2000-2002 Kawasaki Mule 2510 Diesel KAF950 UTV Service & Repair Manual

What's Included?

Fast Download Speeds

Online & Offline Access

Access PDF Contents & Bookmarks

Full Search Facility

Print one or all pages of your manual

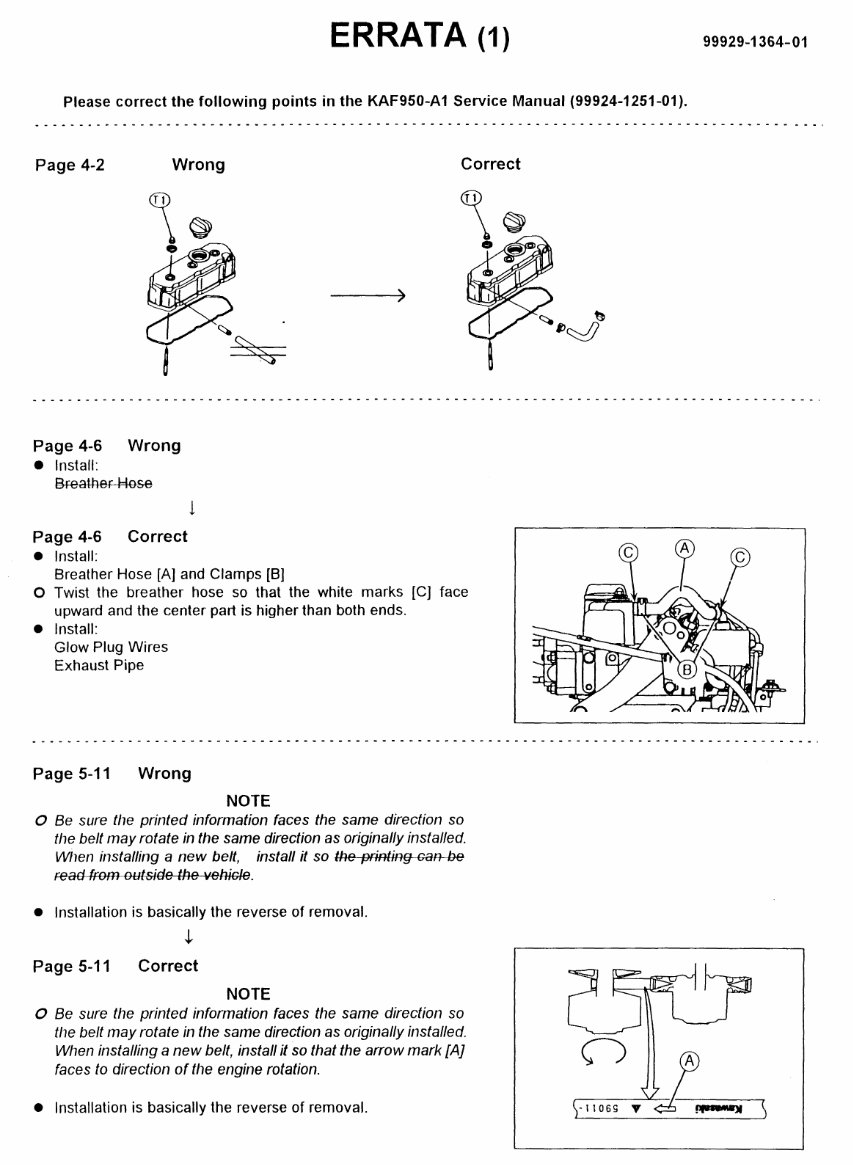

ERRATA (1)

Please correct the following points in the KAF950-A 1 Service Manual (99924-1251-01 ).

Page 4-2 Wrong Correct

Page 4-6 Wrong

• Install:

Breather Hose

l

Page 4-6 Correct

• Install:

Breather Hose [A] and Clamps [B)

0 Twist the breather hose so that the white marks [C) face

upward and the center part is higher than both ends.

• Install:

Glow Plug Wires

Exhaust Pipe

Page 5-11 Wrong

NOTE

0 Be sure the printed information faces the same direction so

the belt may rotate in the same direction as originally installed.

Wilen installing a new belt, install it so the printinf}-£aA--be

r:ead from outside the veRiGie.

