FORD Tractor 900 901 1801 Repair Manual

What's Included?

Fast Download Speeds

Online & Offline Access

Access PDF Contents & Bookmarks

Full Search Facility

Print one or all pages of your manual

SHOP MANUAL

FORD

SERIES

501 -600-601-700-701 -800-801 -900-901 -1801 -2000-4000

The Tractor Model and Serial Num-

bers are stamped on the top of the

transmission housing at the left front

corner. A different model number is

assigned each major product option.

Early agricultural and i n d u s t r i a l

model number consists of three digits,

followed in some cases by a suffix

consisting of a number and/or letter.

The first digit designates the engine

size and tractor type, the second digit

the transmission type and the third

digit the year range of the series. The

following table lists the product op-

tions indicated by the model number:

5**—One-row, 8" offset design

equipped with 134 cu. in. gas-

oline or LP-Gas or 144 cu. in.

diesel engine.

§•*—Four-wheel, adjustable axle

design equipped with 134 cu.

in. gasoline or LP-Gas or 144

cu. in. diesel engine.

7**—High clearance row-crop type

equipped with 134 cu. in.

gasoline or LP-Gas or 144

cu. in. diesel engine.

8* •—Four-wheel ad j ustable axle

design equipped with 172 cu.

in. engine.

9**—High clearance row-crop type

equipped with 172 cu. in. en-

gine.

l^**—Four-wheel, axle type, indus-

trial tractor equipped with

172 cu. in. engine.

•l*_"Select-O-Speed" transmis-

sion without pto.

•2*—Four-speed transmission with-

out pto or hydraulic lift.

•3*—Four-speed transmission with-

out pto. / .

*4*—Four-speed transmission.

•5*—Five-speed transmission with

transmission pto

•6*—Five-speed transmission with

live pto.

•7*—"Select- O- Speed" transmis-

sion with single speed pto.

*8*—"Select - O - Speed" transmis-

sion with two - speed and

ground drive pto.

**0—Series designation built 1955

to 1958.

**l_Series designation built 1958

to 1962.

***_!—^Tricycle type with single

front wheel.

***-4—High clearance, four-wheel,

adjustable axle type.

***_!>—^Diesel engine.

***-L—LP-Gas engine,

•**-37—Equipped with Reversing

transmission.

•**_2i—Equipped with Combination

transmission.

Late agricultural and industrial

model number consists of five digits,

followed in some cases by a suffix

consisting of a number and/or letter.

The first digit designates engine size;

the second digit, successive models;

the third and fourth digits, tractor

type; and the fifth digit, product

options including transmission type.

(NOTE: Options indicated by fifth

digit varies with successive models.)

Suffix letters and numbers are similar

to those used for early agricultural

and industrial types. The following

table lists product options indicated

by the model number:

2****—Indicates 134 cu. in. gasoline

or 144 cu. in. diesel engine.

4****—Indicates 172 cu. in. gasoline

or diesel engine.

*0***—Indicates industrial models

produced prior to 1963.

•1***—Indicates agricultural and in-

dustrial models produced in

1963 and later.

**10*—High clearance agricultural

Row Crop type, with single or

dual tricycle front wheels or

wide adjustable front axle.

**11*—Offset four-wheel agricultural

type for one-row cultivation.

**20*—^Four-wheel All-Purpose type

with adjustable front axle.

**2i*—Four-wheel orchard and grove

type with non-adjustable front

axle.

**30*—Four-wheel utility type indus-

trial with non-adjustable front

axle.

**31*—Four-wheel low center of

gravity type with adjustable

front axle.

**41*—Heavy duty industrial type

with sub frame and cast grille,

extra heavy front axle &

steering.

*1**Q—Four-speed transmission with-

out pto.

*0**i—Four-speed transmission with-

out pto or hydraulic system.

*1**1—Four-speed transmission with

pto.

*0**2—Four-speed transmission and

hydraulic system, without pto.

*1**2—Five-speed transmission with

live pto.

•0**3—Four-speed transmission, hy-

draulic system and pto.

*0**4—Select - O - Speed transmission

without hydraulic system or

pto.

*1**4—Select-O- Speed transmission

without pto.

*0**5—Select - O - Speed transmission,

hydraulic system and 540 rpm

pto.

* 1 * *5—Select - O - Speed transmission

with 540 rpm independent pto.

*0**6—Select - O - Speed transmission,

hydraulic system and 540-1000

rpm and ground speed pto,

*1**6—Select- O - Speed transmission

with 540 and 1000 rpm inde-

pendent pto.

* 1 * *7—Select - O - Speed transmission

with 540 and 1000 rpm inde-

pendent and ground speed pto.

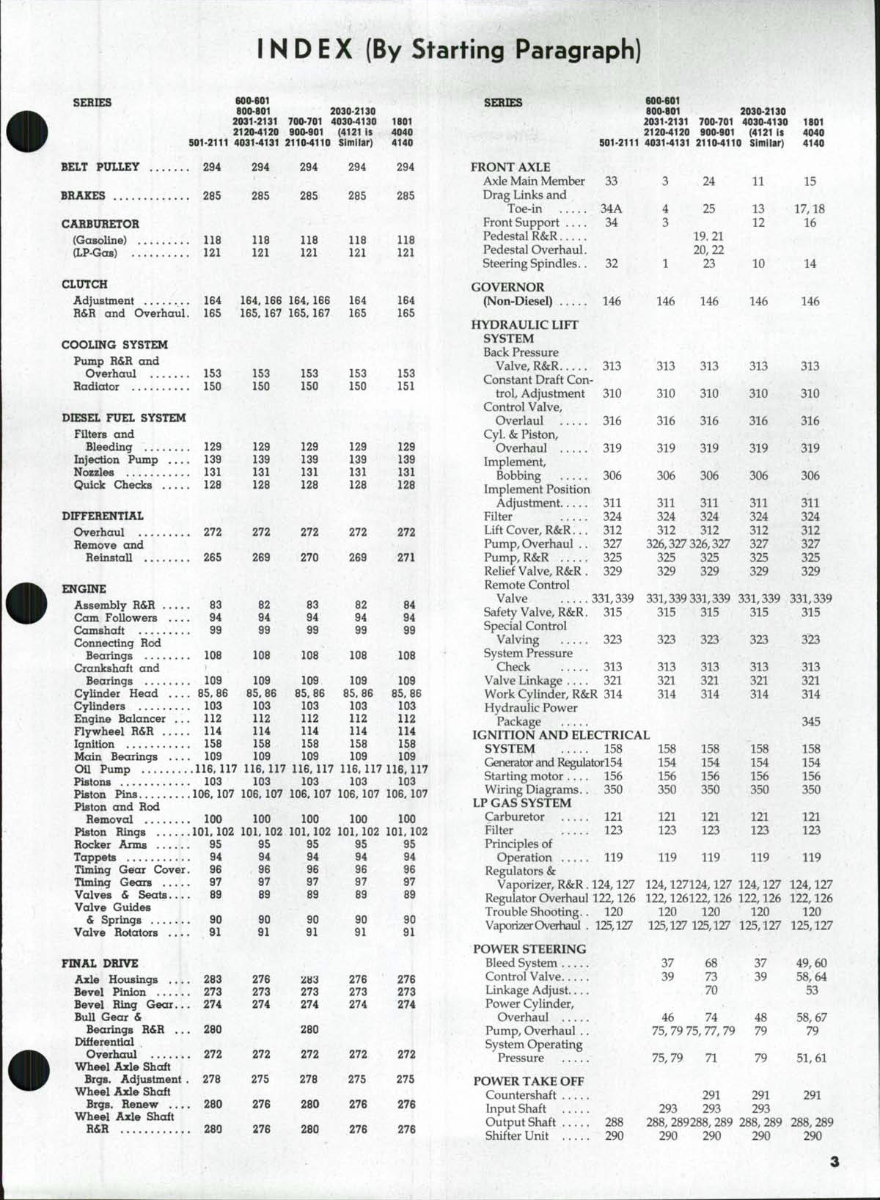

INDEX (By Starting Paragraph)

SERIES 600-601

aOO'BOl 2030-2130

2031-2131 700-701 4030-4130

2120-4120 900-901 (4121 1$

501-2111 4031-4131 2110-4110 Similar)

