Ford 1710 Tractor Service & Parts Catalog Manual -2- Manuals - IMPROVED -

What's Included?

Fast Download Speeds

Online & Offline Access

Access PDF Contents & Bookmarks

Full Search Facility

Print one or all pages of your manual

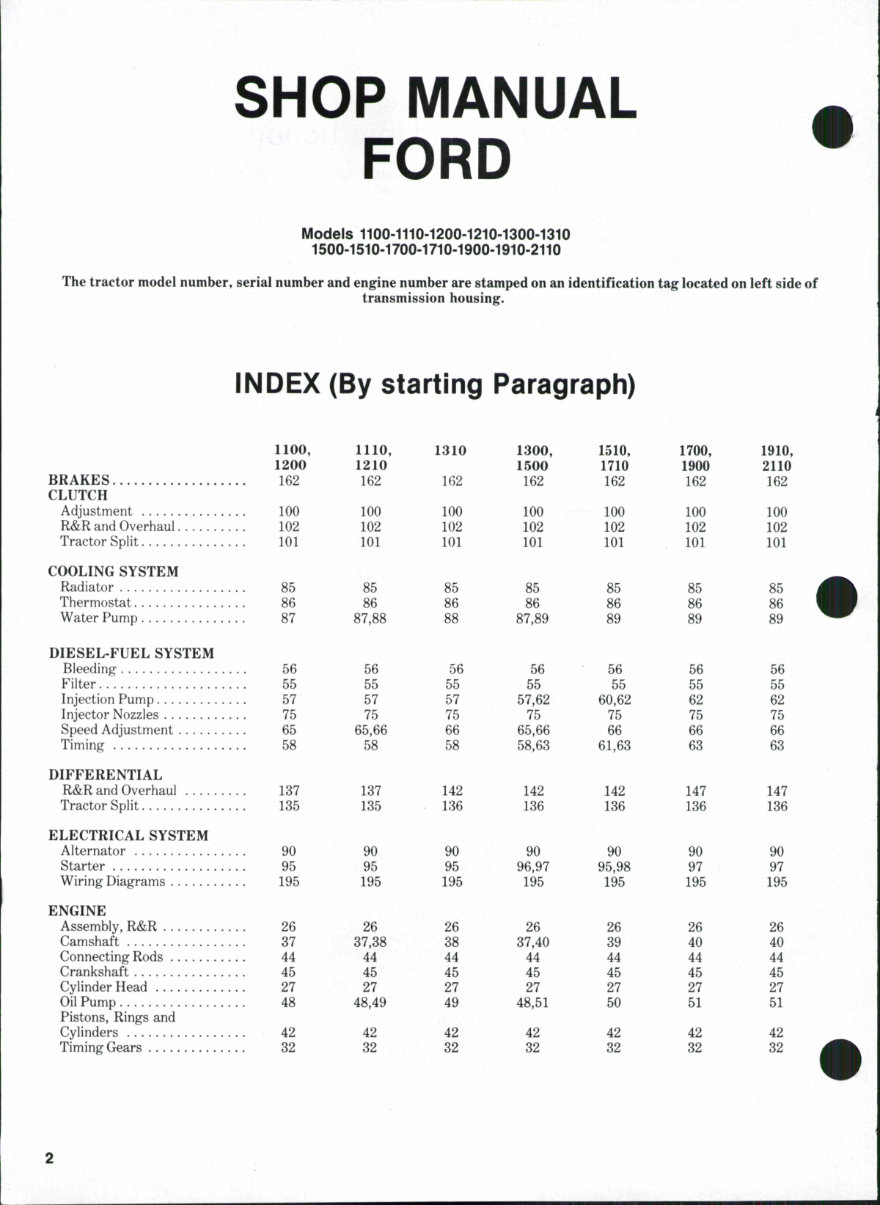

SHOP MANUAL

FORD

Models 1100-1110-1200-1210-1300-1310

1500-1510-1700-1710-1900-1910-2110

The tractor model number, serial number and engine number are stamped on an identification tag located on left side of

transmission housing.

INDEX (By starting Paragraph)

1100,

1200

BRAKES 162

CLUTCH

Adjustment 100

R&R and Overhaul 102

Tractor Split 101

COOLING SYSTEM

Radiator 85

Thermostat 86

Water Pump 87

DIESEL-FUEL SYSTEM

Bleeding 56

Filter 55

Injection Pump 57

Injector Nozzles 75

Speed Adjustment 65

Timing 58

DIFFERENTIAL

R&R and Overhaul 137

Tractor Split 135

ELECTRICAL SYSTEM

Alternator 90

Starter 95

Wiring Diagrams 195

ENGINE

Assembly, R&R 26

Camshaft 37

Connecting Rods 44

Crankshaft 45

Cylinder Head 27

Oil Pump 48

Pistons, Rings and

Cylinders 42

TimingGears 32

1110,

1210

162

100

102

101

85

86

87,88

56

55

57

75

65,66

58

137

135

do

95

195

26

37,38

44

45

27

48,49

42

82

1310

162

100

102

101

85

86

88

56

55

57

75

66

58

142

136

90

95

195

26

38

44

45

27

49

42

32

1300,

1500

162

100

102

101

85

86

87,89

56

55

57,62

75

65,66

58,63

142

136

90

96,97

195

26

37,40

44

45

27

48,51

42

32

1510,

1710

162

100

102

101

85

86

89

56

55

60,62

75

66

61,63

142

136

90

95,98

195

26

39

44

45

27

50

42

32

1700,

1900

162

100

102

101

85

86

89

56

55

62

75

66

63

147

136

90

97

195

26

40

44

45

27

51

42

32

1910,

2110

162

100

102

101

85

86

89

56

55

62

75

66

63

147

136

90

97

195

26

40

44

45

27

51

42

32

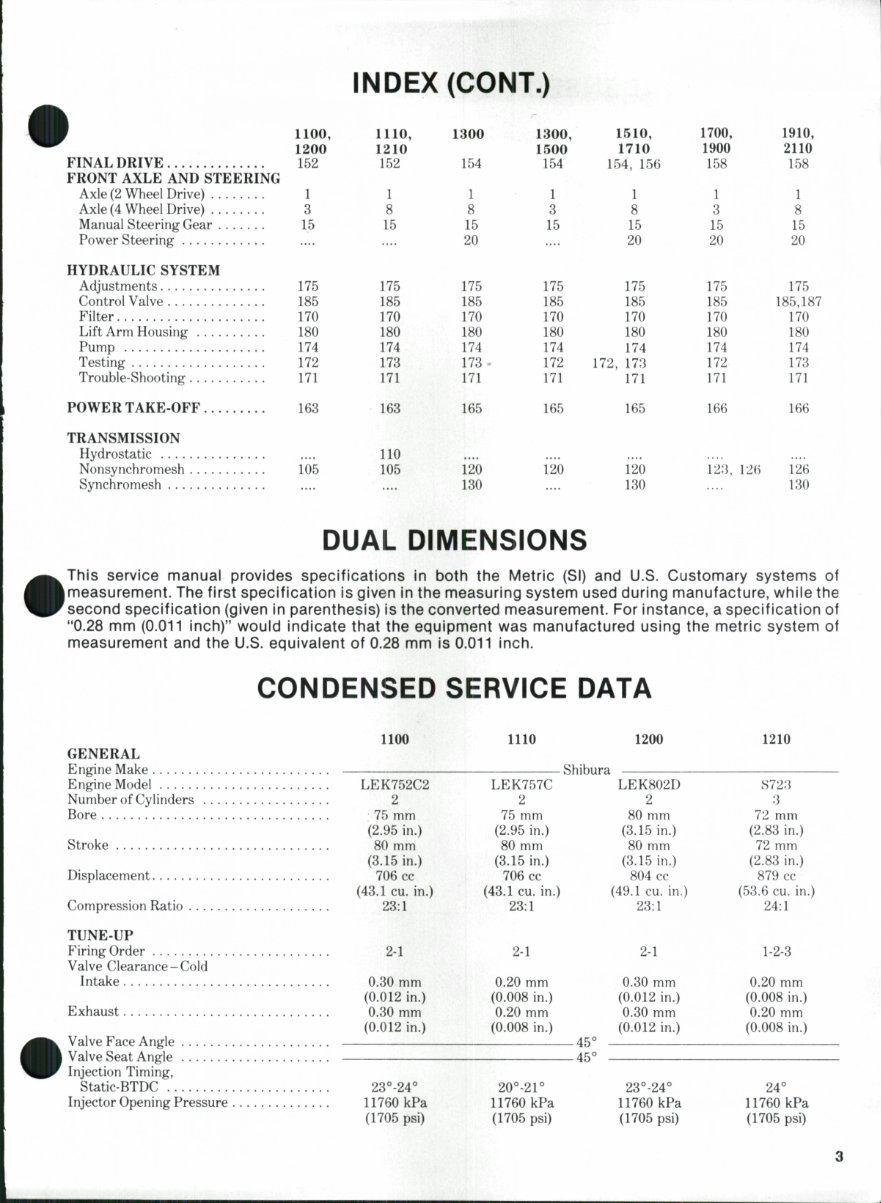

1100,

1200

FINALDRIVE 152

FRONT AXLE AND STEERING

Axle (2 Wheel Drive) 1

Axle (4 Wheel Drive) 3

Manual Steering Gear 15

Power Steering

HYDRAULIC SYSTEM

Adjustments. 175

Control Valve 185

Filter 170

Lift Arm Housing 180

Pump 174

Testing 172

Trouble-Shooting 171

POWER TAKE-OFF 163

TRANSMISSION

Hydrostatic

Nonsynchromesh 105

Synchromesh

INDEX (CONT.)