• Installation is basically the reverse of removal.

,}

Page 5-11 Correct

NOTE

0 Be sure the printed information faces the same direction so

the belt may rotate in the same direction as originally installed.

When installing a new belt, install it so that the arrow mark [A]

faces to direction of the engine rotation.

• Installation is basically the reverse of removal.

99929-1364-01

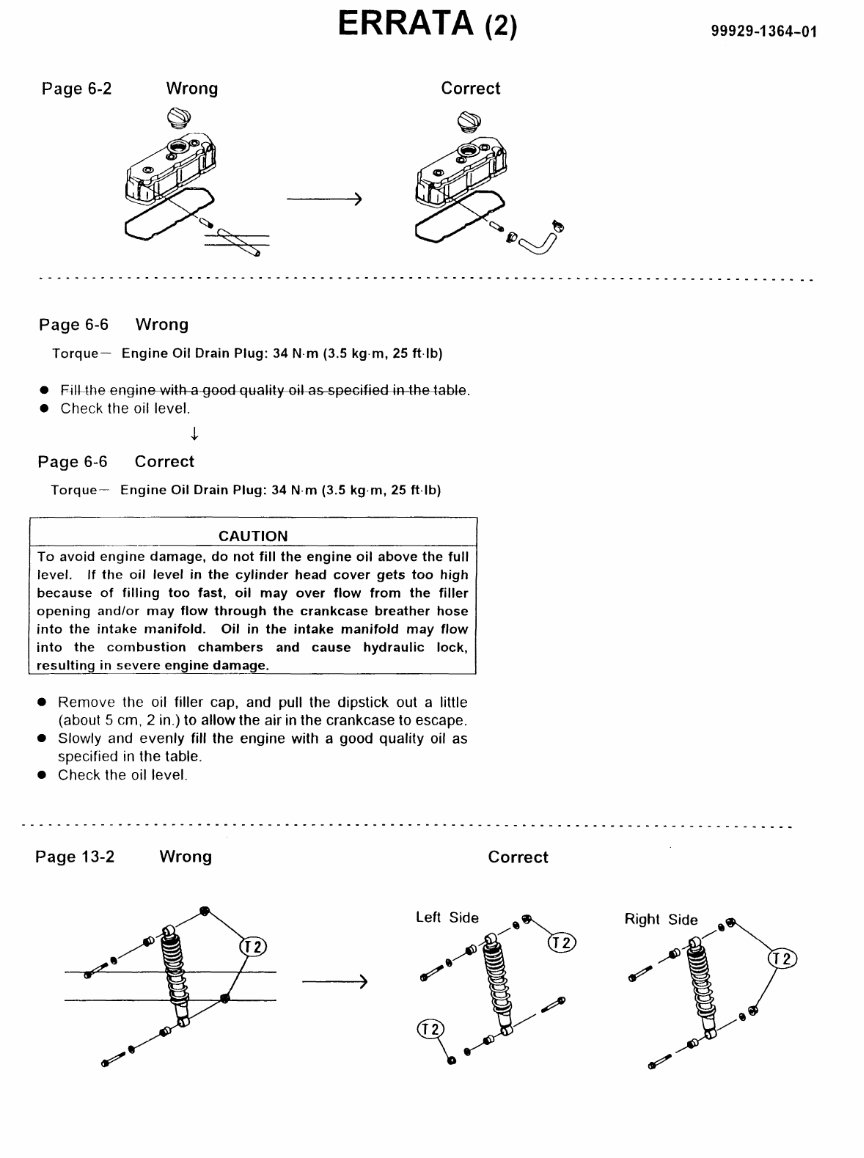

ERRATA (2)

Page 6-2 Wrong Correct

~

Page 6-6 Wrong

Torque- Engine Oil Drain Plug: 34 N·m (3.5 kg·m, 25 ft·lb)

• F~lt-the en§ine with a good quality--00-as--specified in the table.

• Check the oil level.

Page 6-6 Correct

Torque- Engine Oil Drain Plug: 34 N-m (3.5 kg·m, 25 ft-lb)

CAUTION

To avoid engine damage, do not fill the engine oil above the full

level. If the oil level in the cylinder head cover gets too high

because of filling too fast, oil may over flow from the filler

opening and/or may flow through the crankcase breather hose

into the intake manifold. Oil in the intake manifold may flow

into the combustion chambers and cause hydraulic lock,

resulting in severe engine damage.