BELT PULLEY 294 294 294 294

BRAKES 265 285 285 285

CARBURETOR

(Gasoline) 116 118 118 118

(LP-Gas) 121 121 121 121

CLUTCH

Adjustment 184 184. 186 164, 168 164

R&R and Overhaul. 185 165. 167 165. 167 165

COOLING SYSTEM

Pump R&R and

Overhaul 153

Radiator 150

DIESEL FUEL SYSTEM

Filters and

Bleeding 129

Injection Pump 139

Nozzles 131

Quick Checks 126

DIFFERENTIAL

Overhaul 272

Remove and

Reinstall 265

ENGINE

Assembly R&R 83

Cam Followers 94

Camshaft 99

Connecting Rod

Bearings 106

Crankshaft and

Bearings 109

CyUnder Head 85.88

Cylinders 103

Engine Balancer . . . 112

Flywheel R&R 114

Ignition 156

Main Bearings 109

Oil Pump 118,117

Pistons 103

Piston Pins 108, 107

Piston and Rod

Removal 100

Piston Rings 101,102

Rocker Arms 95

Tappets 94

Timing Gear Cover. 96

^ming Gears 97

Valves & Seats 89

Valve Guides

& Springs 90

Valve Rotators 91

FINAL DRIVE

Axle Housings 263

Bevel Pinion 273

Bevel Ring Gear... 274

Bull Gear &

Bearings R&R ... 280

Differential

Overhaul 272

Wheel Axle Shaft

Brgs. Adjustment . 278

Wheel Axle Shaft

Brgs. Renew 280

Wheel Axle Shaft

R&R 280

153

150

129

139

131

128

272

289

82

94

99

108

109

65.86

103

112

114

156

109

153

150

129

139

131

126

272

270

83

94

99

106

109

85,86

103

112

114

158

109

153

150

129

139

131

128

272

269

82

94

99

106

109

85.86

103

112

114

158

109

1801

4040

4140

294

285

118

121

164

165

153

151

129

139

131

126

272

271

84

94

99

106

109

85.86

103

112

114

156

109

116. 117 116.117 116.117 116,117

103 103 103 103

108. 107 106, 107 106. 107 106.107

100 100 100 100

101. 102 101, 102 101. 102 101, 102

95 95 95 95

94 94 94 94

96 96 96 96

97 97 97 97

69 69 89 69

90

91

276

273

274

272

275

276

276

90

91

2H3

273

274

280

272

276

260

280

90

91

276

273

274

272

275

276

276

90

91

276

273

274

272

275

276

276

SERIES

FRONT AXLE

Axle Main Member

Drag Links and

Toe-in

Front Support ....

Pedestal R&R

Pedestal Overhaul.

Steering Spindles..

GOVERNOR

(Non-Diesel)

600-601

600-601 2030-2130

2031-2131 700-701 4030-4130 1601

2120-4120 900-901 (4121 Is 4040

901-2111 4031-4131 2110^110 Simirar) 4140

33

34A

34

32

146 146

24

25

19.21

20,22

23

146

11

13

12

10

146

HYDRAULIC LIFT

SYSTEM

Back Pressure

Valve, R&R 313

Constant Draft Con-

trol Adjustment 310

Control Valve,

Overlaul 316

Cyl. & Piston,

Overhaul 319

Implement

Bobbing 306

Implement Position

Adjustment 311

Filter 324

Lift Cover, R&R... 312

Pump, Overhaul .. 327

Pump, R&R 325

Relief Valve, R&R . 329

Remote Control

Valve 331,339

Safety Valve, R&R. 315

Special Control

Valving 323

System Pressure

Check 313

Valve Linkage 321

Work Cylinder, R&R 314

Hydraulic Power

Package

IGNITION AND ELECTRICAL

SYSTEM 158

Generator and Regulatorl54

Starting motor .... 156

Wiring Diagrams.. 350

LF GAS SYSTEM

Carburetor 121

Filter 123

Principles of

Operation 119

Regulators &

Vaporizer, R&R . 124,127

Regulator Overhaul 122,126

Trouble Shooting.. 120

Vaporizer Overhaul . 125,127

FOWER STEERING

Bleed System

Control Valve

Linkage Adjust ....

Power Cylinder,

Overhaul

Pump, Overhaul ..

System Operating

Pressure

FOWER TAKE OFF

Countershaft

Input Shaft

Output Shaft 288

Shifter Unit 290

313 313

310 310

316 316

319 319

306 306

311

324

312

311

324

312

326,327 326,327

325 325

329 329

331,339 331,339

315 315

323 323

313

321

314

158

154

156

350

121

123

313

321

314

158

154

156

350

121

123

119 119

124,127124,127

122,126122,126

120 120

125,127 125,127

37

39

68

73

70

319

306

311

324

312

327

325

329

331,339

315

323

313

321

314

158

154

156

350

121

123

119

124,127

122,126

120

125,127

37

39

46 74

75, 79 75, 77, 79

75,79 71

48

79

79

15

17,18

16

14

146

313

310

316

313

310

316

291 291

293 293 293

288, 289288, 289 288, 289

290 290 290

319

306

311

324

312

327

325

329

331,339

315

323

313

321

314

345

158

154

156

350

121

123

119

124,127

122,126

120

125,127

49,60

58,64

53

58,67

79

51,61

291

288,289

290

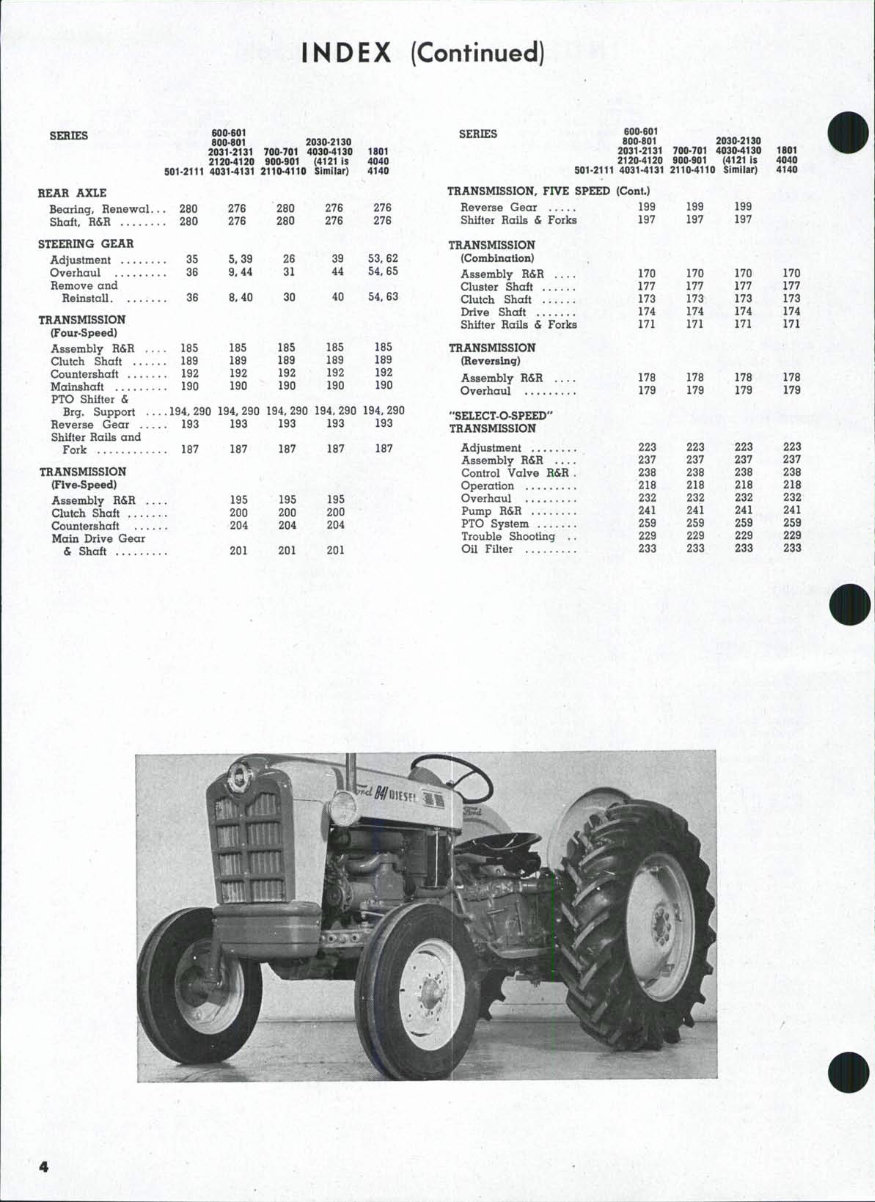

iNDEX (Continued)

SERIES 600-601

^"**^^ 800-801 2030-2130

2031-2131 700-701 4030-4130 1801

2120-4120 900-901 (4121 is 4040

501-2111 4031-4131 2110-4110 Similar) 4140

REAR AXLE

Bearing. Renewal... 280 276 280 276 276

Shaft, R&R 280 276 280 276 276

STEERING GEAR

Adjustment 35 5,39 26 39 53.62

Overhaul 36 9.44 31 44 54.65

Remove and

Reinstall 36 8.40 30 40 54,63

TRANSMISSION

(Four-Speed)

Assembly R&R .... 185 185 185 185 185

Clutch Shaft 189 189 189 189 189

Countershaft 192 192 192 192 192

Mainshatt 190 190 190 190 190

PTO Shifter &

Brg. Support .... 194, 290 194, 290 194, 290 194. 290 194. 290

Reverse Gear 193 193 193 193 193

Shifter Rails and

Fork 187 187 187 187 187

TRANSMISSION

(Five-Speed) ^

Assembly R&R .... '. 195 195 195

Clutch Shaft 200 200 200

Countershaft V ; 204 204 204

Main Drive Gear

& Shaft 201 201 201

SERIES

Reverse Gear

Shifter Rails & Forks

TRANSMISSION

(Combination)

Assembly R&R

Cluster Shaft .

