2001 Honda TRX450S FM Fourtrax Foreman S FM TRX450 ES FE Fourtrax Foreman ES FE Service & Repair Manual

What's Included?

Fast Download Speeds

Online & Offline Access

Access PDF Contents & Bookmarks

Full Search Facility

Print one or all pages of your manual

r-------IMPORTANT SAFETY NOTICE ----------,

Indicates. strong possibility of severe pel$OnlJl injury or death if Instructions .r. not followed.

CAunON: Indicates .. possiblUty of lHluipment dlJmage If instructions are not followed.

NOTE: Gives helpful information,

Detailed descriptions of standard workshop procedures, safety principles and service operations are not included. It is

important to note that this manual contains some warnings and cautions against some specific service methods which

could cause PERSONAL INJURY 10 service personnel or could damage a vehicle or render it unsafe. Please understand

that those warn ings could not cover 811 conceivable ways in wh ich service. whether or not recommended by Honda.

might be done or of the possiblV hazardous consequences of each conceivable way . nor could Honda investigate all

such ways. Anyone using service procedures or tools, whether or not recommended by Honda, must satisfy himself

thoroughly that neither personal safety nor vehicle safety wi ll be jeopardized by the service mel hods or lools selected.

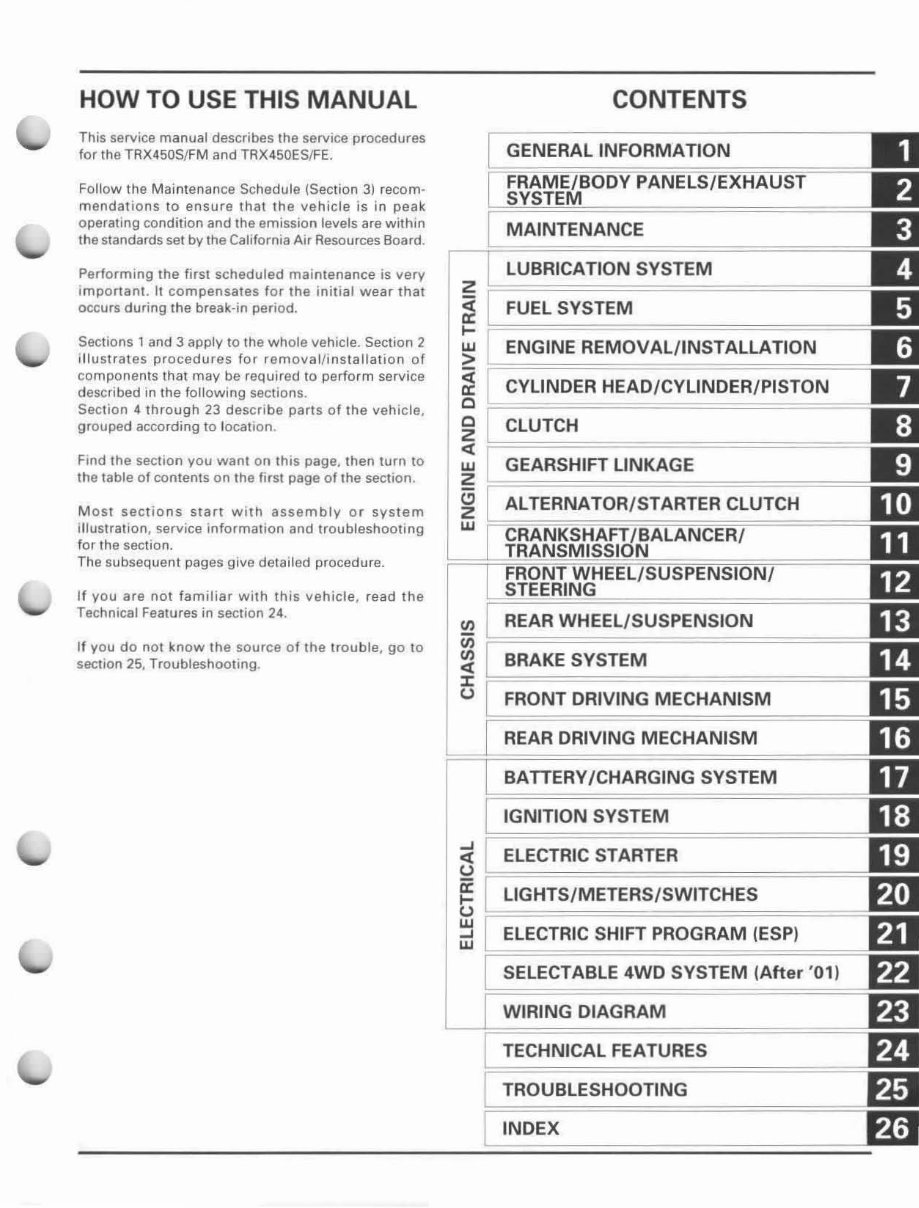

HOW TO USE THIS MANUAL

This service manual describes the service procedures

for the TAX450S/ FM and TAX450ES/FE.

Follow the Maintenance Sc hedule (Section 3) recom-

mendations to ensure tha t t he vehicle is in peak

operating condition and the emission levels are within

the standards sel by the California Air Resources Board.

Performing the first scheduled maintenance is very

i mportant. II compensates for the initial wear that

occurs during the break-in period.

