Wheel Horse tractor hydrostatic transmission service manual

What's Included?

Fast Download Speeds

Online & Offline Access

Access PDF Contents & Bookmarks

Full Search Facility

Print one or all pages of your manual

OF===~---l

o

AUTOMATIC

TRANSMISSION

REPAIR MANUAL

SUNDSTRAND HYDROSTATIC SYSTEMS

Hydrogear & Piston - Piston, 1965-1982

WIIEEL HORSE

1-.---1 lawn & garden tractors

Part No. 492-4206

(Formerly A-1391, 803402)

.....

z

w

~

W

..J

a..

a..

:::l

en

.....

z

w

~

W

..J

a..

a..

:::l

en

.....

z

w

~

W

..J

a..

a..

:::l

en

SUPPLEMENTAL INFORMATION

INTRODUCTION

The following information will assist you with troubleshooting, assembly,

and repair information, in light of changes made and experience gained since this

manual was first published in 1974. It also contains special service information for

1978-82 model year Sundstrand units.

SERVICE AND REPAIR PARTS

• Hydrogear Conversions - Many hydrogear units (1966 to mid-1973)

have been converted to the serviceable piston-piston transmission.

Refer to the photos in this manual to identify the transmission in a

particular tractor.

• Complete Transmissions - Complete replacement transmission

assemblies are no longer available. Independent outside rebuilding

service many be available. Refer to the latest issue of Service

Bulletin 437 for information.

•

Repair Parts - Use this manual to determine replacement part

numbers for 1965 to mid-1973 hydrogear units (Pages 54-56) and

mid-1973 to 1977 piston-piston units (Pages 60-62). Be sure to

check parts price list to determine if all parts needed are still

available before ordering parts.

Piston-piston part numbers for 1978-82 model year tractors are

contained in the particular tractor parts manual.

• D-Series Adjustments - Transmission control linkage adjustments

described in this manual for 1975 models are appropriate for 1976-

77 models. 1978-82 linkage adjustments are covered in the 1978-79

B,C,D- Series Service Manual, PIN 810063R1.

• D-Series Driven Coupling Preload and Pump Alignment - Refer to

Service Bulletins 217 and 305 for special service information .

CONSTRUCTION CHANGES, 1978 AND LATER

• Sundstrand units on 1978 and later tractors differ from earlier units in

that the motor shaft extends through the cover plate, for the

mounting of a parking brake drum. Motor repair operations

described in this manual still apply, except that the motor cover plate

oil seal should be replaced during the repair process.