Clutch Shaft .

Drive Shaft ..

Shifter Rails & Forks

TRANSMISSION

(Reversing)

Assembly R&R ...

Overhaul

"SELECTO-SPEED"

TRANSMISSION

Adjustment

Assembly R&R ...

Control Valve R&R

Operation

Overhaul

Pump R&R

PTO System

Trouble Shooting .

Oil Filter

600-601

800-801

2031-2131

2120-4120

501-2111 4031-4131

SPEED (Cont.)

199

! 197

170

177

173

174

J 171

178

179

223

EO to to

!-• CO CO

CO CO •<]

232

241

259

229

233

700-701

900-901

2110-4110

199

197

170

111

173

174

171

178

179

223

to to to

h^ CO CO

CO CO -<]

232

241

259

229

233

2030-2130

4030-4130

(4121 is

Similar)

199

197

170

177

173

174

171

178

179

223

237

238

218

232

241

259

229

233

1801

4040

4140

170

177

173

174

171

178

179

237

238

21R

232

241

259

229

233

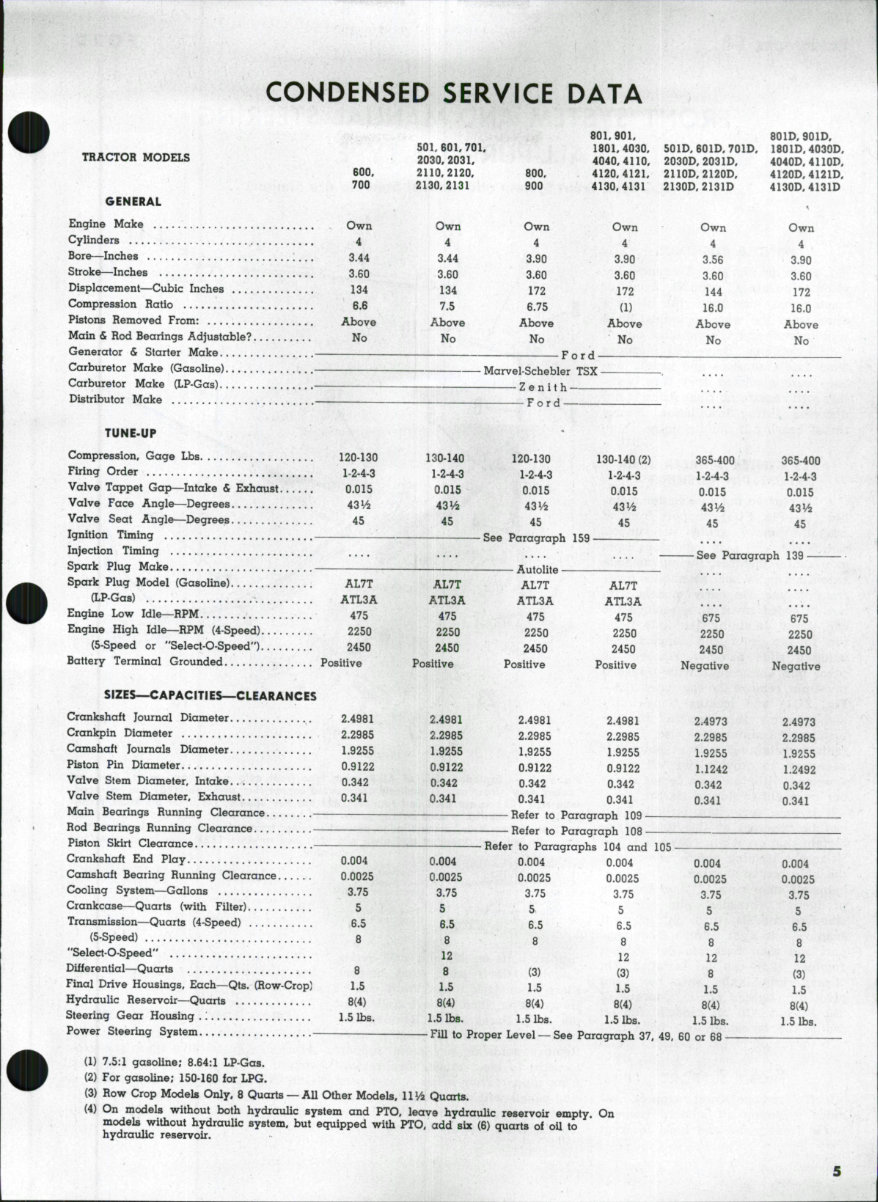

CONDENSED SERVICE DATA

801,901, 801D,901D,

501,601,701, 1801.4030, 501D, 601D, 701D, 1801D,4030D,

TRACTOR MODELS 2030,2031, 4040,4110, 2030D, 2031D, 4040D, 4110D,

600, 2110,2120, 800, 4120,4121, 2110D, 2120D, 4120D,4121D,

700 2130,2131 900 4130,4131 2130D,2131D 4130D,4131D

GENERAL

Engine Make Own Own Own Own Own Own

Cylinders 4 4 4 4 4 4

Bore—Inches 3.44 3.44 3.90 3.90 3.56 3.90

Stroke—Inches 3.60 3.60 3.60 3.60 3.60 3.60

Displacement—Cubic Inches 134 134 172 172 144 172

Compression Ratio 6.6 7.5 6.75 (1) 16.0 16.0

Pistons Removed From: Above Above Above Above Above Above

Main & Rod Bearings Adjustable? No No No No No No

Generator & Starter Make Ford —

Carburetor Make (Gasoline) Marvel-Schebler TSX .

Carburetor Make (LP-Gas) -~ Zenith

Distributor Make .— Ford

TUNE-UP

Compression, Gage Lbs 120-130 130-140 120-130 130-140 (2) 365-400 365-400

Firing Order 1-2-4-3 1-24.3 1-2-4-3 1-2-4-3 1-2-4-3 1-2-4-3

Valve Tappet Gap—Intake & Exhaust 0.015 0.015 0.015 0.015 0.015 0.015

Valve Face Angle—Degrees 43V4 43^2 43V4 43V4 43Vi 43Vi

Valve Seat Angle—Degrees 45 45 45 45 45 45

Ignition Timing See Paragraph 159

Injection Timing .... .... See Paragraph 139

Spark Plug Make . Autolite - •

Spark Plug Model (Gasoline) AL7T AL7T AL7T AL7T

fLP-Gas) ATL3A ATL3A ATL3A ATL3A

Engine Low Idle—RPM 475 475 475 475 675 675

Engine High Idle—RPM (4-Speed) 2250 2250 2250 2250 2250 2250

(5-Speed or "Select-O-Speed") 2450 2450 2450 2450 2450 2450

Battery Terminal Grounded Positive Positive Positive Positive Negative Negative

SIZES^CAPACITIES—CLEARANCES

Crankshaft Journal Diameter 2.4981 2.4981 2.4981 2.4981 2.4973 2.4973

Crankpin Diameter 2.2985 2.2985 2.2985 2.2985 2.2985 2.2985

Camshaft Journals Diameter 1.9255 1.9255 1.9255 1.9255 1.9255 1.9255

Piston Pin Diameter 0.9122 0.9122 0.9122 0.9122 1.1242 1.2492

Valve Stem Diameter. Intake 0.342 0.342 0.342 0.342 0.342 0.342

Valve Stem Diameter, Exhaust 0.341 0.341 0.341 0.341 0.341 0.341

Main Bearings Running Clearance Refer to Paragraph 109

Rod Bearings Running Clearance Refer to Paragraph 108

Piston Skirt Clearance — Refer to Paragraphs 104 and 105

Crankshaft End Play 0.004 0.004 0.004 0.004 0.004 0.004

Camshaft Bearing Running Clearance 0.0025 0.0025 0.0025 0.0025 0.0025 0.0025

Cooling System—Gallons 3.75 3.75 3.75 3.75 3.75 3.75

Crankcase—Quarts {with Filter) 5 5 S 5 5 5

Transmission—Quarts (4-Speed) 6.5 6.5 6.5 6.5 6.5 6.5

(5-Speed) 8 8 8 8 8 8

"Select-O-Speed" 12 12 12 12

Differential—Quarts 8 8 (3) (3) 8 (3)

Final Drive Housings. Each—Qts. (Row-Crop] 1.5 1.5 I.5 1.5 1.5 15

Hydraulic Reservoir—Quarts 8(4) 8(4) 8(4) 8(4) 8(4) 8(4)

Steering Gear Housing .: 1.5 lbs. 1.5 lbs. 1.5 lbs. 1.5 lbs. 1.5 lbs. 1.5 lbs.

