Stihl FS 36, FS 40, FS 44 Brushcutters Service Repair Manual INSTANT

What's Included?

Fast Download Speeds

Online & Offline Access

Access PDF Contents & Bookmarks

Full Search Facility

Print one or all pages of your manual

STIHL FS 36, 40, 44 1

Service Manual

FS 36, FS 40 and FS 44

Brushcutters

You should make use of the illustrated

parts lists while carrying out repair

work. They show the installed positions

of the individual components and

assemblies. Microfilmed parts list are

always more up to date than printed

lists.

A fault on the machine may have

several causes. Consult the

"troubleshooting charts" when tracing

faults.

Refer to the "Technical Information

Bulletins" for engineering changes

which have been introduced since

publication of this service manual.

The STIHL Special Tools manual lists

all special servicing tools currently

available from STIHL.

Always use original STIHL

replacement parts.

Original STIHL parts can be identified

by the STIHL part number, the

STIHl logo and the STIHL parts

symbol ( The symbol may appear

alone on small parts.

STIHl

Service manuals and technical

information bulletins describing

engineering changes are intended

exclusively for the use of STIHL

servicing dealers and staff and must

not be passed on to third parties.

STIHL FS 36, 40, 44 2

CONTENTS

1. Specifications 3

1.1 Engine 3

1.2 Fuel System 4

1.3 Ignition System 4

1.4 Gearhead 5

1.5 Weights 5

1.6 Special Accessories 5

1.6.1 For User 5

1.6.2 For Service Shop 5

1.7 Tightening Torques 6

2. Troubleshooting

Charts 8

2.1 Clutch 8

2.2 Engine 8

2.3 Ignition System 9

2.4 Rewind Starter 10

2.5 Fuel System 11

3. Clutch 13

3.1 Disassembly 13

3.2 Assembly 15

4. Engine 17

4.1 Removing and Refitting

Exhaust Muffler 17

4.2 Exposing the Cylinder 18

4.3 Cylinder and Piston 19

4.3.1 Removal 19

4.3.2 Installation 20

4.4 Piston Ring 21

4.5 Crankcase 21

4.5.1 Removing and Installing

the Crankshaft 21

4.5.2 Ball Bearings and

Oil Seal 22

4.6 Leakage Testing the

Crankcase 24

4.6.1 Preparations 25

4.6.2 Pressure Test 26

4.6.3 Vacuum Test

(for Diaphragm) 27

4.6.4 Vacuum Test

(for Oil Seal) 28

5. Ignition System 29

5.1 Repairing Component

Parts 29

5.1.1 Spark Plug 29

5.1.2 Ignition Module 31

5.1.2.1 Ignition Timing 31

5.1.2.2 Removing and

Installing 31

5.1.3 Contact Spring

(FS 36 and FS 40) 32

5.1.4 Flywheel 32

5.1.5 Spark Plug Terminal 33

5.1.6 Short Circuit Wire

(FS 44) 34

6. Rewind Starter 35

6.1 Routine Maintenance 35

6.2 Replacing the Starter

Rope (with Fan

Housing Fitted) 35

6.3 Tensioning the

Rewind Spring (with

Fan Housing Fitted) 36

6.4 Rope Rotor 37

6.4.1 Removal 37

6.4.2 Installation 38

6.4.3 Tensioning the Rewind

Spring (with Fan

Housing Removed) 39

6.5 Replacing the Rewind

Spring 39

6.6 Starter Pawls 40

7. Throttle Control 41

7.1 Throttle Trigger

(FS 36, FS 40) 41

7.2 Throttle Trigger,

Throttle Trigger Interlock,

Stop Switch (FS 44) 42

7.2.1 Disassembly 42

7.2.2 Assembly 43

7.3 Throttle Trigger,

Throttle Trigger Inter-

lock (FS 44 with Two-

