2000-2006 Yamaha Big Bear 400 ATV Service & Repair Manual

What's Included?

Fast Download Speeds

Online & Offline Access

Access PDF Contents & Bookmarks

Full Search Facility

Print one or all pages of your manual

YFM400FWNP

SUPPLEMENTARY

SERVICE MANUAL

LIT-11616-15-22 5FU-F8197-E1

FOREWORD

This Supplementary Service Manual has been prepared to introduce new service and new data for

the YFM400FWNP. For complete information on service procedures, it is necessary to use this Sup-

plementary Service Manual together with the following manual.

YFM400FWNM/YFM400FWNMC SERVICE MANUAL: LIT-11616-13-22 (5FU-F8197-E0)

YFM400FWNP

SUPPLEMENTARY

SERVICE MANUAL

2001 by Yamaha Motor Corporation, U.S.A.

First Edition, June 2001

All rights reserved.

Any reproduction or unauthorized use

without the written permission of

Yamaha Motor Corporation, U.S.A.

is expressly prohibited.

Printed in U.S.A.

LIT-11616-15-22

EB001000

NOTICE

This manual was produced by the Yamaha Motor Company primarily for use by Yamaha dealers

and their qualified mechanics. It is not possible to include all the knowledge of a mechanic in one

manual, so it is assumed that anyone who uses this book to perform maintenance and repairs on

Yamaha machine has a basic understanding of the mechanical ideas and the procedures of

machine repair. Repairs attempted by anyone without this knowledge are likely to render the

machine unsafe and unfit for use.

Yamaha Motor Company, Ltd. is continually striving to improve all its models. Modifications and sig-

nificant changes in specifications or procedures will be forwarded to all authorized Yamaha dealers

and will appear in future editions of this manual where applicable.

NOTE:

Designs and specifications are subject to change without notice.

IMPORTANT INFORMATION

Particularly important information is distinguished in this manual by the following notations.

The Safety Alert Symbol means ATTENTION! BECOME ALERT! YOUR

SAFETY IS INVOLVED!

Failure to follow WARNING instructions could result in severe injury or death

to the machine operator, a bystander or a person inspecting or repairing the

machine.

A CAUTION indicates special precautions that must be taken to avoid dam-

age to the machine.

A NOTE provides key information to make procedures easier or clearer.

WARNING

CAUTION:

NOTE:

