Gilson Snow Thrower service repair manual maintenance

What's Included?

Fast Download Speeds

Online & Offline Access

Access PDF Contents & Bookmarks

Full Search Facility

Print one or all pages of your manual

Printed in U.S.A.

Snowthrowers

Gilson Brothers Company, Box 152, Plymouth, Wisconsin 53073

Gilson Brothers Company (Canada) Ltd., 3325 Orlando Drive, Mississauga, Ontario

No. SM1201

GlLSON BROTHERS COMPANY, BOX 152, PLYMOUTH, WISCONSIN 53073

n

SNOW THROWERS

Page

.............................. 4 H.P. Model 3-14

Set Up

Maintenance & Lubrication

General Operational Adjustments

Service Manual

5 & 8 H.P. Friction Drive Model .............. 15-22

Set Up

Maintenance & Lubrication

General OperationalAdjustments

Service Manual

.................. 8 H.P. Gear Drive Model .23-37

Set Up

Maintenance & Lubrication

General Operational Adjustments

Service Manual

Refer to Service Bulletins for additional information

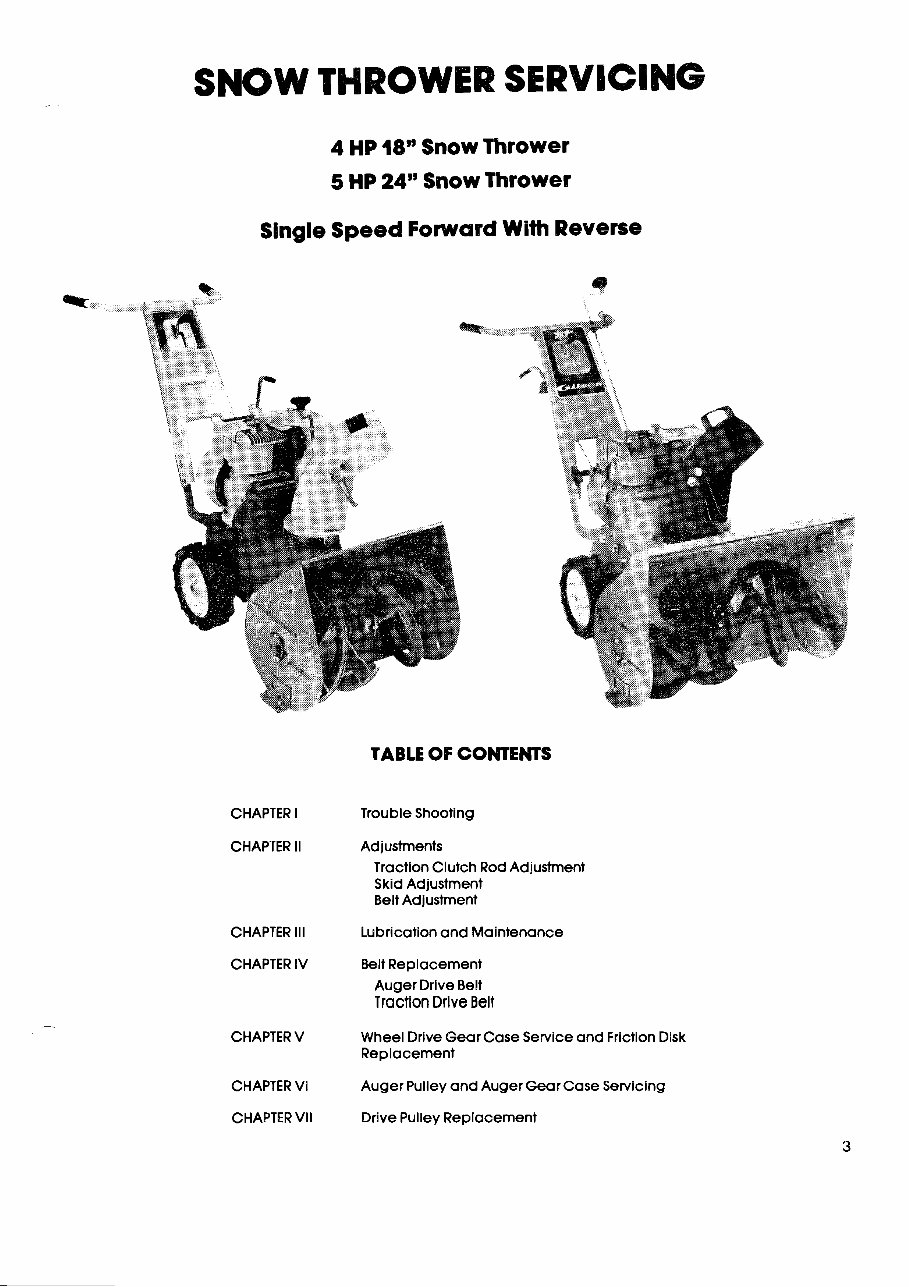

SNOW THROWER SERVICING

4 HP 18" Snow Thrower

5 HP 24" Snow Thrower

Single Speed Forward With Reverse

TABLE OF CONTENTS

CHAPTER I Trouble Shooting

CHAPTER II Adjustments

Traction Clutch RodAdjustment

Skid Adjustment

Belt Adjustment

CHAPTER Ill Lubricationand Maintenance

CHAPTER IV Belt Replacement

Auger Drive Belt

Traction Drive Belt

CHAPTER V Wheel Drive Gear Case Service and Friction Disk

Replacement

CHAPTER VI Auger Pulley and Auger Gear Case Servicing

CHAPTER VII Drive Pulley Replacement

s o SNOW THROWER

-.

