1987-1989 Suzuki QuadRunner 300 LT300E Service & Repair Manual

What's Included?

Fast Download Speeds

Online & Offline Access

Access PDF Contents & Bookmarks

Full Search Facility

Print one or all pages of your manual

VIEW OF SUZUKI L T300E

LEFT SIDE

RIGHT SIDE

GROUP INDEX

GENERAL INFORMATION

PERIODIC MAINTENANCE AND

TUNE-UP PROCEDURES

ENGINE

FUEL AND LUBRICATION SYSTEM

ELECTRICAL SYSTEM

CHASSIS

SERVICING INFORMATION

LT-F300

L T300EJ ('88 MODEL)

L T-F300 ('88 MODEL)

L T300EK ('89 MODEL)

L T-F300 ('89 MODEL)

GENERAL INFORMATION

~---------------CONTENTS----------------~

,,/~ ~~£) ~f:fl/~L. ~LI~lJf:fl L.()~~;r/()~~··································1-1

FLlf:L. ~~£) ()/L. flf:~()~~f:~£)~;rJ()~~ .................................... ·1-1

lJflf:~I{/~~-/~ "fl()~f:£)Llflf:···················································1-1

~"f:~/~L. M~;rf:fl/~L.~·························································· ·1-2

"flf:~~LI;rJ()~~ ~~£) ~f:~f:fl~L. /~~;rflLl~;rJ()~~······················ ·1-5

~"f:~/F/~~;r/()~~· ............................................................... ·1-6