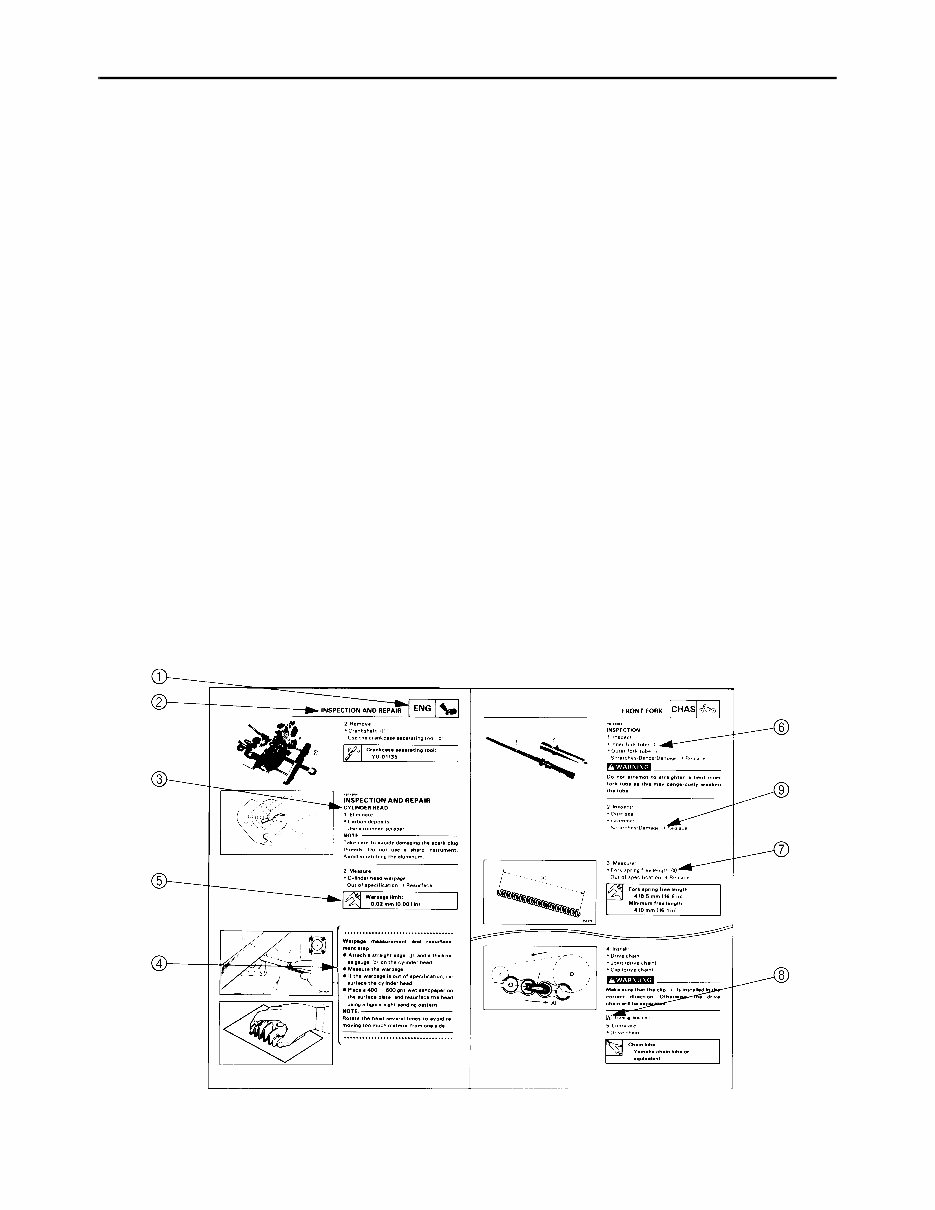

HOW TO USE THIS MANUAL

CONSTRUCTION OF THIS MANUAL

This manual consists of chapters for the main categories of subjects. (See “Illustrated symbols”)

1st title 1: This is a chapter with its symbol on the upper right of each page.

2nd title 2: This title appears on the upper of each page on the left of the chapter sym-

bol. (For the chapter “Periodic inspection and adjustment” the 3rd title

appears.)

3rd title 3: This is a final title.

MANUAL FORMAT

All of the procedures in this manual are organized in a sequential, step-by-step format. The informa-

tion has been compiled to provide the mechanic with an easy to read, handy reference that contains

comprehensive explanations of all disassembly, repair, assembly, and inspections.

A set of particularly important procedure 4 is placed between a line of asterisks “*” with each proce-

dure preceded by “●”.

IMPORTANT FEATURES

● Data and a special tool are framed in a box preceded by a relevant symbol 5.

● An encircled numeral 6 indicates a part name, and an encircled alphabetical letter data or an

alignment mark 7, the others being indicated by an alphabetical letter in a box 8.

● A condition of a faulty component will precede an arrow symbol 9 and the course of action will fol-

low it.

EXPLODED DIAGRAM

Each chapter provides exploded diagrams before each disassembly section for ease in identifying

correct disassembly and assembly procedures.