1EPARATION FOR OPERATION

ASSEMBLY

Your Snow Thrower is factory assembled except for

@

handle assembly,handle brackets, traction clutch rod,

handle grips and shifter knob.

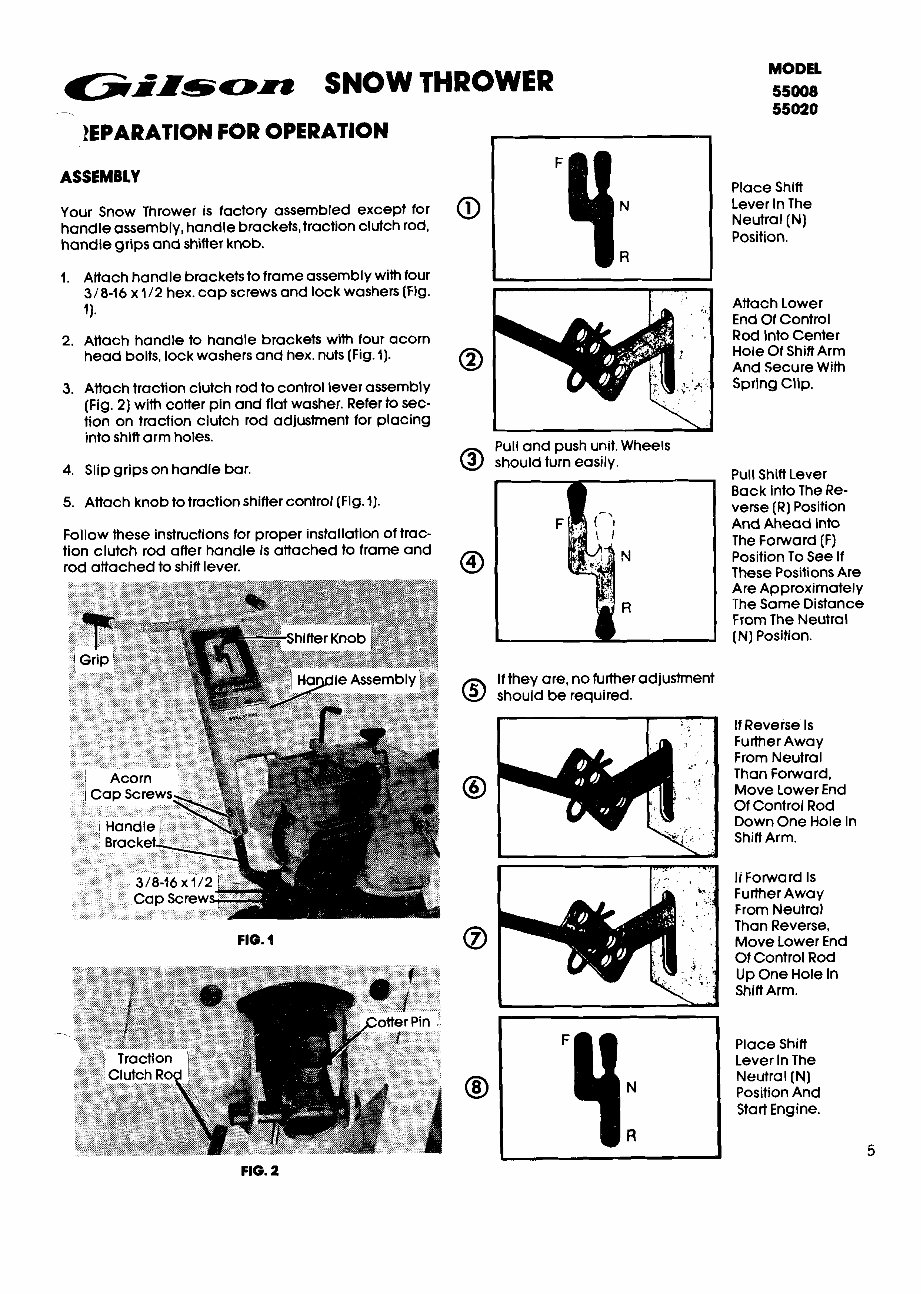

1. Attach handle bracketsto frame assembly with four

3/8-16 x 1/2 hex. cap screws and lock washers (Fig.

1).

2. Attach handle to handle brackets with four acorn

head bolts, lock washers and hex. nuts (Fig. I).

