2012-2013 Mitsubishi Fuso Canter FE FG Service & Repair Manual

What's Included?

Fast Download Speeds

Online & Offline Access

Access PDF Contents & Bookmarks

Full Search Facility

Print one or all pages of your manual

SERVICE MANUAL

2012 Model

FOREWORD

This Service Manual contains maintenance and repair

methods for the Mitsubishi Fuso Truck FE. FG Series.

Read this manual carefully as an aid in providing cor-

rect, efficient maintenance. Please note that the infor-

mation and specifications contained within this manual

may change without notice. This is due to product

modifications and continued vehicle improvements

that are made throughout the model years. Should you

encounter any discrepancy in the information provid-

ed, please do not hesitate to contact your nearest Mi-

tsubishi Fuso Dealer or Mitsubishi Fuso Truck of

America, Inc.

MARCH 2011

GROUP INDEX

GENERAL .............................................. 00

MAINTENANCE SCHEDULE ................. 01

ENGINE................................................... 11

LUBRICATION ........................................ 12

FUEL AND ENGINE CONTROL ............. 13

COMMON RAIL SYSTEM....................... 13E

COOLING................................................ 14

INTAKE AND EXHAUST ........................ 15

EMISSION CONTROL ............................ 17

BlueTec® SYSTEM ................................ 17E

CLUTCH.................................................. 21

TRANSMISSION <DUONIC

TM

> ............. 22

DUONIC

TM

.............................................. 22E

TRANSFER ............................................. 24

PROPELLER SHAFT ............................. 25

FRONT AXLE

<FE> ..................................................... 26A

<FG> ..................................................... 26B

REAR AXLE............................................ 27

WHEEL AND TIRE ................................. 31

FRONT SUSPENSION ........................... 33

REAR SUSPENSION.............................. 34

BRAKE.................................................... 35

ANTI-LOCK BRAKE SYSTEM (ABS) .... 35E

PARKING BRAKE .................................. 36

STEERING .............................................. 37

BUMPER AND FRAME .......................... 41

CAB......................................................... 42

DOOR...................................................... 43

EXTERIOR .............................................. 51

INTERIOR ............................................... 52

ELECTRICAL .......................................... 54

HEATER, AIR-CONDITIONER

AND VENTILATION ................................ 55

FULL AUTOMATIC

AIR-CONDITIONER ................................ 55E

General

Group 00

Pub.No.00ELT0001-00

00-1

INDEX

EQUIPMENT TYPE CODES LIST ....................................................... 00-2

POWER TRAIN TABLE ....................................................................... 00-3

HOW TO READ THIS MANUAL.......................................................... 00-4

CHASSIS NUMBER, ENGINE NUMBER,

POWER TRAIN LABEL..................................................................... 00-12

VEHICLE IDENTIFICATION NUMBER ............................................. 00-13

PRECAUTIONS FOR MAINTENANCE OPERATION

1. Handling Precautions for Electric Circuits .................................. 00-19

2. Service Precautions for Alternators ............................................ 00-22

3. Intermittent Faults ....................................................................... 00-24

4. Precautions for Arc Welding ....................................................... 00-25

5. Cautions When Handling DEF ..................................................... 00-26

6. Precautions When Repainting ..................................................... 00-26

7. Precautions When Handling a Vehicle with DUONIC

TM

System ... 00-26

8. Precautions on Cleaning When Servicing the Engine and

Transmission .............................................................................. 00-27