1110,

1210

152

1

8

15

175

185

170

180

174

173

171

1300

154

1

8

15

20

175

185

170

180

174

173 •

171

1300,

1500

154

1

3

15

175

185

170

180

174

172

171

1510,

1710

154, 156

1

8

15

20

175

185

170

180

174

172, 173

171

1700,

1900

158

1

3

15

20

175

185

170

180

174

172

171

1910,

2110

158

1

8

15

20

175

185,187

170

180

174

173

171

163

110

105

165

120

130

165

120

165

120

130

166 166

123, 12(> 126

130

DUAL DIMENSIONS

This service manuai provides specifications in both the Metric (SI) and U.S. Customary systems of

measurement. The first specification is given in the measuring system used during manufacture, whiie the

second specification (given in parenthesis) is the converted measurement. For instance, a specification of

"0.28 mm (0.011 inch)" wouid indicate that the equipment was manufactured using the metric system of

measurement and the U.S. equivaient of 0.28 mm is 0.011 inch.

CONDENSED SERVICE DATA

1100

GENERAL

Engine Make

Engine Model LEK752C2

Number of Cylinders 2

Bore 75 mm

(2.95 in.)

Stroke 80 mm

(3.15 in.)

Displacement 706 cc

(43.1 cu. in.)

Compression Ratio 23:1

TUNE-UP

Firing Order 2-1

Valve Clearance-Cold

Intake 0.30 mm

(0.012 in.)

Exhaust 0.30 mm

(0.012 in.)

Valve Face Angle

Valve Seat Angle

Injection Timing,

Static-BTDC 23''-24°

Injector Opening Pressure 11760 kPa

(1705 psi)

1110 1200 1210

LEK757C

2

75 mm

(2.95 in.)

80 mm

(3.15 in.)

706 cc

(43.1 cu. in.)

23:1

LEK802D

2

80 mm

(3.15 in.)

80 mm

(3.15 in.)

804 cc

(49.1 cu. in.)

23:1

S723

3

72 mm

(2.83 in.)

72 mm

(2.83 in.)

879 cc

(53.6 cu. in.)

24:1

2-1

0.20 mm

(0.008 in.)

0.20 mm

(0.008 in.)

-45°

-45°

2-1

0.30 mm

(0.012 in.)

0.30 mm

(0.012 in.)

11760 kPa

(1705 psi)

11760 kPa

(1705 psi)

1-2-3

0.20 mm

(0.008 in.)

0.20 mm

(0.008 in.)

24°

11760 kPa

(1705 psi)

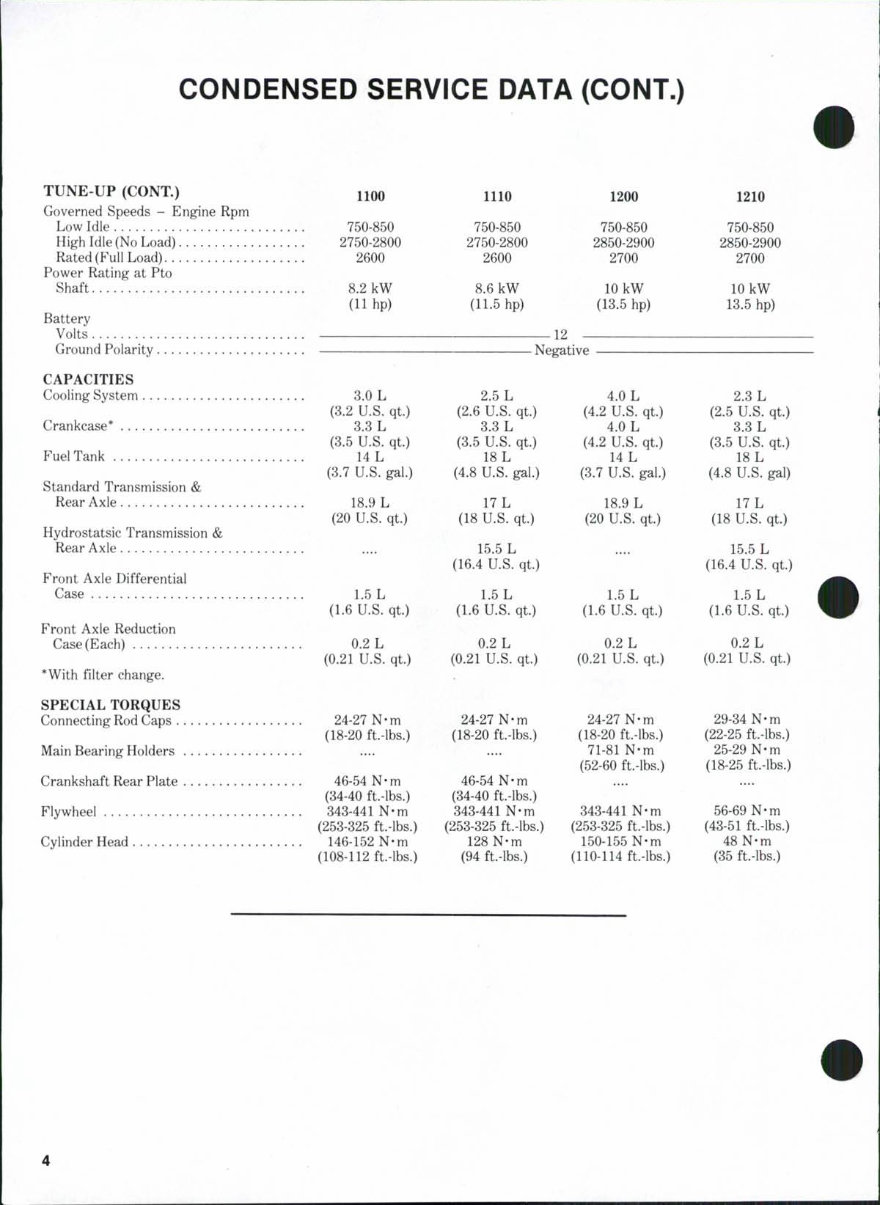

CONDENSED SERVICE DATA (CONT.)

TUNE-UP (CONT.)

Governed Speeds - Engine Rpm

Low Idle 750-850

High Idle (No Load) 2750-2800

Rated (Full Load) 2600

Power Rating at Pto

Shaft 8.2 kW

(11 hp)

Battery

Volts

Ground Polarity

CAPACITIES

Cooling System 3.0 L

(3.2 U.S. qt.)

Crankcase* 3,3 L

(3.5 U.S. qt.)

Fuel Tank 14 L

(3.7 U.S. gal.)

Standard Transmission &

Rear Axle 18.9 L

(20 U.S. qt.)

Hydrostatsic Transmission &

Rear Axle

Front Axle Differential

Case 1.5 L

(1.6 U.S. qt)

Front Axle Reduction

Case(Each) 0.2 L

(0.21 U.S. qt)

*With filter change.

SPECIAL TORQUES

Connecting Rod Caps 24-27 N-m

(18-20 ft.-lbs.)

Main Bearing Holders

Crankshaft Rear Plate 46-54 N-m

(34-40 ft.-lbs.)

Flywheel 343-441 N-m

(253-325 ft.-lbs.)

Cylinder Head 146-152 N-m

(108-112 ft.-lbs.)

1110

750-850

2750-2800

2600

8.6 kW

(11.5 hp)

1200

750-850

2850-2900

2700

10 kW

(13.5 hp)

-12

- Negative

1210

750-850

2850-2900

2700

10 kW

13.5 hp)

2.5 L

(2.6 U.S. qt)

3.3 L

(3.5 U.S. qt)

18 L

(4.8 U.S. gal.)

17 L

(18 U.S. qt)

15.5 L

(16.4 U.S. qt)

1.5 L

(1.6 U.S. qt)

0.2 L

(0.21 U.S. qt)

24-27 N-m

(18-20 ft.-lbs.)

• • •*

46-54 N-m

(34-40 ft.-lbs.)

343-441 N-m

(253-325 ft.-lbs.)

128 N-m

(94 ft.-lbs.)

4.0 L

(4.2 U.S. qt)

4.0 L

(4.2 U.S. qt)

14 L

(3.7 U.S. gal.)

18.9 L

(20 U.S. qt.)

1.5 L

(L6 U.S. qt)

0.2 L

(0.21 U.S. qt)

24-27 N-m

(18-20 ft.-lbs.)

71-81 N-m

(52-60 ft.-lbs.)

343-441 N-m

(253-325 ft.-lbs.)

150-155 N-m

(110-114 ft-lbs.)

2.3 L

(2.5 U.S. qt)

3.3 L

(3.5 U.S. qt)

18 L

(4.8 U.S. gal)

17 L

(18 U.S. qt)

15.5 L

(16.4 U.S. qt)

1.5 L

(1.6 U.S. qt)

0.2 L

(0.21 U.S. qt)

29-34 N-m

(22-25 ft.-lbs.)

