2008-2014 Yamaha Rhino 700 (YXR70FX) Service & Repair Manual

What's Included?

Fast Download Speeds

Online & Offline Access

Access PDF Contents & Bookmarks

Full Search Facility

Print one or all pages of your manual

SERVICE MANUAL

2008

LIT-11616-21-58 5B4-F8197-10

YXR70FX

EBS00001

YXR70FX

SERVICE MANUAL

©2007 by Yamaha Motor Corporation, U.S.A.

First edition, September 2007

All rights reserved.

Any reproduction or unauthorized use

without the written permission of

Yamaha Motor Corporation, U.S.A.

is expressly prohibited.

Printed in U.S.A.

LIT-11616-21-58

EBS00002

IMPORTANT

This manual was produced by the Yamaha Motor Company primarily for use by Yamaha dealers

and their qualified mechanics. It is not possible to include all the knowledge of a mechanic in one

manual, so it is assumed that anyone who uses this book to perform maintenance and repairs on

Yamaha vehicle has a basic understanding of the mechanical ideas and the procedures of vehicle

repair. Repairs attempted by anyone without this knowledge are likely to render the vehicle unsafe

and unfit for use.

This model has been designed and manufactured to perform within certain specifications in regard

to performance and emissions. Proper service with the correct tools is necessary to ensure that the

vehicle will operate as designed. If there is any question about a service procedure, it is imperative

that you contact a Yamaha dealer for any service information changes that apply to this model. This

policy is intended to provide the customer with the most satisfaction from his vehicle and to conform

to federal environmental quality objectives.

Yamaha Motor Company, Ltd. is continually striving to improve all its models. Modifications and sig-

nificant changes in specifications or procedures will be forwarded to all authorized Yamaha dealers

and will appear in future editions of this manual where applicable.

TIP:

_

• This Service Manual contains information regarding periodic maintenance to the emission control

system. Please read this material carefully.

• Designs and specifications are subject to change without notice.

EBS00003

IMPORTANT INFORMATION

Particularly important information is distinguished in this manual by the following notations.

This is the safety alert symbol. It is used to alert you to potential personal injury

hazards. Obey all safety messages that follow this symbol to avoid possible

injury or death.

A WARNING indicates a hazardous situation which, if not avoided, could result

in death or serious injury.

A NOTICE indicates special precautions that must be taken to avoid damage to

the vehicle or other property.

A TIP provides key information to make procedures easier or clearer.

WARNING

NOTICE

TIP:

EBS00004

HOW TO USE THIS MANUAL

MANUAL ORGANIZATION

This manual consists of chapters for the main categories of subjects. (See “symbols”)

1st title 1: This is the title of the chapter with its symbol in the upper right corner of each page.

2nd title 2: This title indicates the section of the chapter and only appears on the first page of each

section. It is located in the upper left corner of the page.

3rd title 3: This title indicates a sub-section that is followed by step-by-step procedures accompa-

nied by corresponding illustrations.