• Remove the oil filler cap, and pull the dipstick out a little

(about 5 em. 2 in.) to allow the air in the crankcase to escape.

• Slowly and evenly fill the engine with a good quality oil as

specified in the table.

• Check the oil level.

99929-1364-01

----------------------------------------·-----------------------------------------------

Page 13-2 Wrong

)

Correct

Left Side

Right Side e

/

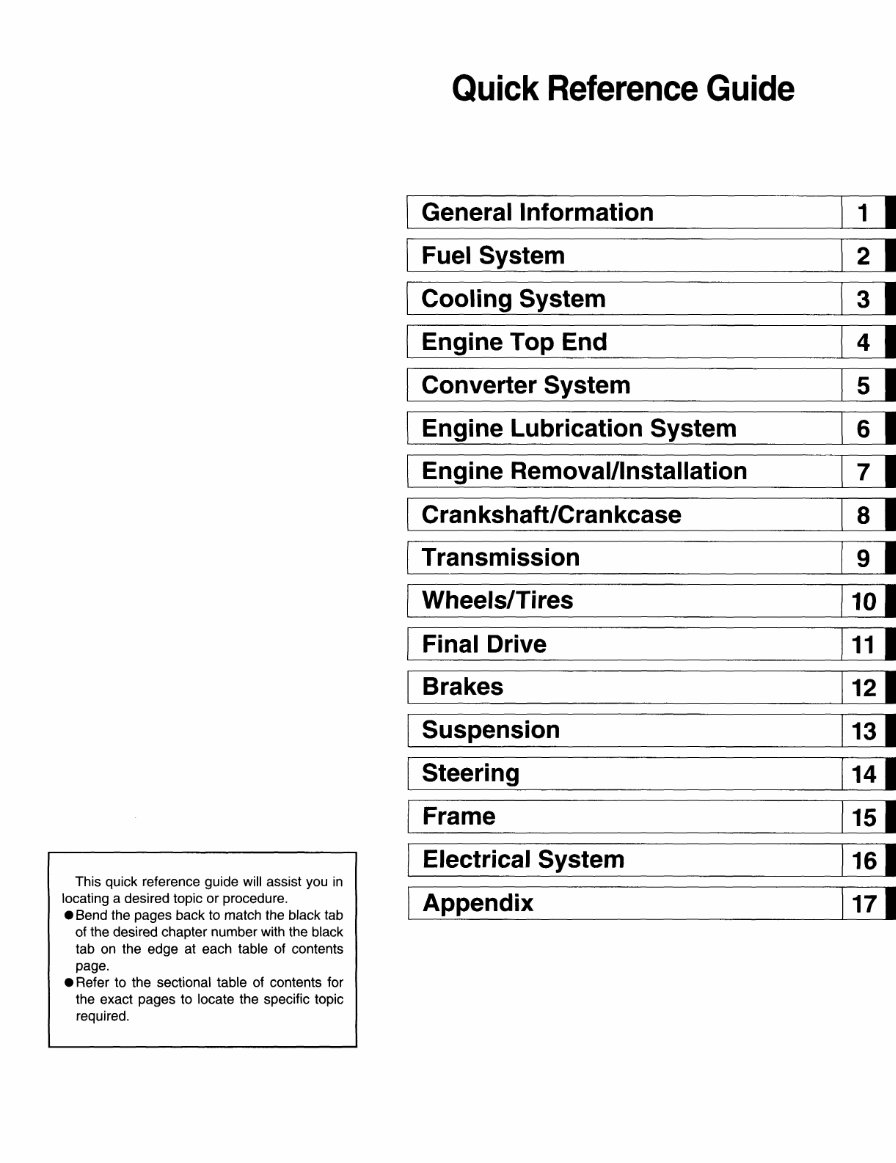

This quick reference guide will assist you in

locating a desired topic or procedure.

• Bend the pages back to match the black tab

of the desired chapter number with the black

tab on the edge at each table of contents

page.

