Toro Groundmaster 3500-D Rotary Mower Service & Repair Manual

What's Included?

Fast Download Speeds

Online & Offline Access

Access PDF Contents & Bookmarks

Full Search Facility

Print one or all pages of your manual

PART NO. 01088SL (Rev. F)

Service Manual

Groundsmaster

R

3500--D

Preface

The purpose of this publication is to provide the service

technician with information for troubleshooting, testing,

and repair of major systems and components on the

Groundsmaster 3500--D.

REFER TO THE OPERATOR’S MANUAL FOR OPER-

ATING, MAINTENANCE AND ADJUSTMENT

INSTRUCTIONS. For reference, insert a copy of the

Operator’s Manual and Parts Catalog for your machine

into Chapter 2 of this service manual. Additional copies

of the Operator’s Manual and Parts Catalog are avail-

able on the internet at www.Toro.com.

The Toro Company reserves the right to change product

specifications or this publication without notice.

This safety symbol means DANGER, WARNING,

or CAUTION, PERSONAL SAFETY INSTRUC-

TION. When you see this symbol, carefully read

the instructions that follow. Failure to obey the

instructions may result in personal injury.

NOTE: A NOTE will give general information about the

correct operation, maintenance, service, testing, or

repair of the machine.

IMPORTANT: The IMPORTANT notice will give im-

portant instructions which must be followed to pre-

vent damage to systems or components on the

machine.

E The Toro Company -- 2001, 2002, 2003, 2004, 2005, 2007, 2009

Downloaded from www.Manualslib.com manuals search engine

Groundsmaster 3500--D

This page is intentionally blank.

Downloaded from www.Manualslib.com manuals search engine

Rev. E Groundsmaster 3500--D

Table Of Contents

Chapter 1 -- Safety

General Safety Instructions 1--1 ..................

Jacking Instructions 1--4 .........................

Chapter 2 -- Product Records and Maintenance

Product Records 2--1 ...........................

Maintenance 2--1 ...............................

Equivalents and Conversions 2--2 ................

Torque Specifications 2--3 .......................

Lubrication 2--7 ................................

Preparation for Seasonal Storage 2 -- 11 ............

Chapter 3 -- Kubota Diesel Engine

Introduction 3--2 ................................

Specifications 3--3 ..............................

General Information 3--4 ........................

Adjustments 3--6 ...............................

Service and Repairs 3--8 ........................

KUBOTA WORKSHOP MANUAL, DIESEL ENGINE,

05 SERIES

Chapter 4 -- Hydraulic System

Specifications 4--2 ..............................

General Information 4--3 ........................

Hydraulic Schematic 4--9 ........................

Hydraulic Flow Diagrams 4 -- 10 ...................

Special Tools 4 -- 22 .............................

Troubleshooting 4 -- 26 ...........................

Testing 4 -- 28 ...................................

Adjustments 4 -- 54 ..............................

Service and Repairs 4 -- 56 .......................

ROSS TORQMOTOR

TM

MG, MF, ME, AND MJ SE-

RIES SERVICE PROCEDURE

EATON MEDIUM DUTY PISTON PUMP REPAIR IN-

FORMATION MODEL 70160 VARIABLE DISPLACE-

MENT PISTON PUMP

ROSS HYDRAGUIDE

TM

HYDROSTATIC STEERING

SYSTEM HGF SERIES SERVICE PROCEDURE

SAUER/DANFOSS STEERING UNIT TYPE OSPM

SERVICE MANUAL

Chapter 5 -- Electrical System

Electrical Schematics and Diagrams 5--2 ..........

Special Tools 5--3 ..............................

Troubleshooting 5--4 ............................

Electrical System Quick Checks 5--7 ..............

Component Testing 5--9 .........................

Service and Repairs 5 -- 24 .......................

Chapter 6 -- Wheels, Brakes, and Chassis

Specifications 6--2 ..............................

Special Tools 6--2 ..............................

Adjustments 6--3 ...............................

Service and Repairs 6--8 ........................

Chapter 7 -- Cutting Units

Specifications 7--2 ..............................

Troubleshooting 7--3 ............................

Special Tools 7--4 ..............................

Adjustments 7--5 ...............................

Service and Repairs 7--8 ........................

Chapter 8 -- Electrical Diagrams

Electrical Schematics and Diagrams 8--3 ..........