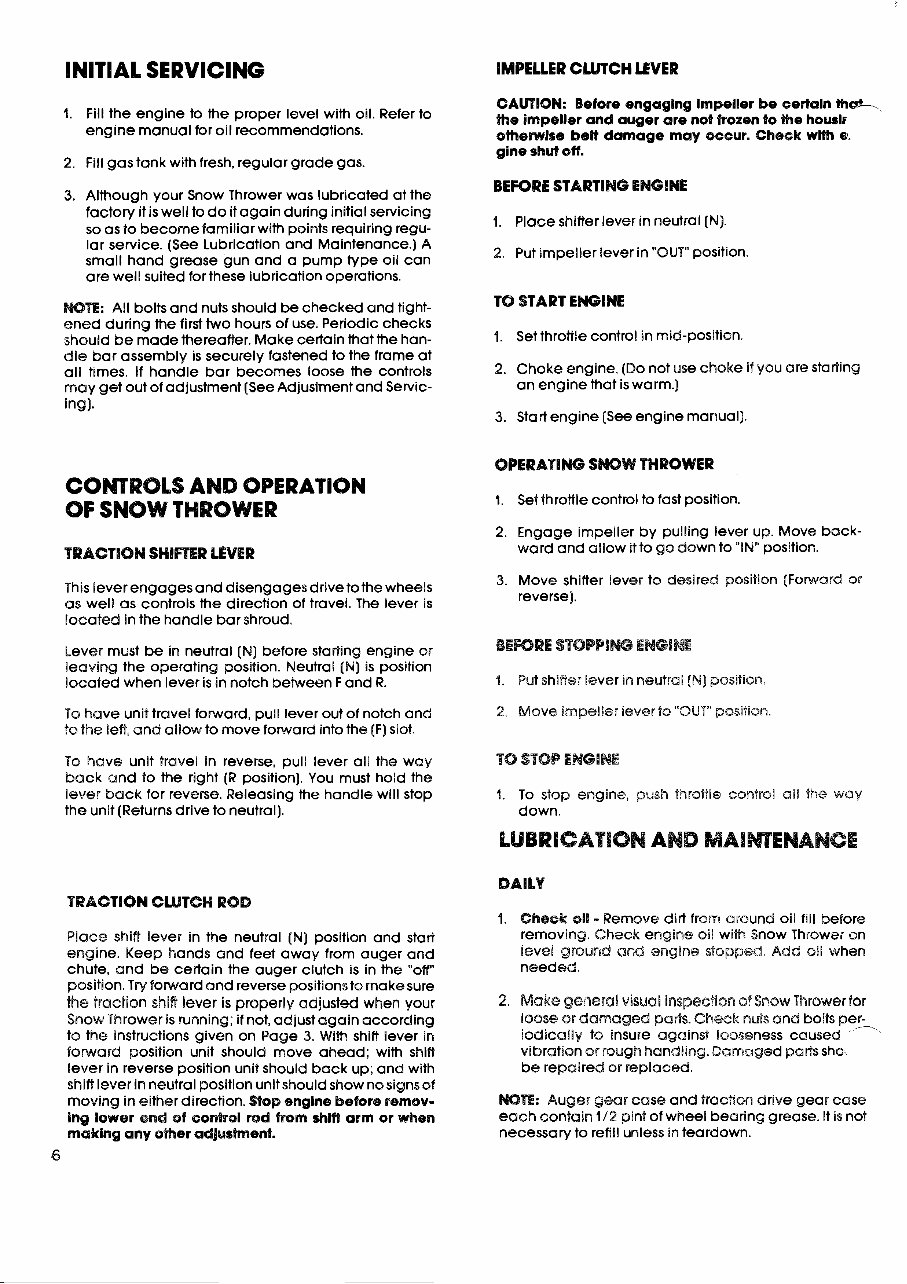

3. Attach traction clutch rod to control lever assembly

(Fig. 2) with cotter pin and flat washer. Refer to sec-

tion on traction clutch rod adjustment for placing

into shift arm holes.

4. Slip grips on handle bar.

5. Attach knob to traction shifter control (Fig. I].

Follow these instructions for proper installation of trac-

tion clutch rod after handle is attached to frame and

rod attachedto shift lever.

FIG. 1

FIG. 2

0

Pull and push unit.Wheels

@) should turn easily.

If they are, no further adjustment

@ should be required.

MODEL

55008

55020

Place Shift

Lever In The

Neutral (N)

Position.

Attach Lower

End Of Control

Rod lnto Center

HoleOf Shift Arm

And Secure With

Spring Clip.

Pull Shift Lever

Back lnto The Re-

verse (R) Position

And Ahead lnto

The Forward (F)

Position To See If

These PositionsAre

Are Approximately

'The Same Distance

From The Neutral

(W) Position.

If Reverse Is

Further Away

From Neutral

Than Forward,

Move Lower End

Of Control Rod

Down One Hole In

Shift Arm.

li Forward Is

Further Away

From Neutral

Than Reverse,

Move Lower End

Of Control Rod

Up One Hole In

Shift Arm.

Place Shift

Lever In The

Neutral [W)

PositionAnd

Start Engine.

INITIAL SERVICING

IMPELLER CLUTCH LEVER

1. Fill the engine to the proper level with oil. Refer to

engine manual for oil recommendations.

2. Fill gas tank with fresh, regular grade gas.

3. Although your Snow Thrower was lubricated at the

factory it is well to do it again during initial servicing

so as to become familiar with points requiring regu-

lar service. (See Lubrication and Maintenance.)A

small hand grease gun and a pump type oil can

are well suited for these lubrication operations.

WE: All bolts and nuts should be checked and tight-

ened during the first two hours of use. Periodic checks

should be made thereafter. Make certain that the han-

dle bar assembly is securely fastened to the frame at

all times. If handle bar becomes loose the controls

may get out of adjustment (SeeAdjustment and Servic-

ing).

COMROLS AND OPERATION

OF SNOW THROWER

TRACTION SHIRER LEVER

This lever engages and disengagesdriveto the wheels

as well as controls the direction of travel. The lever is

located In the handle bar shroud.

Lever must be in neutral [NJ before stafling engine or

leaving the operating position. Neutral (N) is position

I~cated when lever is in notch between F and R.

To have unit travel forward, pull lever out of notch and

fo the left, and ailow to move forward into the (F) slot.

To have unit travel in reverse, pull lever all the way

back and to the right (R position). You must hold the

lever back for reverse. Releasing the handle will stop

the unit (Returnsdrive to neutral).