Sections 1 and 3 apply to the whole vehicle. Section 2

illustrates procedures for remova1l i nstallation of

components that may be required to perform service

described In the following sections.

Section 4 through 23 describe parts of the vehicle,

grouped according to l ocation .

Find the section you want on this page, then turn to

the table of contents on the first page of the section.

Most sections start with assembly or system

illustration, service information and troubleshooting

for the section.

The subsequent pages give detailed procedure.

If you are not familiar with this vehicle, read the

Technical Features in section 24.

If you do not know the source of the trouble , go to

section 25. Troubleshooting .

z

~

....

W

>

«

a:

c

c

z

«

w

z

-

(!l

Z

w

'" <i5

'"

«

:I:

<.J

...J

5

~

W

...J

W

CONTENTS

GENERAL INFORMATION

MAINTENANCE

LUBRICATION SYSTEM

FUEL SYSTEM

ENGINE REMOVAL/INSTALLATION

CYLINDER HEAD/CYLINDER/PISTON

CLUTCH

GEARSHIFT LINKAGE

ALTERNATOR/STARTER CLUTCH

REAR WHEEL/SUSPENSION

BRAKE SYSTEM

FRONT DRIVING MECHANISM

REAR DRIVING MECHANISM

BATIERY/CHARGING SYSTEM

IGNITION SYSTEM

ELECTRIC STARTER

LIGHTS/METERS/SWITCHES

ELECTRIC SHIFT PROGRAM (ESP)

SELECTABLE 4WD SYSTEM (After '01)

WIRING DIAGRAM

TECHNICAL FEATURES

TROUBLESHOOTING

INDEX

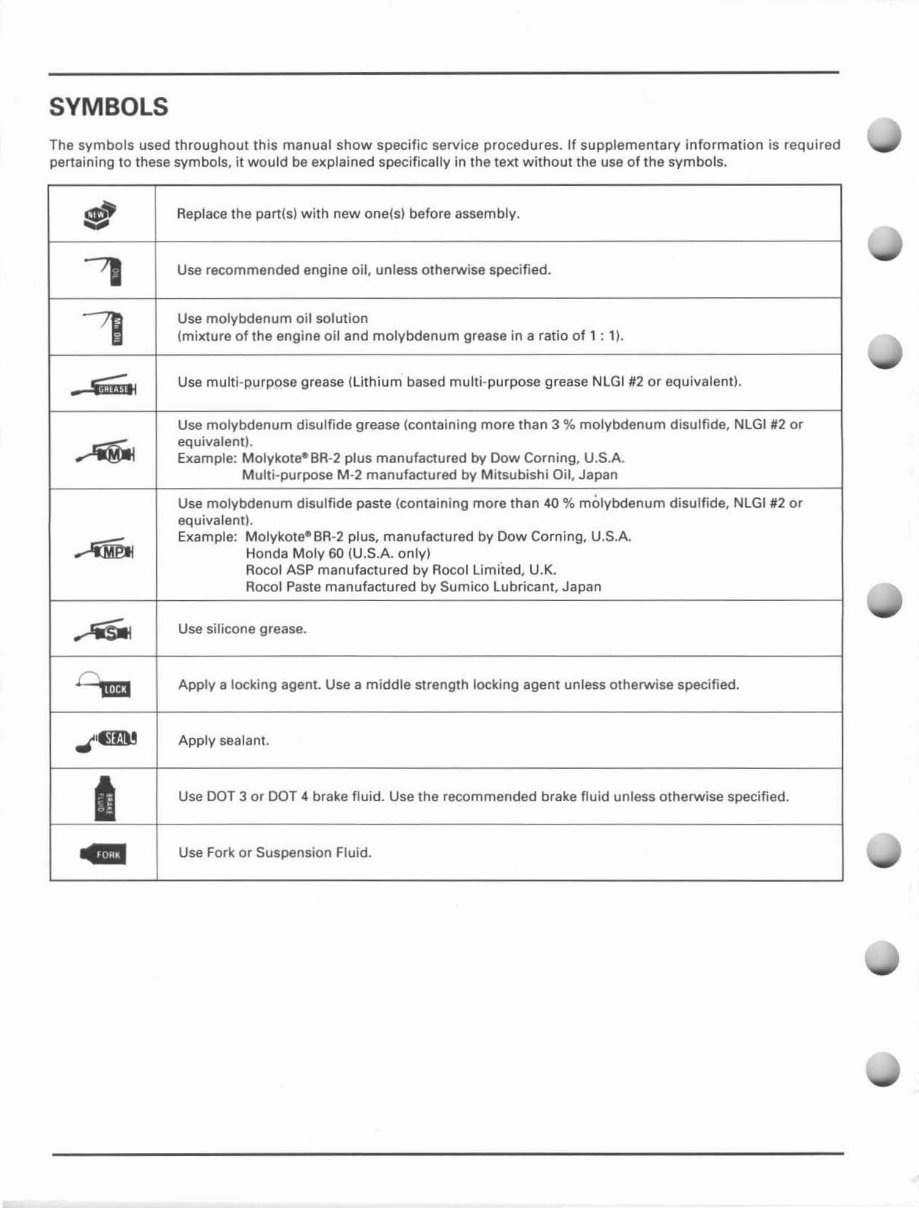

SYMBOLS

The symbols used throughout this manual show specific service procedures. If supplementary information is required

pertaining to these symbols, it would be explained specifically in the text without the use of the symbols.

