Case IH 284 Tractor Complete Workshop Service Repair Manual

What's Included?

Fast Download Speeds

Online & Offline Access

Access PDF Contents & Bookmarks

Full Search Facility

Print one or all pages of your manual

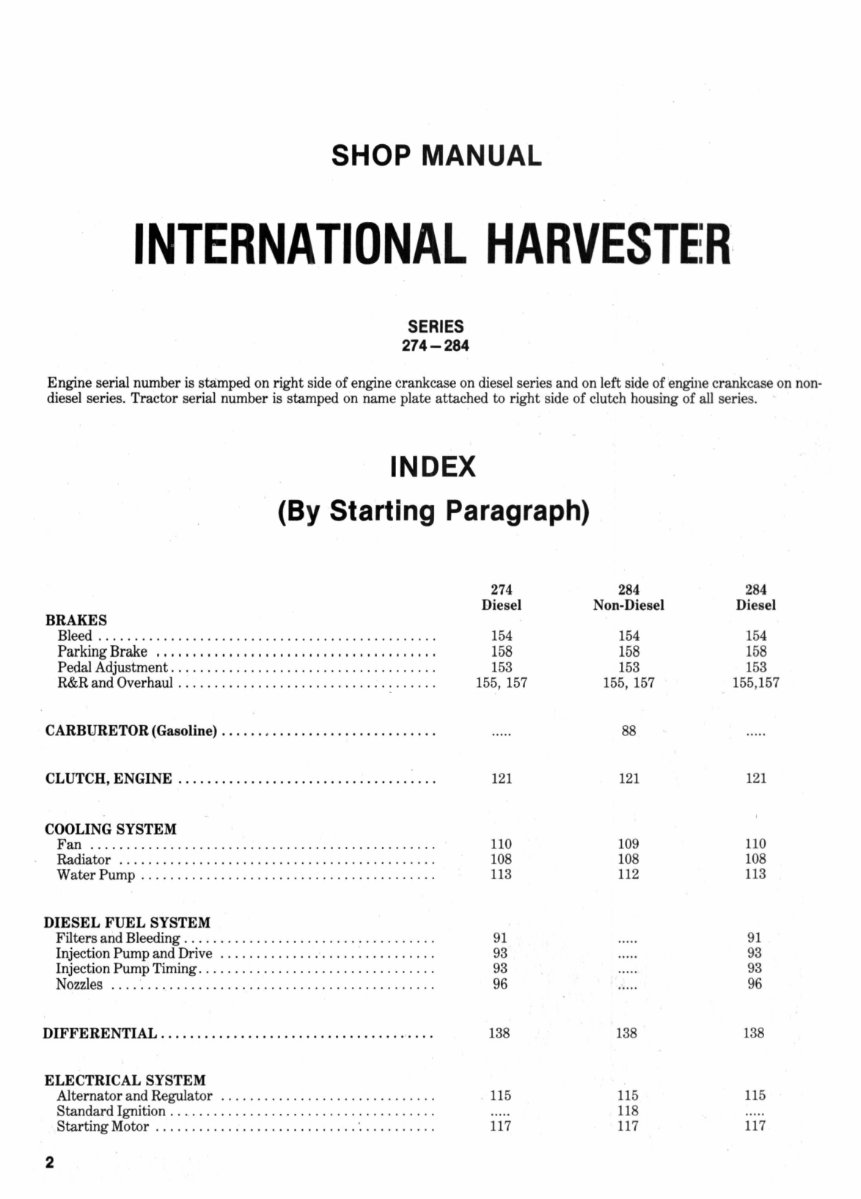

SHOP MANUAL

SERIES:

274 & 284

SHOP MANUAL

INTERNATIONAL HARVESTE:R ',

SERIES

274-284

Engine serial number is stamped on right side of engine crankcase on diesel series and on left side of engine crankcase on non-

diesel series. Tractor serial number is stamped on name plate attached to right side of clutch housing of all series.

INDEX

(By Starting Paragraph)

BRAKES

Bleed ............ . ....... ................ .......... .

Parking Brake ...................................... .

Pedal Adjustment .................................... .

R&R and Overhaul ......... ............. ....... ...... .

CARBURETOR (Gasoline) ...... ... .................... .

CLUTCH, ENGINE ... .. ...... ........ .... ......... : .. .

COOLING SYSTEM

Fan ... ... .............................. .... ....... .

Radiator ............................... . ........... .

Water Pump .... . .............. ... .......... . ....... .

DIESEL FUEL SYSTEM

Filters and Bleeding .................. .. ... .. ..... .... .

Injection Pump and Drive ........... ... ... . ..... . ... . . .

Injection Pump Timing ........ .. ................ .... .. .

Nozzles .... .. .................... . .............. ... .

DIFFERENTIAL . .................................... .

ELECTRICAL SYSTEM

Alternator and Regulator ............ ... ........ . ... . . .

Standard Ignition ... ................... . ....... ... ... .

Starting Motor .......... .. .. .... . ........ . ' ...... .... .

2

274

Diesel

154

158

153

155, 157

121

110

108

113

91

93

93

96

138

115

117

284

Non-Diesel

154

158

153

155, 157

88

121

109

108

112

138

115

118

117

284

Diesel

154

158

153

155,157

121

110

108

113

91

93

93

96

138

115

117

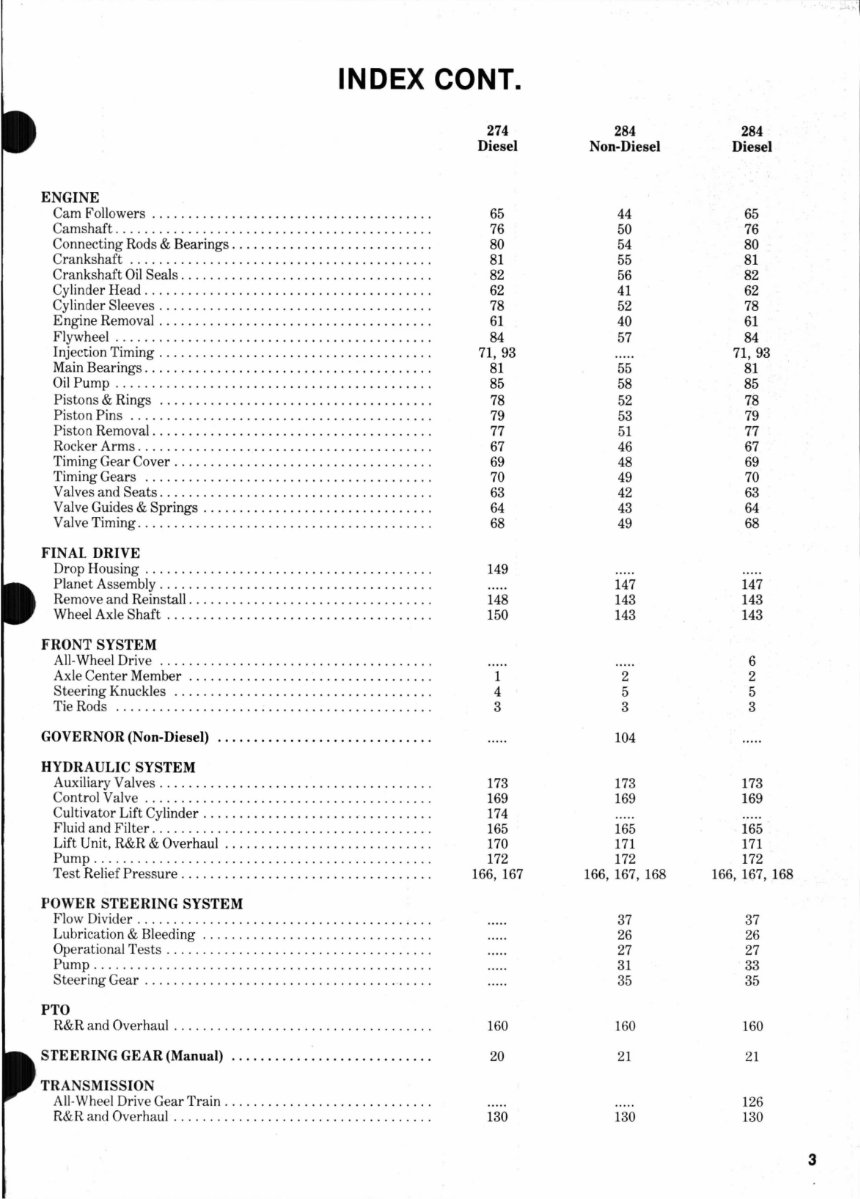

INDEX CONT.

ENGINE

Cam F'ollowers .. ....... . ....................... . ... . .

Camshaft .. . .......... . .. ........ .. .. .... . .... ...... .

Connecting Rods & Bearings ... .. ........ . ......... . ... .

Crankshaft ... ... ... ........ . .... ..... .... .. ... .. . .. .

Crankshaft Oil Seals ............. ... ... .. ........ . ... . .

Cylinder Head .. ... .... . .... . ... .. .... . ........ .. ... . .

Cylinder Sleeves .. ....... .. .. ....... .. .. .. ........... .

Engine Removal .... .. . ... ...... . .... .. . .......... .. . .

Flywheel . .. .. . ........ . ... .. . .... ... . .. ..... . .. .. .. .

InjecLion Timing ... ... .. ............................. .