CAUTION: Before engaglng impeller be certain t h a L

the impeller and auger are not frozen to the houris

ottaemlre belt damage may occur. Check wlVh cu.

gine shut off.

BEFORE STARTING ENGINE

1. Place shifler lever in neutral (N).

2. Put impeller lever in "OUT" position.

TO START ENGINE

4. Set throttle control in mid-position.

2. Choke engine. (Do not use choke if you are star?ing

an engine that is warm.)

3. Start engine [See engine manual).

OPERATING SWW THROWER

1. Set throttle control to fast position.

2. Engage impeller by pulling lever up. Move back-

ward and allow it to go down to "IN" position.

3. Move shifter lever to desired position [Fonvard or

reverse].

1. Put shiner !ever in neutral [N] position.

2. Move impeller lever ts "OUT" position.

I. To stop engine, push %?sotile control ail the way

down

LUBRICATION AND MAIMENANCE

TRACTION CWTGH ROD

Place shifl lever in the neutral (N) position and start

engine. Keep hands and feet away from auger and

chute, and be certain the auger clutch is in the "off"

position.Try foward and reverse positionsto makesure

the traction shifi lever is properly adjusted when your

Snow Thrower is running; if not, adjust again according

to the instructions given on Page 3. With shift lever in

fsmaad position unit should move ahead; with shift

lever in reverse position unit should back up; and with

shift lever in neutral positionunit should show nosignsof

moving in either direction. Stop englne before remsv-

ing lower end of eontroi rsd from &if? arm or when

making any omer ac8gushent.

6

4. Cheek oil - Remove dirt from around oil fill before

removing. Check engine sli wi% Snow Thrower on

level ground and engine stopped. Add oil when

needed.

2. Make general visuaB inspection of Srbsw Thrower for

loose or damaged parts. Cheek nuts and bolts per-

iodlcaily to insure against looseness caused

-,

vibration or rough handling.Damaged sho

be repaired or replaced.

WE: Auger gear case and traction drive gear case

each contain 1/2 pint of wheel bearing grease. It is not

necessary to refill unless in teardown.

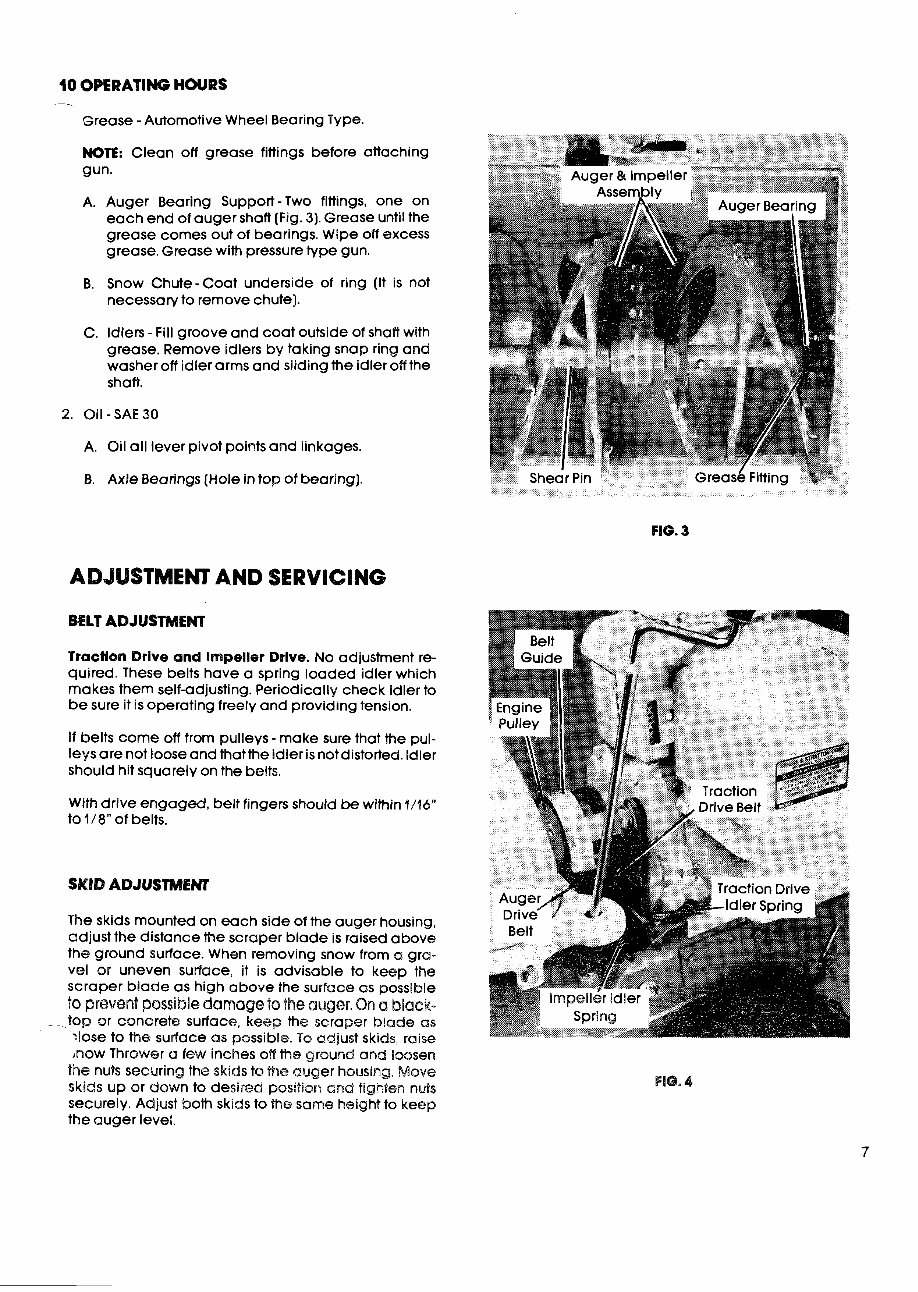

10 OPERATING HOURS

Grease -Automotive Wheel Bearing Type.