JACKING UP THE VEHICLE ............................................................ 00-30

DIAGNOSIS CODES

1. Diagnosis Codes ......................................................................... 00-34

2. Reading and Erasing the Diagnosis Code ................................... 00-40

TABLE OF STANDARD TIGHTENING TORQUES........................... 00-44

00-2

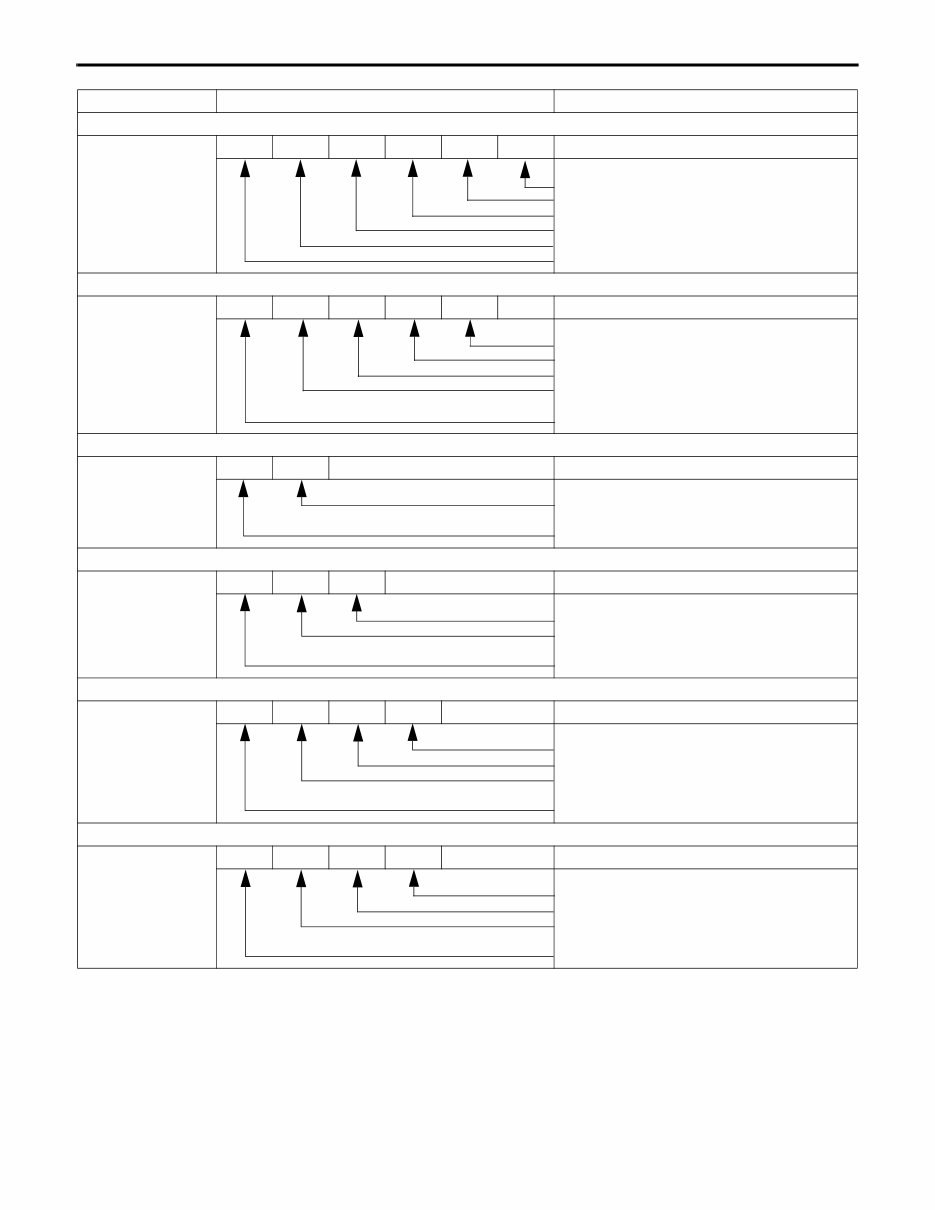

Component Name plate marking Code description

Engine

4P10T5 4 P 1 0 T 5

Power version number

Turbocharged

Order of development within same series

Order of development among different series

Diesel engine

No. of cylinders (4)

Transmission

M038S6W M 038 S 6 W

Variation (W: With directly-mounted transfer)

Forward speeds

Type of mesh (S: Synchromesh)

Load carrying capacity of truck class (tonnage)

on which the clutch is primarily used

Initial letter of the transmission

Propeller shaft

P3 P 3

Load carrying capacity of truck class (tonnage)

on which the clutch is primarily used

Initial letter of the propeller shaft

Front axle

F200T F 200 T

Vehicle type (T: Truck)