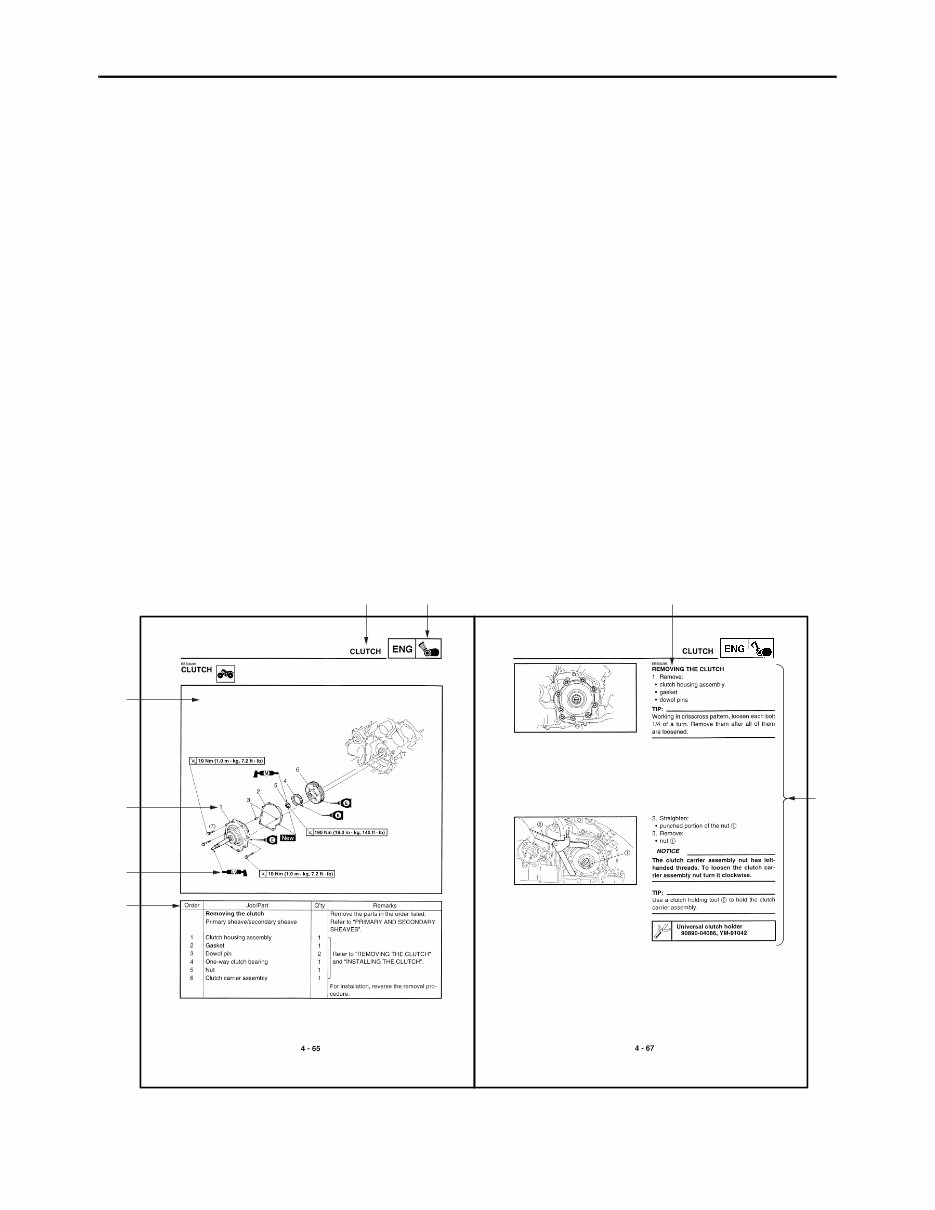

EXPLODED DIAGRAMS

To help identify parts and clarify procedure steps, there are exploded diagrams at the start of each

removal and disassembly section.

1. An easy-to-see exploded diagram 4 is provided for removal and disassembly jobs.

2. Numbers 5 are given in the order of the jobs in the exploded diagram. A number that is enclosed

by a circle indicates a disassembly step.

3. An explanation of jobs and notes is presented in an easy-to-read way by the use of symbol marks

6. The meanings of the symbol marks are given on the next page.

4. A job instruction chart 7 accompanies the exploded diagram, providing the order of jobs, names

of parts, notes in jobs, etc.

5. For jobs requiring more information, the step-by-step format supplements 8 are given in addition

to the exploded diagram and the job instruction chart.

