Ford 2310 2600 2610 3600 3610 4100 4110 4600 4610 4600SU 4610SU Tractor Shop Service Repair Manual

What's Included?

Fast Download Speeds

Online & Offline Access

Access PDF Contents & Bookmarks

Full Search Facility

Print one or all pages of your manual

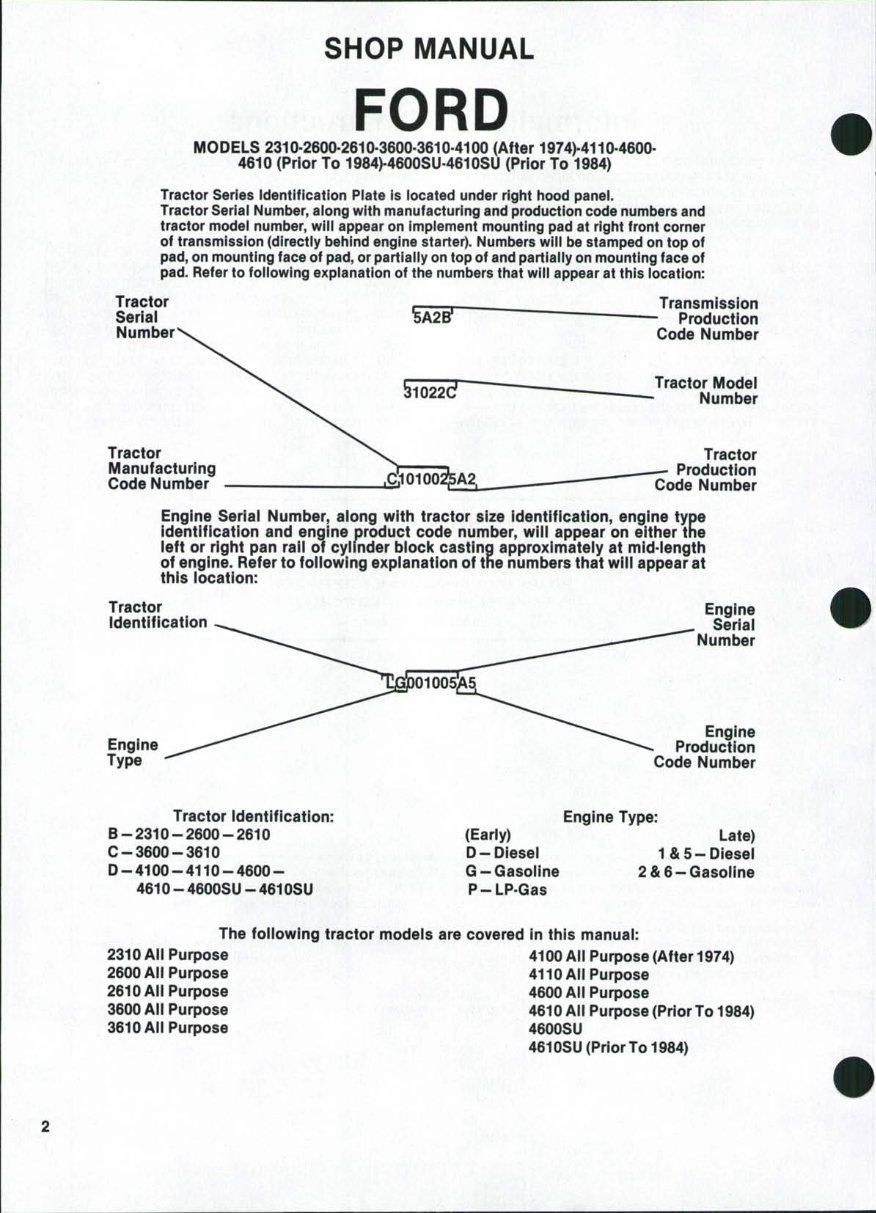

SHOP MANUAL

FORD

MODELS 2310-2600-2610-3600-3610-4100 (After 1974)-4110-4600-

4610 (Prior To 1984)-4e00SU-4610SU (Prior To 1984)

Tractor Series (dentification Piate is iocated under right hood panei.

Tractor Serial Number, aiong with manufacturing and production code numbers and

tractor model number, will appear on implement mounting pad at right front corner

of transmission (directly behind engine starter). Numbers will be stamped on top of

pad, on mounting face of pad, or partially on top of and partially on mounting face of

pad. Refer to foilowing explanation of the numbers that will appear at this location:

Tractor

Serial

Number

Tractor

Manufacturing

Code Number

Transmission

Production

Code Number

Traotor Modei

Number

Tractor

Production

Code Number

Engine Seriai Number, aiong with tractor size identification, engine type

identification and engine product code number, wiii appear on either the

ieft or right pan raii of cyiinder biock casting approximateiy at mid-iength

of engine. Refer to foilowing expianation of the numbers that wiii appear at

this iooation:

Tractor

Identification

Engine

Type

Engine

Seriai

Number

Engine

Production

Code Number

Tractor identification:

B-2310-2600-2610

C-3600-3610

D-4100-4110-4600-

4610-4600SU-4610SU

Engine Type:

(Early) Late)

D-Diesei 1& 5-Diesel

G - Gasoiine 2 & 6 - Gasoiine

P-LPGas

The foliowing traotor modeis are covered in this manuai:

231 OAii Purpose

2600 Aii Purpose

2610 Aii Purpose

3600 Ali Purpose

3610 Aii Purpose

4100 Ali Purpose (After 1974)

4110 Ail Purpose

4600 Aii Purpose

4610 Aii Purpose (Prior To 1984)

4600SU

4610SU (Prior To 1984)

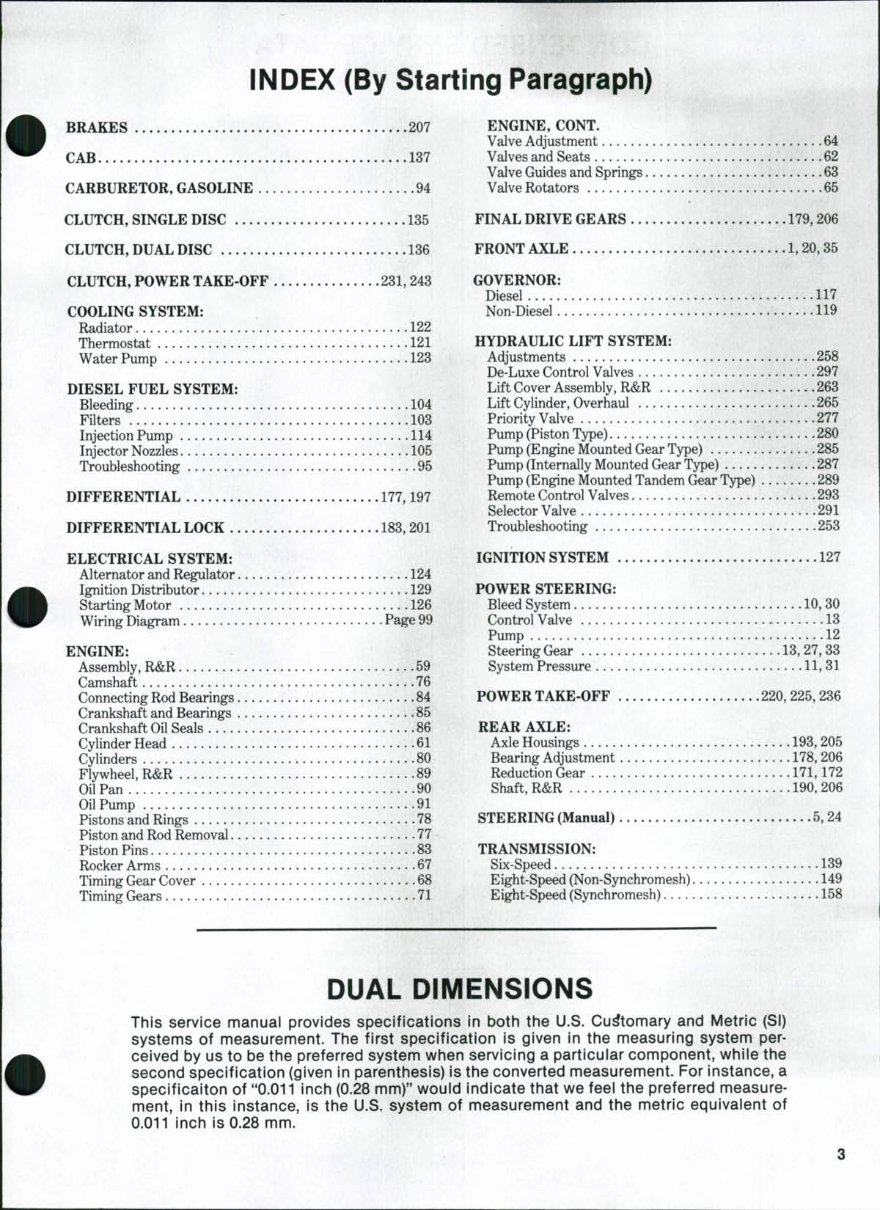

INDEX (By Starting Paragraph)

BRAKES 207

CAB 137

CARBURETOR, GASOLINE 94

CLUTCH, SINGLE DISC 135

CLUTCH, DUAL DISC 136

CLUTCH, POWER TAKE OFF 231,243

COOLING SYSTEM:

Radiator 122

Thermostat 121

Water Pump 123

DIESEL FUEL SYSTEM:

Bleeding 104

Filters 103

Injection Pump 114

Injector Nozzles 105

Troubleshooting 95

DIFFERENTIAL 177,197

DIFFERENTIAL LOCK 183,201

ELECTRICAL SYSTEM:

Alternator and Regulator 124

Ignition Distributor 129

Starting Motor 126

Wiring Diagram Page 99

ENGINE:

Assembly, R&R 59

Camshaft 76

Connecting Rod Bearings 84

Crankshaft and Bearings 85

Crankshaft Oil Seals 86

Cylinder Head 61

Cylinders 80

Flywheel, R&R 89

Oil Pan 90

Oil Pump 91

Pistons and Rings 78

Piston and Rod Removal 77

Piston Pins 83

Rocker Arms 67

Timing Gear Cover 68

Timing Gears 71

ENGINE, CONT.

