Claas Lexion 480 Repair Manual

What's Included?

Fast Download Speeds

Online & Offline Access

Access PDF Contents & Bookmarks

Full Search Facility

Print one or all pages of your manual

188 678.1 - RHB LEXION 480 1.2.1

Safety Rules

SAFETY RULES Important notice

The instructions contained in this manual

should be carefully read and observed by all

persons involved with the operation, mainte-

nance and inspection of this machine in order to

prevent accidents. In particular, read the section

“Safety rules”.

The use of spare parts, accessories and

ancillary equipment other than genuine CLAAS

products or those which have been tested and

approved by CLAAS, may change the specified

design characteristics of this CLAAS machine

or detract from its functional performance, with

a possible adverse effect on the active and/or

passive operational safety of the machine and

its occupational safety standards (accident

prevention).

CLAAS is in no way liable for any damage or

personal injury caused through the use of other

than original or approved CLAAS parts, acces-

sories and ancillary equipment.

Technical data, dimensions and weights are

given as an indication only. CLAAS reserve

the right to make changes subsequently as

technical developments continue.

Responsibility for errors or omissions not

accepted.

Front, rear, right and left refer to the direction of

forward travel.

Safety Rules

1.2.2 RHB LEXION 480 - 188 678.1

Safety Rules

Identification of warning and danger signs

All parts of this manual having to do with your safety

or the safe operation of the machine are marked

with the following signs. Please pass all safety

instructions on to other users, too.

DANGER!

Sign to indicate instructions which must be

observed. Failure to do so would cause

danger to life and limb to the operator and

the people around him.

☞ Preventive measures

ATTENTION!

Sign to indicate instructions which must be

observed. Failure to do so could result in

damage to the machine.

☞ Measures to prevent damage to the

machine.

NOTE!

Sign to indicate instructions for a more

efficient and economic use of the machine.

CAUTION!

Sign to indicate instructions to be followed

during disassembly / assembly.

ENVIRONMENT!

Sign to indicate instructions which must be

observed in order to avoid damage to the

environment.

Danger to the environment is caused by irregular

handling and incorrect disposal of toxic material

(e.g. old oil).

The warning and instruction signs placed on the

machine provide important recommendations for

safe operating. These instructions involve your

safety – observe them at all times!

Correct use of the machine

Fitting and retrofitting of ancillary equipment which

is not originally manufactured by CLAAS, and, in

addition, also modifications and changes may only

be carried out with the consent of CLAAS, as any

such actions may have considerable adverse

effects on the safety and operational function of the

machine.

Any arbitrary modifications carried out on the

machine will relieve the manufacturer of all liability

for any resulting damage or injury.

General safety and accident prevention

regulations

1. In addition to the instructions contained in this

manual, also observe the general safety and

accident prevention regulations.

2. Always comply with local traffic regulations

when driving on public roads.

3. Before starting the engine ensure that the

transmission is in neutral and that all guards

are installed and in their correct position.

4. Start the engine only from the operator's seat.

Never attempt to start the engine by shortening

across the starting motor terminals as the

machine may immediately start to move.

5. Before moving away, always check the

immediate vicinity of the machine. Ensure

adequate visibility. For a warning, always blow

the horn before starting up!

6. Never run the engine in a closed building!

7. Clothing worn by the fitter must be close-fitting.

Avoid wearing loose jackets, shirts or ties.

8. Handle fuel with care. – It is highly flammable.

Never refuel the machine in the vicinity of

naked flames or sparks.

Do not smoke during refuelling!

9. Always stop the engine and remove the ignition

key before refuelling. Fill the fuel tank outdoors.

Clean up any spilled fuel immediately!

10. Prevent fires by keeping the machine clean!

11. Take care when handling brake fluid and

battery acid (toxic and corrosive)!

12. Always blow the horn before starting the engine

and engaging the main drive.

188 678.1 - RHB LEXION 480 1.2.3

Safety Rules

Leaving the machine

1. When leaving the machine, ensure that it will

not roll away (apply parking brake, chock

blocks). Shut off the engine, remove the main

switch key (ignition key) and lock the operator’s

cab (if installed)! – Turn off the battery isolating

switch!