2 3 1

4

5

6

7

8

EBS00006

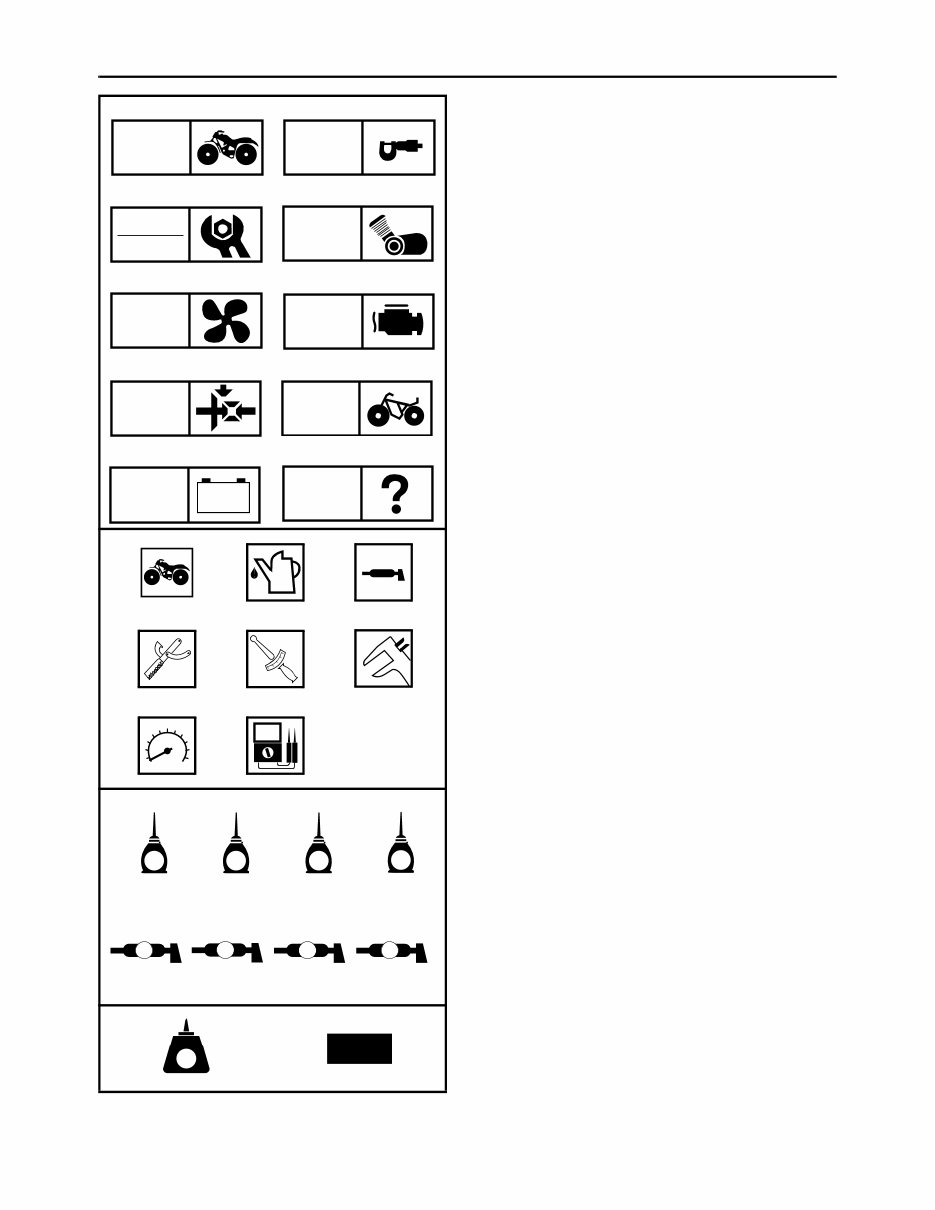

SYMBOLS

The following symbols are not relevant to

every vehicle.

Symbols 1 to 0 indicate the subject of each

chapter.

1 General information

2 Specifications

3 Periodic checks and adjustments

4 Engine

5 Cooling system

6 Fuel injection system

7 Drive train

8 Chassis

9 Electrical

0 Troubleshooting

Symbols A to H indicate the following

A Can be serviced with engine mounted

B Filling fluid

C Lubricant

D Special tool

E Torque

F Wear limit, clearance

G Engine speed

H Electrical data (Ω, V, A)

Symbols I to P in the exploded diagrams

indicate the types of lubricants and lubrication

points.

I Apply engine oil

J Apply gear oil

K Apply molybdenum disulfide oil

L Apply brake fluid

M Apply wheel bearing grease

N Apply lithium-soap-based grease

O Apply molybdenum disulfide grease

P Apply silicone grease

Symbols Q to R in the exploded diagrams

indicate where to apply a locking agent Q and

when to install a new part R.