1-1 GENERAL INFORMATION

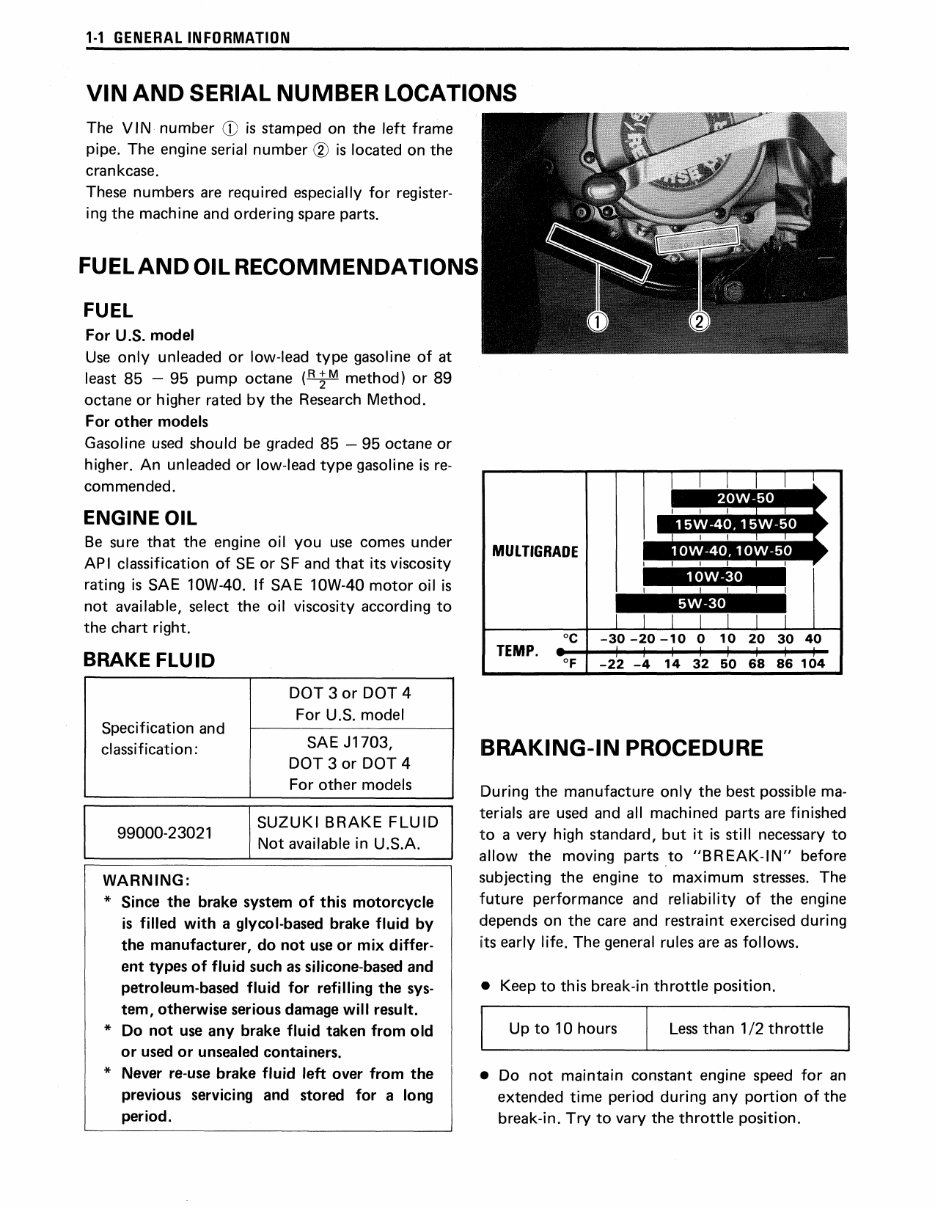

VIN AND SERIAL NUMBER LOCATIONS

The VIN number CD is stamped on the left frame

pipe. The engine serial number ® is located on the

crankcase.

These numbers are required especially for register-

ing the machine and ordering spare parts.

FUEL AND OIL RECOMMENDATIONS

FUEL

For U.S. model

Use only unleaded or low-lead type gasoline of at

least 85 - 95 pump octane (R;M method) or 89

octane or higher rated by the Research Method.

For other models

Gasoline used should be graded 85 - 95 octane or

higher. An unleaded or low-lead type gasoline is re-

commended.

ENGINE OIL

Be sure that the engine oil you use comes under

API classification of SE or SF and that its viscosity

rating is SAE 10W-40. If SAE 10W-40 motor oil is

not available, select the oil viscosity according to

the chart right.

BRAKE FLUID

Specification and

classification:

99000-23021

WARNING:

DOT 3 or DOT 4

For U.S. model

SAE J1703,

DOT 3 or DOT 4

For other models

SUZUKI BRAKE FLUID

Not available in U.S.A.

* Since the brake system of this motorcycle

is filled with a glycol-based brake fluid by

the manufacturer, do not use or mix differ-

ent types of fluid such as silicone-based and

petroleum-based fluid for refilling the sys-

tem, otherwise serious damage will result.

* Do not use any brake fluid taken from old

or used or unsealed containers.

* Never re-use brake fluid left over from the

previous servicing and stored for a long

period.

MULTIGRADE

TEMP.

BRAKING-IN PROCEDURE

During the manufacture only the best possible ma-

terials are used and all machined parts are finished

to a very high standard, but it is still necessary to

allow the moving parts ,to "BREAK-IN" before

subjecting the engine to maximum stresses. The

future performance and reliability of the engi,ne

depends on the care and restraint exercised during

its early life. The general rules are as follows.

• Keep to this break-in throttle position.

Up to 10 hours Less than 1/2 throttle

• Do not maintain constant engine speed for an

extended time period during any portion of the

break-in. Try to vary the throttle position.