NOTE: Clean off grease fittings before attaching

gun.

A. Auger Bearing Support-Two fittings, one on

each end of auger shaft (Fig. 3). Grease until the

grease comes out of bearings. Wipe off excess

grease. Grease with pressuretype gun.

B. Snow Chute-Coat underside of ring (It is not

necessary to remove chute].

C. Idlers - Fill groove and coat outside of shaft with

grease. Remove idlers by taking snap ring and

washer off idler arms and sliding the idler off the

shaft.

A. Oil all lever pivot points and linkages.

B. Axle Bearings(Holein top of bearing).

FIG. 3

ADJUSTMEHT AND SERVICING

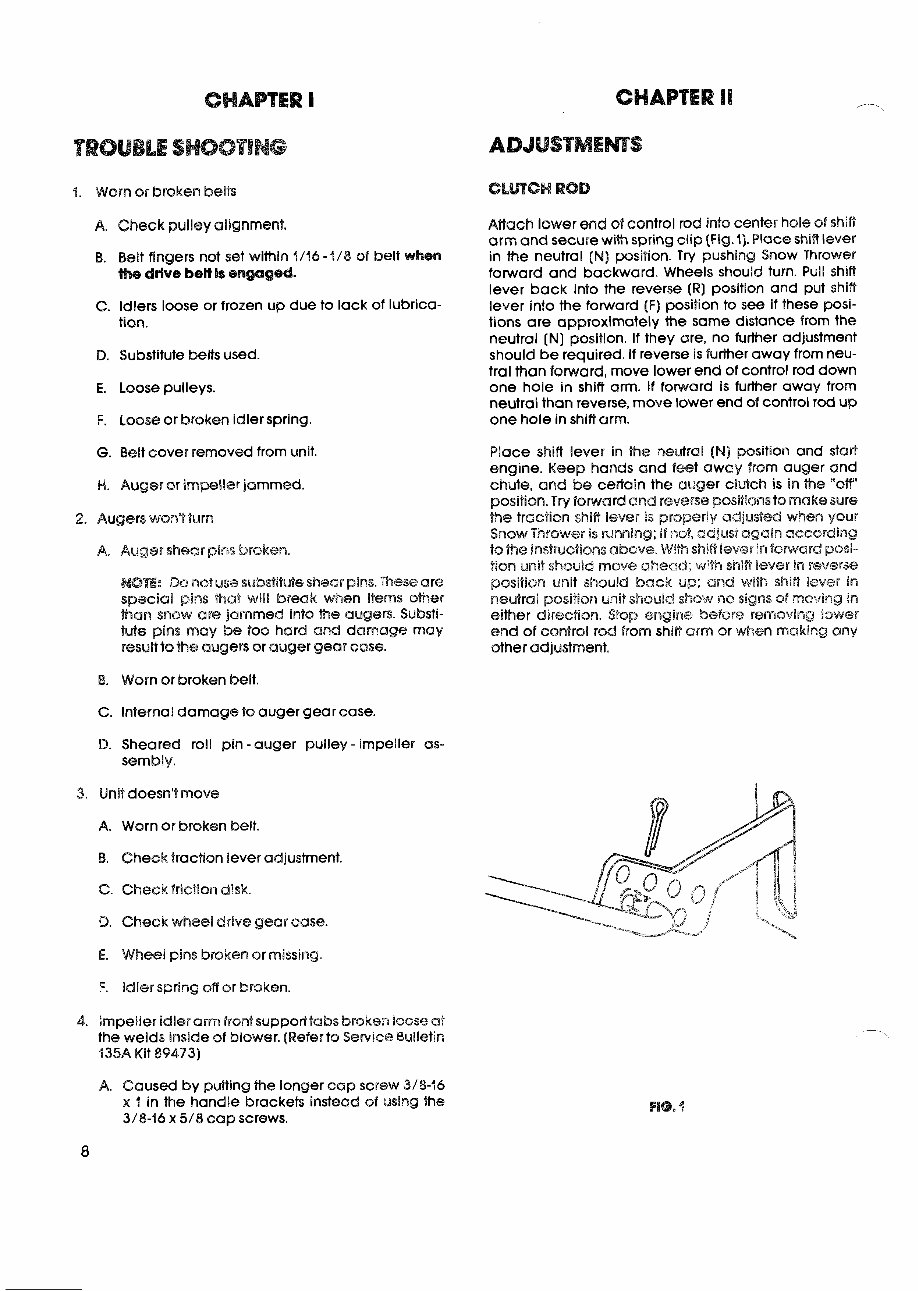

BELT ADJUSTMEHT

Traction Drive and lrnpeller Drive. No adjustment re-

quired. These belts have a spring loaded idler which

makes them self-adjusting. Periodically check idler to

be sure it is operating freely and providing tension.

If belts come off from pulleys - make sure that the pul-

leys are not loose and thatthe idler is not distorted.Idler

should hit squarely on the belts.

With drive engaged, belt fingers should be within 4/46"

to 1/8" of belts.