• Refer to the sectional table of contents for

the exact pages to locate the specific topic

required.

Quick Reference Guide

General Information

1 I

Fuel System

Cooling System

Engine Top End

Converter System

s I

Engine Lubrication System

s I

[}_ngine Removal/Installation

Crankshaft/Crankcase

a I

Transmission

Wheels/Tires

Final Drive

Brakes

Suspension

Steering

Frame

Electrical System

Appendix

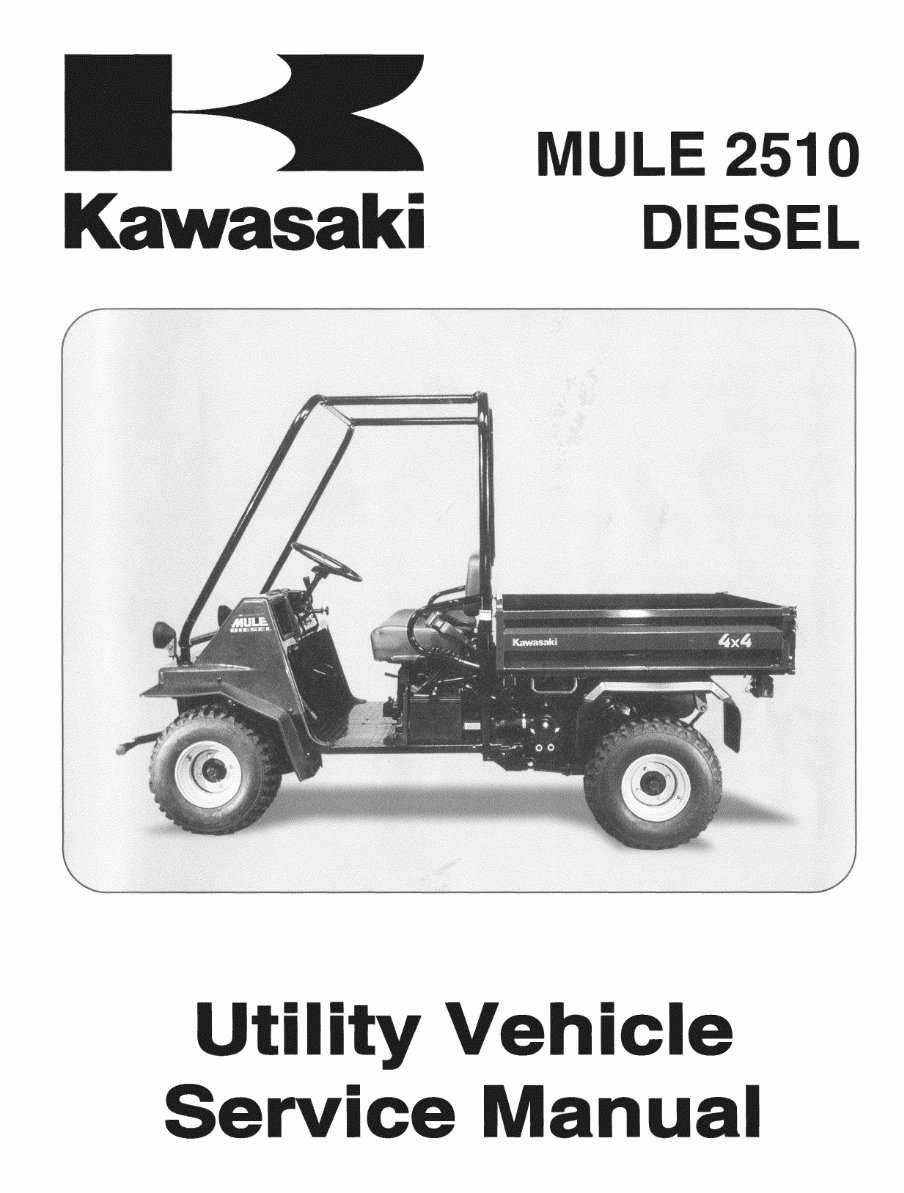

MULE2510

DIESEl

Utility Vehicle

Service Manual

©Kawasaki Heavy Industries. Ltd., 1999 First Edition (1) : Oct. 14, 1999 (M)