GENERAL INFORMATION 1·2

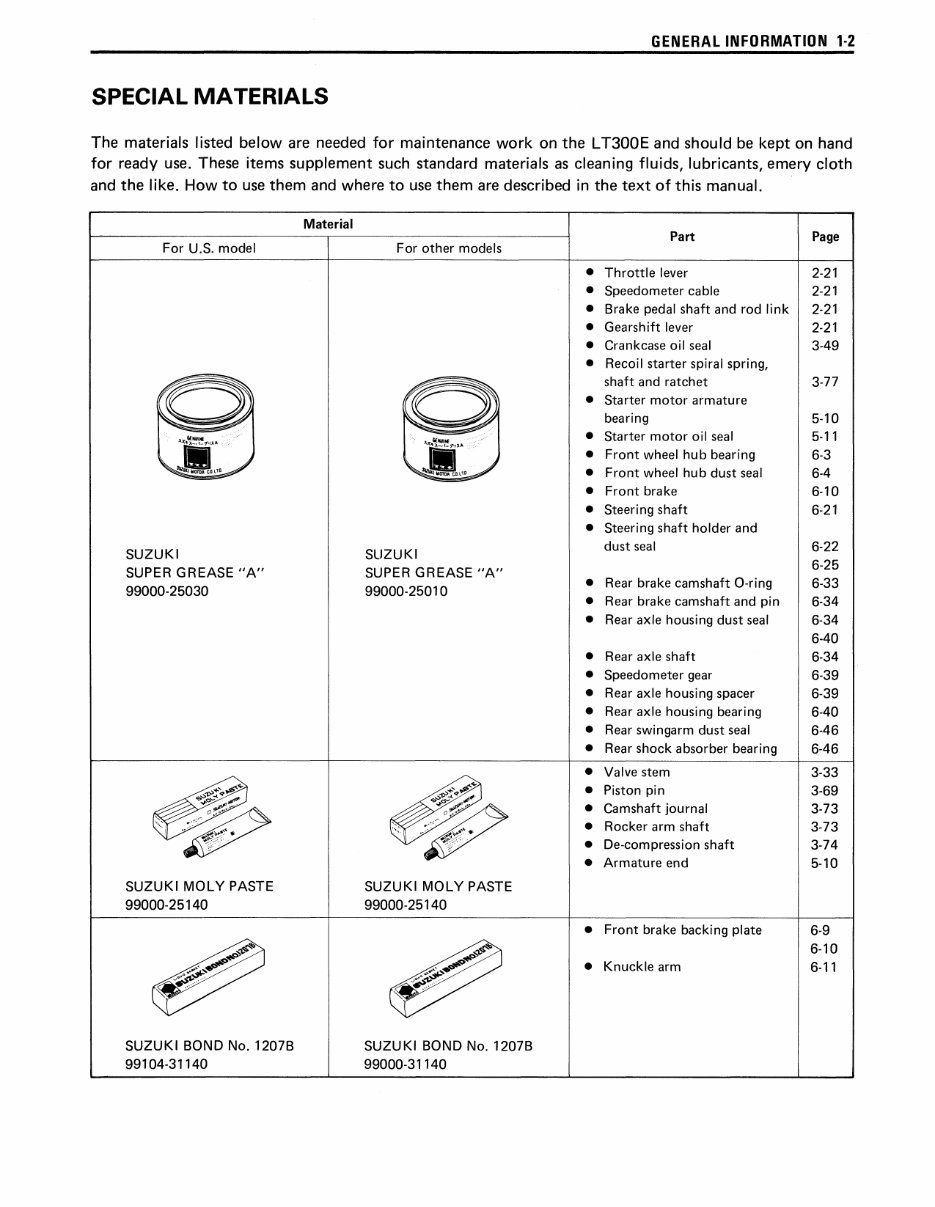

SPECIAL MATERIALS

The materials listed below are needed for maintenance work on the LT300E and should be kept on hand

for ready use. These items supplement such standard materials as cleaning fluids, lubricants, emery cloth

and the like. How to use them and where to use them are described in the text of this manual.

