FORDSON MAJOR Diesel Workshop Manual

What's Included?

Fast Download Speeds

Online & Offline Access

Access PDF Contents & Bookmarks

Full Search Facility

Print one or all pages of your manual

SHOP MANUAL

FORD

FORDSON DEXTA, FORDSON SUPER DEXTA

FORD 2 0 0 0 SUPER DEXTA

NEW PERFORMANCE SUPER DEXTA

Tractor serial number is stamped on ieft side of ciutch iiousing fiange and

prefixed by modei number. Engine seriai number is stamped on ieft hand

side of eyiinder block.

INDEX (By Starting Paragraph)

BELT PULLEY 82

BRAKES 77

CLUTCH

Adjustment 54

R&R and Overhaul 57

COOLING SYSTEM

Pump R&R and Overhaul 51

Radiator ] 5Q

DIESEL FUEL SYSTEM

Filters and Bleeding 35

Injection Pump 45

Nozzles ] ^ / 37

Trouble Shooting [[[[ 30

DIFFERENTIAL

Overhaul $7

Remove and Reinstall 66

ENGINE >. ;

Assembly R&R 9

Cam Followers ][ I3

Camshaft \[\ 20

Connecting Rod Bearings .*'..! 24

Crankshaft and Bearings [[[ 25

Crankshaft Oil Seals !!!!!!!! 26

Cylinder Head !.!.!!!!!! 10

Cylinder Sleeves .*,. 22

Flywheel R&R ...//.,.[./.., 27

Front Oil Seal !.!!!!.!!.!! 26

Main Bearings !,..!.!!!!!!!!! 25

Oil Pump ....,.//,./.]..,,[..[] 28

Pistons !.!!!!!!!!!!!!!! 22

Piston Pins !...!..!.!!!!!.!.!. 23

Piston and Hod Removal .* ........ !...! 21

Piston Rings , 22

Rear OU Seal ' ......... !.!.,.!.*!!!!..!,'.' 26

Rocker Arms [ ^ 14

Toppets ................. ! 13

Timing Gear Cover 15

Timing Gears ..././...[,.,...,...[ 16

Vaives and Seats ...[,....[.[.[. 11

Valve Guides & Springs ,..,,.....,.... 12

ELECTRICAL SYSTEM

Generator and Regulator. 52

Starting Motor !!!!!!!!!!.'! .53

FINAL DRIVE

Axle Housings 7g

Bevel Pinion 70

Bevel Ring Gear 67

Differential Lock ....... ! 68

Differential Overhaul .' 67

Wheel Ajde Shaft Bearing Adjustment .../...,. 74

Wheei Axle Shaft Bearings Renew 75

Wheel Axle Shaft R&H ;...*; 75

FRONT AXLE

Axle Main Member 2

Drag Links and Toe-in ,..[..[. 4

Front Support .../,.. 3

Steering Spindles /....[.[ 1

HYDRAULIC LIFT SYSTEM

Back Pressure Valve, R&R 100

Constant Draft Control, Adjustment 89

Control Valve, Overhaul 95 or 96

Cylinder and Piston, Overhaul 94

Implement, Bobbing * ] 85

Implement Position. Adjustment [,[. 90

Lift Cover, R&R ] ' 91

Pump. Overhaul !! 103

Pump, R&R 102

Relief Valve, R&R ^ IQI

Safety Valve R&R .'*.. 93

System Pressure Check 101

Valve Linkage, Checking 99

Work Cylinder, R&R ['//, 94

POWER TAKE-OFF

Countershaft $2

Input Shaft !!.!!.*. 59

Output Shaft ,[./....]. 79

Shifter Unit /,..../.[.[. 80

REAR AXLE

Bearing Adjustment 74

Shaft, R&R 75

STEERING GEAR

Adjustment g

Overhaul 8

Remove and Reinstall 7

TRANSMISSION

Assembly R&R , 60

Clutch Shaft !..!!! 59

Main Transmission 64

PTO Countershaft 62

Secondary Transmission 63

Shifter Rails and Forks 65

CONDENSED SERVICE DATA

GENERAL

Torque Recommendations See End of Shop Manual

Engine Make Perkins

Cylinders ^

Bore—Inches, Fordson Dexta 3.5

Bore-Inches, Fordson Super Dexta, Ford 2000 Super Dexta,

New Performance Super Dexta 3.6

Stroke —Inches ^

Displacement—Cubiclnches, Fordson Dexta 144

Displacement—Cubic Inches, Fordson Super Dexta,

Ford 2000 Super Dexta, New Performance Super Dexta 152.7

Compression Ratio (144 cu. in.) 16.5:1

(152.7 cu. in.) 17.4:1

Pistons Removed From: Above

Main & Rod Bearings Adjustable? No

Cylinder Sleeves—Type • • • l^^y

Generator & Starter Make Lucas

TUNE-UP

Firing Order 1-2-3

ValveTappetGap-lntake& Exhaust 0.01 OH

Valve Face Angle—Degrees 44

Valve Seat Angle—Degrees 45

Engine Low Idle-RPM 550

Engine High Idle-RPM (New Performance Super Dexta 2450

Engine High Idle-RPM (All Other Models) 2200

PTO High Idle-RPM See Paragraph 47 or 48

Battery Terminal Grounded Positive

SIZES-CAPACITIES-CLEARANCES

Crankshaft Journal Diameter 2.749

Crankpin Diameter 2.249

Camshaftjournals Diameter (Front) 1-87

(Center) 1-86

(Rear) 1-84

Piston Pin Diameter 1-25

Valve Stem Diameter, Intake 0.3115

Valve Stem Diameter, Exhaust 0.3115

Main Bearing Diametral Clearance 0.0025-0.0045

Rod Bearings Diametral Clearance 0.002-0.0035

PistonSkirtClearance(144cu. in. engine) 0.0035-0.0055

Piston Skirt Clearance (152 cu. in. engine) 0.0045-0.0065

Crankshaft End Play 0.002-0.010

Camshaft Bearing Diametral Clearance 0.004-0.008

Cooling System—Quarts 9

Crankcase—Quarts (with Filter) -8

Transmission—Quarts 14

Differential, Final Drive & Hydraulic Reservoir-Quarts 20.4

Steering Gear Housing 1 Pint

FRONT SYSTEM AND STEERING

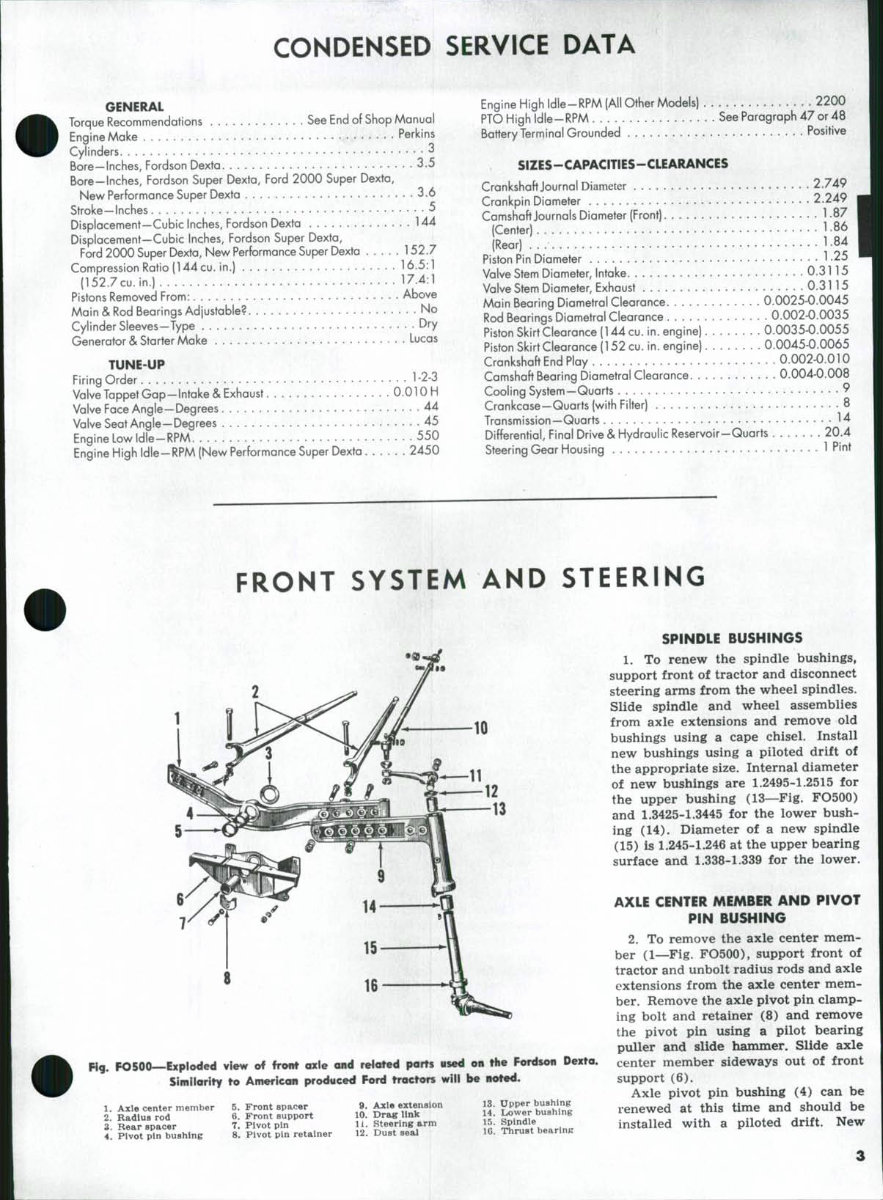

FO500—Exploded view »f front cale and reloted parts used on the Fordson Dexta.

