IH International Harvester 234, Hydro 234, 244, 254 Tractor Service & Repair Workshop Manual

What's Included?

Fast Download Speeds

Online & Offline Access

Access PDF Contents & Bookmarks

Full Search Facility

Print one or all pages of your manual

INTERNATIONAL

HARVESTER

SHOP MANUAL

SERIES:

234

Hydro 234 • 244 • 254

HOW TO USE THE INDEX:

Suppose you want to know the procedure for R&R (remove and

reinstall) of the engine camshaft. Your first step is to look in the

index under the main heading of ENGINE until you find the entry

“Camshaft.” Now read to the right where under the column

covering the tractor you are repairing, you will find a number

that indicates the beginning paragraph pertaining to the

camshaft. To locate this wanted paragraph in the manual, turn

the pages until the running index appearing on the top outside

corner of each page contains the number you are seeking. In

this paragraph you will find the information concerning the

removal of the camshaft.

2

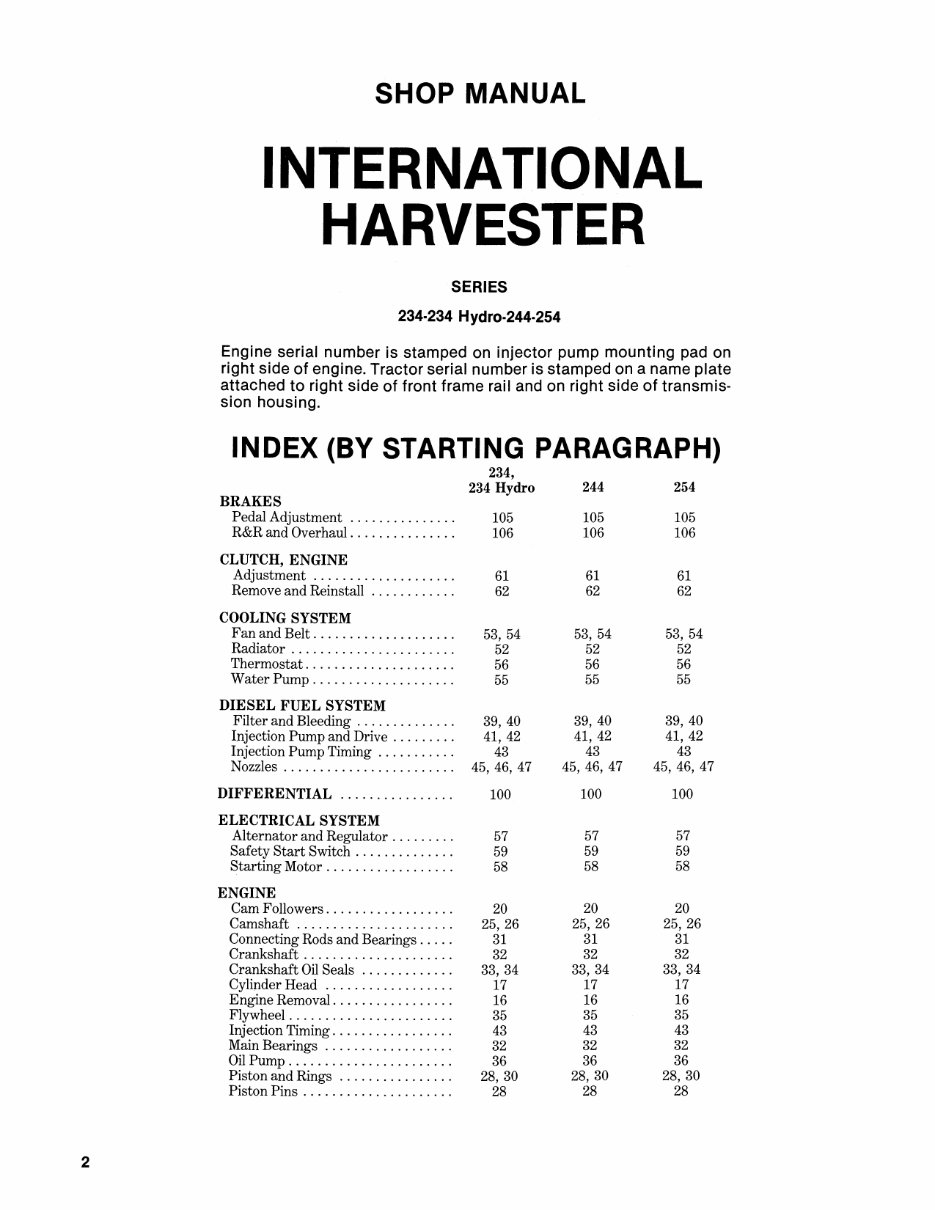

SHOP MANUAL

INTERNATIONAL

HARVESTER

SERIES

234·234 Hydro·244·254

Engine serial number is stamped on injector pump mounting pad on

right side of engine. Tractor serial number is stamped on a name plate

attached to right side of front frame rail and on right side of transmis-

sion housing.

INDEX (BY STARTING PARAGRAPH)

BRAKES

Pedal Adjustment .............. .

R&R and Overhaul .............. .

CLUTCH, ENGINE

Adjustment ................... .

Remove and Reinstall ........... .

COOLING SYSTEM

Fan and Belt ................... .

Radiator ...................... .

Thermostat .................... .

Water Pump ................... .

DIESEL FUEL SYSTEM

Filter and Bleeding ............. .

Injection Pump and Drive ........ .

Injection Pump Timing .......... .

Nozzles ....................... .

DIFFERENTIAL ............... .

ELECTRICAL SYSTEM

Alternator and Regulator ........ .

Safety Start Switch ............. .

Starting Motor ................. .

ENGINE

Cam Followers ................. .

Camshaft ..................... .

Connecting Rods and Bearings .... .

Crankshaft .................... .

Crankshaft Oil Seals ............ .

Cylinder Head ................. .

Engine Removal ................ .

Flywheel ...................... .

Injection Timing ................ .

Main Bearings ................. .

Oil Pump ...................... .

Piston and Rings ............... .

Piston Pins .................... .