EB003000

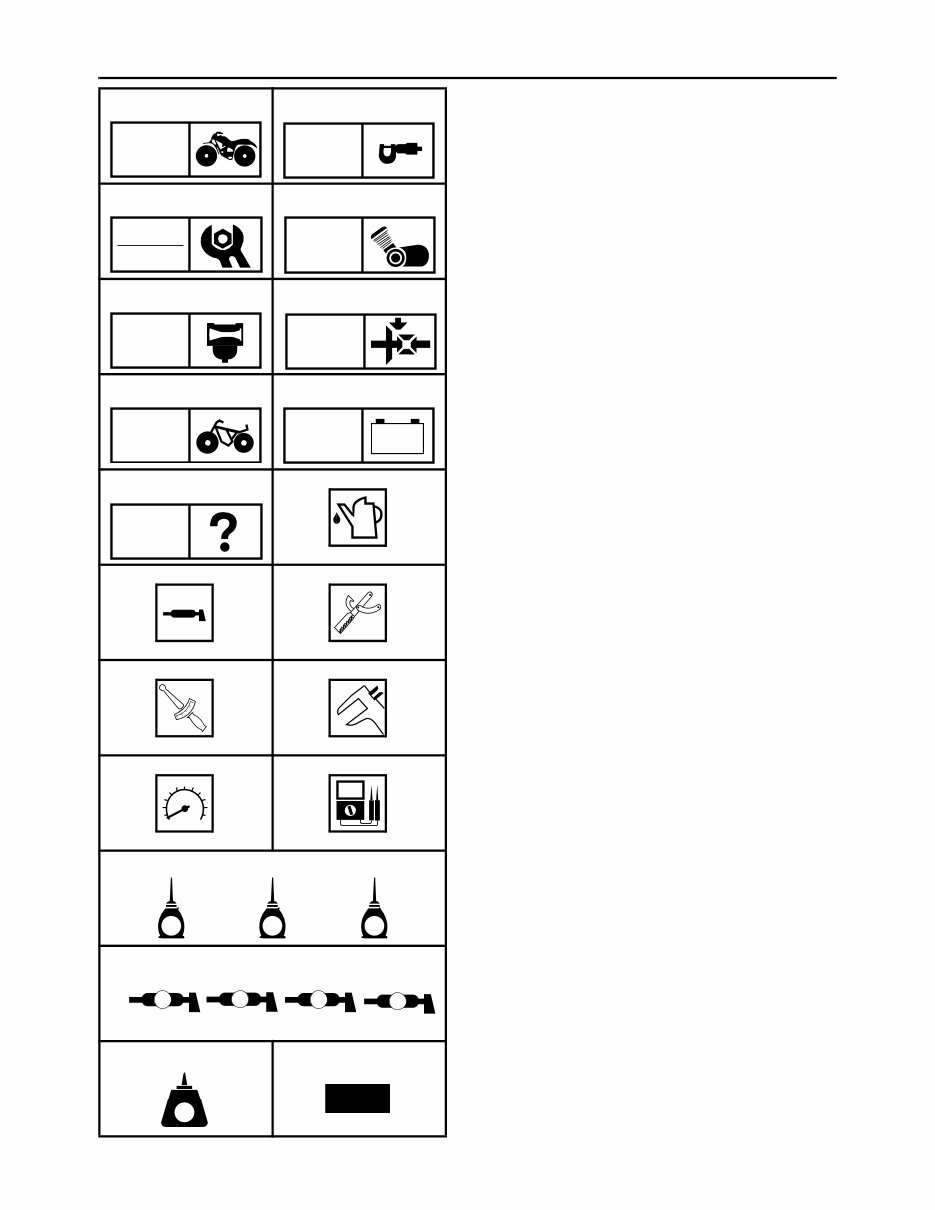

ILLUSTRATED SYMBOLS

Illustrated symbols 1 to 9 are printed on the

top right of each page and indicate the subject

of each chapter.

1 General information

2 Specifications

3 Periodic checks and adjustments

4 Engine

5 Carburetion

6 Drive train

7 Chassis

8 Electrical

9 Troubleshooting

Illustrated symbols 0 to F are used to identify

the specifications appearing in the text.

0 Filling fluid

A Lubricant

B Special tool

C Torque

D Wear limit, clearance

E Engine speed

F Ω, V, A

Illustrated symbols G to M in the exploded

diagrams indicate the types of lubricants and

lubrication points.

G Apply engine oil

H Apply gear oil

I Apply molybdenum disulfide oil

J Apply wheel bearing grease

K Apply lightweight lithium soap base grease

L Apply molybdenum disulfide grease

M Apply silicon grease

Illustrated symbols N to O in the exploded

diagrams indicate where to apply a locking

agent N and when to install a new part O.

N Apply the locking agent (LOCTITE

)

O Replace

1 2

3 4

5 6

7 8

9 0

A B

C D

E F

G H I

J

N O

GEN

INFO

SPEC

CHK

ADJ

ENG

CARB DRIV

CHAS

– +

ELEC

TRBL

SHTG

T

R

.

.