Load carrying capacity of truck class (tonnage)

on which the clutch is primarily used

Initial letter of the front axle

Rear axle

R033T R 03 3 T

Vehicle type (T: Truck)

Order of development within same series

Load carrying capacity of truck class (tonnage)

on which the clutch is primarily used

Initial letter of the rear axle

Reduction and differential

D033H D 03 3 H

Tooth profile (H: Hypoid gear)

Order of development within same series

Load carrying capacity of truck class (tonnage)

on which the clutch is primarily used

Initial letter of the reduction & differential

EQUIPMENT TYPE CODES LIST

00

00-3

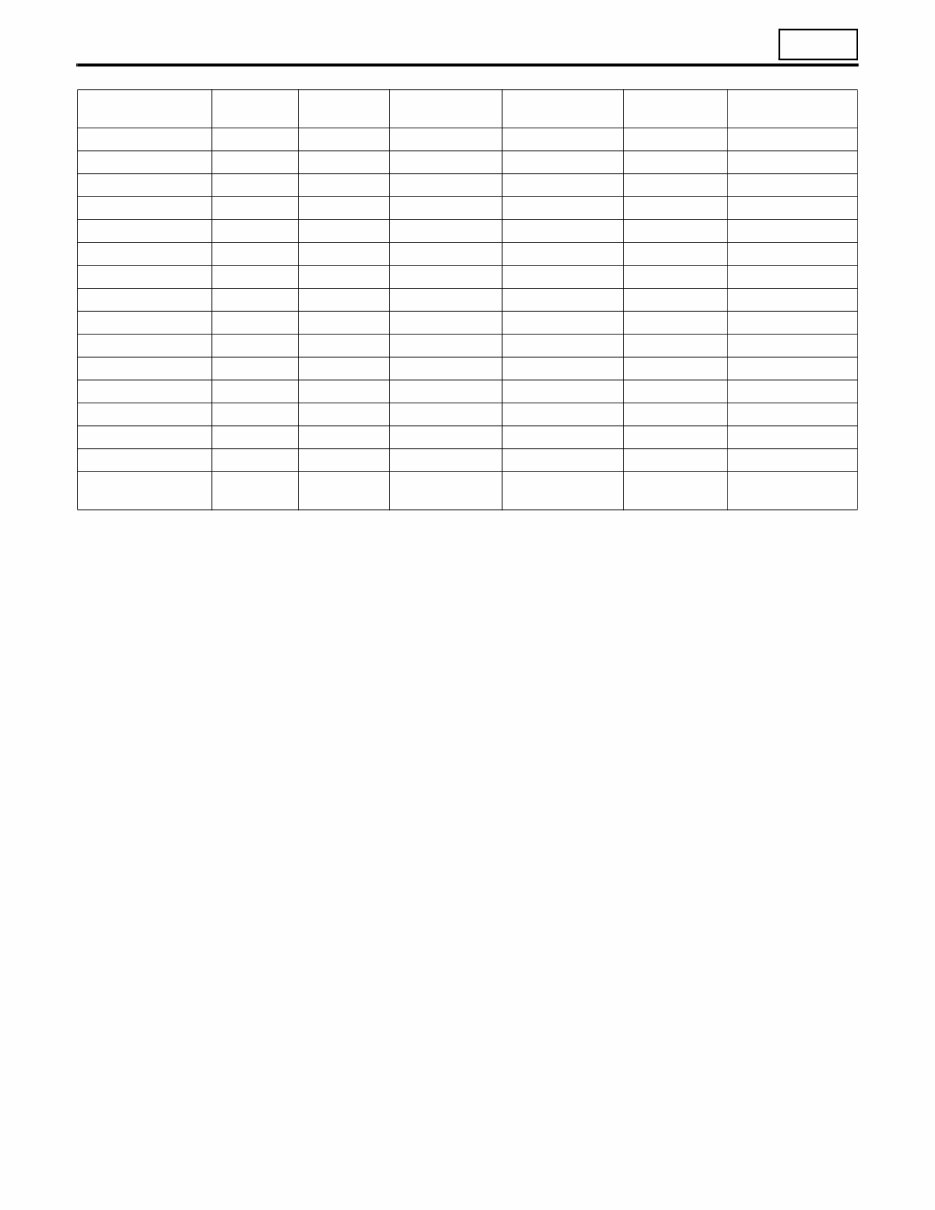

Vehicle model Engine Clutch Transmission Propeller shaft Rear axle

Reduction &

differential

FEC52CL3SUHD 4P10-T5 – M038S6 P3 R033T D033H

FEC52EL3SUHD 4P10-T5 – M038S6 P3 R033T D033H

FEC52GL3SUHD 4P10-T5 – M038S6 P3 R033T D033H

FEC72CL3SUHD 4P10-T5 – M038S6 P3 R035T D035H

FEC72EL3SUHD 4P10-T5 – M038S6 P3 R035T D035H

FEC72GL3SUHD 4P10-T5 – M038S6 P3 R035T D035H

FEC72HL3SUHD 4P10-T5 – M038S6 P3 R035T D035H

FEC72KL3SUHD 4P10-T5 – M038S6 P3 R035T D035H

FEC72HL3WUHD 4P10-T5 – M038S6 P3 R035T D035H

FEC72KL3WUHD 4P10-T5 – M038S6 P3 R035T D035H

FEC92CL3SUHD 4P10-T5 – M038S6 P3 R035T D035H

FEC92EL3SUHD 4P10-T5 – M038S6 P3 R035T D035H

FEC92GL3SUHD 4P10-T5 – M038S6 P3 R035T D035H

FEC92HL3SUHD 4P10-T5 – M038S6 P3 R035T D035H

FEC92KL3SUHD 4P10-T5 – M038S6 P3 R035T D035H

FGB72EL3SUHD 4P10-T5 – M038S6W

Front: P2

Rear: P3

R035T

Front: D1H

Rear: D035H

POWER TRAIN TABLE

00-4

This manual consists of the following parts:

• Specifications

• Structure and Operation

• Troubleshooting

• Circuits

• Electrical Equipment Installation Positions

• Inspection of Electrical Equipment

• On-vehicle Inspection and Adjustment

• Connector configuration chart

On-vehicle Inspection and Adjustment

• Procedures for inspection and adjustment of individual parts and assemblies as mounted on the vehicle are de-