~

Replace the part(s) with new one(s) before assembly .

.,

Use recommended engine oil, unless otherwise specified.

-,

Use molybdenum oil solution

(mixture of the engine oil and molybdenum grease in a ratio of 1 : 1),

~..$iiiiM

Use mUlti-purpose grease (lithium based multi -purpose grease NlGI #2 or equivalent).

Use molybdenum disulfide grease (comaining more than 3 % molybdenum disulfide, NLGI #2 or

~

equivalent).

Exampl e: Molykote

e

BR -2 plus manufactured by Dow Corning , U.S.A.

Mult i-purpose M-2 manufactured by Mitsubishi Oil , Japan

Use molybdenum disulfide paste (containing more than 40 % molybdenum disulfide, NlGI #2 or

equivalent).

...-'iiiPJI

Example: Molykote

e

BR -2 plus, manufactured by Dow Corning, U.S.A .

Honda Moly 60 (U.S.A. only)

Rocol ASP manufactured by Rocol Limited, U.K.

Rocol Paste manufactured by Sumico lubricant, Japan

~

Use silicone grease.

Cl.""

Apply a locking agent. Use a middle strength locking agent unless otherwise specified.

,",'Ilml

Apply sealant.

I

Use DOT 3 or DOT 4 brake fluid. Use the r ecommended brake fluid unless otherwise specified.

-

Use Fork or Suspension Fluid.

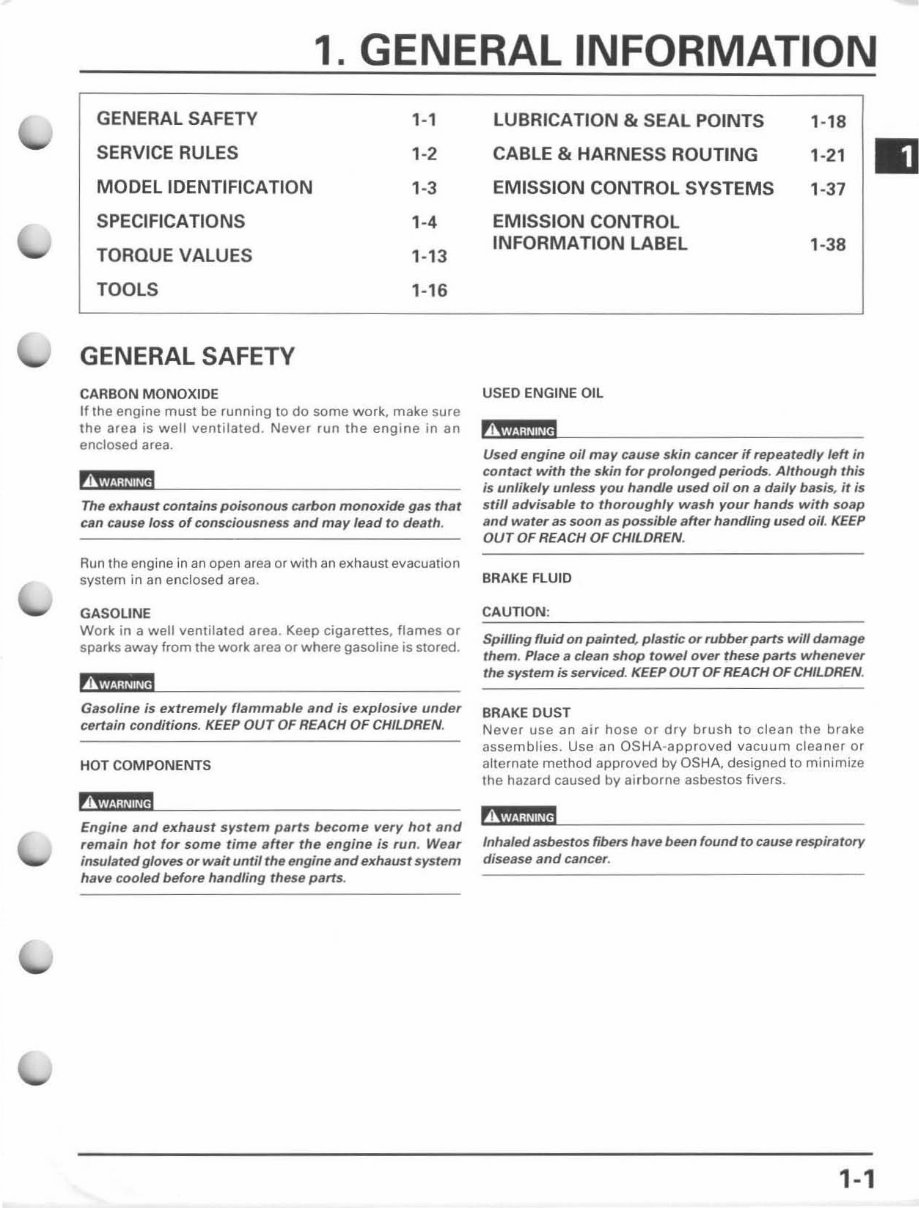

1. GENERAL INFORMATION

GENERAL SAFETY 1-1

SERVICE RULES 1-2

MODEL IDENTIFICATION 1-3

SPECIFICATIONS 1-4

TORQUE VALUES 1-13

TOOLS 1-16

GENERAL SAFETY

CARBON MONOXIDE

If the engine must be running to do some work, make sure

the area is well ventilated. Neve r run the engine in an

enclosed area.