2. Never leave the machine unattended as long as

the engine is still running!

3. Lower the front attachments to the ground

before leaving the combine-harvester.

Compressor-type air conditioner

1. The air conditioning system is filled with HFC

refrigerant R 134 A. HFC refrigerants must not

be vented to the atmosphere! – Therefore,

please take appropriate precautions when

working on the compressor-type air conditioner.

2. Maintenance and repairs are only to be carried

out by competent, professional service centres

qualified to handle refrigerants. Refrigerants

must always be discharged by use of the

correct recovery equipment and disposed of for

recycling.

Maintenance

1. Repair, service and cleaning work and the

elimination of malfunctions should only be

performed with the drive and the tractor engine

switched off – remove the ignition key!

2. Escaping fluid (fuel or hydraulic oil) under high

pressure can penetrate the skin and cause

serious injury. In such a case, consult a doctor

immediately as otherwise serious infections

may result!

3. Always turn off the battery isolating switch

before carrying out any electrical repairs on the

machine.

4. Be careful when opening the radiator cap.

The radiator is under pressure when the engine

is hot!

5. Dispose of oil, fuel and filters in a way that is

harmless to the environment and in accordance

with existing anti-pollution regulations!

6. Do not attempt to mount a tyre unless you have

the proper equipment and experience to

perform the job safely.

7. Retighten the wheel nuts and wheel bolts

regularly!

8. Only have qualified workshops carry out repair

work on the hydraulic system!

9. Always turn off the battery isolating switch

before carrying out any maintenance work on

the machine and on the engine.

Basic rule

Always check the operating and road safety of the

machine before using it.

Pressure accumulator

Be especially careful when working on the pressure

accumulators! Pressure accumulators are under

high pressure!

With valve-controlled pressure accumulators – as

for example on the CLAAS Autopilot – first slacken

the short-circuit bolt before carrying out any repair

work at the pressure accumulator. This is necessary

to dump the hydraulic pressure.