Main Bearings . ............. ....... .. ... . ...... ... ... .

Oil Pump ...... . ..... .................. . ..... . ..... . .

Pistons & Rings ....... .. .. ..... . ... . ... .. ....... .. .. .

Piston Pins .. .. ....... ..... ......................... .

Piston Removal ... ...... .......... . .. .. . ........... . . .

Roc ker Arms . .. .. ............. ... . .. . ........... . .. . .

Timing Gear Cover . ..... ... . ....... ... .. .... .. ....... .

Timing Gears ...... ..... .. ... . ......... . ... . .. ...... .

Valves and Seats .... . ............. ... .. .. . ... .. ... . .. .

Valve Guides & Springs .. ... ... ...... . ..... .. . ....... . .

Valve Timing ..... .... . ........................ . .. .. . .

FINAL DRIVE

Dr op Housing . ..... ... ... .. ........ . .... .. .. . ... .... .

Planet Assembly .. ..... . ............ . .... ... . ... . ... . .

Remove and Reinstall ....... ... .. ..................... .

Wheel Axle Shaft ........ .............. .. .. .. ... .. . .. .

FRONT SYSTEM

All· Wheel Drive . ....... . ........................ .... .

Axle Center Member ... ......... . .... . ... . ....... .... .

Steering Knuckles .... .. ... ... . ..... .. ... .. .. . ..... .. .

TieRods . .... .. ..... .... . ........ ........... .. .. .. . .

GOVERNOR (Non-Diesel) ...... ... ............ .. ...... .

HYDRAULIC SYSTEM

Auxiliary Valves .......... .. .... ... . ... .. .. .. .. .. . ... .

Control Valve . .................. .. ... . ... . ...... .... .

Cultivator Lift Cylinder .. . ..... . ..... ......... ... . ... . .

Fluid and Filter . ..... .............. ... . .......... ... . .

Lift Unit, R&R & Overhaul .......... ... . ........... . . . .

Pump ... . ... ...... ......... . .... . .... . .. . ... .... ... .

Test Relief Pressure .. ... ... .... .. ...... . ....... .... .. .

POWER STEERING SYSTEM

Flow Divider . . .. .. ... ... ...... . ............ . ........ .

Lubrication & Bleeding ........ .... .. ....... .. . ... .. .. .

Op e rati onal Tests .......... ... .... ... .. . .... .. .. ..... .

Pump .. .. ... .. ... .. .......... ...... .... ... .. ... .... .

Steering Gear .. . .. .... ..................... ...... ... .

PTO

R&R and Overhaul . . . ........... ... ... . .. .... .. .... .. .

STEERING GEAR (Manual) ....................... ... . .

TRANSMISSION

All· Wheel Drive Gear Train ...... ... .............. ..... .

R&R and Overhaul .. .. .... .. ...................... .. . .

274

Diesel

65

76

80

81

82

62

78

61

84

71,93

81

85

78

79

77

67

69

70

63

64

68

149

148

150

1

4

3

173

169

174

165

170

172

166, 167

160

20

130

284

Non-Diesel

44

50

54

55

56

41

52

40

57

55

58

52

53

51

46

48

49

42

43

49

147

143

143

2

5

3

104

173

169

165

171

172

166, 167, 168

37

26

27

31

35

160

21

130

284

Diesel

65

76

80

81

82

62

78

61

84

71,93

81

85

78

79

77

67

69

70

63

64

68

147

143

143

6

2

5

3

173

169

165

171

172

166, 167, 168

37

26

27

33

35

160

21

126

130

3

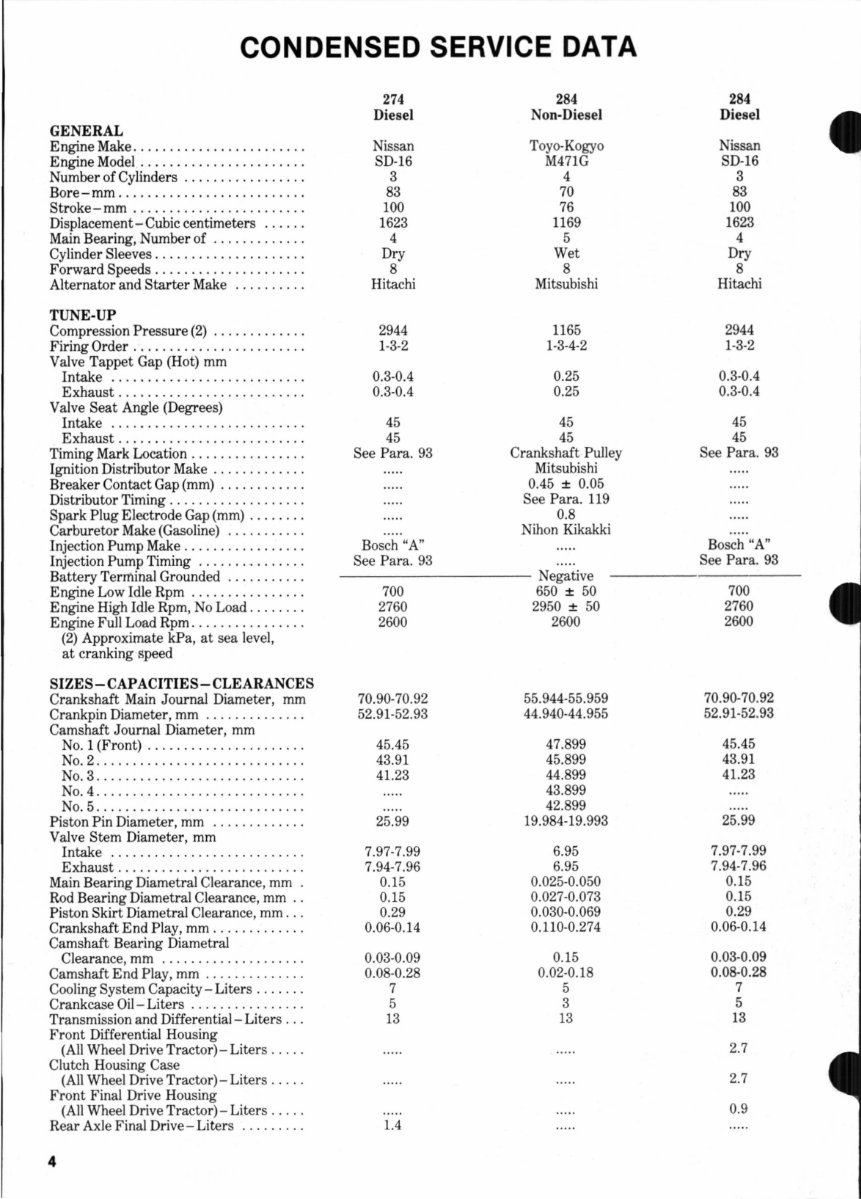

CONDENSED SERVICE DATA

GENERAL

Engine Make ....................... .

Engine Model .... .. ... ...... . ...... .

Number of Cylinders ..... ........... .

Bore-mm .. ....... .......... . ... .. .

Stroke-mm ... ..... ............... .

Di splacement - Cubic centimeters ..... .

Main Bearing, Number of .... .. .. .. .. .

Cylinder Sleeves .................... .

Forward Speeds ... . ......... ....... .

Alternator and Starter Make ......... .

TUNE-UP

Compression Pressure (2) ... .. ....... .

Firing Order . .. ........... ..... .. .. .

Valve Tappet Gap (Hot) mm

Intake .. ... .. .................. . .

Exhaust .......... ...... ..... .... .

Valve Seat Angle (Degrees)

Intake .... _ ..................... .

Exhaust .. .......... .. ...... .. ... .

Timing Mark Location ............... .

Ignition Distributor Make .. .. ....... . .

Breaker Contact Gap (mm) ........... .

Distributor Timing ............ ...... .

Spark Plug Electrode Gap (mm) . ...... .

Carburetor Make (Gasoline) ...... .. .. .

Injection Pump Make ................ .

Injection Pump Timing ..... .. _ ..... . .

Battery Terminal Grounded . ...... ... .

Engine Low Idle Rpm ........... ... . .

Engine High Idle Rpm, No Load ....... .

Engine Full Load Rpm .. .... ......... .

(2) Approximate kPa, at sea level,

at cranking speed

SIZES - CAPACITIES- CLEARANCES

Crankshaft Main Journal Diameter , mm

Crankpin Diameter, mm ............. .

Camshaft Journal Diameter, mm

No.1 (Front) . ......... .. ......... .

No.2 ...... . ... .... .. .... .. .. .. .. .

No.3 .. ........................ .. .

No.4 ...................... .. .... .

No.5 .......... . .. . .. ............ .

Piston Pin Diameter, mm ............ .

Valve Stem Diameter, mm

Intake ...... . ................... .

Exhaust .............. . .......... .

Main Bearing Diametral Clearance, mm .

Rod Bearing Diametral Clearance, mm ..

Piston Skirt Diametral Clearance, mm .. .

Crankshaft End Play, mm ......... . .. .

Camshaft Bearing Diametral

Clearance, mm ... ... ... . .... . .. .. .

Camshaft End Play, mm . .. .. ........ .

Cooling System Capacity - Liters ...... .

Crankcase Oil- Liters ... .. .......... .

Transmission and Differential - Liters .. .

