrust bearing (4)

and felt washer (7). Hub and wheel

bearings can now be removed if neces-

FRONT SYSTEM AXLE TYPE sarv.

Inspect bushings (2) and renew as re-

TWOtypes of front axles are available;

quired. Install new bushings with open

the swept back adjustable (Fig. 1) and ends of lubrication grooves inward.

the straight adjustable (Fig. 2). Press bushings in until they are 1/16-

AXLE MAIN MEMBER

inch below flush with top and bottom

surface of extension bore. Install thrust

bearing (4) with chamfered side down-

ward.

Pack wheel bearings using IH251H

EP or equivalent No. 2 lithium grease.

Tighten bearing adjusting nut while

rotating the hub to 70 ft.-lbs. torque.

Back the nut off and retorque to 50 ft.-

lbs. Back nut off %-turn from this po-

sition and install cotter pin.

The balance of reassembly is the re-

verse of disassembly procedure.

All Models

*

1 -

1. To remove either the swept back

or straight axle main member (10-Fig.

1 or Fig. 2), disconnect tie rods from

steering arms (1 and 17). Identify and

Fig. view of

disconnect steering lines- Cap or plug

the swept back adjustable

openings immediately to prevent en- front axle assembly.

trance of dirt or other foreign material 1. sbring RH.

I

2. Bushings

into the system. Unbolt and remove

3. Axle extension RH.

the cylinder retaining bracket (15) and 4. nrust bearing

5. Steering knuckle

remove the cylinder rod anchor pin.

s. Key

aref fully lower cylinder, steering arm 7. Felt washer

and tie rods from axle. Support front of

: kx$g'," pin

tractor, remove axle adjusting bolts lo. Axle main member

(12) and withdraw axle extensions (3

:;: exg bolt ,*,

and 16), steering knuckles and front 13. Bushings

wheels as assemblies. Place a floor jaek

::: ~~~,"~~,g~rBeket

under axle main member (10). unbolt 16. Axle extension L.H.

and remove axle pivot pin (8), then

::: ~ ~ ~ p " l a ~ L.H.

lower axle main member from front

g: gtgrt

support (19).

Inspect pivot pin (8) and bushings (9,

11 and 13) and renew as required. Re-

install by reversing the removal proce-

dure and if necessary, adjust toe-in as

outlined in paragraph 2.

TIE RODS AND TOE-IN

All Models

2. The procedure for removal and

disassembly of the tie rods on all mod-

els is obvious after an examination of

the units. Tie rod ends are non-adjust-

able and faulty units will require re-

newal.

Adjust toe-in on all models to '14-

inch, plus or minus l/l6-inch. Adjust-

ment is made by varying the length of Fig. 2-Exploded view of

the tie rods. Both tie rods should be the straight adjustable

adjusted an equal amount with not

front ax" assembly. Refer

more than one turn difference when ad-

to Fig. 1 for legend.

justment is complete.

