Jacobsen LF-3400 & LF-3800 Repair Service Manual

What's Included?

Fast Download Speeds

Online & Offline Access

Access PDF Contents & Bookmarks

Full Search Facility

Print one or all pages of your manual

SERVICE & REPAIR

INSTRUCTIONS

LF-3400 & LF-3800

LF-3400 2 Wheel Drive LF-3800 2 Wheel Drive

Product No. 67839 Product No. 67837

Product No. 67869 Product No. 67866

LF-3400 4 Wheel Drive LF-3800 4 Wheel Drive

Product No. 67840 Product No. 67838

Product No. 67869 Product No. 67867

LF-3400 4 Wheel Drive Turbo Engine

Product No. 67889

Includes Attachments

and Product Options

Litho in U.S.A. 5/01

WARNING: If incorrectly used this machine can cause severe injury. Those who

use and maintain the machine should be trained in its proper use, warned of its

dangers and should read the entire manual before attempting to set up, operate,

adjust or service the machine.

!

Copyright 2001 Textron Golf, Turf & Specialty Products

“All rights reserved, including the right to reproduce this

material or portions thereof in any form.”

Publication Registration

Information, specifications, illustrations and procedures in this

manual are based on information in effect at the time of publication.

Product improvements and changes due to advancements of product

design may not be included in this manual. This manual is reviewed

and updated as required to include changes and product improve-

ments. By returning the completed Registration below TGTSP will

notify you when an update is available.

Send Registration to:

Textron Golf,Turf & Specialty Products

1721 Packard Avenue

Racine, WI 53403-2564

Attn: Product and Service Tr aining

Litho Date:

Company Name __________________________________________

Your Name ______________________________________________

Your E-mail Address ______________________________________

Address ________________________________________________

City, State __________________________________ Zip ________

Register Your CD

Use the registration

on back of tray card.

CD-SRI-3400/3800

GOLF , TURF & SPECIALTY PRODUCTS

1

14

2

3

4

5

6

7

8

9

10

11

12

13

INTRODUCTION

CONTROLS

ENGINE

DRIVE TRAIN

BRAKE SYSTEM

STEERING

WHEELS & TIRES

HYDRAULICS

CHASSIS

ELECTRICAL SYSTEM

PREVENTIVE MAINTENANCE

ATTACHMENTS

OPTIONS

MISCELLANEOUS

1

1A. General Information . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1A-1

Contents . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1A-1

Registration . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1A-1

Index Numbers . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1A-1

Replacement Parts . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1A-1

Serial Numbers . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1A-2

General Cleaning . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1A-2

Safety . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1A-2

Torque Values . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1A-2

Torque Specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1A-3

Standard SAE Grade #5 Screws . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1A-3

Metric . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1A-3

SECTION 1

INTRODUCTION

CONTENTS

This manual contains repair instructions for major trac-

tor components, attachments and options. The Table of

Contents at the start of each section lists contents of

that section. Sections are identified by tabs in the right

hand margin.

This manual is to be used in conjunction with the Oper-

ator’s Manual and Parts Catalog.

Normal maintenance, adjustment, and operating proce-

dures are also covered in the user Operator’s Manual

and are only included where appropriate in this Service

and Repair Manual.

Engine repair is not covered in this manual. Refer to

the appropriate engine manufacturer’s instructions for

engine service and repair.

This manual includes all removal, disassembly, inspec-

tion, repair, reassembly, installation, adjustment, and

testing procedures. If you, as user of this machine, do

not consider yourself or your repair facilities capable

of a given procedure, please consult your dealer or

distributor.

Information, specifications, illustrations, and procedures

in this manual are based on information in effect at the

time this manual was published. Improvements and

product changes due to continual advancements of the

product design may cause changes to your product

that may not be included in this manual. Each manual

is reviewed and updated as required to include changes

and product improvements.

Read each section completely before proceeding with

specific repairs in that section. You will minimize errors

by understanding what you will be doing and how the

component relates to others in its system. Lists of

repair tools and materials for each section of the man-

ual are given at the start of that section.

