Freightliner Business Class M2 Trucks OEM Maintenance Manual

What's Included?

Fast Download Speeds

Online & Offline Access

Access PDF Contents & Bookmarks

Full Search Facility

Print one or all pages of your manual

Maintenance Manual

STI-455-6

A24-01238-000

®

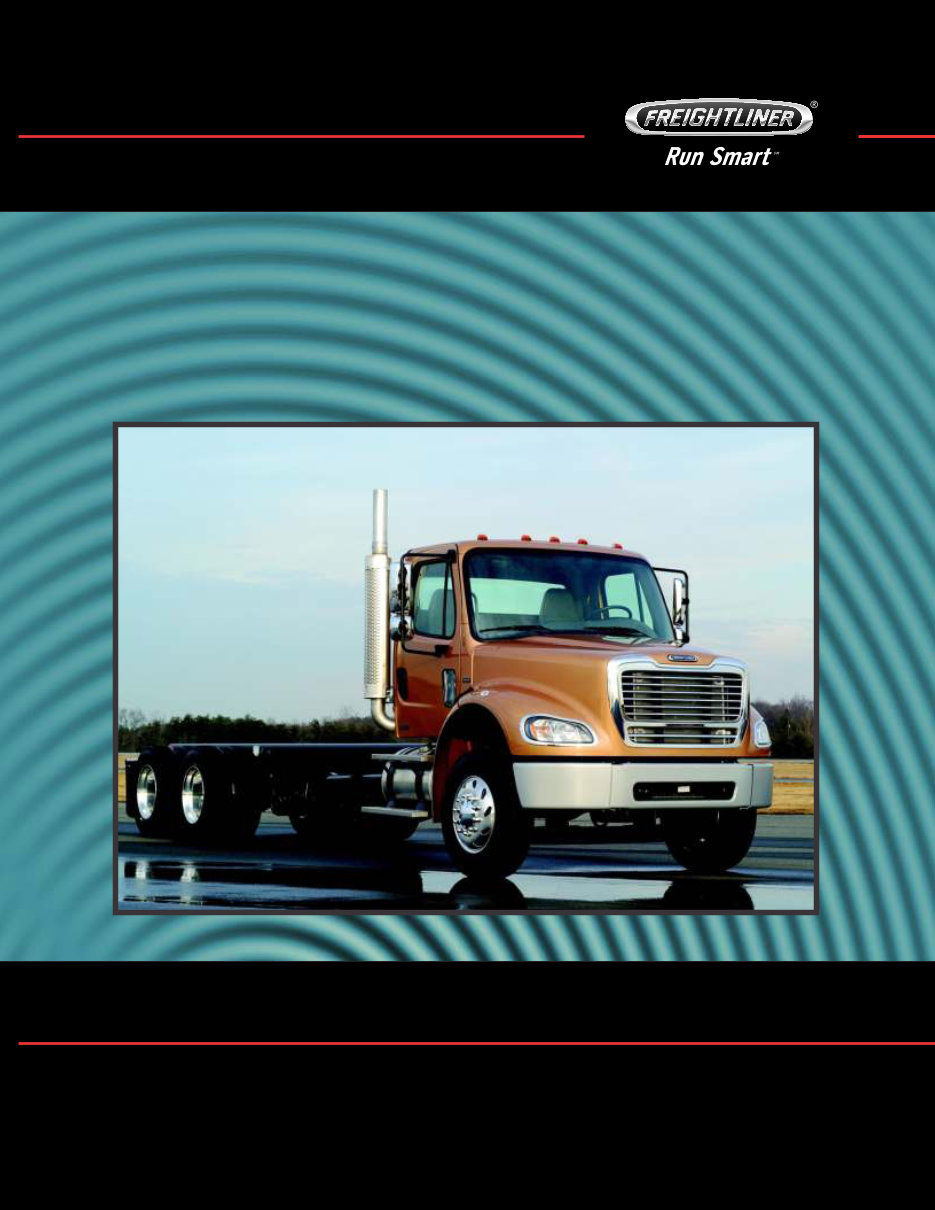

BUSINESS CLASS M2

BUSINESS CLASS M2 MAINTENANCE MANUAL

Models: M2 100

M2 106

M2 106V

M2 112

M2 112V

STI-455-6 (3/16)

Published by

Daimler Trucks North America LLC

4747 N. Channel Ave.

Portland, OR 97217

Printed in U.S.A.