The exhaust contains poi sonous carbon monoxide gas that

can cause loss of consciousness Bnd may lead to death.

Run the engine in an open area or with an exhaust evacuation

system in an enclosed area.

GASOUNE

Wo rk in a well ventil ated area. Keep cigarettes, flames or

sparks away from the work area or where gasoline is stored.

Gasoline is eKtremely flammable and is explosive under

certain conditions. KEEP OUT OF REACH OF CHILDREN.

HOT COMPONENTS

Engine and exhaust system parts become very hot and

remain hot for some tim e ah er the engine is run . Wear

insulated gloves or wait until the engine and eKhaust system

have cooled before handling these parts.

LUBRICATION & SEAL POINTS 1-18

CABLE & HARNESS ROUTING 1-21

EMISSION CONTROL SYSTEMS 1-37

EMISSION CONTROL

INFORMATION LABEL 1-38

USED ENGINE OIL

Used engine oil may cause skin cancer if repeatedly leh in

contact with the skin for prolonged periOds. Although this

is unlikely unless you handle used oil on a daily basis, it is

still advisable to thoroughly wash your hands with soap

and water as soon as possible aher handling used oil. KEEP

OUT OF REACH OF CHILDREN.

BRAKE FLUID

CAUTION:

Spilling fluid on painted, plastic or rubber parts will damage

them. Place a clean shop towel over these parts whenever

the system is serviced. KEEP OUT OF REACH OF CHILDREN.

BRAKE DUST

Never use an ai r hose or dry br u sh to clean the brake

assemblies. Use an OSHA - approved vacuum cleaner or

alternate met hod approved by OSHA, designed to minimize

the hazard caused by air borne asbestos fivers.

Inhaled asbestos fibers have been found to cause respiratory

disease and cancer.

1-1

E

GENERAL INFORMATION

BATTERY HYDROGEN GAS & ElECTAOL YTE

The battery gives off explosive gases; keep sparks, flames

IJnd cigarettes away. Provide adequate ventilation when

charging.

The battery contains sulfuric acid (electrolyte). Contact

with skin or eyes may cause sever. burns . We.'

protective clothing and II face shield.

-If electrolyte gets on your skin, flush with water.

- If el ectrolyte gets in your eyes, flush with water lor at

least 15 minutes lind calla physician immediately.

Electrolyte;s poisonous,

- If swallowed, drink large quantities of watsr or milk

and follow with milk of magnes's or vegetable oi/llnd

call B physician. KEEP OUT OF REACH OF CHILDREN.

SERVICE RULES

1. Use genuine HONDA or HONDA-recommended parts and lubricants or their equivalents. Parts that don 't meet HONDA's

design specifications may cause damage to the vehicle.

2. Use the speci al tools designed for this product to avoid damage and incorrect assembly.

3. Use only metric tools when servicing the vehicle. Metric bolts, nuts and screws are not interchangeable with English

fasteners.

4. Install new gaskets. O-rings, cotter pins, and lock plates when reassembling.

5. When tightening bolts or nuts, begin with the larger diameter or inner bolt first. Then tighten to the specified torque

diagonally in incremental steps unless a particular sequence is specified.