Q Apply the locking agent (LOCTITE

®

)

R Replace

1 2

3 4

5 6

7 8

9 0

A B C

D E F

G H

I J K L

M N O P

Q R

GEN

INFO

SPEC

CHK

ADJ

ENG

COOL FI

DRIV CHAS

– +

ELEC

TRBL

SHTG

T

R

.

.

E G M BF

B

LS M S

LT

New

EBS00008

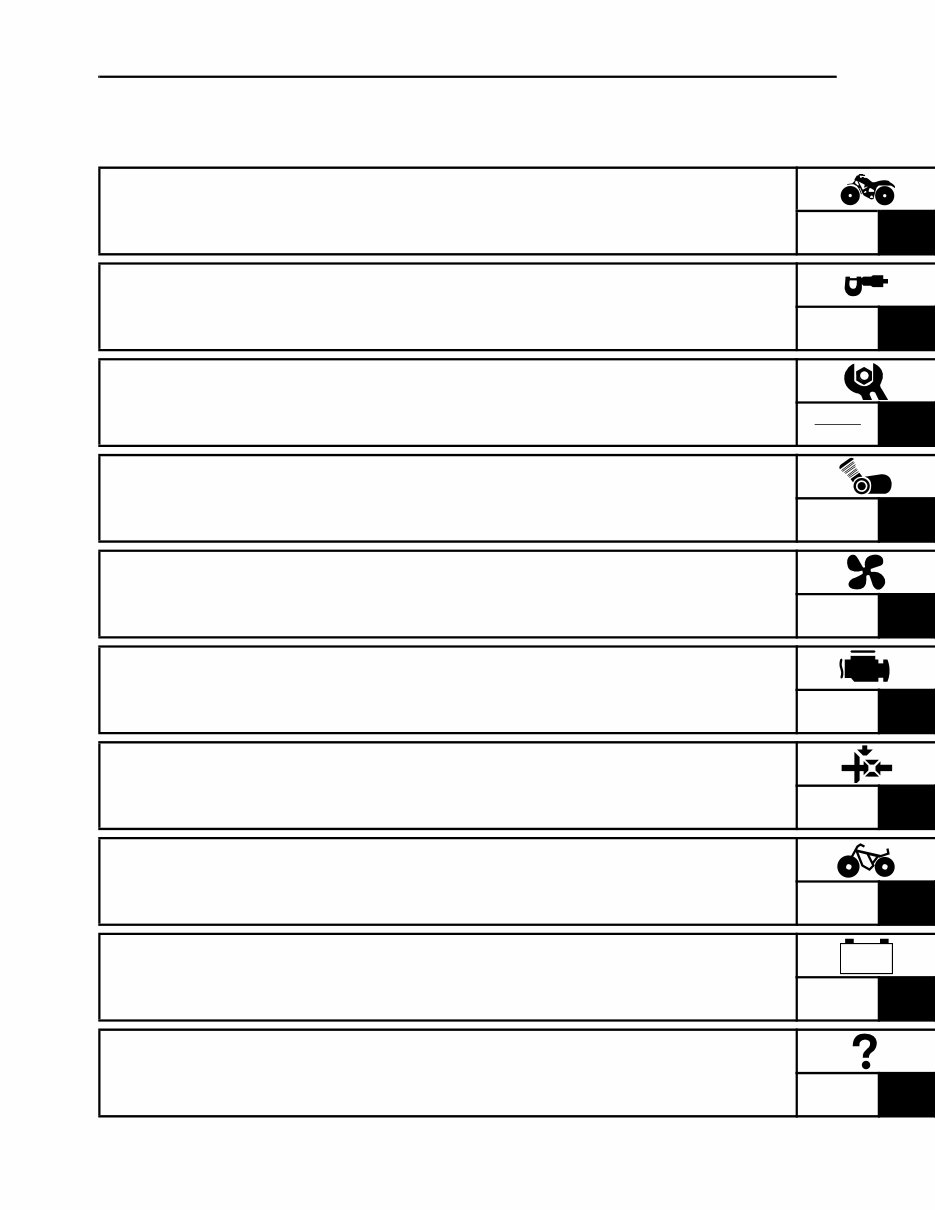

TABLE OF CONTENTS

GENERAL INFORMATION

GEN

INFO

1

SPECIFICATIONS

SPEC

2

PERIODIC CHECKS AND

ADJUSTMENTS

CHK

ADJ

3

ENGINE

ENG

4

COOLING SYSTEM

COOL

5

FUEL INJECTION SYSTEM

FI

6

DRIVE TRAIN

DRIV

7

CHASSIS

CHAS

8

ELECTRICAL

ELEC

9

TROUBLESHOOTING

TRBL

SHTG

10

– +

CONTENTS

CHAPTER 1

GENERAL INFORMATION

VEHICLE IDENTIFICATION............................................................................ 1-1

VEHICLE IDENTIFICATION NUMBER ..................................................... 1-1

MODEL LABEL.......................................................................................... 1-1

FEATURES ...................................................................................................... 1-2

OUTLINE OF THE FI SYSTEM ................................................................. 1-2

FI SYSTEM................................................................................................ 1-3

INSTRUMENT FUNCTIONS ..................................................................... 1-4

IMPORTANT INFORMATION ......................................................................... 1-7

PREPARATION FOR REMOVAL AND DISASSEMBLY........................... 1-7

REPLACEMENT PARTS........................................................................... 1-7

GASKETS, OIL SEALS AND O-RINGS .................................................... 1-7

LOCK WASHERS/PLATES AND COTTER PINS ..................................... 1-8

BEARINGS AND OIL SEALS .................................................................... 1-8

CIRCLIPS .................................................................................................. 1-8

CHECKING THE CONNECTIONS ............................................................ 1-9

SPECIAL TOOLS .......................................................................................... 1-10

CHAPTER 2

SPECIFICATIONS

GENERAL SPECIFICATIONS ........................................................................ 2-1

ENGINE SPECIFICATIONS ............................................................................ 2-5

CHASSIS SPECIFICATIONS ........................................................................ 2-12

ELECTRICAL SPECIFICATIONS ................................................................. 2-15

TIGHTENING TORQUES .............................................................................. 2-17

ENGINE TIGHTENING TORQUES ......................................................... 2-17

CHASSIS TIGHTENING TORQUES ....................................................... 2-20

HOW TO USE THE CONVERSION TABLE.................................................. 2-24

GENERAL TIGHTENING TORQUE SPECIFICATIONS ............................... 2-24

LUBRICATION POINTS AND LUBRICANT TYPES .................................... 2-25

ENGINE ................................................................................................... 2-25

COOLANT FLOW DIAGRAMS ..................................................................... 2-27

OIL FLOW DIAGRAMS ................................................................................. 2-29