25-29 N-m

(18-25 ft.-lbs.)

56-69 N-m

(43-51 ft.-lbs.)

48 N-m

(35 ft.-lbs.)

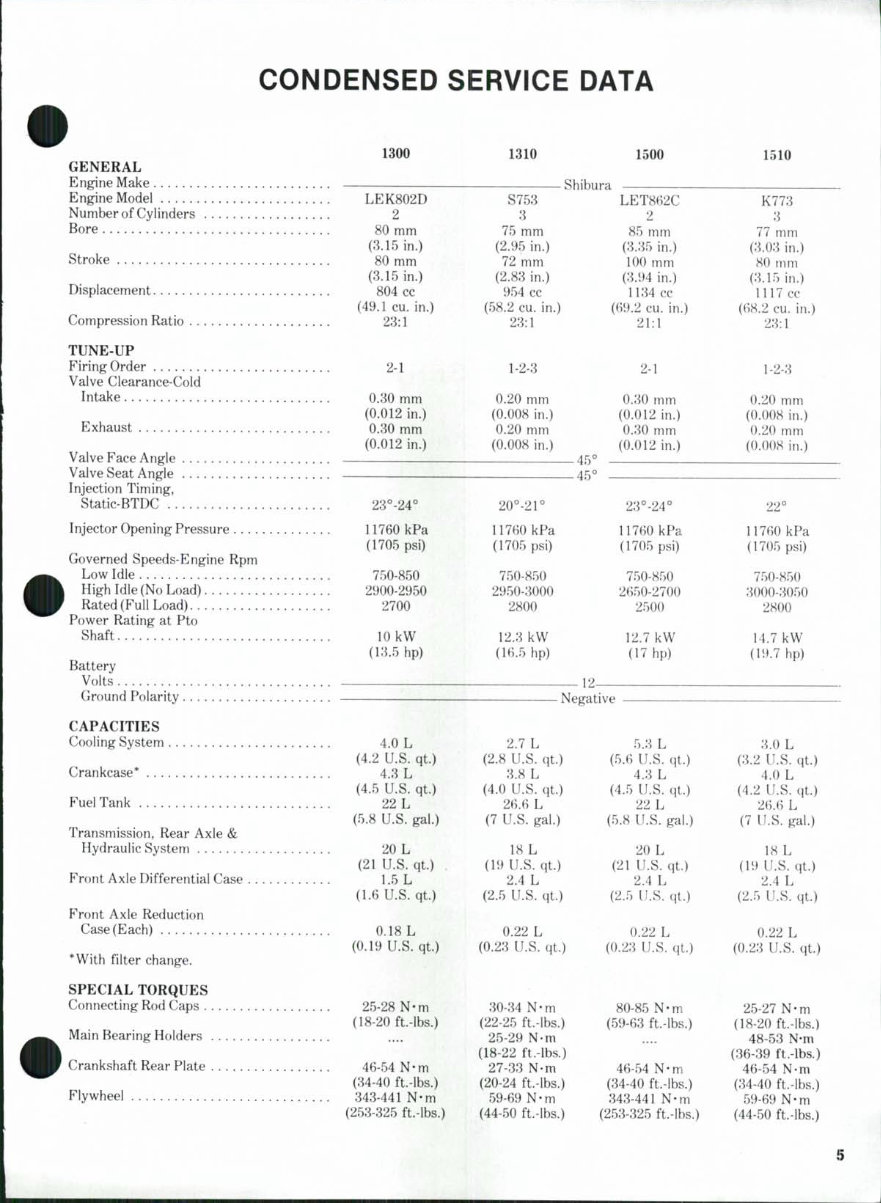

CONDENSED SERVICE DATA

1300

GENERAL

Engine Make

Engine Model LEK802D

Number of Cylinders 2

Bore 80 mm

(3.15 in.)

Stroke 80 mm

(3.15 in.)

Displacement 804 cc

(49.1 cu. in.)

Compression Ratio 23:1

TUNE-UP

Firing Order 2-1

Valve Clearance-Cold

Intake 0.30 mm

(0.012 in.)

Exhaust 0.30 mm

(0.012 in.)

Valve Face Angle

Valve Seat Angle

Injection Timing,

Static-BTDC 23°-24°

Injector Opening Pressure 11760 kPa

(1705 psi)

Governed Speeds-Engine Rpm

Low Idle 750-850

High Idle (No Load) 2900-2950

Rated (Full Load) 2700

Power Rating at Pto

Shaft 10 kW

(13.5 hp)

Battery

Volts

Ground Polarity

CAPACITIES

Cooling System 4.0 L

(4.2 U.S. qt)

Crankcase* 4.'^ L

(4.5 U.S. qt)

Fuel Tank 22 L

(5.8 U.S. gal.)

Transmission, Rear Axle &

Hydraulic System 20 L

(21 U.S. qt) .

Front Axle Differential Case 1.5 L

(1.6 U.S. qt)

Front Axle Reduction

Case(Each) 0.18 L

(0.19 U.S. qt)

*With filter change.

SPECIAL TORQUES

Connecting Rod Caps 25-28 N-m

(18-20 ft.-lbs.)

Main Bearing Holders

Crankshaft Rear Plate 46-54 N-m

(34-40 ft.-lbs.)

Flywheel 343-441 N-m

(253-325 ft.-lbs.)

1310 1500

S753

3

75 mm

(2.95 in.)

72 mm

(2.83 in.)

954 cc

(58.2 cu. in.)

23:1

1-2-3

0.20 mm

(0.008 in.)

0.20 mm

(0.008 in.)

Shibura

-45°

-45°

LET862C

2

85 mm

(3.35 in.)

100 mm

(3.94 in.)

1134 cc

(69.2 cu. in.)

21:1

24

0.30 mm

(0.012 in.)

0.30 mm

(0.012 in.)

11760kPa

(1705 psi)

750-850

2950-3000

2800

12.3 kW

(16.5 hp)

11760 kPa

(1705 psi)

750-850

2650-2700

2500

12.7 kW

(17 hp)

12-

Negative

1510

K773

3

77 mm

(8.03 in.)

80 mm

(3.15 in.)

1117CC

(B8.2 cu. in.)

23:1

1-2-3

0.20 mm

(0.008 in.)

0.20 mm

(0.008 in.)

22°

117H0kPa

(1705 psi)

750-850

8000-3050

2800

14.7 kW

(19.7 hp)

2.7 L

(2.8 U.S. qt)

3.8 L

(4.0 U.S. qt)

2f).6 L

(7 U.S. gal.)

18 L

(19 U.S. qt)

2.4 L

(2.5 U.S. qt)

0.22 L

(0.23 U.S. qt)

30-34 N-m

(22-25 ft.-lbs.)

25-29 N-m

(18-22 ft.-lbs.)

27-33 N-m

(20-24 ft.-lbs.)

59-69 N-m

(44-50 ft-lbs.)

5.3 L

(5.6 U.S. qt)

4.3 L

(4.5 U.S. qt)

22 L

(5.8 U.S. gal.)

20 L

(21 U.S. qt)

2.4 L

(2.5 U.S. qt)

0.22 L

(0.23 U.S. qt)

80-85 N-m

(59-63 ft.-lbs.)

46-54 N-m

(34-40 ft.-lbs.)

343-441 N-m

(253-325 ft.-lbs.)

8.0 L

(8.2 U.S. qt)

4.0 L

(4.2 U.S. qt)

26.6 L

(7 U.S. gal.)

18 L

(19 U.S. qt)

2.4 L

(2.5 U.S. qt)

0.22 L

(0.28 U.S. qt.)

25-27 N-m

(18-20 ft-lbs.)

48-53 N-m

(36-39 ft.-lbs.)

46-54 N-m

(34-40 ft.-lbs.)

59-69 N-m

(44-50 ft.-lbs.)

CONDENSED SERVICE DATA (CONT.)

1300 1310

SPECIAL TORQUES (CONT.)

Cylinder Head 150-155 N-m 48 N-m

(110-114 ft-lbs.) (35 ft-lbs.)

t61 N-m (45 ft.-lbs.) with 10 mm bolts; 95 N-m (70 ft.-lbs.) with 12 mm bolts.

1500 1510

150-155 N-m t

(110-114 ft-lbs.)

CONDENSED SERVICE DATA

LE892

2

90 mm

(3.54 in.)

100 mm

(3.94 in.)

1272 cc

(77.7 cu. in.)

21:1

H843

3

84 mm

(3.31 in.)

84 mm

(3.31 in.)

1396 cc

(85.2 cu. in.)

23:1

Shihura

LEM853

3

85 mm

(3.35 in.)

84 mm

(3.31 in.)

1429 cc

(87.2 cu. in.)

21:1

T853A

3

85 mm

(3.35 in.)

100mm

(3.94 in.)

1702 cc

(103.8 cu. in.)

21:1

T854B

4

85 mm

(3.35 in.)

100mm

(3.94 in.)

2268 cc

(138.4 cu. in.)