scribed including specific items to check and adjust. Specified or otherwise, inspection should be performed for

looseness, play, backlash, crack, damage, etc.

Service procedures

• Procedures for servicing components and parts off the vehicle are described centering on key points in their re-

moval, installation, disassembly, reassembly, inspection, etc.

Inspection

• Check items subject to “acceptable/unacceptable” judgement on the basis of service standards are all given.

• Some routine visual checks and cleaning of some reused parts are not described but must always be included in

actual service work.

Caution

• This service manual contains important cautionary instructions and supplementary information under the following

four headings which identify the nature of the instructions and information:

Terms and Units

• Front and rear

The forward running direction of the vehicle is referred to as the front and the reverse running direction is referred

to as the rear.

• Left and right

Left hand side and right hand side, when facing the forward running direction of the vehicle, are respectively left

and right.

Standard value

• Standard value dimensions in designs indicating: the design dimensions of individual parts, the standard clear-

ance between two parts when assembled, and the standard value for an assembly part, as the case may be.

DANGER

Precautions that should be taken in handling potentially dangerous substances

such as battery fluid and coolant additives.

WARNING

Precautionary instructions, which, if not observed, could result in serious injury or

death.

CAUTION

Precautionary instructions, which, if not observed, could result in damage to or de-

struction of equipment or parts.

NOTE

Suggestions or supplementary information for more efficient use of equipment or

better understanding.

HOW TO READ THIS MANUAL

00

00-5

Limit

• When the value of a part exceeds this, it is no longer serviceable in respect of performance and strength and must

be replaced or repaired.