For U.S. model

SUZUKI

SUPER GREASE "A"

99000-25030

SUZUKI MOLY PASTE

99000-25140

SUZUKI BOND No. 1207B

99104-31140

Material

For other models

SUZUKI

SUPER GREASE "A"

99000-2501 0

SUZUKI MOLY PASTE

99000-25140

SUZUKI BOND No. 1207B

99000-31140

Part Page

•

Throttle lever 2-21

•

Speedometer cable 2-21

•

Brake pedal shaft and rod link 2-21

•

Gearshift lever 2·21

•

Crankcase oil seal 3-49

•

Recoil starter spiral spring,

shaft and ratchet 3-77

•

Starter motor armature

bearing 5-10

•

Starter motor oil seal 5·11

•

Front wheel hub bearing 6-3

•

Front wheel hub dust seal 6-4

•

Front brake 6-10

•

Steering shaft 6-21

•

Steering shaft holder and

dust seal 6-22

6-25

•

Rear brake camshaft a-ring 6-33

•

Rear brake camshaft and pin 6-34

•

Rear axle housing dust seal 6-34

6-40

•

Rear axle shaft 6-34

•

Speedometer gear 6-39

•

Rear axle housing spacer 6-39

•

Rear axle housing bearing 6-40

•

Rear swingarm dust seal 6-46

•

Rear shock absorber bearing 6-46

•

Valve stem 3-33

•

Piston pin 3-69

•

Camshaft journal 3-73

•

Rocker arm shaft 3-73

•

De-compression shaft 3-74

•

Armature end 5-10

• Front brake backing plate 6-9

6-10

• Knuckle arm 6-11

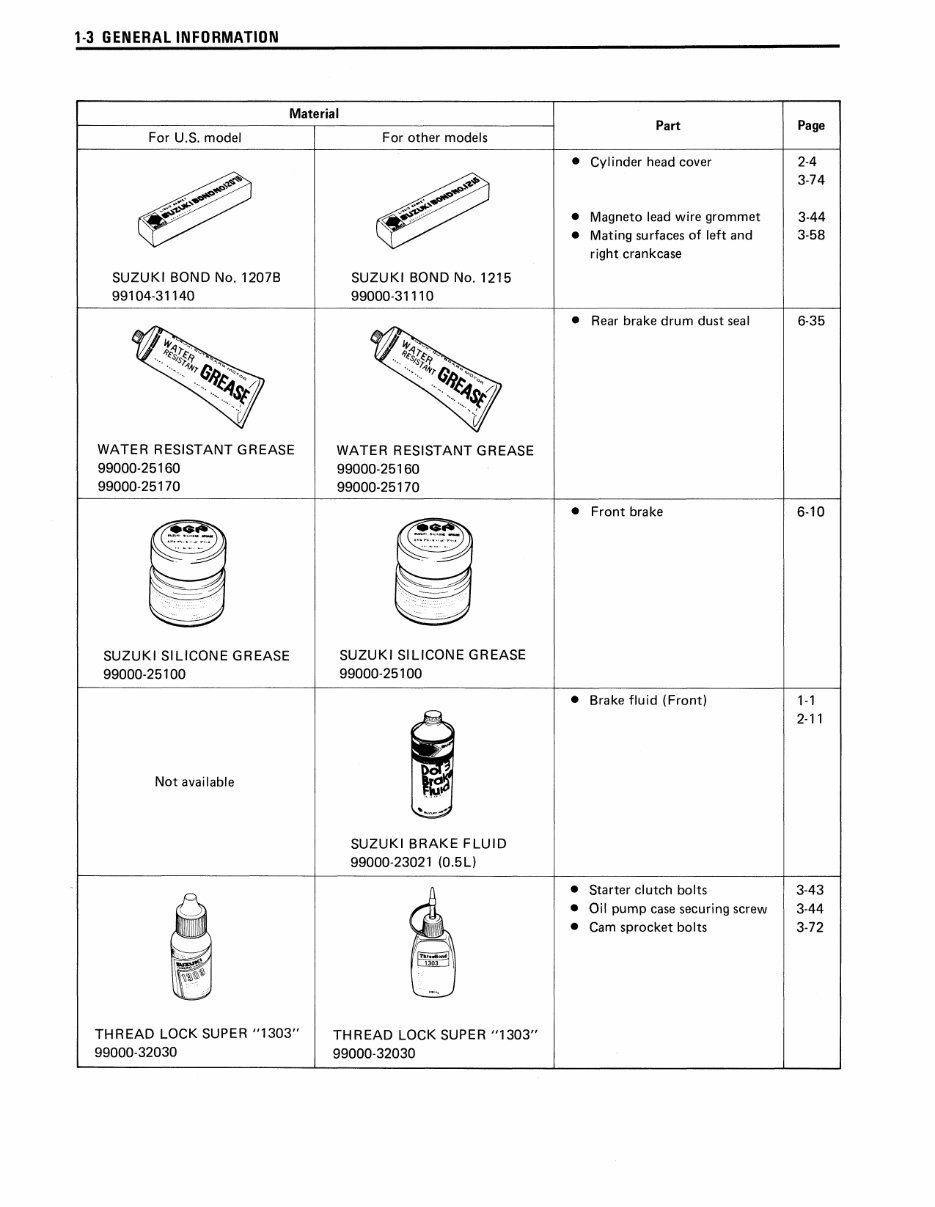

1·3 GENERAL INFORMATION

Material

For U.S. model

~.~

~

~~

SUZUKI BOND No. 1207B

99104·31140

WATER RESISTANT GREASE

99000-25160

99000-25170

SUZUKI SILICONE GREASE

99000·25100

Not available

THREAD LOCK SUPER "1303"

99000·32030

For other models

SUZUKI BOND No. 1215

99000-3111 0

WATER RESISTANT GREASE

99000-25160

99000-25170

SUZUKI SILICONE GREASE

99000-25100

SUZUKI BRAKE FLUID

99000-23021 (0.5L)

THREAD LOCK SUPER "1303"

99000·32030

Part

• Cylinder head cover

•

Magneto lead wire grommet

•

Mating surfaces of left and

right crankcase

•

Rear brake drum dust seal

• Front brake

• Brake fluid (Front)