STEERING KNUCKLES

All Models

Q

3. To remove either steering knuckle

(6-Fig. 1 or Fig. 21, jaek up under axle

extension and remove front wheel. Dis-

connect tie rod from steering arm,

remove steering arm retaining bolt and

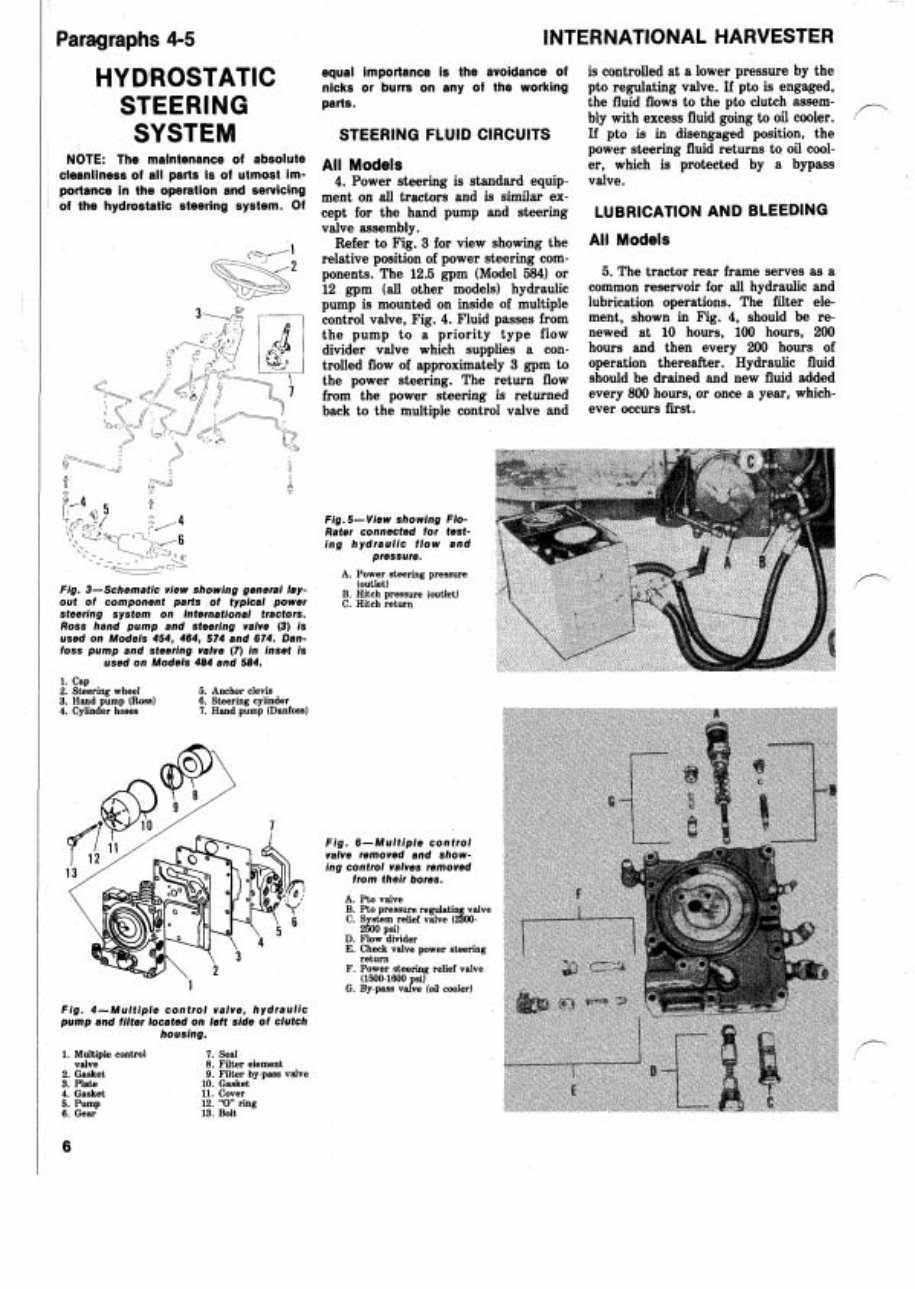

Paragraphs 4-5

HYDROSTATIC

STEERING

SYSTEM

NOTE: The malntenance of absolute

cleanliness of all parts Is of utmost im-

portance in the operation and servicing

of the hydrostatic steering system. Of

Fig. 3-Schematic view showing general lay-

out of component parts of typical power

steering system on International tractors.

Ross hand pump and steering valve (3) is

used on Models 454, 464, 574 and 674. Dan-

foss pump and steering valve (7) in inset is

used on Models 484 and 584.

INTERNATIONAL HARVESTER

equal importance is the avoidance of is controlled at a lower pressure by the

nicks or burrs on any of the working pto regulating valve. If pto is engaged,

parts. the fluid flows to the pto clutch assem-

bly with excess fluid going to oil cooler.

P

STEERING FLUID CIRCUITS

If pto is in disengaged position, the

power steering fluid returns to oil cool-

All Models er, which is protected by a bypass

4. Power steering is standard equip- valve.

ment on all tractors and is similar ex-

cept for the hand pump and steering LUBRICATION AND BLEEDING

valve assembly.

Refer to Fig. 3 for view showing the

All Models

relative position of power steering com-

ponents. The 12.5 gpm (Model 584) or

5. The tractor rear frame serves as a

12 gpm (all other models) hydraulic

common reservoir for all hydraulic and

pump is mounted on inside of multiple

lubrication operations. The filter ele-

control valve, Fig. 4. Fluid passes from

ment, shown in Fig. 4, should be re-

the pump to a priority type flow

newed at 10 hours, 100 hours, 200

divider valve which supplies a con-

hours and then every 200 hours of

trolled flow of approximately 3 gpm to

operation thereafter. Hydraulic fluid

the power steering. The return flow

should be drained and new fluid added

from the power steering is returned

every 800 hours, or once a year, which-

back to the multiple control valve and

ever occurs first.

Fig. 5- View showing Flo-

Rater connected for test-

ing hydraulic flow and

pressure.

A. Power steering pressure

(outlet)

B. Hitch pressure (outlet)

C. Hitch return

1. Cap

2. Steering wheel 5. Anchor clevis

3. Hand pump (Ross) 6. Steering cylinder

4. Cylinder hoses 7. Hand pump (Danfoss)

Fig. 6-Multiple control

valve removed and show-

ing control valves removed

from their bores.

A. Pto valve

B. Pto pressure regidatin valve

C. System relief valve (400-

2500 psi)

D. Flow divider

E. Check valve power steering

Fig. 4-Multiple control valve, hydraulic

pump and filter located on left side of clutch

housing.

1. Multiple control 7. Seal

valve 8. Filter element

2. Gasket 9. Filter by-pass valve

3. Plate 10. Gasket

4. Gasket 11. Cover

5. Pump 12. "0 ring

6. Gear 13. Bolt

return

F. Power steering relief valve

(1500-1600 si)