Supplement 1

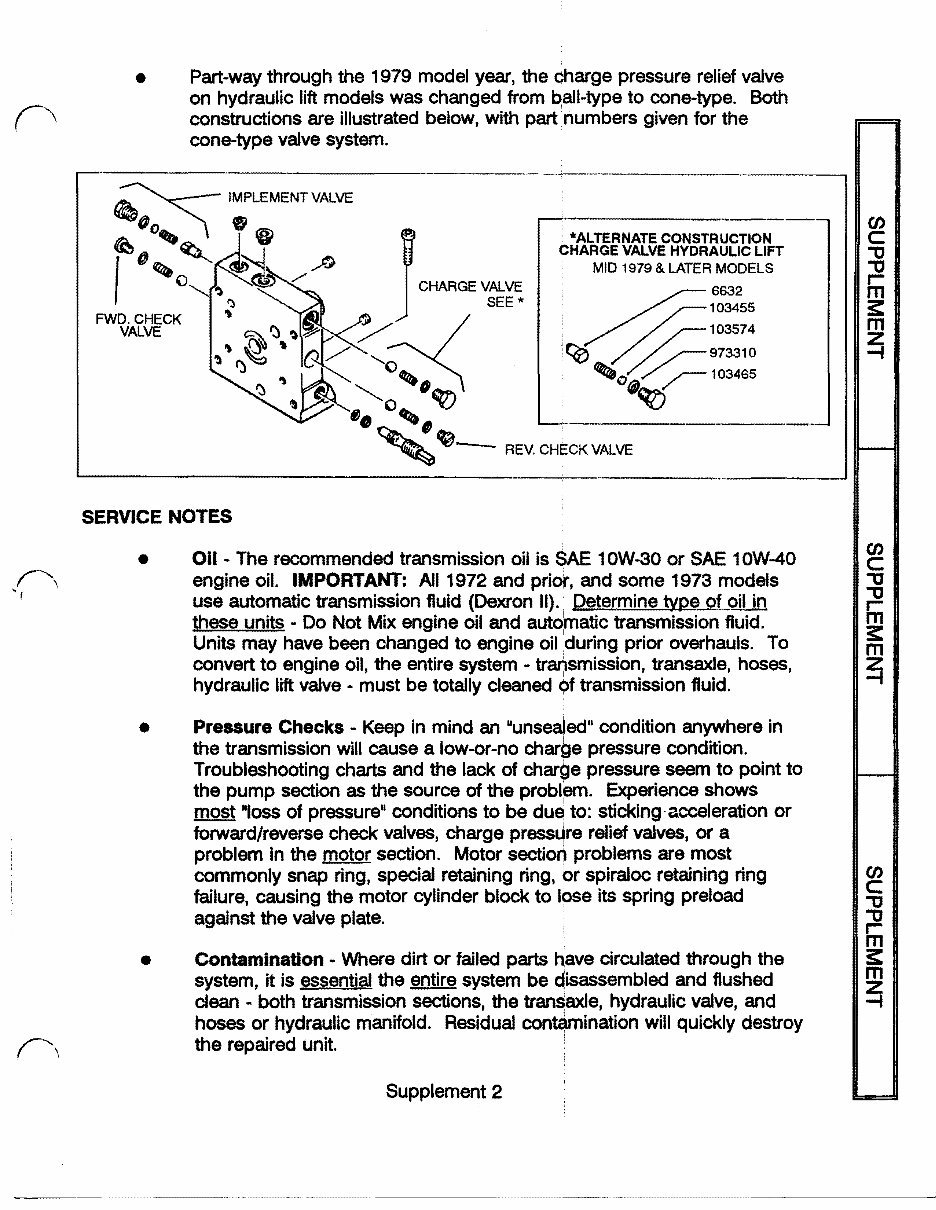

• Part-way through the 1979 model year, the charge pressure relief valve

on hydraulic lift models was changed from ~all-type to cone-type. Both

constructions are illustrated below, with part numbers given for the

cone-type valve system.

FWD. CHECK

VALVE

*ALTERNATE CONSTRUCTION

CHARGE VALVE HYDRAULIC LIFT

MID 1979 & LATER MODELS

4

6632

~

103455

~~103574

'ce /~973310

~o /~103465

:'0 0... ~ <lqzj

o ~, ~~--------------------~

~~- REV.CHECKVALVE

SERVICE NOTES

•

•

•

Oil - The recommended transmission oil is SAE 10W-30 or SAE 10W-40

engine oil. IMPORTANT: All 1972 and pritt, and some 1973 models

use automatic transmission fluid (Dexron II).' Determine type of oil in

these units - Do Not Mix engine oil and autqmatic transmission fluid.

Units may have been changed to engine oil during prior overhauls. To

convert to engine oil, the entire system - transmission, transaxle, hoses,

hydraulic lift valve - must be totally deaned bf transmission fluid.

Pressure Checks - Keep in mind an uunsealedll condition anywhere in

the transmission will cause a low-or-no charge pressure condition.

Troubleshooting charts and the lack of charge pressure seem to point to

the pump section as the source of the problem. Experience shows

most ·,oss of pressure" conditions to be du~ to: sticking-acceleration or

forward/reverse check valves, charge press~re relief valves, or a

problem in the motor section. Motor section problems are most

commonly snap ring, special retaining ring, br spiraloc retaining ring

failure, causing the motor cylinder block to Ipse its spring preload

against the valve plate.