1.2.4 RHB LEXION 480 - 188 678.1

Safety Rules

188 678.1 - RHB LEXION 480 1.5.1

Specifications

SPECIFICATIONS

Lubricants chart

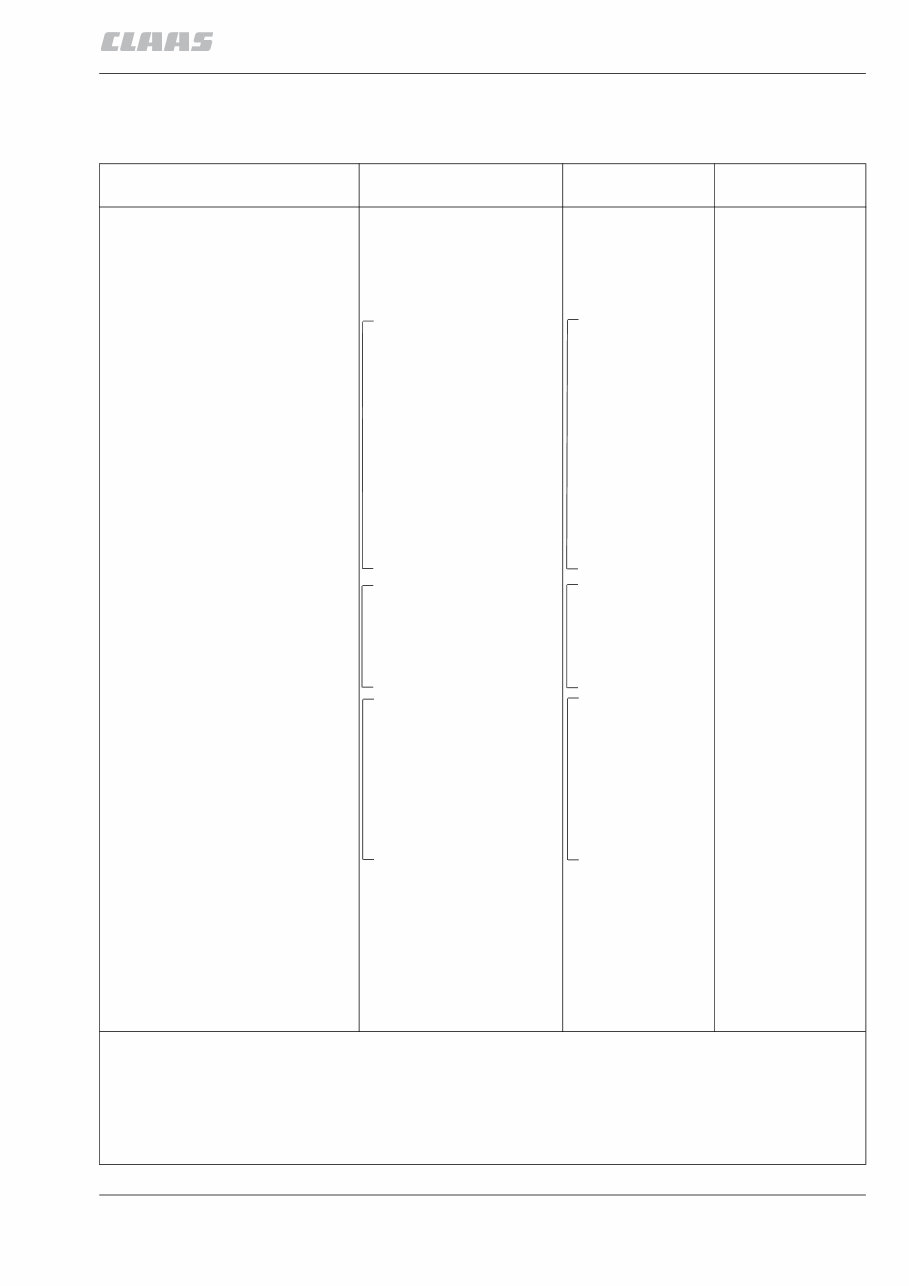

Component Type of lubricant Viscosity Capacity

Hydraulic system Multi-grade hydraulic oil

ISO-VG 46 conforming to

DIN 51 524 specifications,

part 3**

approx. 20 litres

(oil change)

approx. 70 litres

(new system filling)

Manual gearbox

20 t / 17 t

Multi-grade gearbox oil

conforming to

(MIL-L-2105 B)

API-GL-5-90 specifications

90

7.0 litres

Manual gearbox

20 t HD

6.5 litres

Final drives

20 t / 17 t

8.0 litres each

Planetary gearbox

20 t

5.0 litres each

Uni-spreader fan gearbox

(751 480.1)

0.48 litres

Uni-spreader fan gearbox

(763 099.1)

0.6 litres

Threshing drum

reduction gearbox

Multi-grade gearbox oil

conforming to

(MIL-L-2105)

API-GL-4-90 specifications

90

1.8 litres

Transfer gearbox

(engine output shaft)

3.0 litres

Rotor drives 1.75 litres each

Grain tank unloading tube

Upper angle drive

Rolling bearing grease,

e.g. Alvania R3

270 g

Grain tank unloading tube

Lower angle drive

(up to serial no. …)

530 g

Grain tank unloading tube

Lower angle drive

(from serial no. …)

900 g

Foot brake ATE brake fluid SAE-specifications

DOT 4

Reservoir must

always be full

SANDEN compressor SD 7 H 15 Sanden oil SP 20 PAG as required

(approx. 300 cm³

for initial filling)

Refrigerant R 134a 1800 g

** When selecting the hydraulic oil, the following conditions need to be met:

Pour point < -25 °C (DIN ISO 3016)

Viscosity 0 °C < 600 cSt. (DIN 51 562)

Viscosity 40 °C max. 50.6 cSt. (DIN 51 562)

Viscosity index > 170 (DIN ISO 2909)

The oil must have detergent properties!