Valve Adjustment 64

Valves and Seats 62

Valve Guides and Springs 63

Valve Rotators 65

FINAL DRIVE GEARS 179,206

FRONT AXLE 1, 20,35

GOVERNOR:

Diesel 117

Non-Diesel 119

HYDRAULIC LIFT SYSTEM:

Adjustments 258

De-Luxe Control Valves 297

Lift Cover Assembly, R&R ,, 263

Lift Cylinder, Overhaul 265

Priority Valve 277

Pump (Piston Type) 280

Pump (Engine Mounted Gear Type) 285

Pump (Internally Mounted Gear Type) 287

Pump (Engine Mounted Tandem Gear Type) 289

Remote Control Valves .293

Selector Valve 291

Troubleshooting 253

IGNITION SYSTEM .127

POWER STEERING:

Bleed System 10,30

Control Valve 13

Pump 12

SteeringGear 13,27,33

System Pressure 11,31

POWER TAKE-OFF 220,225,236

REAR AXLE:

Axle Housings 193,205

Bearing Adjustment 178, 206

Reduction Gear 171,172

Shaft, R&R 190, 206

STEERING (Manual) 5,24

TRANSMISSION:

Six-Speed 139

Eight-Speed (Non-Synchromesh) 149

Eight-Speed (Synchromesh) 158

DUAL DIMENSIONS

This service manuai provides specifications in both the U.S. Customary and Metric (SI)

systems of measurement. The first specification is given in the measuring system per-

ceived by us to be the preferred system when servicing a particuiar component, whiie the

second specification (given in parenthesis) is the converted measurement. For instance, a

specificaiton of "0.011 inch (0.28 mm)" would indicate that we feei the preferred measure-

ment, in this instance, is the U.S. system of measurement and the metric equivalent of

0.011 inch is 0.28 mm.

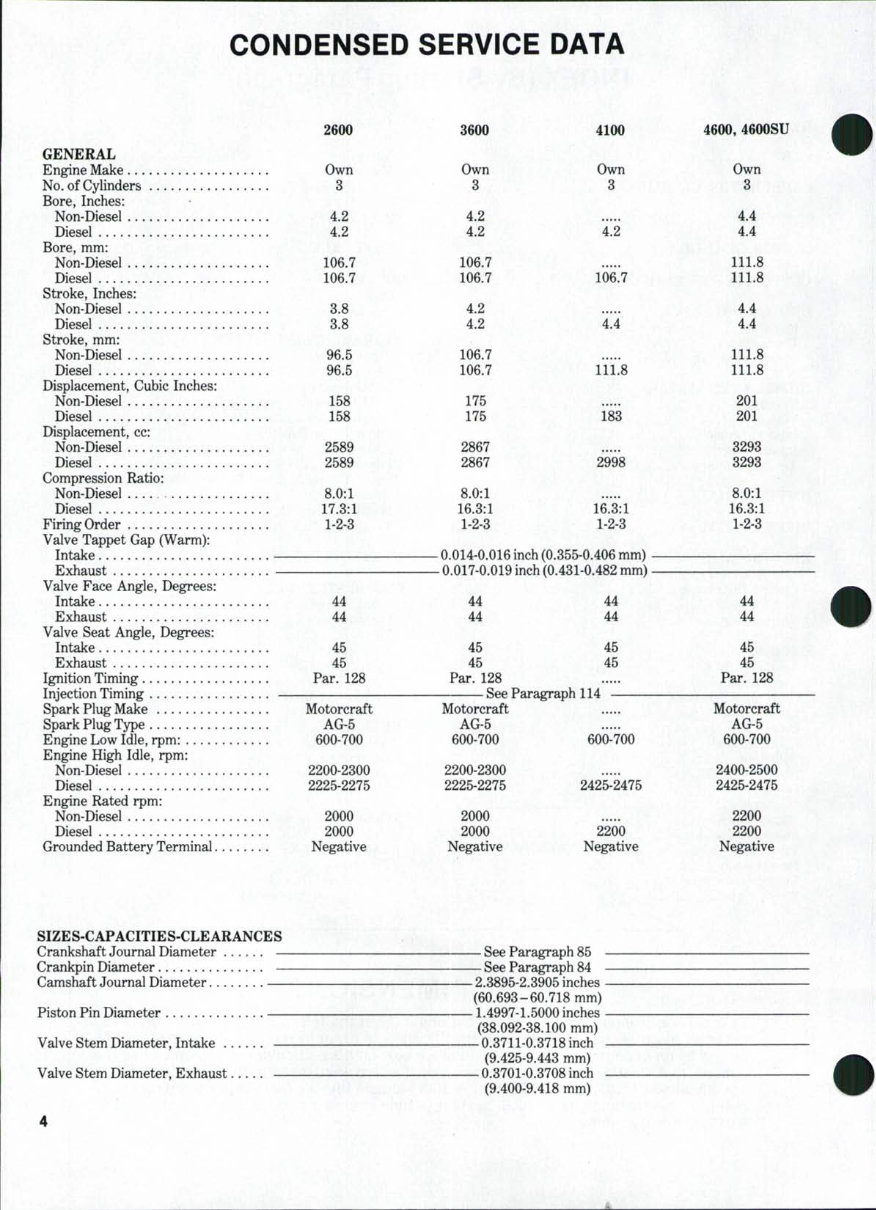

CONDENSED SERVICE DATA

GENERAL

Engine Make

No. of Cylinders

Bore, Inches:

Non-Diesel

Diesel

Bore, mm:

Non-Diesel

Diesel

Stroke, Inches:

Non-Diesel

Diesel

Stroke, mm:

Non-Diesel

Diesel

Displacement, Cubic Inches:

Non-Diesel

Diesel . . . . .

Displacement, cc:

Non-Diesel ....

Diesel

Compression Ratio:

Non-Diesel

Diesel

Firing Order

Valve Tappet Gap (Warm):

Intake

Valve Face Angle, Degrees:

Intake

Exhaust

Valve Seat Angle, Degrees:

Intake

Exhaust

Ignition Timing

SDark Pluer Make

Soark Pluff Tvpe .

Engine Low Idle rpm*

Engine High Idle, rpm:

Non-Diesel

Diesel

Engine Rated rpm:

Non-Diesel

Diesel ..

Grounded Battery Terminal

2600

Own

3

4.2

4.2

106.7

106.7

3.8

3.8

96.5

96.5

158

158

2589

2589

8.0:1

17.3:1

1-2-3

44

44

45

45

Par. 128

Motorcraft

AG-5

600-700

2200-2300

2225-2275

2000

2000

Negative

3600

Own

3

4.2

4.2

106.7

106.7

4.2

4.2

106.7

106.7

175

175

2867

2867

8.0:1

16.3:1

4100

Own

3 \'-'',:

4.2

106.7

4.4

111.8

183

2998

16.3:1

1-2-3 1-2-3

0 014-0 016 inch (0 355-0 406 mm)

0 017-0 019 inch ^^ A9.^ M A9,9. mm^

44

44

45

45

Par. 128

Motorcraft

AG-5

600-700

2200-2300

2225-2275

2000

2000

Negative

44

44

45

45

TTflTlh 11^

600-700

2425-2475

2200

Negative

4600, 4600SU

Own

3

4.4

4.4

111.8

111.8

4.4

4.4

111.8

111.8

201

201

3293

3293

8.0:1

16.3:1

1-2-3

44

44

45

45

Par. 128

Motorcraft

AG-5

600-700

2400-2500

2425-2475

2200

2200

Negative

SIZES-CAPACITIES-CLEARANCES

Crankshaft Journal Diameter —

Crankpin Diameter —

Camshaft Journal Diameter —

Piston Pin Diameter —

Valve Stem Diameter, Intake —

Valve Stem Diameter, Exhaust —

— See Paragraph 85 -

— See Paragraph 84 -

-2.3895-2.3905inches-

(60.693-60.718 mm)

-1.4997-1.5000 inches-

(38.092-38.100 mm)

-0.3711-0.3718 inch -

(9.425-9.443 mm)

-0.3701-0.3708 inch -

(9.400-9.418 mm)