Safety Product Records

and Maintenance

Kubota

Diesel Engine

Hydraulic

System

Electrical

System

Wheels, Brakes,

and Chassis

Cutting

Units

Electrical

Diagrams

Downloaded from www.Manualslib.com manuals search engine

Groundsmaster 3500--D

This page is intentionally blank.

Downloaded from www.Manualslib.com manuals search engine

Rev. F

Groundsmaster 3500--D

Page1 -- 1

Safety

Chapter 1

Safety

Table of Contents

GENERAL SAFETY INSTRUCTIONS 1 ............

Supervisor’s Responsibilities 1 .................

Before Operating 1 ............................

While Operating 2 .............................

Maintenance and Service 3 ....................

JACKING INSTRUCTIONS 4 .....................

General Safety Instructions

The GROUNDSMASTER 3500--D was tested and certi-

fied by TORO for compliance with existing standards

and specifications as identified in the Operator’s Manu-

al. Although hazard control and accident prevention are

dependent partially upon the design and configuration

of the machine, these factors are also dependent upon

the awareness, concern, and proper training of the per-

sonnel involved in the operation, transport, mainte-

nance, and storage of the machine. Improper use or

maintenance by the operator or owner of the machine

can result in injury. To reduce the potential for any injury,

comply with the following safety instructions.

WARNING

To reduce the potential for injury or death, com-

ply with the following safety instructions.

Supervisor’s Responsibilities

1. Make sure operators are thoroughly trained and fa-

miliar with the Operator’s Manual, Operator’s Video,

and all the operating and safety decals on the machine.

2. Be sure to establish your own special procedures

and work rules for unusual operating conditions (e.g.

slopes too steep for machine operation). Survey mow-

ing site completely to determine which hills can be

operated on safely. When performing this site survey,

always use common sense and take into consideration

the turf condition and the rollover risk. To determine

which hills or slopes may be safely operated on, use the

inclinometer provided with each machine. To perform a

site survey, lay a 4 foot long, 2 by 4 inch piece of wood

on the slope surface and measure the angle of the slope.

The piece of wood will average the slope but will not take

into consideration dips or holes. THE MAXIMUM SIDE

HILL ANGLE SHOULD NOT BE GREATER THAN 25

DEGREES.

Before Operating

1. Operate machine only after reading and understand-

ing the contents of the Operator’s Manual and viewing

the Operator’s Video. Copies of the Operator’s Manual

are available on the internet at www.Toro.com.

2. Only trained operators who are skilled in slope op-

eration and who have read the Operator’s Manual and

viewed the Operator’s Video should operate the ma-

chine. Never allow children to operate the machine or

adults to operate it without proper instructions.

3. Become familiar with the controls and know how to

stop the machine and engine quickly.

4. Do not carry passengers on the machine. Keep ev-

eryone, especially children and pets, away from the

areas of operation.

Safety

Downloaded from www.Manualslib.com manuals search engine

Rev. F

Groundsmaster 3500--D

Page1 -- 2

Safety

5. Keep all shields, safety devices, and decals in place.

Repair or replace damaged, malfunctioning, or illegible

shields, safety devices, or decals before operating the

machine.

6. Always wear substantial shoes. Do not operate ma-

chine while wearing sandals, tennis shoes or sneakers.

Do not wear loose fitting clothing because it could get

caught in moving parts and possibly cause personal in-

jury.

7. Wearing safety glasses, safety shoes, long pants

and a helmet is advisable and required by some local or-

dinances and insurance regulations.

8. Make sure the work area is clear of objects which

might be picked up and thrown by the blades.

9. Fill fuel tank with diesel fuel before starting engine.

Avoid spilling any fuel. Since fuel is highly flammable,

handle it carefully.

A. Use an approved fuel container.

B. Do not remove cap from fuel tank when engine is

hot or running.

C. Do not smoke while handling diesel fuel.

D. Fill fuel tank outdoors and not over one inch from

the top of the tank (bottom of the filler neck). Do not

overfill.

While Operating

1. Always wear your seatbelt.

2. Do not run the engine in a confined area without ade-

quate ventilation. Exhaust fumes are hazardous and

could be deadly.

3. Sit on the seat when starting and operating the ma-

chine.

4. Check interlock switches daily for proper operation

(see Chapter 5 -- Electrical System). Do not rely entirely

on safety switches: shut off engine before getting off

seat. If a switch fails, replace it before operating the ma-

chine. The interlock system is for your protection, so do

not bypass it.

5. Operator must be skilled and trained in how to drive

on hillsides. Failure to use caution on slopes or hills may

cause vehicle to tip or roll, possibly resulting in personal

injury or death.