Specifications

1.5.2 RHB LEXION 480 - 188 678.1

Specifications

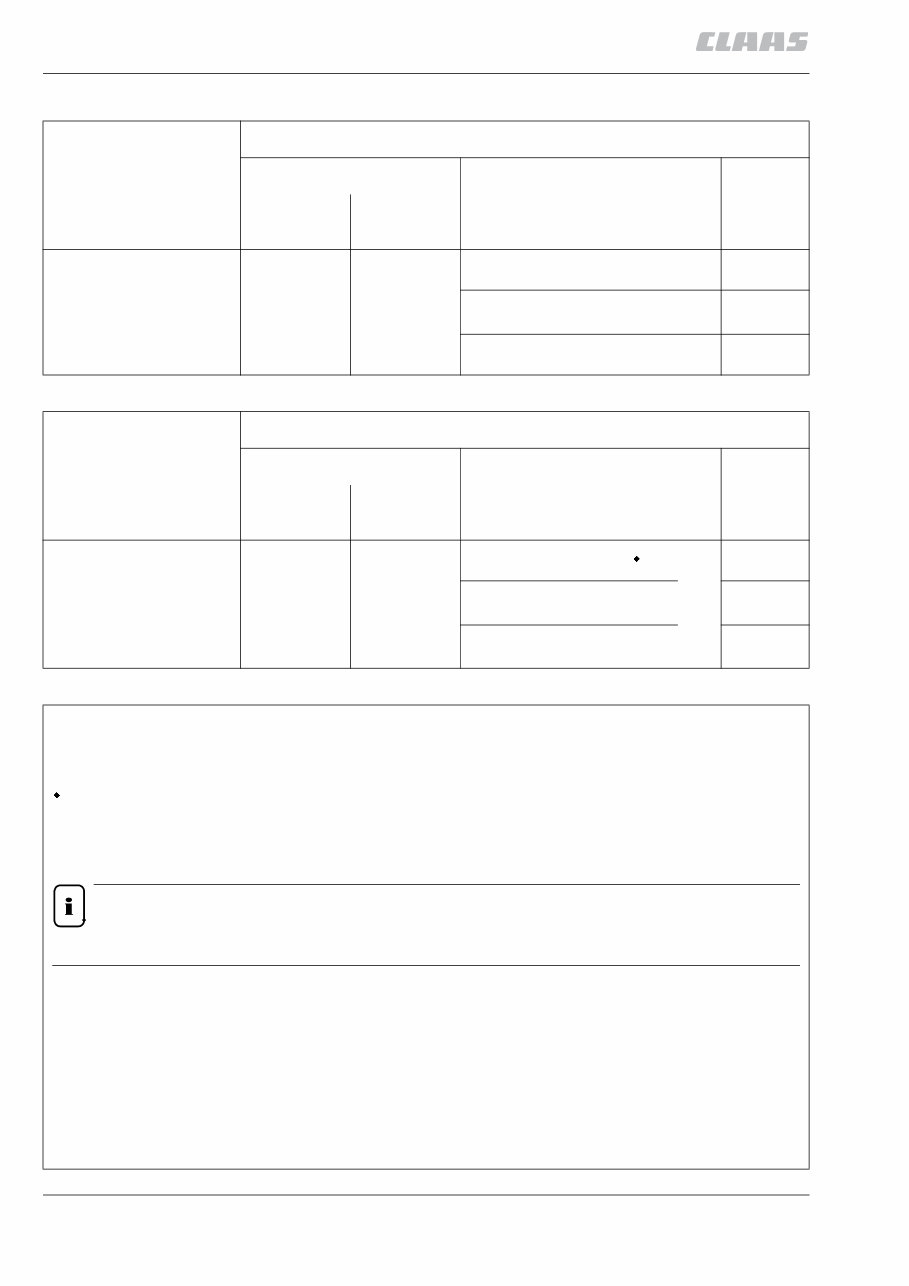

Hydraulic pressure values

Machine type

Working hydraulics

Quantity / Litres Set pressure

bar

Refill Oil change

at corresponding pressure relief

valve

LEXION 480 approx. 70 approx. 20

Lifting hydraulics

175

+15

Steering

* 150

+15

Low pressure

19

+2

Machine type

Hydrostatic ground drive

Quantity / Litres Set pressure bar

Refill Oil change

at corresponding pressure relief

valve

LEXION 480 approx. 70 approx. 20

Operating pressure

S4

420

+30

Filling pressure

**

Purge pressure

23

*

= When making new settings, note the circulation

pressure and add the value to the one given.