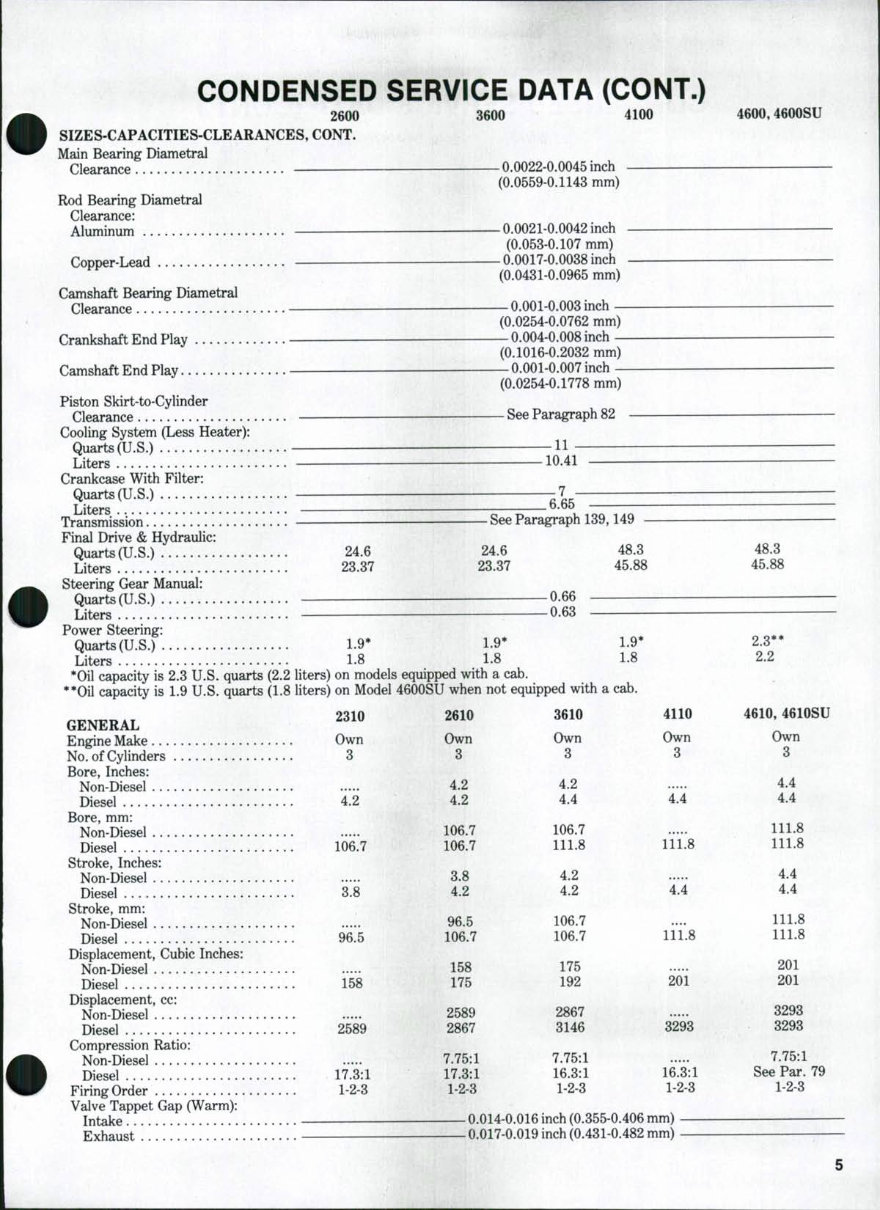

CONDENSED SERVICE DATA (CONT.)

2600 3600 4100 4600,4600SU

SIZES-CAPACITIES-CLEARANCES, CONT.

Main Bearing Diametral

Clearance — 0.0022-0.0045 inch

(0.0559-0.1143 mm)

Rod Bearing Diametral w

Clearance:

Aluminum 0.0021-0.0042 inch

(0.053-0.107 mm)

Copper-Lead 0.0017-0.0038 inch

(0.0431-0.0965 mm)

Camshaft Bearing Diametral

Clearance 0.001-0.003 inch

(0.0254-0.0762 mm)

Crankshaft End Play 0.004-0.008 inch •

(0.1016-0.2032 mm)

Camshaft End Play 0.001-0.007 inch

(0.0254-0.1778 mm)

Piston Skirt-to-Cylinder

Clearance See Paragraph 82

Cooling System (Less Heater):

Quarts(U.S.) H —

Liters 10.41

Crankcase With Filter:

Quarts(U.S.) 7

Liters —- 6.65 — —

Transmission!!!!!!!!!!!!!!!!!!!! See Paragraph 139,149

Final Drive & Hydraulic:

Quarts(U.S.) 24.6 24.6 48.3 48.3

Liters 23.37 23.37 45.88 45.88

Steering Gear Manual:

Quarts (U.S.) —0.66

Liters. 0.63

Power Steering:

Quarts(U.S.) 1.9* 1.9* 1.9* 2.3**

Liters ...... 1.8 1.8 1.8 2.2

*Oil capacity is 2.3 U.S. quarts (2.2 liters) on models equipped with a cab.

**Oil capacity is 1.9 U.S. quarts (1.8 liters) on Model 4600SU when not equipped with a cab.

2310 2610 3610 4110 4610,4610SU

GENERAL

Engine Make Own Own Own Own Own

No. of Cylinders 3 3 3 3 3

Bore, Inches:

Non-Diesel... 4.2 4.2 ..... 4.4

Diesel 4.2 4.2 4.4 4.4 4.4

Bore, mm:

Non-Diesel 106.7 106.7 111.8

Diesel 106.7 106.7 111.8 111.8 111.8

Stroke, Inches:

Non-Diesel 3.8 4.2 4.4

Diesel 3.8 4.2 4.2 4.4 4.4

Stroke, mm:

Non-Diesel ..... 96.5 106.7 .... 111.8

Diesel 96.5 106.7 106.7 111.8 111.8

Displacement, Cubic Inches:

Non-Diesel 158 175 201

Diesel 158 175 192 201 201

Displacement, cc:

Non-Diesel 2589 2867 3293

Diesel 2589 2867 3146 3293 3293

Compression Ratio:

Non-Diesel 7.75:1 7.75:1 7.75:1

Diesel 17.3:1 17.3:1 16.3:1 16.3:1 See Par. 79

Firing Order 1-2-3 1-2-3 1-2-3 1-2-3 1-2-3

Valve Tappet Gap (Warm):

Intake 0.014-0.016 inch (0.355-0.406 mm)

Exhaust 0.017-0.019 inch (0.431-0.482 mm) —

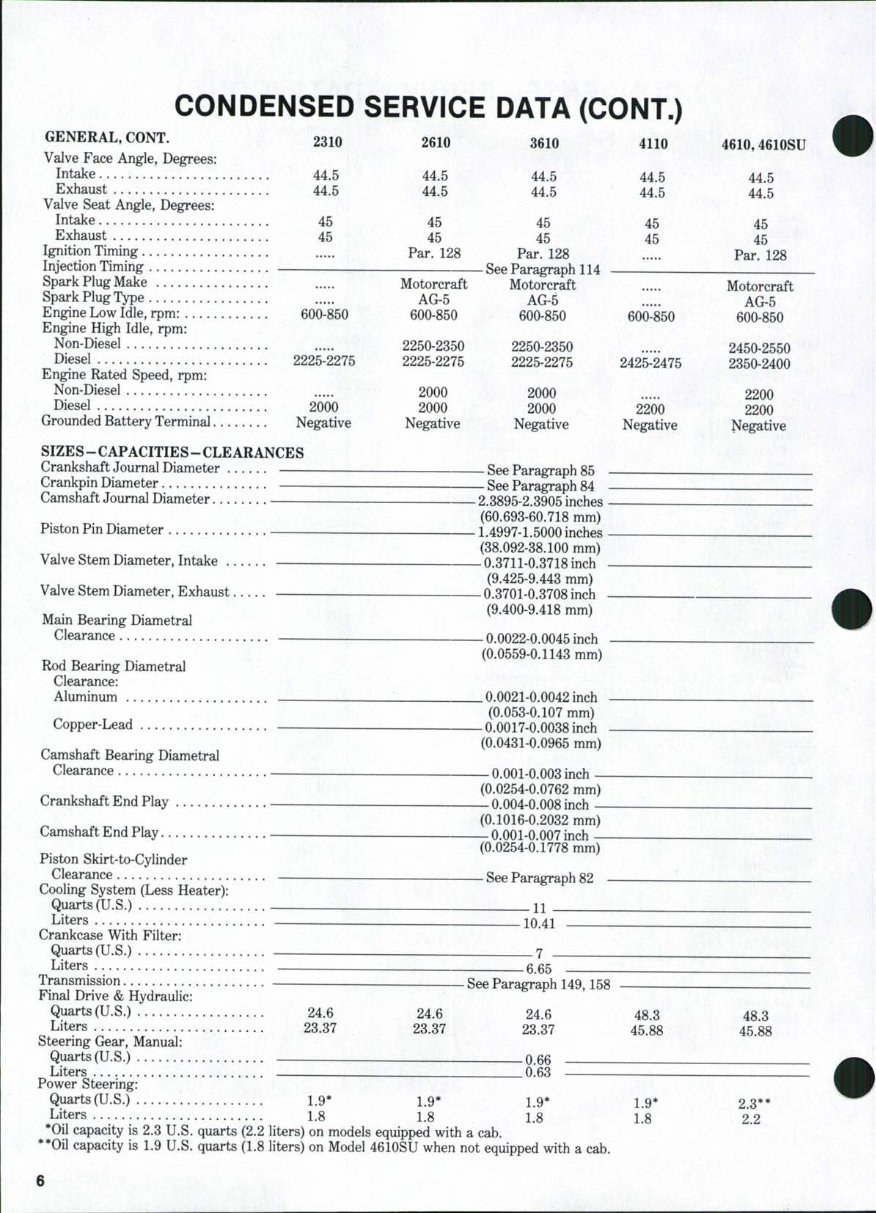

CONDENSED SERVICE DATA (CONT.)