Foreword

Performing scheduled maintenance operations is important in obtaining safe, reliable operation of your

vehicle. A proper maintenance program will also help to minimize downtime and safeguard warranties.

IMPORTANT: The maintenance operations in this manual are not all-inclusive. Also refer to other

component and body manufacturers’ instructions for specific inspection and maintenance instruc-

tions.

Perform the operations in this maintenance manual at scheduled intervals. Perform the pretrip and post-trip

inspections, and daily/weekly/monthly maintenance, as outlined in the vehicle driver’s manual. Major

components, such as engines, transmissions, and rear axles, are covered in their own maintenance and

operation manuals, that are provided with the vehicle. Perform any maintenance operations listed at the

intervals scheduled in those manuals. Your Freightliner Dealership has the qualified technicians and

equipment to perform this maintenance for you. They can also set up a scheduled maintenance program

tailored specifically to your needs. Optionally, they can assist you in learning how to perform these

maintenance procedures.

IMPORTANT: Descriptions and specifications in this manual were in effect at the time of printing.

Freightliner Trucks reserves the right to discontinue models and to change specifications or design

at any time without notice and without incurring obligation. Descriptions and specifications contained

in this publication provide no warranty, expressed or implied, and are subject to revision and editions

without notice.

Refer to www.Daimler-TrucksNorthAmerica.com and www.FreightlinerTrucks.com for more information,

or contact Daimler Trucks North America LLC at the address below.

Environmental Concerns and Recommendations

Whenever you see instructions in this manual to discard materials, you should attempt to reclaim and recycle

them. To preserve our environment, follow appropriate environmental rules and regulations when disposing of

materials.

NOTICE: Parts Replacement Considerations

Do not replace suspension, axle, or steering parts (such as springs, wheels, hubs, and steering gears) with

used parts. Used parts may have been subjected to collisions or improper use and have undetected structural

damage.

© 2001–2016 Daimler Trucks North America LLC

All rights reserved. No part of this publication, in whole or in part, may be translated, reproduced, stored in a

retrieval system, or transmitted in any form by any means, electronic, mechanical, photocopying, recording, or

otherwise, without the prior written permission of Daimler Trucks North America LLC. Daimler Trucks North

America LLC is a Daimler company.

Daimler Trucks North America LLC

Service Systems and Documentation (CVI-SSD)

P.O. Box 3849

Portland, Oregon 97208-3849

Daimler Trucks North America LLC distributes the following major service publications in paper and electronic

(via ServicePro®) formats.

Workshop/Service

Manual

Workshop/service manuals contain service and repair information for all vehicle

systems and components, except for major components such as engines, trans-

missions, and rear axles. Each workshop/service manual section is divided into

subjects that can include general information, principles of operation, removal,

disassembly, assembly, installation, and specifications.

Maintenance Manual Maintenance manuals contain routine maintenance procedures and intervals for

vehicle components and systems. They have information such as lubrication

procedures and tables, fluid replacement procedures, fluid capacities, specifica-

tions, and procedures for adjustments and for checking the tightness of fasten-

ers. Maintenance manuals do not contain detailed repair or service information.

Driver’s/Operator’s

Manual

Driver’s/operator’s manuals contain information needed to enhance the driver’s

understanding of how to operate and care for the vehicle and its components.

Each manual contains a chapter that covers pretrip and post-trip inspections,

and daily, weekly, and monthly maintenance of vehicle components.

Driver’s/operator’s manuals do not contain detailed repair or service information.

Service Bulletins Service bulletins provide the latest service tips, field repairs, product improve-

ments, and related information. Some service bulletins are updates to informa-

tion in the workshop/service manual. These bulletins take precedence over

workshop/service manual information, until the latter is updated; at that time, the

bulletin is usually canceled. The service bulletins manual is available only to

dealers. When doing service work on a vehicle system or part, check for a valid

service bulletin for the latest information on the subject.

IMPORTANT: Before using a particular service bulletin, check the current

service bulletin validity list to be sure the bulletin is valid.

Parts Technical Bulletins Parts technical bulletins provide information on parts. These bulletins contain

lists of parts and BOMs needed to do replacement and upgrade procedures.

Web-based repair, service, and parts documentation can be accessed using the following applications on the

AccessFreightliner.com website.