SKID ADJUSTMENT

The skids mounted on each side of the auger housing,

adjust the distance the scraper blade is raised above

the ground surface. When removing snow from a gra-

vel or uneven surface, it is advisable to keep the

scraper blade as high above the surface as possible

to prevent possible damage to the auger. On a black-

- top or concrete surface, keep the scraper blade as

:lose to the sudace as possible. To adjust skids. raise

mow Thrower a few inches off the ground and loosen

the nuts securing the skids to the auger housing. Move

skids up or down to desired position and tighten nuts

securely. Adjust both skids to the same height to keep

the auger level.

FIG. 4

CHAPTER B

TROUBLE SHOOTING

4. Worn OF broken belts

A. Check pulley alignment.

B. Belt fingers not set within 4/46 -f/8 sf belt when

the drlve bett Is engaged.

C. Idlers loose or frozen up due to lack of lubrica-

tion.

D. Substitute belts used.

E. Loose pulleys.

F. Lossa or taroken idler spring.

G. Belt cover removed f r ~ m unit.

H. Auger or impller jammed.

2. Augers won't turn

A~ Auger shew plns broken.

WE: Do nod usa substitute shear piws. These are

special pins &at "will break when items other

%an snow are? jammed into the augers. Substi-

tute plns may be too herd and damage may

result to %-ae augers or auger gear case.

B. Worn or broken belt.

C. Internal damage to auger gear case.

D. Sheared roll pin -auger pulley - impeller as-

sembly.

3. Unit doesn't move

A. Worn or broken belt.

5. Check traction lever adjustment.

C. Check friction disk.

B. Check wheel drive gear case.

E. Wheel piws broken or missing.

F. idler spring off or broken.

4. Impeller idler arm front suppor68abs broken Oo~ae a.t

the welds inside ef blower.(Referto Sewice Bulletin

135A Kit $9473)

A. Caused by puSPing the longer cap screw 3/8-46

x 3 in the handle brackets instead of using :he

3/8-16 x 5/8 cap screws.

Aflach lower end of control rod into center hole of $Riff

arm and secure with spring clip (Fig. I]. Place shin lever

in the neutral (N) position. Try pushing Snow Thrower

forward and backward. Wheels should turn. Pull shift

lever back into the reverse (R) position and put shift

lever into the forward (F) position to see if these posi-

tions are approximately the same distance from the

neutral (N) position. If they are, no further adjustment

should be required. If reverse is further away from neu-

tral than forward, move lower end of control rod down

one hole in shift arm. If forward is further away from

neutral than reverse,move lower end of control rod up

one hole in shift arm.

Place shift lever in the neutral (Nj position and star3

engine. Keep hands and feet away from auger and

chute, and be certain the auger clutch is in he "OW'

position. T~P/ forward and revene pO%itir;Pns to make sure

the traction shifi iever Is properly adjusted when your

Swsw Thrower is mwning; If 14~9, adjust again a~~ording

to 'he instruet!snsabovg. LVWi sbifi igevsb In faward posi-

tian unlB should move ahecrad; with hlfi lever in revsne

position unit should back up; and wim shift lever in

neutral position unit should shmv nnc? signs sf rnm~ing 8n

either direction. Stop englr%e befoss removing lower

end of eontr~l rod from sh i W aim or when making any

other adjustment.