G. By-pass vage (oil cooler)

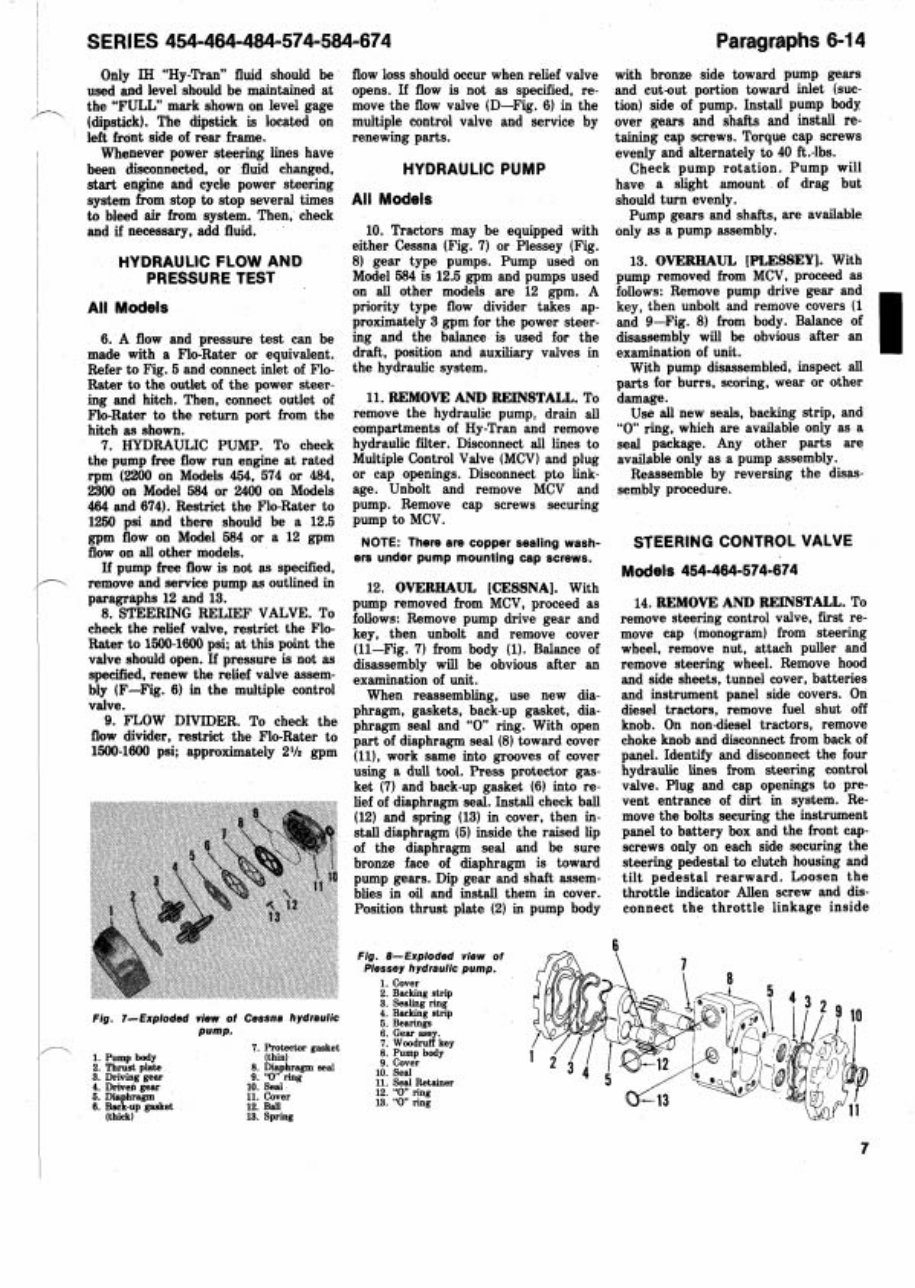

SERlES 454-464-484-574-584-674 Paragraphs 6-1 4

Only IH "Hy-Tran" fluid should be

used and level should be maintained at

n

the "FULL mark shown on level gage

(dipstick). The dipstick is located on

left front side of rear frame.

I Whenever power steering lines have

~

been disconnected, or fluid changed,

~

start engine and cycle power steering

I

system from stop to stop several times

to bleed air from system. Then, check

I

and if necessary, add fluid.

I

i

HYDRAULIC FLOW AND

PRESSURE TEST

I

All Models

~ 6. A flow and pressure test can be

made with a Flo-Rater or equivalent.

Refer to Fig. 5 and connect inlet of Flo-

I

Rater to the outlet of the power steer-

ing and hitch. Then, connect outlet of

Flo-Rater to the return port from the

hitch as shown.

7. HYDRAULIC PUMP. To check

the pump free flow run engine at rated

rpm (2200 on Models 454, 574 or 484,

2900 on Model 584 or 2400 on Models

464 and 674). Restrict the Flo-Rater to

1250 psi and there should be a 12.5

gpm flow on Model 584 or a 12 gpm

flow on all other models.

If pump free flow is not as specified,

p remove and service pump as outlined in

paragraphs 12 and 13.

8. STEERING RELIEF VALVE. To

check the relief valve, restrict the Flo-

Rater to 1500-1600 psi; at this point the

valve should open. If pressure is not as

specified, renew the relief valve assem-

bly (F-Fig. 6) in the multiple control

valve.

9. FLOW DIVIDER. To check the

flow divider, restrict the Flo-Rater to

1500-1600 psi; approximately 2% gpm

Fig. 7-Exploded view of Cessna hydraulic

pump.

7. Protector gasket

1. Pump body (thin)

2. Thrust plate 8. Diaphragm seal

3. Drmmg gear 9. '0" ring

4. Driven gear 10. Seal

5. Dia hragm 11. Cover

S. B J - u p gasket 12. B~U,

(thick) 13. Sprmg

flow loss should occur when relief valve

opens. If flow is not as specified, re-

move the flow valve (D-Fig. 6) in the

multiple control valve and service by

renewing parts.

HYDRAULIC PUMP

All Models

10. Tractors may be equipped with

either Cessna (Fig. 7) or Plessey (Fig.

8) gear type pumps. Pump used on

Model 584 is 12.5 gpm and pumps used

on all other models are 12 gpm. A

priority type flow divider takes ap-

proximately 3 gpm for the power steer-

ing and the balance is used for the

draft, position and auxiliary valves in

the hydraulic system.

11. REMOVE AND REINSTALL. To

remove the hydraulic pump, drain all

compartments of Hy-Tran and remove

hydraulic filter. Disconnect all lines to

Multiple Control Valve (MCV) and plug

or cap openings. Disconnect pto link-

age. Unbolt and remove MCV and

pump. Remove cap screws securing

pump to MCV.

NOTE: There are copper sealing wash-

ers under pump mounting cap screws.

12. OVERHAUL [CESSNA]. With

pump removed from MCV, proceed as

follows: Remove pump drive gear and

key, then unbolt and remove cover

(11-Fig. 7) from body (1). Balance of

disassembly will be obvious after an

examination of unit.

When reassembling, use new dia-

phragm, gaskets, back-up gasket, dia-

phragm seal and "0 ring. With open

part of diaphragm seal (8) toward cover

(ll), work same into grooves of cover

using a dull tool. Press protector gas-

ket (7) and back-up gasket (6) into re-

lief of diaphragm seal. Install check ball

(12) and spring (13) in cover, then in-

stall diaphragm (5) inside the raised lip

of the diaphragm seal and be sure

bronze face of diaphragm is toward

pump gears. Dip gear and shaft assem-

blies in oil and install them in cover.

Position thrust plate (2) in pump body

with bronze side toward pump gears

and cut-out portion toward inlet (suc-

tion) side of pump. Install pump body

over gears and shafts and install re-

taining cap screws. Torque cap screws

evenly and alternately to 40 ft.-lbs.