234,

234 Hydro

105

106

61

62

53,54

52

56

55

39, 40

41,42

43

45,46,47

100

57

59

58

20

25, 26

31

32

33, 34

17

16

35

43

32

36

28, 30

28

244

105

106

61

62

53, 54

52

56

55

39,40

41, 42

43

45, 46, 47

100

57

59

58

20

25, 26

31

32

33, 34

17

16

35

43

32

36

28, 30

28

254

105

106

61

62

53, 54

52

56

55

39, 40

41, 42

43

45, 46, 47

100

57

59

58

20

25, 26

31

32

33, 34

17

16

35

43

32

36

28, 30

28

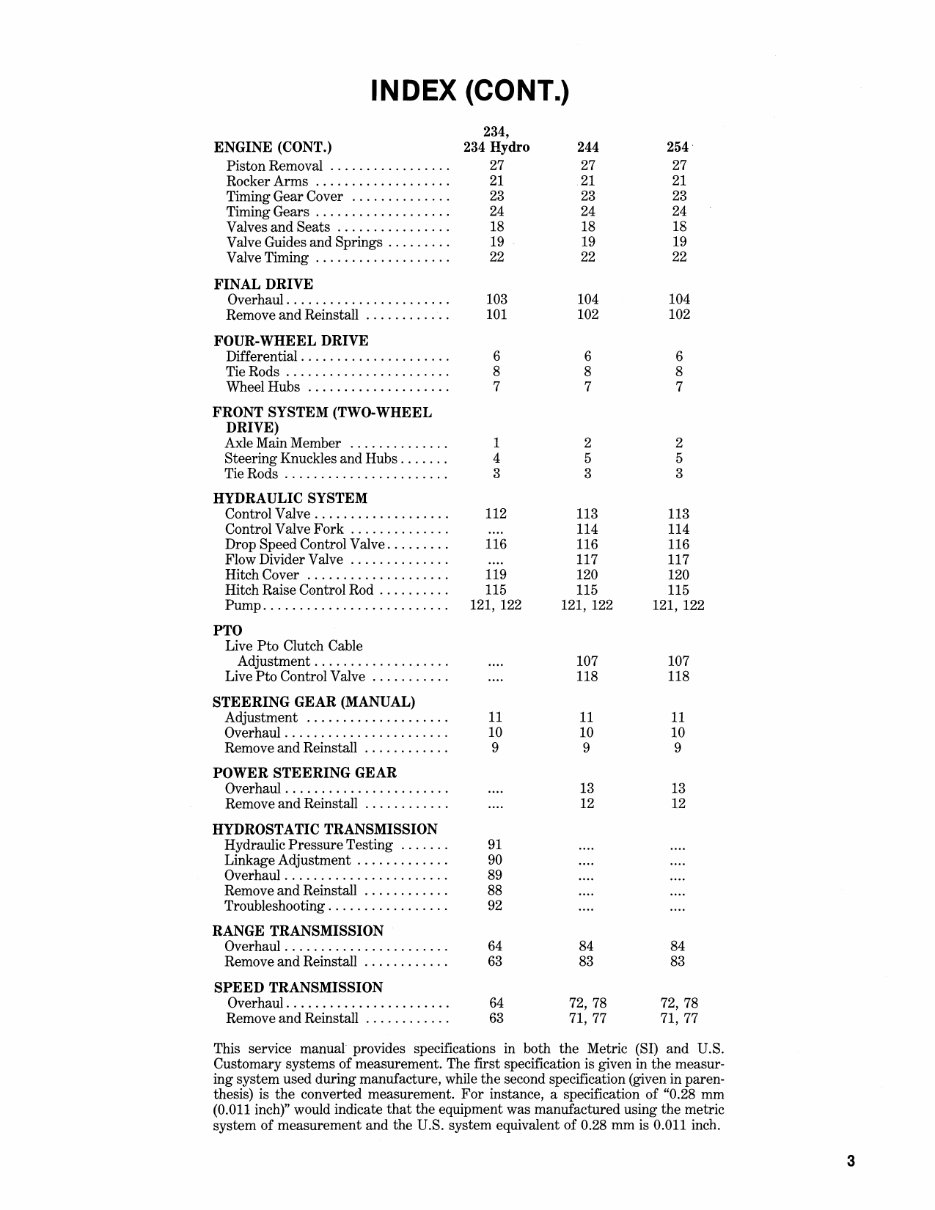

INDEX (CONT.)

234,

ENGINE (CONT.) 234 Hydro 244 254

Piston Removal ................. 27 27 27

Rocker Arms ................... 21 21 21

Timing Gear Cover .............. 23 23 23

Timing Gears ................... 24 24 24

Valves and Seats ................ 18 18 18

Valve Guides and Springs ......... 19 19 19

Valve Timing ................... 22 22 22

FINAL DRIVE

Overhaul ....................... 103 104 104

Remove and Reinstall ............ 101 102 102

FOUR-WHEEL DRIVE

Differential. .................... 6 6 6

TieRods ....................... 8 8 8

Wheel Hubs .................... 7 7 7

FRONT SYSTEM (TWO-WHEEL

DRIVE)

Axle Main Member .............. 1 2 2

Steering Knuckles and Hubs ....... 4 5 5

TieRods ....................... 3 3 3

HYDRAULIC SYSTEM

Control Valve ................... 112 113 113

Control Valve Fork .............. 114 114

Drop Speed Control Valve ......... 116 116 116

Flow Divider Valve .............. 117 117

Hitch Cover .................... 119 120 120

Hitch Raise Cemtrol Rod .......... 115 115 115

Pump .......................... 121, 122 121, 122 121, 122

PTO

Live Pto Clutch Cable

Adjustment ................... 107 107

Live Pto Control Valve ........... 118 118

STEERING GEAR (MANUAL)

Adjustment .................... 11 11 11

Overhaul ....................... 10 10 10

Remove and Reinstall ............ 9 9 9

POWER STEERING GEAR

Overhaul ....................... 13 13

Remove and Reinstall ............ 12 12

HYDROSTATIC TRANSMISSION

Hydraulic Pressure Testing ....... 91

Linkage Adjustment ............. 90

Overhaul ....................... 89

Remove and Reinstall ............ 88

Troubleshooting ................. 92

RANGE TRANSMISSION

Overhaul ....................... 64 84 84

Remove and Reinstall ............ 63 83 83

SPEED TRANSMISSION

Overhaul ....................... 64 72,78 72,78

Remove and Reinstall ............ 63 71,77 71,77

This service manual provides specifications in both the Metric (SI) and U.S.

Customary systems of measurement. The first specification is given in the measur-

ing system used during manufacture, while the second specification (given in paren-

thesis) is the converted measurement. For instance, a specification of "0.28 mm

(0.011 inch)" would indicate that the equipment was manufactured using the metric

system of measurement and the U.S. system equivalent of 0.28 mm is 0.011 inch.