21:1

1700 1710 1900 1910 2110

GENERAL

Engine Make

Engine Model

Number of Cylinders

Bore

Stroke

Displacement

Compression Ratio

TUNE-UP

Firing Order 2-1 1-2-3 1-2-3 1-2-3 1-3-4-2

Valve Clearance-Cold

Intake 0.30 mm 0.20 mm 0.30 mm 0.30 mm 0.30 mm

(0.012 in.) (0.008 in.) (0.012 in.) (0.012 in.) (0.012 in.)

Exhaust 0.30 mm 0.20 mm 0.30 mm 0.30 mm 0.30 mm

(0.012 in.) (0.008 in.) (0.012 in.) (0.012 in.) (0.012 in.)

Valve Face Angle 45°

Valve Seat Angle 45*^

Injection Timing,

Static-BTDC 20°-22

Injector Opening Pressure

Governed Speeds-Engine Rpm

Low Idle 750-850 750-850 750-850 750-850 750-850

High Idle (No Load) 2600-2650 2825-2875 2900-2950 2650-2700 2650-2700

Rated (Full Load) 2500 2700 2800 2500 2500

Power Rating at Pto

Shaft 17.4 kW 17.8 kW 20 kW 21.3 kW 25.9 kW

(23.3 hp) (23.9 hp) (26.9 hp) (28.6 hp) (34.8 hp)

Battery

Volts 12

Ground Polarity Negative

CAPACITIES

CoolingSystem 5.3 L 5.5 L 6.8 L 7.0 L 8.5 L

(5.6 U.S. qt) (5.8 U.S. qt) (7.2 U.S. qt) (7.4 U.S. qt) (9.1 U.S. qt)

Crankcase* 5.0 L** 5.3 L 5.5 L 6.5 L 7.5 L

(5.3 U.S. qt) (5.6 U.S. qt) (5.8 U.S. qt) (6.9 U.S. qt) (7.9 U.S. qt)

Fuel Tank 22 L 29 L 29 L 35 L 40 L

(5.8 U.S. gal.) (7.6 U.S. gal.) (7.6 U.S. gal.) (9.3 U.S. gal.) (10.6 U.S. gal.)

23V2°-24V2°

11760 kPa

-(1705 psi)

23V2°-24V2°

Paragraph 1

CONDENSED SERVICE DATA (CONT.)

'CAPACITIES (CONT.) "00 ^™ ^^^ 191" 2110

Transmission, Rear Axle &

Hydraulic System 22 L 18 L 24 L 28 L 32.2 L

(23.2 U.S. qt.) (19 U.S. qt.) (25.4 U.S. qt) (29.6 U.S. qt.) (34 U.S. qt.)

Rear Axle Final Drive

Case (Each) .... 2.4 L

(2.5 U.S. qt)

Front Axle Differential Case 2.4 L 3.3 L 2.4 L 4.2 L 5.2 L

(2.5 U.S. qt) (3.5 U.S. qt.) (2.5 U.S. qt) (4.5 U.S. qt) (5.5 U.S. qt)

Front Axle Reduction

Case(Each) 0.22 L 0.22 L 0.22 L 0.22 L 0.22 L

(0.23 U.S. qt) (0.28 U.S. qt.) (0.23 U.S. qt.) (0.28 U.S. qt) 0.28 U.S. qt.)

* With filter change.

** Crankcase capacity is 0.5 L (0.53 U.S. quarts) less when equipped with front wheel drive.

SPECIAL TORQUES

Connecting Rod Caps 80-85 N • m 45-50 N • m 45-50 N - m 78-88 N - m 78-88 N - m

(59-68 ft.-lbs.) (82-36 ft.-lbs.) (32-86 ft.-lbs.) (58-62 ft.-lbs.) (58-62 ft.-lbs.)

Main Bearing Holders .... 48-58N-m 71-81 N-m 71-81 N-m 71-81 N-m

(86-39 ft.-lbs.) (52-60 ft.-lbs.) (52-60 ft-lbs.) (52-60 ft.-lbs.)

Crankshaft Rear Plate 46-54 N-m 46-54 N-m 46-54 N-m 46-54 N-m 46-54 N-m

84-40 ft-lbs.) (34-40 ft.-lbs.) (84-40 ft.-lbs.) (84-40 ft.-tbs.) (84-40 ft.-lbs.)

Crankshaft Pulley 49-59 N - m 49-59 N - m 49-59 N - m 49-59 N - m 49-59 N - m

(86-48 ft.-lbs.) (86-48 ft.-lbs.) (86-48 ft.-lbs.) (8(>48 ft-lbs.) (86-48 ft.-lbs.)

Flywheel 348-441 N-m 848-441 N-m 848-441 N-m 848-441 N-m 848-441 N-m

(258-325 ft.-lbs.) (258-825 ft.-lbs.) (258-825 ft-lbs.) (258-825 ft.-lbs.) (258-825 ft-lbs.;

Cylinder Head 150-155 N-m Note 1 Note 2 95 N-m 95 N-m

•

(110-114 ft.-lbs.) (70 ft.-lbs.) (70 ft.-lbs.)

Note 1: 61 N-m (45 ft.-lbs.) with 10 mm bolts; 129 N-m (95 ft-lbs.) with 14 mm bolts.

Note 2: 150-155 N-m (110-114 ft.-lbs.) for 11 large nuts and 58-62 N-m (48-46 ft.-lbs.) for 6 small nuts.

FRONT AXLE AND STEERING

SYSTEM

FRONT AXLE

(TWO WHEEL DRIVE)

All Models So Equipped

1. The front axle may be fixed tread

width type or adjustable type for 1100,

1110, 1200, 1210, 1300, 1810, 1500 and

1510 models as shown in Figs. 1, 2 and

3. The adjustable axle used on 1700,

1710, 1900 and 1910 models is shown in

Fig. 4. Adjustable axle used on 1710 Off-

set tractor is shown in Fig. 5, and ad-

justable axle used on 2110 tractor is

shown in Fig. 6.

Front wheel toe-in is set by adjusting

the length of the tie rod. Toe-in should

be 0-5 mm (0-3/16 inch) on all models.

Clearance between axle pivot shaft

and bushings (26-Figs. 1, 2, 8, 4, 5 and

6) should be 0.02-0.15 mm (0.001-0.006

inch). Bushings should be renewed if

clearance exceeds 0.30 mm (0.012 inch).

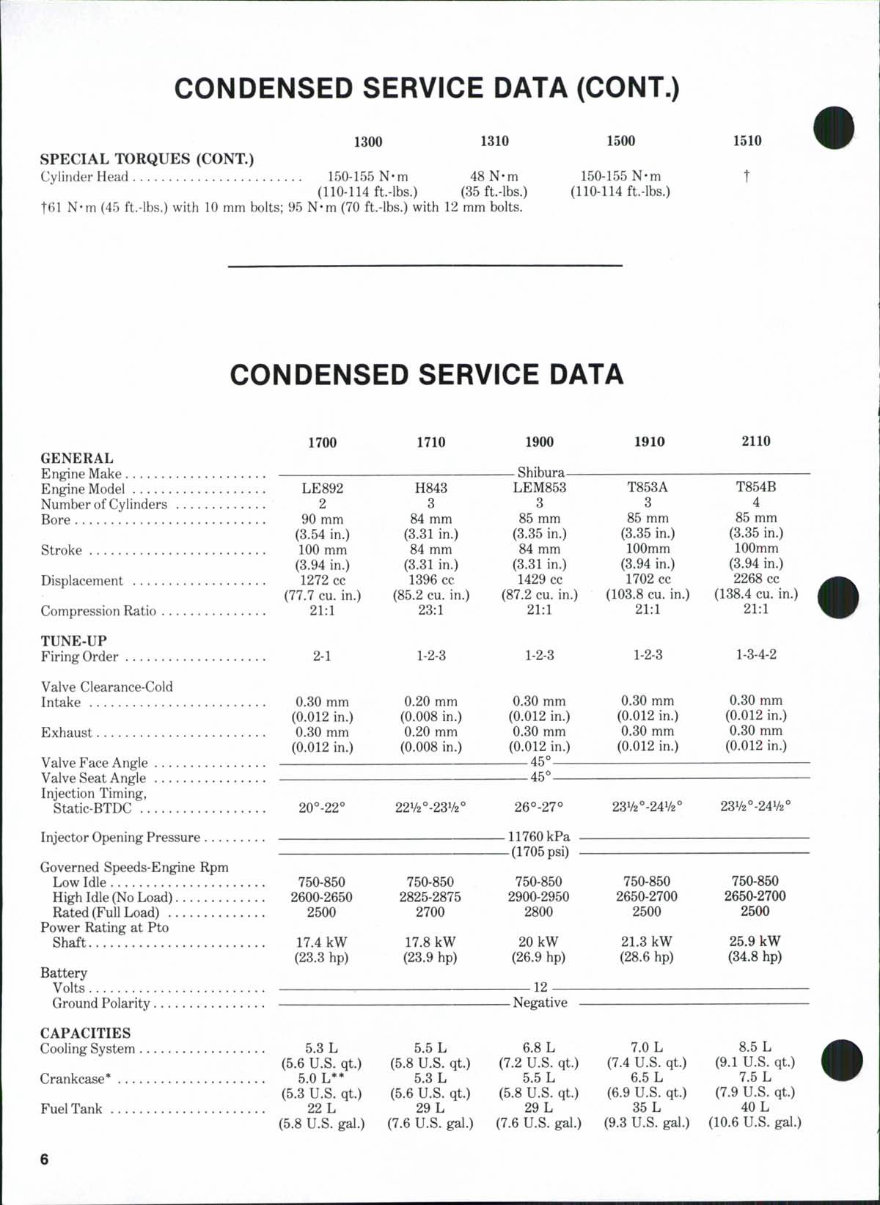

Fig. 1-exploded view of

ftxed tread front axle

assembly used on two wheel

drtve 1100, 1110, 1200 and

1210 models.