The designations L.H. (left hand) and R.H. (right hand)

used throughout this manual refer to the operator’s left

or right when sitting in the normal operating position.

REGISTRATION

A registration card is provided in the back of this man-

ual (bottom portion of page). Fill out the card, remove

and mail immediately upon opening the manual for the

first time.

The registration entitles you to receive manual updates

for a period of two years. Updates are sent free of

charge.

NOTE

Only the original registration card will be accept-

ed. Photo copies, cards from other manuals, sug-

gestion cards, or any facsimile are not acceptable

and will not constitute a registration.

INDEX NUMBERS

Illustrations showing removal, disassembly, reassembly

and installation may have index numbers to call out the

sequence of procedure.

Where the sequence of procedure is not important or

self-evident (eg. linkages, hoses, clamps, etc.) index

numbers are not included.

Repair procedures for items not subject to wear (eg.

panels, brackets, frames) are not included in this man-

ual except for the general procedures given below.

Exercise common sense during disassembly or reas-

sembly; remove only the items required to accomplish

necessary repair or service.

REPLACEMENT PARTS

Use the appropriate Parts Catalog when ordering re-

placement parts. Follow installation instructions shipped

with service parts or kits. When ordering parts, always

give the serial number and product number of your

machine as well as quantity, part number and descrip-

tion of the parts needed.

To eliminate error and speed delivery:

1. Write your NAME and ADDRESS on your order

plainly.

2. Explain WHERE and HOW to make shipment.

3. Give PRODUCT NUMBER, NAME and SERIAL

NUMBER that is stamped on the NAME and SERI-

AL PLATE of your product.

4. Order by QUANTITY DESIRED, the PART NUM-

BER and the DESCRIPTION OF PART.

5. Send your order to or visit your nearest dealer or

distributor.

6. INSPECT ALL SHIPMENTS ON RECEIPT. If any

parts are damaged or missing, file a claim with the

carrier before accepting.

7. Do not return material to your dealer or distributor

without a letter of explanation. Make a list of all

returned parts, show your name and address, and

include it with the shipment. TRANSPORTATION

CHARGES MUST BE PREPAID.