3

4

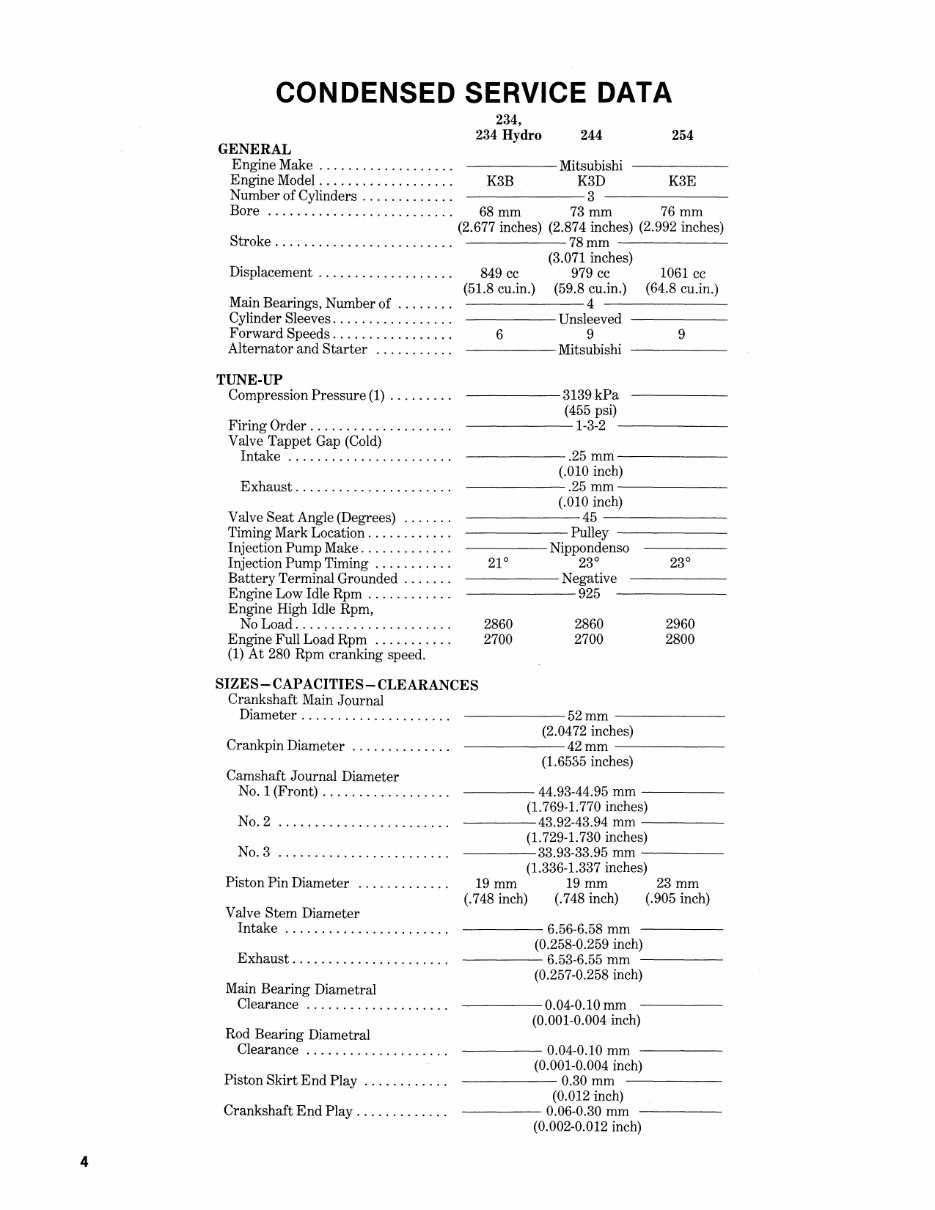

CONDENSED SERVICE DATA

GENERAL

234,

234 Hydro 244 254

Engine Make . . . . . . . . . . . . . . . . . . . Mitsubishi -----

Engine Model. . . . . . . . . . . . . . . . . . . K3B K3D K3E

Number of Cylinders . . . . . . . . . . . . . 3

Bore .......................... 68 mm 73 mm 76 mm

(2.677 inches) (2.874 inches) (2.992 inches)

Stroke. . . . . . . . . . . . . . . . . . . . . . . . . 78 mm ------

Displacement .................. .

Main Bearings, Number of ....... .

Cylinder Sleeves ................ .

Forward Speeds ................ .

Alternator and Starter .......... .

TUNE-UP

Compression Pressure (1) ........ .

Firing Order ................... .

Valve Tappet Gap (Cold)

Intake ...................... .

Exhaust ..................... .

Valve Seat Angle (Degrees) ...... .

Timing Mark Location ........... .

Injection Pump Make ............ .

Injection Pump Timing .......... .

Battery Terminal Grounded ...... .

Engine Low Idle Rpm ........... .

Engine High Idle Rpm,

No Load ..................... .

Engine Full Load Rpm .......... .

(1) At 280 Rpm cranking speed.

(3.071 inches)

849 cc 979 cc 1061 cc

(51.8 cu.in.) (59.8 cu.in.) (64.8 cu.in.)

-------4 -------

-----Unsleeved -----

6 9

-----Mitsubishi

-----3139kPa

9

(455 psi)

------1-3-2 ------

------.25 mm------

(.010 inch)

-~----.25 mm------

(.010 inch)

------45-------

------Pulley ------

---- Nippondenso

23°

-----Negative

------925 ------

2860

2700

2860

2700

2960

2800

SIZES-CAPACITIES-CLEARANCES

Crankshaft Main Journal

Diameter .................... .

Crankpin Diameter ............. .

Camshaft Journal Diameter

No.1 (Front) ................. .

No.2

No.3

Piston Pin Diameter ............ .

Valve Stem Diameter

Intake ...................... .

Exhaust ..................... .

Main Bearing Diametral

Clearance ................... .

Rod Bearing Diametral

Clearance ................... .

Piston Skirt End Play ........... .

Crankshaft End Play ............ .

------52mm------

(2.0472 inches)

------42mm------

(1.6535 inches)

---- 44.93-44.95 mm -----

(1. 769-1. 770 inches)

----43.92-43.94 mm -----

(1. 729-1. 730 inches)

----33.93-33.95 mm -----

(1.336-1.337 inches)

19mm 19mm

(.748 inch)

23mm

(.905 inch) (.748 inch)

---- 6.56-6.58 mm

(0.258-0.259 inch)

---- 6.53-6.55 mm -----

(0.257-0.258 inch)

----0.04-0.10 mm

(0.001-0.004 inch)

---- 0.04-0.10 mm

(0.001-0.004 inch)

-----0.30mm -----

(0.012 inch)

---- 0.06-0.30 mm

(0.002-0.012 inch)

SERIES 234·244·254

CONDENSED SERVICE DATA (CONT.)

234,

234 Hydro 244

SIZES-CAPACITIES-CLEARANCES (CONT.)

Camshaft Bearing Diametral

Clearance ................... . -----0.05-0.15 mm

254

Camshaft End Play ............. .

Cooling System Capacity ......... .

(0.002.-0.006 inch)

------(1) ------

------5.0 liters

(5.3 quarts)

Crankcase Oil Capacity (2) ....... . 3.0 liters

(3.2 quarts)

4.0 liters 4.0 liters

(4.25 quarts) (4.25 quarts)

Transmission and Differential

Capacity ..................... 12 liters 21 liters 21 liters

(12.7 quarts) (22.2 quads) (22.2 quarts)

Hydrostatic Transmission and

Differential Capacity .......... . 14 liters

(14.8 quarts)

Front Differential Housing

(Four Wheel Drive) ............ . ------ 2.5 liters

(2.6 quarts)

(1) No specification; controlled by thrust plug in timing cover.

(2) Including filter.