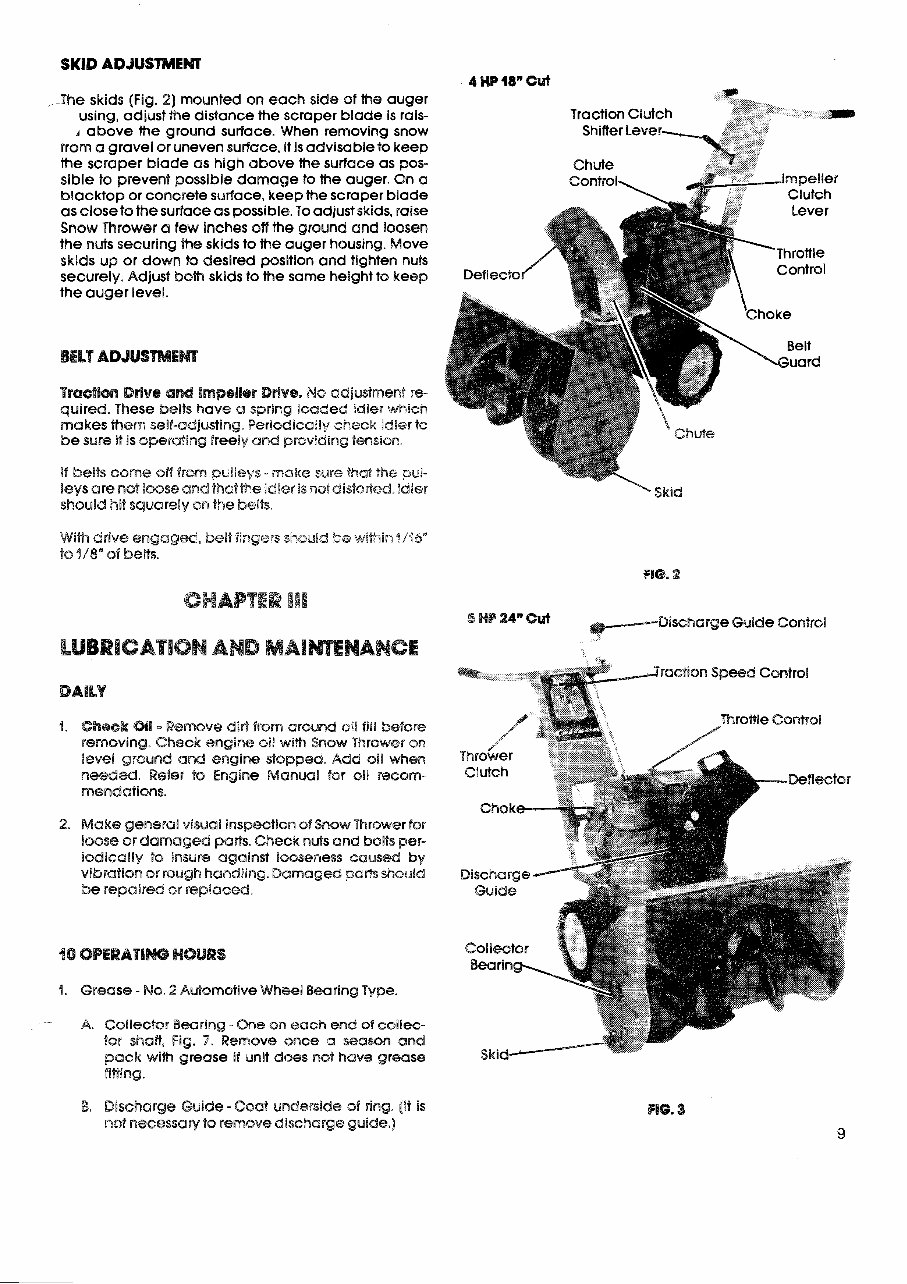

SKID ADJUSTMENT

4 HP 18" Cut

The skids (Fig. 2) mounted on each side of the auger

using, adjust the distance the scraper blade is rais- Traction Clutch

A above the ground surface. When removing snow Shifter Lever-

rrsm a gravel or uneven surface, it is advisable to keep

the scraper blade as high above the surface as pos-

sible to prevent possible damage to the auger. On a

blacktop or concrete surface, keep the scraper blade

as closets the surface as possible.To adjust skids, raise

Snow Thrower a few inches off the ground and loosen

the nuts securing the skids to the auger housing. Move

skids up or down to desired position and tighten nuts

securely. Adjust bslh skids k the same height to keep Deflecto

the auger level.

BELT ADSIISWBWEW

TB~(G@OW Ddw8 and impeller Ddve. No adgustmen! re-

quired. These belts have a spring loaded idler which

makes %hem self-adjusting.periodicadly check lases to

be sure it Is operating freeiy and proviaing tension.

I% belts come sfl from pulleys - ,make sure that the pus-

leys are ws8 loose and thatme :dBerBs i?atdi~t~ded,?di@r

shsuid hit squarely on the $sits

2Vih drive en gag^, belt fi~gers s!-@uk2 ". atitherin 4/16"

to "$8" sf beits.

f 10.2

GHAPTER III

5 HB 24" cut

DischargeGuide Control

LUBRICATION AND MAI WENANCE

d >ractJon S~wd Control

1. Chsek OBI - Remove diri from around oil fill before

removing. Check engine 019 wi% Snow Thrower on

OeveI ground and engine stopped. Add oil when

weeded. Refer $0 Engine Manual far oil ;eccsm-

menaafions.

2. Make general visual inspection of Snow Thrower for

loose or damaged parts. Check nuts and bolts per-

lsdicallly ts insure against Bosseasess caus& by

vibration or rough handling. Damaged parts shouid

be repaired sr repicreed.

1. Grease - No. 2 Adomotive Wheel Bearing Type.

- A. Collector Bearing -One ow each end of collec-

Zsr shaff, Fig. 7. Remove once a season and

pack with grease if unit does not have grease

fi88ing.

4 '

Thrower

Discharge

Guide

Skid

8. Discharge Guide - Coat underside of ring. [it is

nsl necessaw to remove discharge guide.]

C. Wheel Assemblies -Remove wheels and coat

axle shafts.

MTE: Collector gear case and traction drive gear

case each contain 1/2 pint of wheel bearing

grease. It is not necessary to refill unless in tear-

down.