GENERAL, CONT. 2310 2610 3610

Valve Face Angle, Degrees:

Intake 44.5 44.5 44.5

Exhaust 44.5 44.5 44.5

Valve Seat Angle, Degrees:

Intake 45 45 45

Exhaust 45 45 45

Ignition Timing Par. 128 Par. 128

Injection Timing See Paragraph 114

Spark Plug Make Motorcraft Motorcraft

Spark PlugType AG-5 AG-5

Engine Low Idle, rpm: 600-850 600-850 600-850

Engine High Idle, rpm:

Non-Diesel 2250-2350 2250-2350

Diesel 2225-2275 2225-2275 2225-2275

Engine Rated Speed, rpm:

Non-Diesel 2000 2000

Diesel 2000 2000 2000

Grounded Battery Terminal Negative Negative Negative

SIZES - CAPACITIES - CLEARANCES

Crankshaft Journal Diameter See Paragraph 85

Crankpin Diameter See Paragraph 84

Camshaft Journal Diameter — 2.3895-2.3905 inches

(60.693-60.718 mm)

Piston Pin Diameter —_ 1.4997-1.5000 inches

(38.092-38.100 mm)

Valve Stem Diameter, Intake ~ 0.3711-0.3718 inch

(9.425-9.443 mm)

Valve Stem Diameter, Exhaust 0.3701-0.3708 inch

, , . „ . (9.400-9.418 mm)

Mam Bearmg Diametral '

Clearance — 0.0022-0.0045 inch

(0.0559-0.1143 mm)

Rod Bearing Diametral

Clearance:

Aluminum . 0.0021-0.0042 inch

(0.053-0.107 mm)

Copper-Lead 0.0017-0.0038 inch

(0.0431-0.0965 mm)

Camshaft Bearing Diametral

Clearance 0.001-0.003 inch

(0.0254-0.0762 mm)

Crankshaft End Play _ 0.004-0.008 inch

(0.1016-0.2032 mm)

Camshaft End Play _ 0.001-0.007 inch

(0.0254-0.1778 mm)

Piston Skirt-to-Cylinder

Clearance _ See Paragraph 82

Cooling System (Less Heater):

Quarts (U.S.) H

Liters - JQ 41

Crankcase With Filter:

Quarts (U.S.) . 7

Liters-. _ 6.65

Transmission See Paragraph 149,158

Final Drive & Hydraulic:

Quarts(U.S.) 24.6 24.6 24.6 48 3

Liters 23.37 23.37 23.37 45.88

Steering Gear, Manual:

Quarts(U.S.) 0.66

Liters . 0.63

Power Steering:

Quarts (U.S.) 1.9* 1.9* 1.9* 1.9*

Liters 1.8 1.8 1.8 1.8

*Oil capacity is 2.3 U.S. quarts (2.2 liters) on models equipped with a cab.

**Oil capacity is 1.9 U.S. quarts (1.8 liters) on Model 4610SU when not equipped with a cab.

4110

44.5

\ 44.5

45

45

600-850

2425-2475

2200

Negative

4610,4610SU

44.5

44.5

45

45

Par. 128

Motorcraft

AG-5

600-850

2450-2550

2350-2400

2200

2200

Negative

48.3

45.88

2.3**

2.2

6

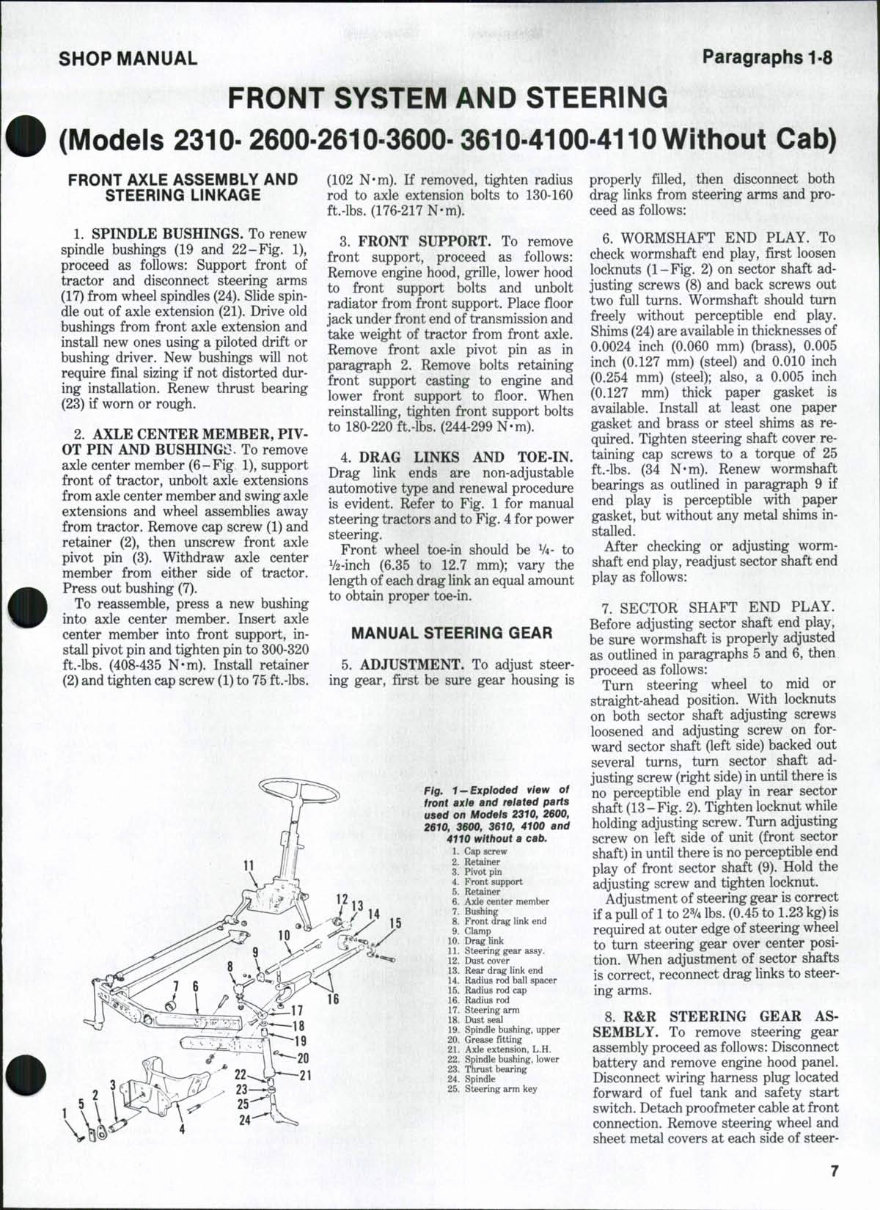

SHOP MANUAL Paragraphs 1-8

FRONT SYSTEM AND STEERING

(Models 2310-2600-2610-3600-3610-4100-4110 Without Cab)

FRONT AXLE ASSEMBLY AND

STEERING LINKAGE

1. SPINDLE BUSHINGS. To renew

spindle bushings (19 and 22-Fig. 1),

proceed as follows: Support front of

tractor and disconnect steering arms

(17) from wheel spindles (24). Slide spin-

dle out of axle extension (21). Drive old

bushings from front axle extension and

install new ones using a piloted drift or

bushing driver. New bushings will not

require final sizing if not distorted dur-

ing installation. Renew thrust bearing

(23) if worn or rough.

2. AXLE CENTER MEMBER, PIV-

OT PIN AND BUSHINGS. To remove

axle center member (6-Fig 1), support

front of tractor, unbolt axle extensions

from axle center member and swing axle

extensions and wheel assemblies away

from tractor. Remove cap screw (1) and

retainer (2), then unscrew front axle

pivot pin (3). Withdraw axle center

member from either side of tractor.

Press out bushing (7).

To reassemble, press a new bushing

into axle center member. Insert axle

center member into front support, in-

stall pivot pin and tighten pin to 300-320

ft.-lbs. (408-435 N-m). Install retainer

(2) and tighten cap screw (1) to 75 ft.-lbs.

(102 N'm). If removed, tighten radius

rod to axle extension bolts to 130-160

ft.-lbs. (176-217 N-m).

3. FRONT SUPPORT. To remove

front support, proceed as follows:

Remove engine hood, grille, lower hood

to front support bolts and unbolt

radiator from front support. Place floor

jack under front end of transmission and

take weight of tractor from front axle.

Remove front axle pivot pin as in

paragraph 2. Remove bolts retaining

front support casting to engine and

lower front support to floor. When

reinstalling, tighten front support bolts

to 180-220 ft.-lbs. (244-299 N-m).

4. DRAG LINKS AND TOE-IN.

Drag link ends are non-adjustable

automotive type and renewal procedure

is evident. Refer to Fig. 1 for manual

steering tractors and to Fig. 4 for power

steering.