1. Front wheel hub outer

half

2. Nut

3. Outer bearinjj

4. "0" ring

5. Collar

6. Inner bearing

7. Seal

8. Seal

9. Wheel hub inner half

10. Spacer

U. Spindle

12. Oil seal

13. Bearing washers

14. Needle thrust bearing

15. Bushings

16. Axle

17. "0" ring

18. Washer

19. Steering arm

20. Cotter pin

21. Castelated nut

22. Washer

23. Washer

24. Shim

25. Shim

26. Bushing

27. Pivot shaft

Paragraphs 2-3

FORD

Axle end play should not exceed 0.20

mm (0.008 inch). If end play is excessive,

renew thrust washers (23) and/or add

shims (24) as required.

When renewing spindle bushings (15),

the top bushing should be pressed into

bore until bushing is 4.7 mm (3/16 inch)

below top surface of axle on models

equipped with an "0" ring (17-Figs, 1

and 2) at top of spindle (11). On models

equipped with a lip type seal (12-Figs.

3, 4, 5 and 6) at top of spindle, top

bushing should be pressed into bore until

top of bushing is 7 mm (9/32 inch) below

top surface of axle. Install seal with lip

facing upward.

Front wheel bearings should be re-

moved, cleaned, inspected, renewed if

damaged and packed with a good quality

No. 2 EP lithium base grease after each

600 hours of operation. Tighten wheel

bearing retaining nut (2) until slight

drag is noticed while rotating wheel hub,

then loosen nut to first castellation and

install cotter pin.

FRONT AXLE

(FOUR WHEEL DRIVE)

2. The front axle of four wheel drive

models includes the differential as-

sembly, axle housings, drive shafts,

universal joints and final drives. Refer

to appropriate paragraphs 3 through 12

for service to components.

Tie rod length should be adjusted to

provide front wheel toe-in of 0-5 mm

(0-3/16 inch) on all models.

Models 1100-1200-1300-1500-1700

-1900 So Equipped

3. REMOVE AND REINSTALL. To

remove the complete front drive axle as-

sembly, first raise front of tractor and

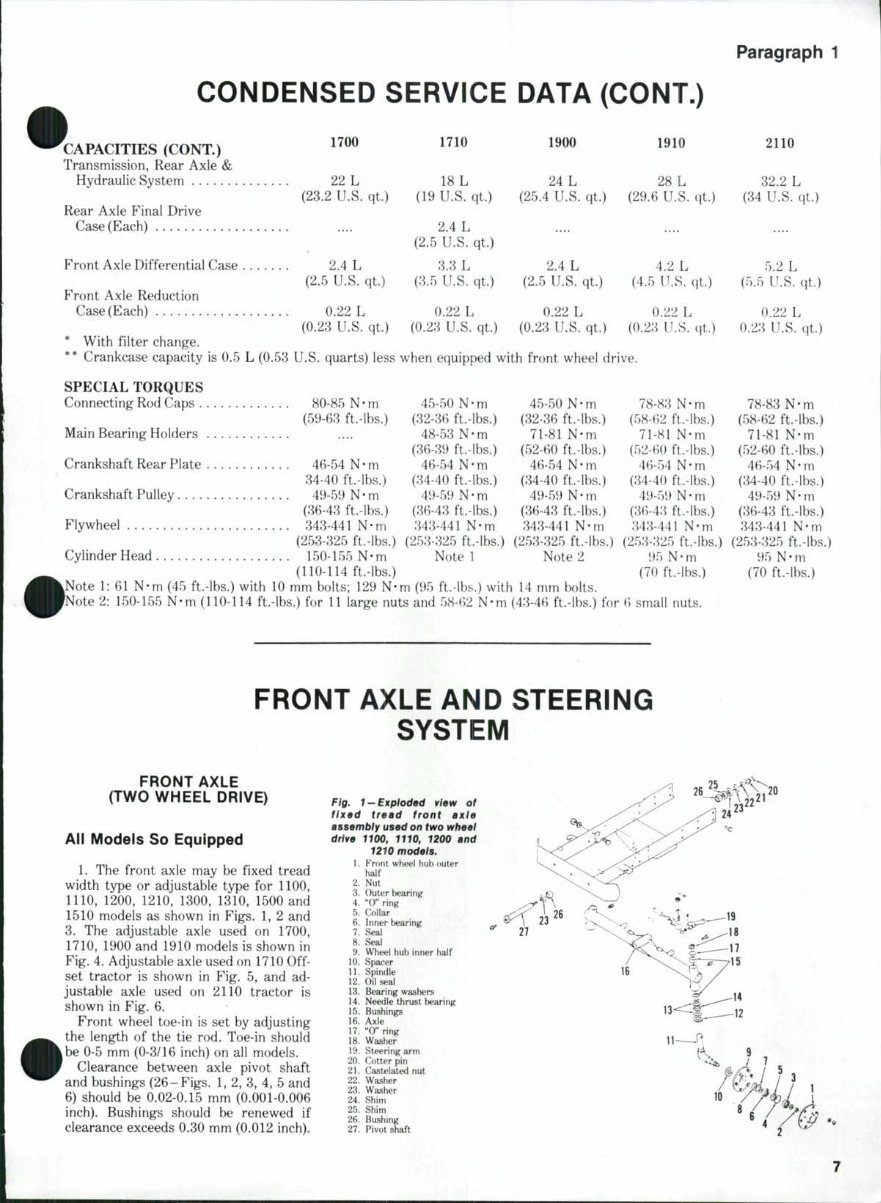

Fig. 3-Exploded view of fix-

ed tread front axle (16) used

an 1300 and 1500 models.

Axle center member (2S) and

extensions (29} are used on

1300, 1310, 1500 and 1510

adiustable axie modeis.

1. Cover

2. llastelatcd nut

:i. Outer b(»aring

(i. Inner iH'aring

7. Seal

8. Spacer

9. Hub

11. Spindle

12. Seal

13. Bearing washer

14. Needle thrust bearing

15. Bushings

16. Fixed tread axle

17. "0" ring

18. Shims

19. Steering arm

23. Washers

24. Shim

26. Bushing

28. Axle center member

29. Axle extension

30. Pivot casting

31. "0" ring

32. Gasket

33. Washer

34. Snap ring

30

37

18

Ftg. 4 — Expioded view of ad-

iustabie front axle used on

1700, 1710, 1900 and 1910

models with two wheei drive.

Refer to Fig. 3 for iegend ex-

cept for the foiiowing:

'•\^y. Spacer

'•\i\. Spacer

'M. Retainer

Fig. 2-Exploded view of ad-

iustabie tread width front ax-

le avaliabie on 1100, 1110,

1200 and 1210 models. Refer

to Fig. 1 for legend except

for the foltowtng:

28. Axle center member

29. Axle extensions

place a support behind the axle. Detach

drag link from steering arm. Place front

wheel drive control lever in "disengaged"

position. Loosen clamps that attach

drive shaft cover at the rear. Support

axle to prevent tipping, then remove cap

screws attaching axle pivot brackets to

front support. Carefully lower axle until

it can be moved forward out of drive

shaft splines.