Front Differential Housing

(All Wheel Drive Tractor) - Liters .... .

Clutch Housing Case

(All Wheel Drive Tractor) - Liters ... ..

Front Final Drive Housing

(All Wheel Drive Tractor) - Liters .... .

Rear Axle Final Drive - Liters ..... ... .

4

274

Diesel

Nissan

SD-16

3

83

100

1623

4

Dry

8

Hitachi

2944

1-3-2

0.3-0.4

0.3-0.4

45

45

See Para. 93

Bosch "A"

See Para. 93

284

Non-Diesel

Toyo-Kogyo

M471G

4

70

76

1169

5

Wet

8

Mitsubishi

1165

1-3-4-2

0.25

0.25

45

45

Crankshaft Pulley

Mitsubishi

0.45 ± 0.05

See Para. 119

0.8

Nihon Kikakki

---------------------Negative

700

2760

2600

70.90-70.92

52.91-52.93

45.45

43.91

41.23

25.99

7.97-7.99

7.94-7.96

0.15

0.15

0.29

0.06-0.14

0.03-0.09

0.08-0.28

7

5

13

1.4

650 ± 50

2950 ± 50

2600

55.944-55.959

44.940-44.955

47.899

45.899

44.899

43.899

42.899

19.984-19.993

6.95

6.95

0.025-0.050

0.027-0.073

0.030-0.069

0.110-0.274

0.15

0.02-0.18

5

3

13

284

Diesel

Nissan

SD-16

3

83

100

1623

4

Dry

8

Hitachi

2944

1-3-2

0.3-0.4

0.3-0.4

45

45

See Para. 93

Bosch "An

See Para. 93

700

2760

2600

70.90-70.92

52.91-52.93

45.45

43.91

41.23

25.99

7.97-7.99

7.94-7.96

0.15

0.15

0.29

0.06-0.14

0.03-0.09

0.08-0.28

7

5

13

2.7

2.7

0.9

SERIES 274-284

FRONT AXLE

SYSTEM

AXLE MAIN MEMBER

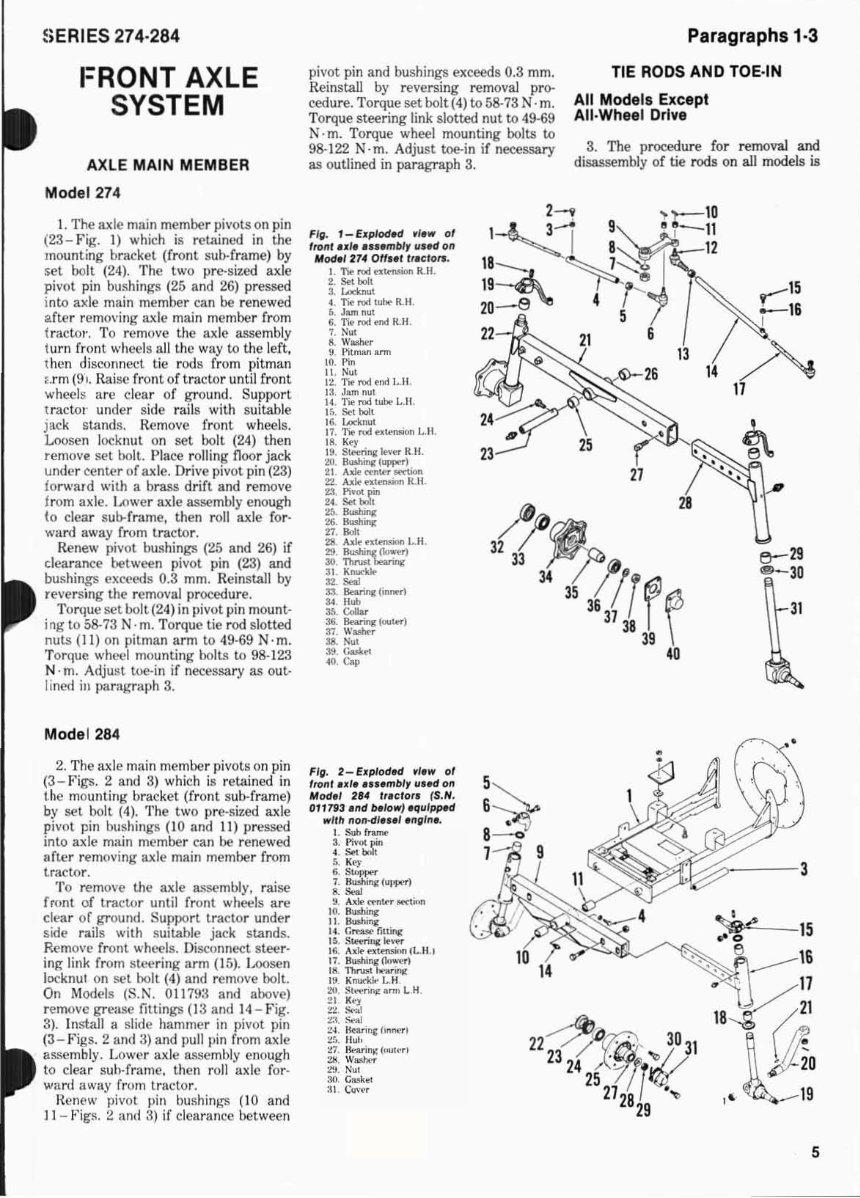

Model 274

I. The axle main member pivots on pin

(23- Fig. I) which is retained in the

mounting bracket (front. sub-frame) by

set bolt (24). The two pre-sized axle

pivot pin bushings (25 and 26) pressed

l nw axle main member can be renewed

after removing axle main member from

t ractor', To remove the axle assembly

turn front ..... heels all the way to the left.

then dis(.'onnect tic rods from pitman

urn (91. Raise front of tr aclor until front

wheels arc clear of ground. Support

tractor under side rails wi th suitable

jack st.1.nds. Remove front wheels.

Loosen locknut on set bolt (24) then

remove set bolt. Place rolling noor jack

under center of axle. Drive pivot. pin (23)

fo rward with a brass drift and remove

from axle. Lower axle assembly enough

to clear sub-fr.!me, then roll axle for-

ward away from tractor.

Renew pivot bushings (25 and 26) if

clearance between pivot pin (23) and

bushings exceeds 0.3 mm. Reinstall by

reversing the removal procedure.

Torque setbol t(24) in pivot pin mount-

ing to 58-73 N· m. Torque tie rod slotted

nuts (II) on pitman arm to 49-69 N· m.

Torque wheel mounting bolts to 98-1 23

N· m. Adjust toe·in if necessary as out·

lined in parab'Taph 3.

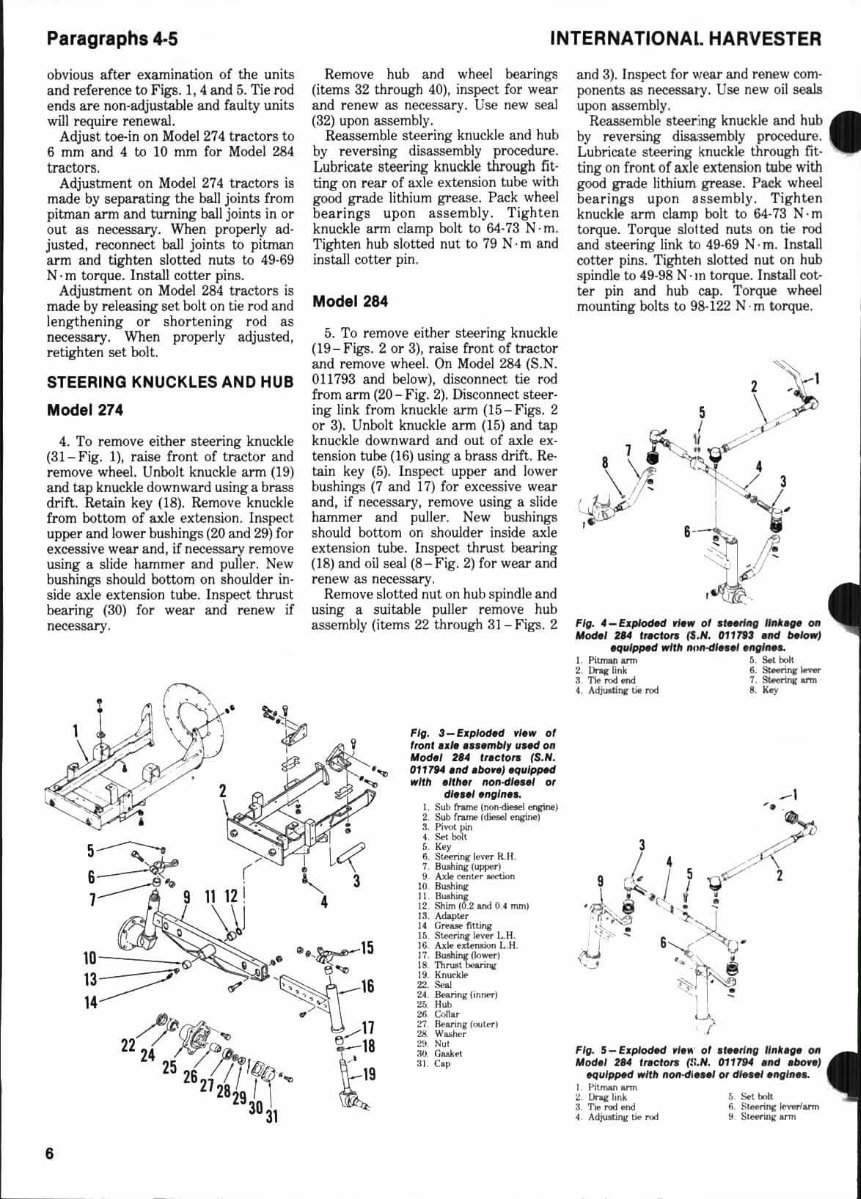

Mode l 284

2. The axle main member pivots on pin

(3- Figs. 2 and 3) which is relained in

the mounting bracket (front sub-frame)

by set bolt (4). The two pre·sized axle

pivot pin bushings (10 and II) pressed

into axle main member can be renewed

after removing axle main member from

tractor.