Front wheel toe-in should be V4- to

V2-inch (6.35 to 12.7 mm); vary the

length of each drag link an equal amount

to obtain proper toe-in.

MANUAL STEERING GEAR

5. ADJUSTMENT. To adjust steer-

ing gear, first be sure gear housing is

Fig. 1-Exploded view of

front axte and related parts

used on Models 2310, 2600,

2610, 3600, 3610, 4100 and

4110 without a cab.

1. Cap screw

2. Retainer

3. Pivot pin

4. Front support

5. Retainer

6. Axle center member

7. Bushing

8. Front drag link end

9. Clamp

10. Drag link

11. Steering gear assy.

12. Dust cover

13. Rear drag link end

14. Radius rod ball spacer

15. Radius rod cap

16. Radius rod

17. Steering arm

18. Dust seal

19. Spindle bushing, upper

20. Grease fitting

21. Axle extension, L.H.

22. Spindle bushing, lower

23. Thrust bearing

24. Spindle

25. Steering arm key

properly filled, then disconnect both

drag links from steering arms and pro-

ceed as follows:

6. WORMSHAFT END PLAY. To

check wormshaft end play, first loosen

locknuts (1-Fig. 2) on sector shaft ad-

justing screws (8) and back screws out

two full turns. Wormshaft should turn

freely without perceptible end play.

Shims (24) are available in thicknesses of

0.0024 inch (0.060 mm) (brass), 0.005

inch (0.127 mm) (steel) and 0.010 inch

(0.254 mm) (steel); also, a 0.005 inch

(0.127 mm) thick paper gasket is

available. Install at least one paper

gasket and brass or steel shims as re-

quired. Tighten steering shaft cover re-

taining cap screws to a torque of 25

ft.-lbs. (34 N'm). Renew wormshaft

bearings as outlined in paragraph 9 if

end play is perceptible with paper

gasket, but without any metal shims in-

stalled.

After checking or adjusting worm-

shaft end play, readjust sector shaft end

play as follows:

7. SECTOR SHAFT END PLAY.

Before adjusting sector shaft end play,

be sure wormshaft is properly adjusted

as outlined in paragraphs 5 and 6, then

proceed as follows:

Turn steering wheel to mid or

straight-ahead position. With locknuts

on both sector shaft adjusting screws

loosened and adjusting screw on for-

ward sector shaft (left side) backed out

several turns, turn sector shaft ad-

justing screw (right side) in until there is

no perceptible end play in rear sector

shaft (13-Fig. 2). Tighten locknut while

holding adjusting screw. Turn adjusting

screw on left side of unit (front sector

shaft) in until there is no perceptible end

play of front sector shaft (9). Hold the

adjusting screw and tighten locknut.

Adjustment of steering gear is correct

if a pull of 1 to 2% lbs. (0.45 to 1.23 kg) is

required at outer edge of steering wheel

to turn steering gear over center posi-

tion. When adjustment of sector shafts

is correct, reconnect drag links to steer-

ing arms.

8. R&R STEERING GEAR AS-

SEMBLY. To remove steering gear

assembly proceed as follows: Disconnect

battery and remove engine hood panel.

Disconnect wiring harness plug located

forward of fuel tank and safety start

switch. Detach proofmeter cable at front

connection. Remove steering wheel and

sheet metal covers at each side of steer-

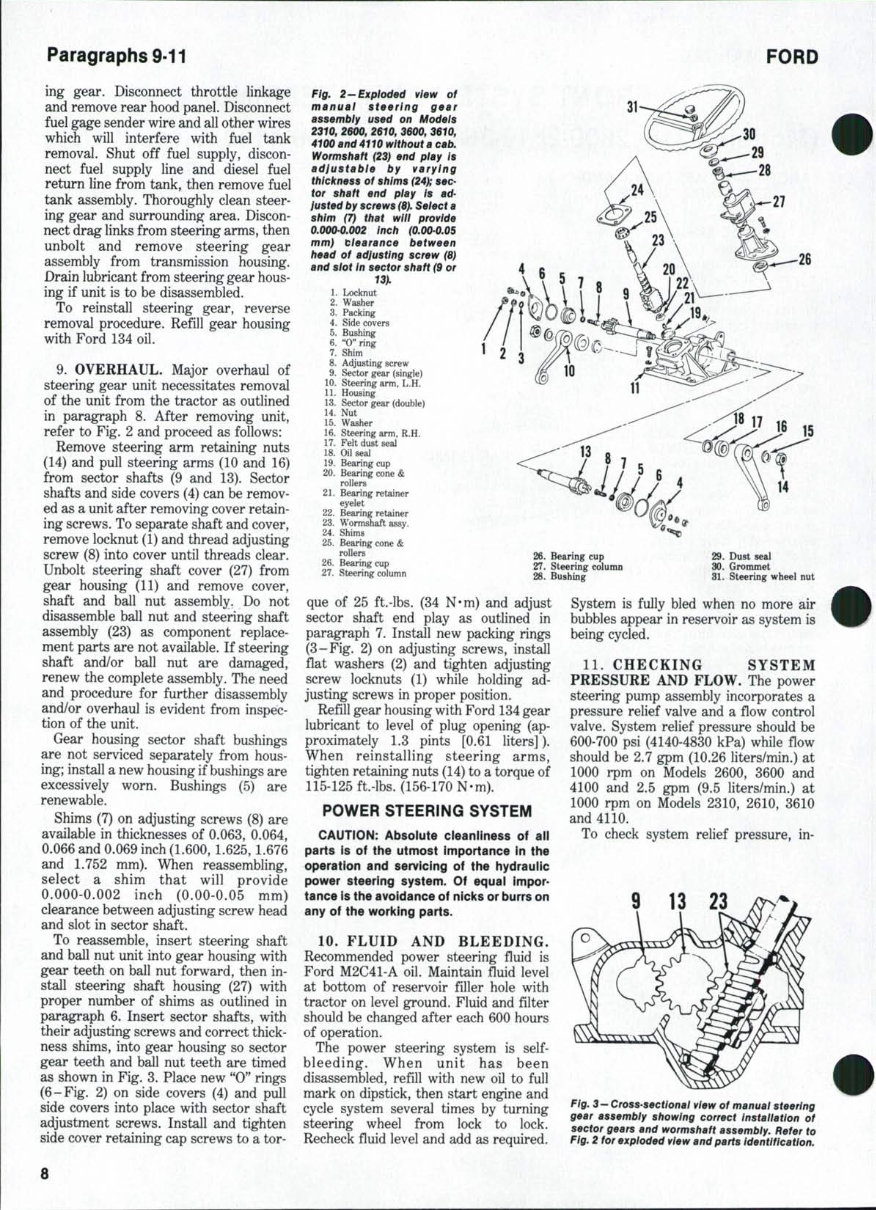

Paragraphs 9-11 FORD

ing gear. Disconnect throttle linkage

and remove rear hood panel. Disconnect

fuel gage sender wire and all other wires

which will interfere with fuel tank

removal. Shut off fuel supply, discon-

nect fuel supply line and diesel fuel

return line from tank, then remove fuel

tank assembly. Thoroughly clean steer-

ing gear and surrounding area. Discon-

nect drag links from steering arms, then

unbolt and remove steering gear

assembly from transmission housing.

Drain lubricant from steering gear hous-

ing if unit is to be disassembled.

To reinstall steering gear, reverse

removal procedure. Refill gear housing

with Ford 134 oil.

9. OVERHAUL. Major overhaul of

steering gear unit necessitates removal

of the unit from the tractor as outlined

in paragraph 8. After removing unit,

refer to Fig. 2 and proceed as follows:

Remove steering arm retaining nuts

(14) and pull steering arms (10 and 16)

from sector shafts (9 and 13). Sector

shafts and side covers (4) can be remov-

ed as a unit after removing cover retain-

ing screws. To separate shaft and cover,

remove locknut (1) and thread adjusting

screw (8) into cover until threads clear.

Unbolt steering shaft cover (27) from

gear housing (11) and remove cover,

shaft and ball nut assembly. Do not

disassemble ball nut and steering shaft

assembly (23) as component replace-

ment parts are not available. If steering

shaft and/or ball nut are damaged,

renew the complete assembly. The need

and procedure for further disassembly

and/or overhaul is evident from inspec-

tion of the unit.

Gear housing sector shaft bushings

are not serviced separately from hous-

ing; install a new housing if bushings are

excessively worn. Bushings (5) are

renewable.

Shims (7) on adjusting screws (8) are

available in thicknesses of 0.063, 0.064,

0.066 and 0.069 inch (1.600,1.625,1.676

and 1.752 mm). When reassembling,

select a shim that will provide

0.000-0.002 inch (0.00-0.05 mm)

clearance between adjusting screw head

and slot in sector shaft.