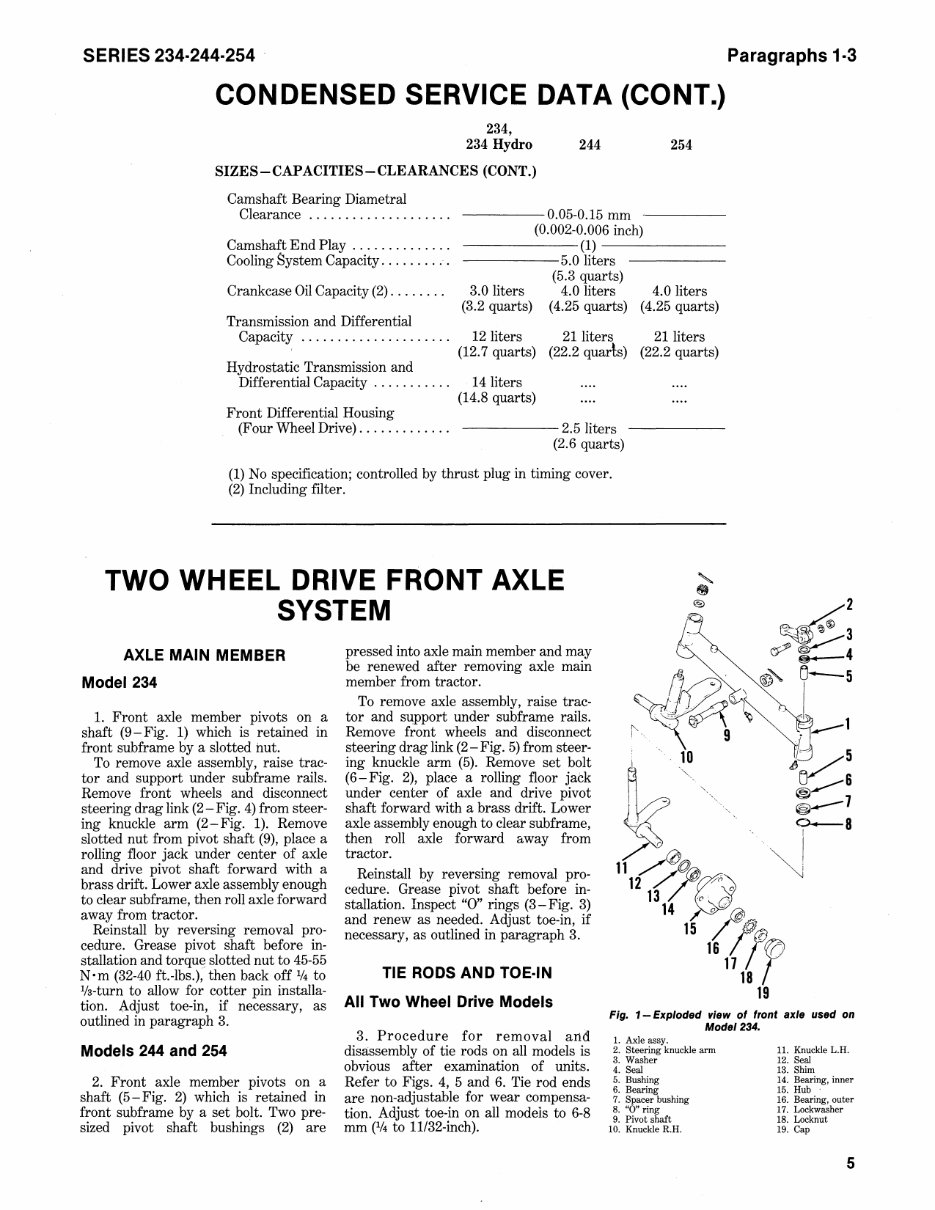

TWO WHEEL DRIVE FRONT AXLE

SYSTEM

AXLE MAIN MEMBER

Model 234

1. Front axle member pivots on a

shaft (9-Fig. 1) which is retained in

front subframe by a slotted hut.

To remove axle assembly, raise trac-

tor and support under subframe rails.

Remove front wheels and disconnect

steering drag link (2-Fig. 4) from steer-

ing knuckle arm (2-Fig. 1). Remove

slotted nut from pivot shaft (9), place a

rolling floor jack under center of axle

and drive pivot shaft forward with a

brass drift. Lower axle assembly enough

to clear subframe, then roll axle forward

away from tractor.

pressed into axle main member and may

be renewed after removing axle main

member from tractor.

To remove axle assembly, raise trac-

tor and support under subframe rails.

Remove front wheels and disconnect

steering drag link (2 - Fig. 5) from steer-

ing knuckle arm (5). Remove set bolt

(6-Fig. 2), place a rolling floor jack

under center of axle and drive pivot

shaft forward with a brass drift. Lower

axle assembly enough to clear subframe,

then roll axle forward away from

tractor.

Reinstall by reversing removal pro-

cedure. Grease pivot shaft before in-

stallation. Inspect "0" rings (3 - Fig. 3)

and renew as needed. Adjust toe-in, if

necessary, as outlined in paragraph 3.

TIE RODS AND TOE·IN

All Two Wheel Drive Models

Paragraphs 1·3

Reinstall by reversing removal pro-

cedure. Grease pivot shaft before in-

stallation and torqu~ slotted nut to 45-55

N'm (32-40 ft.-Ibs.), then back off 1/4 to

Va-turn to allow for cotter pin installa-

tion. A.djust toe-in, if necessary, as

outlined in paragraph 3.

3. Procedure for removal and

disassembly of tie rods on all models is

obvious after examination of units.

Refer to Figs. 4, 5 and 6. Tie rod ends

are non-adjustable for wear compensa-

tion. Adjust toe-in on all models to 6-8

mm (1f4 to 11/32-inch).

Fig. 1- Exploded "lew of front axle used on

Model 234.