**

= Filling pressure 4 – 6 bar above purge pressure

= Max. absolute pressure

Hydrostatic ground drives:

S4 = SAUER 90 R 130 / 90 M 100

When selecting the hydraulic oil, the following

conditions need to be met:

Pour point < -25 °C (DIN ISO 3016)

Viscosity 0 °C < 600 cSt. (DIN 51 562)

Viscosity 40 °C max. 50.6 cSt. (DIN 51 562)

Viscosity index > 170 (DIN ISO 2909)

The oil must have detergent properties!

NOTE!

The working and the ground drive hydraulics have one common hydraulic oil tank.

+2

–1

188 678.1 - RHB LEXION 480 1.1.1

General

GENERAL Introduction

This CLAAS REPAIR MANUAL is to assist in pre-

serving the permanent working order and therefore

the high value of your CLAAS combine-harvester by

careful maintenance and service.

Experience gathered by both our service engineers

and factory staff has been compiled in this REPAIR

MANUAL.

The figures explain the procedure of repairs and the

text describes the different adjustments to be made,

the use of CLAAS special tools etc.

The illustrations included in support to the expla-

nations show the sequence of major repairs so that

minor repairs can easily be followed.

The CLAAS REPAIR MANUAL is filled in a folder

which allows to insert supplementary pages as issued

following technical developments and to always have

an updated manual at hand for reference.

To be sure, always compare settings and filling

capacities with specifications stated in the current

Operator’s Manual which applies to the combine-

harvester.

CLAAS KGaA mbH

Service Department

General

1.1.2 RHB LEXION 480 - 188 678.1

General

Introduction to the CLAAS Repair Manual The CLAAS REPAIR MANUAL is divided into main

groups and subgroups.

The first figure at the bottom of each page refers to

the main group whereas the second figure following

the point indicates the subgroup; the figure behind

the second point indicates the page number. In each

subgroup, the figures and pages are numbered

consecutively, starting at 1.

Where differences between the machine types must

be observed, this is indicated in headings. Where a

service procedure applies to all machines covered by

this book, the machine names are not specifically

given.

When supplements are to be added, the subgroups

are supplemented or exchanged. Any possible

supplements are filed in the respective main group /

subgroup and the table of contents is updated and

replaced.

The symbols communicate brief messages when

recurring service procedures are described. Their

meaning is explained at the beginning of this manual.

The section “GENERAL REPAIR INSTRUCTIONS” at

the beginning of this manual contains useful practical

hints. Read and follow these fundamental instructions.

They are the basis for reliable service and durability of

parts after repairs have been carried out.

The description of a particular service procedure

can easily be found by checking the table of

contents of the appropriate main group /

subgroup.