To remove the axle assembly, rai se

front of tr actor until front wheels are

clt'ar of ground. Support tractor under

side r:iils with suit.able jack stands.

Remove front wheels. Di sconnect ste€r-

jng link from stl.'t'ring arm (15). Loosen

locknul on set boll (4) and remove bolt.

On Model s (S .N. 011793 and above)

remove grease liuings (13 and 14 - Fig.

3). Install a slide hammer in pivot pin

(3 - Fig s. 2 and 3) and ]lull pin from axle

assembly. Lower axle assembly enough

to clear suh-frame. then roll axle for-

ward away from trnctor.

Henew pivot pin bushinl,,>"S (10 and

11 - Figs. 2 and :~) if clearance between

pivot pin and bushings exceeds 0.3 mm.

Reinstall by reversing removal pro--

cedure. Torque set bolt (4) 0058·73 N ·m.

Torque steering link slotted nut to 49·69

N . m. Torque wheel mounting bolts to

98-122 N·m. Adjust toe-in if necessary

as outlined in paragraph 3.

Fit. 1- flfplod.d , 1. 111' 01

Itonl ul ..... mblr lI .. d on

Mod.,274 on .. , tl .eIOrl'.

I. -no rod"~ lUI.

2. Sd bolt

. """,,",

4. Tie rod t~ R.lI.

&. Jam nul

6. Tie rod ~nd R.II .

7. Nut

8 . WaoIwr

9. Pitman ann

LO. Pin

LI. Nul

L2. T~ rOO fro:! 1-11.

13. Jam nul

14. Tie rod tub<> L.II.

If •. Scot bolt

16. Lodmlll

17. Tie rod MI<'f>IIion 1..11 .

18. KfY

19. Sttmng ~ R_H.

20. 8uobine (upptr)

21 Axle ~n~ R't\>On

22. Axle~R.H.

23. PIv<JC •

Paragraphs 1-3

TIE RODS AND TOE-IN

All Models Except

AII·Wheel Drive

3. The procedure for removaJ and

disassembly of tie rods on aJl models is

13

~ 26

14

24. Set:J:"

:u.. ~

~ Bushir«

n. "'"

2:11 • .ult' •• t.o-nsiooo LH .

:29. a..nll(~'

28

3~~

33 3 t:(l;'r@

30. Thrust~

:u. K....-kIo-

"- ,..,

3S. lltannc (in......

34. lIub

"- "'"

36. Bearinc !wI .... '

37. WMho.

38. Nut

" ....

... eo,

Fig. 2_ElIplodH ,I.w 0/

lront ul • .... mbl' "' H on

Mod.1 284 tr,clot' (S.N.

OU7113 end ""0111' , .qlll pptd

III' ltl! non-dl ".'.ngln •.

I. Sub Ir .....

3. Pivot: pin

4. SeI. bNt

:. . K<')'

. . ......

1. llushilllll ("l!Jlt1'1

."""

Y. AU! rmt.-r OKIion

10. 8..ming

II . ButI>in&'

L4. Grnse fittiro«

L5. Slm'i"l '""'

15. AU! '""tmsio ... {LH.1

17. 8uohinl"'"""

18. 'ThnIM .-ariII«

19. li nud<le I_H

2(1. SI.....,~."" I..H.

tl K~)

2:l. So", 1

~l. Sea)

~4 ~v'''' /'n ......

~:,. lIuI,

~7. ~I""h'rl

~. W""""r

:l!I. :->UI

30 G...k.t

al Qr,'(',

5

6 ~

8 -<>

7 9

36

37

I ~

38

39

\

40

~-- 3

5

Paragraphs 4-5 INTERNATIONAL HARVESTER

obvious after examination of the units

and reference to Figs. 1,4 and 5. Tie rod

ends are non-adjustable and faulty units

will require renewal.

Adjust toe-in on Model 274 tractors tI:I

6 mm and 4 to 10 mm for Model 284

tractors.

Adjustment on Model 274 tractors is

made by separating the ball joints from

pitman arm and turning ball joints in or

out as necessary. When properl y ad·

justed, reconnect bal l joints to pitman

arm and tighten slotted nuts to 49·69

N· m torque. Install cotter pins.

Adjustment on Model 284 tractors is

made by releasing set bolt on tie rod and

lengthening or shor tening rod as

necessary. When properl y adjusted,

retighten set bolt.

STEERING KNUCKLES AND HUB

Model 274

4. To remove either steering knuckle

(3I-Fig. 1), Taise front of tractor and

remove wheel. Unbolt knuckle arm (19)

and tap knuckle downward using a brass

drift. Retain key (18). Remove knuckle

from bottom of axle extension. Inspect

upper and lower bushings (20 and 29) for

excessive wear and, if necessary remove

usi ng a slide hammer and puller. New

bushings should bottom on shoulder in-

side axle extension tube. Inspect thrust

bearing (30) for wear and renew if

necessary.

Remove hub and wheel bearings

(items 32 through 40) , inspect for wear

and renew as necessary. Use new seal

(32) upon assembly.

Reassemble steering knuckle and hub

by reversing disassembly procedure.

Lubricate steering knuckle through fit-

ting on rear of axle extension tube with

good grade lithium grease. Pack wheel

bea rings up on assembly. Tighten

knuckle arm damp bolt to 64-73 N· m.

Tighten hub slotted nut to 79 N· m and

install cotter pin .

Mod.1264

5. To remove either steering knuckle

(19 - Figs. 2 or 3), raise front of tractor

and remove wheel. On Model 284 (S.N.

0 11 793 and below), disconnect tie rod

from arm (20 - Fig. 2). Disconnect steer·

ing link from knuckle arm (I5-Figs. 2

or 3). Unbolt knuckle ann (15) and tap

knuckle downward and out of axle ex-

tension tube (16) using a brass drift. Re-

tain key (5). Inspect upper and lower

bushings (7 and 17) fo r excessive wear

and, if necessary, remove using a slide

hammer and puller. New bushings

should bottom on should er inside axle

extension tube. Inspect thrust bearing

(I S) and oil seal (8- Fig. 2) for wear and

renew as necessary.

Remove slotted nul on hub spindle and

using a suitable puller remove hub

assembly (items 22 through 31 - Figs. 2

! l cf

'--.,, 3

4

10 •• ,~15

..,.. -"'e:"'tI

13 ~---' '~" 16

14 ------ " ,

~~.. • / 11

22 24 ~?-- ~18

25

26

/ /T'Il(f·~ t 19

21

28

29

1,\ ~

30

31

6

and 3). Inspect for wear and renew com·

ponents as necessary. Use new oil seal!!

upon assembly.

Reassemble steering knuckle and hub

by reversing disassembly procedure.

Lubricate steering knuckle through fit·

ting on front of axle extension tube with

good grade lithium grease. Pack wheel

bearings upon 8ssembly. Tighten

knuckle arm clamp bolt to 64·73 N· m

torque. Torque slot ted nu ts on tie rod

and stee ring link to 49-69 N · m. Install

cotter pins. Tighteh slotted nut on hub

spindle to 49-98 N· In torque. Install cot-

ter pin and hub cap. Torque wheel

mounting bolts to 98-122 N· m torque.

Fig. 4_EJ.pIoded fie,. 0' .lMrlnt IlMi ... 011

",061' , ... ',acton (S. N. 011 7t! .1Id "Jowl

",ulpped ,.11/, IHIft-dle• ., 'II{/III'"

l. PiurwI &ml 5. Sol. ~

2. Dnoe ~nk 6. S&-'nr .......

3_ '!'I."""ond 7. ~ .....

4 Adjuod".. tit r9d 8. K.y

F/rl. 5_ ElCpIodfi/ ~I .. · 01 "Nt/Itg 1I"t. .. 011

MrxHl '14 fraelo,. r.:' N. 0117SN ."d .bore}

~ul~ ..nit IIOII-dl .. " Of dle .. ,.ltglll ...