Power Steering System FiU to Proper Level — See Paragraph 37, 49, 60 or 68

(1) 7.5:1 gasoline; 8.64:1 LP-Gas.

(2) For gasoline; 150-160 for LPG.

(3) Row Crop Models Only, 8 Quarts — All Other Models, llV^ Quarts.

(4) On models without both hydraulic system and PTO, leave hydraulic reservoir empty. On

models without hydrauUc system, but equipped with PTO, add six (6) quarts of oU to

hydraulic reservoir.

Paragraphs 1-4

FORD

FRONT SYSTEM AND MANUAL STEERING

ALL-PURPOSE TYPE

(LCG Type Front System and Manual Steering are Similar)

11 12

SPINDLE BUSHINGS

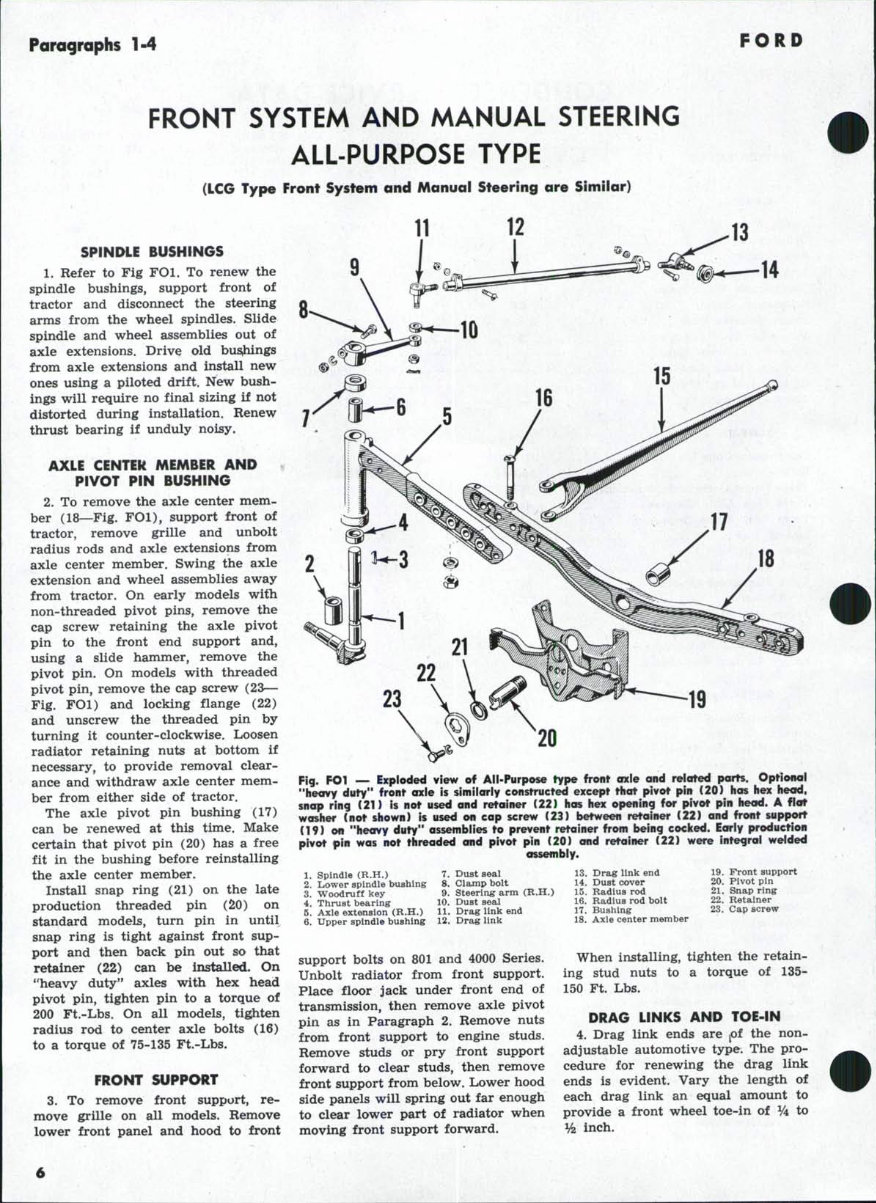

1. Refer to Fig FOl. To renew the

spindle bushings, support front of

tractor and disconnect the steering

arms from the wheel spindles. Slide

spindle and wheel assemblies out of

axle extensions. Drive old busihings

from axle extensions and install new

ones using a piloted drift. New bush-

ings will require no final sizing if not

distorted during installation. Renew

thrust bearing if unduly noisy,

AXLE CENTEk MEMBER AND

PIVOT PIN BUSHING

2. To remove the axle center mem-

ber (18—Fig. FOl), support front of

tractor, remove grille and unbolt

radius rods and axle extensions from

axle center member. Swing the axle

extension and wheel assemblies away

from tractor. On early models with

non-threaded pivot pins, remove the

cap screw retaining the axle pivot

pin to the front end support and,

using a slide hammer, remove the

pivot pin. On models with threaded

pivot pin, remove the cap screw (23—

Fig. FOl) and locking flange (22)

and unscrew the threaded pin by

turning it counter-clockwise. Loosen

radiator retaining nuts at bottom if

necessary, to provide removal clear-

ance and withdraw axle center mem-

ber from either side of tractor.

The axle pivot pin bushing (17)

can be renewed at this time. Make

certain that pivot pin (20) has a free

fit in the bushing before reinstalling

the axle center member.

Install snap ring (21) on the late

production threaded pin (20) on

standard models, turn pin in until

snap ring is tight against front sup-

port and then back pin out so that

retainer (22) can be installed. On

''heavy duty" axles with hex head

pivot pin, tighten pin to a torque of

200 Ft.-Lbs. On all models, tigjiten

radius rod to center axle bolts (16)

to a torque of 75-135 Ft.-Lbs.

FRONT SUPPORT

3. To remove front support, re-

move grille on all models. Remove

lower front panel and hood to front

14

19

20

Fig. FOl — Exploded view of All-Purpose type front oxie and rejated ports. Optionol

"heovy duty" front axle is similarly constructed except that pivot pin (20) has hex heod,

snop ring (21) is not used and retainer (22) has hex opening for pivot pin head. A flot

washer (not shown) is used on cop screw (23) between retainer (22) and front support

(19) on "heavy duty" assemblies to prevent retainer from being cocked. Early production

pivot pin was not threaded and pivot pin (20) and retainer (22) were integral welded

assembly.

1. Spindle (R.H.)

2. Lower spindle bushing

3. Woodruff key

4. Thrust bearing

5. Axle extension (R.H.)

7. Dust seal

8. Clamp boit

9. Steering arm (R.H.)

10. Dust seal

11. Drag link end

6. Upper spindl© bushing 12. Drag link

support bolts on 801 and 4000 Series.

Unbolt radiator from front support.

Place floor jack under front end of

transmission, then remove axle pivot

pin as in Paragraph 2. Remove nuts

from front support to engine studs.

Remove studs or pry front support

forward to clear studs, then remove

front support from below. Lower hood

side panels will spring out far enough

to clear lower part of radiator when

moving front support forward.

13. Drag link end

14. Dust cover

15. Radius rod

16. Radius rod bolt

17. Bushing

18. Axle center member

19. Front support

20. Pivot pin

21. Snap ring

22. Retainer

23. Cap screw

When installing, tighten the retain-

ing stud nuts to a torque of 135-

150 Ft. Lbs.

DRAG LINKS AND TOE-IN

4. Drag link ends are pt the non-

adjustable automotive type. The pro-

cedure for renewing the drag link

ends is evident. Vary the length of

each drag link an equal amount to

provide a front wheel toe-in of V4 to

% inch.