6. Clean parts in cleaning solvent upon disassembly. Lubricate any sliding surfaces before reassembly.

7. After reassembl y, check all parts for proper installation and operation.

B. Route all cable and harness routing as shown on pages 1- 21 through 1-29 Cable and Harness Routing.

1-2

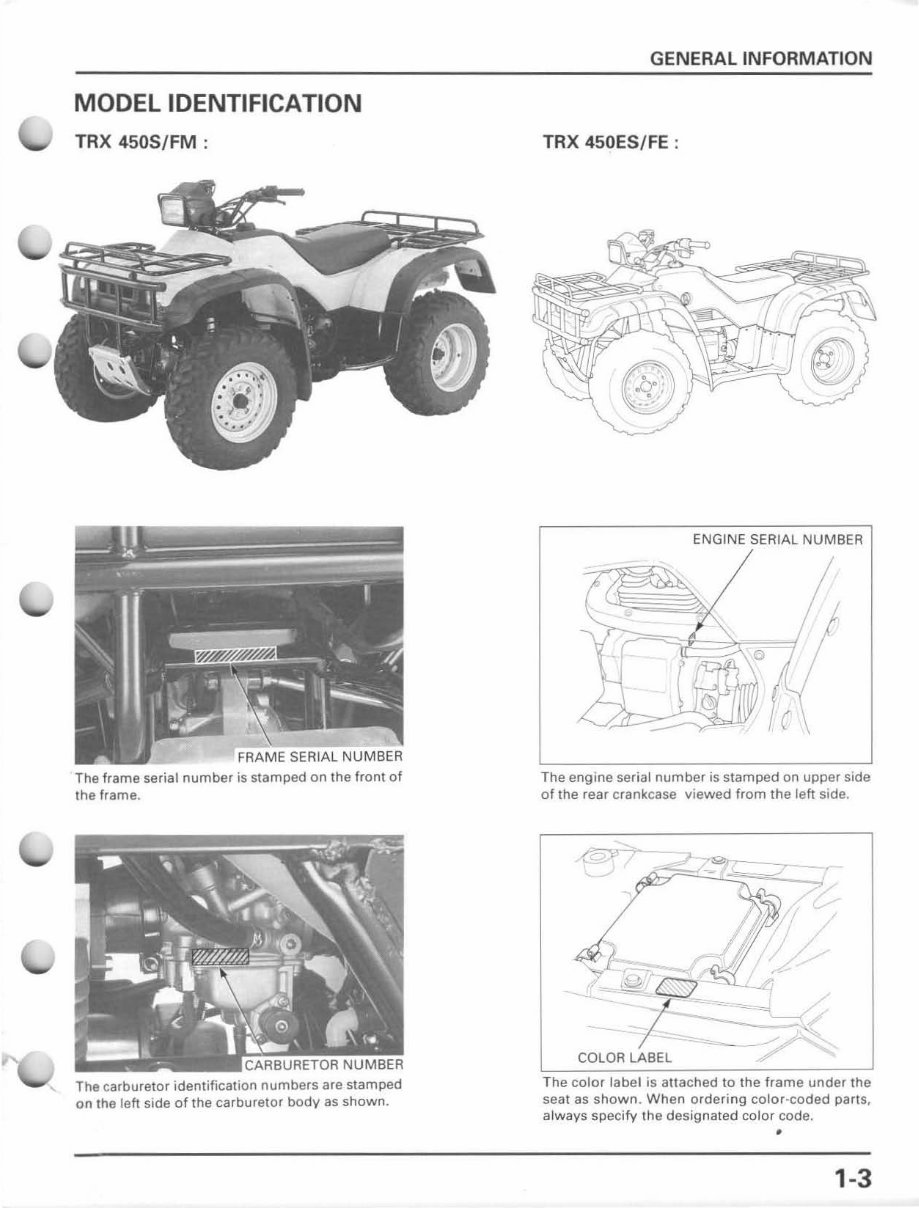

MODEL IDENTIFICATION

TRX 450S/FM :

The frame serial number is stamped on the front of

the frame.

The carburetor identification numbers are stamped

on the left side of the carburetor body as shown.

GENERAL INFORMATION

TRX 450ES/FE :

ENGINE SERIAL NUMBER

The engine seri al number is stamped on upper side

of the rear crankcase viewed from the left side.

COLOR LABEL

The color label is attached to the frame under the

seat as shown . When ordering color-coded paris ,

always specify the designated color code .