I 1'iI ........ ann

~ On.r Imk

3 'J)o I"Od ond

4 AdjuoQnj,: tJto ,,'01

~ 5K1roII

GS~~...,.,

~ SIHrlllll &nil

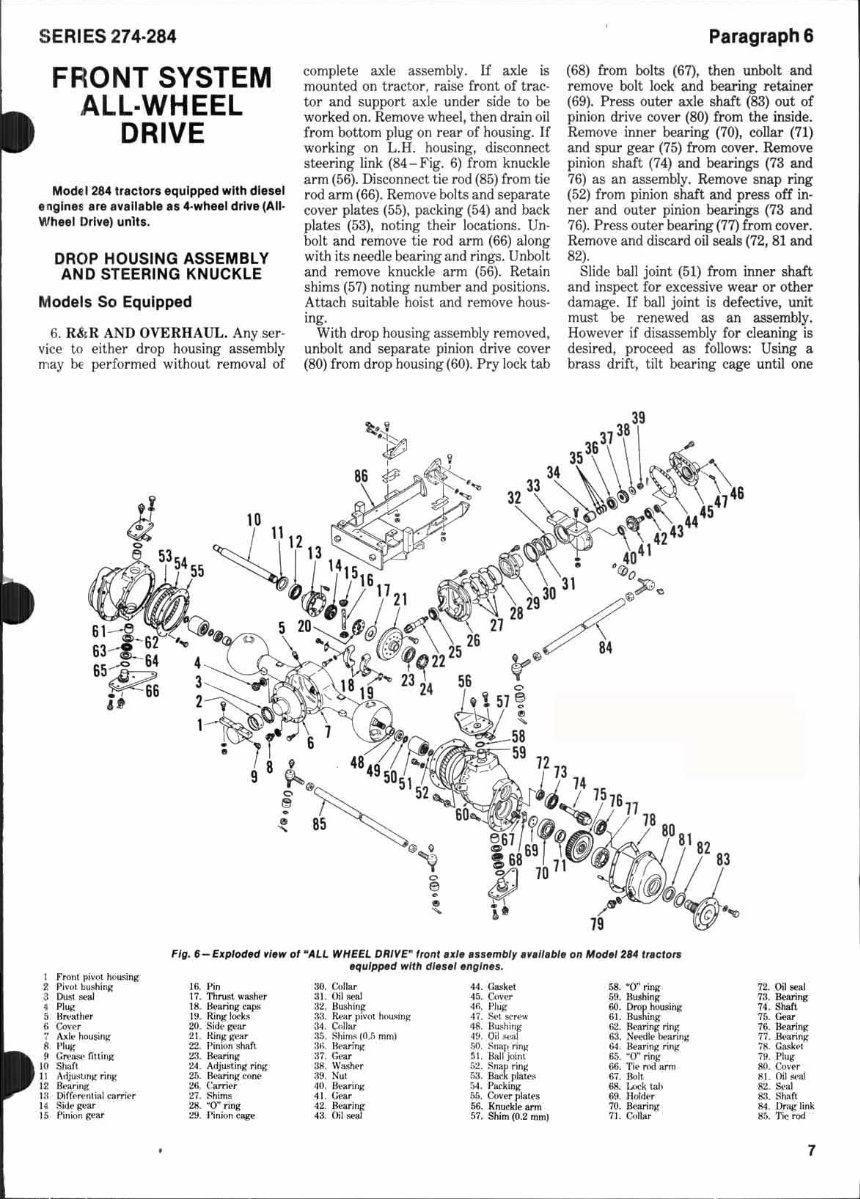

SE RIES 274-284

FRONT SYSTEM

ALL-WHEEL

DRIVE

Model2841raclors equipped with diesel

e nglnel are available n. ·wheel drlye (All ·

Whe. 1 Drive) unlls.

DROP HOUSING ASSEMBLY

AND STEERING KNUCKLE

Models So Equipped

6. R&R AND OVERHA UL. Any se r·

vice to either dr op housing assembly

may be per fo rmed without re moval of

complete axle assembly. LfaxJe is

mounted on tractor, raise front. of trac-

tor and support axle under side to be

worked on . Remove wheel, then drain oil

(rom bottom plug on rear of housing. If

wo rking on L.B. ho usi ng, disconnect

steering link (84 - Fig. 6) from knuckle

arm (56). Disco nnect tie rod (85) from tie

rod arm (66). Remove bolts and separate

cover plates (55), packing (54) and back

plates (53), noting their locations. Un-

bolt and remove tie r od arm (66) along

with its needle bearing and rings. Unbolt

and remove knuckle arm (56). Retain

shims (57) noting number and positions.

Attach suitable hoist and remove hous·

ing.

With drop housi ng assembly removed,

unbolt and separate pinion drive cover

(80) from drop housing (60). Pry l ock tab

ParagraphS

(68) from bolts (67), then unbolt and

remove bolt lock and bearing retainer

(69). Press outer axle shaft (83) out of

pinion drive cover (80) from the inside.

Remove inner beari ng (70), collar (7 1)

and spur gear (75) from cover. Remove

pinion shaft (74) and bearings (73 and

76) as an assembly. Remo ve snap ring

(52) from pinion shaft and press off in·

ne r and outer pinion bearings (73 and

76). Press outer bearing (77) fr om cover.

Remove and discard oil seals (72, 81 and

82).

Slide ball joint (5 1) from inner shaft

and inspect for excessive wear or other

damage. If ball joint is defective, unit

must be rene wed as an assembly.

Howe ve r if disassembly for cleaning is

desired, proceed as foll ows: Using a

brass drifl, tilt bearing cage until one

FI~. 8- E1Iploded ylew 0' - ALL WHEEL DRIVE- 'r01l 181l1e numbly e"ne ble 011 Model 214 '".:10,..

equlp".d WIlli d ln el ell"llIn.

I Fron, piW>! hou$in,o;

2 Pi,-", bushln j/

3 ~,....l

. "~

5 11" .,.1111"

r. (;00.• .".

1 ..... k· hou!Oi'lK

8 Plug

~ Gn· ..... ·fininK

I II Shat,

11 A'ijuAA.!"1! ""K

12 lkarl "ll

I~ PiI(,·,,·I\".1 nnW.

It ~Jto~1IT

15 !"in;"" It"ar

16. I~n

11. Thrusl wWt.-,

18. IlMring •• JlI'

19. RinK k>r.~

20. Si<k·1t"1IT

21. Itin/lW""

22. l"n o»l!!M1l

:1.1. IlearinK

~4. Adj... uinK ring

2',. Il«orinj/ cfII>I'

:!II. C:.r,;..,

n ~hi ....

2lI."O"ril'lj(

:19. F~n""' _

:W. C.~"'r

31 . Oil ot1Il

3'l . HU!lhlnp

33. fk,.., 1''''(>1 ......... ''01

301 . (;t.II",

:1:.. !ihlms In .. ~ mml

3/;. B .... ri l1l

37. r .......

:III. W""","r

:.19. Nu'

~O. U ... nng

41. (...,.,.

42. }\ellJitljf

~~. 0I1..".j

72. OIl 8e~1

'13. 8wing

74 . Shat\

75. Go>a.r

76. Hte.riIII:

77. K, .. arinK

;~. GUIM

;9. 1'1u~

~. C",·tr

~1. Oil "">11

Rt. Sral

83. ~h:on

1!4 . Urnt: link

H~. ')'ioo, rod

7

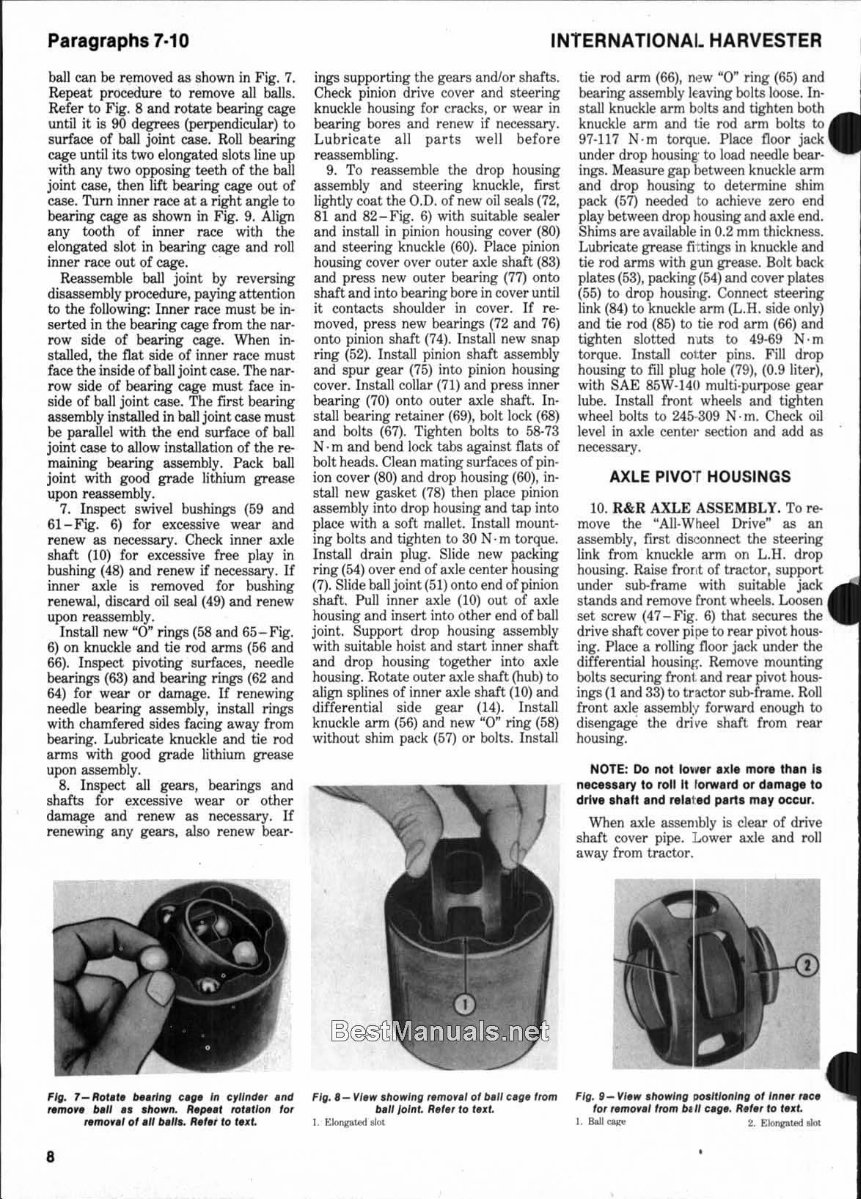

Paragraphs 7·10

ball can be removed as shown in Fig. 7.