SECTION 1A. GENERAL INFORMATION

1A-1

1A

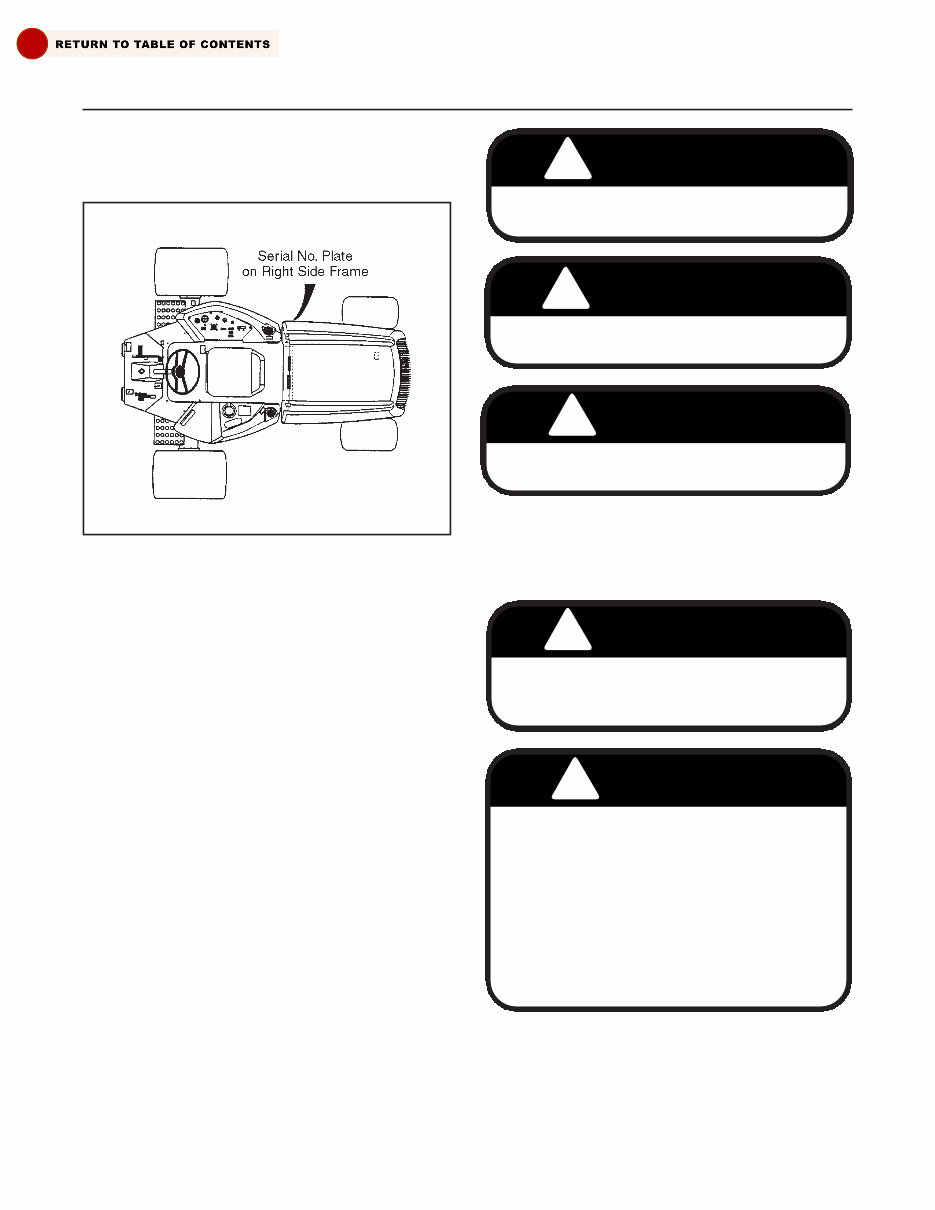

SERIAL NUMBERS

See Figure 1A-1 for location of tractor assembly serial

number.

GENERAL CLEANING

Improper cleaning and lubrication of your machine

results in many equipment failures. Before any repairs

are undertaken, thoroughly clean the exterior of the

component to be removed.

Use a clean surface to lay out parts being removed.

Keep lubricants clean and cover containers not being

used. Plug or cap all hydraulic lines and ports to hy-

draulic components immediately after disconnecting.

SAFETY

Safety should always be the rule when working on or

with machinery. Always use safe practices and com-

mon sense when using hand or power tools. Use the

suggested procedures in this manual when working

with the tractor.

Throughout this manual signal words will be used to

highlight special procedures. The signal words and

their meaning are as follows:

NOTE

Any procedure needing special care when per-

forming a procedure.

Decals on the machine denote cautions, warnings and

dangers. These cautions, warnings and danger decals

must be on the machine at all times. If they become

worn, torn or painted over, new decals should be in-

stalled as shown in Section 14 of this manual.