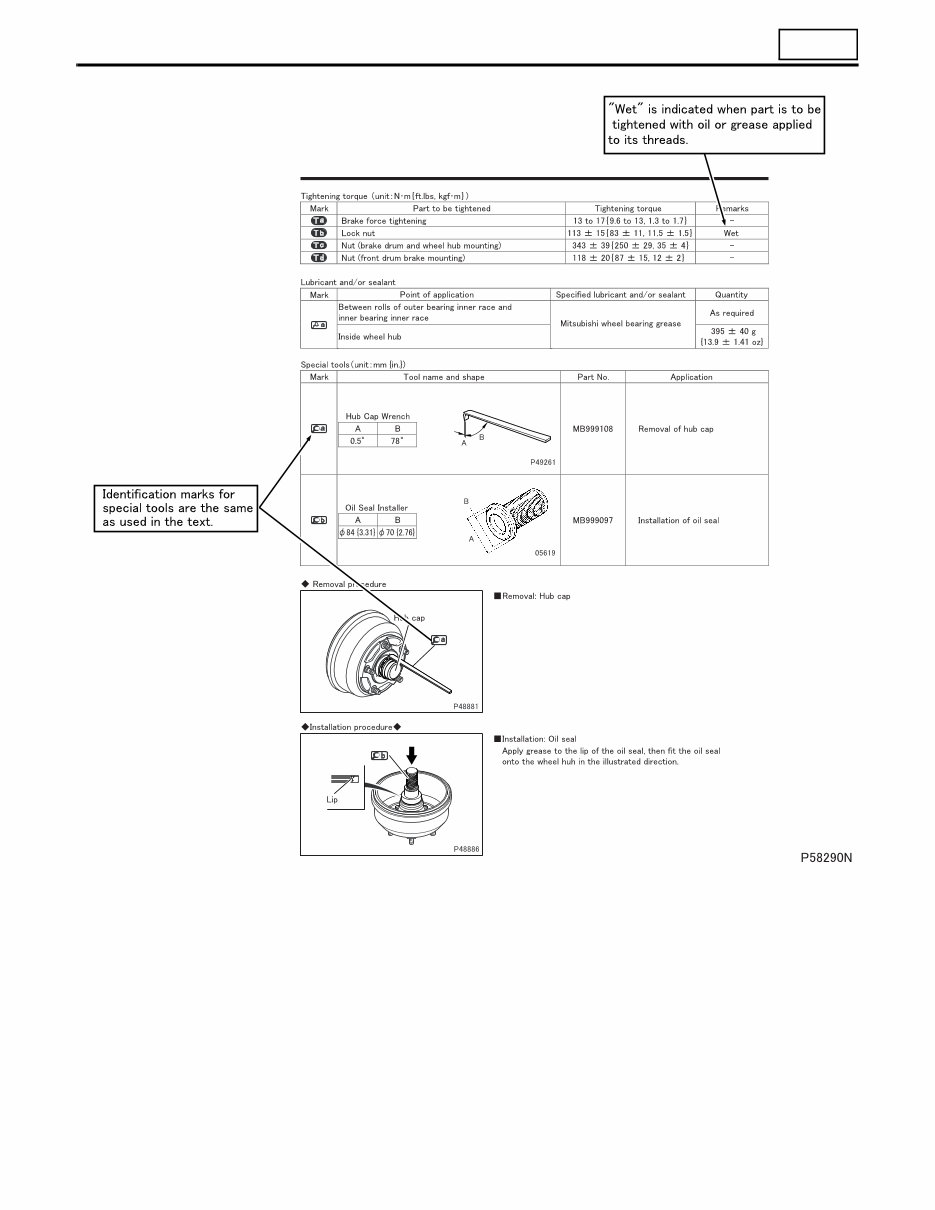

Tightening torque

• Values are directly specified for out-of-standard tightening torques for bolts and nuts.

• Where there is no specified figure for tightening torque, follow the table covering standard tightening torques.

(Values for standard tightening torques are based on thread size and material.)

• When the item is to be tightened in a wet state, “wet” is indicated. Where there is no indication, read it as dry.