Contamination - Where dirt or failed parts have circulated through the

system, it is essential the entire system be Qisassembled and flushed

dean - both transmission sections, the transaxle, hydraulic valve, and

hoses or hydraulic manifold. Residual contamination will quickly destroy

the repaired unit.

Supplement 2

(J)

C

"0

"0

,...

m

;:

m

~

(J)

C

"0

"0

Iii

;:

m

~

(J)

C

"0

"0

,...

m

;:

m

~

•

Valve Plates - Note the difference betWeen the pump and motor valve

plates (Fig. 44). Ensure the correct valve plate is ordered when

replacing, as the motor plate will fit in place of the pump plate, but will

not function properly. Scratches in the brass surface of the plate that

can be felt with a fingernail indicate an unserviceable valve plate. The

.....

cylinder block may also be unserviceable in this case.

Z

W

~

•

Charge and Implement Valves - Note the location of these valves,

W

-I

depending on whether the tractor has manual or hydraulic lift (Fig. 61).

a..

a..

Using the appropriate valve parts in the correct hole permits setting up

:::> any piston-piston unit for either type of lift system.

C/)

•

Ch~rge Pump - Refer to the installation of the charge pump (Fig. 49).

With the pump end cap positioned as shown, note that the dowel pin is

down (nearest the sealing surface of the pump end cap). The charge

-

pump can be put on upside-down, and will fail to function.

Also note that the charge pump needle bearing, Fig. 54, must protrude

above the housing surface, to hold the valve plate in place. Use care to

prevent accidentally pressing the dowel pin into the housing. Be sure

.....

the valve plate notch is over the dowelJllil on assembly, or the valve

Z

W

plate will be ruined.

!\.

~

I

W

•

Control Shaft/Stub Shaft - On 1978 and later transmissions, the longer

--

-I

a..

control shaft is used on both sides of the pump housing (Fig. 57).

a..

Using a later transmission on an earlier tractor may require cutting a

:::>

C/)

clearance hole in the tractor's sheet metal for the longer shaft.

•

Acceleration Valves - Original equipment valves are different (Fig. 68)

and must not be exchanged during repair. However, the forward valve

is used as the service replacement part for both locations.

If an acceleration valve seems to be malfunctioning, ensure the metering

plug hole is open (Fig. 70). If clogged, it will prevent the valve from

closing. The hole is extremely smalj, and it may take a magnifying glass

.....

to see it.

Z

W

•

Motor Section - Note that the webbed section of motor housing must

~

W

be "up" (Fig. 74), or motor will run opposite the intended direction.

...J

a..

a.. Special Assembly Note

:::>

C/)

Ensure you use new retaining parts in the motor section (Items

23,70,73,74, Pages 61-62), to ensure the integrity of the cylinder block

~I

attachment to the motor shaft. On assembly, make absolute~ ~ur~ the

cylinder block is locked securely on the motor shaft. Be sure the notch

in the valve plate is over the dowel pin in the motor end cap.

Supplement 3

'~--~---------~- -- ~

-----

FOREWORD

This service and repair manual has been compiled to provide

authorized Wheel Horse service personnel with the proper procedures

and techniques for servicing Wheel Horse automatic transmissions.

The following index lists all areas covered. It is advisable to read

all of the introductory sections first to gain a proper understanding of

the Wheel Horse automatic transmission.

The automatic transmission is a sophisticated piece of machinery.

Maintain strict cleanliness control during all stages of service and

repair. Even a small amount of dirt or other contamination can severely

damage the system.

Although this manual deals primarily with the Sundstrand piston-

piston type hydrostatic transmission, service and repair procedures for

the older hydrogear type transmission have beeo included in a separate

section.