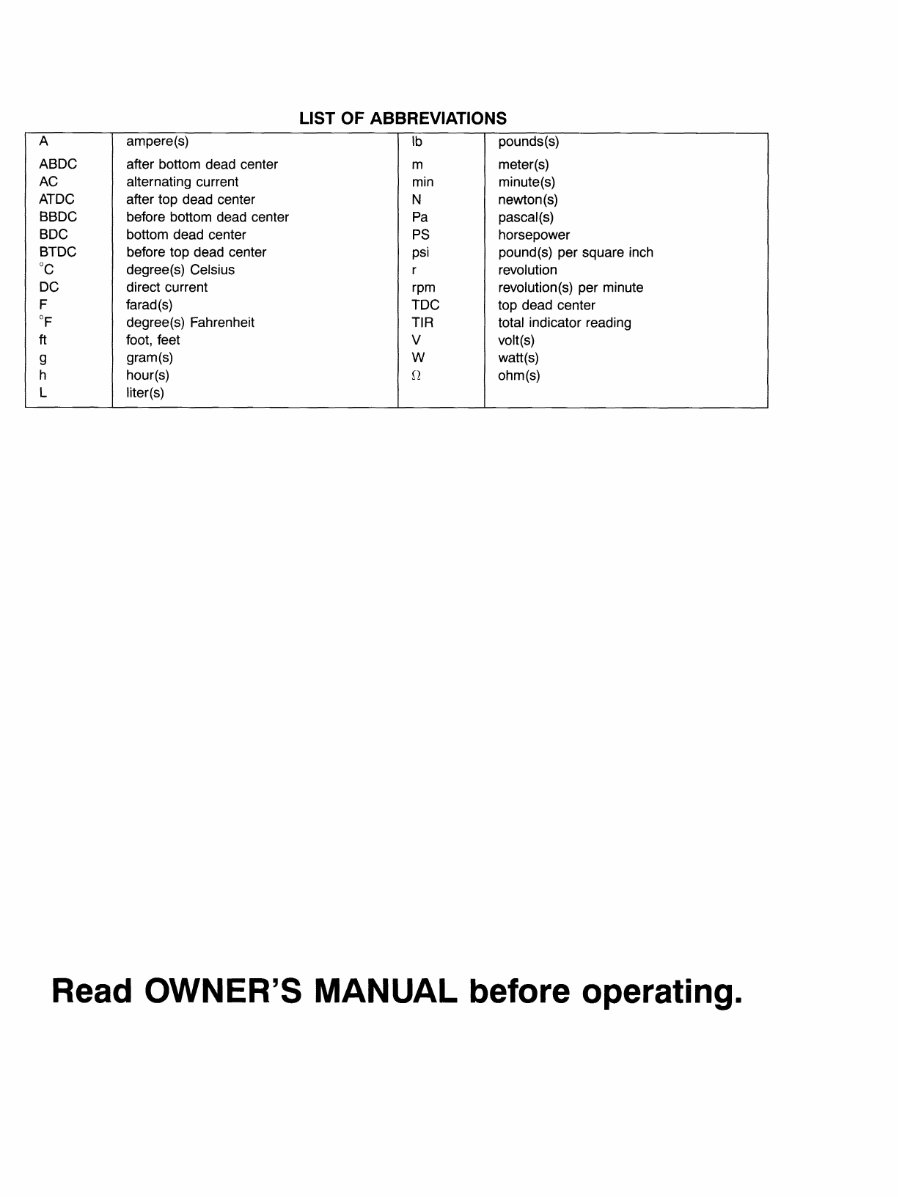

LIST OF ABBREVIATIONS

A ampere(s) lb pounds(s)

ABDC after bottom dead center m meter(s)

AC alternating current min minute(s)

ATDC after top dead center N newton(s)

BBDC before bottom dead center Pa pascal(s)

BDC bottom dead center PS horsepower

BTDC before top dead center psi pound(s) per square inch

oc

degree(s) Celsius r revolution

DC direct current rpm revolution(s) per minute

F farad(s) TDC top dead center

OF

degree(s) Fahrenheit TIR total indicator reading

ft foot, feet v volt(s)

g gram(s) w watt(s)

h hour(s) n ohm(s)

L liter(s)

Read OWNER'S MANUAL before operating.