501-600-601-700-701-800-801 -900-901 -1801 -2000-4000 Paragraphs 5-8

30

31

1. Lock nuts

2. Flat washers

3. Packing

4. End covers

5. Bushings

6. "O" ring

8. Adjusting screw

9. Sector gear (double)

9A. Sector g&ar (single)

10. Pitman arms

11. Dustseais

12. Packing retainera

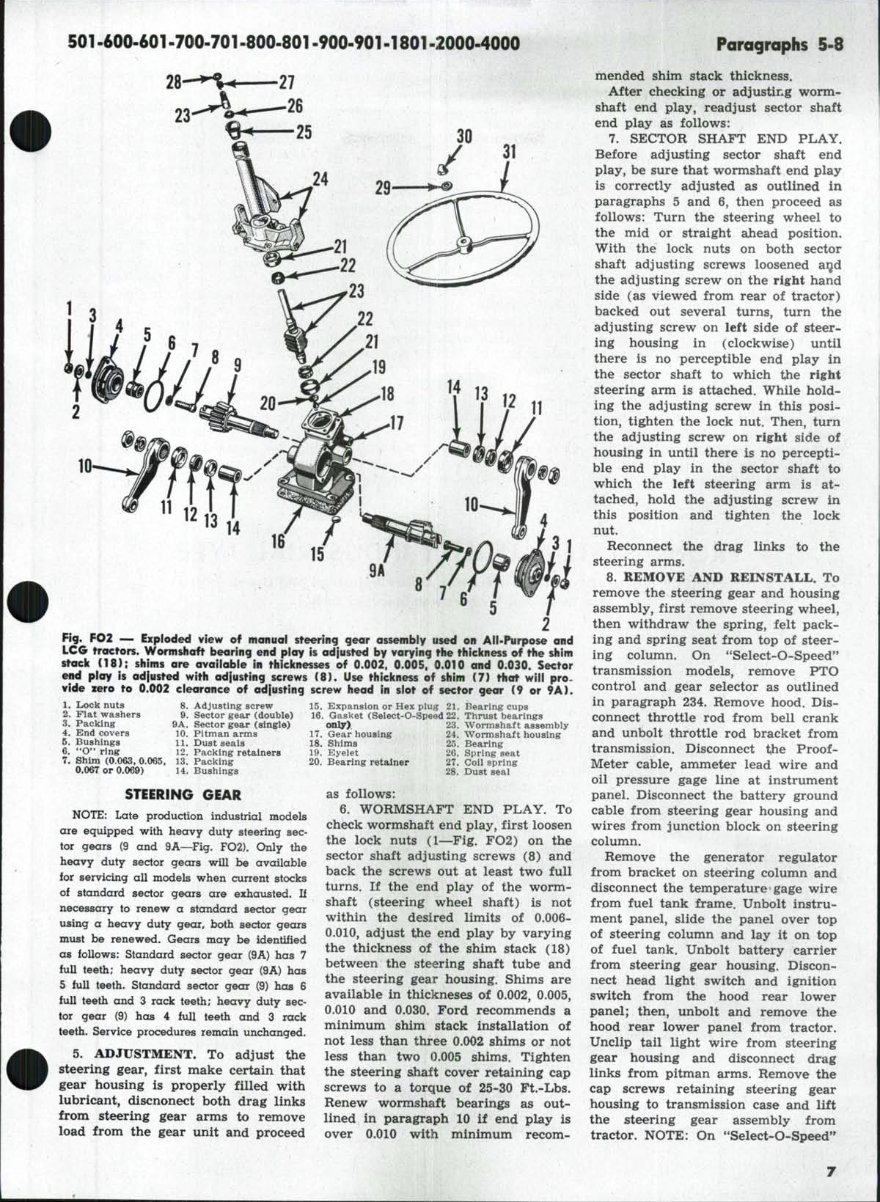

Fig. FO2 — Exploded view of manual steering gear assembly used on All-Purpose and

LCG tractors. Wormshaft bearing end play is adjusted by varying the thickness of the shim

stack (18); shims are available in thicknesses of 0.002. 0.005. 0.010 and 0.030. Sector

end play is adiusted with adfusting screws ( 8 ) . Use thickness of shim (7) that will pro.

vide zero to 0.002 clearance of adjusting screw head in slot of sector gear (9 or 9A).

15. Expansion or Hex piug 21. Bearing cups

16. Gasket (Select-0-Speed 22. Thrust bearings

(MLly). 23. Wormshaft assembly

17. Gear housing 24. Wormshaft housing

18. Shims 25. Bearing

19. Eyelet 26. Spring seat

20. Bearing retainer 27. Coil spring

28. Dust seai

as follows:

6. WORMSHAFT END PLAY. To

check wormshaft end play, first loosen

the lock nuts (1—Fig. FO2) on the

sector shaft adjusting screws (8) and

back the screws out at least two full

turns. If the end play of the worm-

shaft (steering wheel shaft) is not

within the desired limits of 0,006-

0.010, adjust the end play by varying

the thickness of the shim stack (18)

between the steering shaft tube and

the steering gear housing. Shims are

available in thickneses of 0.002, 0.005,

0.010 and 0.030. Ford recommends a

minimum shim stack installation of

not less than three 0.002 shims or not

less than two 0.005 shims. Tighten

the steering sJiaft cover retaining cap

screws to a torque of 25-30 Ft.-Lbs.

Renew wormshaft bearings as out-

lined in paragraph 10 if end play is

over 0.010 with minimum recom-

7. Shim (0.063, 0.065, 13. Packing

0.067 or 0.069) 14. Bushings

STEERING GEAR

NOTE: Late production industrial models

are equipped with heavy duty steering sec-

tor gears (9 and 9A—Fig. FO2). Only the

heavy duty sector gears will be available

for servicing all modeb when current stocks

of standard sector gears are exhausted. If

necessary to renew a standard sector gear

using a heavy duty gear, both sector gears

must be renewed. Gears may be identified

as follows: Standard sector gear (9A) has 7

full teeth; heavy duty sector gear {9A) has

5 full teeth. Standard sector gear (9) has 6

full teeth and 3 rack teeth; heavy duty sec-

tor gear (9) has 4 full teeth and 3 rack

teeth. Service procedures remain unchanged.

5. ADJUSTMENT. To adjust t;he

steering gear, first make certain that

gear housing is properly filled with

lubricant, discnonect both drag links

from steering gear arms to remove

load from the gear unit and proceed

mended shim stack thickness.

After checking or adjusting worm-

shaft end play, readjust sector shaft

end play as follows:

7. SECTOR SHAFT END PLAY.

Before adjusting sector shaft end

play, be sure that wormshaft end play

is correctly adjusted as outlined in

paragraphs 5 and 6, then proceed as

follows: Turn the steering wheel to

the mid or straight ahead position.

With the lock nuts on both sector

shaft adjusting screws loosened aijd

the adjusting screw on the right hand

side (as viewed from rear of tractor)

backed out several turns, turn the

adjusting screw on left side of steer-

ing housing in (clockwise) until

there is no perceptible end play in

the sector shaft to which the right

steering arm is attached. While hold-

ing the adjusting screw in this posi-

tion, tighten the lock nut. Then, turn

the adjusting screw on right side of

housing in until there is no percepti-

ble end play in the sector shaft to

which the left steering arm is at-

tached, hold the adjusting screw in

this position and tighten the lock

nut.

Reconnect the drag links to the

steering arms.

8. REMOVE AND REINSTALL. To

remove the steering gear and housing

assembly, first remove steering wheel,

then withdraw the spring, felt pack-

ing and spring seat from top of steer-

ing column. On **Select-O-Speed"

transmission models, remove PTO

control and gear selector as outlined

in paragraph 234. Remove hood. Dis-

connect throttle rod from bell crank

and unbolt throttle rod bracket from

transmission. Disconnect the Proof-

Meter cable, ammeter lead wire and

oil pressure gage line at instrument

panel. Disconnect the battery ground

cable from steering gear housing and

wires from junction block on steering

column.

Remove the generator regulator

from bracket on steering column and

disconnect the temperature gage wire

from fuel tank frame. Unbolt instru-

ment panel, slide the panel over top

of steering column and lay it on top

of fuel tank. Unbolt battery carrier

from steering gear housing. Discon-

nect head light switch and ignition

switch from the hood rear lower

panel; then, unbolt and remove the

hood rear lower panel from tractor.

Unclip tail light wire from steering

gear housing and disconnect drag

links from pitman arms. Remove the

cap screws retaining steering gear

housing to transmission case and lift

the steering gear assembly from

tractor. NOTE: On *'Select-O-Speed"

Paragraphs 9-13

transmission models, a gasket is used

between steering gear and transmis-

sion housings. Gasket should be left

in place or opening in transmission

covered when steering gear housing

is removed. Be sure that gasket is in

good condition before reinstalling

steering gear assembly.