Handed Handlebar) 44

7.4 Contact Springs in

Control Handle (FS 44

with Two-Handed

Handlebar) 45

7.5 Handle Support 46

7.6 Throttle Cable 47

8. Fuel System 48

8.1 Air Filter 48

8.2 Leakage Testing the

Carburetor 48

8.3 Removing the

Carburetor 50

8.4 Servicing the

Carburetor 50

8.5 Carburetor Adjustment 56

8.6 Diaphragm Carrier,

Diaphragm 58

8.7 Pickup Body and

Fuel Hose 59

8.8 Fuel Tank 60

8.9 Tank Vent 60

8.10 Fuel Pump 61

9. AV System

(FS 40 and FS 44) 62

9.1 Repair 62

10. Cutting Tool Drive 63

10.1 Bearing Housing

(FS 36, FS 40) 63

10.2 Gearhead (FS 44) 65

10.2.1 Disassembly 65

10.2.2 Assembly 66

10.3 Drive Shaft 68

10.4 Drive Tube 69

11. Special Servicing

Tools and Aids 71

11.1 Special Servicing Tools 71

11.2 Servicing Aids 72

STIHL FS 36, 40, 44 3

1. SPECIFICATIONS

STIHL single-cylinder two-stroke engine with special

impregnated cylinder bore.

Displacement:

Bore:

Stroke:

Power output:

Max. permissible engine

speed without cutting tool:

Cut-out speed without

cutting tool:

Idle speed:

Bearings:

Rewind starter:

Remaining pull on rope rotor:

Pawl/flywheel clearance:

Starter rope:

Clutch:

Clutch engages at:

Crankcase leakage test

at gauge pressure:

under vacuum:

Silencing:

30.2 cm

3

(1.84 cu. in)

34.8 mm (1.36 in)

31.8 mm (1.25 in)

0.7 kW (0.95 bhp)

10,000 rpm

9,300 rpm (± 700 rpm)

3,100 rpm

Crankshaft supported in

heavy-duty ball bearings;

needle cages at big and

small ends

Pawl system with automatic

starter rope rewind

1/4 to 1 3/4 turns

0.05-0.4 mm

(0.002-0.016 in)

3.5 mm (0.14 in) dia. x 850 mm

(33.5 in)

Centrifugal clutch without linings

4,000 rpm (± 500 rpm)

0.5 bar (7.25 psi)

0.4 bar (5.8 psi)

Intake air silencer and

exhaust muffler

1.1 Engine

STIHL FS 36, 40, 44 4

Carburetor:

Basic setting

High speed adjusting screw H:

Low speed adjusting screw L:

Carburetor leakage test at

gauge pressure:

Fuel tank capacity:

Fuel mixture:

Octane number:

Mix ratio:

Air filter:

Type:

Air gap:

Ignition timing:

Spark plug (suppressed):

Electrode gap:

Spark plug thread:

Length of thread:

Heat range:

All-position diaphragm carburetor

with integral fuel pump

Back off approx. 1 turn

(only for service shop)

Back off approx. 1 turn

(Basic setting with screws

initially moderately tight against

their seats)

0.8 bar (11.6 psi)

0.51 I (1 .1 US pt)

Regular brand-name gasoline

(leaded or unleaded) and

STIHL two-stroke engine oil

min. 90 RON

50:1

with STIHL 50:1 two-stroke

engine oil;

25:1

with other branded two-stroke,

air-cooled engine oils

Foam element

Electronic (breakerless)

magneto ignition

0.1-0.5 mm (0.004-0.020 in)

1.3-1.9 mm (0.05-0.07 in)

B.T.D.C. at 6,000 rpm

GM AC CSR 45 or

NGK BMR 6 A

0.7-0.8 mm (0.027-0.030 in)

M14x1.25

9.5 mm (0.37 in)

200

1.2 Fuel System

1.3 Ignition System

STIHL FS 36, 40, 44 5

FS 44

Spiral-toothed

bevel gears

1.33

Deep groove ball bearings

STIHL gear lubricant

0781 120 1117

6.1 kg

13.4 lb

Full harness

STIHL multi-purpose

grease

(80 g tube)

0781 120 1109

STIHL gear lubricant

(80 g tube)