To reassemble, insert steering shaft

and ball nut unit into gear housing with

gear teeth on ball nut forward, then in-

stall steering shaft housing (27) with

proper number of shims as outlined in

paragraph 6. Insert sector shafts, with

their adjusting screws and correct thick-

ness shims, into gear housing so sector

gear teeth and ball nut teeth are timed

as shown in Fig. 3. Place new "0" rings

(6-Fig. 2) on side covers (4) and pull

side covers into place with sector shaft

adjustment screws. Install and tighten

side cover retaining cap screws to a tor-

Fig. 2-Exploded view of

manual steering gear

assembly used on Models

2310, 2600, 2610, 3600, 3610,

4100 and 4110 without a cab,

Wormshaft (23) end play Is

adjustable by varying

thickness of shims (24^ sec-

tor shaft end play Is ad-

justed by screws (8), Select a

shim (7) that will provide

0.0000.002 inch (0.000.05

mm) clearance between

head of adjusting screw (8)

and slot In sector shaft (9 or

1. Locknut - r

2. Washer

3. Packing

4. Side covers

5. Bushing

6. "O"ring

7. Shim

8. Adjusting screw

9. Sector gear (single)

10. Steering arm, L.H.

11. Housing

13. Sector gear (double)

14. Nut

15. Washer

16. Steering arm, R.H.

17. Felt dust seal

18. Oil sea]

19. Bearing cup

20. Bearing cone &

rollers

21. Bearing retainer

eyelet

22. Bearing retainer

23. Wormshaft assy.

24. Shims

25. Bearing cone &

rollers

26. Bearing cup

27. Steering column

26. Bearing cup

27. Steering column

28. Bushing

29. Dust seal

30. Grommet

31. Steering wheel nut

que of 25 ft.-lbs. (34 N*m) and adjust

sector shaft end play as outlined in

paragraph 7. Install new packing rings

(3-Fig. 2) on adjusting screws, install

flat washers (2) and tighten adjusting

screw locknuts (1) while holding ad-

justing screws in proper position.

Refill gear housing with Ford 134 gear

lubricant to level of plug opening (ap-

proximately 1.3 pints [0.61 liters]).

When reinstalling steering arms,

tighten retaining nuts (14) to a torque of

115-125 ft.-lbs. (156-170 N-m).

POWER STEERING SYSTEM

CAUTION: Absolute cleanliness of all

parts Is of the utmost importance in the

operation and servicing of the hydraulic

power steering system. Of equal impor-

tance is the avoidance of nicks or burrs on

any of the working parts.

10. FLUID AND BLEEDING.

Recommended power steering fluid is

Ford M2C41-A oil. Maintain fluid level

at bottom of reservoir filler hole with

tractor on level ground. Fluid and filter

should be changed after each 600 hours

of operation.

The power steering system is self-

bleeding. When unit has been

disassembled, refill with new oil to full

mark on dipstick, then start engine and

cycle system several times by turning

steering wheel from lock to lock.

Recheck fiuid level and add as required.

System is fully bled when no more air

bubbles appear in reservoir as system is

being cycled.

11. CHECKING SYSTEM

PRESSURE AND FLOW. The power

steering pump assembly incorporates a

pressure relief valve and a fiow control

valve. System relief pressure should be

600-700 psi (4140-4830 kPa) while fiow

should be 2.7 gpm (10.26 liters/min.) at

1000 rpm on Models 2600, 3600 and

4100 and 2.5 gpm (9.5 liters/min.) at

1000 rpm on Models 2310, 2610, 3610

and 4110.

To check system relief pressure, in-

9 13 23

Fig. 3- Cross-sectlonai view of manual steering

gear assembly showing correct Installation of

sector gears and wormshaft assembly. Refer to

Fig. 2 for exploded view and parts Identification.

8

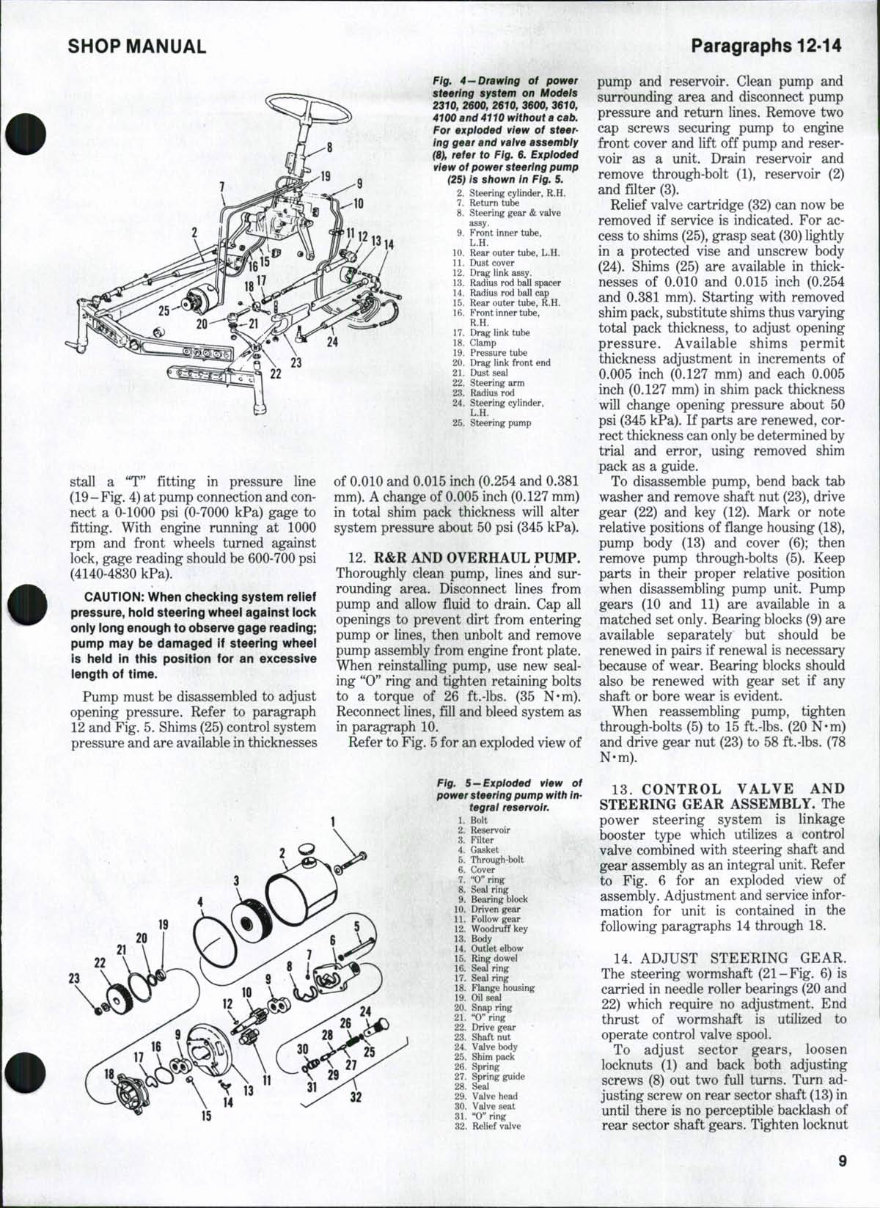

SHOP MANUAL Paragraphs 12-14

stall a **T" fitting in pressure line

(19 - Fig. 4) at pump connection and con-

nect a 0-1000 psi (0-7000 kPa) gage to

fitting. With engine running at 1000

rpm and front wheels turned against

lock, gage reading should be 600-700 psi

(4140-4830 kPa).

CAUTION: When checking system relief

pressure, hold steering wheei against iock

oniy iong enough to observe gage reading;

pump may be damaged if steering wheei

is held in this position for an excessive

length of time.

Pump must be disassembled to adjust

opening pressure. Refer to paragraph

12 and Fig. 5. Shims (25) control system

pressure and are available in thicknesses

Fig. 4 —Drawing of power

steering system on Models

2310, 2600, 2610, 3600, 3610,

4100 and 4110 without a cab.

For exploded view of steer-

ing gear and vaive assembly

(8), refer to Fig. 6. Exploded

view of power steering pump

(25> /5 shown in Fig. 5.

2. Steering cylinder, R.H.

7. Return tube

8. Steering gear & valve

assy.

9. Front inner tube,

L.H.

10. Rear outer tube, L.H.

11. Dust cover

12. Drag link assy.

13. Radius rod bEill spacer

14. Radius rod ball cap

15. Rear outer tube, R.H.

16. Front inner tube,

R.H.

17. Drag link tube

18. Clamp

19. Pressure tube

20. Drag link front end

21. Dust seal

22. Steering arm

23. Radius rod

24. Steering cylinder,

L.H.

25. Steering pump

of 0.010 and 0.015 inch (0.254 and 0.381

mm). A change of 0.005 inch (0.127 mm)

in total shim pack thickness will alter

system pressure about 50 psi (345 kPa).

12. R&R AND OVERHAUL PUMP.

Thoroughly clean pump, lines and sur-

rounding area. Disconnect lines from

pump and allow fiuid to drain. Cap all

openings to prevent dirt from entering

pump or lines, then unbolt and remove

pump assembly from engine front plate.

When reinstalling pump, use new seal-

ing "0" ring and tighten retaining bolts

to a torque of 26 ft.-lbs. (35 N-m).

Reconnect lines, fill and bleed system as

in paragraph 10.

Refer to Fig. 5 for an exploded view of

Fig. 5 — Exploded view of

power steering pump with in-

tegral reservoir.