EMISSION CONTROL INFORMATION

To protect the environment in which we all live, Kawasaki has incorporated crankcase emission (1) and exhaust emission

(2) control systems in compliance with applicable regulations of the United States Environmental Protection Agency and

California Air Resources Board.

1. Crankcase Emission Control System

A sealed-type crankcase emission control system is used to eliminate blow-by gases. The blow-by

gases are led to the breather chamber through the crankcase to the intake manifold.

Oil is separated from the gases while passing through the inside of the breEither chamber from the

crankcase, and then returned to the bottom of the crankcase.

2. Exhaust Emission Control System

The exhaust emission control system applied to this engine family is engine modifications that consist

of a modified injection pump and injection timing characteristics.

The fuel system has been calibrated to provide lean air/fuel mixture characteristics, with a suitable air

cleaner and exhaust system.

A maintenance free injection system provides the most appropriate injection timing and helps maintain

a thorough combustion process within the engine which contributes to a reduction of exhaust pollutants

entering the atomosphere.

The Clean Air Act, which is the Federal law covering motor vehicle pollution, contains what is commonly referred to as

the Act's "tampering provisions."

"Sec. 203(a) The following acts and the causing thereof are prohibited ...

(3)(A) for any person to remove or render inoperative any device or element of design installed on or

in a motor vehicle or motor vehicle engine in compliance with regulationfS under this title prior to

its sale and delivery to the ultimate purchaser, or for any manufacturer or dealer knowingly to

remove or render inoperative any such device or element of design after such sale and delivery

to the ultimate purchaser.

(3)(8) for any person engaged in the business of repairing, servicing, selling, l~asing, or trading motor

vehicles or motor vehicle engines, or who operates a fleet of motor vehicles knowingly to remove

or render inoperative any device or element of design installed on or in a motor vehicle or motor

vehicle engine in compliance with regulations under this title following its sale and delivery to the

ultimate purchaser ... "

(Continued on next page.)

NOTE

u The phrase "remove or render inoperative any device or element of design" has been generally

interpreted as follows:

1. Tampering does not include the temporary removal or rendering inoperative of devices or

elements of design in order to perform maintenance.

2. Tampering could include:

a. Maladjustment of vehicle components such that the emission standards are exceeded.

b. Use of replacement parts or accessories which adversely affect the performance or

durability of the vehicle.

c. Addition of components or accessories that result in the vehicle exceeding the standards.

d. Permanently removing, disconnecting, or rendering inoperative any component or element

of design of the emission control systems.

WE RECOMMEND THAT All DEALERS OBSERVE THESE PROVISIONS OF FEDERAL LAW, THE VIOLATION OF

WHICH IS PUNISHABLE BY CIVIL PENALTIES NOT EXCEEDING $10,000 PER VIOLATION.

PLEASE DO NOT TAMPER WITH NOISE CONTROL SYSTEM

(US Model only)

To minimize the noise emissions from this product, Kawasaki has equipped it with effective inta.ke and exhaust silencing

systems. They are designed to give optimum performance while maintaining a low noise level. Please do not remove

these systems, or alter them in any way which results in an increase in noise level.

Foreword

This manual is designed primarily for use by trained

mechanics in a properly equipped shop. However, it

contains enough detail and basic information to make

it useful to the owner who desires to perform his own

basic maintenance and repair work. A basic knowledge

of mechanics, the proper use of tools, and workshop

procedures must be understood in order to carry out

maintenance and repair satisfactorily. Whenever the

owner has insufficient experience or doubts his ability to

do the work, all adjustments, maintenance, and repair

should be carried out only by qualified mechanics.

In order to perform the work efficiently and to avoid

costly mistakes, read the text, thoroughly familiarize

yourself with the procedures before starting work, and

then do the work carefully in a clean area. Whenever

special tools or equipment are specified, do not use

makeshift tools or equipment. Precision measurements

can only be made if the proper instruments are used,

and the use of substitute tools may adversely affect safe

operation.

For the duration of the warranty period, we rec-

ommend that all repairs and scheduled maintenance be

performed in accordance with this service manual. Any

owner maintenance or repair procedure not performed in

accordance with this manual may void the warranty.