Check pump rotation. Pump will

have a slight amount of drag but

should turn evenly.

Pump gears and shafts, are available

only as a pump assembly.

13. OVERHAUL [PLESSEY]. With

pump removed from MCV, proceed as

follows: Remove pump drive gear and

key, then unbolt and remove covers (1

and 9-Fig. 8) from body. Balance of

disassembly will be obvious after an

examination of unit.

With pump disassembled, inspect all

parts for burrs, scoring, wear or other

damage.

I

Use all new seals, backing strip, and

"0 ring, which are available only as a

seal package. Any other parts are

available only as a pump assembly.

Reassemble by reversing the disas-

sembly procedure.

STEERING CONTROL VALVE

Models 454-464-574-674

14. REMOVE AND REINSTALL. To

remove steering control valve, first re-

move cap (monogram) from steering

wheel, remove nut, attach puller and

remove steering wheel. Remove hood

and side sheets, tunnel cover, batteries

and instrument panel side covers. On

diesel tractors, remove fuel shut off

knob. On nondiesel tractors, remove

choke knob and disconnect from back of

panel. Identify and disconnect the four

hydraulic lines from steering control

valve. Plug and cap openings to pre-

vent entrance of dirt in system. Re-

move the bolts securing the instrument

panel to battery box and the front cap-

screws only on each side securing the

steering pedestal to clutch housing and

tilt pedestal rearward. Loosen the

throttle indicator Allen screw and dis-

connect the throttle linkage inside

Fie. 8-Exploded view of 6-23

6

\

fiessey hydraulic pump. J&,)lA

1. Cover

2. Backing strip

3. Sealing ring

4. Backing strip

5. Bearings

6. Gear assy.

7. Woodruff key

8. Pump body

9. Cover

in Seal

12. '0" ring

13. "0 ring

- - . - ---

11. Seal Retainer

INTERNATIONAL HARVESTER

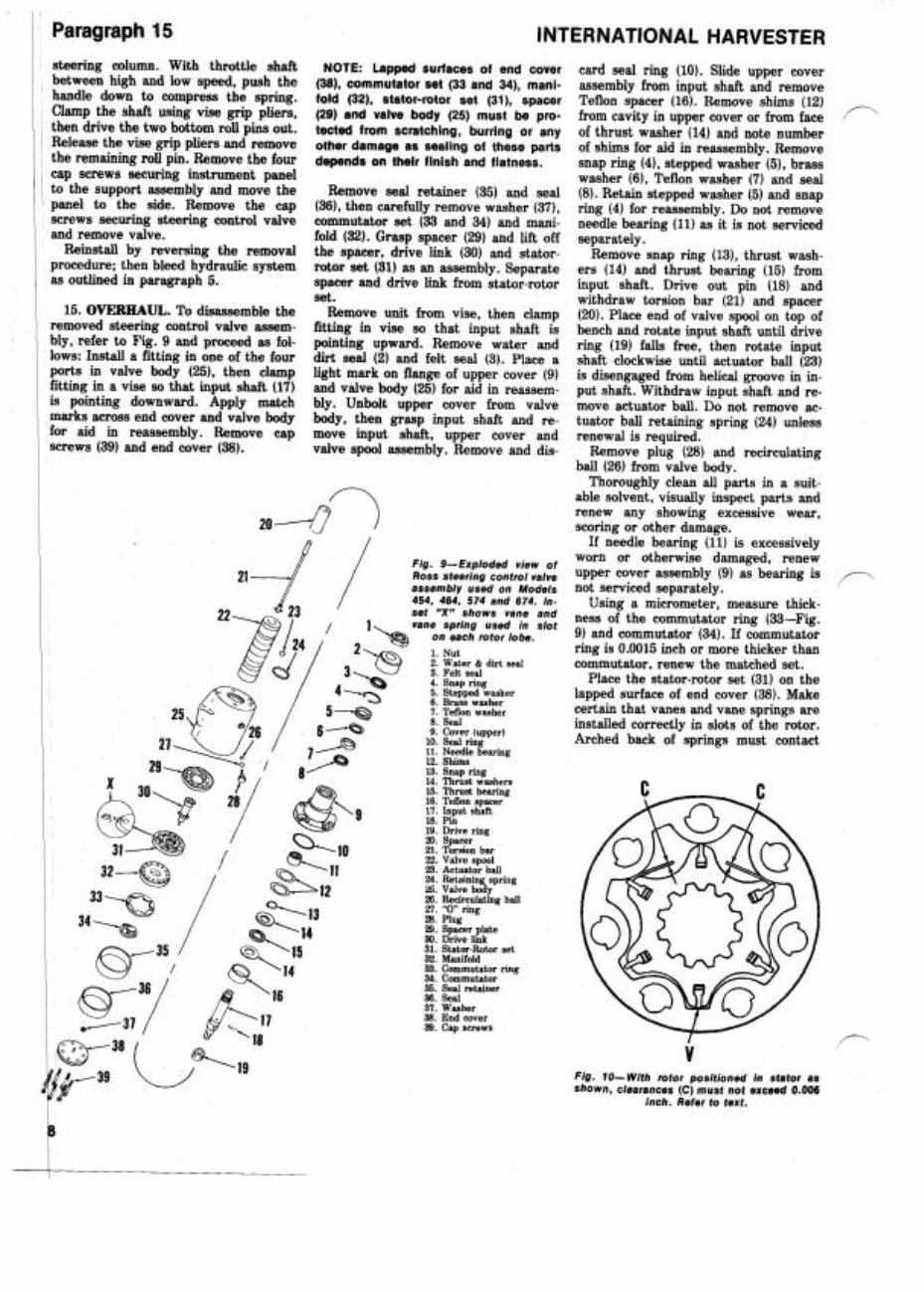

steering eolumn. With throttle shaft NOTE: Lapped surfaces of end cover

card seal ring (10). Slide upper cover

between high and low speed, push the

(38), commutator set (33 and 34), mani- assembly from input shaft and remove

handle d ~ w n to compress the spring. fold (32). stator-rotor set (31), spacer Teflon spacer (16). Remove shims (12)