Models 244 and 254

2. Front axle member pivots on a

shaft (5-Fig. 2) which is retained in

front subframe by a set bolt. Two pre-

sized pivot shaft bushings (2) are

1. Axle assy.

2. Steering knuckle arm

3. Washer

4. Seal

5. Bushing

6. Bearing

7. Spacer bushing

8. "0" ring

9. Pivot shaft

10. Knuckle R.H.

11. Knuckle L.H.

12. Seal

13. Shim

14. Bearing, inner

15. Hub

16. Bearing, outer

17. Lockwasher

18. Locknut

19. Cap

5

Paragraph 4 INTERNATIONAL HARVESTER

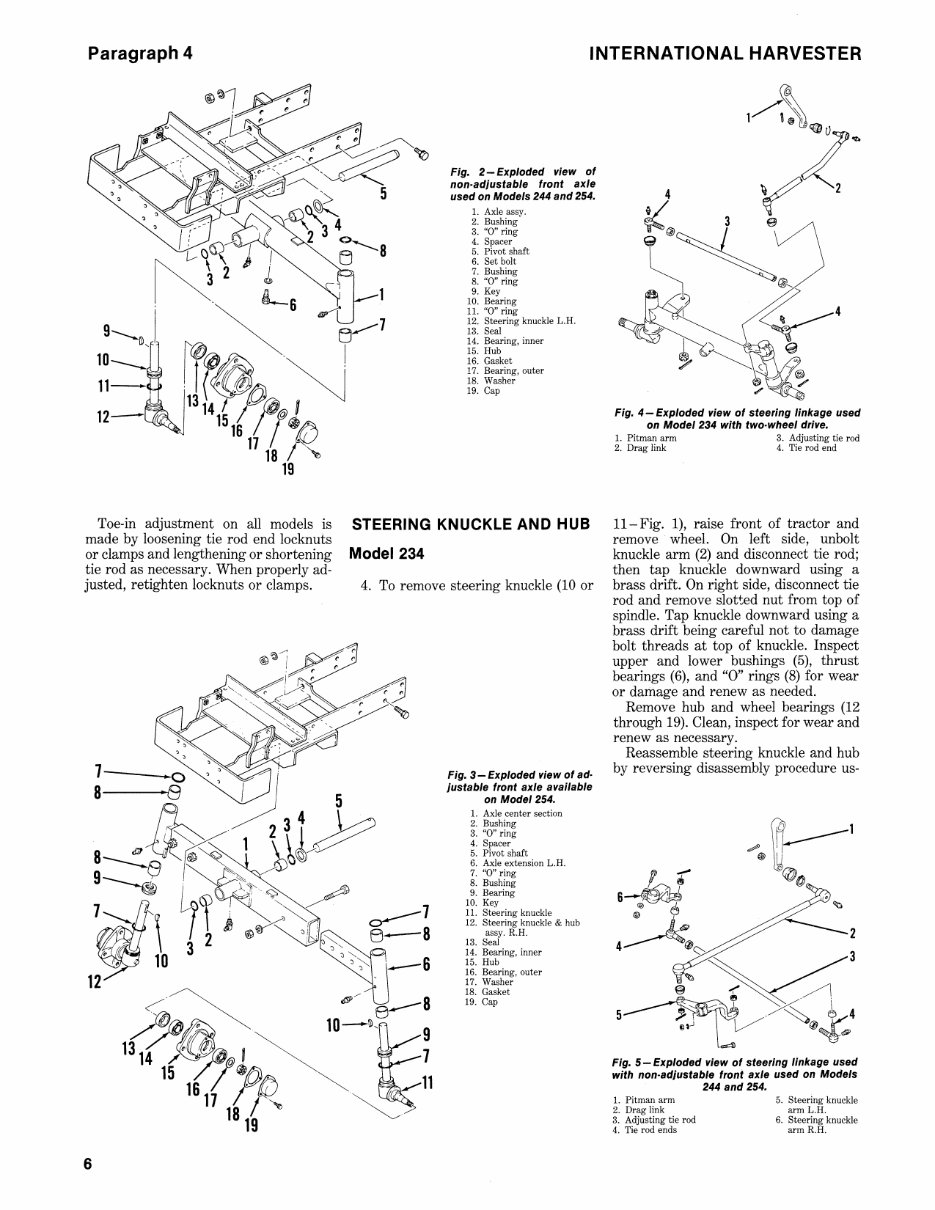

Fig. 2-Exploded view of

non·adjustable front axle

used on Models 244 and 254.

1. Axle assy.

2. Bushing

3. "0" ring

4. Spacer

5. Pivot shaft

6. Set bolt

7. Bushing

8. "0" ring

9. Key

10. Bearing

11. "0" ring

12. Steering knuckle L.R.

13. Seal

14. Bearing, inner

15. Rub

16. Gasket

17. Bearing, outer

18. Washer

19. Cap

Toe-in adjustment on all models is STEERING KNUCKLE AND HUB

made by loosening tie rod end locknuts

or clamps and lengthening or shortening Model 234

tie rod as necessary. When properly ad-

justed, retighten locknuts or clamps. 4. To remove steering knuckle (10 or

6

0---

7

B-B

Fig. 3 - Exploded view of ad·

justable front axle available

on Model 254.

1. Axle center section

2. Bushing

3. "0" ring

4. Spacer

5. Pivot shaft

6. Axle extension L.R.

7. "0" ring

8. Bushing

9. Bearing

10. Key

11. Steering knuckle

12. Steering knuckle & hub

assy. R.R.

13. Seal

14. Bearing, inner

15. Rub

16. Bearing, outer

17. Washer

18. Gasket

19. Cap

Fig. 4 - Exploded view of steering linkage used

on Model 234 with two· wheel drive.

1. Pitman arm 3. Adjusting tie rod

2. Drag link 4. Tie rod end

ll-Fig. 1), raise front of tractor and

remove wheel. On left side, unbolt

knuckle arm (2) and disconnect tie rod;

then tap knuckle downward using a

brass drift. On right side, disconnect tie

rod and remove slotted nut from top of

spindle. Tap knuckle downward using a

brass drift being careful not to damage

bolt threads at top of knuckle. Inspect

upper and lower bushings (5), thrust

bearings (6), and "0" rings (8) for wear

or damage and renew as needed.

Remove hub and wheel bearings (12

through 19). Clean, inspect for wear and

renew as necessary.

Reassemble steering knuckle and hub

by reversing disassembly procedure us-

Fig. 5-Exploded view of steering linkage used

with non·adjustable front axle used on Models

244 and 254.

1. Pitman arm

2. Drag link

3. Adjusting tie rod

4. Tie rod ends

5. Steering knuckle

arm L.R.

6. Steering knuckle

arm R.R.

SERIES 234·244·254

~~'

5A~i @"K2

r~~3

<4' 4

~\I

--»@ ~

2 ~ ®~~l

W /~~

--,. f" \ '&fV' /'

6 ":.) U 5

Fig. 6 - Exploded view of steering linkage used

with adjustable front axle available on Model

'. 254.

1. Pitman arm

2. Dr~g link ends

3. Drag link rod

4. Adjusting tie rod

5. Tie rod ends

6. Steering knuckle

arm L.H.

7. Steering knuckle

arm R.H.

ing a new wheel bearing seal (12).

Lubricate steering knuckle through fit-

ting on axle and pack wheel bearings

with a good grade multi-purpose grease.

Models 244 and 254

5. To remove either steering knuckle

(11 or 12-Fig. 3), raise front of tractor

and remove wheel. Unbolt knuckle arm

(5 or 6-Fig. 5), remove Woodruff key

(10-Fig. 3) and tap knuckle downward

using a brass drift. Inspect upper and

lower bushings (8), thrust bearing (9)