To get the longest life out of your vehicle:

• Follow the Periodic Maintenance Chart in the Service

Manual.

• Be alert for problems and non-scheduled maintenance.

• Use proper tools and genuine Kawasaki vehicle parts.

Special tools, gauges, and testers that are necessary

when servicing Kawasaki vehicles are introduced by

the Special Tool Catalog or Manual. Genuine parts

provided as spare parts are listed in the Parts Catalog.

• Follow the procedures in this manual carefully. Don't

take shortcuts.

• Remember to keep complete records of maintenance

and repair with dates and any new parts installed.

How to Use This Manual

In preparing this manual, we divided the product into

its major systems. These systems became the manual's

chapters. All information for a particular system from

adjustment through disassembly and inspection is located

in a single chapter.

The Quick Reference Guide shows you all of the

product's system and assists in locating their chapters.

Each chapter in turn has its own comprehensive Table of

Contents.

The Periodic Maintenance Chart is located in the

General Information chapter. The chart gives a time

schedule for required maintenance operations.

If you want engine oil information, for example, go to

the Periodic Maintenance Chart first. The chart tells you

how frequently to change the oil. Next, use the Quick

Reference Guide to locate the Engine Lubrication System

chapter. Then, use the Table of Contents on the first page

of the chapter to find the Engine Oil section.

Whenever you see these WARNING and CAUTION

symbols, heed their instructions! Always follow safe

operating and maintenance practices.

A WARNING

This warning symbol identifies special instruc-

tions or procedures which, if not correctly fol-

lowed, could result in personal injury, or loss of

life.

CAUTION

This caution symbol identifies special instruc-

tions or procedures which, if not strictly ob-

served, could result in damage to or destruction

of equipment.

This manual contains four more symbols (in addition to

WARNING and CAUTION) which will help you distinguish

different types of information.

NOTE

o This note symbol indicates points of particular in-

terest for more efficient and convenient operation.

• Indicates a procedural step or work to be done.

0 Indicates a procedural sub-step or how to do the work

of the procedural step it follows. It also precedes the

text of a NOTE.

*Indicates a conditional step or what action to take based

on the results of the test or inspection in the procedural

step or sub-step it follows.

In most chapters an exploded view illustration of the

system components follows the Table of Contents. In

these illustrations you will find the instructions indicating

which parts require specified tightening torque, oil, grease

or a locking agent during assembly.

GENERAL INFORMATION 1-1

General Information

Table of Contents

Before Servicing ......................................................... ,. ........................................................................................................ 1-2

Model Identification ................................................................................................. ,. ............................................................. 1-4

General Spec1ifications ................................................................................................ ,. .......................................................... 1-5

Periodic Maintenance Chart . ............................................................................................................................................... 1-7

Technicalllnlformation- Fuel1 Injection System Components ............................................................................................... 11-9

Torque and Locking Agent .......................................................................................... ,. .. ,. .................................................... 1-10

Special Tools, Sealant . ................................................................................ ,. ....................................................................... 1-14

Cable, Wire, and Hose Routing ....................................................................................... ,. ................................................ 1-19

You're Reading a Preview

What's Included?

Fast Download Speeds

Online & Offline Access

Access PDF Contents & Bookmarks

Full Search Facility

Print one or all pages of your manual

$31.99

$41.99

Viewed 59 Times Today

Loading...

Secure transaction

What's Included?

Fast Download Speeds

Online & Offline Access

Access PDF Contents & Bookmarks

Full Search Facility

Print one or all pages of your manual

$31.99

$41.99

Get your hands on the comprehensive repair manual for the 2000-2002 Kawasaki Mule 2510 diesel UTV. This manual covers everything from complete tear down and rebuild to pictures and part diagrams, torque specs, maintenance, troubleshooting, and more. With 334 pages, it's a valuable resource for both professional mechanics and DIY enthusiasts.

This manual features clickable chapters and is searchable, making it easy to locate the information you need. There are no restrictions on printing or saving/burning to disc, providing you with convenient access to the manual.

For a wide range of Kawasaki Mule manuals, simply copy and paste this link into your browser:

http://www.tradebit.com/filesharing.php/search/0/mule/0/1/58622