Clamp the shaft using vise grip pliers,

(29) and valve body (25) must be pro- from cavity in upper cover or from face

then drive the two bottom roll pins out. tected from scratching, burring or any

of thrust washer (14) and note number

Release the vise grip pliers and remove

other damage as sealing of these parts of shims for aid in reassembly. Remove

the remaining roll pin. Remove the four depends on their finish and flatness. snap ring (41, stepped washer (51, brass

cap screws securing instrument panel

washer (61, Teflon washer (7) and seal

to the support assembly and move the Remove seal retainer (35) and seal

(8). Retain stepped washer (5) and snap

panel to the side. Remove the cap (361, then carefully remove washer (371, ring (4) for reassembly. Do not remove

screws securing steering control valve commutator set (33 and 34) and mani- needle bearing (11) as it is not serviced

and remove valve. fold (32). Grasp spacer (29) and lift off separately.

Reinstall by reversing the removal

the spacer, drive link (30) and stator- Remove snap ring (13), thrust wash-

procedure; then bleed hydraulic system rotor set (31) as an assembly. Separate ers (14) and thrust bearing (15) from

as outlined in paragraph 5. spacer and drive link from stator-rotor input shaft. Drive out pin (18) and

set.

withdraw torsion bar (21) and spacer

15. OVERHAUL. To disassemble the Remove unit from vise, then clamp (20). Place end of valve spool on top of

removed steering control valve assem- fitting in vise so that input shaft is

bench and rotate input shaft until drive

bly, refer to Fig. 9 and proceed as fol- pointing upward. Remove water and ring (19) falls free, then rotate input

lows: Install a fitting in one of the four dirt seal (2) and felt seal (3). Place a shaft clockwise until actuator ball (23)

ports in valve body (251, then clamp light mark on flange of upper cover (9) is disengaged from helical groove in in-

fitting in a vise so that input shaft (17) and valve body (25) for aid in reassem- put shaft. Withdraw input shaft and re-

is pointing downward. Apply match bly. Unbolt upper cover from valve move actuator ball. Do not remove ac-

marks across end cover and valve body body, then grasp input shaft and re- tuator ball retaining spring (24) unless

for aid in reassembly. Remove cap

move input shaft, upper cover and renewal is required.

screws (39) and end cover (38). valve spool assembly. Remove and dis- Remove plug (28) and recirculating

ball (26) from valve body.

Thoroughly clean all parts in a suit-

able solvent, visually inspect parts and

renew any showing excessive wear,

scoring or other damage.

If needle bearing (11) is excessively

Fig. 9-Exploded view of

worn or otherwise damaged, renew

ROSS steering control valve

upper cover assembly (9) as bearing is

,-

assembly used on Models not serviced separately.

454, 464, 574 and 674. In-

Using a micrometer, measure thick-

set "'" vane and ness of the commutator ring (=-Fig.

vans spring used in slot

on each rotor lobe.

9) and commutator (34). If commutator

ring is 0.0015 inch or more thicker than

2. Water & dirt seal commutator, renew the matched set.

Place the stator-rotor set (31) on the

5. Stepped washer

6. Brass washer

lapped surface of end cover (38). Make

7. Teflon washer

certain that vanes and vane springs are

9. Cover (upper)

installed correctly in slots of the rotor.

10. Seal ring

Arched back of springs must contact

11. Needle bearing

12. Shims

13. Snap ring

14. Thrust washers

15. Thrust bearing

19. Drive ring

20. Spacer

21. Torsion bar

22. Valve spool

28. Plug

B. Spacer plate

30. Drive link

31. Stator-Rotor set

32. Manifold

33. Commutator ring

34. Commutator

35. Seal retainer

36. Seal

37. Washer

38. End wver

39. Cap screws

V

Fig. 10-With rotor positioned in stator as

shown, clearances (C) must not exceed 0.006

inch. Refer to text.

SERl ES 454-464-484-574-584-674 Paragraphs 16-1 7

vanes. See inset X-Fig. 9. Position

lobe of rotor in valley of stator as

shown at (V-Fig. 10). Center opposite

lobe on crown of stator, then using two

feeler gages, measure clearance (C)

between rotor lobes and stator. If clear-

ance is more than 0.006 inch, renew

stator-rotor assembly. Using a microm-

eter, measure thickness of stator and

rotor. If stator is 0.002 inch or more

thicker than rotor, renew the assembly.

Stator, rotor, vanes and vane springs

are available only as an assembly.

Before reassembling, wash all parts

in clean solvent and air dry. All parts,

unless otherwise indicated, are in-

stalled dry. Install recirculating ball

(26-Fig. 9) and plug (28) with new "0

ring (27) in valve body and tighten plug

to a torque of 10-14 ft.-lbs. Clamp

fitting (installed in valve body port) in

a vise so that top end of valve body is

facing upward. Install thrust washer

(14). thrust bearing (15), second thrust

washer (14) and snap ring (13) on input

shaft (17). If actuator ball retaining

ring (24) was removed, install new re-

taining ring. Place actuator ball (23) in

its seat inside valve spool (22). Insert

input shaft into valve spool, engaging

the helix and actuator ball with a

counterclockwise motion. Use the mid-

section of torsion bar (21) as a gage be-

tween end of valve spool and thrust

washer, then place the assembly in a

vertical position with end of input shaft

resting on a bench. Insert drive ring

(19) into valve spool until drive ring is

engaged on input shaft spline. Remove

torsion bar gage. Install spacer (20) on

torsion bar and insert the assembly

into valve spool. Align crossholes in

torsion bar and input shaft and install

pin (18). Pin must be pressed into shaft

until end of pin is about 1132-inch be-

low flush. Place spacer (16) over spool

and install spool assembly into valve

body. Position original shims (12) on

thrust washer (141, lubricate new seal

ring (10). place seal ring in upper cover

(9) and install upper cover assembly.