E G M

B LS M

S

K L M

LT

New

CONTENTS

SPECIFICATIONS ........................................................................................... 1

GENERAL SPECIFICATIONS ................................................................. 1

MAINTENANCE SPECIFICATIONS ........................................................ 2

ENGINE................................................................................................ 2

CHASSIS.............................................................................................. 3

ELECTRICAL ....................................................................................... 4

CABLE ROUTING .................................................................................... 5

PERIODIC CHECKS AND ADJUSTMENTS ................................................. 16

INTRODUCTION .................................................................................... 16

PERIODIC MAINTENANCE/LUBRICATION INTERVALS ..................... 16

CHASSIS ................................................................................................ 18

ADJUSTING THE FRONT BRAKE .................................................... 18

ADJUSTING THE REAR BRAKE LIGHT SWITCH ............................ 18

DRIVE TRAIN ................................................................................................. 19

CONSTANT VELOCITY JOINTS AND DIFFERENTIAL GEAR ............. 19

ASSEMBLING THE DIFFERENTIAL GEAR ...................................... 21

MEASURING AND ADJUSTING

THE DIFFERENTIAL GEAR LASH .................................................... 22

ELECTRICAL ................................................................................................. 24

CHECKING THE SWITCH ..................................................................... 24

CHECKING THE SWITCH ................................................................. 24

CHECKING A SWITCH SHOWN IN THE MANUAL .......................... 24

IGNITION SYSTEM ................................................................................ 25

CIRCUIT DIAGRAM ........................................................................... 25

TROUBLESHOOTING ....................................................................... 26

ELECTRIC STARTING SYSTEM ........................................................... 31

CIRCUIT DIAGRAM ........................................................................... 31

TROUBLESHOOTING ....................................................................... 32

LIGHTING SYSTEM ............................................................................... 35

CIRCUIT DIAGRAM ........................................................................... 35

CHECKING THE LIGHTING SYSTEM .............................................. 36

SIGNAL SYSTEM ................................................................................... 37

CIRCUIT DIAGRAM ........................................................................... 37

TROUBLESHOOTING ....................................................................... 38

CHECKING THE SIGNAL SYSTEM .................................................. 40

2WD/4WD SELECTING SYSTEM ......................................................... 42

CIRCUIT DIAGRAM ........................................................................... 42

TROUBLESHOOTING ....................................................................... 43

YFM400FWNP WIRING DIAGRAM

– 1 –

SPEC

GENERAL SPECIFICATIONS

SPECIFICATIONS

GENERAL SPECIFICATIONS

Model YFM400FWNP

Model code: 5FUA (USA)