ServicePro ServicePro® provides Web-based access to the most up-to-date versions of the

publications listed above. In addition, the Service Solutions feature provides di-

agnostic assistance with Symptoms Search, by connecting to a large knowledge

base gathered from technicians and service personnel. Search results for both

documents and service solutions can be narrowed by initially entering vehicle

identification data.

PartsPro PartsPro® is an electronic parts catalog system, showing the specified vehicle’s

build record.

EZWiring EZWiring

™

makes Freightliner, Sterling, Western Star, Thomas Built Buses, and

Freightliner Custom Chassis Corporation products’ wiring drawings and floating

pin lists available online for viewing and printing. EZWiring can also be ac-

cessed from within PartsPro.

Introduction

Descriptions of Service Publications

Business Class M2 Maintenance Manual, May 2011 I–1

Warranty-related service information available on the AccessFreightliner.com website includes the following

documentation.

Recall Campaigns Recall campaigns cover situations that involve service work or replacement of

parts in connection with a recall notice. These campaigns pertain to matters of

vehicle safety. All recall campaigns are distributed to dealers; customers receive

notices that apply to their vehicles.

Field Service Campaigns Field service campaigns are concerned with non-safety-related service work or

replacement of parts. All field service campaigns are distributed to dealers; cus-

tomers receive notices that apply to their vehicles.