0781 120 1117

Safety goggles

Transport guard for

steel cutting tools

4130 007 1060

4130 007 1050

0457 281 3803

FS 40

5.3 kg

11.7 lb

STIHL multi-

purpose grease

(80 g tube)

0781 120 1109

Safety goggles

4130 007 1060

4130 007 1050

0457 281 3803

FS 36

4.9 kg

10.8 lb

1.6 Special Accessories

1.6.1 For User

1.6.2 For Service Shop

STIHL multi-

purpose grease

(80 g tube)

0781 120 1109

Safety goggles

Carburetor parts kit

Gasket kit

Gasket panel

4130 007 1060

4130 007 1050

0457 281 3803

1.4 Gearhead

Type:

Gear ratio:

Bearings:

Lubrication:

1.5 Weights

without cutting tool

and deflector

STIHL FS 36, 40, 44 6

1.7 Tightening Torques

(Ibf.ft)

(1.8)

(12.5)

(2.2)

(1 .5)

(1 .8)

(1 .8)

(2.6)

(2.6)

(4.0)

(4.0)

(2.6)

(2.6)

For component

Clutch drum to

crankshaft

Clutch to crankshaft

Fixing screw on

deflector

Support plate,

diaphragm, diaphragm

carrier

Control handle

Loop handle

Cap on clutch

housing (FS 40, 44)

Clutch housing to

fan housing

Fan housing to

spiral housing

Diaphragm carrier to

crankcase

Shroud to fan

housing

Shroud, carburetor,

diaphragm carrier

However, it is essential to always use a torque wrench to

tighten the screw to the specified torques. If pneumatic or

electric screwdrivers are used to fit DG screws in polymer

components, always select a tightening torque below the

value given in the table. Then use a torque wrench to

check the tightening torque and correct it as necessary.

Thread size

IS 8-32*

3/8" 24*

B3.5x9.5

B3.9x19

IS-DG5x16

IS-DG5x16

IS-DG5x16

IS-DG5x16

IS-DG5x16

IS-DG5x24

IS-DG5x60

Fastener

Spline screw

(captive)

Clutch

Self-tapping

screw

Self-tapping

screw

Spline screw

Spline screw

Spline screw

Spline screw

Spline screw

Spline screw

Spline screw

Torque

Nm

2.5

17.0

3.0

2.0

2.5

2.5

3.5

3.5

5.5

5.5

3.5

3.5

Remarks

The new "DG" screws are used in the light-alloy and

fiberglass reinforced polymer components of models FS

36, 40 and 44. When screwed in for the first time, DG

screws form a permanent thread in the parts concerned.

They can be released and retightened as often as

necessary without affecting the strength of the screwed

assembly.

STIHL FS 36, 40, 44 7

Fastener

Spline screw

Spline screw

Spline screw

Spline screw

Spline screw

Spline screw

Spline screw

Spline screw

Spark plug

Special screw

" inch thread

Thread size

IS-DG5x60

IS-M4x20

IS-M5x18

IS-M5x18

IS-M5x20

IS-DG6x18

IS-M6x12

M6x50

M14x1.25

P5x14

For component

Muffler to cylinder

Ignition module to

cylinder

Clamp on clutch

housing

Clamp on bearing

housing

Clamp screw on

gearhead (FS 44)

Cylinder to

crankcase

Spiral housing to

crankcase

Clamp screw in

loop handle

Spark plug

Filter cover to

shroud

Remarks

Torque

Nm

6.5

3.5

6.5

6.5

5.5

14.0

14.0

3.5

19.0

2.5

(Ibf.ft)

(4.8)

(2.6)

(4.8)

(4.8)

(4.0)

(10.3)

(10.3)

(2.6)

(14.0)

(1 .8)

STIHL FS 36, 40, 44 8

2. TROUBLESHOOTING

CHARTS

2.1 Clutch

Condition

Insufficient frictional

contact - clutch slips

Cutting tool rotates while

engine is idling

2.2 Engine

Condition

Engine does not start easily,

stalls at idle speed, but

operates normally at full

throttle

Engine does not deliver full

power or runs erratically

Engine overheating

Cause

Clutch springs stretched or

fatigued, spring hooks broken

Engine idle speed too high

Clutch springs stretched or

fatigued, spring hooks broken

Cause

Oil seal in crankcase

leaking

Gaskets on diaphragm

carrier leaking

Diaphragm faulty

Cylinder base gasket

leaking

Crankcase damaged (cracks)

Diaphragm carrier damaged

(cracks)

Secondary air seepage through

faulty gaskets on diaphragm

carrier

Piston ring leaking or broken

Muffler carbonized

Insufficient cylinder cooling.