Repeat procedure to remove all balls.

Refer to Fig. 8 and rotate bearing cage

until it is 90 degrees (perpendicular) to

surface of ball joint case. Roll bearing

cage un til its two elongated slots line up

with any two opposing teeth of the ball

joint case, then lift bearing cage out of

case. Turn inner race at a right angle to

bearing cage as shown in Fig. 9. Align

any tooth of inner race with the

el ongated sl ot in bearing cage and roll

inner race out of cage.

Reassemble ball joint by reversing

disassembly procedure, paying attention

to the fo ll owing: Inner race must be in-

serted in the bearing cage from the nar-

row side of bearing cage. When in-

stalled, the flat side of inner race must

face the inside of ball joint case. The nar -

row side of bearing cage must (ace in-

side of ball joint case. The fi r st bearing

assembly installed in ball j oint case must

be parallel with the end surface of ball

joint case to a ll ow installation of the re-

maining bearing assembly. Pack ball

joint with good grad e lithium grease

upon reassembly.

7. Inspect swivel bushings (59 and

61 -Fig. 6) for excessive wear and

renew as necessary. Check inner axle

s haft (10) for excessive free play in

bushing (48) and renew if necessary. If

inner axle is removed for bushing

renewal, discard oil seal (49) and renew

upon reassembly.

Install new "0 " rings (58 and 65- Fig.

6) on knuckle and tie rod arms (56 and

66). Inspect pivoting surfaces, needle

bearings (63) and bearing rings (62 and

64) fo r wear or damage. If renewing

needle bearing assembly, install rings

with chamfered sid es facing away from

bearing. Lubricate knuckl e and tie rod

arms with good grade lithium grease

upon assembl y.

8. Inspect all gears, bearings and

shafts for excessive wear or other

damage and renew as necessary. If

renewing any gears, wso renew bear-

FIg. 7 _ Rol.,. be.rllIg ug. III e,/llId" .lId

... mo" bell ••• hOWII. R,~" ro"tloll 10'

... mo'" 01.11 &.11 •• ""'f 10 lut

8

INTERNATIONAL HARVESTER

ings supporting the gears andlor shafts.

Check pinion dr ive cover and steering

knuckle housing for cracks, or wear in

bearing bores and renew if necessary.

Lubri cate all parts well be fo re

reassembling.

9. To reassemble the drop housi ng

assembly and steer ing knuckle, first

lightly coat the 0 .0 , of new oil seals (72,

81 and 82- F ig. 6) with suitable sewer

and in stall in pinion housing cover (SO)

and steering knuckle (60). Place pinion

housing cover over outer axle shaft (83)

and press new outer bear ing (77) onto

shaft and into bearing bore in cover until

it contacts shoulder in cover. If re-

moved, press new bearings (72 and 76)

onto pinion shaft (74). Install new snap

ring (52). Install pinion shaft assembly

and s pur gear (75) into pinion housing

cover. Install collar (71) and press inner

bearing (70) onto outer axle shaft. In-

stall bearing retainer (69), bolt lock (68)

and bolts (67). Tighten bolts to 58-73

N . m and bend lock tabs against flats of

bolt heads. Clean mating surfaces of pin-

ion cover (80) and drop hous in g (60), in-

stall new gasket (78) then place pinion

assembly into drop housing and tap into

place with a soft mallet. Install mount-

ing bolts and tighten to 30 N· m torque.

Install drain plug. Slide new packing

ring (54) over end of axle center housing

(7). Slide ball joint (51) onto end of pinion

shaft. Pull inner axle (10) out of axle

housing and insert into other end of ball

joint. Suppo rt drop housing assembly

with suitable hoist and start inner shaft

a nd dr op housing together into axle

housing. Rotate outer axle shaft (hub) to

align splines of inner axle shaft (10) and

differential side gear (14). In stall

knuc kl e arm (56) and new ~O" r ing (58)

without shim pack (57) or bolts. Install

FIg.'- VI.w .how/lIg ,.mor.' 01 b.1I e.g. lrom

b./I jolllt. " .,., to lut

I. ~\.Od oIot

ti e rod arm (66), ne w ~O" ring (65) a nd I

bearing assembly leaving bolts loose. In- I

stall knuckle arm bolta and tighten both .

knuckle arm and tie rod arm bolts to

97- 117 N·m torque. Place Doo r jack

under drop housing' to load needle bear-

ings. Measure gap between knuckle arm

and drop housing to determine shim

pack. (57) needed to achieve zero end

play between drop housing and axle end.

Shims are available in 0,2 mm Lhickness.

Lubricate grease fittings in knuckle and

tie rod arms with gun grease. Bolt back

plates (53), packing (54) and cover plates

(55) to drop housing. Connect steering

link (84) to knuckle arm (L.H. side only)

and tie rod (85) to tie rod arm (66) and

tighten slotted nuts to 49-69 N· m

torque. Install colter pins. Fill drop

housing to fill plug hole (79), (0.9 liter ),

with S AE 85W-141l multi·purpose gear

lube. Install front wheels and tighten

wheel bolts to 245-309 N·m. Check oil

level in axle cente.· section and add as

necessary.

AXLE PIVOT HOUSINGS

1 0. R&R AXLE ASSEMBLY. To re-

move the "All· Wheel Drive" as an

assembly, first disconnect the steering

link from knuckle arm on L.H. drop

housing. Rai se front of tractor, s upport

under sul:rframe with suitable jack

stands and remove front wheels. Loosen

set screw (47-Fig. 6) that secures the

drive shaft cover pi pe to rea r pivot hous-

i ng. Place a ro lli ng floor jack under the

differential housinf~. Remove mounting

bolts securing front and rear pivot bous·

ings( 1 and 33) to tractor sub-frame. Roll

front axl~ assembly forward enough to

disengage the dri ve shaft from rear

hous ing.

NOTE: Do not low.r exl. more thin I.

nec .... ry to roll II / orwud or dlmlge to

drlv •• hllt Ind r.tl t.d Plrt. may occur.

When axle assembly is clear of drive

shaft cover pipe. Lower axle and roll

away from tractor.

F/g. 8_ VI ... • how/lIg PO.lllolllllg 01 In n., ,.e.

for ,.mor.,lrom bill ctg • . " .,,, 10 lu' .

I. Ball can 2. EIMp\.Od oIot

SERIES 274·284

Insu..nation of axle assembly is the

reverso! of removal procedure. Lightly

coat sl ,li nes of drive shaft. and coupling

•

fik'eve~ with Molykote lubricant. Apply

Loctit{ 1262 or equivalent to thr eads of

IIXle mounting bolts. Torque mounting

I:olts to 244 ·307 N· m. Torque slotted

rut 011 sleering link to 49·69 N· m.

Torque fronl wheel mounting bolts to

245·30~) N ·m.

II. R&R AND OVERHAUL PfVQT

JIOUS.l NGS. Service of the front and

r2ar pi vot housings (1 a nd 33 - Fig. 6) reo

<Iuires removal of the comple te axle

assemtly as outlined in paragraph 1 0.

SCrviCf of the front housing is limited to

r ~placemenl of the dust seal (3) and

bushinl[ (2).

NOTI:: Rlmo .... 1 01 grea •• IIIlIng may be

necessary tor (emoul of !tont pivot

bu.hln, •.

Whcli replacing (ront pivot bushing,

line up hole in bushing with grease fit-

ting hole. Always install new dust seal.

Lubri cE.te bushing wi th multi·purpose

Ii :.hium grease.

To I 'e move rear p ivot housing

(~.3 - FiJ. 6) first drain center housing (7)

a 1d remove bolts from housing cover

(~5), then using two of the bolts, turn

tllem hto jackscrew hol es on cover.

Turn b)lts evenly to push cover Crom

h' lUsi n!! . Discard gasket (4 4). Using a

bl 1l.SS dl-ift, tap gear and bearings (items

4t), 41 and 42) (rom cover (45). Inspect

g'~nr Imd bea rings and renew iJ

nl!<!essa ry. Remove and discard oil seal

(43). Rpm ovl! housing oil seal (3 1) and

drive out bushing (32). Drive in new

bushing and install new oi l seal. Press

la rge lwaring (42) onto input shaft side

01' gear (41) and small bearing (40) onto

hnus ing side of gear. Tap bearing and

gl: ar as.;embly into bore of housing. I n-

:itall ne'N oil seal (43) and cover gas ket

144). th~'n bol t on cover (45) to housing

l3l). Fi I center housing (5) to fillllevel

10 -I'I.w tllowl n" P'OC~Il'. 10' ell.dlng

prffol d 01 pInIon b", 'n" . A.I., Ig lUI.