Inspect axle pivot bushings (13 and

36-Figs. 7, 8 and 9) for wear or

damage. Renew bushings if clearance

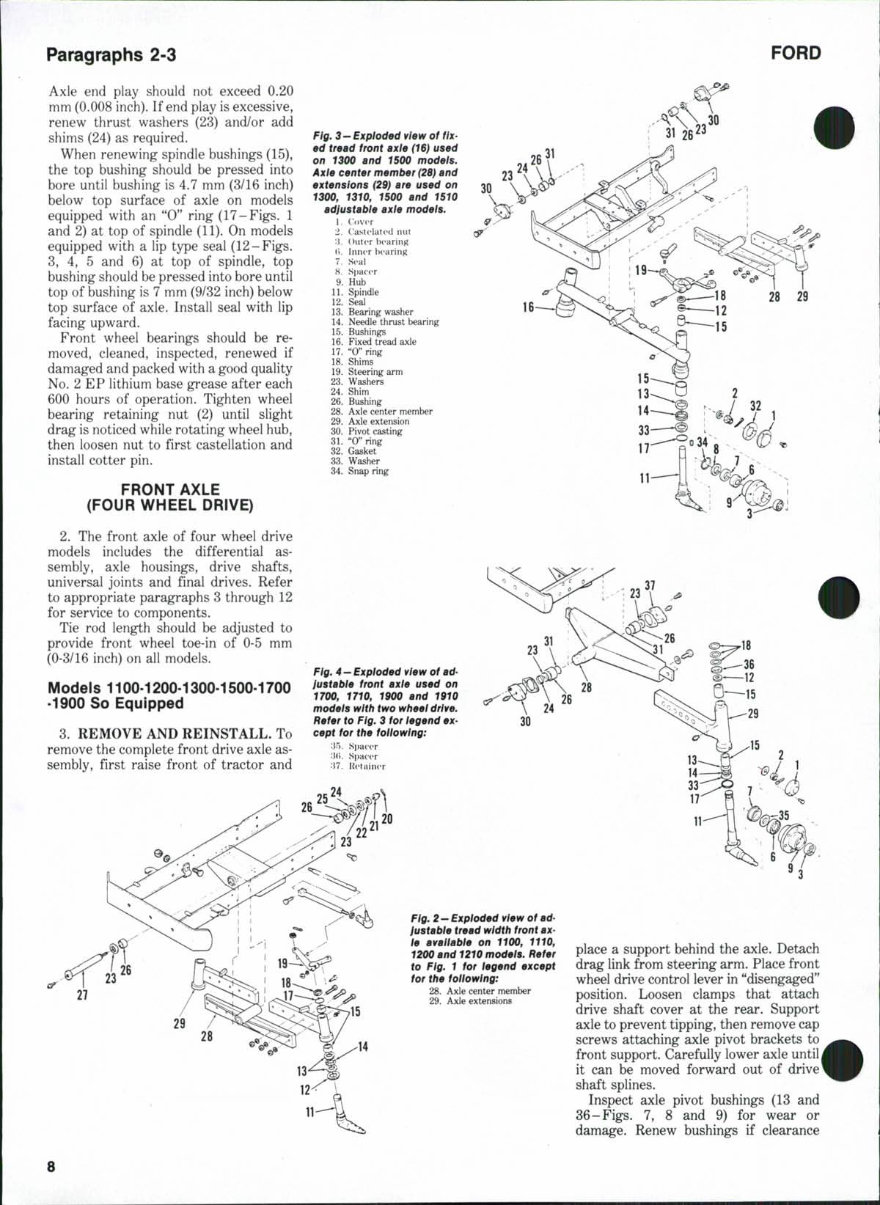

SHOP MANUAL Paragraph 4

Fig. 5 - Exploded view of adiustabie front axie assembiy used on

1710 Offset tractors. Refer to Fig. 3 for iegend except for the follow-

ing:

35. Spacer

36. Spacer

37. Retainer

inch) for 1100 and 1200 models; 82 mm

(I-V4 inches) for 1300 and 1500 models;

between differential case trunnions and

Fig. 6 —Expioded view of adiustable front axle used on Model 2110.

1. Cover

2. Nut 14. Needle thrust l)earirig 28. Axle tenter ?nemU?r

3. Outer tearing 15. Bushings 21>. Axle extension

6. Injier hearing 17. "0" ring 30. Pivot casting

7. Seal 18. Shim 31. "()" ring

11. Spindle 23. Washers 33. Washer

12. Seal 24. Shim 3fi. Spacer

13. Bearing washer 2H. Bushings 38. Thrust washer

bushings exceeds 0.35 mm (0.014 inch).

Use a suitable driver to install bushings

and make certain bushings are recessed

4 mm (5/32 inch) in pivot carriers to

allow for installation of "0" rings (14 and

35).

When reinstalling axle, observe the

following: Move axle assembly carefully

into position while sliding drive shaft

splines and pinion shaft splines into

coupling. Tighten screws attaching pivot

brackets to front support, then check ax-

le housing fore and aft end play. Desired

end play is 0.30 mm (0.012 inch) or less.

If end play exceeds 0.50 mm (0.020

inch), shims should be installed in front

pivot bracket as required to obtain de-

sired end play.

Stop bolts (49 - Figs. 7, 8 and 9) should

be adjusted to provide correct turning

radius and to prevent drag link inter-

ference. Stop bolt setting is measured

from head of bolt to surface of mounting

pad. Correct length is 24 mm (15/16

40 mm (1-9/16 inches) for 1700 and 1900

models.

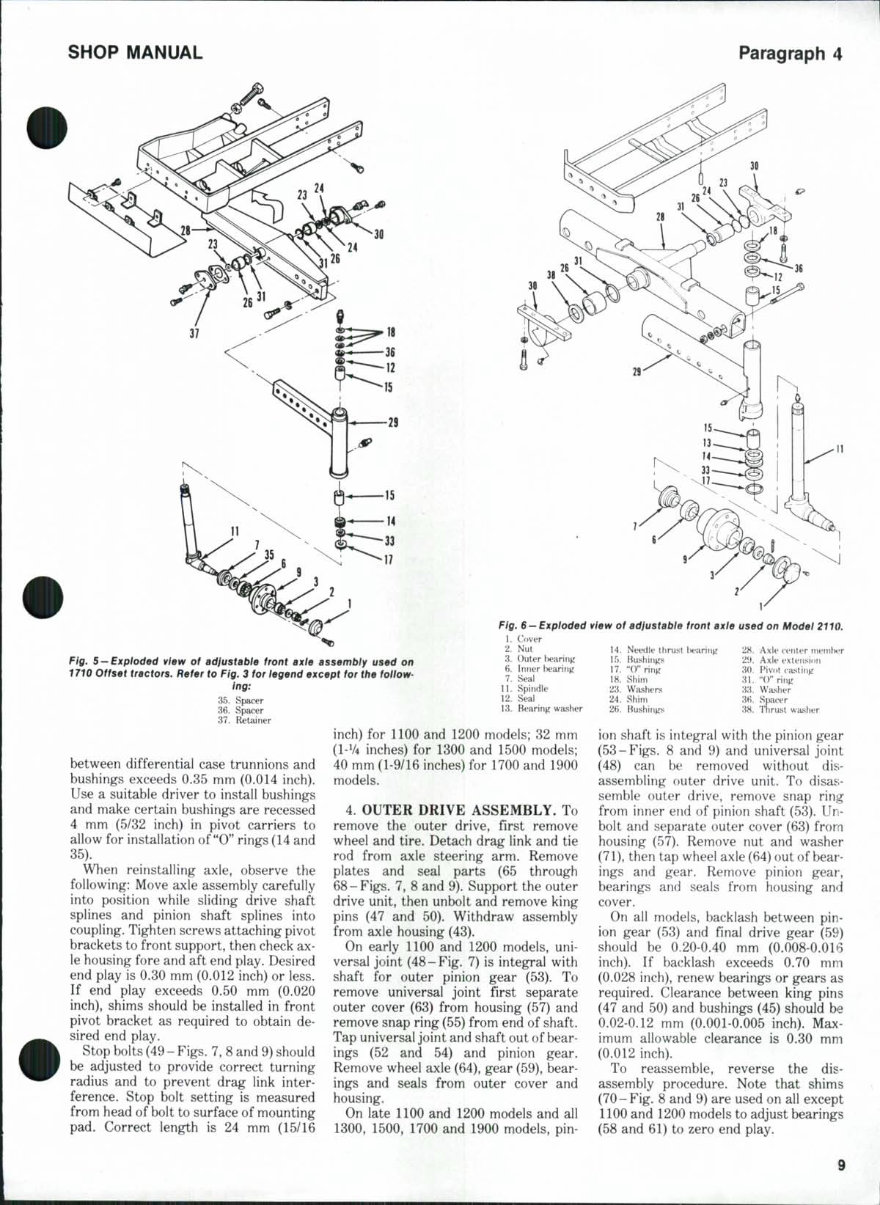

4. OUTER DRIVE ASSEMBLY. To

remove the outer drive, first remove

wheel and tire. Detach drag link and tie

rod from axle steering arm. Remove

plates and seal parts (65 through

68-Figs. 7, 8 and 9). Support the outer

drive unit, then unbolt and remove king

pins (47 and 50). Withdraw assembly

from axle housing (43).

On early 1100 and 1200 models, uni-

versal joint (48-Fig. 7) is integral with

shaft for outer pinion gear (53). To

remove universal joint first separate

outer cover (63) from housing (57) and

remove snap ring (55) from end of shaft.

Tap universal joint and shaft out of bear-

ings (52 and 54) and pinion gear.

Remove wheel axle (64), gear (59), bear-

ings and seals from outer cover and

housing.

On late 1100 and 1200 models and all

1300, 1500, 1700 and 1900 models, pin-

ion shaft is integral with the pinion gear

(53-Figs. 8 and 9) and universal joint

(48) can be removed without dis-

assembling outer drive unit. To disas-

semble outer drive, remove snap ring

from inner end of pinion shaft (53). Un-

bolt and separate outer cover (63) from

housing (57). Remove nut and washer

(71), then tap wheel axle (64) out of bear-

ings and gear. Remove pinion gear,

bearings and seals from housing and

cover.

On all models, backlash between pin-

ion gear (53) and final drive gear (59)

should be 0.20-0.40 mm (0.008-0.016

inch). If backlash exceeds 0.70 mm

(0.028 inch), renew bearings or gears as

required. Clearance between king pins

(47 and 50) and bushings (45) should be

0,02-0.12 mm (0.001-0.005 inch). Max-

imum allowable clearance is 0.30 mm

(0.012 inch).