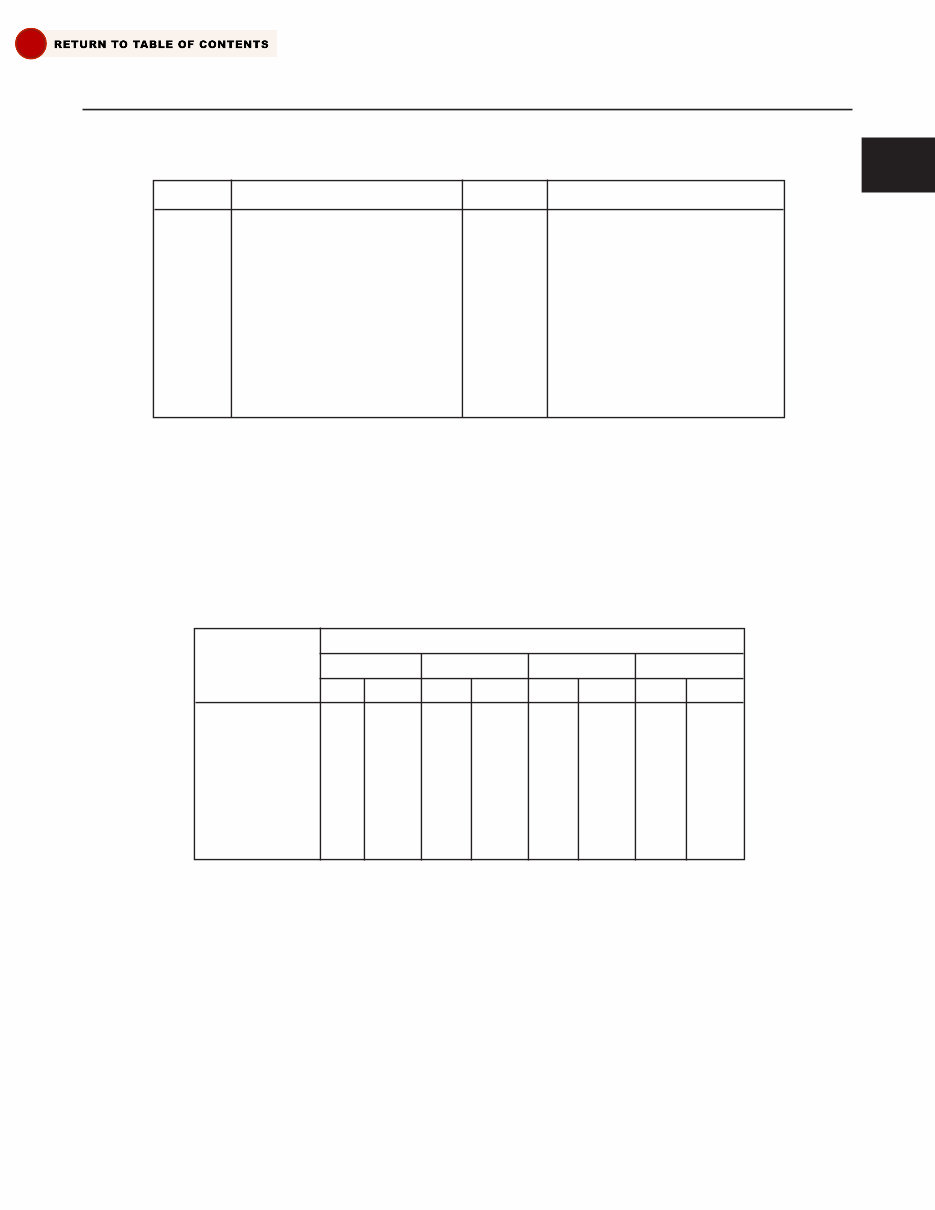

TORQUE VALUES

Torque values are given in the following “Torque Speci-

fication Chart”. Special torque values are called out on

illustrations and text throughout this manual.

SECTION 1A. GENERAL INFORMATION

1A-2

Figure 1A-1. Serial Number Location

! CAUTION

Hazards or unsafe practices which could result

in personal injury or product or property damage.

! WARNING

Hazards or unsafe practices which could result

in severe personal injury or death.

! DANGER

Imminent hazards which will result in severe per-

sonal injury or death if precautions are not taken.

! CAUTION

Disconnect leads at alternator before electric

welding is done on components in common

ground with engine.

! DANGER

This machine is equipped with an interlock sys-

tem which is intended to protect the operator

and others from injury, by preventing the engine

from starting, unless the reel switch is in the “Off”

position, traction pedal is in the “Neutral” position

and the brake set. The system also shuts off the

engine if the operator leaves the seat with the

reel switch in “Cut” position. In the interest of safe

operating conditions, this machine must never be

operated with the interlock relays or interlock sys-

tem disconnected or malfunctioning.