6. This triplex mower has a unique drive system for su-

perior traction on hills. The uphill wheel will not spin out

and limit traction like conventional triplexes. If operated

on a side hill that is too steep, rollover may occur before

losing traction.

7. Before backing up, look to the rear and assure no

one is behind the machine. Watch out for traffic when

near or crossing roads. Always yield the right of way.

8. Keep hands, feet and clothing away from moving

parts and the deck discharge area.

9. The slope angle at which the machine will tip is de-

pendent on many factors. Among these are mowing

conditions such as wet or undulating turf, speed (espe-

cially in turns), position of the cutting units, tire pressure,

and operator experience. At side hill slope angles of 20

degrees or less the risk of a rollover is low. As the slope

angle increases to a Toro recommended maximum limit

of 25 degrees, the risk of a rollover increases to a moder-

ate level. DO NOT EXCEED A 25 DEGREE SIDE HILL

ANGLE BECAUSE THE RISK OF A ROLLOVER AND

SERIOUS INJURY OR DEATH IS VERY HIGH. The

Groundsmaster 3500--D is equipped with an angle indi-

cator, mounted on the steering tube, which indicates the

side hill angle the machine is operating on and identifies

the recommended maximum limit of 25 degrees.

Stay alert for holes in terrain and other hidden hazards

which can cause a sudden change in side hill angle. Use

extreme caution when operating close to sand traps,

ditches, creeks, steep hillsides, or other hazards. Re-

duce speed when making sharp turns. Do not turn on

hills. Avoid sudden stops and starts. Use reverse pedal

for braking. Cutting units must be lowered when going

down slopes for steering control.

10.When starting the engine:

A. Engage parking brake.

B. Be sure traction pedal is in neutral and blade drive

is in disengage position.

C. After engine starts, release parking brake and

keep foot off traction pedal. Machine must not move.

If movement is evident, the neutral control linkage is

incorrectly adjusted: therefore, shut engine off and

adjust until machine does not move when traction

pedal is released (see Adjust Traction Drive for Neu-

tral in the Adjustments section of Chapter 4 -- Hy-

draulic System).

11. This product may exceed noise levels of 85 dB(A) at

the operator position. Ear protectors are recommended

for prolonged exposure to reduce the potential of per-

manent hearing damage.

Downloaded from www.Manualslib.com manuals search engine

Rev. F

Groundsmaster 3500--D

Page1 -- 3

Safety

12.Raise the cutting units when driving from one work

area to another.

13.Do not touch engine, muffler, exhaust pipe or hydrau-

lic tank while engine is running or soon after it has

stopped because these areas could be hot enough to

cause burns.

14.If a cutting unit strikes a solid object or vibrates ab-

normally, stop immediately. Turn engine off, wait for all

motion to stop and inspect for damage.

15.Before getting off the seat:

A. Move traction pedal to neutral.

B. Set the parking brake.

C. Disengage the cutting units and wait for the

blades to stop spinning.

D. Stop the engine and remove key from the ignition

switch.

16.Whenever machine is left unattended, make sure

key is removed from ignition switch and parking brake

is set.

Maintenance and Service

1. Before servicing or making adjustments to the ma-

chine, stop the engine and remove key from switch to

prevent accidental starting of the engine.

2. Check performance of all interlock switches daily. Do

not defeat interlock system. It is for your protection.

3. To ensure entire machine is in good operating condi-

tion, frequently check and keep all nuts, bolts, screws

and hydraulic fittings tight.

4. Make sure all hydraulic line connectors are tight, and

all hydraulic hoses and lines are in good condition be-

fore applying pressure to the system.

5. Keep body and hands away from pin hole leaks or

nozzles that eject hydraulic fluid under high pressure.

Use paper or cardboard, not hands, to search for leaks.

Hydraulic fluid escaping under pressure can have suffi-

cient force to penetrate skin and do serious damage. lf

fluid is injected into the skin it must be surgically re-

moved within a few hours by a doctor familiar with this

form of injury or gangrene may result.

6. Before disconnecting or performing any work on the

hydraulic system, all pressure in system must be re-

lieved by stopping engine and lowering cutting units to

the ground.

7. If major repairs are ever needed, or if assistance is

desired, contact an Authorized Toro Distributor.

8. To reduce potential fire hazard, keep the engine area

free of excessive grease, grass, leaves and accumula-

tion of dirt.