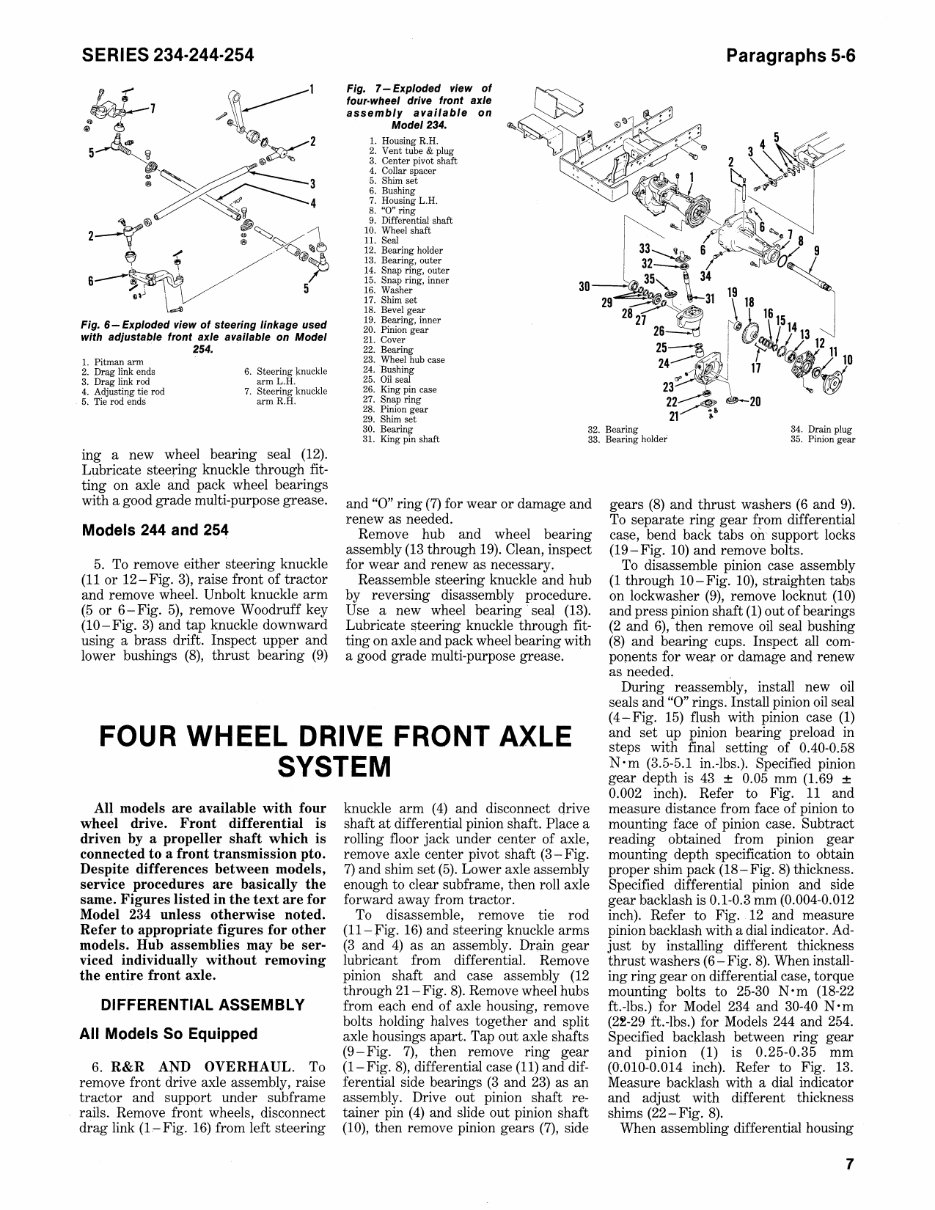

Fig. 7 - Exploded view of

four·wheel drive front axle

assembly available on

Model 234.

1. Housing R.H.

2. Vent tube & plug

3. Center pivot shaft

4. Collar spacer

5. Shim set

6. Bushing

7. Housing L.H.

8. "0" ring

9. Differential shaft

to. Wheel shaft

11. Seal

12. Bearing holder

13. Bearing, outer

14. Snap ring, outer

15. Snap ring, inner

16. Washer

17. Shim set

18. Bevel gear

19. Bearing, inner

20. Pinion gear

21. Cover

22. Bearing

23. Wheel hub case

24. Bushing

25. Oil seal

26. King pin case

27. Snap ring

28. Pinion gear

29. Shim set

Paragraphs 5·6

30. Bearing 32. Bearing 34. Drain plug

31. King pin shaft 33. Bearing holder 35. Pinion gear

and "0" ring (7) for wear or damage and

renew as needed.

Remove hub and wheel bearing

assembly (13 through 19). Clean, inspect

for wear and renew as necessary.

Reassemble steering knuckle and hub

by reversing disassembly procedure.

Use a new wheel bearing' seal (13).

Lubricate l'\teering knuckle through fit-

ting on axle and pack wheel bearing with

a good grade multi-purpose grease.

gears (8) and thrust washers (6 and 9).

To separate ring gear from differential

case, bend back tabs oil.' support locks

(19-Fig. 10) and remove bolts.

To disassemble pinion case assembly

(1 through 10-Fig. 10), straighten tabs

on lockwasher (9), remove locknut (10)

and press pinion shaft (1) out of bearings

(2 and 6), then remove oil seal bushing

(8) and bearing cups. Inspect all com-

ponents for wear or damage and renew

as needed. ,

FOUR WHEEL DRIVE FRONT AXLE

SYSTEM

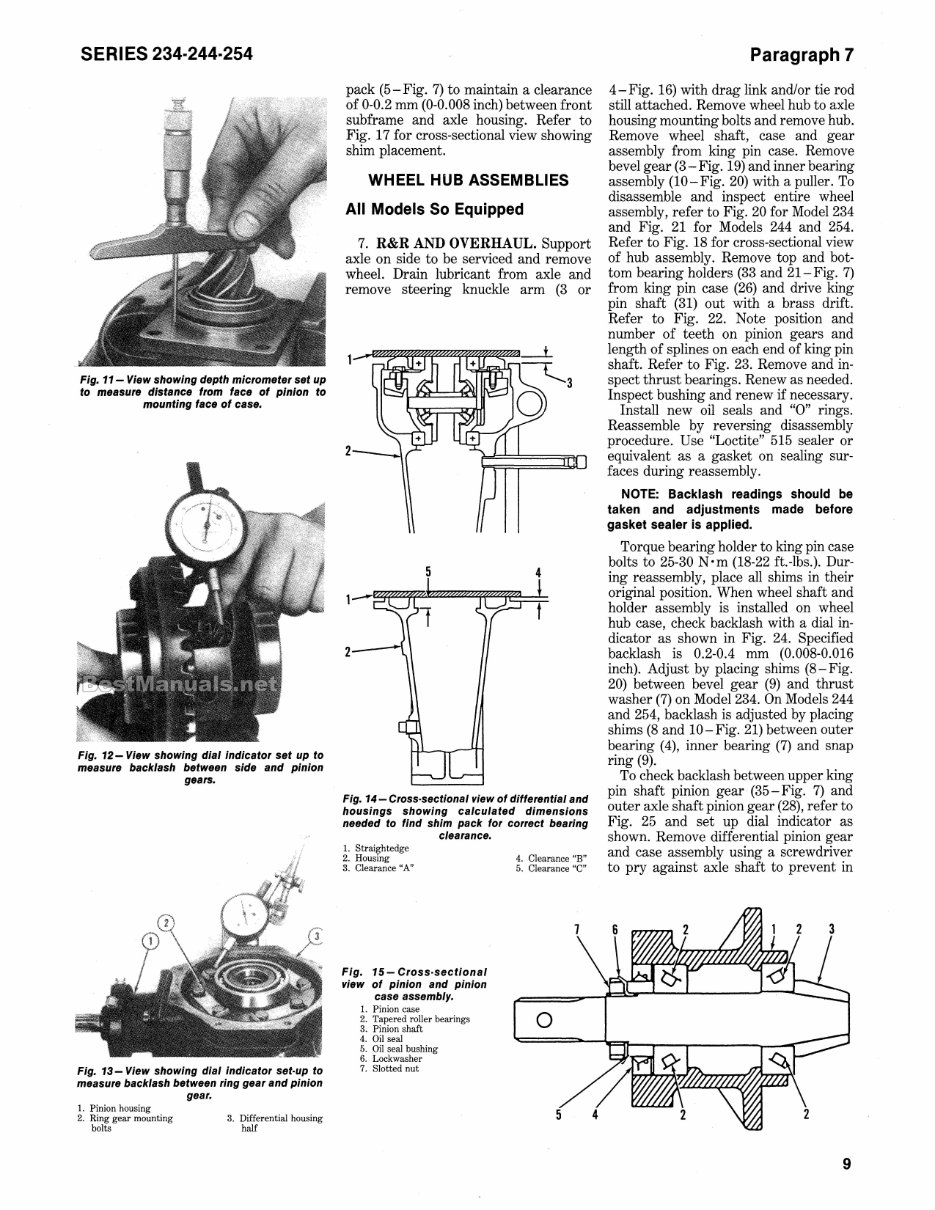

During reassembly, install new oil

seals and "0" rings. Install pinion oil seal

(4-Fig. 15) flush with pinion case (1)

and set up pinion bearing preload in

steps with final setting of 0.40-0.58

N'm (3.5-5.1 in.-Ibs.). Specified pinion

gear depth is 43 ± 0.05 mm (1.69 ±

0.002 inch). Refer to Fig. 11 and

measure distance from face of pinion to

mounting face of pinion case. Subtract

reading obtained from pinion gear

mounting depth specification to obtain

proper shim pack (18- Fig. 8) thickness.