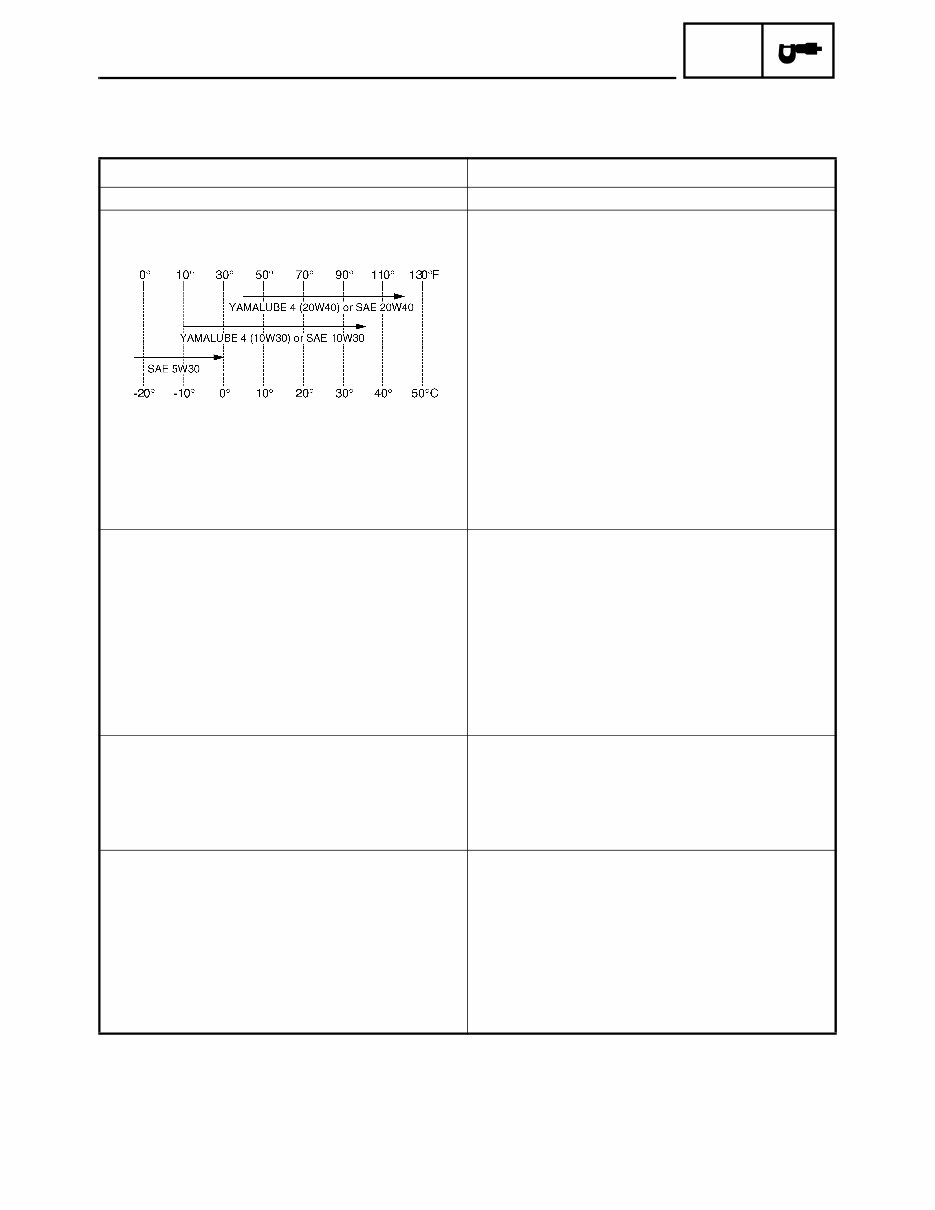

Oil type or grade:

Engine oil

API service SE, SF, SG type or higher

Final gear oil SAE 80 API “GL-4” Hypoid gear oil

Differential gear oil SAE 80 API “GL-4” Hypoid gear oil

Differential gear case oil

Periodic oil change 0.35 L (0.31 Imp qt, 0.37 US qt)

Total amount 0.4 L (0.35 Imp qt, 0.42 US qt)

Chassis:

Frame type Steel tube frame

Caster angle 4°

Camber angle 1°

Kingpin angle 13°

Trail 21 mm (0.83 in)

Tread (STD) front 860 mm (33.86 in)

Tread (STD) rear 820 mm (32.28 in)

Toe-in 5 ~ 15 mm (0.20 ~ 0.59 in)

Brake:

Front brake type Dual disc brake

operation Right hand operation

Rear brake type Drum brake

operation Left hand and right foot operation

Bulb wattage × quantity:

Headlight 12 V 30 W/30 W × 2

Tail/brake light 12 V 5 W/21 W × 1

Meter light 12 V 3.4 W × 1

Neutral indicator light 12 V 1.7 W × 1

Reverse indicator light 12 V 1.7 W × 1

Oil temperature warning light 12 V 1.7 W × 1

Four-wheel drive indicator light 12 V 1.7 W × 1

– 2 –

SPEC

MAINTENANCE SPECIFICATIONS

MAINTENANCE SPECIFICATIONS

ENGINE

Model YFM400FWNP

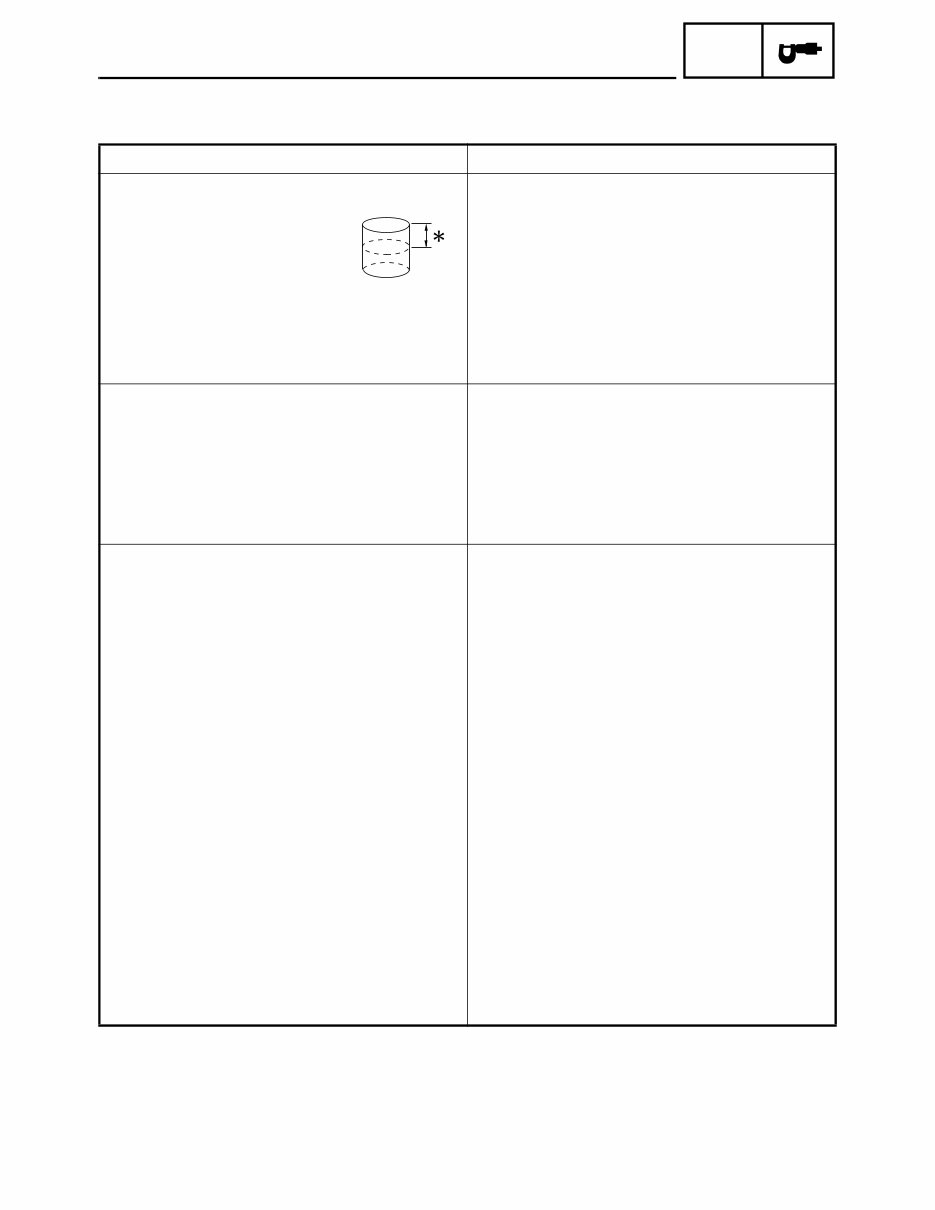

Cylinder:

Bore size 82.97 ~ 83.02 mm (3.267 ~ 3.269 in)

Out of round limit 0.05 mm (0.0020 in)

*

Measuring point 40 mm (1.57 in)

<Wear limit> <83.15 mm (3.274 in)>

Rocker arm/rocker arm shaft:

Bearing inside diameter 11.980 ~ 11.998 mm (0.4717 ~ 0.4724 in)

<Limit> <12.058 mm (0.4747 in)>

Shaft outside diameter 11.961 ~ 11.971 mm (0.4709 ~ 0.4713 in)

<Limit> <11.931 mm (0.4697 in)>

Arm-to-shaft clearance 0.009 ~ 0.037 mm (0.0004 ~ 0.0015 in)

<Limit> <0.08 mm (0.0031 in)>

Carburetor:

I. D. mark 5FUA 12

Main jet (M.J.) #112.5

Main air jet (M.A.J.) #70

Jet needle (J.N.) 5EP4-55-3

Needle jet (N.J.) P-0M (#826)