Introduction

Descriptions of Service Publications

I–2 Business Class M2 Maintenance Manual, May 2011

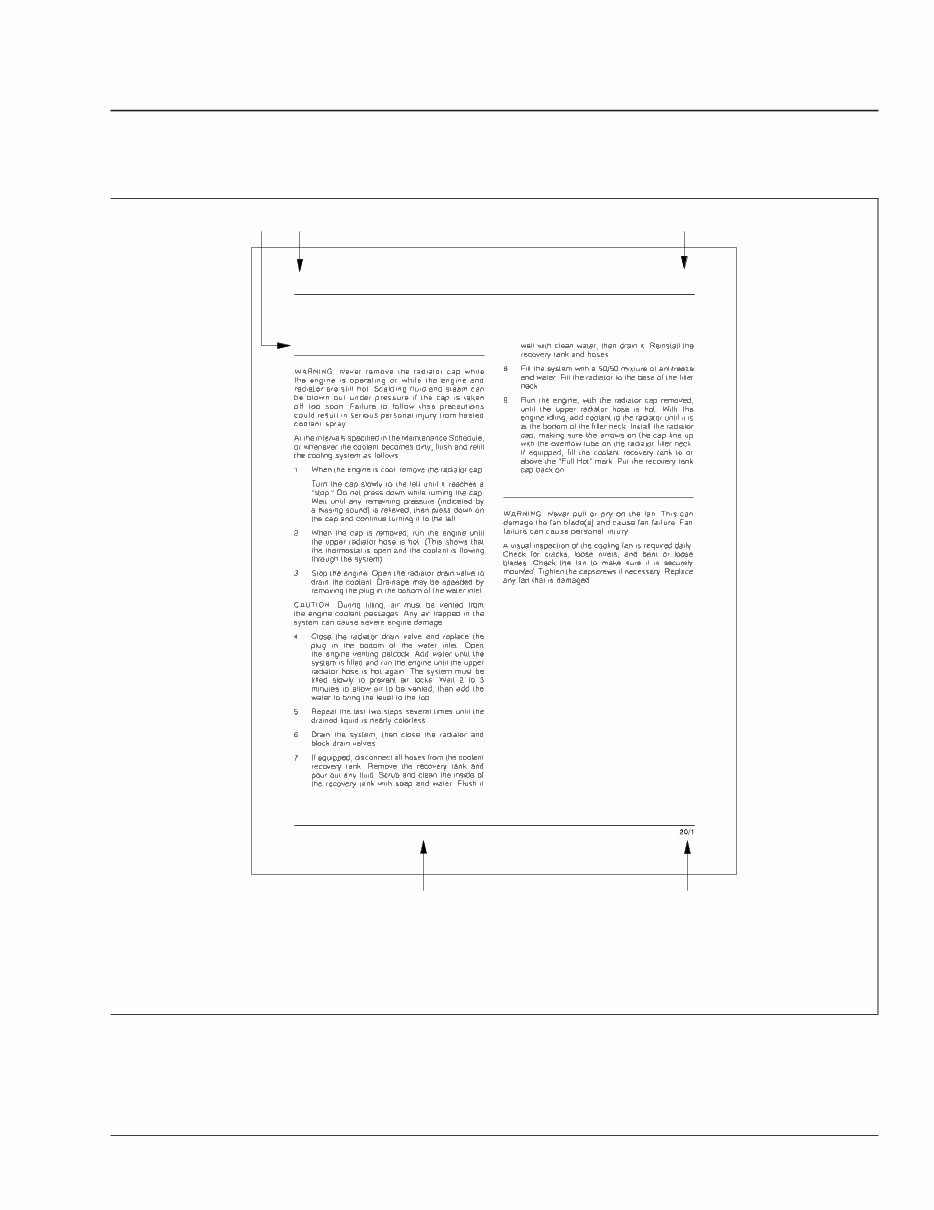

For an example of a Business Class M2 Maintenance Manual page, see Fig. 1.

f020125

A B C

D E

Cooling

12/06/2001

Business Class M2 Maintenance Manual, December 2001

20-01 Coolant Replacement

20-02 Cooling Fan Inspection

20

A. Maintenance Operation Number consists of the Group Number followed by the Sequence Number

B. Group Title

C. Group Number

D. Release Date

E. Group Number/Page Number

Fig. 1, Example of a Business Class M2 Maintenance Manual Page

Introduction

Page Description

Business Class M2 Maintenance Manual, May 2011 I–3

Group No. Group Title

00 ...................... General Information

01 ................................ Engine

09 .............................. Air Intake

13 ......................... Air Compressor

15 ................... Alternators and Starters

20 ................... Engine Cooling/Radiator

25 ................................ Clutch

26 ........................... Transmission

31 ............. Frame and Frame Components

32 ............................ Suspension

33 ............................. Front Axle

35 ............................. Rear Axle

40 ........................ Wheels and Tires

41 .............................. Driveline

42 ................................ Brakes

46 ............................... Steering

47 ................................. Fuel

49 ............................... Exhaust

60 .................................. Cab

72 ................................ Doors

83 ................. Heater and Air Conditioner

88 .............. Hood, Grille, and Cab Fenders

Introduction

Maintenance Manual Contents

I–4 Business Class M2 Maintenance Manual, May 2011

Title of Maintenance Operation (MOP) MOP Number

Determining Scheduled Maintenance Intervals............................................. 00–01

Initial Maintenance (IM) Operations ..................................................... 00–06

M1 Lubrication and Fluid Level Check................................................... 00–12

M1 Maintenance Operations .......................................................... 00–07

M2 Lubrication and Fluid Level Check................................................... 00–13

M2 Maintenance Operations .......................................................... 00–08

M3 Maintenance Operations .......................................................... 00–09

M4 Maintenance Operations .......................................................... 00–10

M5 Maintenance Operations .......................................................... 00–11

Maintenance Intervals for Schedule I.................................................... 00–03

Maintenance Intervals for Schedules II and III ............................................. 00–04

Maintenance Schedules ............................................................. 00–02

Noise Emission Controls............................................................. 00–15

Overview of Maintenance Operations ................................................... 00–05

Verification of Inspections Log......................................................... 00–16

General Information 00

Index, Alphabetical

Business Class M2 Maintenance Manual, March 2016

Determining Scheduled

Maintenance Intervals

Performing regular maintenance will help ensure that

your vehicle delivers safe, reliable service and opti-

mum performance. A proper maintenance program

will also help to minimize downtime and safeguard

warranties.

To determine the correct maintenance intervals for

your vehicle, you must first determine the type of ser-

vice or conditions the vehicle will be operating in.

Most vehicles operate in conditions that fall within

one of the three schedules. Before placing your ve-

hicle in service, determine whether Schedule I, II, or

III applies to your vehicle.

Schedules I-III

Schedule I (severe service) applies to vehicles that

travel up to 6000 miles (10 000 kilometers) annually

or that operate under severe conditions. Examples of

Schedule I usage are:

• operation on extremely poor roads or where

there is heavy dust accumulation

• constant exposure to extreme hot, cold, salt air,

or other extreme climates

• frequent short-distance travel

• construction-site operation

• city operation such as fire truck and garbage

truck.