Specified differential pinion and side

gear backlash is 0.1-0.3 mm (0.004-0.012

inch). Refer to Fig. 12 and measure

pinion backlash with a dial indicator. Ad-

just by installing different thickness

thrust washers (6- Fig. 8). When install-

ing ring gear on differential case, torque

mounting bolts to 25-30 N'm (18-22

ft.-Ibs.) for Model 234 and 30-40 N'm

(2£-29 ft.-Ibs.) for Models 244 and 254.

Specified baCklash between ring gear

and pinion (1) is 0.25-0.35 mm

(0.010-0.014 inch). Refer to Fig. 13.

Measure backlash with a dial indicator

and adjust with different thickness

shims (22-Fig. 8).

All models are available with four

wheel drive. Front differential is

driven by a propeller shaft which is

connected to a front transmission pto.

Despite differences between models,

service procedures are basically the

same. Figures listed in the text are for

Model 234 unless otherwise noted.

Refer to appropriate figures for other

models. Hub assemblies may be ser-

viced individually without removing

the entire front axle.

DIFFERENTIAL ASSEMBLY

All Models So Equipped

6. R&R AND OVERHAUL. To

remove front drive axle assembly, raise

tractor and support under subframe

rails. Remove front wheels, disconnect

drag link (I-Fig. 16) from left steering

knuckle arm (4) and disconnect drive

shaft at differential pinion shaft. Place a

rolling floor jack under center of axle,

remove axle center pivot shaft (3-Fig.

7) and shim set (5). Lower axle assembly

enough to clear subframe, then roll axle

forward away from tractor.

To disassemble, remove tie rod

(11- Fig. 16) and steering knuckle arms

(3 and 4) as an assembly. Dril,in gear

lubricant from differential. Remove

pinion shaft and case assembly (12

through 21- Fig. 8). Remove wheel hubs

from e~ch end of axle housing, remove

bolts holding halves together and split

axle housings apart. Tap out axle shafts

(9-Fig. 7), then remove ring gear

(1- Fig. 8), differential case (11) and dif-

ferential side bearings (3 and 23) as an

assembly. Drive out pinion shaft re-

tainer pin (4) and slide out pinion shaft

(10), then remove pinion gears (7), side When assembling differential housing

7

Paragraph 6 Cont.

, ~\~

•• ~\\1312

~~8 11 16

~ 20

19

21

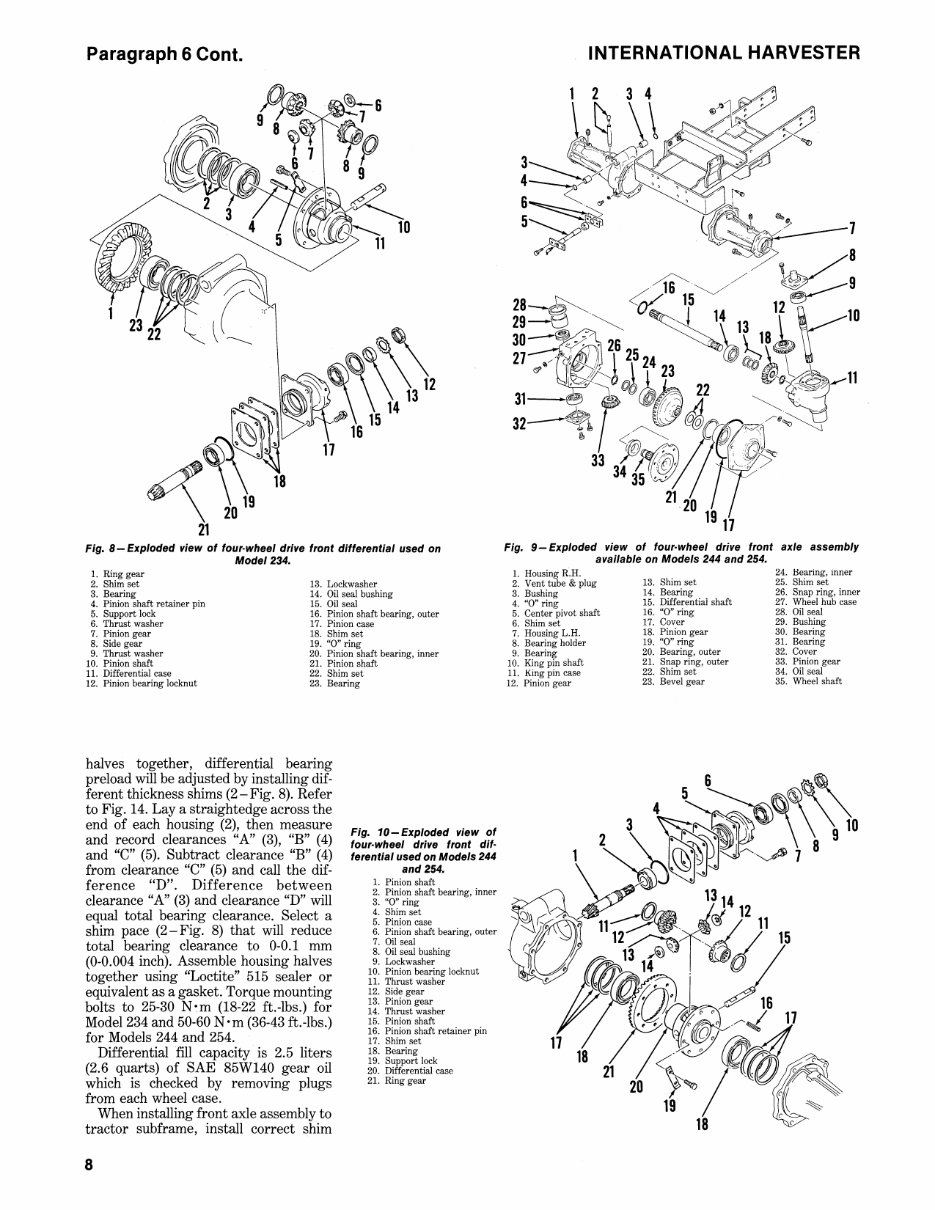

Fig. 8-Exploded view of four·wheel drive front differential used on

Model 234.