' Similarity to American produced Ford tractors will be noted.

1. Axle center member

2. Radius rod

3. Rear spacer

4. Pivot pin bushing

5. Front spacer

6. Front support

7. Pivot pin

8. Pivot pin retainer

9. Axle extenaion

10. Drag link

11. Steering arm

12. Dust seal

13. Upper bushing

14. Lower bushing

15. Spindle

lC. Thrust bearing

SPINDLE BUSHINGS

1. To renew the spindle bushings,

support front of tractor and disconnect

steering arms from the wheel spindles.

Slide spindle and wheel assemblies

from axle extensions and remove old

bushings using a cape chisel. Install

new bushings using a piloted drift of

the appropriate size. Internal diameter

of new bushings are 1.2495-1.2515 for

the upper bushing (13—Fig. FO500)

and 1.3425-1.3445 for the lower bush-

ing (14). Diameter of a new spindle

(15) is 1.245-1.246 at the upper bearing

surface and 1.338-1.339 for the lower.

AXLE CENTER MEMBER AND PIVOT

PIN BUSHING

2. To remove the axle center mem-

ber (1—Fig. FO500), support front of

tractor and unbolt radius rods and axle

extensions from the axle center mem-

ber. Remove the axle pivot pin clamp-

ing bolt and retainer (8) and remove

the pivot pin using a pilot bearing

puller and slide hammer. Slide axle

center member sideways out of front

support (6).

Axle pivot pin bushing (4) can be

renewed at this time and should be

installed with a piloted drift. New

Paragraphs 3-6

FORD AND FORDSON

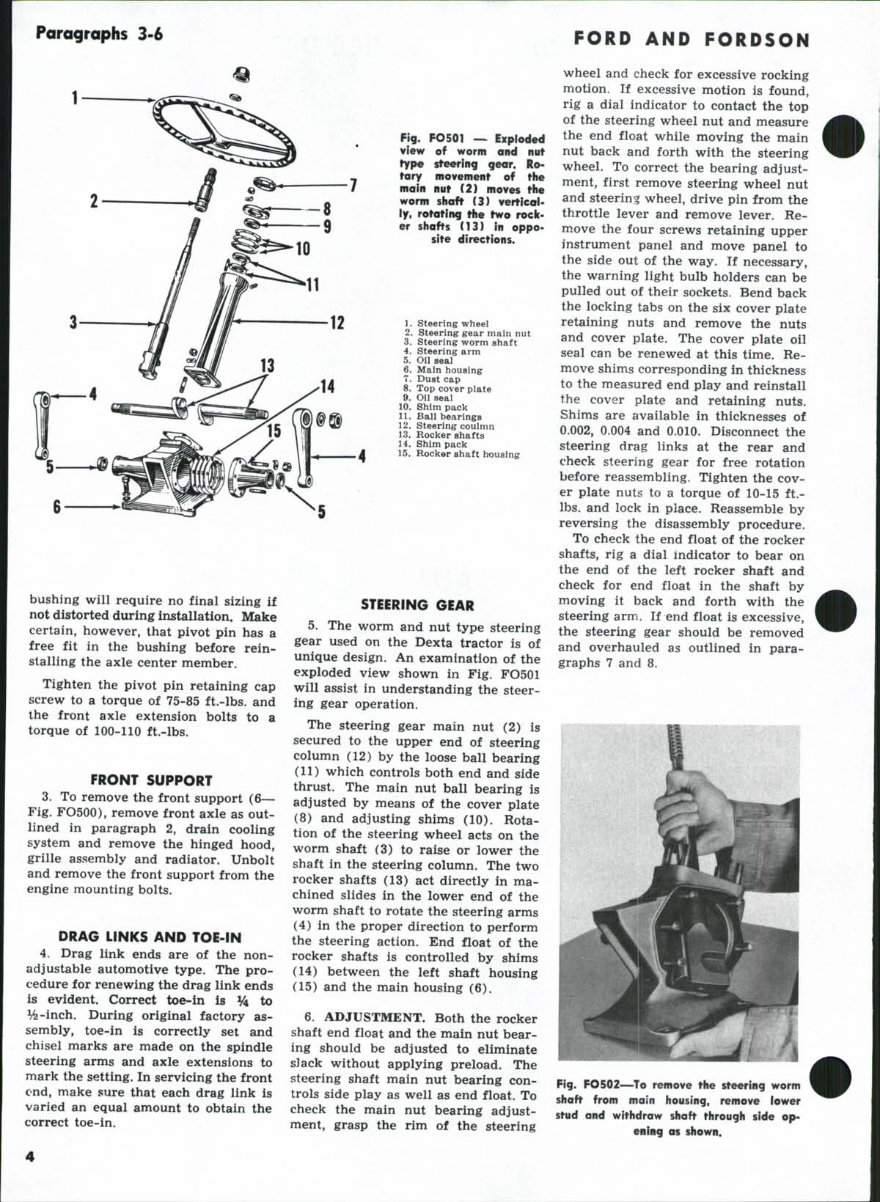

Fig. FO501 — Exploded

view of worm and nut

type steering gear. Ro-

tary movement of the

main nut (2) moves the

worm shaft (3) vertical-

ly, rotating the two rock-

er shafts (13) in oppo-

site directions.

1. steering wheel

2. Steering gear main nut

3. Steering worm shaft

4. Steering arm

5. on seal

6. Main housing

7. Dust cap

8. Top cover piate

9. Oil seai

10. Shim pack

11. Bali bearings

12. Steering coulmn

13. Rocker shafts

14. Shim pack

15. Rocker shaft housing

bushing will require no final sizing if

not distorted during installation. Make

certain, however, that pivot pin has a

free fit in the bushing before rein-

stalling the axle center member.

Tighten the pivot pin retaining cap

screw to a torque of 75-85 ft.-lbs. and

the front axle extension bolts to a

torque of 100-110 ft.-lbs.

FRONT SUPPORT

3. To remove the front support (6—

Fig. FO500), remove front axle as out-

lined in paragraph 2, drain cooling

system and remove the hinged hood,

grille assembly and radiator. Unbolt

and remove the front support from the

engine mounting bolts.

DRAG LINKS AND TOE-IN

4. Drag link ends are of the non-

adjustable automotive type. The pro-

cedure for renewing the drag link ends

is evident. Correct toe-in is % to

%-inch. During original factory as-

sembly, toe-in is correctly set and

chisel marks are made on the spindle

steering arms and axle extensions to

mark the setting. In servicing the front

end, make sure that each drag link is

varied an equal amount to obtain the

correct toe-in.

STEERING GEAR

5. The worm and nut type steering

gear used on the Dexta tractor is of

unique design. An examination of the

exploded view shown in Fig. FO501

will assist in understanding the steer-

ing gear operation.

The steering gear main nut (2) is

secured to the upper end of steering

column (12) by the loose ball bearing

(11) which controls both end and side

thrust. The main nut ball bearing is

adjusted by means of the cover plate

(8) and adjusting shims (10). Rota-

tion of the steering wheel acts on the

worm shaft (3) to raise or lower the

shaft in the steering column. The two

rocker shafts (13) act directly in ma-

chined slides in the lower end of the

worm shaft to rotate the steering arms

(4) in the proper direction to perform

the steering action. End float of the

rocker shafts is controlled by shims

(14) between the left shaft housing

(15) and the main housing (6).

6. ADJUSTMENT. Both the rocker

shaft end float and the main nut bear-

ing should be adjusted to eliminate

sJack without applying preload. The

steering shaft main nut bearing con-

trols side play as well as end float. To

check the main nut bearing adjust-

ment, grasp the rim of the steering

wheel and check for excessive rocking

motion. If excessive motion is found,

rig a dial indicator to contact the top

of the steering wheel nut and measure

the end float while moving the main

nut back and forth with the steering

wheel. To correct the bearing adjust-

ment, first remove steering wheel nut

and steering wheel, drive pin from the

throttle lever and remove lever. Re-

move the four screws retaining upper

instrument panel and move panel to

the side out of the way. If necessary,

the warning light bulb holders can be

pulled out of their sockets. Bend back

the locking tabs on the six cover plate

retaining nuts and remove the nuts

and cover plate. The cover plate oil

seal can be renewed at this time. Re-

move shims corresponding in thickness

to the measured end play and reinstall

the cover plate and retaining nuts.

Shims are available in thicknesses of

0.002, 0.004 and 0.010. Disconnect the

steering drag links at the rear and

check steering gear for free rotation

before reassembling. Tighten the cov-

er plate nuts to a torque of 10-15 ft.-

lbs. and lock in place. Reassemble by

reversing the disassembly procedure.

To check the end float of the rocker

shafts, rig a dial indicator to bear on

the end of the left rocker shaft and

check for end float in the shaft by

moving it back and forth with the

steering arm. If end float is excessive,

the steering gear should be removed

and overhauled as outlined in para-

graphs 7 and 8.

Fig. FO502—To remove the steering worm

shaft from main housing, remove lower

stud and withdraw shaft through side op-

ening as shown.