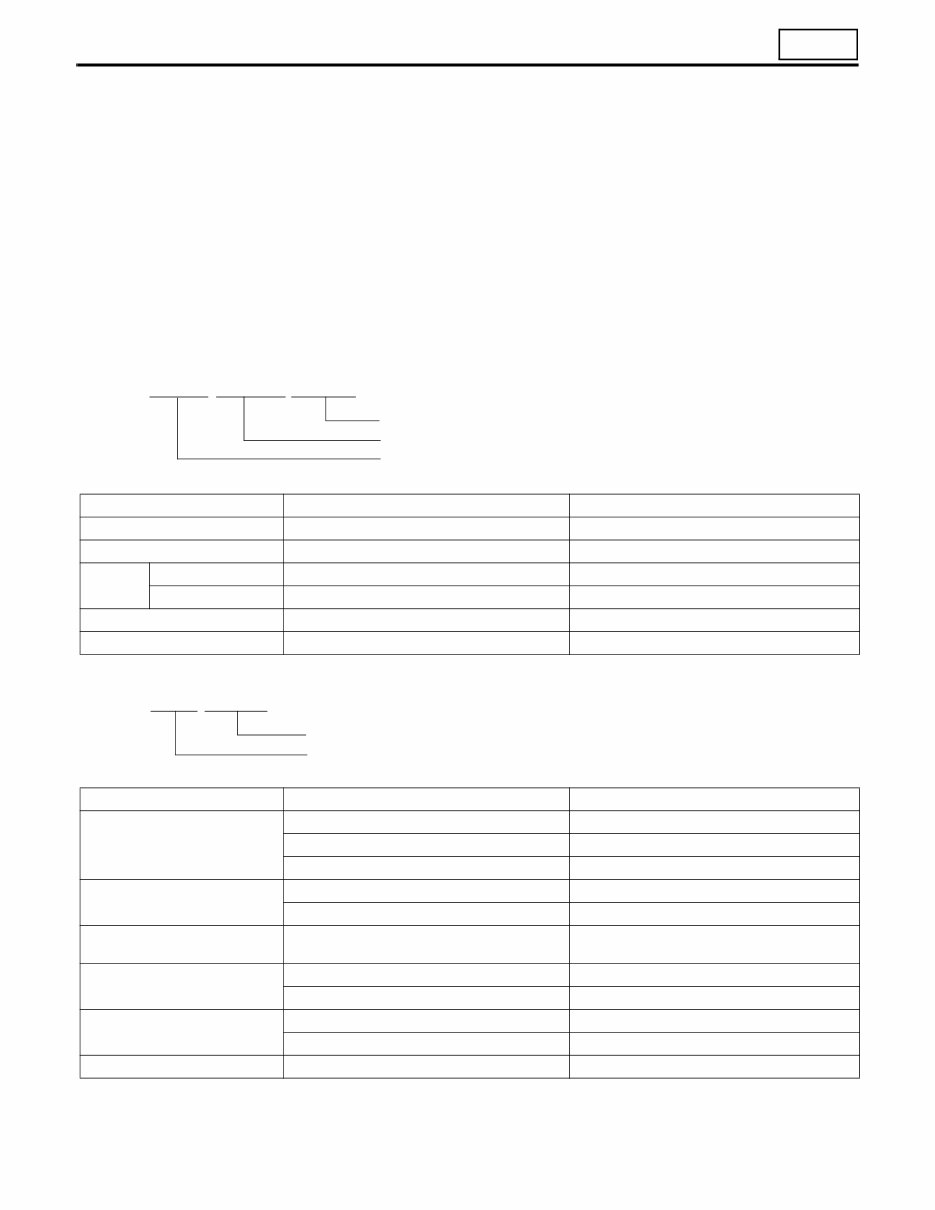

Units

• Tightening torques and other parameters are given in SI* units with imperial unit and metric units added in brack-

ets { }.