Cooling fins very dirty

Remedy

Fit new springs

Correct at idle speed

adjusting screw

Fit new springs

Remedy

Replace oil seal

Replace gaskets

Replace diaphragm

Replace gasket

Replace crankcase

Replace diaphragm carrier

Replace gaskets

Fit new piston ring

Clean muffler (inlet and

exhaust), replace spark

arrestor screen

Thoroughly clean cylinder

fins

STIHL FS 36, 40, 44 9

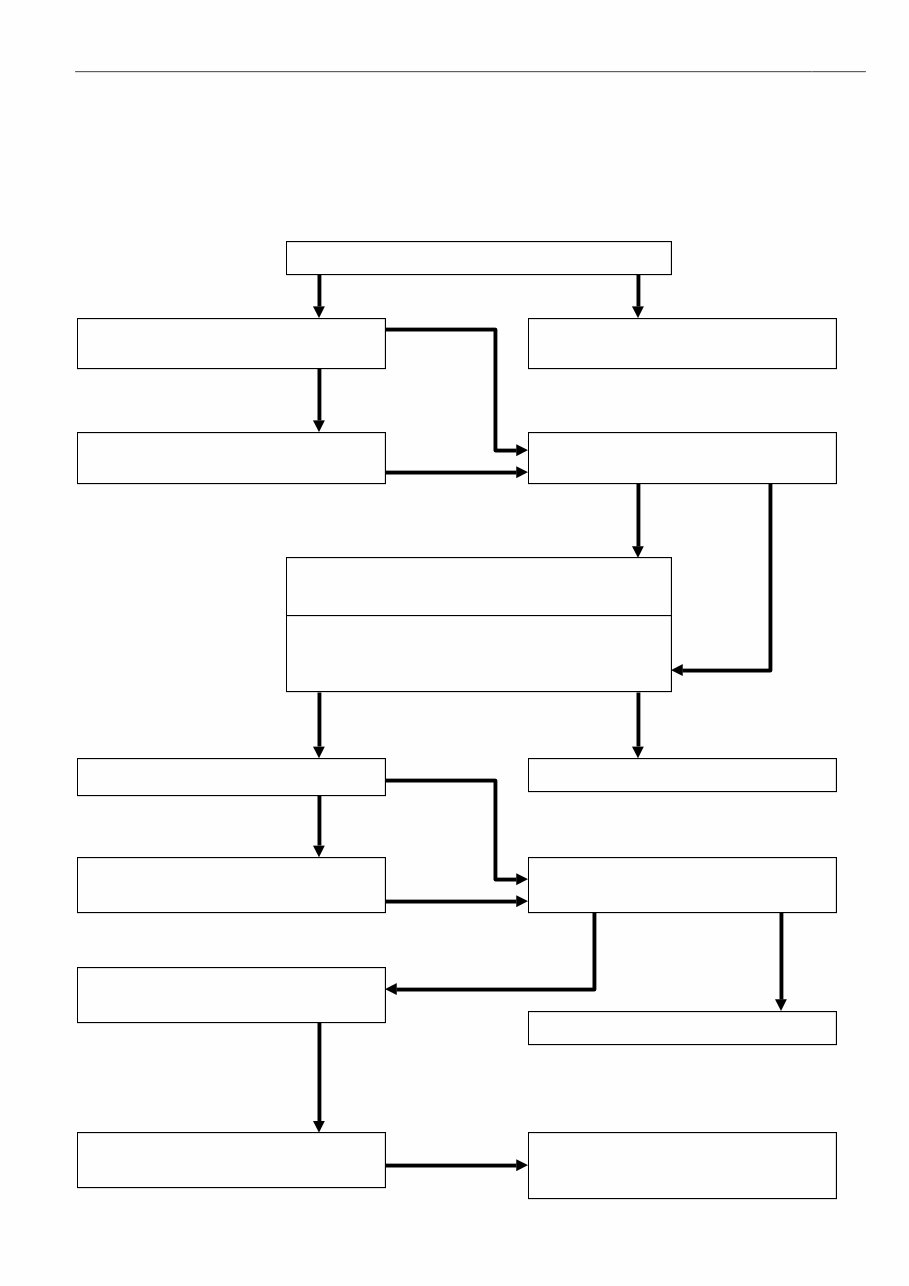

2.3 Ignition System

Warning: Exercise extreme caution while carrying out maintenance and repair work on the ignition system,

The high voltages which occur can cause serious or fatal accidents!

Ignition system in order.

Look for fault in fuel system and

carburetor.

yes

Replace ignition module. Does engine

now run after positive spark test?

Fit new flywheel.

Does spark test now

produce sparkover?

Does flywheel appear to be

in good condition?

Fit new spark plug. Is air gap correct?

Adjust air gap (0.1 - 0.5 mm).

Is spark test positive?

Insert screwdriver in place of spark plug in spark plug

terminal and hold about 4 mm (1/8") away from

ground. Sparkover?

Replace faulty ignition lead of short

circuit wire. Repair contact spring.

Faulty insulation on ignition

lead or short circuit wire?

Clean spark plug and reset electrode gap.

Does spark test produce powerful spark?

Press terminal firmly onto spark

plug and fit spring if necessary.

Spark plug terminal firmly seated on spark plug?

Remove spark plug.

Is it in good condition?

no

no

no

no

yes

no

no

yes

yes no

no

no

no

yes

yes

STIHL FS 36, 40, 44 10

Condition

Starter rope broken

Rewind spring broken

Starter rope can be pulled out

almost without resistance

(crankshaft does not turn)

Starter rope is difficult to

pull and rewinds very

slowly

Cause

Rope pulled out too

vigorously as far as