SECTION 1A. GENERAL INFORMATION

1A-3

1A

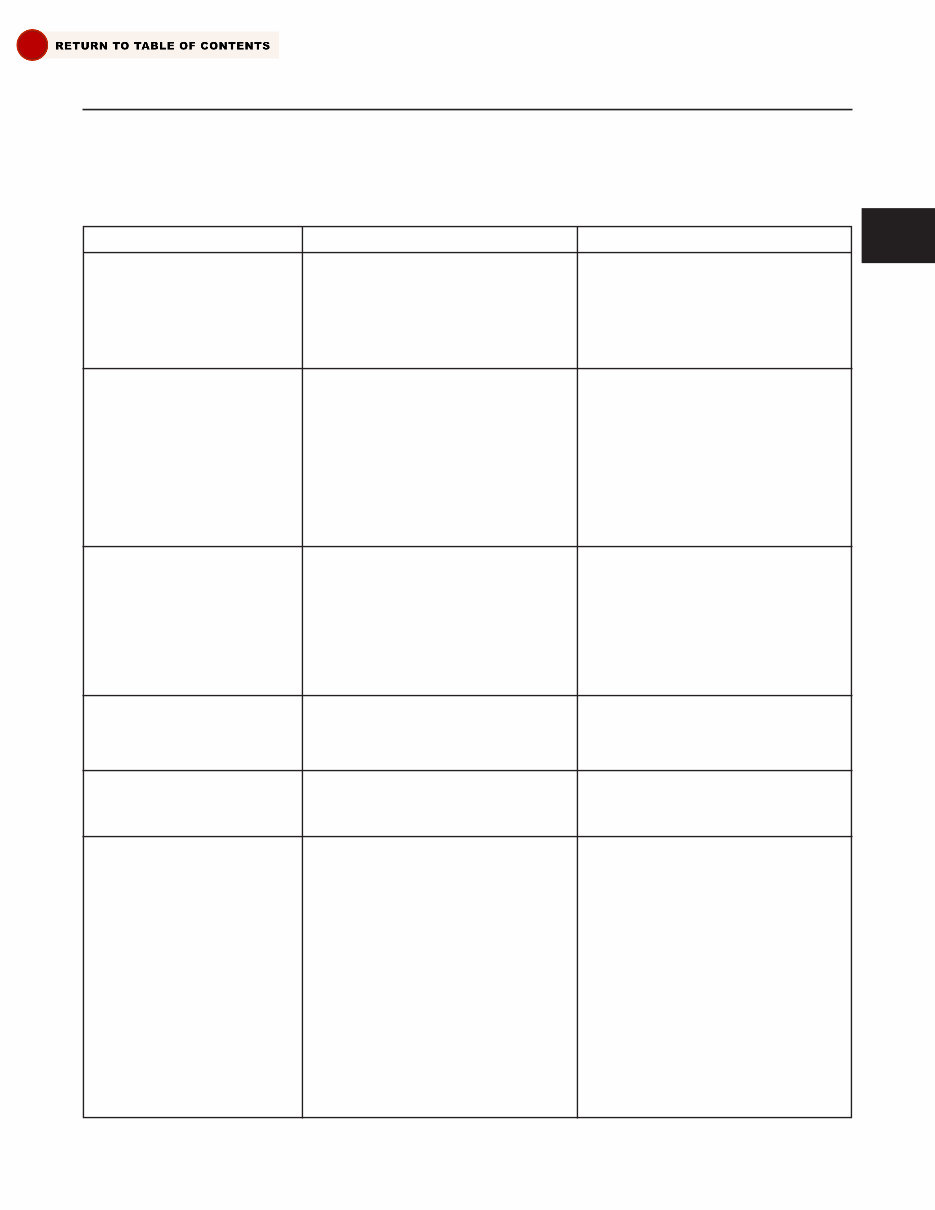

TORQUE SPECIFICATIONS

STANDARD SAE GRADE #5 SCREWS

Size Torque Values Size Torque Values

8-32 27-33 in-lbs. (3-4 N.m)