*SI: Le Système International d’Unités

Unit SI unit {imperial unit, metric unit} Conversion factor

Force N {lbs, kgf} 9.80665 N {2.2046 lbs, 1 kgf}

Moment of force N·m {ft.lbs, kgf·m} 9.80665 N·m {7.2329 ft.lbs, 1 kgf·m}

Pressure

Positive pressure kPa {psi, kgf/cm

2

} 98.0665 kPa {14.22 psi, 1 kgf/cm

2

}

Vacuum pressure kPa {in.Hg, mmHg} 0.133322 kPa {0.03937 in.Hg, 1 mmHg}

Volume J {BTU, kcal} 4186.05 J {3.96825BTU, 1 kcal}

Heat quantity W {BTU/h, kcal/h} 1.16279W {3.96825BTU/h, 1 kcal/h}

Unit SI unit {imperial unit} Conversion factor

Length

mm {in.} 1 mm {0.03937 in.}

m {ft.} 1 m {3.2808 ft.}

km {mile} 1 km {0.6214 mile}

Mass

kg {lb} 1 kg {2.2046 lb}

g {oz} 1 g {0.035274 oz}

Temperature

(in degree Celsius)

°C {°F} 1°C {(1°C × 1.8 + 32)°F}

Velocity

km/h {mph} 1 km/h {0.6214 mph}

m/s {ft/s} 1 m/s {3.281 ft/s}

Volume

L {qts}, L {gal} 1 L {1.05336 qts}, 1 L {0.2642 gal}

cm

3

{cu.in.} 1 cm

3

{0.061023 cu.in.}

Area m

2

{in

2

}, m

2

{ft

2

} 1 m

2

{1.550 × 10

3

in

2

}, 1 m

2

{1.076 × 10 ft

2

}

Example: 390 N·m {290 ft.lbs, 40 kgf·m}

Metric unit

SI unit

Imperial unit

Example: 30 mm {1.18 in.}

SI unit

Imperial unit

00-6

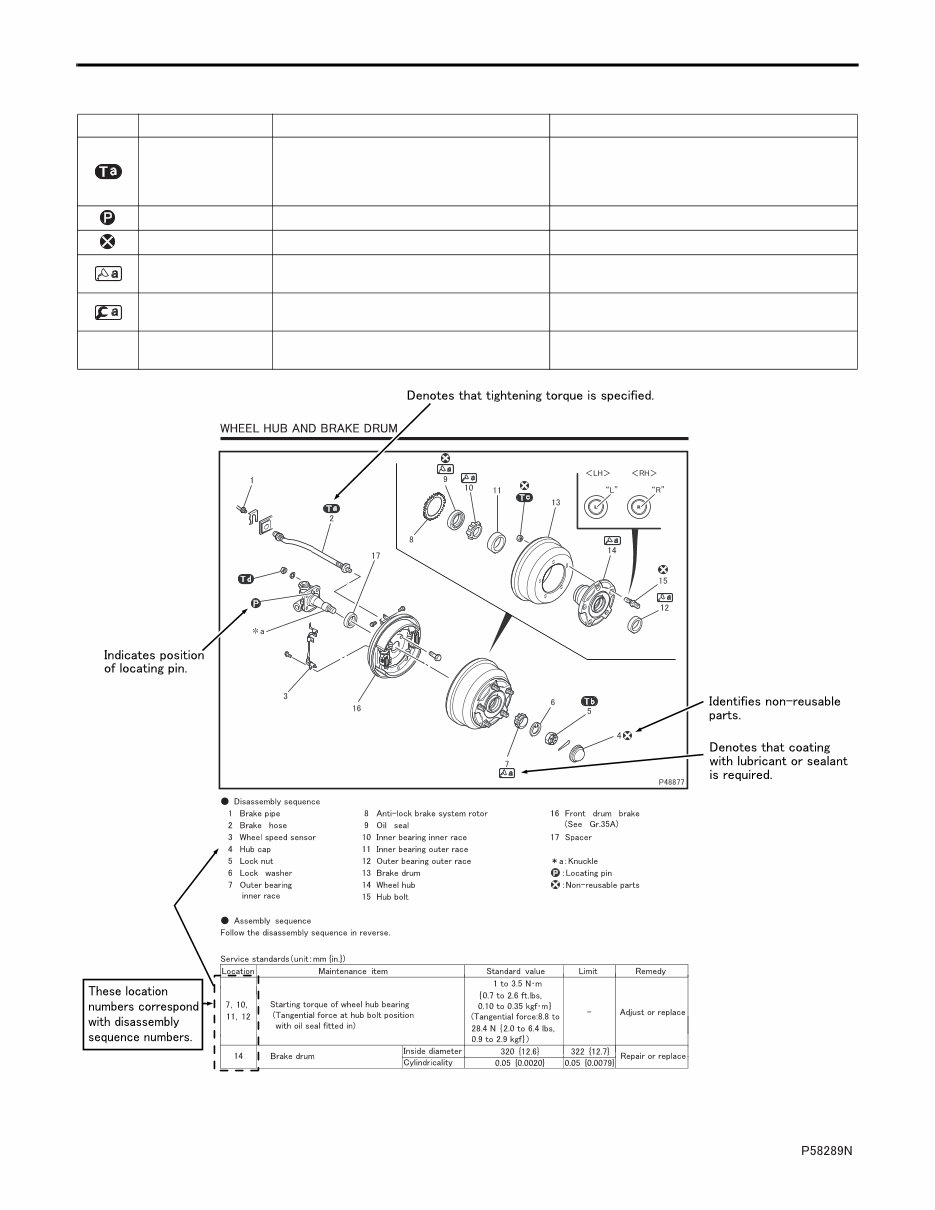

Illustrated Parts Breakdown and Service Procedures

Symbol Denotation Application Remarks

Tightening torque

Parts not tightened to standard torques

(standard torques specified where neces-

sary for servicing)

Specified values shown in table

See Table of Standard Tightening Torques for

parts for which no tightening torques are speci-

fied.

Locating pin Parts to be positioned for installation

Non-reusable parts Parts not to be reused

Lubricant and/or

sealant

Parts to be coated with lubricant or sealant

for assembly or installation

Necessary lubricant and/or sealant, quantity re-