DEXTA-SUPER DEXTA-2000 DEXTA

Paragraphs 7-8

7. REMOVE AND REINSTALL. To

remove the steering gear assembly,

first remove the hood, battery and

steering housing lower side plates.

Drain approximately Vz gallon of cool-

ant from the radiator and remove the

temperature indicator sending unit

from the engine block. Remove the

steering wheel, drive the pin from the

throttle lever and remove lever. Re-

move the four screws retaining the

upper instrument panel plate and re-

move the plate. Disconnect the fuel,

primer and bleed back lines from the

fuel tank and unbolt and remove the

tank complete with upper instrument

panel and temperature gage. Discon-

nect and remove the vertical throttle

rod. Disconnect the drag links from

the steering arms and unbolt and re-

move the steering gear assembly.

To reinstall, reverse the removal

procedure. Secure the warning light

bulb holders to the upper steering col-

umn with a piece of string before in-

stalling the fuel tank. Make sure the

three rubber mounting pads are in

place before fastening the fuel tank

in place.

8. OVERHAUL. First remove the

unit from the tractor as outlined in

paragraph 7, then unstake and remove

the six nuts retaining the steering

gear top cover and remove the cover

(8—Fig. FO501). Remove the main

nut upper race and the fifteen loose

balls and unscrew the main nut (2)

from the steering worm shaft (3). In-

vert the steering assembly over a

drain pan and drain the oil. Unstake

and remove the four nuts retaining

the steering column (12) to the main

housing and remove the column. The

main nut bearing lower race can be

removed from the upper end of the

steering column at this time by drift-

ing it out from below with a suitable

drift.

Unstake and remove the six nuts

retaining the left rocker shaft housing

(15) to the main housing and remove

the housing and left rocker shaft (13).

Keep the adjusting shims (14) to-

gether in a safe place to avoid dam-

age to the shims. Remove the lower

stud from the main housing and re-

move the steering worm shaft from

the side opening as shown in Fig.

FO502.

Clean the parts in a suitable solvent

and examine. Renew those that are

scored, worn or otherwise damaged.

Always renew the oil seals when the

steering gear is disassembled. The

outer and inner rocker shaft bushings

are serviced and should be sized after

installation if necessary.

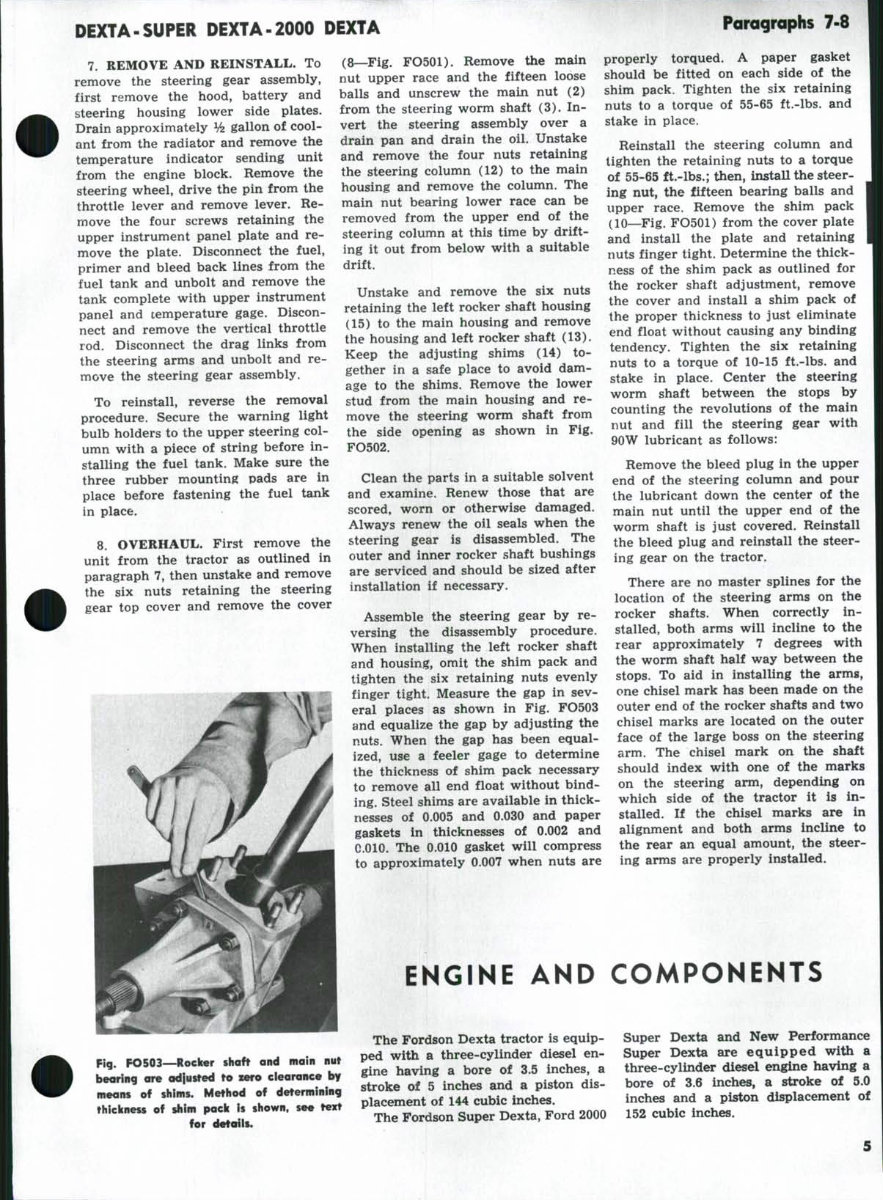

Assemble the steering gear by re-

versing the disassembly procedure.

When installing the left rocker shaft

and housing, omit the shim pack and

tighten the six retaining nuts evenly

finger tight. Measure the gap in sev-

eral places as shown in Fig. FO503

and equalize the gap by adjusting the

nuts. When the gap has been equal-

ized, use a feeler gage to determine

the thickness of shim pack necessary

to remove all end float without bind-

ing. Steel shims are available in thick-

nesses of 0.005 and 0.030 and paper

gaskets in thicknesses of 0.002 and

0.010. The 0.010 gasket will compress

to approximately 0.007 when nuts are

properly torqued. A paper gasket

should be fitted on each side of the

shim pack. Tighten the six retaining

nuts to a torque of 55-65 ft.-lbs. and

stake in place.

Reinstall the steering column and

tighten the retaining nuts to a torque

of 55-65 ft.-lbs.; then, install the steer-

ing nut, the fifteen bearing balls and

upper race. Remove the shim pack

(10—Fig. FO501) from the cover plate

and install the plate and retaining

nuts finger tight. Determine the thick-

ness of the shim pack as outlined for

the rocker shaft adjustment, remove

the cover and install a shim pack of

the proper thickness to just eliminate

end float without causing any binding

tendency. Tighten the six retaining

nuts to a torque of 10-15 ft.-lbs. and

stake in place. Center the steering

worm shaft between the stops by

counting the revolutions of the main

nut and fill the steering gear with

90W lubricant as follows:

Remove the bleed plug in the upper

end of the steering column and pour

the lubricant down the center of the

main nut until the upper end of the

worm shaft is just covered. Reinstall

the bleed plug and reinstall the steer-

ing gear on the tractor.

There are no master splines for the

location of the steering arms on the

rocker shafts. When correctly in-

stalled, both arms will incline to the

rear approximately 7 degrees with

the worm shaft half way between the

stops. To aid in installing the armg,

one chisel mark has been made on the

outer end of the rocker shafts and two

chisel marks are located on the outer

face of the large boss on the steering

arm. The chisel mark on the shaft

should index with one of the marks

on the steering arm, depending on

which side of the tractor it is in-

stalled. If the chisel marks are in

alignment and both arms incline to

the rear an equal amount, the steer-

ing arms are properly installed.

ENGINE AND COMPONENTS

Fig. FO503—Roeiier shaft and main nut

bearing are adjusted to zero clearance by

means of shims. Method of determining

thickness of shim pack is shown, see text

for details.

The Fordson Dexta tractor is equip-

ped with a three-cylinder diesel en-

gine having a bore of 3.5 inches, a

stroke of 5 inches and a piston dis-

placement of 144 cubic inches.

The Fordson Super Dexta, Ford 2000

Super Dexta and New Performance

Super Dexta are equipped with a

three-cylinder diesel engiie having a

bore of 3.6 inches, a stroke of 5.0

inches and a piston displacement of

152 cubic inches.

Paragraphs 9-11

FORD AND FORDSON

Fig. FO504 — Cyiinder

head nuts shouid be Hghf-

ened to a forque 55-60

Ff.-Lbs. in the sequence

shown. Cyiinder head

bolts on left side of en-

gine extend to retain in-

jectors; a deep socicet is

therefore required.

shewn in Fig. FO504 to a torque of

55-60 ft.-lbs. Make certain that the

bores and seats for the injectors are

clean and free from dirt and carbon.

Install the injectors using a new cop-

per sealing washer and tighten the

injector holding nuts evenly to avoid

cocking the injector. After restarting

the engine, check the injectors for

compression blow-by. Adjust the

valve tappet clearance to 0.010 for

each valve after the engine has been

brought up to operating temperature.

Both the 144 and 152 cubic inch en-

gines are similarly constructed. Dif-

ferences in the 144 cubic inch engine

due to production changes and be-

tween the 144 and 152 cubic inch en-

gines are noted in the text where serv-

ice procedures and/or specifications

are affected.