Page

2-4

3-74

3-44

3·58

6-35

6-10

1-1

2-11

• Starter clutch bolts 3-43

• Oil pump case securing screw 3-44

• Cam sprocket bolts 3-72

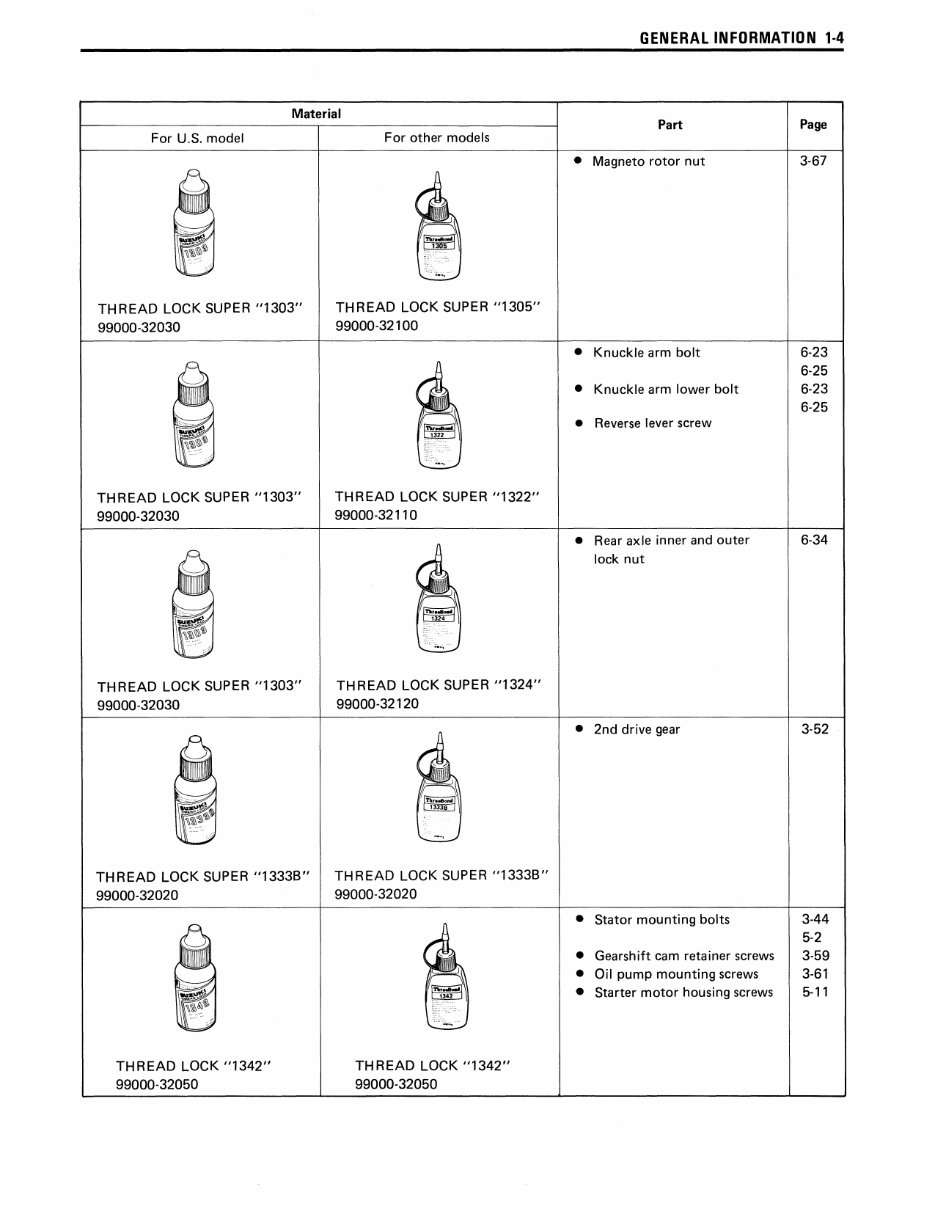

Material

For U.S. model

THREAD LOCK SUPER "1303"

99000·32030

THREAD LOCK SUPER "1303"

99000-32030

THREAD LOCK SUPER "1303"

99000-32030

For other models

THREAD LOCK SUPER "1305"

99000-32100

THREAD LOCK SUPER "1322"

99000-32110

THREAD LOCK SUPER "1324"

99000-32120

THREAD LOCK SUPER "13338" THREAD LOCK SUPER "13338"

99000-32020 99000-32020

THREAD LOCK "1342"

99000-32050

THREAD LOCK "1342"

99000-32050

GENERAL INFORMATION 1·4

Part

• Magneto rotor nut

• Knuckle arm bolt

Page

3-67

6-23

6-25

• Knuckle arm lower bolt 6-23

6-25

• Reverse lever screw

• Rear axle inner and outer 6-34

lock nut

• 2nd drive gear

3-52

• Stator mounting bolts 3-44

5-2

• Gearshift cam retainer screws 3-59

• Oil pump mounting screws 3-61

• Starter motor housing screws 5-11

1·5 GENERAL INFORMATION

PRECAUTIONS AND GENERAL INSTRUCTIONS

Observe the following items without fail when servicing, disassembling and reassembling motorcycles.

o Do not run engine indoors with little or no ventilation.

o Be sure to replace packings, gaskets, circlips, O-rings and cotter pins with new ones.

CAUTION:

Never reuse a circlip. After a circlip has been removed from a shaft, it should be discarded and a new

circlip must be installed.

When installing a new circlip, care must be taken not to expand the end gap larger than required to

slip the circlip over the shaft.

After installing a circlip, always insure that it is completely seated in its groove and securely fined.

o Tighten cylinder head and case bolts and nuts beginning with larger diameter and ending with smaller

diameter, and from inside to out-side diagonally, to the specified tightening torque.

o Use special tools where specified.

o Use genuine parts and recommended oils.

o When 2 or more persons work together, pay attention to the safety of each other.

o After a reassembly, check parts for tightness and operation.

o Treat gasoline, whkh is extremely flammable and highly explosive, with greatest care. Never use gasoline

as cleaning solvent.