•

1-3

GENERAL INFORMATION

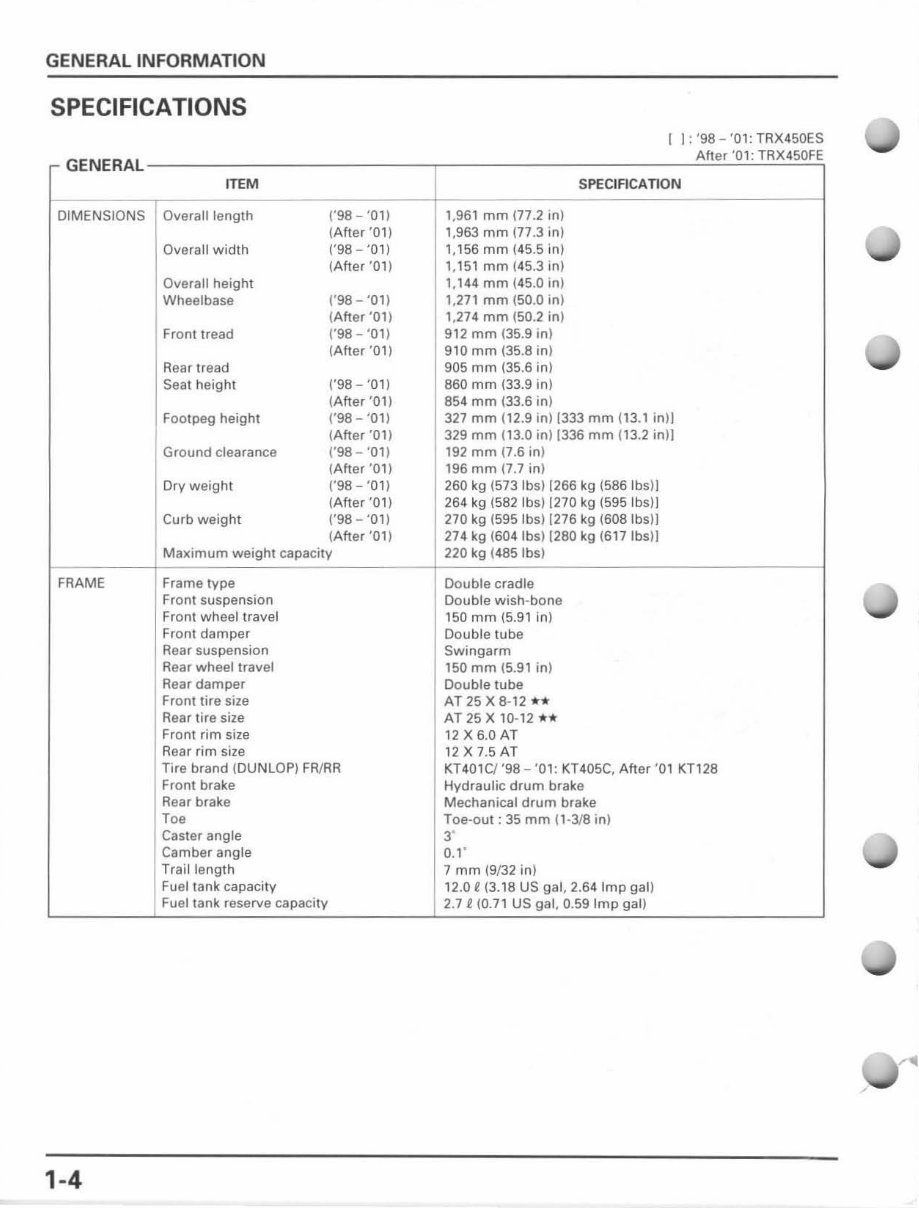

SPECIFICATIONS

- GENERAL

ITEM

DIMENSIONS Overall length ('98 - '01 I

(After '01)

Overall width ('98-'01'

(Ahe r '01)

Overall height

Wheelbase ('98 - '01)

(After '01)

Front tread ('98 - '01)

(After '01)

Rear tread

Seat height ('98-'01'

(Afte r '01)

Foolpeg height ('98 - '01)

(After '011

Ground clearance ('98-'011

(After '011

Dry weigh t ('98-'01'

(After '011

Curb weight ('98 - '01)

(Aher '01)

Maximum weight capacity

FRAME Frame type

Front suspension

Front wheel travel

Fron t damper

Rear suspension

Rear wheel travel

Rear damper

Front tire size

Rear tire size

Front rim size

Rear rim si ze

Tire brand (DUNLOP) FAIAR

Front brake

Rear brake

Toe

Caster angle

Camber angle

Trail length

Fuel tank capacity

Fuel tank reserve capacity

1-4

S PECIFICATION

1,961 mm (77.2 in)

1,963 mm (77.3 in)

1, 1 56 mm (45.5 i n)

1, 151 mm (45.3 in)

1,144 mm (45.0 in)

1,271 mm (50.0 in)

1,274 mm (50.2 in)

912 mm (35.9 in)

910 mm (35.8 in)

905 mm (35.6 in)

860 mm (33.9 in)

854 mm (33.6 in)

327 mm (12.9 in) 1333 mm (13.1 inll

329 mm (13.0 in) 1336 mm (13.2 inll

192 mm (7.6 in)

196 mm (7.7 in)

260 kg (573 Ibs) (266 kg (586 Ibsll

264 kg (582 Ibs) [270 kg (595 Ibsll

270 kg (595 Ibs) [276 kg (608Ibs))

274 kg (604 Ibs) (280 kg (617lbs))

220 kg (485 Jbs)

Double cradle

Double wish-bone

150 mm (5.91 in)

Doub le tube

Swingarm

150 mm (5.91 in)

Double tube

AT25XB-12 **

AT 25 X 10-12 **

12X6.0AT

12X7.5AT

I: '98 - '01: TAX450ES

After '01' TRX450FE

KT401CI '98 - '0 1: KT405C, After '01 KT128

Hydraulic drum brake

Mechanical drum brake

Toe-out: 35 mm (1-3/8 in)

3·

0.1 '

7 mm (9/32 in)

12.0 i (3. 18 US gal, 2.64 Imp gat)

2.7 f (0.71 US gat, 0.59 Imp gat)