1

/ 2-13 67-83 ft-lbs. (90-113 N.m)

8-36 28-34 in-lbs. (3-4 N.m)

1

/ 2-20 81-99 ft-lbs.(110-134 N.m)

10-24 39-47 in-lbs. (4-5 N.m)

9

/ 16-12 99-121 ft-lbs. (134-164 N.m)

10-32 44-54 in-lbs. (5-6 N.m)

9

/ 16-18 108-132 ft-lbs. (146-179 N.m)

1

/ 4-20 7-9 ft-lbs. (9-12 N.m)

5

/ 8-11 135-165 ft-lbs. (183-223 N.m)

1

/ 4-28 9-11 ft-lbs. (12-15 N.m)

5

/ 8-18 162-198 ft-lbs. (220-268 N.m)

5

/ 16-18 15-18 ft-lbs. (20-24 N.m)

3

/ 4-10 234-286 ft-lbs. (317-388 N.m)

5

/ 16-24 17-21 ft-lbs. (23-28 N.m)

3

/ 4-16 270-330 ft-lbs. (366-447 N.m)

3

/ 8-16 27-33 ft-lbs. (37-45 N.m)

7

/ 8-9 360-440 ft-lbs. (488-597 N.m)

3

/ 8-24 31-39 ft-lbs. (42-53 N.m)

7

/ 8-14 396-484 ft-lbs. (537-656 N.m)

7

/ 16-14 45-55 ft-lbs. (61-75 N.m) 1-8 522-638 ft-lbs. (708-865 N.m)

7

/ 16-20 49-61 ft-lbs. (66-83 N.m) 1-12 576-704 ft-lbs. (780-954 N.m)

NOTE: These torque values are to be used for all hardware excluding: locknuts, self-tapping

screws, thread forming screws, sheet metal screws and socket head setscrews.

Metric Grade

Diameter —

5.6 8.8 10.9 12.9

Coarse Thread N.m ft-lbs. N.m ft-lbs. N.m ft-lbs. N.m ft-lbs.

M6 4.6 3.3 10.5 7.7 15 11 18 13

M7 7.8 5.6 17.5 12.9 26 18.4 29 21.3

M8 11 8.1 26 19 36 26 43 31

M10 22 16 51 37 72 53 87 64

M12 39 28 89 66 125 92 150 110

M14 62 45 141 103 198 146 240 177

M16 95 70 215 158 305 224 365 269

M18 130 95 295 217 420 309 500 368

M20 184 135 470 309 590 435 710 623

METRIC

2

2A. Repair and Service Tools and Materials . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2A-1

2B. Failure Analysis . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2B-1

General . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2B-1

2C. Control Adjustments . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2C-1

General . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2C-1

Throttle Adjustment . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2C-1

Traction Speed Adjustment . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2C-2

Traction Neutral Adjustment . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2C-2

Mow Speed Adjustment . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2C-3

Brake Adjustment . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2C-3

Reel Limit Switch Adjustment . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2C-3

Cruise Control . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2C-4

2D. Gauges and Instruments . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2D-1

Repair . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2D-1

SECTION 2

CONTROLS

Tools required: Standard automotive hand tools.

Cleaning materials: Stoddard or equivalent solvent.

Detergent and water.

Lubricants: Refer to Section 11.

SECTION 2A. REPAIR AND SERVICE TOOLS AND MATERIALS

2A-1

2A

SECTION 2B. FAILURE ANALYSIS

2B-1

2B

PROBLEM PROBABLE CAUSE REMEDY

1. Engine turns over but a. Glow plug defective. a. Test and replace (if necessary)

will not start. glow plug (Section 10L).

b. Fuel supply. b. Check fuel supply.

c. Fuel filter. c. Change.

d. Fuel solenoid inoperative. d. Test solenoid (Section 10K).