R&R ENGINE ASSEMBLY

9. To remove the engine and clutch

assembly first drain the cooling sys-

tem, remove hood and if the engine is

to be disassembled, drain oil pan. Dis-

connect the radiator hoses, headlight

wire and the grille braces from top

water outlet. Disconnect the radius

rods and steering drag links at rear,

support the tractor under transmission

housing and unbolt the front support

assembly from engine. Roll the front

axle, front support and radiator as an

assembly away from tractor and block

same in an upright position.

Shut off the fuel and disconnect the

fuel primer and bleed back lines. Re-

move the battery, battery support and

fire wall. Disconnect wires from the

oil pressure warning light sender, gen-

erator, starter, cold starting unit and

lights. Disconnect the tachometer

cable, heat indicator sending unit,

starter cable and starter control rod.

Remove the air cleaner, throttle link

or governor control rod, swing the en-

gine from the two engine mounting

hooks and unbolt engine from the

transmission case.

CYLINDER HEAD

10. To remove the cylinder head,

first drain cooling system and remove

the hood. Loosen the injector lines at

the pump and disconnect lines from

injectors. Remove the bleed-back line.

Immediately cap all exposed fuel line

connections to protect the system

from dirt and remove injectors. Re-

move the rocker arm cover and rocker

arms assembly. Disconnect battery

cables and remove battery. Remove

the heat indicator sending unit and

disconnect the water outlet casting

from cylinder head. Disconnect the

fire wall from the two brackets lo-

cated on cylinder head, then discon-

nect the air cleaner mounting bolts

and upper hose. Unbolt and remove

the right fire wall bracket and rear

engine lifting plate from the cylinder

head. Disconnect the external oil feed

line from the right rear corner of the

cylinder head. Loosen the two bolts

securing the fire wall to the clutch

housing and rock the fire wall back

enough to remove the clip attaching

the governor vacuum line to the cyl-

inder head. Disconnect the primer fuel

line, governor vacuum line, heater

unit electrical lead and throttle link

from the intake manifold. Unbolt and

remove the cylinder head.

The head gasket is marked "Top—

Front.*' Coat the head gasket on both

sides with an approved sealing com-

pound before installing. Tighten the

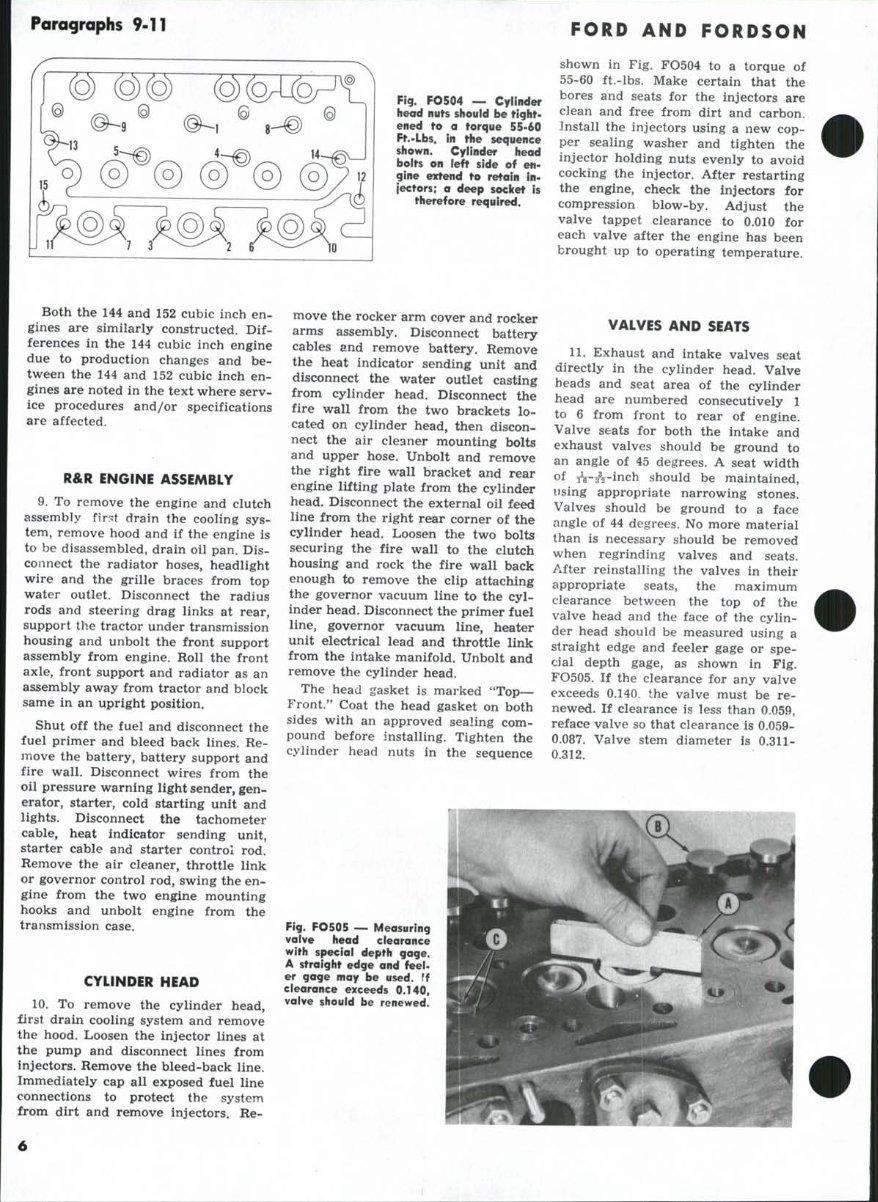

cylinder head nuts in the sequence

VALVES AND SEATS

11. Exhaust and intake valves seat

directly in the cylinder head. Valve

heads and seat area of the cylinder

head are numbered consecutively 1

to 6 from front to rear of engine.

Valve seats for both the intake and

exhaust valves should be ground to

an angle of 45 degrees. A seat width

of A-A-inch should be maintained,

using appropriate narrowing stones.

Valves should be ground to a face

angle of 44 degrees. No more material

than is necessary should be removed

when regrinding valves and seats.

After reinstalling the valves in their

appropriate seats, the maximum

clearance between the top of the

valve head and the face of the cylin-

der head should be measured using a

straight edge and feeler gage or spe-

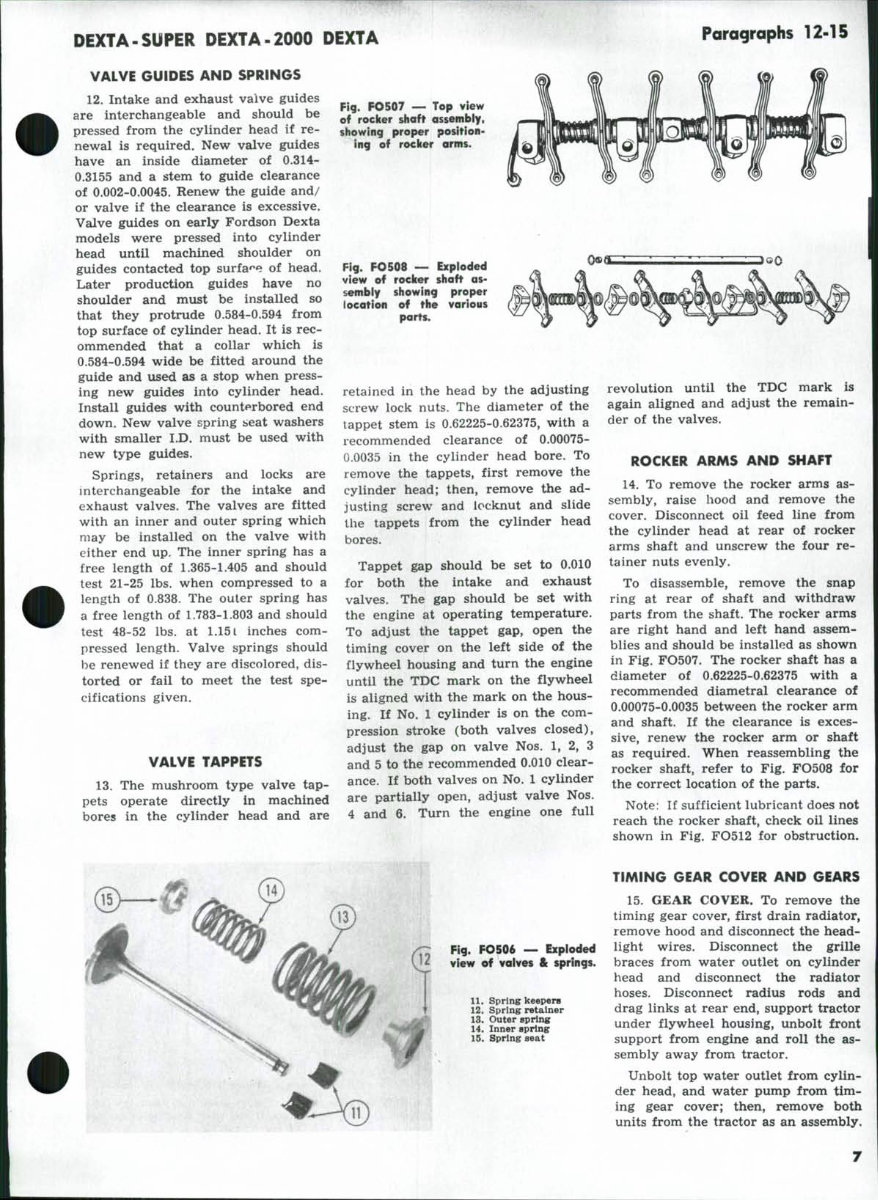

cial depth gage, as shown in Fig.