9. If the engine must be running to perform a mainte-

nance adjustment, keep hands, feet, clothing, and any

other parts of the body away from the cutting units and

any moving parts. Keep everyone away.

10.Do not overspeed the engine by changing governor

settings. To assure safety and accuracy, have an Autho-

rized Toro Distributor check maximum engine speed

with a tachometer.

11.Engine must be shut off before checking oil or adding

oil to the crankcase.

12.To insure optimum performance and safety, use gen-

uine TORO replacement parts and accessories. Re-

placement parts and accessories made by other

manufacturers could be dangerous, and such use could

void the product warranty of The Toro Company.

Safety

Downloaded from www.Manualslib.com manuals search engine

Groundsmaster 3500--D

Page1 -- 4

Safety

Jacking Instructions

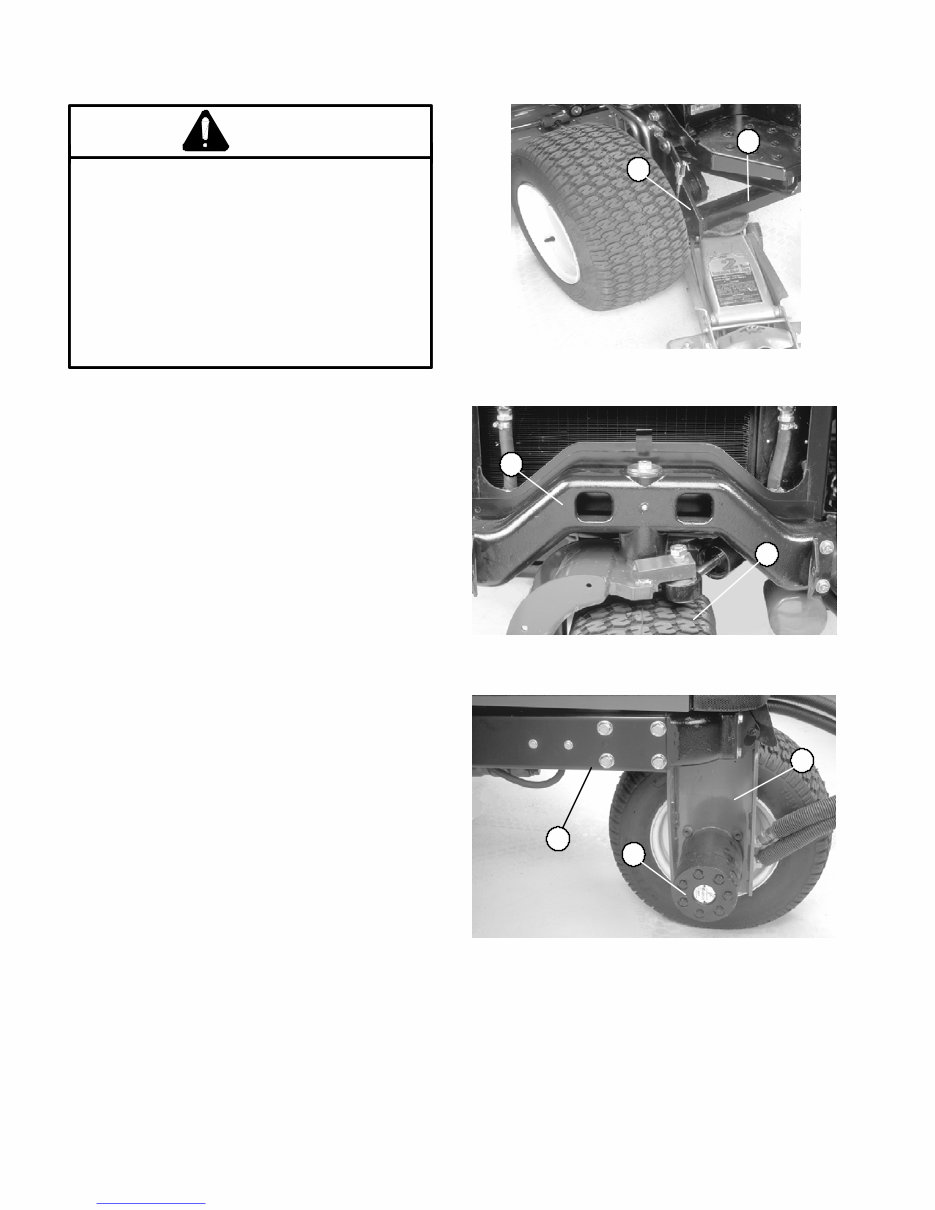

CAUTION

When changing attachments, tires, or performing

other service, use correct blocks, hoists, and

jacks. Make sure machine is parked on a solid lev-

el floor such as a concrete floor. Prior to raising

machine, remove any attachments that may inter-

fere with the safe and proper raising of the ma-

chine. Always chock or block wheels. Use jack

stands or solid wood blocks to support the raised

machine. If the machine is not properly sup-

ported by blocks or jack stands, the machine may

move or fall, which may result in personal injury.