CABLE ROUTING ......................................................................................... 2-32

CHAPTER 3

PERIODIC CHECKS AND ADJUSTMENTS

INTRODUCTION.............................................................................................. 3-1

PERIODIC MAINTENANCE CHART FOR THE EMISSION CONTROL

SYSTEM ......................................................................................................... 3-1

GENERAL MAINTENANCE AND LUBRICATION CHART ............................ 3-2

ENGINE ........................................................................................................... 3-3

ADJUSTING THE VALVE CLEARANCE .................................................. 3-3

ADJUSTING THE THROTTLE CABLE ..................................................... 3-6

CHECKING THE SPARK PLUG ............................................................... 3-7

CHECKING THE IGNITION TIMING ......................................................... 3-9

MEASURING THE COMPRESSION PRESSURE .................................. 3-10

CHECKING THE ENGINE OIL LEVEL.................................................... 3-13

CHANGING THE ENGINE OIL ............................................................... 3-14

CLEANING THE AIR FILTER ELEMENT................................................ 3-16

CHECKING THE THROTTLE BODY JOINT ........................................... 3-19

CHECKING THE FUEL HOSE ................................................................ 3-19

CHECKING THE BREATHER HOSES ................................................... 3-19

CHECKING THE COOLANT LEVEL ....................................................... 3-20

CHANGING THE COOLANT................................................................... 3-21

CHECKING THE COOLING SYSTEM .................................................... 3-25

CHECKING THE COOLANT TEMPERATURE WARNING LIGHT ......... 3-26

CHECKING AND REPLACING THE V-BELT ......................................... 3-27

CHECKING THE EXHAUST SYSTEM.................................................... 3-28

CLEANING THE SPARK ARRESTER .................................................... 3-29

CHASSIS ....................................................................................................... 3-30

ADJUSTING THE BRAKE PEDAL .......................................................... 3-30

ADJUSTING THE PARKING BRAKE...................................................... 3-31

CHECKING THE BRAKE FLUID LEVEL................................................. 3-32

CHECKING THE FRONT BRAKE PADS ................................................ 3-33

CHECKING THE REAR BRAKE PADS .................................................. 3-34

CHECKING THE PARKING BRAKE PADS ............................................ 3-34

CHECKING THE BRAKE HOSES AND BRAKE PIPES ......................... 3-35

BLEEDING THE HYDRAULIC BRAKE SYSTEM ................................... 3-36

ADJUSTING THE SELECT LEVER SHIFT ROD .................................... 3-37

ADJUSTING THE BRAKE LIGHT SWITCH ............................................ 3-38

CHECKING THE FINAL GEAR OIL LEVEL ............................................ 3-38

CHANGING THE FINAL GEAR OIL ........................................................ 3-39

CHECKING THE DIFFERENTIAL GEAR OIL ......................................... 3-40