1. Bolt

2. Reservoir

3. Filter

4. Gasket

5. Through-bolt

6. Cover

7. "0" ring

8. Seal ring

9. Bearing block

10. Driven gear

11. Follow gear

12. Woodruff key

13. Body

14. Outlet elbow

15. Ring dowel

16. Seal ring

17. Seal ring

18. Flange housing

19. Oil seal

20. Snap ring

21. "O"ring

22. Drive gear

23. Shaft nut

24. Valve body

25. Shim pack

26. Spring

27. Spring guide

28. Seal

29. Valve head

30. Valve seat

31. "Oaring

32. Relief valve

32

pump and reservoir. Clean pump and

surrounding area and disconnect pump

pressure and return lines. Remove two

cap screws securing pump to engine

front cover and lift off pump and reser-

voir as a unit. Drain reservoir and

remove through-bolt (1), reservoir (2)

and filter (3).

Relief valve cartridge (32) can now be

removed if service is indicated. For ac-

cess to shims (25), grasp seat (30) lightly

in a protected vise and unscrew body

(24). Shims (25) are available in thick-

nesses of 0.010 and 0.015 inch (0.254

and 0.381 mm). Starting with removed

shim pack, substitute shims thus varying

total pack thickness, to adjust opening

pressure. Available shims permit

thickness adjustment in increments of

0.005 inch (0.127 mm) and each 0.005

inch (0.127 mm) in shim pack thickness

will change opening pressure about 50

psi (345 kPa). If parts are renewed, cor-

rect thickness can only be determined by

trial and error, using removed shim

pack as a guide.

To disassemble pump, bend back tab

washer and remove shaft nut (23), drive

gear (22) and key (12). Mark or note

relative positions of fiange housing (18),

pump body (13) and cover (6); then

remove pump through-bolts (5). Keep

parts in their proper relative position

when disassembling pump unit. Pump

gears (10 and 11) are available in a

matched set only. Bearing blocks (9) are

available separately but should be

renewed in pairs if renewal is necessary

because of wear. Bearing blocks should

also be renewed with gear set if any

shaft or bore wear is evident.

When reassembling pump, tighten

through-bolts (5) to 15 ft.-lbs. (20 N-m)

and drive gear nut (23) to 58 ft.-lbs. (78

N-m).

13. CONTROL VALVE AND

STEERING GEAR ASSEMBLY. The

power steering system is linkage

booster type which utilizes a control

valve combined with steering shaft and

gear assembly as an integral unit. Refer

to Fig. 6 for an exploded view of

assembly. Adjustment and service infor-

mation for unit is contained in the

following paragraphs 14 through 18.

14. ADJUST STEERING GEAR.

The steering wormshaft (21-Fig. 6) is

carried in needle roller bearings (20 and

22) which require no adjustment. End

thrust of wormshaft is utilized to

operate control valve spool.

To adjust sector gears, loosen

locknuts (1) and back both adjusting

screws (8) out two full turns. Turn ad-

justing screw on rear sector shaft (13) in

until there is no perceptible backlash of

rear sector shaft gears. Tighten locknut

9

Paragraphs 15-17

while holding adjusting screw in this

position. With rear sector shaft ad-

justed, turn adjusting screw on front

sector shaft (9) in until there is no

perceptible backlash of front sector

shaft gears, then tighten locknut while

holding adjusting screw in this position.

15. R&R STEERING GEAR AND

CONTROL VALVE ASSEMBLY.

Remove steering gear by disconnecting

oil lines and using procedure outlined in

paragraph 8.

To reinstall steering gear assembly,

reverse removal procedure. Refill and

bleed power steering system as outlined

in paragraph 10. Refill steering gear

with Ford 134 oil.

16. RENEW CONTROL VALVE

UPPER SEAL. If power steering fiuid

leaks from steering column housing, the

control valve upper seal (40-Fig. 6) is

leaking and can be renewed as follows:

Follow general procedures outlined in

paragraph 15, except that fuel lines do

not need to be disconnected nor does

fuel tank need to be removed.

Thoroughly clean steering gear and con-

trol valve assembly. Remove cap screws

retaining steering column (41) to steer-

ing gear and remove steering column.

Remove seal from lower end of steering

column with a suitable puller. Drive

bushing (42) from upper end of steering

column with a 1-inch (25.4 mm) diameter

dowel.

n

'

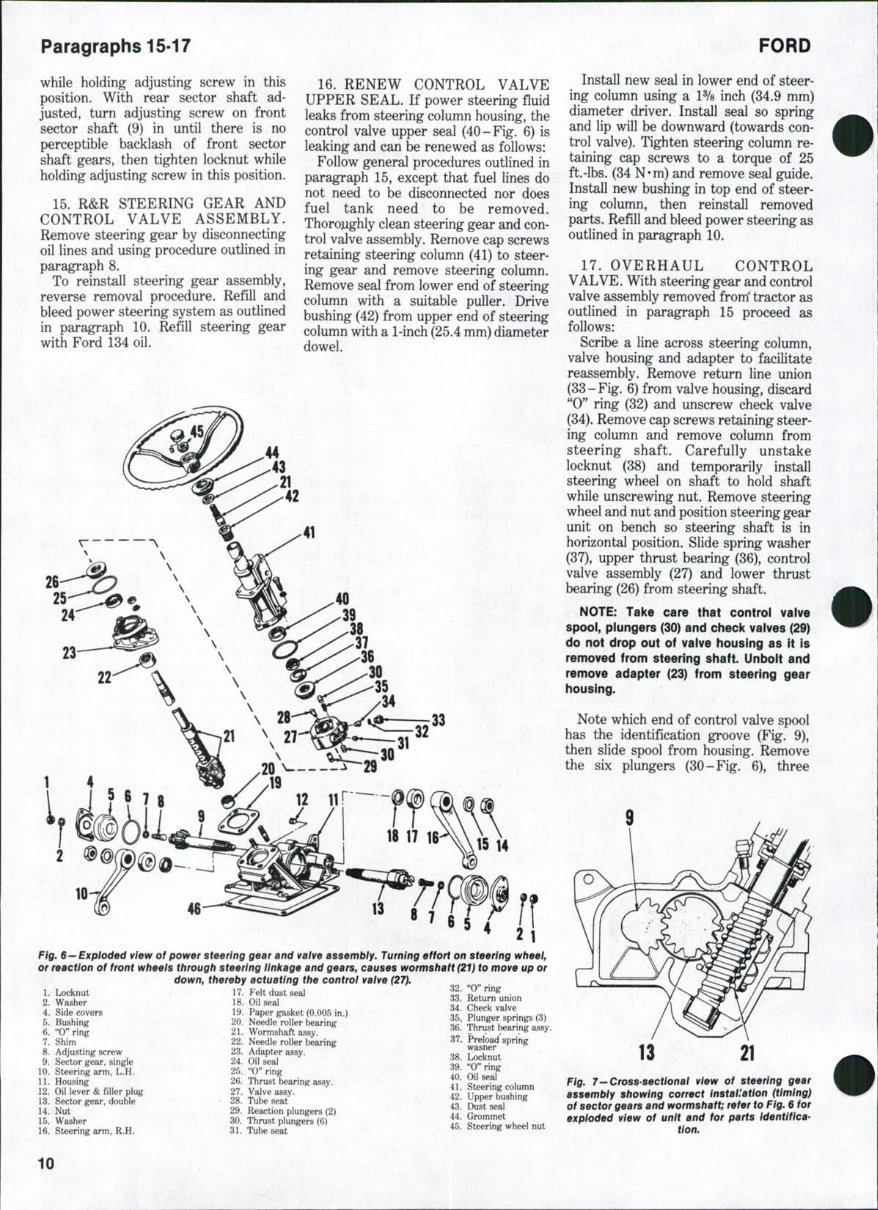

Fig. 6 — Exploded view of power steering gear and vaive assembiy. Turning effort on steering wheel,

or reaction of front wheels through steering linkage and gears, causes wormshaft (21) to move up or

down, thereby actuating the control valve (27).

1. Locknut 17. Felt dust seal

2. Washer 18. Oil seal ^^•

4. Side covers 19. Paper gasket (0.005 in.) «g

37. Preload spring

39. "O" ring

40. Oil seal

41. Steering column

42. Upper bushing

45. Steering wheel nut

7. Shim

8. Adjusting screw

9. Sector gear, single

10. Steering arm, L.H.

11. Housing

12. Oil lever &fillerplug

13. Sector gear, double

14. Nut

15. Washer

16. Steering arm, R.H.

22. Needle roller bearing

23. Adapter assy.

24. Oil seal

25. "O"ring

26. Thrust bearing assy.

27. Valve assy.

28. Tube seat

29. Reaction plungers (2)

30. Thrust plungers (6)

31. Tube seat

FORD

Install new seal in lower end of steer-

ing column using a 1% inch (34.9 mm)

diameter driver. Install seal so spring

and lip will be downward (towards con-

trol valve). Tighten steering column re-

taining cap screws to a torque of 25

ft.-lbs. (34 N-m) and remove seal guide.

Install new bushing in top end of steer-

ing column, then reinstall removed

parts. Refill and bleed power steering as

outlined in paragraph 10.

17. OVERHAUL CONTROL

VALVE. With steering gear and control

valve assembly removed from' tractor as

outlined in paragraph 15 proceed as

follows:

Scribe a line across steering column,

valve housing and adapter to facilitate

reassembly. Remove return line union

(33-Fig. 6) from valve housing, discard

"0" ring (32) and unscrew check valve

(34). Remove cap screws retaining steer-

ing column and remove column from

steering shaft. Carefully unstake

locknut (38) and temporarily install

steering wheel on shaft to hold shaft

while unscrewing nut. Remove steering

wheel and nut and position steering gear

unit on bench so steering shaft is in

horizontal position. Slide spring washer

(37), upper thrust bearing (36), control

valve assembly (27) and lower thrust

bearing (26) from steering shaft.