I :;"rillll: "" ....

2 ' ''1.. 3. 1'1.",

plug (4), (2.7 liters), with SAE 86W- 140

multi·purpose gear lube.

DIFFERENTIAL

12. R&R AND OVERHAUL. To re-

move the differential assembly for ser-

vice, first remove axle assem bl y as

out lined in paragraph 10 , then remove

dr op housing assemblies as out lined in

paragraph 6. Remove front and rear

pivot housings as outlined in paragraph

11 . Pull both axle shafts (I O- Fig. 6) out

of axle housing. Remove pinion cage (29)

mounting bolts , then using two of the

bolts, turn them into the jackscrew holes

on flange of cage. Tum bolts evenly and

push pinion cage (29) from car rier

assembly (26). Retain shims (27) and

discard "0" ring (28). Attach lifting

brackets and a suitable hoist to the dif-

ferential carrier assembly (26). Remove

bolts and lift carrier assembly out of axle

housing. Flatten tabs on ring locks ( 19)

and remove. Unbolt and remove bearing

caps (1 8).

NOTE: B •• rlng e.p •• hould b. Ind.xitd

lor eorr.cl r ..... mbly .

Remove bearing adjusting rings (1 1

and 24 ) and lift differential carrier

asse mbly out of housi ng. Unbolt and

separate r ing gea r (2 1) from carrier (13)

using a soft hammer. Remove side gear

(20) and thrust washer (17) from ring

gear recess. Remove ring gear bearing

(23) using a suitable puller. Remove pin

retaining screw in differential carrier

(13), then drive out p in (16) and remove

s id e and pinion gears (14 and J5).

Remove differential carrier bearing (1 2)

using a suitable puller.

13. To remove the drive pinion

assembly from the pinion cage, remove

cotter pin then remove slotted nu t

(39 - Fig. 6), was her (38) and gear (37).

Press pin ion sha ft (22) out of small bear-

A

d .

L

Ii'"

~

•

,j,

,

•

""

'c

,

IT J

FI" . 11- Cro .. tKllfnI.' dl.",.m g/ pfnkln u".

.tId dlll.,.nl l.1 . 1I0wl n" dlm.n,Ion, 10' pinI on

mOllnlln" dl. l.ne • . 1f., ,, 10 ptr ."rtptt 15.

Paragraphs 11·15

ing (36) and pinion cage (29). Press off

bearing cone (25) and retain coll ar (34)

and shim pack (35) noting thickness of

shim pack after removal to aid in

reassembly. Press bearing cups Crom

pini on cage.

14. Clean and inspect all part3 (o r ex·

cessive wear or o ther damage and

replace as necessary. Lubricate all mov·

ing parts with petroleum jelly prior to

assembly. Press large bearing cone (25)

onto pinion shaft (22). Press new hear-

ing cups, if removed, into p in io n cage

(29). Install collar (34) and sh im pack

(equal to one removed) onto pinion shaft.

Insert pinion shaft with shims and collar

into pini on cage and, using a suitable

piece of pipe, press small bearing cone

(36) onto pinion shafl Leave pinion

assembly on press and wrap a stri ng

around pinion cage, then connect a hand

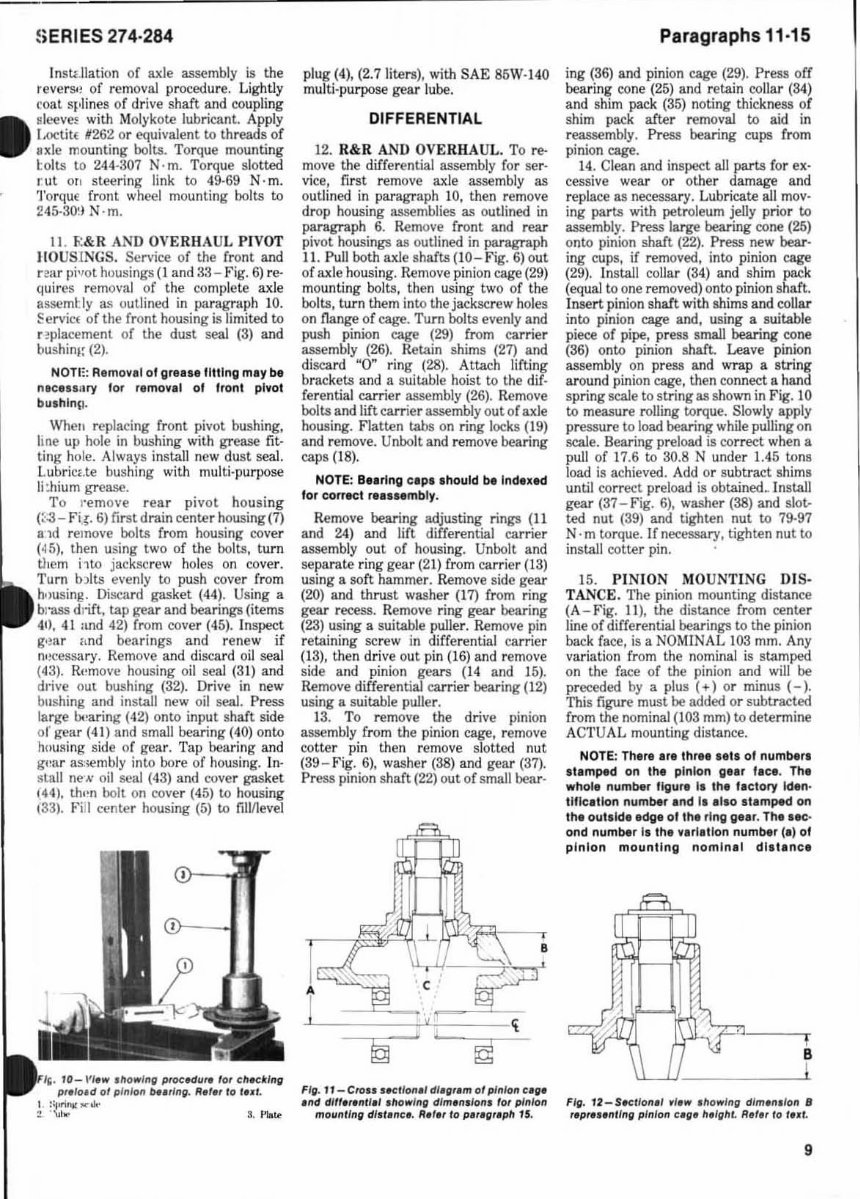

spring scale to string as shown in Fig. 10

to measure rolling torque. Slowly app ly

pressure to load bearing while pulling on

scale. Bearing preload is correct when a

pull of 17.6 to 30.8 N under 1.45 tons

load is achieved. Add or subtract s him s

until co rr e<:t preload is obtained~ Install

gear (37-Fig. 6), washer (38) and slot,..

ted nut (39) and tighten nut to 79-97

N· m torque. U necessary, tighten nut to

install cotter pin.

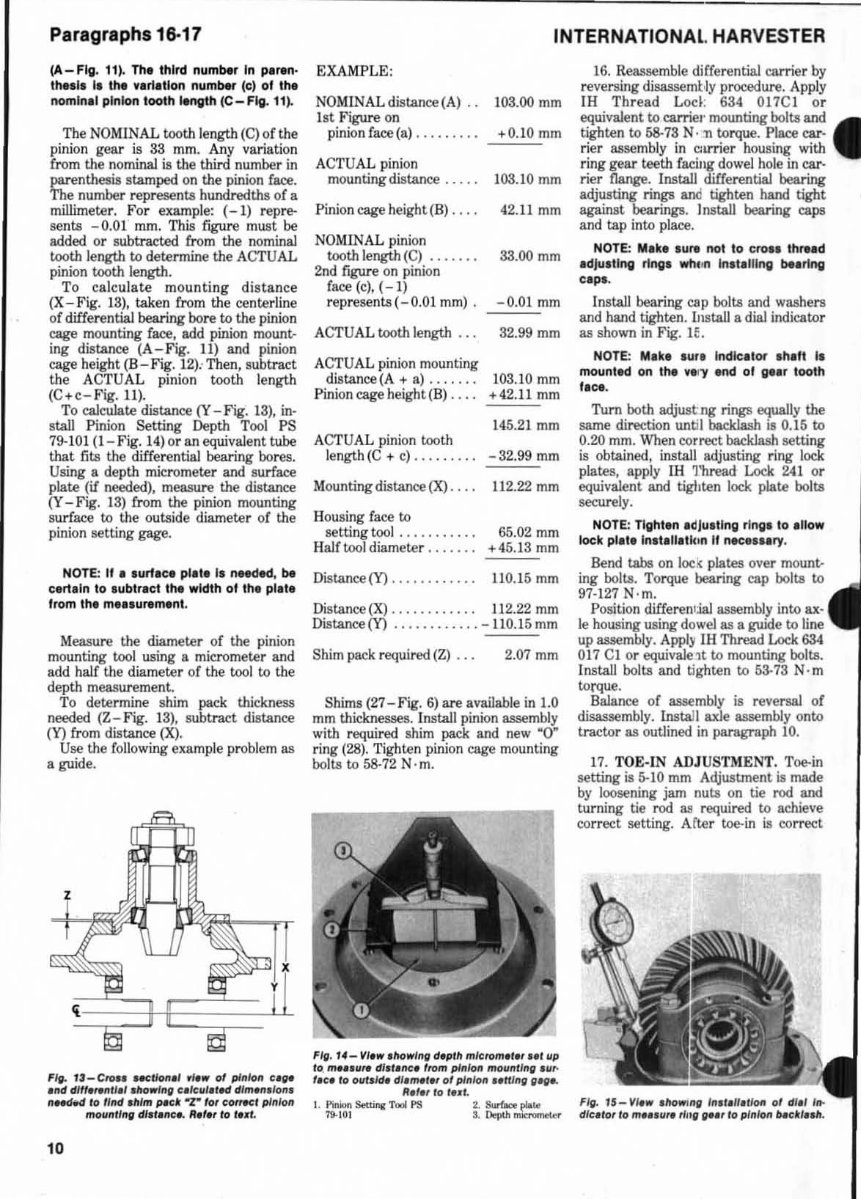

15. PI NION MO UNT ING DIS-

TANCE. The pinion mounting distance

(A- Fig. 11 ), the distance from center

line of differential bearings to the pi nion

back face, is a NOM INAL 103 mm. Any

variation from the nominal is stamped

on the face of the pinion and will be

preceded by a plus (+) or mi nus (-).