Warning, Caution and Note are included in this manual occasionally, describing the following contents.

WARNING ............. .when personal safety of the rider is involved, disregard of the information

could result in injury.

CAUTION ............... For the protection of the motorcycle, the instruction or rule must be strictly

adhered to.

NOTE .................. Advice calculated to facilitate the use of the motorcycle is given under this

heading.

USE OF GENUINE SUZUKI PARTS

To replace any part of the machine, use genuine

SUZUK I replacement parts. Imitation parts or

parts supplied from any other source than SUZUKI,

if used to replace SUZUKI parts can reduce the

machine's performance and, even worse, could

induce costly mechanical troubles.

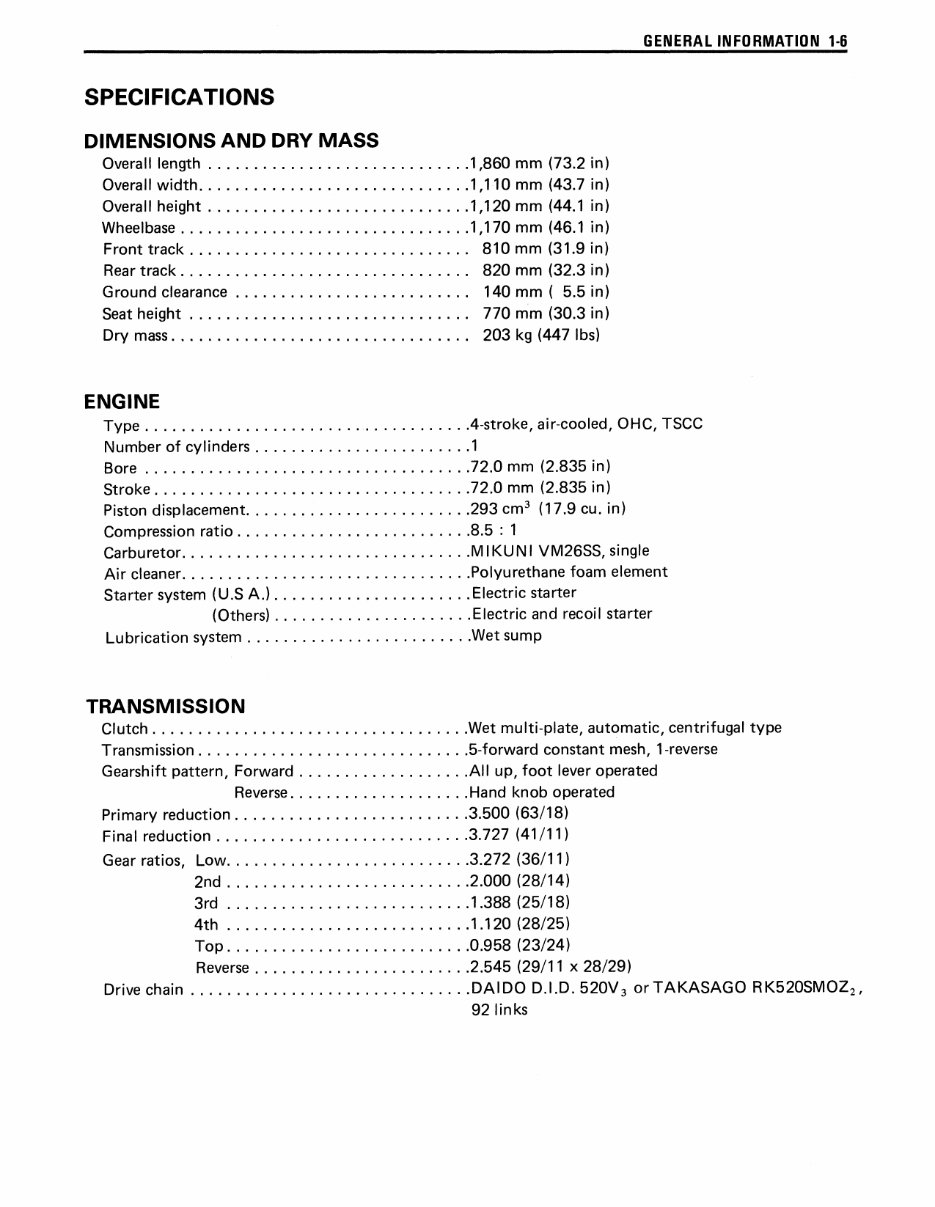

SPECIFICATIONS

DIMENSIONS AND DRY MASS

Overall length ............................. 1,860 mm (73.2 in)

Overall width .............................. 1,110 mm (43.7 in)

Overall height ............................. 1,120 mm (44.1 in)

Wheelbase ................................ 1,170 mm (46.1 in)

Front track ............................... 810 mm (31.9 in)

Rear track. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .. 820 mm (32.3 in)

Ground clearance. . . . . . . . . . . . . . . . . . . . . . . . .. 140 mm ( 5.5 in)

Seat height. . . . . . . . . . . . . . . . . . . . . . . . . . . . . .. 770 mm (30.3 in)

Dry mass. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .. 203 kg (447 Ibs)

ENGINE

GENERAL INFORMATION 1·6

Type ................................... .4-stroke, air-cooled, OHC, TSCC

Number of cylinders ........................ 1

Bore .................................... 72.0 mm (2.835 in)

Stroke ................................... 72.0 mm (2.835 in)

Piston displacement ......................... 293 cm

3

(17.9 cu. in)

Compression ratio .......................... 8.5 : 1

Carburetor ................................ M I KUN I VM26SS, single

Air cleaner ................................ Polyurethane foam element

Starter system (U.S A.l ...................... Electric starter