stop or over edge

Spring overtensioned -

no reserve when rope is

fully extended

Pawl arm is worn

Pawl spring fatigued

or broken

Starter mechanism is

very dirty

Lubricating oil on rewind

spring becomes viscous at

very low outside tempera-

tures (spring windings stick

together)

Remedy

Fit new starter rope

Fit new rewind spring

Fit new pawl

Fit pawl spring

Thoroughly clean complete

starter mechanism

Apply a few drops of kerosine

(paraffin) to spring, then pull

rope carefully several times

until normal action is restored

2.4 Rewind Starter

You're Reading a Preview

What's Included?

Fast Download Speeds

Online & Offline Access

Access PDF Contents & Bookmarks

Full Search Facility

Print one or all pages of your manual

$31.99

Viewed 18 Times Today

Loading...

Secure transaction

What's Included?

Fast Download Speeds

Online & Offline Access

Access PDF Contents & Bookmarks

Full Search Facility

Print one or all pages of your manual

$31.99

Get the comprehensive service and repair manual for the Stihl FS 36, FS 40, FS 44 Brushcutters. Whether you're a professional mechanic or a DIY enthusiast, this manual provides top-quality diagrams and instructions for easy repairs. It's compatible with all Windows and Mac operating systems and comes in English language.

Model Covers:

- Stihl FS 36 Brushcutter

- Stihl FS 40 Brushcutter

- Stihl FS 44 Brushcutter

Manual Covers:

- Introduction

- Specifications

- TROUBLESHOOTING CHARTS

- CLUTCH

- Engine

- Ignition System

- Rewind Starter

- Throttle Control

- Fuel System

- AV SYSTEM (FS 40 and FS 44)

- CUTTING TOOL DRIVE

- Special Servicing Tools And Aids

Instantly access the manual upon payment completion, saving on shipping fees and delivery time. Start your repairs immediately and keep your equipment working properly. Have a nice day!