2. Oil - Engine Oil. (S.A.E. 5W-20 or S.A.E. 10W)

A. QII all lever pivot points and linkages.

B. Axle bearings.

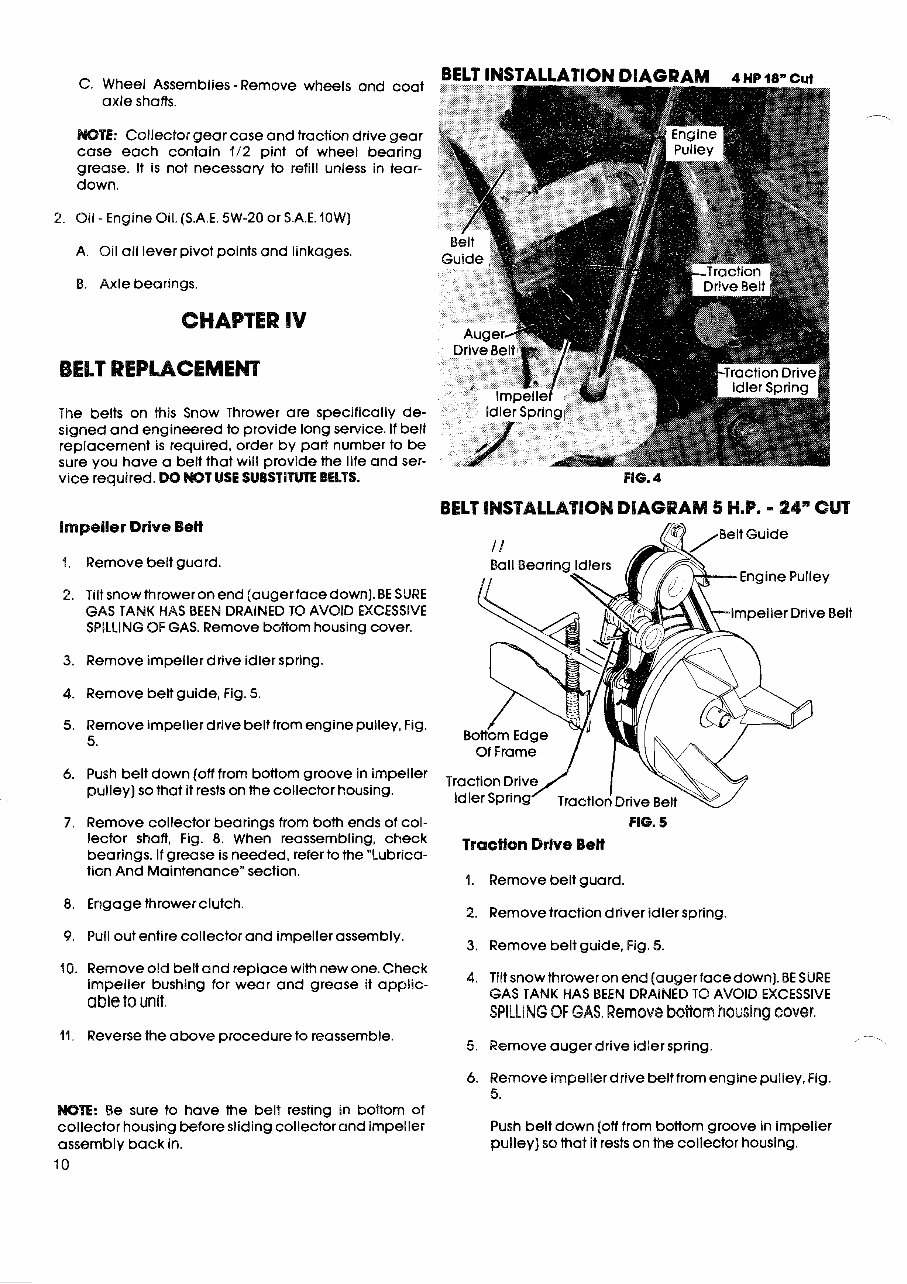

CHAPTER IV

BELT REPWCEMEM

The belts on this Snow Thrower are specifically de-

signed and engineered to provide long service. If belt

replacement is required, order by part number to be

sure you have a belt that will provide the life and ser-

vice required. DO NQT USE SUBST~PWE BELTS.

impeller Drive Bett

4. Remove belt guard.

2. Tilt snowthroweronend [augerfacedown]. BE SURE

GAS TANK HAS BEEN DRAINED TO AVOID EXCESSIVE

SPILLING OF GAS. Remove boRom housing cover.

3. Remove impeller drive idler spring.

4. Remove belt guide, Fig. 5.

5. Remove impeller drive belt from engine pulley, Fig.

5.

6. Push belt down (off from bottom groove in impeller

pulley) so that it rests on the collector housing.

- 24" CUT

elt Guide

FIG. 4

BELT ledSBAbLATCQN DIAGRAM 5 H.P. - 24" CUT

7. Remove collector bearings from both ends of col- FIG. 5

lector shaft, Fig. 8. When reassembling, check Traction BeH

bearings. If grease is needed, refer to the "Lubrica-

tion And Maintenance"section.

1. Remove belt guard.

8. Engage thrower clutch.

2. Removetraction driver idler spring.

9. Pull out entire collector and impeller assembly.

3. Remove belt guide, Fig. 5.

40. Removeold belt and replace with new one. Check

impeller bushing for wear and grease it applic-

4. Tilt snowthrower on end (auger facedown). BE SURE

able to unit.

GAS TANK HAS BEEN DRAINED TO AVOID EXCESSIVE

SPILLING OF GAS. Remove bstiom housing cover.

11. Reverse the above procedureto reassemble. --

5. Remove auger drive idler spring.

,

6. Remove impellerdrive beltfromengine pulley,Fig.

5.

WE: Be sure to have the belt resting in boRom of

collector housing before sliding collector and impeller Push belt down (off from bottom groove in impeller

assembly back in.

pulley) so that it rests on the collector housing.

10

You're Reading a Preview

What's Included?

Fast Download Speeds

Online & Offline Access

Access PDF Contents & Bookmarks

Full Search Facility

Print one or all pages of your manual

$39.99

Viewed 95 Times Today

Loading...

Secure transaction

What's Included?

Fast Download Speeds

Online & Offline Access

Access PDF Contents & Bookmarks

Full Search Facility

Print one or all pages of your manual

$39.99

Get the comprehensive maintenance service manual for the Gilson Snow Thrower. This manual covers the ST series and includes 38 pages of detailed instructions, along with exploded views and images. It is designed for use with 5 & 8 HP friction drive and 8 HP gear drive snow throwers. Whether you're a professional mechanic or a DIY enthusiast, this manual is an invaluable resource for keeping your snow thrower in top condition.

Additionally, we offer the Briggs engine manual on Tradebit for your convenience.