188 678.1 - RHB LEXION 480 1.1.3

General

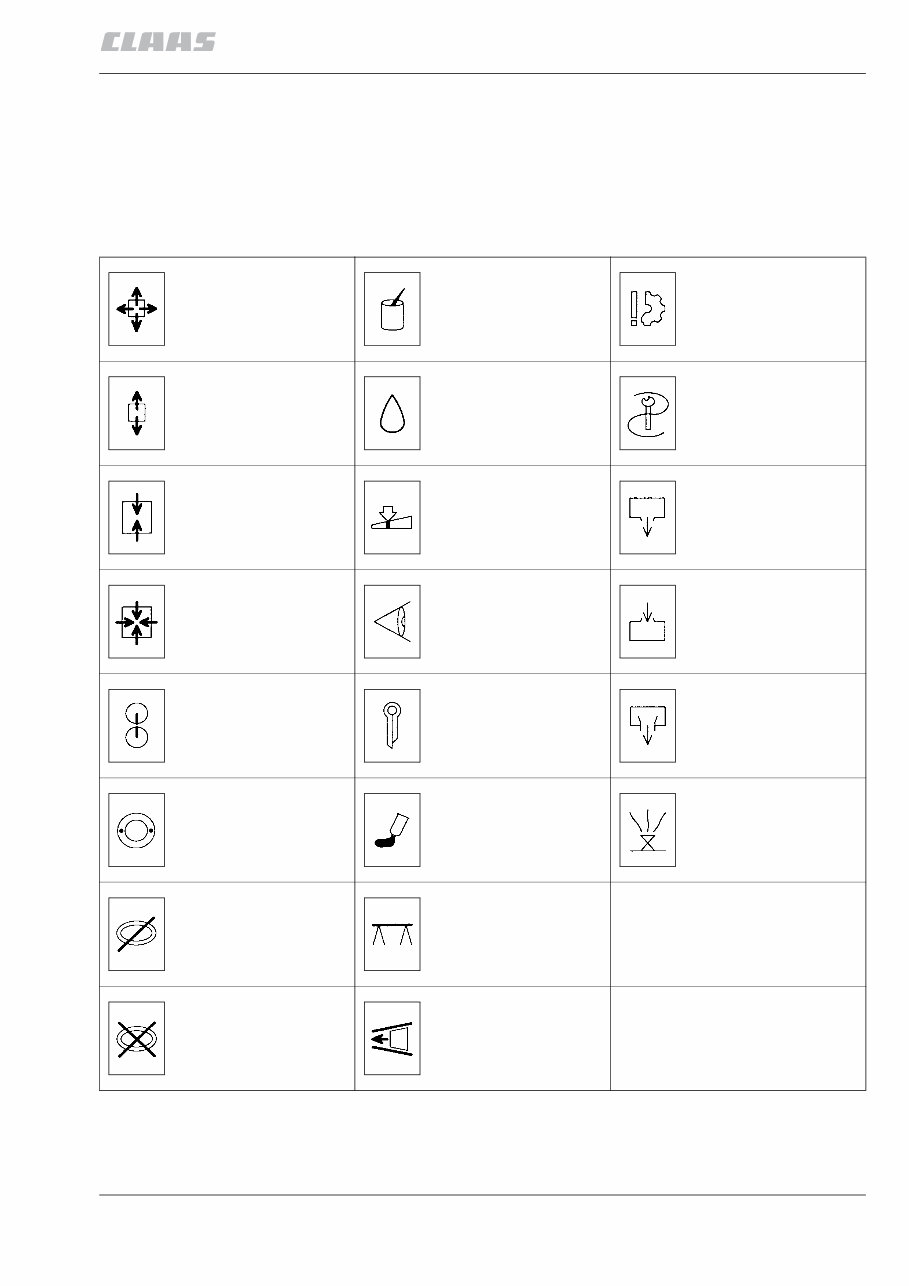

Key to symbols

This CLAAS REPAIR MANUAL uses some symbols as

defined in the “DIN 30600 Symbol summary” by the

German Standardisation Institute.

The meaning of these symbols will be easily

recognised and remembered by the user. These

symbols are to help to quickly recognise recurring

service procedures and they also help to communicate

information shown on the illustrations.

Dismantle,

remove

Grease

Prevent damage

to materials

Disassemble Oil Use special tool

Assemble Adjust / set

Drain,

outlet

Install,

mount on

Check visually

Fill,

filler opening

Mark

Unlock, release,

secure

Overflow

Balance

Lock by means of

liquids,

glue, seal

Bleed

Possibly reusable

Underprop,

support

Renew on each

assembly

Observe direction

of installation

General

1.1.4 RHB LEXION 480 - 188 678.1

General

You're Reading a Preview

What's Included?

Fast Download Speeds

Online & Offline Access

Access PDF Contents & Bookmarks

Full Search Facility

Print one or all pages of your manual

$52.99

Viewed 61 Times Today

Loading...

Secure transaction

What's Included?

Fast Download Speeds

Online & Offline Access

Access PDF Contents & Bookmarks

Full Search Facility

Print one or all pages of your manual

$52.99

The Claas Lexion 480 Repair Service Manual provides general repair information, service intervals, and diagrams for various components including drives, axles, belts, chopper drive, engine electric system, fuel system, axial rotors, cooling system, hydraulic system, circuit, brakes, grain tank drive, hydrostatic motors, manual gearbox, oil cooler, sieve pan, steering, air conditioner, and tightening torques.

- Format: PDF

- Compatibility: Windows, Mac

- Language: English

- Printable: Yes