-1-

SUNDSTRAND HYDROSTATIC TRANSMISSION MANUAL

Table of Contents – Page 1 of 3

SUPPLEMENTAL INFORMATION

INTRODUCTION

SERVICE AND REPAIR PARTS

CONSTRUCTION CHANGES, 1978 AND LATER

SERVICE NOTES

SPECIAL ASSEMBLY NOTE

FOREWORD

PRINCIPLES OF OPERATION

RELIEF VALVES

FORWARD TRAVEL

REVERSE TRAVEL

ACCELERATION VALVES

PUSH VALVE

DIAGNOSIS

TROUBLE-SHOOTING CHARTS

ENGINE CHART

SPEED CONTROL LINKAGE AND ADJUSTMENTS--STANDARD SYSTEM

NEUTRAL ADJUSTMENT

FRICTION ADJUSTMENT

SPEED CONTROL LINKAGE AND ADJUSTMENTS—SEPARATED SYSTEM

1973 18 HP AUTOMATIC--NEUTRAL ADJUSTMENT

FRICTION ADJUSTMENT

PARKING BRAKE ADJUSTMENT

1974 "D" SERIES TRACTORS--NEUTRAL ADJUSTMENT (FIG. 8)

LEVER POSITION ADJUSTMENT

FRICTION ADJUSTMENT -- SPEED CONTROL LEVER

FRICTION ADJUSTMENT--PARKING BRAKE

PARKING BRAKE ADJUSTMENT

1975 "D" SERIES TRACTORS -- NEUTRAL ADJUSTMENT

LEVER FRICTION ADJUSTMENT

PARKING BRAKE ADJUSTMENT

PRESSURE TESTING

CHARGE PRESSURE TEST

IMPLEMENT PRESSURE TEST

REPAIR PROCEDURES -

SEPARATION OF PUMP AND MOTOR

SEAL RING INSTALLATION & ASSEMBLY OF PUMP TO MOTOR

SUNDSTRAND HYDROSTATIC TRANSMISSION MANUAL

Table of Contents – Page 2 of 3

REMOVAL OF HYDROSTATIC UNIT FROM A STANDARD SYSTEM

INSTALLATION OF HYDROSTATIC UNIT IN A STANDARD SYSTEM

REMOVAL OF HYDROSTATIC UNIT FROM A SEPARATED SYSTEM

MOTOR REMOVAL

PUMP REMOVAL

INSTALLATION OF HYDROSTATIC UNIT IN A SEPARATED

PUMP INSTALLATION

MANIFOLD INSTALLATION

MOTOR INSTALLATION

INSPECTION OF PARTS

PUMP AND MOTOR SHAFTS

CYLINDER BLOCK ASSEMBLIES--GENERAL

CYLINDER BLOCK FACE

PISTONS AND SLIPPERS

SLIPPER RETAINERS

VALVE PLATES

THRUST PLATES

CHARGE PUMP ASSEMBLY

BEARINGS (FOR REPLACEMENT SEE DISASSEMBLY AND ASSEMBLY SECTION)