FO505. If the clearance for any valve

exceeds 0.140, the valve must be re-

newed. If clearance is less than 0.059,

reface valve so that clearance is 0.059-

0.087. Valve stem diameter is 0.311-

0.312.

Fig. FO505 — Measuring

vaive head clearance

with speciai depth gage.

A straight edge and feei-

er gage may be used. If

ciearance exceeds 0.140,

vaive should be renewed.

DEXTA-SUPER DEXTA-2000 DEXTA

Paragraphs 12-15

VALVE GUIDES AND SPRINGS

12. Intake and exhaust valve guides

are interchangeable and should be

pressed from the cylinder head if re-

newal is required. New valve guides

have an inside diameter of 0.314-

0.3155 and a stem to guide clearance

of 0.002-0.0045. Renew the guide and/

or valve if the clearance is excessive.

Valve guides on early Fordson Dexta

models were pressed into cylinder

head until machined shoulder on

guides contacted top surfa'^e of head.

Later production guides have no

shoulder and must be installed so

that they protrude 0.584-0.594 from

top surface of cylinder head. It is rec-

ommended that a collar which is

0.584-0.594 wide be fitted around the

guide and used as a stop when press-

ing new guides into cylinder head.

Install guides with count*»rbored end

down. New valve spring seat washers

with smaller I.D. must be used with

new type guides.

Springs, retainers and locks are

interchangeable for the intake and

exhaust valves. The valves are fitted

with an inner and outer spring which

may be installed on the valve with

either end up. The inner spring has a

free length of 1.365-1.405 and should

test 21-25 lbs. when compressed to a

length of 0.838. The outer spring has

a free length of 1.783-1.803 and should

test 48-52 lbs. at 1.151 inches com-

pressed length. Valve springs should

be renewed if they are discolored, dis-

torted or fail to meet the test spe-

cifications given.

VALVE TAPPETS

13. The mushroom type valve tap-

pets operate directly in machined

bores in the cylinder head and are

Fig. FO507 — Top view

of rocicer shaft assembiy,

showing proper position-

ing of rocker arms.

Fig. FO508 — Expioded

view of rocker shaft as-

sembiy showing proper

location of the various

parts.

retained in the head by the adjusting

screw lock nuts. The diameter of the

tappet stem is 0.62225-0.62375, with a

recommended clearance of 0.00075-

0.0035 in the cylinder head bore. To

remove the tappets, first remove the

cylinder head; then, remove the ad-

justing screw and locknut and slide

the tappets from the cylinder head

bores.

Tappet gap should be set to 0.010

for both the intake and exhaust

valves. The gap should be set with

the engine at operating temperature.

To adjust the tappet gap, open the

timing cover on the left side of the

flywheel housing and turn the engine

until the TDC mark on the flywheel

is aiigned with the mark on the hous-

ing. If No. 1 cylinder is on the com-

pression stroke (both valves closed),

adjust the gap on valve Nos. 1, 2, 3

and 5 to the recommended 0.010 clear-

ance. If both valves on No. 1 cylinder

are partially open, adjust valve Nos.

4 and 6. Turn the engine one full

revolution until the TDC mark is

again aligned and adjust the remain-

der of the valves.

ROCKER ARMS AND SHAFT

14. To remove the rocker arms as-

sembly, raise hood and remove the

cover. Disconnect oil feed line from

the cylinder head at rear of rocker

arms shaft and unscrew the four re-

tainer nuts evenly.

To disassemble, remove the snap

ring at rear of shaft and withdraw

parts from the shaft. The rocker arms

are right hand and left hand assem-

blies and should be installed as shown

in Fig. FO507. The rocker shaft has a

diameter of 0.62225-0.62375 with a

recommended diametral clearance of

0.00075-0.0035 between the rocker arm

and shaft. If the clearance is exces-

sive, renew the rocker arm or shaft

as required. When reassembling the

rocker shaft, refer to Fig. FO508 for

the correct location of the parts.

Note: If sufficient lubricant does not

reach the rocker shaft, check oil lines

shown in Fig. FO512 for obstruction.

Fig. FO506 ~ Expioded

view of vaives & springs.

11. Spring keepers

12. Spring retainer

13. Outer spHncr

14. Inner spring

15. Spring seat

TIMING GEAR COVER AND GEARS

15. GEAR COVER. To remove the

timing gear cover, first drain radiator,

remove hood and disconnect the head-

light wires. Disconnect the grille

braces from water outlet on cylinder

head and disconnect the radiator

hoses. Disconnect radius rods and

drag links at rear end, support tractor

under flywheel housing, unbolt front

support from engine and roll the as-

sembly away from tractor.

Unbolt top water outlet from cylin-

der head, and water pump from tim-

ing gear cover; then, remove both

units from the tractor as an assembly.

Paragraphs 16-18

Remove the starting jaw and crank-

shaft pulley, then unbolt and remove

the timing gear cover. The crankshaft

front oil seal can be renewed at this

time and should be installed with a

suitable driver so that lip faces rear

of engine.

16. TIMING GEARS. Before remov-

ing any gears in the timing gear train,

first remove rocker arm cover and

rocker arms assembly to avoid the

possibility of damage to the pistons or

valve train if either the camshaft or

crankshaft should be turned inde-

pendently of the other.

The timing gear train consists of the

crankshaft gear, camshaft gear, pump

drive gear and an idler gear connect-

ing the other three gears of the train.

Timing gear backlash should be

0.003-0.006 between the idler gear

and any of the other timing gears.

Replacement gears are available in

standard size only. If backlash is not

within recommended limits, renew

the idler gear, idler gear shaft and/or

any other gears concerned.

Unstake and remove the idler gear

retaining bolt and slip the gear off

the idler shaft. The shaft has a light

press fit in the engine block and is

further positioned by the pin shown

in Fig. FO509. Pry shaft from its place

in the block if renewal is indicated.

The crankshaft gear is keyed in

place and fits the shaft with 0.001

press fit to 0.001 clearance. If the old

gear is a loose fit, it may be possible

SCRIBE LINE BETWEEN 8TH

AND 9TH TEETH

CAMSHAFT GEAR

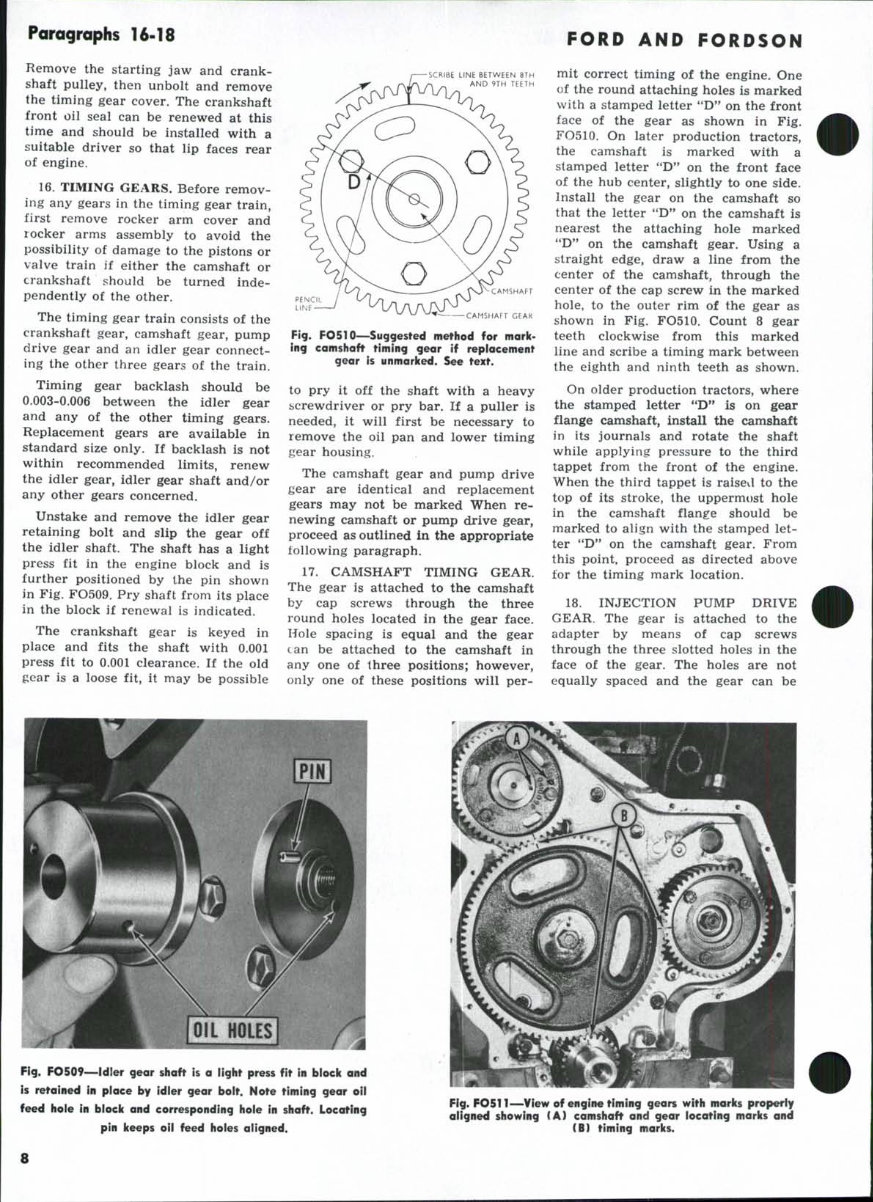

Fig. FO510—Suggested method for mark-

ing camshaft timing gear if replacement

gear is unmarked. See text.

to pry it off the shaft with a heavy

screwdriver or pry bar. If a puller is

needed, it will first be necessary to

remove the oil pan and lower timing

gear housing.