9. OVERHAUL. Major overhaul of

the steering gear unit necessitates the

removal of the unit from tractor as

outlined in paragraph 8. Remove the

pitman arm retaining nuts and pull

pitman arms from sector shafts. Un-

bolt the sector shaft side covers and

remove the adjusting screw lock nuts

(1—Fig. FO2), Using a screwdriver,

turn the adjusting screws in and re-

move the side covers and sector

shafts. Unbolt steering housing upper

cover from housing and remove cover,

shaft and ball nut assembly. Do not

disassemble the ball nut and steering

shaft assembly (23) as component re-

placement parts are not available. If

the steering shaft and/or ball nut are

damaged, renew the complete assem-

bly. The need and procedure for

further disassembly and/or overhaul

is self-evident.

The renewable bushings in steering

gear covers have a bore diameter of

1.1255-1.1260; bushings in housing

have a bore diameter of 1.245-1.250.

S,hims (7) on the adjusting screws

(8) are available in thicknesses of

0.063, 0.065, 0.067 and 0.069. When

reassembling, use a shim that will

provide zero to 0.002 clearance be-

tween adjusting screw head and slot

in sector shafts.

When reassembling, center the ball

nut on wormshaft and insert shaft in

housing. Bolt the housing upper cover

assembly in position, using the neces-

sary number of shims (18) to provide

an end play of 0.006-0.010 of worm-

shaft in bearing. Minimum shim stack

should be three 0.002 shims or two

0.005 shims. If end play is more than

0.010 with minimum recommended

thickness of shims, renew the worm-

FORD

shaft bearings. Shims (18) are avail-

able in thicknesses of 0.002, 0.005,

0.010 and 0.030. Tighten the cover

cap screws to a torque of 25-30 Ft.-

Lbs. Assemble the sectors and their

adjusting screws (8) to their covers.

Hold the left sector shaft (the one

with the greater number of teeth)

and side cover assembly with the

block tooth up, and install the sector

so that middle tooth on sector meshes

with middle groove on the ball nut

rack. Install the right sector shaft,

meshing the fourth tooth with the

fourth groove of the left sector shaft.

Tighten the side cover cap screws to

a torque of 25-30 Ft.-Lbs. and install

the adjusting screw lock nuts.

Turn steering gear to its mid or

straight ahead position and install

pitman arms.

When installation is complete, fill

gear housing with lubricant and ad-

just the sector shaft end play as out-

lined in paragraph 7. Reconnect the

drag link.

FRONT SYSTEM, UTILITY INDUSTRIAL TYPE

(Front System of Grove Type is Similar. Utiiity Industrial and Grove Types

Are Equipped With Power Steering Only.)

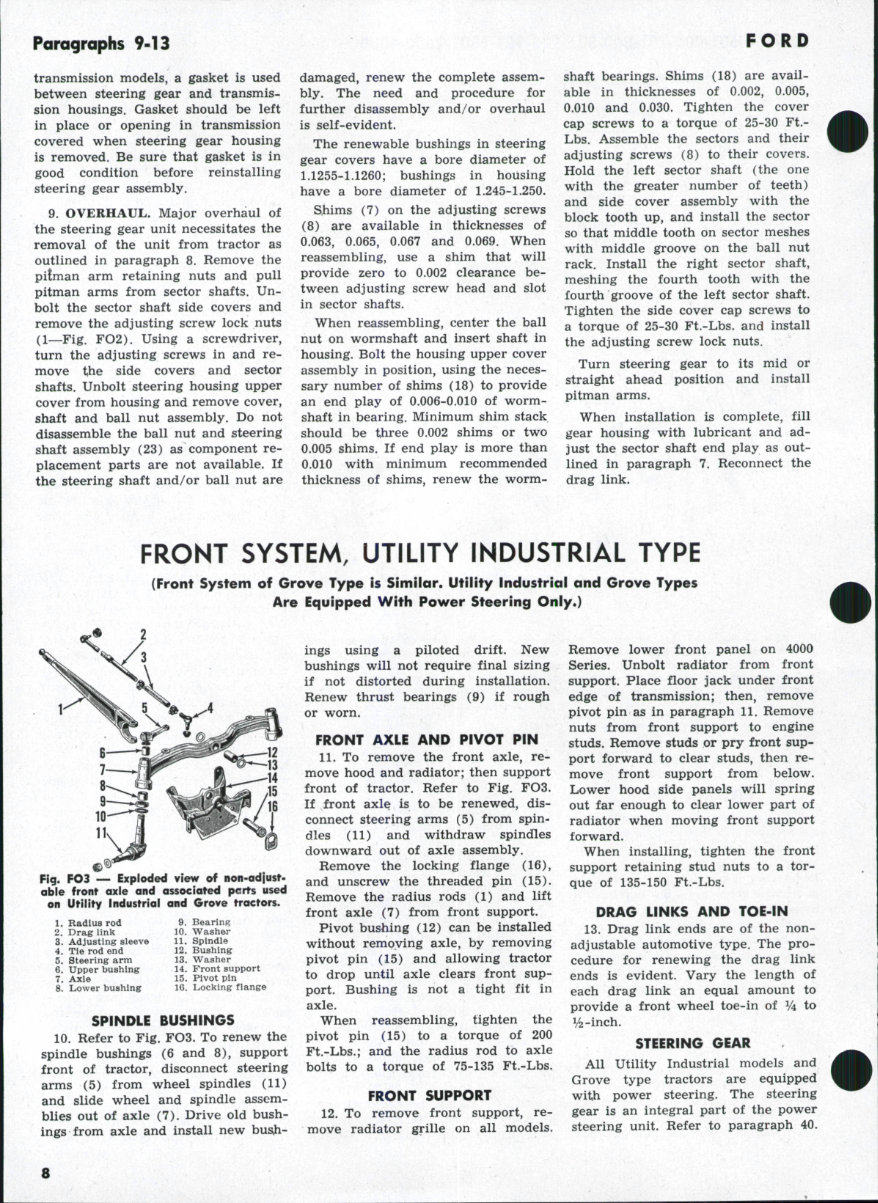

Fig. FO3 — Exploded view of non-adjust-

able front axle and associated pcrts used

on Utility Industrial and Grove tractors.

1. Badius rod

2. Drag link

3. Adjusting sleeve

4. Tie rod end

5. Steering arm

6. Upper bushing

7. Axle

8. Lower bushing

9. Bearing

10. Washer

11. Spindle

12. Bushing

13. Washer

14. Front support

15. Pivot pin

16. Locking fiange

SPINDLE BUSHINGS

10. Refer to Fig. FO3. To renew the

spindle bushings (6 and 8), support

front of tractor, disconnect steering

arms (5) from wheel spindles (11)

and slide wheel and spindle assem-

blies out of axle (7). Drive old bush-

ings from axle and install new busli-

ings using a piloted drift. New

bushings will not require final sizing

if not distorted during installation.

Renew thrust bearings (9) if rough

or worn,

FRONT AXLE AND PIVOT PIN

11. To remove the front axle, re-

move hood and radiator; then support

front of tractor. Refer to Fig. FO3.

If front axle is to be renewed, dis-

connect steering arms (5) from spin-

dles (11) and withdraw spindles

downward out of axle assembly.

Remove the locking flange (16),

and unscrew the threaded pin (15).

Remove the radius rods (1) and lift

front axle (7) from front support.

Pivot bushing (12) can be installed

without removing axle, by removing

pivot pin (15) and allowing tractor

to drop until axle clears front sup-

port. Bushing is not a tight fit in

axle.

When reassembling, tighten the

pivot pin (15) to a torque of 200

Ft.-Lbs.; and the radius rod to axle

bolts to a torque of 75-135 Ft.-Lbs.

FRONT SUPPORT

12. To remove front support, re-

move radiator grille on all models.

Remove lower front panel on 4000

Series. Unbolt radiator from front

support. Place floor jack under front

edge of transmission; then, remove

pivot pin as in paragraph 11. Remove

nuts from front support to engine

studs. Remove studs or pry front sup-

port forward to clear studs, then re-

move front support from below.

Lower hood side panels will spring

out far enough to clear lower part of

radiator when moving front support

forward.

When installing, tighten the front

support retaining stud nuts to a tor-

que of 135-150 Ft.-Lbs.

DRAG LINKS AND TOE-IN

13. Drag link ends are of the non-

adjustable automotive type. The pro-

cedure for renewing the drag link

ends is evident. Vary the length of

each drag link an equal amount to

provide a front wheel toe-in of V^ to

STEERING GEAR

All Utility Industrial models and

Grove type tractors are equipped

with power steering. The steering

gear is an integral part of the power

steering unit. Refer to paragraph 40.

8

501-600-601-700-701-800-801-900-90M 801 -2000-4000 Parographs 14-15

FRONT SYSTEM, H. D. INDUSTRIAL TYPE

14

19

18-

Fig. F04 — Expioded view (from rear) of front cnle assembly used on early Heavy Duty

Industrial tractor with full power steering.