1. Ring gear

2. Shim set 13. Lockwasher

3. Bearing 14. Oil seal bushing

4. Pinion shaft retainer pin 15. Oil seal

5. Support lock 16. Pinion shaft bearing, outer

6. Thrust washer 17. Pinion case

7. Pinion gear 18. Shim set

8. Side gear 19. "0" ring

9. Thrust washer 20. Pinion shaft bearing, inner

10. Pinion shaft 21. Pinion shaft

11. Differential case 22. Shim set

12. Pinion bearing locknut 23. Bearing

halves together, differential bearing

preload will be adjusted by installing dif-

ferent thickness shims (2 - Fig. 8). Refer

to Fig. 14. Lay a straightedge across the

end of each housing (2), then measure

and record clearances "A" (3), "B" (4)

and "C" (5). Subtract clearance "B" (4)

from clearance "C" (5) and call the dif-

ference "D". Difference between

clearance "A" (3) and clearance "D" will

equal total bearing clearance. Select a

shim pace (2-Fig. 8) that will reduce

total bearing clearance to 0-0.1 mm

(0-0.004 inch). Assemble housing halves

together using "Loctite" 515 sealer or

equivalent as a gasket. Torque mounting

bolts to 25-30 Nom (18-22 ft.-lbs.) for

Model 234 and 50-60 Nom (36-43 ft.-lbs.)

for Models 244 and 254.

Differential fill capacity is 2.5 liters

(2.6 quarts) of SAE 85W140 gear oil

which is checked by removing plugs

from each wheel case.

When installing front axle assembly to

tractor subframe, install correct shim

8

Fig. 10- Exploded view of

four· wheel drive front dif·

ferentlal used on Models 244

and 254.

1. Pinion shaft

2. Pinion shaft bearing, inner

3. "0" ring

4. Shim set

5. Pinion case

6. Pinion shaft bearing, outer

7. Oil seal

8. Oil seal bushing

9. Lockwasher

10. Pinion bearing locknut

11. Thrust washer

12. Side gear

13. Pinion gear

14. Thrust washer

15. Pinion shaft

16. Pinion shaft retainer pin

17. Shim set

18. Bearing

19. Support lock

20. Differential case

21. Ring gear

INTERNATIONAL HARVESTER

Fig. 9-Exploded view of four· wheel drive front axle assembly

available on Models 244 and 254.

1. Housing R.H.

2. Vent tube & plug

3. Bushing

4. "0' ring

5. Center pivot shaft

6. Shim set

24. Hearing, mner

25. Shim set

26. Snap ring, inner

27. Wheel hub case

28. Oil seal

29. Bushing

13. Shim set

14. Bearing

15. Differential shaft

16. "0" ring

17. Cover

7. Housing L.H.

8. Bearing holder

9. Bearing

10. King pin shaft

11. King pin case

12. Pinion gear

30. Bearing

31. Bearing

32. Cover

33. Pinion gear

34. Oil seal

35. Wheel shaft

18. Pinion gear

19. "0" ring

20. Bearing, outer

21. Snap ring, outer

22. Shim set

23. Bevel gear

SERIES 234·244·254

Fig. 11- View showing depth micrometer set up

to measure distance from face of pinion to

mounting face of case.

Fig. 12- View showing dial Indicator set up to

measure backlash between side and pinion

gears.

Fig. 13- View showing dial indicator set·up to

measure backlash between ring gear and pinion

gear.

I. Pinion housing

2. Ring gear mounting

bolts

3. Differential housing

half

pack (5-Fig. 7) to maintain a clearance

of 0-0.2 mm (0-0.008 inch) between front

subframe and axle housing. Refer to

Fig. 17 for cross-sectional view showing

shim placement.

WHEEL HUB ASSEMBLIES

All Models So Equipped

7. R&R AND OVERHAUL. Support

axle on side to be serviced and remove

wheel. Drain lubricant from axle and

remove steering knuckle arm (3 or

2

5 4

Fig. 14-Cross·sectional view of differential and

housings showing calculated dimensions

needed to find shim pack for correct bearing

clearance.

I. Straightedge

2. Housing

3. Cl earance "A"

Fig. 15 - Cross·sectional

view of pinion and pinion

case assembly.

1. Pinion case

2. Tapered roller bearings

3. Pinion shaft

4. Oil seal

5. Oil seal bushing

6. Lockwasher

7. Slotted nut

4. Cl earance "B"

5. Cl earance "C"

o

5

Paragraph 7

4-Fig. 16) with drag link and/or tie rod

still attached. Remove wheel hub to axle

housing mounting bolts and remove hub.

Remove wheel shaft, case and gear

assembly from king pin case. Remove

bevel gear (3 - Fig. 19) and inner bearing

assembly (10-Fig. 20) with a puller. To

disassemble and inspect entire wheel

assembly, refer to Fig. 20 for Model 234

and Fig. 21 for Models 244 and 254.

Refer to Fig. 18 for cross-sectional view

of hub assembly. Remove top and bot-

tom bearing holders (33 and 21-Fig. 7)

from king pin case (26) and drive king

pin shaft (31) out with a brass drift.

Refer to Fig. 22. Note position and

number of teeth on pinion gears and

length of splines on each end of king pin

shaft. Refer to Fig. 23 . Remove and in-

spect thrust bearings. Renew as needed.

Inspect bushing and renew if necessary.

Install new oil seals and "0" rings.

Reassemble by reversing disassembly

procedure. Use "Loctite" 515 sealer or

equivalent as a gasket on sealing sur-

faces during reassembly.

NOTE: Backlash readings should be

taken and adjustments made before

gasket sealer is applied.

Torque bearing holder to king pin case

bolts to 25-30 N' m (18-22 ft. -lbs.). Dur-

ing reassembly, place all shims in their

original position. When wheel shaft and

holder assembly is installed on wheel

hub case, check backlash with a dial in-

dicator as shown in Fig. 24. Specified

backlash is 0.2-0.4 mm (0.008-0.016

inch). Adjust by placing shims (8-Fig.

20) between bevel gear (9) and thrust

washer (7) on Model 234. On Models 244

and 254, backlash is adjusted by placing

shims (8 and 10-Fig. 21) between outer

bearing (4), inner bearing (7) and snap

ring (9).

To check backlash between upper king

pin shaft pinion gear (35 - Fig. 7) and

outer axle shaft pinion gear (28), refer to

Fig. 25 and set up dial indicator as

shown. Remove differential pinion gear

and case assembly using a screwdriver

to pry against axle shaft to prevent in

9

You're Reading a Preview

What's Included?

Fast Download Speeds

Online & Offline Access

Access PDF Contents & Bookmarks

Full Search Facility

Print one or all pages of your manual

$39.99

Viewed 87 Times Today

Loading...

Secure transaction

What's Included?

Fast Download Speeds

Online & Offline Access

Access PDF Contents & Bookmarks

Full Search Facility

Print one or all pages of your manual

$39.99

- This workshop manual is a comprehensive guide for servicing and repairing IH International Harvester 234, Hydro 234, 244, 254 tractors.

- It is suitable for professional mechanics and DIY enthusiasts, providing detailed procedures, diagrams, and photos for all repairs and troubleshooting.

- Users can easily print out specific pages or the entire manual as per their requirement.

- The manual is not limited or trial version and does not expire, offering lifetime access without any renewal fees.

- It is compatible with both Windows and MAC computers.

Get your hands on this comprehensive workshop manual to efficiently service and repair your IH International Harvester tractors.