The camshaft gear and pump drive

gear are identical and replacement

gears may not be marked When re-

newing camshaft or pump drive gear,

proceed as outlined in the appropriate

following paragraph.

17. CAMSHAFT TIMING GEAR.

The gear is attached to the camshaft

by cap screws through the three

round holes located in the gear face.

Hole spacing is equal and the gear

can be attached to the camshaft in

any one of three positions; however,

only one of these positions will per-

FORD AND FORDSON

mit correct timing of the engine. One

of the round attaching holes is marked

with a stamped letter "D" on the front

face of the gear as shown in Fig.

FO510. On later production tractors,

the camshaft is marked with a

stamped letter "D" on the front face

of the hub center, slightly to one side.

Install the gear on the camshaft so

that the letter "D" on the camshaft is

nearest the attaching hole marked

"D" on the camshaft gear. Using a

straight edge, draw a line from the

center of the camshaft, through the

center of the cap screw in the marked

hole, to the outer rim of the gear as

shown in Fig. FO510. Count 8 gear

teeth clockwise from this marked

line and scribe a timing mark between

the eighth and ninth teeth as shown.

On older production tractors, where

the stamped letter *'D" is on gear

flange camshaft, install the camshaft

in its journals and rotate the shaft

while applying pressure to the third

tappet from the front of the engine.

When the third tappet is raisevl to the

top of its stroke, the uppermost hole

in the camshaft flange should be

marked to align with the stamped let-

ter "D*' on the camshaft gear. From

this point, proceed as directed above

for the timing mark location.

18. INJECTION PUMP DRIVE

GEAR. The gear is attached to the

adapter by means of cap screws

through the three slotted holes in the

face of the gear. The holes are not

equally spaced and the gear can be

Fig. FOS09—idler gear shaft is a light press fit In biock and

is retained in piace by idier gear boit. Note timing gear oil

feed hoie in biock and corresponding hole in shaft. Locating

pin keeps oii feed holes aligned.

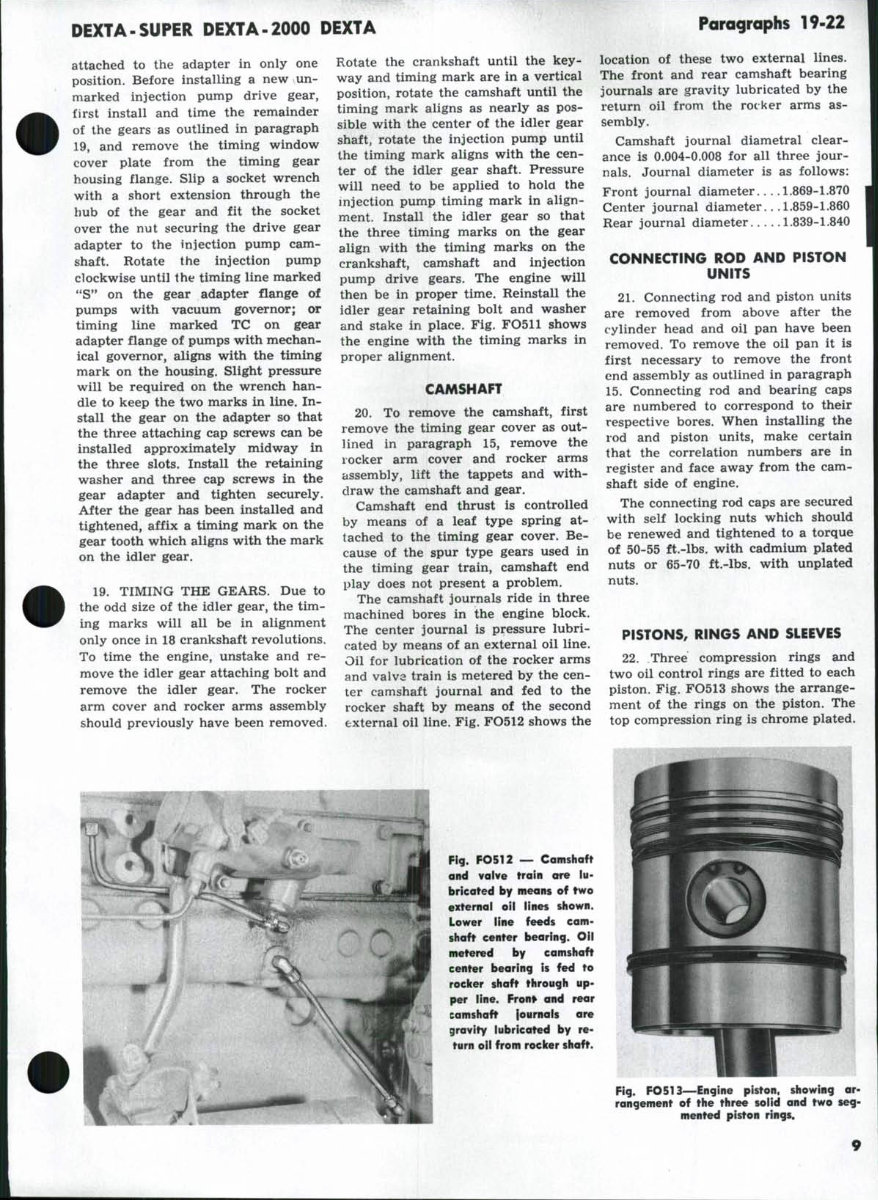

Fig. F0511—View of engine timing gears with marks properiy

aiigned showing (A) camshaft and gear iocating marks and

(B) timing marks.

8

DEXTA-SUPER DEXTA-2000 DEXTA

Paragraphs 19-22

attached to the adapter in only one

position. Before installing a new un-

marked injection pump drive gear,

first install and time the remainder

of the gears as outlined in paragraph

19, and remove the timing window

cover plate from the timing gear

housing flange. Slip a socket wrench

with a short extension through the

hub of the gear and fit the socket

over the nut securing the drive gear

adapter to the injection pump cam-

shaft. Rotate the injection pump

clockwise until the timing line marked

"S" on the gear adapter flange of

pumps with vacuum governor; or

timing line marked TC on gear

adapter flange of pumps with mechan-

ical governor, aligns with the timing

mark on the housing. Slight pressure

will be required on the wrench han-

dle to keep the two marks in line. In-

stall the gear on the adapter so that

the three attaching cap screws can be

installed approximately midway in

the three slots. Install the retaining

washer and three cap screws in the

gear adapter and tighten securely.

After the gear has been installed and

tightened, affix a timing mark on the

gear tooth which aligns with the mark

on the idler gear.

19. TIMING THE GEARS. Due to

the odd size of the idler gear, the tim-

ing marks will all be in alignment

only once in 18 crankshaft revolutions.

To time the engine, unstake and re-

move the idler gear attaching bolt and

remove the idler gear. The rocker

arm cover and rocker arms assembly

should previously have been removed.

Rotate the crankshaft until the key-

way and timing mark are in a vertical

position, rotate the camshaft until the

timing mark aligns as nearly as pos-

sible with the center of the idler gear

shaft, rotate the injection pump until

the timing mark aligns with the cen-

ter of the idler gear shaft. Pressure

will need to be applied to hold the

injection pump timing mark in align-

ment. Install the idler gear so that

the three timing marks on the gear

align with the timing marks on the

crankshaft, camshaft and injection

pump drive gears. The engine will

then be in proper time. Reinstall the

idler gear retaining bolt and washer

and stake in place. Fig. FO511 shows

the engine with the timing marks in

proper alignment.

CAMSHAFT

20. To remove the camshaft, first

remove the timing gear cover as out-

Uned in paragraph 15, remove the

rocker arm cover and rocker arms

assembly, lift the tappets and with-

draw the camshaft and gear.

Camshaft end thrust is controlled

by means of a leaf type spring at-

tached to the timing gear cover. Be-

cause of the spur type gears used in

the timing gear train, camshaft end

play does not present a problem.

The camshaft journals ride in three

machined bores in the engine block.

The center journal is pressure lubri-

cated by means of an external oil line.

Oil for lubrication of the rocker arms

and valvs train is metered by the cen-

ter camshaft journal and fed to the

rocker shaft by means of the second

external oil line. Fig. FO512 shows the

location of these two external lines.

The front and rear camshaft bearing

journals are gravity lubricated by the

return oil from the rocker arms as-

sembly.

Camshaft journal diametral clear-

ance is 0.004-0.008 for all three jour-

nals. Journal diameter is as follows:

Front journal diameter 1.869-1.870

Center journal diameter.. .1.859-1.860

Rear journal diameter 1.839-1.840

CONNECTING ROD AND PISTON

UNITS

21. Connecting rod and piston units

are removed from above after the

cylinder head and oil pan have been

removed. To remove the oil pan it is

first necessary to remove the front

end assembly as outlined in paragraph

15. Connecting rod and bearing caps

are numbered to correspond to their

respective bores. When installing the

rod and piston units, make certain

that the correlation numbers are in

register and face away from the cam-

shaft side of engine.