2. Engine does not turn a. Traction pedal not in “neutral”. a. Adjust traction pedal (Section 2C).

over.

b. Brake pedal not latched. b. Set brake.

c. Mower switch in ON position. c. Move switch to OFF.

d. One of several switches d. Test switches and adjust if

damaged or loose. required (Section 10G).

e. Neutral start switch out of e. Adjust switch (Section 2C).

adjustment or defective. Test switch (Section 10G).

f. Battery defective or bad ground. f. Test battery (Section 10D).

3. Engine speed does not a. Throttle control is not properly a. Adjust (Section 2C).

increase when throttle adjusted.

control is moved.

b. Throttle control is broken. b. Repair or replace (Section 2C).

c. Fuel shutoff solenoid linkage is c. Adjust linkage (Section 2C).

not properly adjusted.

d. Fuel shutoff solenoid is not func- d. Perform test (Section 10K).

tioning properly.

4. The unit “creeps” in a. Traction pedal linkage out of a. Adjust traction (Section 2C).

either direction when the adjustment.

traction pedal is not

depressed.

5. Parking brake fails. a. Brake not adjusted. a. Adjust brake (Section 2C).

b. Worn brake disks or linings. b. Replace disks or linings

(Section 5B).

6. Mowers do not lift or a. Lift/lower lever switches faulty. a. Test, replace if necessary

lower properly as lift/ (Section 10G).

lower pedal is activated.

b. Control valve leaking or defective. b. Test valve (Section 8O).

Repair valve (Section 8M),

depending on serial number.

c. Faulty lift limit switch adjustment. c. Adjust (Section 2C).

d. Faulty lift cylinder. d. Test and repair cylinder

(Section 8M).

GENERAL

The following table gives common problems, probable

causes and suggested remedies with page references

to detailed description of remedial procedures.

GENERAL

The repair of controls is limited to adjustment of link-

ages, straightening of bent rods or replacement of

defective parts and hardware.

Control functions are monitored by an electronic con-

troller at the front of the engine compartment. See

Section 10 for electronic controller tests/repairs.