To reassemble, reverse the dis-

assembly procedure. Note that shims

(70-Fig. 8 and 9) are used on all except

1100 and 1200 models to adjust bearings

(58 and 61) to zero end play.

9

Paragraph 5 FORD

1. "(»• liufi

2 Ilolder

l Huol

-t. Drive shall housing

5. Snap rings

6. Universal joint

7. Drive shaft

8. "0" ring

9. Coupling

10. Pin (6x32 mm)

11. Seal

12. Rear carrier bracket

13. Bushing

14. "0" ring

15. Nut

16. Washer

17. Pinion bearing

18. Snap rings

19. Shims

20. Snap ring

21. Pinion gear

22. Ring gear

23. Differential carrier

24. Thrust washer

25. Spider gear

26. Spider shaft

27. Pin (5 X 40 mm)

28. Side gear

29. Thrust washer

30. Carrier cover

31. Carrier hearings

32. Shim

33. Shim

34. Center housing

35. "0" ring

36. Bushing

37. Carrier bracket

38. Plug

39. Gasket

40. Seal

41. Shaft

42. Pin

43. Housing

44. Thrust bearing

assy.

45. King pin bearing

46. Bushing 1

47. Pin

48. Universal joint

49. Stop bolt

50. Pin & steering arm

51. Seal

52. Bearing

53. Outer pinion

54. Bearing

55. Snap ring

56. Fill plug

57. Housing

58. Bearing

59. Gear

60. Snap ring

61. Bearing

62. Seal

63. Outer cover

64. Wheel axie

65. Plate

66. Seal

67. Felt

68. Plate

69. Support assy.

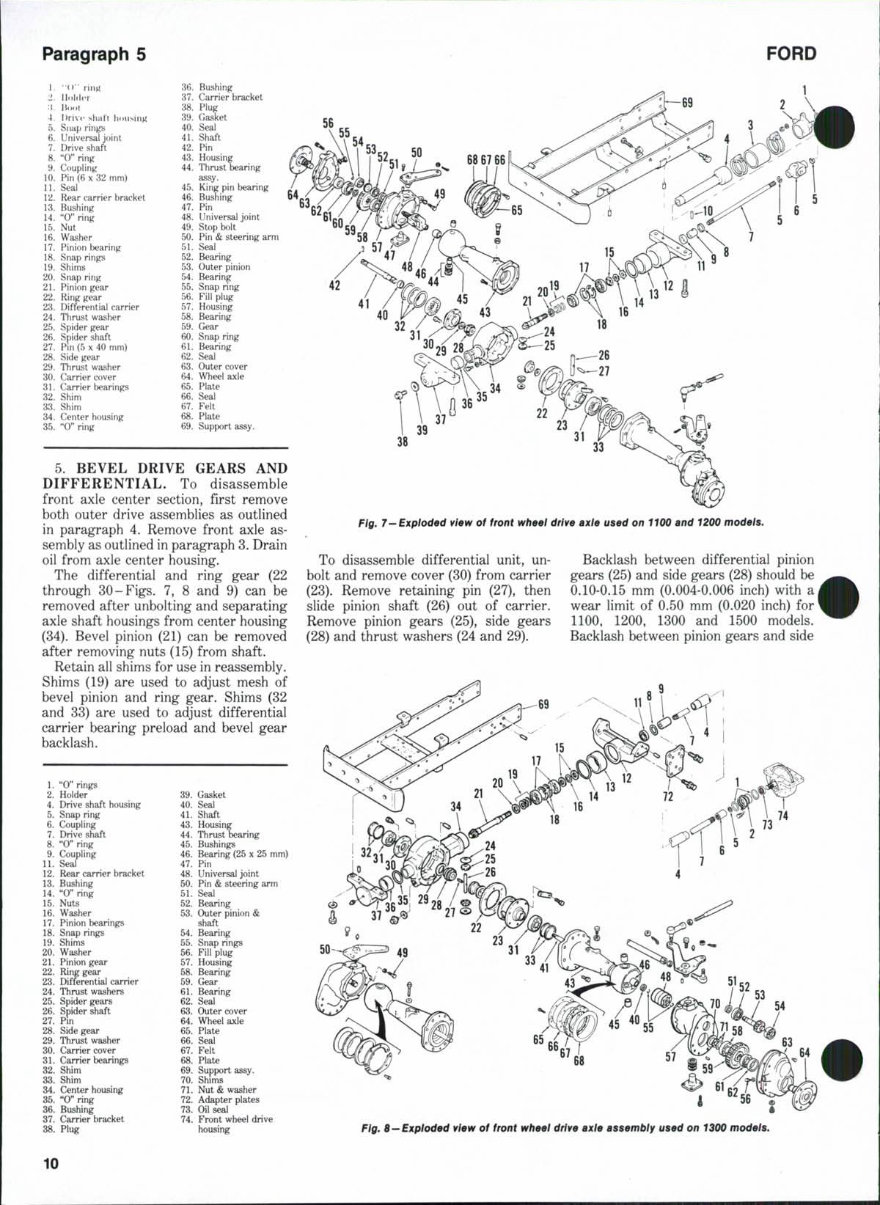

5. BEVEL DRIVE GEARS AND

DIFFERENTIAL. To disassemble

front axle center section, first remove

both outer drive assemblies as outlined

in paragraph 4. Remove front axle as-

sembly as outlined in paragraph 3. Drain

oil from axle center housing.

The differential and ring gear (22

through 30-Figs. 7, 8 and 9) can be

removed after unbolting and separating

axle shaft housings from center housing

(34). Bevel pinion (21) can be removed

after removing nuts (15) from shaft.

Retain all shims for use in reassembly.

Shims (19) are used to adjust mesh of

bevel pinion and ring gear. Shims (32

and 33) are used to adjust differential

carrier bearing preload and bevel gear

backlash.

1. "0" rings

2. Holder

4. Drive shaft housing

5. Snap ring

6. Coupling

7. Drive shaft

8. "0" ring

9. Coupling

11. Seal

12. Rear carrier bracket

13. Bushing

14. "0" ring

15. Nuts

16. Washer

17. Pinion bearings

18. Snap rings

19. Shims

20. Washer

21. Pinion gear

22. Ring gear

23. Differential carrier

24. Thrust washers

25. Spider gears

26. Spider shaft

27. Pin

28. Side gear

29. Thrust washer

30. Carrier cover

31. Carrier bearings

32. Shim

33. Shim

34. Center housing

35. "0" ring

36. Bushing

37. Carrier bracket

38. Plug

39. Gasket

40. Seal

41. Shaft

43. Housing

44. Thrust bearing

45. Bushings

46. Bearing (25 x 25 mm)

47. Pin

48. Universal joint

50. Pin & steering arm

51. Seal

52. Bearing

53. Outer pinion &

shaft

54. Bearing

55. Snap rings

56. Fill plug

57. Housing

58. Bearing

59. Gear

61. Bearing

62. Seal

63. Outer cover

64. Wheel axle

65. Plate

66. Seal

67. Felt

68. Plate

69. Support assy.

70. Shims

71. Nut & washer

72. Adapter plates

73. Oil seal

74. Front wheel drive

housing

Fig. 7-Exploded vtew of front wheei drive axie used on 1100 and 1200 models.

To disassemble differential unit, un-

bolt and remove cover (30) from carrier

(23). Remove retaining pin (27), then

slide pinion shaft (26) out of carrier.

Remove pinion gears (25), side gears

(28) and thrust washers (24 and 29),

Backlash between differential pinion

gears (25) and side gears (28) should be

0.10-0.15 mm (0.004-0.006 inch) with a

wear limit of 0.50 mm (0.020 inch) for

1100, 1200, 1300 and 1500 models.

Backlash between pinion gears and side

Fig. 8—Expioded vtew of front wheel drive axle assembly used on 1300 models.