CHANGING THE DIFFERENTIAL GEAR OIL ........................................ 3-41

CHECKING THE CONSTANT VELOCITY JOINT DUST BOOTS .......... 3-43

CHECKING THE STEERING SYSTEM .................................................. 3-43

ADJUSTING THE TOE-IN ....................................................................... 3-44

ADJUSTING THE FRONT SHOCK ABSORBERS ................................. 3-45

ADJUSTING THE REAR SHOCK ABSORBERS .................................... 3-48

CHECKING THE TIRES .......................................................................... 3-51

CHECKING THE WHEELS ..................................................................... 3-53

CHECKING AND LUBRICATING THE CABLES .................................... 3-54

LUBRICATING THE PEDAL, ETC. ......................................................... 3-54

ELECTRICAL SYSTEM................................................................................. 3-55

CHECKING AND CHARGING THE BATTERY ....................................... 3-55

CHECKING THE FUSES ........................................................................ 3-61

ADJUSTING THE HEADLIGHT BEAMS ................................................. 3-64

CHANGING THE HEADLIGHT BULBS................................................... 3-64

CHANGING THE TAIL/BRAKE LIGHT BULB ......................................... 3-65

CHAPTER 4

ENGINE

ENGINE REMOVAL ........................................................................................ 4-1

V-BELT COOLING DUCTS, MUFFLER AND EXHAUST PIPES .............. 4-1

INSTALLING THE V-BELT COOLING DUCTS ......................................... 4-4

SHIFT ARM ............................................................................................... 4-5

HOSES AND LEADS................................................................................. 4-6

ENGINE MOUNTING BOLTS ................................................................... 4-8

INSTALLING THE ENGINE..................................................................... 4-10

You're Reading a Preview

What's Included?

Fast Download Speeds

Online & Offline Access

Access PDF Contents & Bookmarks

Full Search Facility

Print one or all pages of your manual

$31.99

$41.99

Viewed 91 Times Today

Loading...

Secure transaction

What's Included?

Fast Download Speeds

Online & Offline Access

Access PDF Contents & Bookmarks

Full Search Facility

Print one or all pages of your manual

$31.99

$41.99

- The 2008-2014 Yamaha Rhino 700 (YXR70FX) Service & Repair Manual is a comprehensive guide for fixing problems on your UTV, suitable for both professional mechanics and DIY enthusiasts.

- It contains every troubleshooting and replacement procedure provided by the manufacturer, including step-by-step instructions, clear images, and exploded-view illustrations.

- Regular maintenance is essential for the durability of your UTV, and this manual provides the manufacturer's recommended troubleshooting charts and replacement procedures to help you save on repairs and increase your UTV’s reliability.

- It offers the convenience of easily searching, bookmarking, and carrying the manual on electronic devices such as PC & Mac computers, Android and Apple smartphones & tablets, etc.

- The manual is available in English and can be printed out if a physical copy is preferred.

- File Format: .PDF

- Requirements: Adobe Reader (free)