NOTE: Take care that control valve

spool, plungers (30) and check vaives (29)

do not drop out of vaive housing as it is

removed from steering shaft. Unboit and

remove adapter (23) from steering gear

housing.

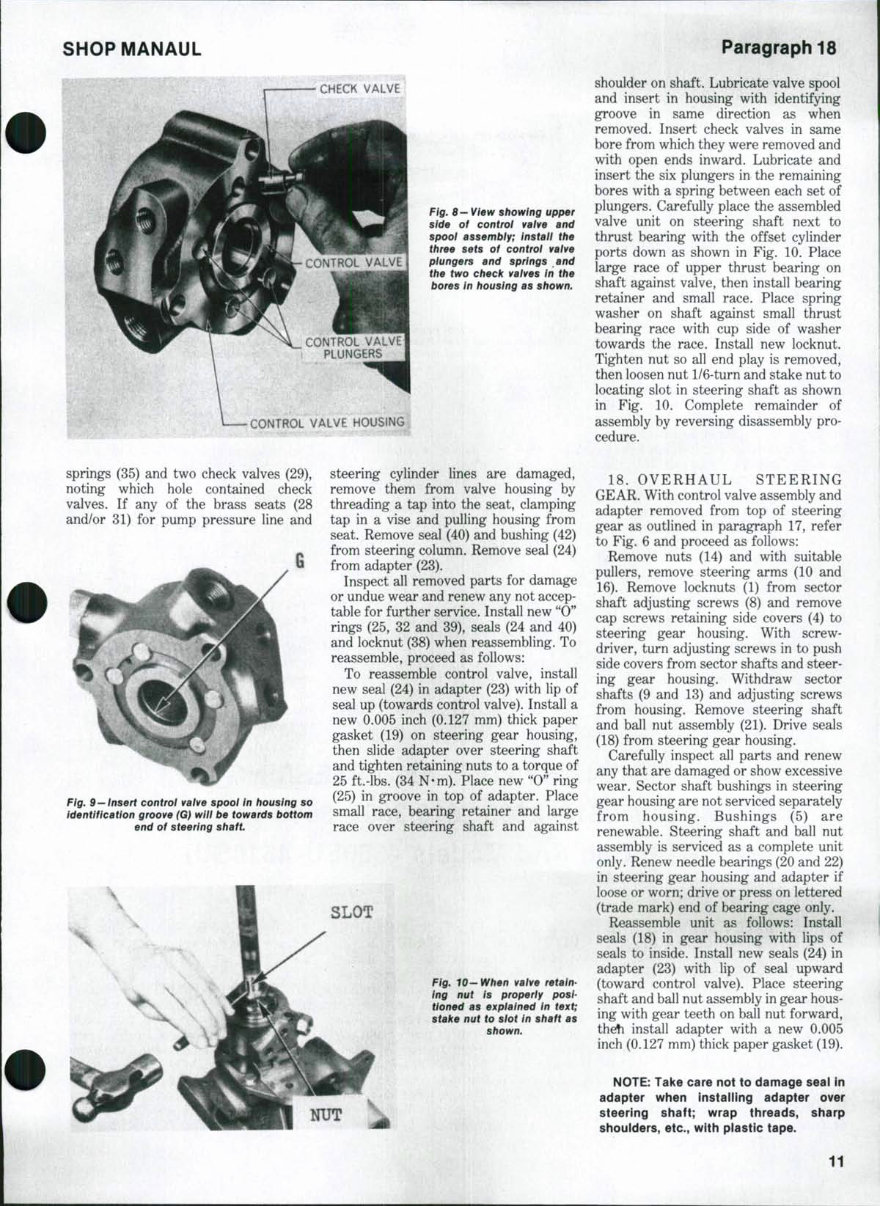

Note which end of control valve spool

has the identification groove (Fig. 9),

then slide spool from housing. Remove

the six plungers (30-Fig. 6), three

Fig. 7—Cross-sectional view of steering gear

assembly showing correct Installation (timing)

of sector gears and wormshaft; refer to Fig. 6 for

exploded view of unit and for parts Identifica-

tion.

10

SHOPMANAUL Paragraph 18

CHECK VALVE

CONTROL VALVE

PLUNGERS

Fig. 8 — View showing upper

side of control valve and

spool assembly; install the

three sets of control valve

plungers and springs and

the two check vaives in the

bores In housing as shown.

CONTROL VALVE HOUSING

shoulder on shaft. Lubricate valve spool

and insert in housing with identifying

groove in same direction as when

removed. Insert check valves in same

bore from which they were removed and

with open ends inward. Lubricate and

insert the six plungers in the remaining

bores with a spring between each set of

plungers. Carefully place the assembled

valve unit on steering shaft next to

thrust bearing with the offset cylinder

ports down as shown in Fig. 10. Place

large race of upper thrust bearing on

shaft against valve, then install bearing

retainer and small race. Place spring

washer on shaft against small thrust

bearing race with cup side of washer

towards the race. Install new locknut.

Tighten nut so all end play is removed,

then loosen nut 1/6-turn and stake nut to

locating slot in steering shaft as shown

in Fig. 10. Complete remainder of

assembly by reversing disassembly pro-

cedure.

springs (35) and two check valves (29),

noting which hole contained check

valves. If any of the brass seats (28

and/or 31) for pump pressure line and

Fig. 9—Insert control valve spool In housing so

identification groove (G) will be towards bottom

end of steering shaft.

\

steering cylinder lines are damaged,

remove them from valve housing by

threading a tap into the seat, clamping

tap in a vise and pulling housing from

seat. Remove seal (40) and bushing (42)

from steering column. Remove seal (24)

from adapter (23).

Inspect all removed parts for damage

or undue wear and renew any not accep-

table for further service. Install new "0"

rings (25, 32 and 39), seals (24 and 40)

and locknut (38) when reassembling. To

reassemble, proceed as follows:

To reassemble control valve, install

new seal (24) in adapter (23) with lip of

seal up (towards control valve). Install a

new 0.005 inch (0.127 mm) thick paper

gasket (19) on steering gear housing,

then slide adapter over steering shaft

and tighten retaining nuts to a torque of

25 ft.-lbs. (34 N-m). Place new "0" ring

(25) in groove in top of adapter. Place

small race, bearing retainer and large

race over steering shaft and against

SLOT

Fig. 10-When valve retain-

ing nut is properly posi-

tioned as explained in text;

stake nut to slot in shaft as

shown.

18. OVERHAUL STEERING

GEAR. With control valve assembly and

adapter removed from top of steering

gear as outlined in paragraph 17, refer

to Fig. 6 and proceed as follows:

Remove nuts (14) and with suitable

pullers, remove steering arms (10 and

16). Remove locknuts (1) from sector

shaft adjusting screws (8) and remove

cap screws retaining side covers (4) to

steering gear housing. With screw-

driver, turn adjusting screws in to push

side covers from sector shafts and steer-

ing gear housing. Withdraw sector

shafts (9 and 13) and adjusting screws

from housing. Remove steering shaft

and ball nut assembly (21). Drive seals

(18) from steering gear housing.

Carefully inspect all parts and renew

any that are damaged or show excessive

wear. Sector shaft bushings in steering

gear housing are not serviced separately

from housing. Bushings (5) are

renewable. Steering shaft and ball nut

assembly is serviced as a complete unit

only. Renew needle bearings (20 and 22)

in steering gear housing and adapter if

loose or worn; drive or press on lettered

(trade mark) end of bearing cage only.

Reassemble unit as follows: Install

seals (18) in gear housing with lips of

seals to inside. Install new seals (24) in

adapter (23) with lip of seal upward

(toward control valve). Place steering

shaft and ball nut assembly in gear hous-

ing with gear teeth on ball nut forward,

thefi install adapter with a new 0.005

inch (0.127 mm) thick paper gasket (19).

NOTE: Take care not to damage seai in

adapter when installing adapter over

steering shaft; wrap threads, sharp

shouiders, etc., with piastic tape.

11

You're Reading a Preview

What's Included?

Fast Download Speeds

Online & Offline Access

Access PDF Contents & Bookmarks

Full Search Facility

Print one or all pages of your manual

$36.99

Viewed 54 Times Today

Loading...

Secure transaction

What's Included?

Fast Download Speeds

Online & Offline Access

Access PDF Contents & Bookmarks

Full Search Facility

Print one or all pages of your manual

$36.99

This manual is suitable for both first-time owners and amateur enthusiasts, as well as professional technicians. It is designed in an easy-to-read format and provides all the necessary information to perform procedures accurately. Keeping this service manual accessible and referring to it regularly is recommended. Regular and preventive maintenance outlined in the manual can help save time and money by preventing premature failure and unnecessary repairs.

- BRAKES

- CLUTCH

- COOLING SYSTEM

- DIESEL FUEL SYSTEM

- DIFFERENTIAL

- DIFFERENTIAL LOCK

- ELECTRICAL SYSTEM

- ENGINE

- FINAL DRIVE

- FRONT SYSTEM

- HYDRAULIC SYSTEM

- POWER TAKE-OFF

- TRANSMISSION

File Format: PDF

Compatibility: All Versions of Windows & Mac

Language: English

Requirements: Adobe Reader