Align the match marks on cover flange

and valve body and install cap screws

finger tight. Tighten a worm drive type

hose clamp around cover flange and

valve body to align the outer dia-

meters, then tighten cap screws to a

torque of 18-22 ft.-lbs.

NOTE: If either input shaft (17) or

upper cover (9) or both have been re-

newed, the following procedure for

shimming must be used. With upper

cover installed (with original shims) as

outlined above, invert unit in vise so

that input shaft is pointing downward.

Grasp input shaft, pull downward and

prevent It from rotating. Engage drive

link (30) spllnes in valve spool and ro-

tate drive link until end of spool is flush

with end of valve body. Remove drive

link and check alignment of drive link

slot to torsion bar pin. Install drive link

until its slot engages torsion bar pin.

Check relationship of spool end to body

end. If end of spool is within 0.0025

inch of being flush with end of body,

no additional shimming is required. It

not within 0.0025 inch of being flush,

remove cover and add or remove shims

(12) as necessary. Reinstall cover and

recheck spool to valve body position.

With drive link installed, place

spacer plate (29) on valve body with

plain side up. Install stator-rotor set

over drive link splines and align cap

screw holes. Make certain vanes and

vane springs are properly installed. In-

stall &mifold (32)' with circular slotted

side up and align cap screw holes with

stator, spacer and valve body. Install

commutator ring (33) with slotted side

up, then install commutator (34) over

drive link end making certain that link

end is engaged in the smallest elon-

gated hole in commutator. Install seal

(36) and retainer (35). Apply a few

drops of hydraulic fluid on commutator.

Use a small amount of grease to stick

washer (37) in position over pin on end

cover (38). Install end cover making

sure that pin engages center hole in

commutator. Align holes and install cap

screws (39). Alternately and progres-

sively tighten cap screws while rotat-

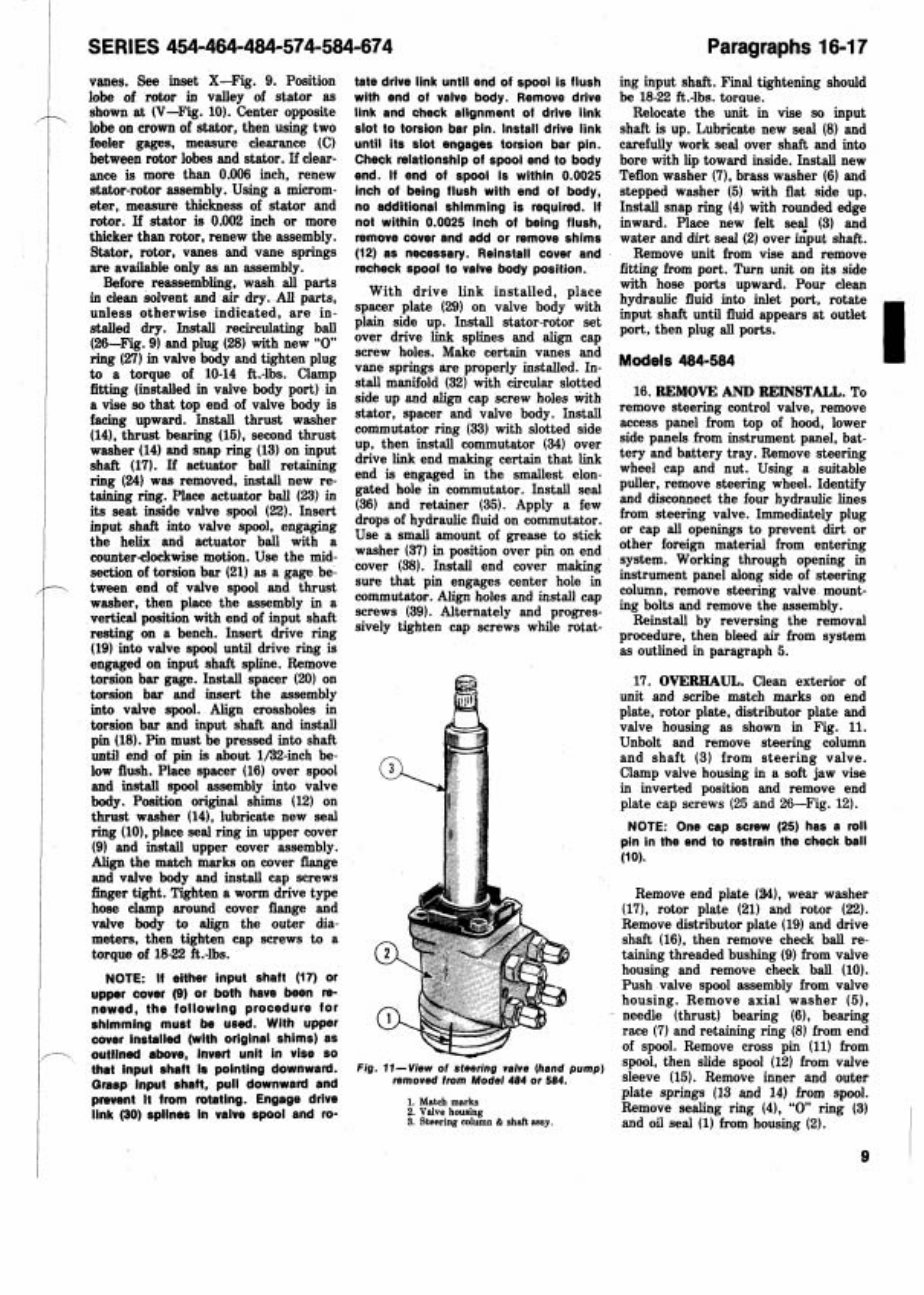

Fig. 11-View of steering valve (hand pump)

removed from Model 484 or 584.