Use the following positions when jacking up the ma-

chine:

Jacking the Front End

1. If the front wheel motor is to be removed, position

jack securely under the square tube of the lower frame

as closely to the side plate as possible (Fig. 1).

2. If the front tire is to be removed, position the jack se-

curely under the front wheel motor.

3. Use jack stands or hardwood blocks under the

square tube or wheel motors to support the machine.

Jacking the Rear End

1. The preferred method for removing the rear fork, the

rear wheel, or the rear wheel motor is to lift the rear end

of the machine from above:

A. Secure a chain fall or hoist to the rear casting (Fig

2).

B. Chock both front tires. Lift rear tire off the ground.

C. Use jack stands or hardwood blocks under the

frame to support the machine (Fig. 3).

2. If the rear of the machine cannot be lifted from above:

A. Chock both front tires.

IMPORTANT: Make sure jack is as close to the rear

fork as possible when jacking the rear wheel.

B. Place jack securely under the rear wheel motor

as close to the fork as possible (Fig. 3). Jack rear tire

off the ground.

C. Use jack stands or blocks under the frame to sup-

port the machine.

1. Square tube 2. Side plate

Figure 1

2

1

1. Rear tire 2. Rear casting

Figure 2

2

1

1. Frame

2. Rear wheel motor

3. Rear fork

Figure 3

2

3

1

Downloaded from www.Manualslib.com manuals search engine

Rev. F

Groundsmaster 3500--D

Page2 -- 1

Product Records and Maintenance

Chapter 2

Product Records and Maintenance

Table of Contents

PRODUCT RECORDS 1 .........................

MAINTENANCE 1 ...............................

EQUIVALENTS AND CONVERSIONS 2 ...........