1. Left steering amn

2. Spindle

3. Spindle buahlng

4. SplndTepln

6. Pin seal

6. Tapered re tain lag pin

7. Axle nnember

8. Pivot pin

9. Woodruff key

10. Thrust washer

11. Rear pivot bushing

12. Front pivot bushing

13. Thrust bearing

14. Tab washer

15. Jam nut

16. Tie rod end

17. Tie rod

18. Tie rod end

19. Right steering

arm

STEERING GEAR

18

SPINDLE BUSHINGS

All Models

14. To renew spindle bushings, jack

up the front axle and remove wheel

and hub assembly. Cut lock wire or

bend locking tabs down and unbolt

steering arm from spindle. Tie-rod

and/or power steering cylinder need

not be disconnected from steering

arm. Remove nut and lock washer

from tapered lock pin (6—Fig. FO4

or Fig. FO5) and drive out tapered

pin. Drive spindle pin upward

enough to relieve the pressure on

upper spindle pin seal, remove upper

seal, then drive spindle pin down-

ward out of axle.

Spindle bushings are pre-sized and

will require no final sizing if care-

fully installed. Renew thrust bearing

if unduly noisy. Thrust bearing is

installed with the indentation up as

shown in Fig. FO7. The detent in the

spindle pin is off center. Install spin-

dle pin with stamped "T** mark facing

upward so that spindle pin will be

properly located in axle. Torque steer-

ing arm bolts to 100 Ft.-Lbs., and se-

cure with safety wire or locking tabs.

FRONT AXLE AND PIVOT PIN

15. To remove the front axle (7—

Fig. FO4 or 7A—Fig. FO5), first dis-

connect the tie rod from either steer-

ing arm and swing tie rod rearward.

Disconnect power cylinder pressure

and return lines at cylinder; then,

disconnect the power cylinder from

the axle and lower the cylinder as-

sembly to the floor. Remove the radi-

ator grille door, pass a chain loop

through hole of front axle support

and secure chain with a bolt or short

rod as shown in Fig. FO6. Attach a

hoist to chain and tighten enough to

take up slack. Place a rolling floor

jack under center of front axle and

raise jack just enough to take the

axle weight off of pivot pin. Straight-

en tabs on keyed lock washer at front

end of pivot pin and remove jam

nut, keyed washer and lock nut as

Fig. FO5 » Expioded view of iate production Heavy Duty Industriol axle assembiy with

drag iink (power assist) steering. View is from front of unit.

lA.

2.

3.

4.

5.

6.

7A.

8.

9.

10.

11.

12.

13.

14.

15.

Left steering arm

Spindles

Spindle bushings

Spindle pins

Spindle pin seals

16.

17.

18.

19.

20.

Tapered retaining pins 21.

Front axle

Pivot pin

Woodruff key

Thrust washer:

Rear pivot bushing

Front pivot biishlng

Thrust spacer

Tab washer

Jam nuts

22.

23.

24.

25.

26.

27.

28.

29.

Tie rod end

Tie rod

Tie rod end

Right steering ar

Dust cover

Thrust bearings

Power steering

cylinder

Dust cover

Retainer

Drag link end

Lock nut

Drag link

Lock nut

Drag link end

Paragraph 16

FORD

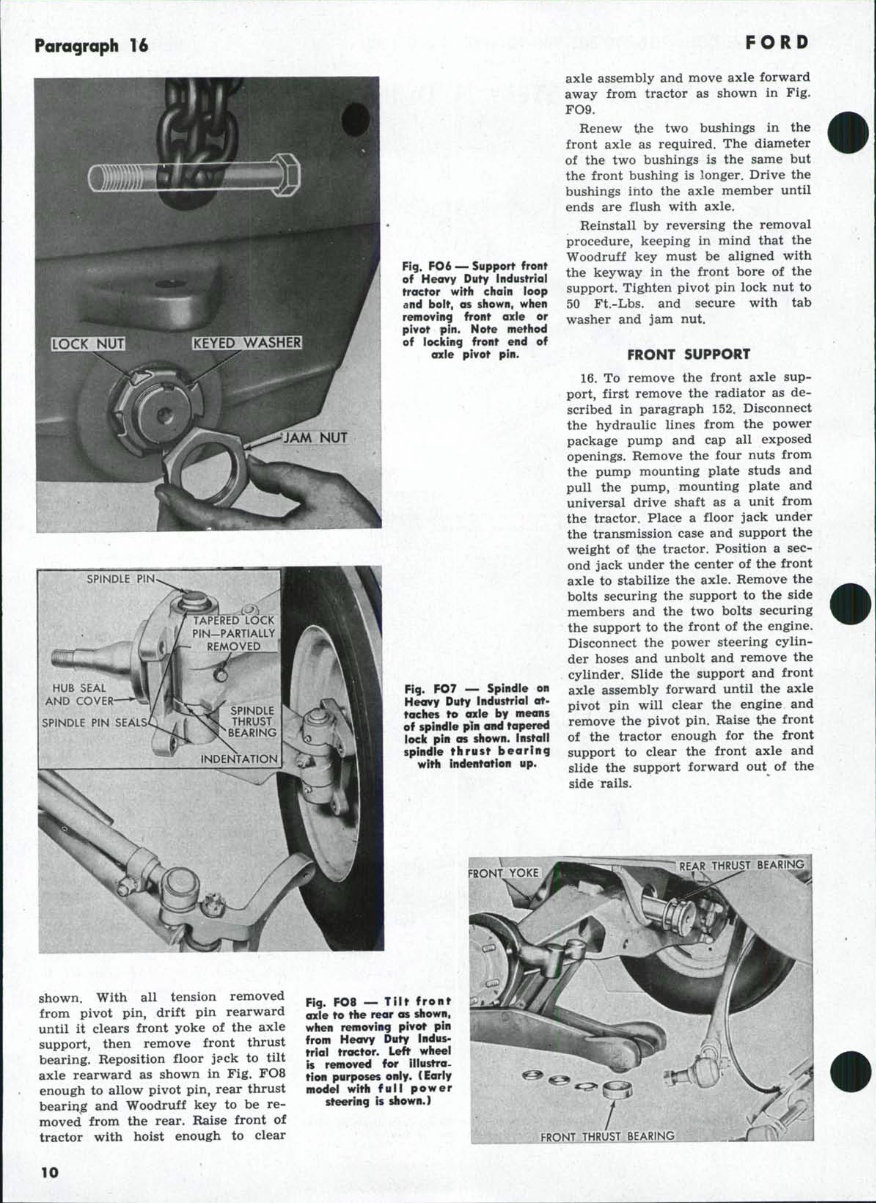

Fig. FO6 — Support front

of Heavy Duty Industrial

tractor with chain loop

and bolt, as shown, when

removing front axle or

pivot pin. Note method

of locking front end of

axle pivot pin.

SPINDLE PIN

/

/

"^^^ ' WltliMi 1

HUB SEAL «

AND COVER—*^i

/

SPINDLE PIN SEALSC

7

1/

LA

fm

^1

^^1^ ~ ''

nrAPEREDTdCK

PIN-PARTIALLY

- REMOVED

SC^ SPINDLE

N^ THRUST

INDENTATION

Fig. FO7 ~ Spindle on

Heavy Duty Industrial ot-

toches to axle by means

of spindle pin and tapered

lock pin as shown. Install

spindle thrust bearing

with indentation up.

axle assembly and move axle forward

away from tractor as shown in Fig.

FO9.

Renew the two bushings in the

front axle as required. The diameter

of the two bushings is the same but

the front bushing is longer. Drive the

bushings into the axle member until

ends are flush with axle.

Reinstall by reversing the removal

procedure, keeping in mind that the

Woodruff key must be aligned with

the keyway in the front bore of the

support. Tighten pivot pin lock nut to

50 Ft.-Lbs. and secure with tab

washer and jam nut.

FRONT SUPPORT

16. To remove the front axle sup-

port, first remove the radiator as de-

scribed in paragraph 152. Disconnect

the hydraulic lines from the power

package pump and cap all exposed

openings. Remove the four nuts from

the pump mounting plate studs and

pull the pump, mounting plate and

universal drive shaft as a unit from

the tractor. Place a floor jack under

the transmission case and support the

weight of the tractor. Position a sec-

ond jack under the center of the front

axle to stabilize the axle. Remove the

bolts securing the support to the side

members and the two bolts securing

the support to the front of the engine.

Disconnect the power steering cylin-

der hoses and unbolt and remove the

cylinder. Slide the support and front

axle assembly forward until the axle

pivot pin will clear the engine and

remove the pivot pin. Raise the front

of the tractor enough for the front

support to clear the front axle and

slide the support forward out of the

side rails.