GENERAL INFORMATION

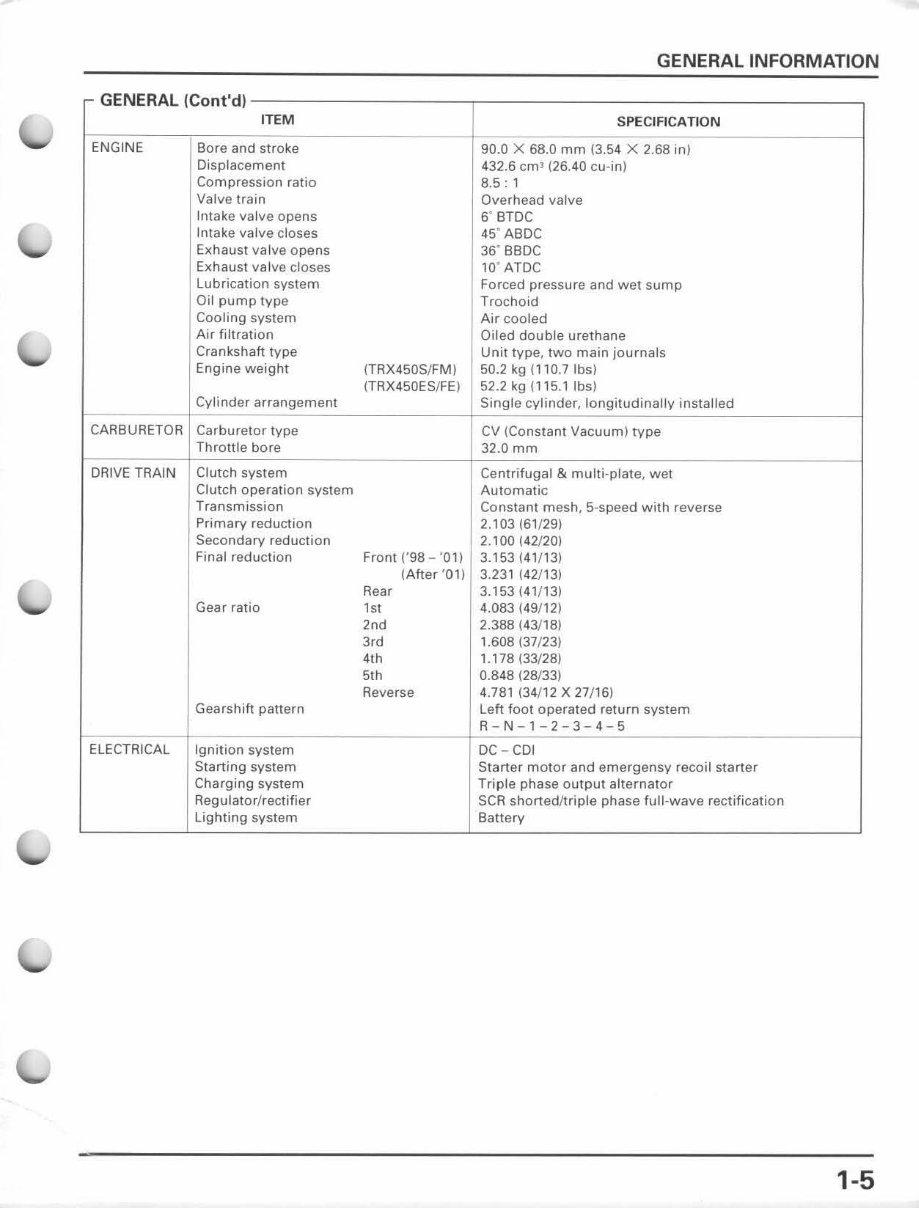

GENERAlICont'd)

ITEM

SPE CIFICATION

ENGINE Bore and stroke 90.0 X 68.0 mm /3.54 X 2.68 in)

Displacement 432.6 em

l

(26.40 cu-in)

Compression ratio 8.5 : 1

Valve train Overhead valve

Int ake valve o pens 6' BlOC

Intake valve closes 45' ABDC

Exhaust valve opens 36' BBDC

Exhaust valve closes 10' AlOe

Lubrication system Forced pressure and wet sump

Oil pump type Trochoid

Cooling system Air cooled

Air filtration Oited double urethane

Crankshaft type Unit type , two main journals

Engine weight (TRX450S/FM) 50.2 kg 01D.7 Ibsl

(TRX450ESjFEj 52.2 kg (115.1 Ibs)

Cylinder arrangement Single cylinder, longitudinally installed

CARBURETOR Carburetor type CV (Cons tant Vacuum) type

Throttle bore 32.0 mm

DRIVE TRAIN Clutch system Centrifugal & multi-plate, wet

Clutch operation system Automatic

Transmission Constant mesh, 5-speed with reverse

Primary reduction 2.103 (61/29)

Secondary reduction 2.100 (42/20)

Final reduction Front ('98 - '0 1) 3.153 (41/13)

(A fter '01) 3.231 (42/13)

Rear 3.153 (41/13)

Gear ratio

,,,

4.083 (49/ 12 )

2nd 2.388 (43/18)

3,d 1.608 (37/23)

4th 1.178 (33/28)

5th 0.848 (28/33)

Reverse 4.781 (34/12 X 27/16)