quired, etc. are specified in table.

Special tool

Parts for which special tools are required for

service operation

Tool name/shape and part number are shown in

table.

*a Associated part

Parts associated with those removed/disas-

sembled for servicing

HOW TO READ THIS MANUAL

00

00-7

You're Reading a Preview

What's Included?

Fast Download Speeds

Online & Offline Access

Access PDF Contents & Bookmarks

Full Search Facility

Print one or all pages of your manual

$52.99

Viewed 76 Times Today

Loading...

Secure transaction

What's Included?

Fast Download Speeds

Online & Offline Access

Access PDF Contents & Bookmarks

Full Search Facility

Print one or all pages of your manual

$52.99

The Mitsubishi-Fuso Canter 2012-2013 factory workshop/repair manual is a valuable resource for both professional mechanics and DIY enthusiasts. It is a searchable manual that covers a wide range of technical information essential for car repair.

- GENERAL

- MAINTENANCE SCHEDULE - 01

- ENGINE - 4P10T5

- LUBRICATION

- FUEL AND ENGINE CONTROL - 13

- COMMON RAIL SYSTEM - 13E

- COOLING

- INTAKE AND EXHAUST - 15

- EMISSION CONTROL - 17

- BlueTec® SYSTEM - 17E

- CLUTCH

- TRANSMISSION - M038S6W

- DUONICTM

- TRANSFER

- PROPELLER SHAFT - 25

- FRONT AXLE 2WD and 4WD

- REAR AXLE

- WHEEL AND TIRE - 31

- FRONT SUSPENSION - 33

- REAR SUSPENSION - 34

- BRAKE

- ANTI-LOCK BRAKE SYSTEM (ABS) - 35E

- PARKING BRAKE - 36

- STEERING

- BUMPER AND FRAME - 41

- CAB

- DOOR

- EXTERIOR

- INTERIOR

- ELECTRICAL

- HEATER, AIR-CONDITIONER AND VENTILATION

- FULL AUTOMATIC AIR-CONDITIONER

These manuals provide comprehensive information on the repair and maintenance of the Mitsubishi-Fuso Canter, making them an indispensable tool for anyone working on these vehicles.