FRONT YOKE

shown. With all tension removed

from pivot pin, drift pin rearward

until it clears front yoke of the axle

support, then remove front thrust

bearing. Reposition floor j?ck to tilt

axle rearward as shown in Fig. FO8

enough to allow pivot pin, rear thrust

bearing and Woodruff key to be re-

moved from the rear. Raise front of

tractor with hoist enough to clear

Fig, FO8 — Tilt front

axle to the rear os shown,

when removing pivot pin

from Heavy Duty Indus-

trial troctor. Left wheel

is removed for illustra-

tion purposes only. (Early

model with full power

steering is shown.)

10

501 -600-601 -700-701-800-801 -900-901-1801-2000-4000 Paragraphs 17-20

DRAG LINK, TIE ROD

AND TOE-IN

17. On models with power assist

steering, the installed length of the

drag link should be adjusted to 46^3^

to 46^ inches, measured between

centers of sockets at each end of the

drag link. The offset (elbow) in the

drag link must be towards the front

end of the tractor, and point 15 to 20

degrees below horizontal and away

from the engine. If tractor is

equipped with loader, check clear-

ance between drag link and left-hand

cylinder on loader in all positions of

front axle, loader and drag link. If

interference exists, loosen lock nuts

at each end of drag link, rotate sleeve

slightly to provide clearance and re-

tighten lock nuts.

18. The tie rod ends (and drag link

ends on power-assist steering models)

are of the non-adjustable automotive

type. Renewal procedure is evident.

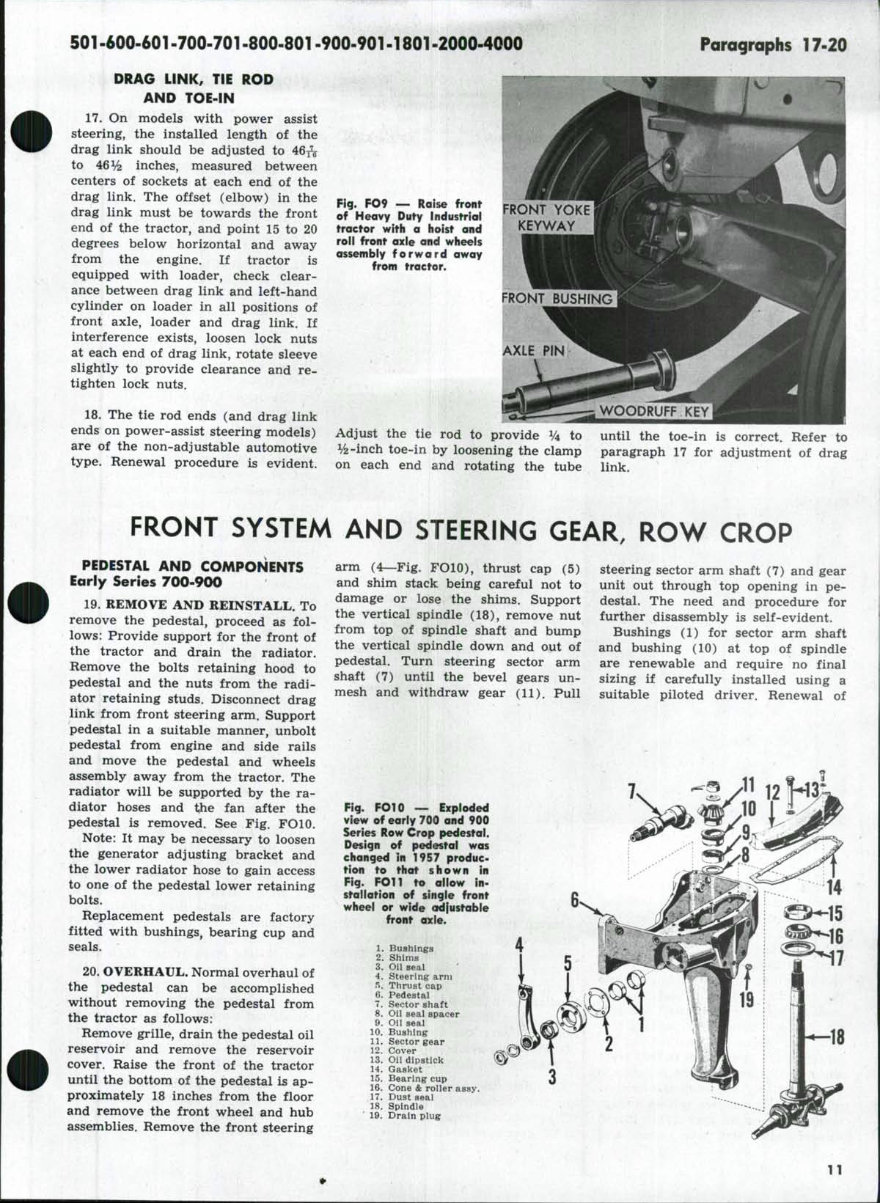

Fig. FO9 — Roise front

of Heavy Duty industrioi

tractor with a hoist and

roil front axie and wheeis

assembly forward away

from tractor.

Adjust the tie rod to provide V4 to

V^-inch toe-in by loosening the clamp

on each end and rotating the tube

until the toe-in is correct. Refer to

paragraph 17 for adjustment of drag

link.

FRONT SYSTEM AND STEERING GEAR, ROW CROP

PEDESTAL AND COMPONENTS

Early Series 700-900

19. REMOVE AND REINSTALL. To

remove the pedestal, proceed as fol-

lows: Provide support for the front of

the tractor and drain the radiator.

Remove the bolts retaining hood to

pedestal and the nuts from the radi-

ator retaining studs. Disconnect drag

link from front steering arm. Support

pedestal in a suitable manner, unbolt

pedestal from engine and side rails

and move the pedestal and wheels

assembly away from the tractor. The

radiator will be supported by the ra-

diator hoses and the fan after the

pedestal is removed. See Fig. FOIO.

Note: It may be necessary to loosen

the generator adjusting bracket and

the lower radiator hose to gain access

to one of the pedestal lower retaining

bolts.

Replacement pedestals are factory

fitted with bushings, bearing cup and

seals.

20. OVERHAUL. Normal overhaul of

the pedestal can be accomplished

without removing the pedestal from

the tractor as follows:

Remove grille, drain the pedestal oil

reservoir and remove the reservoir

cover. Raise the front of the tractor

until the bottom of the pedestal is ap-

proximately 18 inches from the floor

and remove the front wheel and hub

assemblies. Remove the front steering

arm (4—Fig. FOIO), thrust cap (5)

and shim stack being careful not to

damage or lose the shims. Support

the vertical spindle (18), remove nut

from top of spindle shaft and bump

the vertical spindle down and out of

pedestal. Turn steering sector arm

shaft (7) until the bevel gears un-

mesh and withdraw gear (11). Pull

steering sector arm shaft (7) and gear

unit out through top opening in pe-

destal. The need and procedure for

further disassembly is self-evident.

Bushings (1) for sector arm shaft

and bushing (10) at top of spindle

are renewable and require no final

sizing if carefully installed using a

suitable piloted driver. Renewal of

Fig. FOIO — Exploded

view of eoriy 700 and 900

Series Row Crop pedestai.

Design of pedestal was

changed in 1957 produc

tion to thot shown in

Fig. FOT1 to aliow In-

stallation of single front

wheel or wide adjustable

front axle.

1. Bushings

2. Shims

3. Oil seal

4. Steering arm

5. Thrust cap

6. Pedestal

7. Sector shaft

8. Oil seal spacer

9. Oil seal

10. Bushing

11. Sector gear

12. Cover

13. Oil dipstick

14. Gasket

15. Bearing cup

16. Cone & roller assy.

17. Dust seal

18. Spindle

' 19. Drain plug

n

You're Reading a Preview

What's Included?

Fast Download Speeds

Online & Offline Access

Access PDF Contents & Bookmarks

Full Search Facility

Print one or all pages of your manual

$39.99

Viewed 12 Times Today

Loading...

Secure transaction

What's Included?

Fast Download Speeds

Online & Offline Access

Access PDF Contents & Bookmarks

Full Search Facility

Print one or all pages of your manual

$39.99

This repair manual is a comprehensive guide for maintaining and repairing the FORD TRACTOR 900, 901, and 1801 models. It provides step-by-step procedures and detailed illustrations to assist both professional mechanics and DIY enthusiasts in performing necessary maintenance and repairs. The manual includes extensive illustrations and exploded views to aid users in understanding the processes involved. The expert text offers complete information on maintenance, tune-up, and repair, helping users save on repair costs by addressing vehicle issues themselves.

- Front System

- Steering System

- Brake System

- Fuel System

- Transmission

- Hydraulic System

- ...and much more...

Gain instant access to this valuable resource and make secure payments using your credit card or PayPal.