• farm operation

Schedule II (short-haul transport) applies to vehicles

that travel up to 60,000 miles (100 000 kilometers)

annually and operate under normal conditions. Ex-

amples of Schedule II usage are:

• operation primarily in cities and densely popu-

lated areas

• local transport with infrequent freeway travel

• high percentage of stop-and-go travel

Schedule III (long-haul transport) is for vehicles that

travel more than 60,000 miles (100 000 kilometers)

annually with minimal city or stop-and-go operation.

Examples of Schedule III usage are:

• regional delivery that is mostly freeway miles

• interstate transport

• any road operation with high annual mileage

Maintenance Schedules

After determining the schedule appropriate to your

vehicle, refer to the Maintenance Schedules to deter-

mine when to perform the Initial Maintenance (IM)

and the frequency of performing subsequent mainte-

nance intervals for each schedule.

Maintenance Intervals

Refer to Maintenance Intervals for Schedule I,

Schedule II, and Schedule III to determine which

maintenance interval(s) should be performed when

your vehicle reaches the mileage or hours of opera-

tion listed in these tables.

Maintenance Operations

Groups 01 through 83 in this manual have an index

at the beginning of each Group. The index lists the

Title of Maintenance Operations and the mainte-

nance Operation (MOP) Numbers for that Group.

Follow the instructions under the MOP number to

perform the required maintenance.

In addition to the maintenance operations required

for the maintenance interval, perform all the daily

maintenance procedures in Chapter 11, "Pretrip In-

spection and Daily Maintenance," in the Business

Class® M2 Driver’s Manual.

General Information 00

Determining Scheduled Maintenance Intervals: 00–01

Business Class M2 Maintenance Manual, March 2016 00/1

Maintenance Schedules

Schedule

Maintenance Intervals

Maintenance Interval Frequency Mileage km Hours

Schedule I

*

(severe service)

for vehicles that travel up to

6000 miles (10 000 km) annually

Initial Maintenance (IM) first 1000 1600 100

Maintenance 1 (M1) every 1000 1600 100

Maintenance 2 (M2) every 4000 6400 400

Maintenance 3 (M3) every 8000 12 800 800

Maintenance 4 (M4) every 16,000 25 600 1600

Maintenance 5 (M5) every 32,000 51 200 3200

Schedule II

(short-haul transport)

for vehicles that travel up to

60,000 miles (100 000 km)

annually

Initial Maintenance (IM) first 8000 12 000

—

Maintenance 1 (M1) every 8000 12 000

Maintenance 2 (M2) every 16,000 24 000

Maintenance 3 (M3) every 32,000 48 000

Maintenance 4 (M4) every 64,000 96 000

Maintenance 5 (M5) every 128,000 192 000

Schedule III

(long-haul transport)

for vehicles that travel over

60,000 miles (100 000 km)

annually

Initial Maintenance (IM) first 10,000 16 000

—

Maintenance 1 (M1) every 10,000 16 000

Maintenance 2 (M2) every 20,000 32 000

Maintenance 3 (M3) every 40,000 64 000

Maintenance 4 (M4) every 80,000 128 000

Maintenance 5 (M5) every 160,000 256 000

* For Schedule I vehicles equipped with an hourmeter, use maintenance intervals based on hours of operation rather than mileage.

Table 1, Maintenance Schedules

General Information 00

Maintenance Schedules: 00–02

Business Class M2 Maintenance Manual, March 2016 00/2

You're Reading a Preview

What's Included?

Fast Download Speeds

Online & Offline Access

Access PDF Contents & Bookmarks

Full Search Facility

Print one or all pages of your manual

$31.99

$41.99

Viewed 96 Times Today

Loading...

Secure transaction

What's Included?

Fast Download Speeds

Online & Offline Access

Access PDF Contents & Bookmarks

Full Search Facility

Print one or all pages of your manual

$31.99

$41.99

Freightliner Business Class M2 Trucks Maintenance Manual provides precise guidance for maintaining M2 100, M2 106, M2 106V, M2 112, and M2 112V models. It includes detailed procedures, specifications, and clear illustrations for addressing mechanical, electrical, and other systems. This manual is essential for both professional mechanics and DIY enthusiasts, facilitating efficient and accurate servicing to minimize downtime.

Please note:

This is not a generic repair manual. It contains troubleshooting and replacement procedures provided by the manufacturer, including step-by-step instructions, exploded-view illustrations, and clear images. It is available in .PDF format for Windows/Mac and is printable.