This figure must be added or subt racted

from the nominal (103 mm) to determine

ACTUAL mounting di s ta nce.

NOTE: There .r. Ihr ••• els 01 numbe.-.

slamped on Ih. pinion g •• r I.e •. Th.

whol. number IIgur. I. thl Iletory Iden·

tIIle.tlon number and I •• 110 atamped on

the outlld. edge 01 the ring gelr. Th. ,.c,

ond number Is the v.rl.tlon number (.) 01

pinion mounting nomln.1 dllt.ne.

L

Fig. 12 -SKtion.' ,I .w t ll o wln " dlm.ntlon 8

r.pr".nlln" p inion u". ".1",,1. 1f. I" 10 I • ., .

9

Paragraphs 16-17

(A-Fig . 11). The third number In perin·

Itt .. ,. I, 1M "'In,tlon number (el 01 the

nomln.1 pinion tooth length (e - F~. 11).

The NOMI NAL tooth length (C) of the

pinion gear is 33 mm. Any variation

from the nominal is the third number in

parenthesis stamped on the pinion face.

The number represents hundredths of a

millimeter. For example: (- 1) repre-

sents -0.01 mm. This figure must be

added or subtracted from the nominal

tooth length to determine the ACTUAL

pinion tooth length.

To cal culate mounting distance

(X - Fig. 13), taken from the centerline

of differential bearing bore to the pinion

cage mounting face. add pinion mount-

ing dista~ (A - Fig. 11) and pinion

cage height (B - Fig. 12): Then, subtract

the ACTUAL pinion tooth length

(C+c-Fig. 11 ).

To ca1culate distance (Y - Fig. 1 3), in-

stall Pinion Setting Depth Tool PS

79-101 (1 - Fig. 14) or an equivalent tube

that fits the differential bearing bores.

Using a depth micrometer and surface

plate (if needed), measure the distance

(Y -Fig. 13) from the pinion mounting

surface to the ou tside diameter of the

pinion setting gage.

NOTE: If • luri.ce pl.le II needed, be

cert.ln to lublr.ct Ihe width of the pl.le

from the m ... ur.ment.

Measure the diameter of the pinion

mounting tool using a micrometer and

add half the diameter of the tool to the

depth measurement.

To determine shim pack thickness

needed (Z- Fig. 13). subtract distance

(Y) from distance 00.

Use the following example probl em as

a guide.

Fit . U -Cro .. ueUon.' NW 01 pI"lon CI.,.

.1Id dltt .... nll.,.howfn ll f:./f:ul.," dl m.". lo".

nHCWd to lind . hlm pglr 'T' 101 f:QnWCf pinion

mov"I1,,'1 dl.f.nf: •. It.,., 10 I.,d.

10

INTERNATIONAl. HARVESTER

NOMI NAL distance (A) .. 103.00 mm

1 st Figure on

pinion face (a) ......... +0.10 mm

ACTUAL pinion

mounting distance ..... 103.10 mm

Pinion cage height(B) . . . . 42.11 mm

NOMINAL pinion

tooth length (C) ....... 33.00 mm

2nd figure on pinion

r ... (,),(-I)

represen ts( - O.OI mm) . -0.01 mm

ACTUAL tooth length. . . 32.99 mm

ACTUAL pinion mounting

distance (A + a) . . . . . . . 103.10 mm

Pinion cage height (B) .... +42. 11 mm

145.21 mm

ACTUAL pinion tooth

length(C + c) ......... - 32.99 mm

Mounting distance (X) . . .. 112.22 mm

Housing face to

setting tool . . . . . . . . . . . 65.02 mm

Half tool diameter ....... +45.13 mm

Distance(¥) ............ 110.15 mm

Distance (X) .... • ....... 112.22 mm

Distance(¥) .. . ......... -1l0.15mm

Shim pack required (Z) ... 2.07 mm

Shims (27-Fig. 6) are available in 1.0

mm thicknesses. Install pinion assembly

with required shim pack and new "O~

ring (28). Tighten pinion cage mounting

bolts to 58-72 N · m.

"II . '4- VI.w .lIow''''1 d.plll mlclQIII.III .1t lip

to. m ... u... dl.I .nf:. f rom pinion mou"tl"'1'U,,

I.c. /0 OIll,Id. dl.mI'" 01 p1" Io" .. lIlnllll"'''

It.I., 10 I .... .

I. Pinion Settillj( Tool PS 2. SurlJo::e plaw

79-10 1 3. ~ mim>Inet«

16. Reassemble differential camer by

reversing disassembly procedure. Apply

IH Thread Lod : 684 017C I or

equivalent to carriel' mounting bolts and •

tighten to 5&-73 N· n torque. Place car ·

rier assembly in camer housing with

ring gear teeth facing dowel hole in ear-

rier !lange. Install differential bearing

adjusting rings and tighten hand tight

against bearings. Jnstall bearing caps

and tap into place.

NOTE: Mlk. lure not to CIO .. th,e. d

.djuiling Ilngl whim Inlt.lllng beerlng

C.pl.

Install bearing cap bolts and washers

and hand tighten. J..IlstaU a dial indicator

as shown in Fig. JE.

NOTE: M.ke .Utl I ndk.tor Ih.ft II

mounltd on the veJ OY .nd 01 g'.' tooth

f.c •.

Tum both adjustng rings equally the

same direction until backlash is 0.15 to

0.20 mm. When correct backlash setting

is obtained. install adjusting ring lock

plates, apply lH 1'hread Lock 241 or

equivalent and tigllten lock plate bolts

securely.

NOTE: Tlght.n edlultlng rlngl to . lIow

lock pl.te Inlt.llltkin II nee .... ".

Bend tabs on loc .( plates over mount.-

ing bolts. Torque beating cap bolts to

97-127 N · m.

Position differential assembly into ax-

le housing using dowel as a guide to line

up assembly. Appl)' IH Thread Lock 6S4

0 17 CI or equivale1t. to mounting bolts.

Install bolts and tighten to 53-73 N·m

torque.

Balance of assembly is reversal of

disassembly. Install axle assembly onto

tractor as out lined in paragraph 10.

1 7. TOE-IN ADJUSTMENT. Toe-in

setting is &-10 mm Adjustment is made

by loosening jam nuUl on tie rod and

turning t ie rod as required to achieve

correct setting. After toe-in is correct

Fit. TS - Vllw .lIow",'1 In,t.lI.tloft 01 d l./ lit-

dlf:llot'O mll , ur. rill , tN' 10 pI"lon o.ct/ .. II.

You're Reading a Preview

What's Included?

Fast Download Speeds

Online & Offline Access

Access PDF Contents & Bookmarks

Full Search Facility

Print one or all pages of your manual

$41.99

Viewed 75 Times Today

Loading...

Secure transaction

What's Included?

Fast Download Speeds

Online & Offline Access

Access PDF Contents & Bookmarks

Full Search Facility

Print one or all pages of your manual

$41.99

Thank you for considering this comprehensive Service Repair Workshop Manual for the Case IH 284 Tractor.

This manual is an invaluable resource covering every Service & Repair Procedure, designed to save you significant costs by enabling you to perform your own repairs. It provides easy-to-follow, step-by-step instructions and detailed illustrations for all servicing and repairs.

Upon acquisition, this manual becomes your permanent asset, allowing you to print individual pages, chapters, or the entire manual. It is also compatible for viewing on tablets and smartphones.

MODELS COVERED:

- All Models/Engines/Trim/Transmissions Types Are Covered.

CONTENTS:

- This high-quality Service Repair Workshop Manual encompasses all repair procedures from A to Z, ensuring comprehensive coverage of every repair and service procedure.

COMPUTER REQUIREMENTS:

- This manual is compatible with all PC & MAC Computers, tablets, and mobile phones. It only requires adobe reader, which is typically pre-installed on most computers or can be downloaded for free.

DELIVERY:

- Upon payment via Visa, MasterCard, or PayPal, the manual will be instantly emailed to the address provided during checkout.

Customer Satisfaction Guaranteed.