Gearshift pattern Left foot operated return system

R-N-1-2-3-4-5

ELECTRICAL Ignition system DC - CDI

Starting system Starter motor and emergensy recoil starter

Charging system Trip le phase output alternator

Reg ulato rlrecti fier SCR shorted/triple phase full-wave rectification

Lighting system Battery

1-5

GENERAL INFORMATION

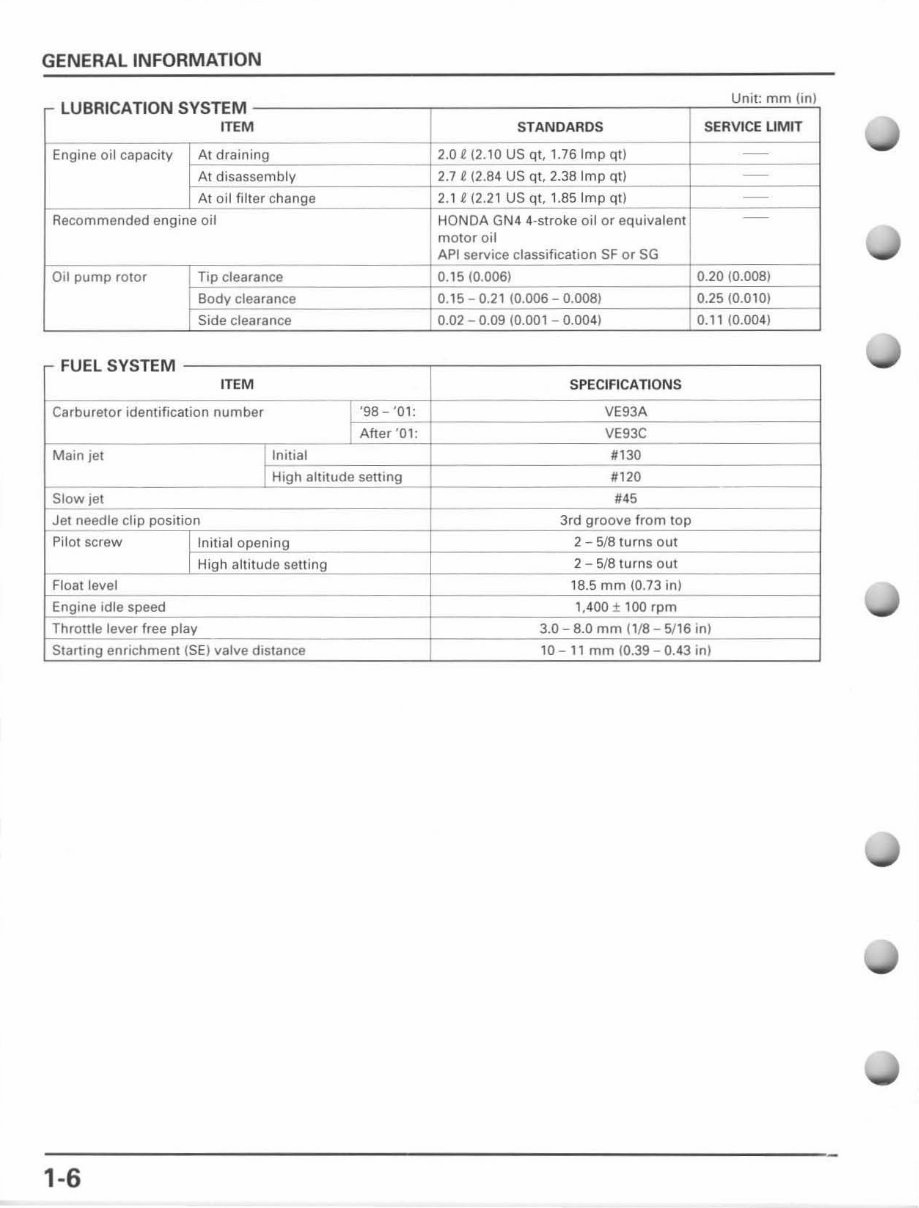

LUBRICATION SYSTEM

Unir mm (in)

ITEM STANDARDS SERVICE LIMIT

Engine oil capacity AI draining 2.0 e (2 . 10 US qt, 1.761mp qt)

At disassembly 2.7 t (2.84 US qt, 2.38 Imp qt)

At oil filter change 2.1 t (2.21 US qt, 1.851mp qtl -

Recommended engine oil HONDA GN4 4-stroke oil or equiva lent

motor oil

API service classification SF or SG

Oil pump rotor Tip clearance 0.15 (0.006) 0.20 (0.008)

Body clearance 0.15 - 0.21 (0.006 - 0.008) 0.25 (0.010)

Side clearance 0.02 - 0.09 to.OOl - 0.004) 0.11 (0.004)

, FUEL SYSTEM

ITEM SPECIFICATIONS

Carburetor identification number '98 - '01: VE93A

After '01: VE93C

Main jet Initial #130

High allilUde setting #120

Slow jet '45

.-

Jet needle clip position 3rd groove from l Op

Pi lol screw I Inilial opening 2 - 5/8 turns out

I High altitude setting 2 - 5/8 turns out

Float level 18.5 mm (0.73 in)

Engine idle speed 1,400 ± 100 rpm

Throttle lever free play 3.0 - 8.0 mm (1/8 - 5/16 in)

Starting enrichment (SE) valve distance 10 - 11 mm (0.39 - 0.43 in)

1-6

You're Reading a Preview

What's Included?

Fast Download Speeds

Online & Offline Access

Access PDF Contents & Bookmarks

Full Search Facility

Print one or all pages of your manual

$37.99

Viewed 13 Times Today

Loading...

Secure transaction

What's Included?

Fast Download Speeds

Online & Offline Access

Access PDF Contents & Bookmarks

Full Search Facility

Print one or all pages of your manual

$37.99

This manual contains maintenance and repair procedures for the Honda TRX450S/FM/Fourtrax Foreman S FM/TRX450 ES FE/Fourtrax Foreman ES FE 2001.

It is specifically written for both do-it-yourself enthusiasts and experienced mechanics. The manual provides step-by-step instructions based on the complete disassembly of the machine. It includes a high level of detail, along with hundreds of photos and illustrations to guide you through each service and repair procedure.

This manual contains:

- General information

- Frame/body panels/exhaust system

- Maintenance

- Lubrication system

- Fuel system

- Cooling system

- Engine removal/installation

- Cylinder head/cylinder/piston

- Clutch

- Gearshift linkage

- Alternator/starter clutch

- Crankshaft/balancer/transmission

- Front wheel/suspension/steering

- Rear wheel/suspension

- Brake system

- Front driving mechanism

- Rear driving mechanism

- Battery/charging system

- Ignition system

- Electric starter

- Lights/meters/switches

- Electric shift program (ESP)

- Selectable 4WD system (after 01)

- Wiring diagram

- Technical features

- Troubleshooting

- Index

Language: English

Printable: Yes

File Format: PDF

Compatibility: WINDOWS and MAC

Requirements: Adobe Reader