DISASSEMBLY & ASSEMBLY OF HYDROSTATIC PUMP

PUMP HOUSING DISASSEMBLY & ASSEMBLY

DISASSEMBLY

ASSEMBLY OF PUMP HOUSING

ASSEMBLY OF PUMP SECTION

REMOVAL & REPLACEMENT OF ACCELERATION VALVES

DISASSEMBLY

ASSEMBLY

DISASSEMBLY AND ASSEMBLY OF HYDROSTATIC MOTOR

DISASSEMBLY OF MOTOR

ASSEMBLY OF MOTOR

DISASSEMBLY AND ASSEMBLY OF CYLINDER BLOCKS AND PISTON ASSEMBLIES

DISASSEMBLY

ASSEMBLY

SUNDSTRAND HYDROSTATIC TRANSMISSION MANUAL

Table of Contents – Page 3 of 3

HYDROGEAR SECTION

HYDROGEAR TROUBLE-SHOOTING CHART

TROUBLE SHOOTING GUIDE

PRELIMINARY CHECKS

HYDROGEAR TUNE-UP

HYDROGEAR SERVICE NOTE

HYDROGEAR

HYDROGEAR PARTS DRAWING/LIST 1965-73

PUMP SHAFT SEAL REPLACEMENT

THE TRANSAXLE

REMOVAL OF TRANSAXLE COMPLETE WITH HYDROSTATIC UNIT

REMOVAL OF HYDROSTATIC UNIT FROM THE TRANSAXLE

TRANSAXLE DISASSEMBLY

PARKING BRAKE AND OIL FILTER

TRANSAXLE GASKET INSTALLATION

PISTON-PISTON HYDROSTATIC TRANSMISSION 1973-1977

SERVICE BULLETIN RECORD

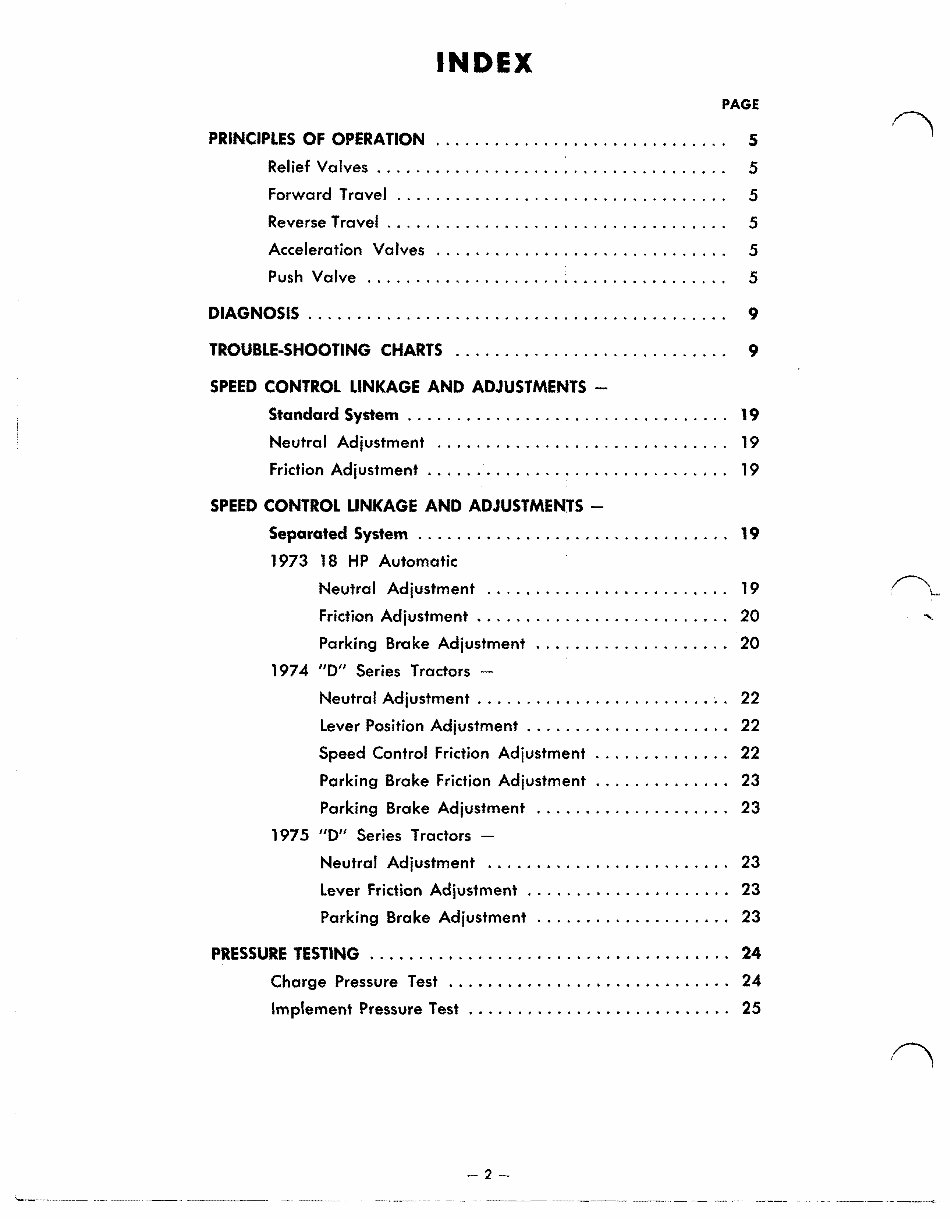

INDEX

PAGE

PRINCIPLES OF OPERATION 5

Relief Valves .................................. " 5

Forward Travel .................................. 5

Reverse Travel . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .. 5

Acceleration Valves .............................. 5

Push Valve ..................................... 5

DIAGNOSIS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .. 9

TROUBLE-SHOOTING CHARTS ............................ 9

SPEED CONTROL LINKAGE AND ADJUSTMENTS -

Standard System . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .. 19

Neutral Adjustment .............................. 19

Friction Adjustment . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .. 19

SPEED CONTROL LINKAGE AND ADJUSTMENTS -

Separated System ............................... . 19

1973 18 HP Automatic

Neutral Adjustment ........................ . 19 ~ ..

Friction Adjustment ......................... . 20

"

Parking Broke Adjustment ................... . 20

1974- "0

11

Series Tractors -

Neutral Adjustment ........................ ; . 22

Lever Position Adjustment .................... . 22

Speed Control Friction Adjustment ............. . 22

Parking Brake Friction Adjustment ............. . 23

Parking Brake Adjustment ................... . 23

1975 "0" Series Tractors -

Neutral Adjustment ........................ . 23

Lever Friction Adjustment .................... . 23

Parking Brake Adjustment ................... . 23

PRESSURE TESTING .................................... . 24

Charge Pressure Test .................... • ........ 24-

Implement Pressure Test .......................... . 25

2-

.~ .... -~-~--