Pilot air jet (P.A.J.1) #80

Pilot air jet (P.A.J.2) 1.3

Pilot outlet (P.O.) 0.8

Pilot jet (P.J.) #17.5

Bypass 1 (B.P.1) 0.8

Bypass 2 (B.P.2) 0.8

Bypass 3 (B.P.3) 0.8

Valve seat size (V.S.) 2.0

Starter jet (G.S.1) #70

Starter jet (G.S.2) 0.9

Throttle valve size (Th.V.) #100

Float height (F.H.) 12 ~ 14 mm (0.47 ~ 0.55 in)

Fuel level (F.L.) 3 ~ 4 mm (0.12 ~ 0.16 in)

Engine idle speed 1,450 ~ 1,550 r/min

Intake vacuum 33.3 kPa (250 mmHg, 10 inHg)

– 3 –

SPEC

MAINTENANCE SPECIFICATIONS

CHASSIS

Tightening torques

Model YFM400FWNP

Front suspension:

Shock absorber travel 102 mm (4.02 in)

Fork spring free length 318.4 mm (12.5 in)

Spring rate (K1) 12.3 N/mm (1.25 kg/mm, 70.2 lb/in)

Stroke (K1) 0 ~ 102 mm (0.00 ~ 4.02 in)

Optional spring No

Rear suspension:

Shock absorber travel 100 mm (3.94 in)

Spring free length 296 mm (11.7 in)

Fitting length 253 mm (9.96 in)

Spring rate (K1) 30.4 N/mm (3.10 kg/mm, 174 lb/in)

Stroke (K1) 0 ~ 100 mm (0.00 ~ 3.94 in)

Optional spring No

Brake lever & brake pedal:

Brake lever free play (at lever end) 0 mm (0 in)

Brake lever free play (left) 5 ~ 8 mm (0.20 ~ 0.31 in)

Brake pedal position 5 mm (0.2 in)

Brake pedal free play 20 ~ 30 mm (0.8 ~ 1.2 in)

Throttle lever free play 3 ~ 5 mm (0.1 ~ 0.2 in)

Part to be tightened Thread size

Tightening torque

Remarks

Nm m·kg ft·lb

Engine stay (front-upper) and frame M8 34 3.4 24

Engine stay (front-lower) and frame M8 34 3.4 24

Engine stay (front-upper) and engine M8 34 3.4 24

Engine stay (front-lower) and engine M10 69 6.9 50

Engine and frame (rear-upper) M10 69 6.9 50

Engine and frame (rear-under) M10 69 6.9 50

Differential gear case and frame M10 64 6.4 46

Steering knuckle and front arm M12 30 3.0 22

– 4 –

SPEC

MAINTENANCE SPECIFICATIONS

ELECTRICAL

Model YFM400FWNP

Ignition system:

Ignition timing (B.T.D.C.) 10° at 1,000 r/min

Advanced timing (B.T.D.C.) 33° at 5,000 r/min

Advancer type Digital type

C.D.I.:

Magneto model/manufacturer F4T423/MITSUBISHI

Pickup coil resistance/color 459 ~ 561 Ω at 20 °C (68 °F)/White/Red –

White/Green

C.D.I. unit model/manufacturer F8T38673/MITSUBISHI

Rectifier:

Regulator type Semi conductor-short circuit

Model/manufacturer SH640E-11/SHINDENGEN

No load regulated voltage 14.1 ~ 14.9 V

Capacity 14 A

Withstand voltage 200 V

Circuit breaker:

Type Fuse

Amperage for individual circuit

Main fuse 30 A × 1

Headlight fuse 15 A × 1

Ignition fuse 10 A × 1

Auxiliary DC jack fuse 10 A × 1

Carburetor warmer fuse 10 A × 1

Reserve fuse 30 A × 1

15 A × 1

10 A × 1

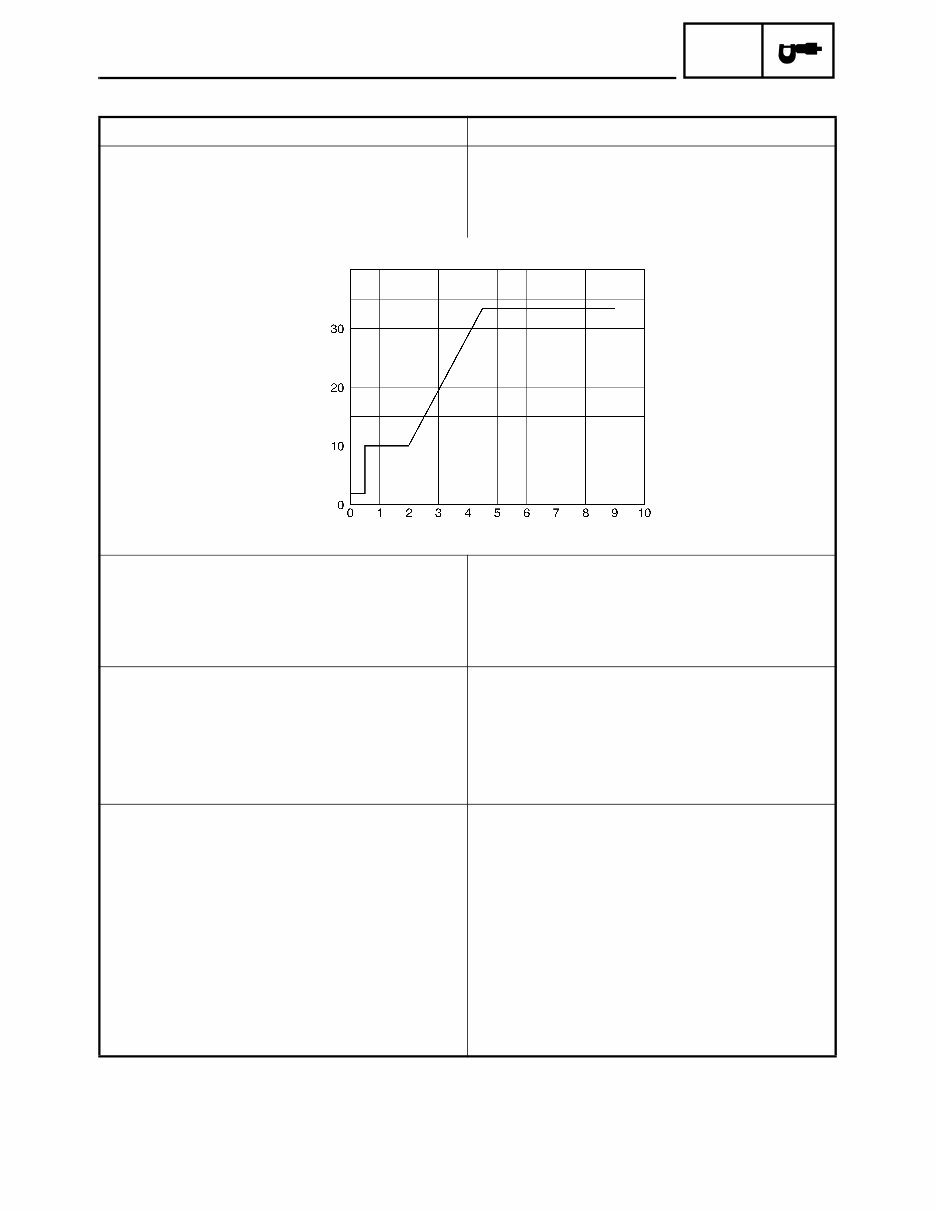

Engine speed (× 10³ r/min)

Ignition timing

(B.T.D.C.)

You're Reading a Preview

What's Included?

Fast Download Speeds

Online & Offline Access

Access PDF Contents & Bookmarks

Full Search Facility

Print one or all pages of your manual

$31.99

$41.99

Viewed 84 Times Today

Loading...

Secure transaction

What's Included?

Fast Download Speeds

Online & Offline Access

Access PDF Contents & Bookmarks

Full Search Facility

Print one or all pages of your manual

$31.99

$41.99

- This complete factory service repair workshop manual is available for instant access on your computer, tablet, or smartphone.

- It covers all repairs, servicing, and troubleshooting procedures with detailed photos and diagrams.

- Professional mechanics and technicians use this manual, which contains step-by-step instructions and highly detailed exploded diagrams and pictures.

- You have the option to print out a single page or the entire manual.

- This manual can be used on multiple computers without any limitations or trial periods.

- There is no expiry date or renewal fee; you can use this manual for life.

- It is fully compatible with Windows and MAC computers.

For more information, please click on the button.