(Others) ...................... Electric and recoil starter

Lubrication system ........................ .wet sump

TRANSMISSION

Clutch ................................... Wet multi-plate, automatic, centrifugal type

Transmission .............................. 5-forward constant mesh, 1-reverse

Gearshift pattern, Forward ................... AII up, foot lever operated

Reverse .................... Hand knob operated

Primary reduction .......................... 3.500 (63/18)

Final reduction ............................ 3.727 (41/11)

Gear ratios, Low ........................... 3.272 (36/11)

2nd ........................... 2.000 (28/14)

3rd ........................... 1.388 (25/18)

4th ........................... 1.120 (28/25)

Top ........................... 0.958 (23/24)

Reverse ........................ 2.545 (29/11 x 28129)

Drive chain ........ , ...................... DAIDO 0.1.0. 520V 3 orTAKASAGO RK520SMOZ 2,

92 links

You're Reading a Preview

What's Included?

Fast Download Speeds

Online & Offline Access

Access PDF Contents & Bookmarks

Full Search Facility

Print one or all pages of your manual

$31.99

Viewed 90 Times Today

Loading...

Secure transaction

What's Included?

Fast Download Speeds

Online & Offline Access

Access PDF Contents & Bookmarks

Full Search Facility

Print one or all pages of your manual

$31.99

A comprehensive repair manual for the 1987-1989 Suzuki QuadRunner 300 ATV, covering both LT300E and LT-F300 models. This manual includes detailed instructions for complete tear down and rebuild, along with part diagrams, torque specifications, maintenance procedures, troubleshooting guidelines, and more, spanning across 283 pages.

Featuring clickable chapters and a searchable interface, this manual allows for easy navigation to quickly locate the desired information. Additionally, there are no restrictions on printing or saving/burning to disc.

- Complete tear down and rebuild instructions

- Detailed part diagrams and pictures

- Torque specifications

- Maintenance procedures

- Troubleshooting guidelines

- Clickable chapters and searchable interface

- No restrictions on printing or saving/burning to disc