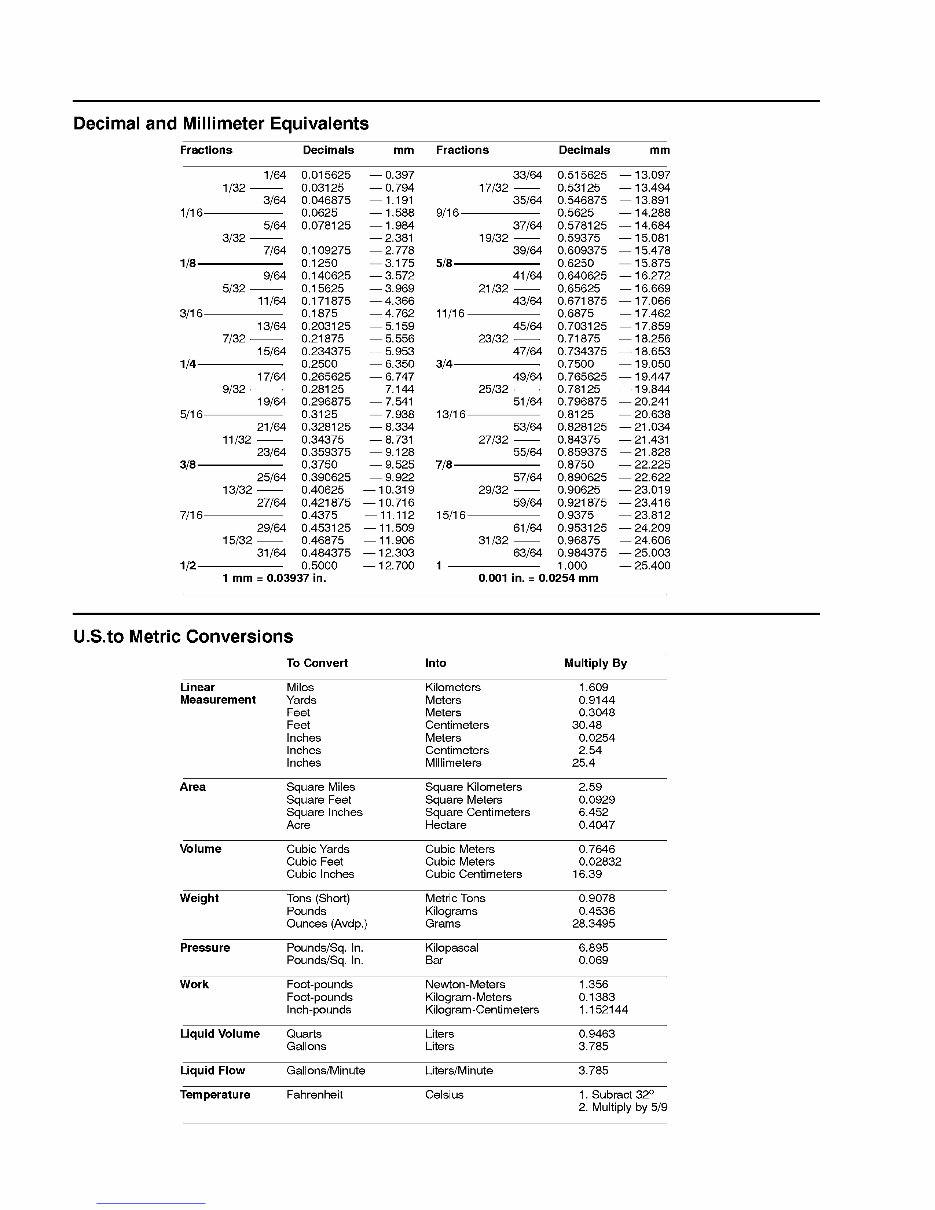

Decimal and Millimeter Equivalents 2 ............

U.S. to Metric Conversions 2 ...................

TORQUE SPECIFICATIONS 3 ....................

Fastener Identification 3 .......................

Standard Torque (Inch Series) 4 ................

Standard Torque (Metric Fasteners) 5 ...........

Other Torque Specifications 6 ..................

Conversion Factors 6 ..........................

Product Records

Insert a copy of the Operator’s Manual and Parts Cata-

log for your Groundsmaster 3500--D at the end of this

chapter. Additionally, if any optional equipment or ac-

cessories have been installed to your Groundsmaster,

insert the Installation Instructions, Operator’s Manuals

and Parts Catalogs for those options at the end of this

chapter.

Maintenance

Maintenance procedures and recommended service in-

tervals for the Groundsmaster 3500--D are covered in

the Operator’s Manual. Refer to that publication when

performing regular equipment maintenance.

Safety Product Records

and Maintenance

Kubota

Diesel Engine

Hydraulic

Systems

Electrical

System

Wheels, Brakes,

and Chassis

Downloaded from www.Manualslib.com manuals search engine

0.09375

Rev. E

Groundsmaster 3500--D

Page2 -- 2

Product Records and Maintenance

Equivalents and Conversions

Downloaded from www.Manualslib.com manuals search engine

You're Reading a Preview

What's Included?

Fast Download Speeds

Online & Offline Access

Access PDF Contents & Bookmarks

Full Search Facility

Print one or all pages of your manual

$37.99

Viewed 63 Times Today

Loading...

Secure transaction

What's Included?

Fast Download Speeds

Online & Offline Access

Access PDF Contents & Bookmarks

Full Search Facility

Print one or all pages of your manual

$37.99

This workshop service repair manual is for the Toro Groundmaster 3500-D Rotary Mower Service & Repair Manual featuring an engine with a 1123 cc 3-cylinder, 4-cycle, liquid-cooled Kubota diesel engine. The manual covers essential topics and procedures specific to this model.

- Comprehensive content including preface, safety precautions, maintenance & record keeping, engine specifications, engine system operation and adjustment, muffler & air cleaner, fuel system, cooling system, fuel tank & radiator, engine removal and re-installation, hydraulic system details, hydraulic schematic and flow diagram, testing & adjustment procedures, fluid & oil filter, traction belt & hoses, wheel motors, rotary cutting motors, hydraulic manifold, control valve service, piston & gear pump, steering control valve, lift cylinder service, steering cylinder service, electrical system, component testing, battery system, fork & wheel system, brake system, steering column, lift arms & hood system, cutting unit, roller service, special tools, troubleshooting, and electrical diagrams.

This manual is available in PDF format and features detailed exploded views along with step-by-step written procedures accompanied by pictures and diagrams, making it fully printable. It is the same professional resource used by technicians for repairs, maintenance, and servicing on the Toro Groundmaster 3500-D Rotary Mower, catering to both professional mechanics and DIY enthusiasts.