The connecting rod caps are secured

with self locking nuts which should

be renewed and tightened to a torque

of 50-55 ft,-lbs. with cadmium plated

nuts or 65-70 ft.-lbs. with unplated

nuts.

PISTONS, RINGS AND SLEEVES

22. Three compression rings and

two oil control rings are fitted to each

piston. Fig. FO513 shows the arrange-

ment of the rings on the piston. The

top compression ring is chrome plated.

Fig. FO512 — Camshaft

and vaive train are iu-

bricated by means of two

external oil lines shown.

Lower iine feeds cam-

shaft center bearing. Oii

metered by camshaft

center bearing is fed to

rocker shaft through up-

per iine. Fron» and rear

camshaft lournals are

gravity tubricated by re-

turn oii from rocker shaft.

Fig. FO513—Engine piston, showing ar-

rangement of the three solid and two seg-

mented piston rings.

Paragraphs 23-25

FORD AND FORDSON

The third compression ring and the

top oil control ring are of laminated

steel construction. End gap of these

rings should be as follows:

Third compression ring.. .0.008-0.010

Top oil control ring 0.018-0.037

Installation of the first and second

compression rings and the lower oil

control ring is conventional. These

rings should have 0.002-0.004 side

clearance in the ring grooves and end

gaps as follows:

First compression ring 0.010-0.015

Second compression ring.. .0.009-0.013

Lower oil control ring 0.009-0.013

The solid rings are non-directional

and may be installed either side up.

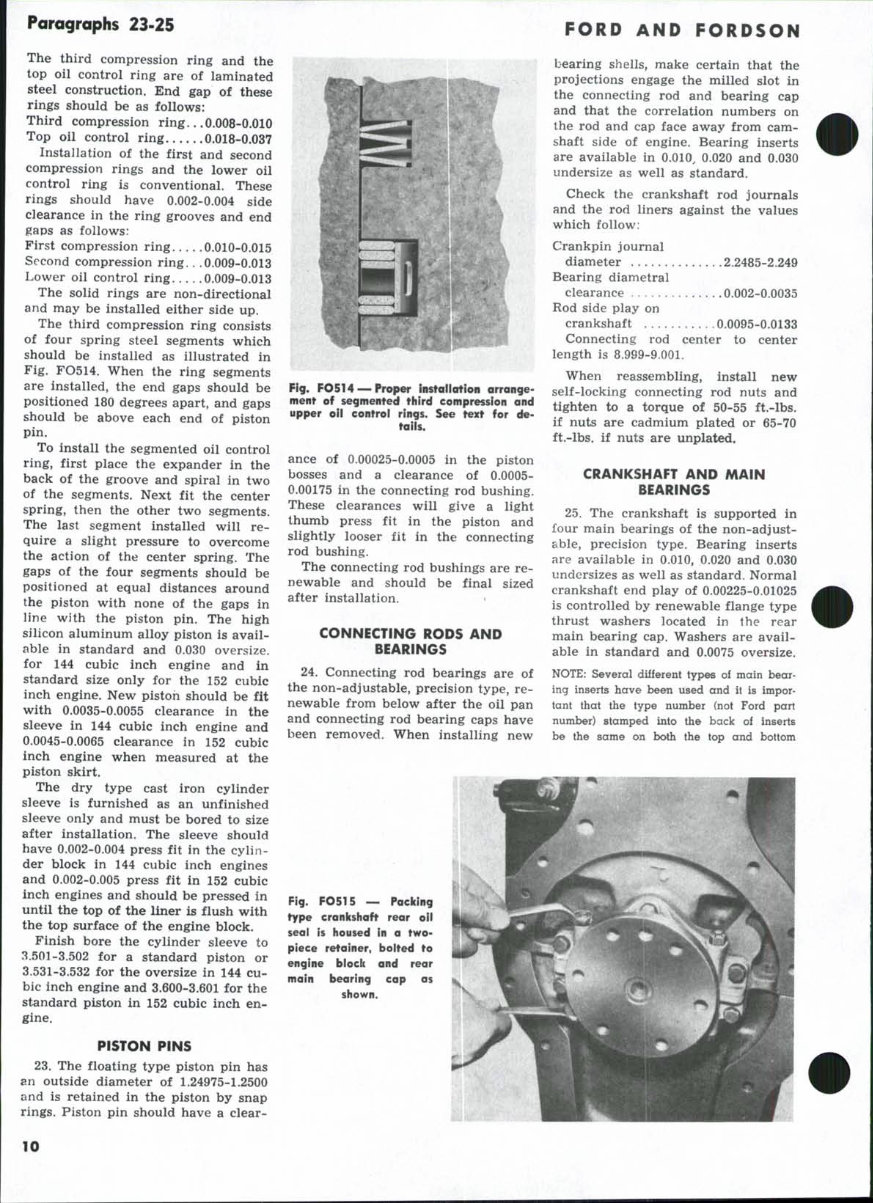

The third compression ring consists

of four spring steel segments which

should be installed as illustrated in

Fig. FO514. When the ring segments

are installed, the end gaps should be

positioned 180 degrees apart, and gaps

should be above each end of piston

pin.

To install the segmented oil control

ring, first place the expander in the

back of the groove and spiral in two

of the segments. Next fit the center

spring, then the other two segments.

The last segment installed will re-

quire a slight pressure to overcome

the action of the center spring. The

gaps of the four segments should be

positioned at equal distances around

the piston with none of the gaps in

line with the piston pin. The high

silicon aluminum alloy piston is avail-

able in standard and 0.030 oversize,

for 144 cubic inch engine and in

standard size only for the 152 cubic

inch engine. New piston should be fit

with 0.0035-0.0055 clearance in the

sleeve in 144 cubic inch engine and

0.0045-0.0065 clearance in 152 cubic

inch engine when measured at the

piston skirt.

The dry type cast iron cylinder

sleeve is furnished as an unfinished

sleeve only and must be bored to size

after installation. The sleeve should

have 0.002-0,004 press fit in the cylin-

der block in 144 cubic inch engines

and 0.002-0.005 press fit in 152 cubic

inch engines and should be pressed in

until the top of the liner is flush with

the top surface of the engine block.

Finish bore the cylinder sleeve to

3.501-3.502 for a standard piston or

3.531-3.532 for the oversize in 144 cu-

bic inch engine and 3.600-3.601 for the

standard piston in 152 cubic inch en-

gine.

PISTON PINS

23. The floating type piston pin has

an outside diameter of 1.24975-1.2500

and is retained in the piston by snap

rings. Piston pin should have a clear-

Fig. FO5T4 — Proper instoMotiofi arrange-

ment of segmented third compression ond

upper oil control rings. See text for de-

tails.

ance of 0.00025-0.0005 in the piston

bosses and a clearance of 0.0005-

0.00175 in the connecting rod bushing.

These clearances will give a light

thumb press fit in the piston and

slightly looser fit in the connecting

rod bushing.

The connecting rod bushings are re-

newable and should be final sized

after installation.

CONNECTING RODS AND

BEARINGS

24. Connecting rod bearings are of

the non-adjustable, precision type, re-

newable from below after the oil pan

and connecting rod bearing caps have

been removed. When installing new

bearing shells, make certain that the

projections engage the milled slot in

the connecting rod and bearing cap

and that the correlation numbers on

the rod and cap face away from cam-

shaft side of engine. Bearing inserts

are available in 0.010, 0.020 and 0.030

undersize as well as standard.

Check the crankshaft rod journals

and the rod liners against the values

which follow:

Crankpin journal

diameter 2.2485-2.249

Bearing diametral

clearance 0.002-0.0035

Rod side play on

crankshaft 0.0095-0.0133

Connecting rod center to center

length is 8.999-9.001.

When reassembling, install new

self-locking connecting rod nuts and

tighten to a torque of 50-55 ft.-lbs.

if nuts are cadmium plated or 65-70

ft.-lbs. if nuts are unplated.

CRANKSHAFT AND MAIN

BEARINGS

25. The crankshaft is supported in

four main bearings of the non-adjust-

able, precision type. Bearing inserts

are available in 0.010, 0.020 and 0.030

undersizes as well as standard. Normal

crankshaft end play of 0.00225-0.01025

is controlled by renewable flange type

thrust washers located in the rear

main bearing cap. Washers are avail-

able in standard and 0.0075 oversize.

NOTE: Several diiferent types of main bear-

ing inserts have been used and it is impor-

tant that the type number (not Ford part

number) stamped into the back oi inserts

be the same on both the top and bottom

Fig. FO515 — Packing

type crankshaft rear oil

seal is housed in a two-

piece retainer, bolted to

engine block and rear

main bearing cap as

shown.

10

DEXTA-SUPER DEXTA-2000 DEXTA

Paragraphs 26-28

Insert of any one bearinc, journal. It is rec-

ommended that the main bearing inserts be

all of one type number. Also, the locking tab

on the bottom Gaearing cap) thrust washer

has been changed in production at engine

Serial No. 1449364 and the correct thrust

washer must be used.