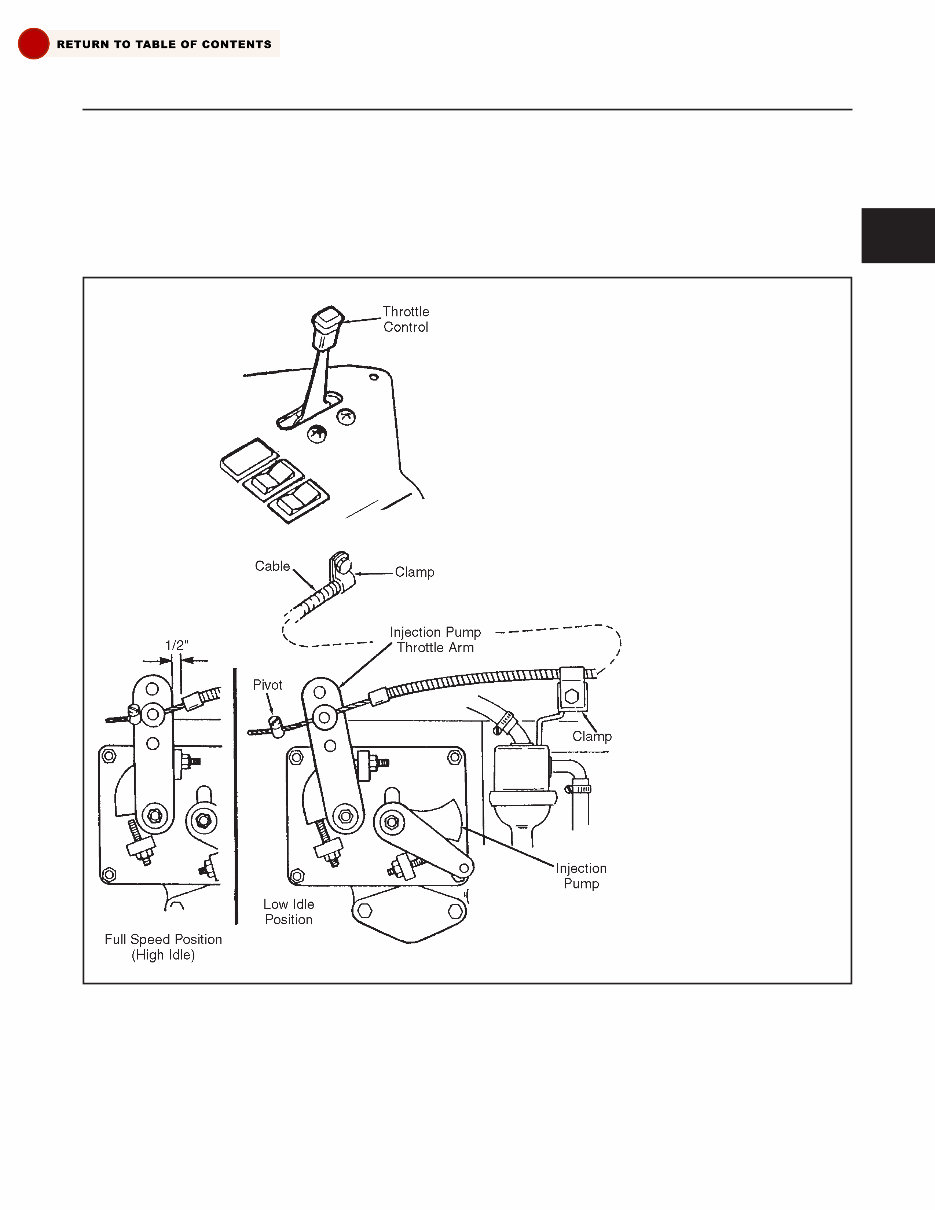

THROTTLE ADJUSTMENT

(See Figure 2C-1)

Located on the control panel to the right of the opera-

tors seat, the throttle control is used to regulate

engine speed. Adjust the throttle as shown in Figure

2C-1.

SECTION 2C. CONTROL ADJUSTMENTS

2C-1

2C

Figure 2C-1. Throttle Control Adjustment

STEP 1

Push throttle to high idle position.

Push injector pump throttle arm to

the high idle (speed position.

STEP 2

Slide outer cable housing in

clamp until housing is 1/2 inch

from injector pump throttle lever.

Tighten clamp.

STEP 3

Install wire stop against injector

pump throttle pivot and tighten.

STEP 4

Start engine and check low and

high idle speeds of engine. Low

idle should be 1330 RPM and

high is 3150 RPM. Make fine

adjustments using the injector

pump throttle arm stop screws.

You're Reading a Preview

What's Included?

Fast Download Speeds

Online & Offline Access

Access PDF Contents & Bookmarks

Full Search Facility

Print one or all pages of your manual

$33.99

$44.99

Viewed 53 Times Today

Loading...

Secure transaction

What's Included?

Fast Download Speeds

Online & Offline Access

Access PDF Contents & Bookmarks

Full Search Facility

Print one or all pages of your manual

$33.99

$44.99

The Jacobsen LF-3400 & LF-3800 Repair Service Manual is a comprehensive guide covering the repair and maintenance of the LF-3400 2 Wheel Drive, LF-3800 2 Wheel Drive, LF-3400 4 Wheel Drive, LF-3800 4 Wheel Drive, and LF-3400 4 Wheel Drive Turbo Engine models.

- Language: English

- Pages: 273

- Format: PDF

- Platform: Windows and MAC

Professionals and DIY enthusiasts will find this manual invaluable as it includes detailed sections on controls, engine, drive train, brake system, steering, wheels & tires, hydraulics, chassis, electrical system, preventive maintenance, attachments, options, and miscellaneous information, along with specifications.