r,

, \

INDEX

PAGE

REPAIR PROCEDURES ................................... 25

Separation of Pump and Motor ........... '.' ........ 25

Seal Ring Installation ............................. 26

Assembly of Pump to Motor ........................ 26

REMOVAL OF HYDROSTATIC UNIT

FROM A STANDARD SYSTEM . . . . . . . . . . . . . . . . . . . . . . . . . . . .. 26

INSTALLATION OF HYDROSTATIC UNIT

IN A STANDARD SYSTEM . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .. 26

REMOVAL OF HYDROSTATIC UNIT

FROM A SEPARATED SYSTEM . ............................ 27

Motor Removal .................................. 27

Pump Removal .................................. 27

INSTALLATION OF HYDROSTATIC UNIT

IN A SEPARATED SYSTEM . .............................. 27

Pump Installation ................................ 27

Manifold Installation ............................. 28

Motor Installation ................................ 30

INSPECTION OF PARTS . . . . . . . . . . . . . . . . . .. . . . . . . . . . . . . . .. 32

Pump and Motor Shafts .. . . . . . . . . . . . . . . . . . . . . . . . .. 32

Cylinder Block Assemblies ......................... 32

Cylinder Block Face .............. '. . . . . . . . . . . . . . .. 32

Pistons and Slippers .............................. 32

Slipper Retainers ................................ 33

Valve Plates .................................... 33

Thrust Plates ... . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .. 33

Charge Pump Assembly ....... • .................. 33

Bearings ....................................... 33

DISASSEMBLY AND ASSEMBLY OF HYDROST~TIC PUMP ....... 34

PUMP HOUSING DISASSEMBLY AND ASSEMB~ Y ....... . . . . . .. 37

Disassembly .................................... 37

Assembly of Pump Housing ........................ 38

Assembly of Pump Section ......................... 38

-3-

You're Reading a Preview

What's Included?

Fast Download Speeds

Online & Offline Access

Access PDF Contents & Bookmarks

Full Search Facility

Print one or all pages of your manual

$39.99

Viewed 75 Times Today

Loading...

Secure transaction

What's Included?

Fast Download Speeds

Online & Offline Access

Access PDF Contents & Bookmarks

Full Search Facility

Print one or all pages of your manual

$39.99

A Wheel Horse tractor hydrostatic transmission service manual from 1965 to 1982 is available for repair and maintenance. This manual spans 69 pages and includes detailed parts listings and exploded views. It is a valuable resource for both professional mechanics and DIY enthusiasts. The manual covers the sundstrand transmissions used in the specified range of Wheel Horse tractors.