10

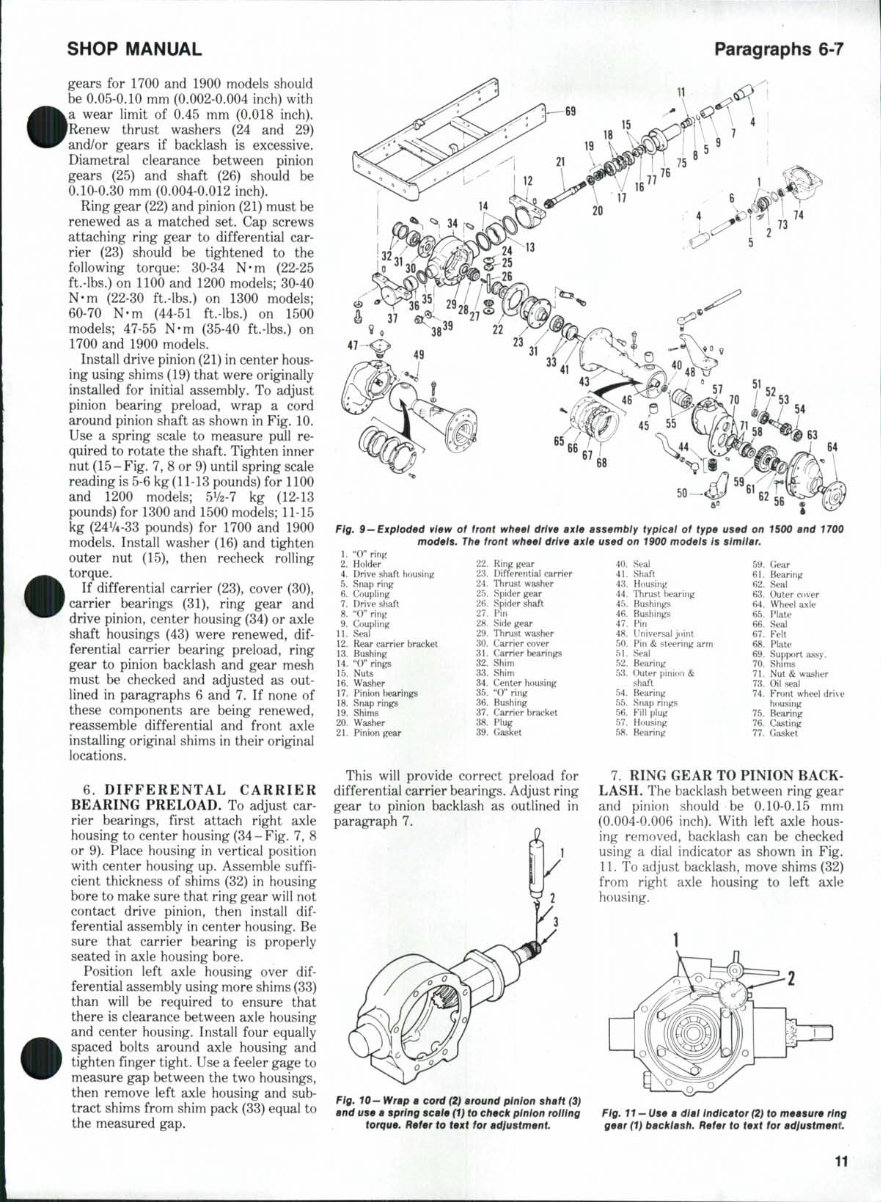

SHOP MANUAL Paragraphs 6-7

gears for 1700 and 1900 models should

be 0.05-0.10 mm (0.002-0.004 inch) with

a wear limit of 0.45 mm (0.018 inch).

'Renew thrust washers (24 and 29)

and/or gears if backlash is excessive.

Diametral clearance between pinion

gears (25) and shaft (26) should be

0.10-0.30 mm (0.004-0.012 inch).

Ring gear (22) and pinion (21) must be

renewed as a matched set. Cap screws

attaching ring gear to differential car-

rier (23) should be tightened to the

following torque: 30-34 N-m (22-25

ft.-lbs.) on 1100 and 1200 models; 30-40

N-m (22-30 ft.-lbs.) on 1300 models;

60-70 N-m (44-51 ft.-lbs.) on 1500

models; 47-55 N-m (35-40 ft.-lbs.) on

1700 and 1900 models.

Install drive pinion (21) in center hous-

ing using shims (19) that were originally

installed for initial assembly. To adjust

pinion bearing preload, wrap a cord

around pinion shaft as shown in Fig. 10.

Use a spring scale to measure pull re-

quired to rotate the shaft. Tighten inner

nut (15-Fig. 7, 8 or 9) until spring scale

reading is 5-6 kg (11-13 pounds) for 1100

and 1200 models; 5V2-7 kg (12-13

pounds) for 1300 and 1500 models; 11-15

kg (24V4-33 pounds) for 1700 and 1900

models. Install washer (16) and tighten

outer nut (15), then recheck rolling

torque.

If differential carrier (23), cover (30),

carrier bearings (31), ring gear and

drive pinion, center housing (34) or axle

shaft housings (43) were renewed, dif-

ferential carrier bearing preload, ring

gear to pinion backlash and gear mesh

must be checked and adjusted as out-

lined in paragraphs 6 and 7. If none of

these components are being renewed,

reassemble differential and front axle

installing original shims in their original

locations.

6. DIFFERENTAL CARRIER

BEARING PRELOAD. To adjust car-

rier bearings, first attach right axle

housing to center housing (34-Fig. 7, 8

or 9). Place housing in vertical position

with center housing up. Assemble suffi-

cient thickness of shims (32) in housing

bore to make sure that ring gear will not

contact drive pinion, then install dif-

ferential assembly in center housing. Be

sure that carrier bearing is properly

seated in axle housing bore.

Position left axle housing over dif-

ferential assembly using more shims (33)

than will be required to ensure that

there is clearance between axle housing

and center housing. Install four equally

spaced bolts around axle housing and

tighten finger tight. Use a feeler gage to

measure gap between the two housings,

then remove left axle housing and sub-

tract shims from shim pack (33) equal to

the measured gap.

Fig. 9—Exploded view of front wh99l drtve axle assembly typical of type

models. The front wheel drive axle used on 1900 models is

1. "0" rinp

2. Holder 22. Ring gear

4. Drive shaft housing 23. Differential carrier

S i 24. Thrust washer

25. Spider gear

26. Spider shaft

27. Pin

28. Side gear

29. Thrust washer

30. Carrier cover

31. Carrier bearings

32. Shinn

33. Shim

34. Center housing

35. "O" ring

36. Bushing

37. Carrier bracket

38. Plug

39. Gasket

used on 1500 and 1700

similar.

5. Snap ring

6. Coupling:

7. Drive shaft

8. "0" ring

9. Coupling

11. Seal

12. Rear carrier bracket

13. Bushing

14. "0" rings

15. Nuts

16. Washer

17. Pinion l)earings

18. Snap rings

19. Shims

20. Washer

21. Pinion gear

40. Seal

41. Shaft

43. Housing

44. Thrust hearing

45. Bushings

46. Bushings

47. Pin

48. Universal j(tint

50. Pin & steering arm

51. Seal

52. Bearing

53. Outer pinion &

shaft

54. Bearing

55. Snap rings

56. Fill plug

57. Housing

58. Bearing

59.

61.

62.

63.

64.

65.

66.

67.

68.

69.

70.

71.

73.

74.

75.

76.

77.

CJear

Bearing

Seal

Outer cover

Wheel axle

Plate

Seal

Felt

Plate

Support assy-

Shims

Nut & washer

Oil seal

Front wheel dri\e

housing

Bearing

Casting

Gasket

This will provide correct preload for

differential carrier bearings. Adjust ring

gear to pinion backlash as outlined in

paragraph 7,

7. RING GEAR TO PINION BACK-

LASH. The backlash between ring gear

and pinion should be 0.10-0.15 mm

(0.004-0.006 inch). With left axle hous-

ing removed, backlash can be checked

using a dial indicator as shown in Fig.

11. To adjust backlash, move shims (32)

from right axle housing to left axle

housing.

Fig. 10— Wrap a cord (2) around pinion shaft (3)

and use a spring scale (1} to check pinion rolling

torque. Refer to text for adiustment.

Fig. 11 — Use a dial Indicator (2) to measure ring

gear (1) backlash. Refer to text for adjustment

You're Reading a Preview

What's Included?

Fast Download Speeds

Online & Offline Access

Access PDF Contents & Bookmarks

Full Search Facility

Print one or all pages of your manual

$55.99

Viewed 44 Times Today

Loading...

Secure transaction

What's Included?

Fast Download Speeds

Online & Offline Access

Access PDF Contents & Bookmarks

Full Search Facility

Print one or all pages of your manual

$55.99

- The Ford New Holland 1710 Tractor Service Manual provides detailed instructions for repairing, servicing, and replacing parts on your tractor. It includes comprehensive diagrams and manufacturer specifications.

- Key features of the improved manuals include bookmarks, searchable text, indexing, and enhanced quality.

- The package consists of two manuals: the Ford 1710 3-Cylinder Compact Utility Tractor Service Manual and the Ford 1710 3-Cylinder Compact Utility Tractor Illustrated Parts Manual Catalog.

- Both manuals are instantly accessible, available in English, and in .PDF format, compatible with all versions of Windows, Mac, iOS, BB, Android, etc. They are also searchable, bookmarked, and indexed for convenience.

- The Ford New Holland 1710 Tractor Service Shop Manual is completely indexed, searchable, and bookmarked. It covers various sections including Axle Center Housing, Brakes, Clutch, Cooling System, Diesel Fuel System, Electrical System, Engine, and more.

- The Ford New Holland 1710 Tractor Illustrated Parts Catalog Manual provides a complete list of parts for the tractor and is an excellent resource for reassembling the tractor. It is also completely indexed, searchable, and bookmarked.

- The Parts Catalog outlines every part on the Ford 1710 tractors, featuring exploded views, diagrams, part numbers, and descriptions. Parts are categorized into groups such as Engine, Wheels, Fuel System, and more.

- These manuals are suitable for both DIY restorers and professional mechanics, offering easy navigation through bookmarking and searchability. They include comprehensive illustrations, exploded diagrams, drawings, and photos to guide through service repair procedures.

- Technical details and step-by-step instructions are included, allowing for easy zooming, printing, and saving of specific pages or the entire manual.

- For optimal viewing, the documents may require the latest version of Acrobat Reader. In case of any issues, upgrading to the latest version of Adobe Acrobat Reader is recommended.