To remove the front main bearing

cap, it is first necessary to remove

the timing gear cover, lower timing

gear housing and oil pump. To re-

move the rear main bearing cap, it is

first necessary to remove the engine

as outlined in paragraph 9 and re-

move the clutch, flywheel, adapter

plate and rear oil seal retainer.

Check the crankshaft and main

bearing inserts against the values

which follow:

Crankpin diameter 2.2485-2.249

Main journal diameter.. .2.7485-2.749

Main bearing diametral

clearance 0.0025-0.0045

Main bearing bolt

torque .90-95 ft.-lbs.

CRANKSHAFT OIL SEALS

26. The crankshaft front oil seal is

mounted in the timing gear cover and

may be renewed after the front cover

is removed. Removal procedure for

the timing gear cover is outlined in

paragraph 15. Press the new seal into

the cover with the lip to the inside.

The crankshaft rear oil seal can be

renewed after detaching engine from

clutch housing as outlined in para-

graph 56 and removing the clutch,

flywheel and engine adapter plate.

The rear oil seal retainer is secured

to the rear of the engine block and

rear main bearing cap by six cap

screws and the two halves of the re-

tainer are held together by two long

bolts and self-locking nuts as shown

Fig. FO516—After insfallatioii of

runout should be eliecked as shown. Run-

out shouid not exceed 0.004.

in Fig. FO515. The packing type seal

halves should be soaked in clean en-

gine oil for a period of one hour be-

fore installing in the retainer halves.

Press the packings firmly in their re-

tainers, leaving 0.010-0.020 of the

packing ends protruding above the

face of the retainer. Using new gas-

kets, fit the two halves of the retainer

around the crankshaft and install and

tighten the long bolts and self-locking

nuts holding the retainer together;

then, install and tighten the six cap

screws securing the oil seal assembly

to engine block and main bearing cap.

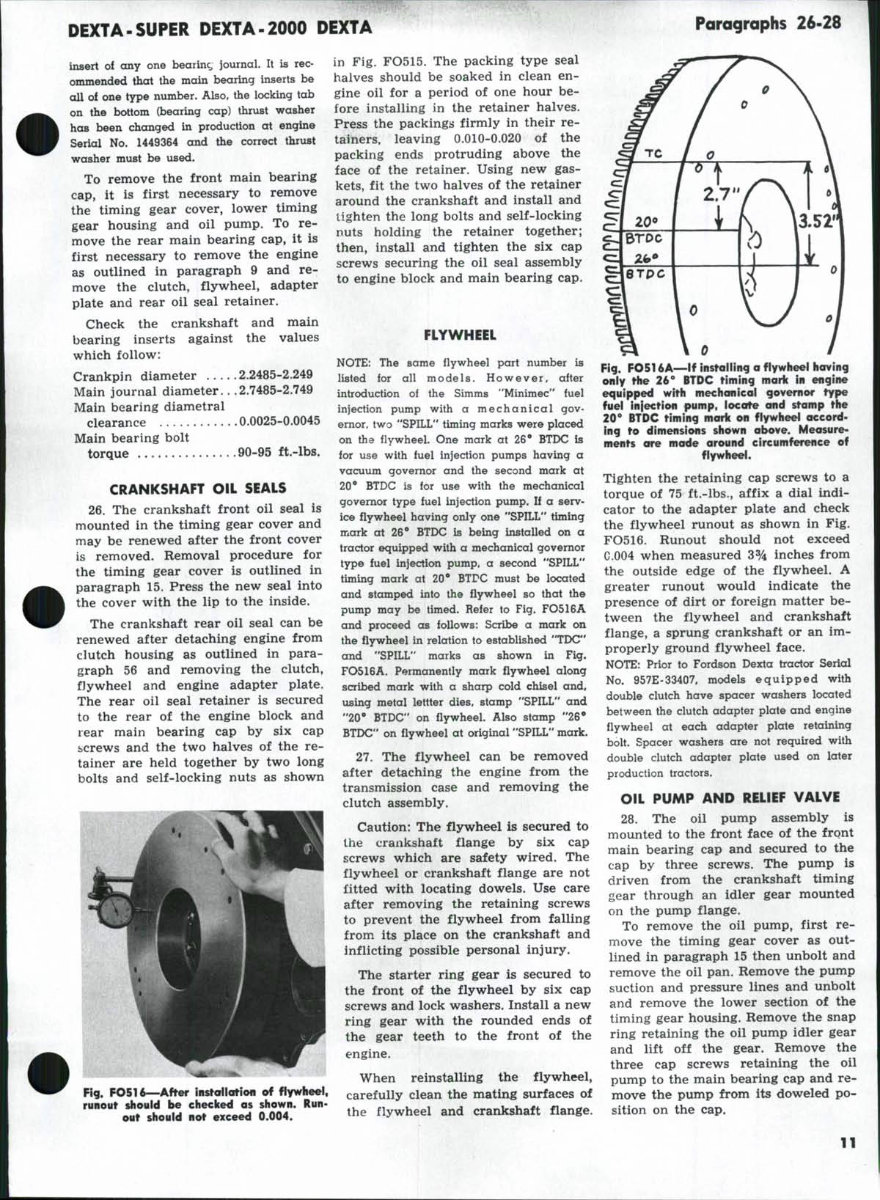

FLYWHEEL

NOTE: The same flywheel part number is

listed for all models. However, after

introduction of the Simms "Minimec" fuel

injection pump with a m e c h a n i c a l gov-

ernor, two "SPILL" timing marks were placed

on the flywheel. One mark at 26' BTDC is

for use with fuel injection pumps having a

vacuum governor and the second mark at

20" BTDC is lor use with the mechanical

governor type fuel injection pump. If a serv-

ice flywheel having only one "SPILL" timing

mark at 26" BTDC is being installed on a

tractor equipped with a mechanical governor

type fuel injection pump, a second "SPILL"

timing mark at 20* BTDC must be located

and stamped into the flywheel so that the

pump may be timed. Refer to Fig. FO516A

and proceed as follows: Scribe a mark on

the flywheel in relation to established "TDC"

and "SPILL" marks as shown in Fig.

FO516A. Permanently mark flywheel along

scribed mark with a sharp cold chisel and,

using metal lettter dies, stamp "SPILL" and

"20* BTDC" on flywheel. Also stamp "26"

BTDC" on flywheel at original "SPILL" mark.

27. The flywheel can be removed

after detaching the engine from the

transmission case and removing the

clutch assembly.

Caution: The flywheel is secured to

the crankshaft flange by six cap

screws which are safety wired. The

flywheel or crankshaft flange are not

fitted with locating dowels. Use care

after removing the retaining screws

to prevent the flywheel from falling

from its place on the crankshaft and

inflicting possible personal injury.

The starter ring gear is secured to

the front of the flywheel by six cap

screws and lock washers. Install a new

ring gear with the rounded ends of

the gear teeth to the front of the

engine.

When reinstalling the flywheel,

carefully clean the mating surfaces of

the flywheel and crankshaft flange.

Fig. FO516A—If insfalling a flywkeel having

only the 26" BTDC timing mark in engine

equipped wirh mechanical governor type

fuel infection pump, locate and stamp the

20** BTDC timing mark on flywheel accord-

ing to dimensions shown above. Measure-

ments ore made around circumference of

flywheel.

Tighten the retaining cap screws to a

torque of 75 ft.-lbs., affix a dial indi-

cator to the adapter plate and check

the flywheel runout as shown in Fig.

FO516. Runout should not exceed

C.004 when measured 3% inches from

the outside edge of the flywheel. A

greater runout would indicate the

presence of dirt or foreign matter be-

tween the flywheel and crankshaft

flange, a sprung crankshaft or an im-

properly ground flywheel face.

NOTE: Prior to Fordson Dexta tractor Serial

No. 957E-33407, models equipped with

double clutch have spacer washers located

between the clutch adapter plate and engine

flywheel at each adapter plate retaining

bolt. Spacer washers are not required with

double clutch adapter plate used on later

production tractors.

OIL PUMP AND RELIEF VALVE

28. The oil pump assembly is

mounted to the front face of the front

main bearing cap and secured to the

cap by three screws. The pump is

driven from the crankshaft timing

gear through an idler gear mounted

on the pump flange.

To remove the oil pump, first re-

move the timing gear cover as out-

lined in paragraph 15 then unbolt and

remove the oil pan. Remove the pump

suction and pressure lines and unbolt

and remove the lower section of the

timing gear housing. Remove the snap

ring retaining the oil pump idler gear

and lift off the gear. Remove the

three cap screws retaining the oil

pump to the main bearing cap and re-

move the pump from its doweled po-

sition on the cap.

11

You're Reading a Preview

What's Included?

Fast Download Speeds

Online & Offline Access

Access PDF Contents & Bookmarks

Full Search Facility

Print one or all pages of your manual

$26.99

Viewed 79 Times Today

Loading...

Secure transaction

What's Included?

Fast Download Speeds

Online & Offline Access

Access PDF Contents & Bookmarks

Full Search Facility

Print one or all pages of your manual

$26.99

This workshop manual is an essential resource for FMD tractor owners looking to save on repair and servicing costs. It contains extensive detailed diagrams, technical references, and step-by-step guides to assist in carrying out repairs and servicing. Whether you are a professional mechanic or a DIY enthusiast, this comprehensive package is a must-have for maintaining your Ford tractor.

- Comprehensive catalogue of workshop manuals for FMD tractors

- Supplied in PDF format for easy printing

- Extensive detailed diagrams and technical references

- Step-by-step guides for repair and servicing