1. Mateh marks

2. Valve housing

3. Steering mlumn & shaft assy.

ing input shaft. Final tightening should

be 18-22 ft.-lbs. toraue.

Relocate the unit in vise so input

shaft is up. Lubricate new seal (8) and

carefully work seal over shaft and into

bore with lip toward inside. Install new

Teflon washer (7). brass washer (6) and

stepped washer (5) with flat side up.

Install snap ring (4) with rounded edge

inward. Place new felt sea? (3) and

water and dirt seal (2) over input shaft.

Remove unit from vise and remove

fitting from port. Turn unit on its side

with hose ports upward. Pour clean

hydraulic fluid into inlet port, rotate

input shaft until fluid appears at outlet

port, then plug all ports.

Models 484-584 1

16. REMOVE AND REINSTALL. To

remove steering control valve, remove

access panel from top of hood, lower

side panels from instrument panel, bat-

tery and battery tray. Remove steering

wheel cap and nut. Using a suitable

puller, remove steering wheel. Identify

and disconnect the four hydraulic lines

from steering valve. Immediately plug

or cap all openings to prevent dirt or

other foreign material from entering

system. Working through opening in

instrument panel along side of steering

column, remove steering valve mount-

ing bolts and remove the assembly.

Reinstall by reversing the removal

~rocedure. then bleed air from svstem

i s outlined in paragraph 5.

17. OVERHAUL. Clean exterior of

unit and scribe match marks on end

plate, rotor plate, distributor plate and

valve housing as shown in Fig. 11.

Unbolt and remove steering column

and shaft (3) from steering valve.

Clamp valve housing in a soft jaw vise

in inverted position and remove end

plate cap screws (25 and 26-Fig. 12).

NOTE: One cap screw (25) has a roll

pin in the end to restrain the check ball

(10).

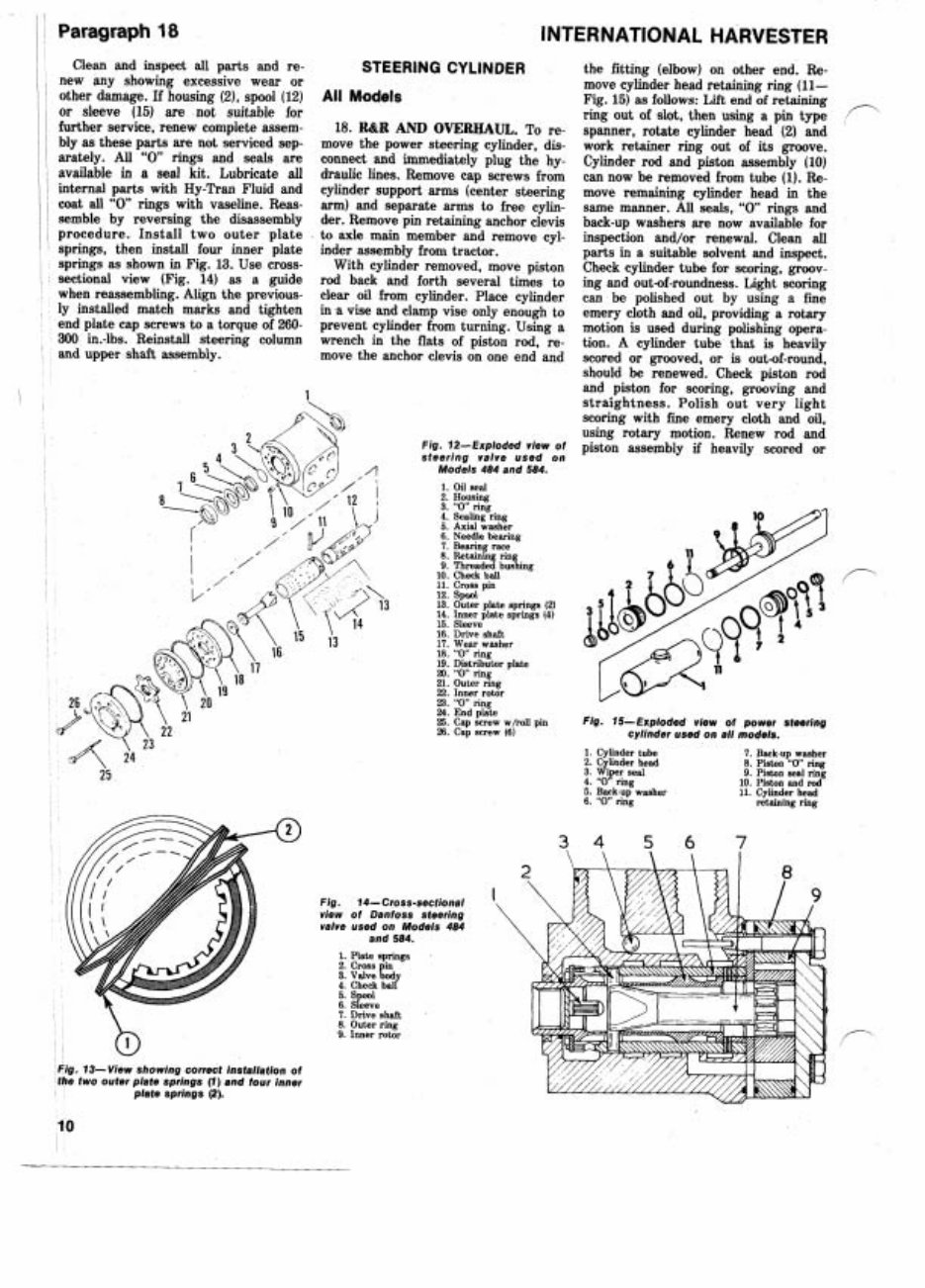

Remove end plate (a), wear washer

(171, rotor plate (21) and rotor (22).

Remove distributor plate (19) and drive

shaft (16). then remove check ball re-

taining threaded bushing (9) from valve

housing and remove check ball (10).

Push valve spool assembly from valve

housing. Remove axial washer (5),

needle (thrust) bearing (6). bearing

race (7) and retaining ring (8) from end

of spool. Remove cross pin (11) from

spool, then slide spool (12) from valve

sleeve (15). Remove inner and outer

plate springs (13 and 14) from spool.

Remove sealing ring (4), "0 ring (3)

and oil seal (1) from housing (2).

l 1

1 Paragraph 18

(

Clean and inspect all parts and re-

, new any showing excessive wear or

1

other damage. If housing (2). spool (12)

I or sleeve (15) are not suitable for

further service, renew complete assem-

I bly as these parts are not serviced sep-

1 ' arately. All "0 rings and seals are

I available in a seal kit. Lubricate all

! internal parts with Hy-Tran Fluid and

coat all "0 rings with vaseline. Reas-

semble by reversing the disassembly

rocedure. Install two outer plate

four inner plate

s shown in Fig. 13. Use eross-

view (Fig. 14) as a guide

ssembling. Align the previous-

ed match marks and tighten

o a torque of 260-

steering column

and upper shaft assembly.

STEERING CYLINDER

All Models

18. R&R AND OVERHAUL. To re-

move the power steering cylinder, dis-

connect and immediately plug the hy-

draulic lines. Remove cap screws from

cylinder support arms (center steering

arm) and separate arms to free cylin-

der. Remove pin retaining anchor clevis

to axle main member and remove cyl-

inder assembly from tractor.

With cylinder removed, move piston

rod back and forth several times to

clear oil from cylinder. Place cylinder

in a vise and clamp vise only enough to

prevent cylinder from turning. Using a

wrench in the flats of piston rod, re-

move the anchor clevis on one end and

w

Fig. 13- View showing correct installation of

the two outer plate springs (1) and four inner

plate springs (2).

INTERNATIONAL HARVESTER

Fig. 12-Exploded view of

steering valve used on

Models 484 and 584.

1. Oil seal

2. Housing

3. "0 ring

4. Sealing ring

5. Axial washer

6. Needle bearing

7. Bearing race

8. Retaining rin

9. Threaded bus%ing

10. Check ball

11. Cross pin

12. Spool

13. Outer plate springs (2)

14. Inner plate springs (4)

15. Sleeve

16. Drive shaft

17. Wear washer

18. "0" ring

19. Distributor plate

20. "0 ring

21. Outer ring

22. Inner rotor

23. "0" ring

24. End plate

25. Cap screw w/roll pin

26. Cap screw (6)

Fig. 74-Cross-sectional

view of Danfoss steering

valve used on Models 484

and 584.

1. Plate springs

2 Cross in

3: Valve L y

4. Check ball

5. Spool

6. Sleeve

7. Drive shaft

8. Outer ring

9. Inner rotor

the fitting (elbow) on other end. Re-

move cylinder head retaining ring (11-

Fig. 15) as follows: Lift end of retaining

n

ring out of slot, then using a pin type

,

spanner, rotate cylinder head (2) and

work retainer ring out of its groove.

Cylinder rod and piston assembly (10)

can now be removed from tube (1). Re-

move remaining cylinder head in the

same manner. All seals, "0 rings and

back-up washers are now available for

inspection and/or renewal. Clean all

parts in a suitable solvent and inspect.

Check cylinder tube for swring, groov-

ing and out-of-roundness. Light scoring

can be polished out by using a fine

emery cloth and oil, providing a rotary

motion is used during polishing opera-

tion. A cylinder tube that is heavily

scored or grooved, or is out-of-round,

should be renewed. Check piston rod

and piston for scoring. grooving and

straightness. Polish out very light

scoring with fine emery cloth and oil,

using rotary motion. Renew rod and

piston assembly if heavily scored or

Fig. 15-Exploded view of power steering

cylinder used on all models.

1. Cylinder tube 7. Back-up washer

2. Cylinder head 8. Piston "0 ring

3. Wiper seal 9. Piston seal ring

4. "0' ring 10. Piston and rod

5. Back-up washer 11. Cylinder head

6. "0 ring retaining ring

You're Reading a Preview

What's Included?

Fast Download Speeds

Online & Offline Access

Access PDF Contents & Bookmarks

Full Search Facility

Print one or all pages of your manual

$31.99

Viewed 48 Times Today

Loading...

Secure transaction

What's Included?

Fast Download Speeds

Online & Offline Access

Access PDF Contents & Bookmarks

Full Search Facility

Print one or all pages of your manual

$31.99

- The IH International Harvester 674 Workshop Repair Service Manual is a comprehensive resource designed to provide all the necessary information for servicing, maintaining, and troubleshooting the IH International Harvester 674.

- This manual covers all models, engines, trim, and transmission types, ensuring access to accurate and complete information.

- Written by the manufacturers, it contains detailed diagrams and instructions for repairing specific components, covering every aspect from the engine to the electrical system.

- It provides step-by-step repair procedures, critical specifications, illustrations, and pictures to guide through each repair process, suitable for professional technicians and DIY enthusiasts.

- The manual includes detailed sections on the engine, lubrication system, cooling system, fuel system, disassembly and servicing, general maintenance, and advanced troubleshooting, along with a comprehensive wiring diagram.

- Available in electronic format, it offers easy access from a computer, allowing for printing of desired sections and instant download.

- Both the paper and electronic versions offer the same features and information, with the electronic version providing instant access and download to a computer within seconds.

- Investing in this manual will save money on repair costs and help properly maintain the IH International Harvester 674 for years to come.

- Don't miss out on this opportunity to have a complete and reliable manual at your fingertips. Get your IH International Harvester 674 Workshop Repair Service Manual today and take control of your vehicle's maintenance and repairs.